Analog Devices ADSP-21060LKS-160, ADSP-21060LKS-133, ADSP-21060LKB-160, ADSP-21060LAB-160, ADSP-21060KS-160 Datasheet

...

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

Complete 12-Bit, 3 MSPS

Monolithic A/D Converter

AD1672

© Analog Devices, Inc., 1995

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

FEATURES

Single Supply

Pin Configurable Input Voltage Ranges

Power Dissipation: 240 mW

No Missing Codes Guaranteed

Differential Nonlinearity Error: 0.5 LSB

Complete: On-Chip Sample-and-Hold Amplifier and

Voltage Reference

Signal-to-Noise and Distortion Ratio: 68 dB

Spurious-Free Dynamic Range: –77 dB

Out of Range Indicator

Binary Output Data

Digital I/Os Compatible with +5 V or +3.3 V Logic

28-Pin PLCC Package

input combined with the power and cost savings over previously

available solutions will enable new designs in communications,

imaging and medical applications. The AD1672 provides both

reference output and reference input pins allowing the onboard

reference to serve as a system reference. An external reference

can also be chosen to suit the dc accuracy and temperature drift

requirements of the application. The digital output data is presented in a straight binary output format for the unipolar input

ranges of 0 V to 2.5 V and 0 V to 5.0 V. For the bipolar input

range of –2.5 V to +2.5 V, the digital output data is presented in

an offset binary format. An out-of-range (OTR) signal indicates

an overflow condition. It can be used with the most significant

bit to determine low or high overflow.

The AD1672 is packaged in a 28-pin PLCC package and is

specified for operation from –40°C to +85°C.

PRODUCT HIGHLIGHT

The AD1672 offers a complete single-chip sampling 12-bit,

3 MSPS analog-to-digital conversion function in a 28-pin

PLCC package.

The AD1672 at 240 mW consumes a fraction of the power of

presently available solutions and provides exceptional performance relative to other monolithic solutions.

OUT OF RANGE (OTR)—The OTR output bit indicates

when the input signal is beyond the AD1672’s input range.

Ease-of-Use—The single supply AD1672 is complete with SHA

voltage reference and pin strappable input ranges. It is compatible with a wide range of amplifiers.

PRODUCT DESCRIPTION

The AD1672 is a monolithic, single supply 12-bit, 3 MSPS

analog-to-digital converter with an on-chip, high performance

sample-and-hold amplifier (SHA) and voltage reference. The

AD1672 uses a multistage pipelined architecture with output

error correction logic to provide 12-bit accuracy at 3 MSPS data

rates and guarantees no missing codes over the full operating

temperature range. The AD1672 combines a high performance

BiCMOS process and a novel architecture to achieve its high

performance levels.

The fast settling input SHA is equally suited for both multiplexed systems that switch negative to positive full-scale voltage

levels in successive channels and sampling single-channel inputs

at frequencies up to the Nyquist rate. The AD1672’s wideband

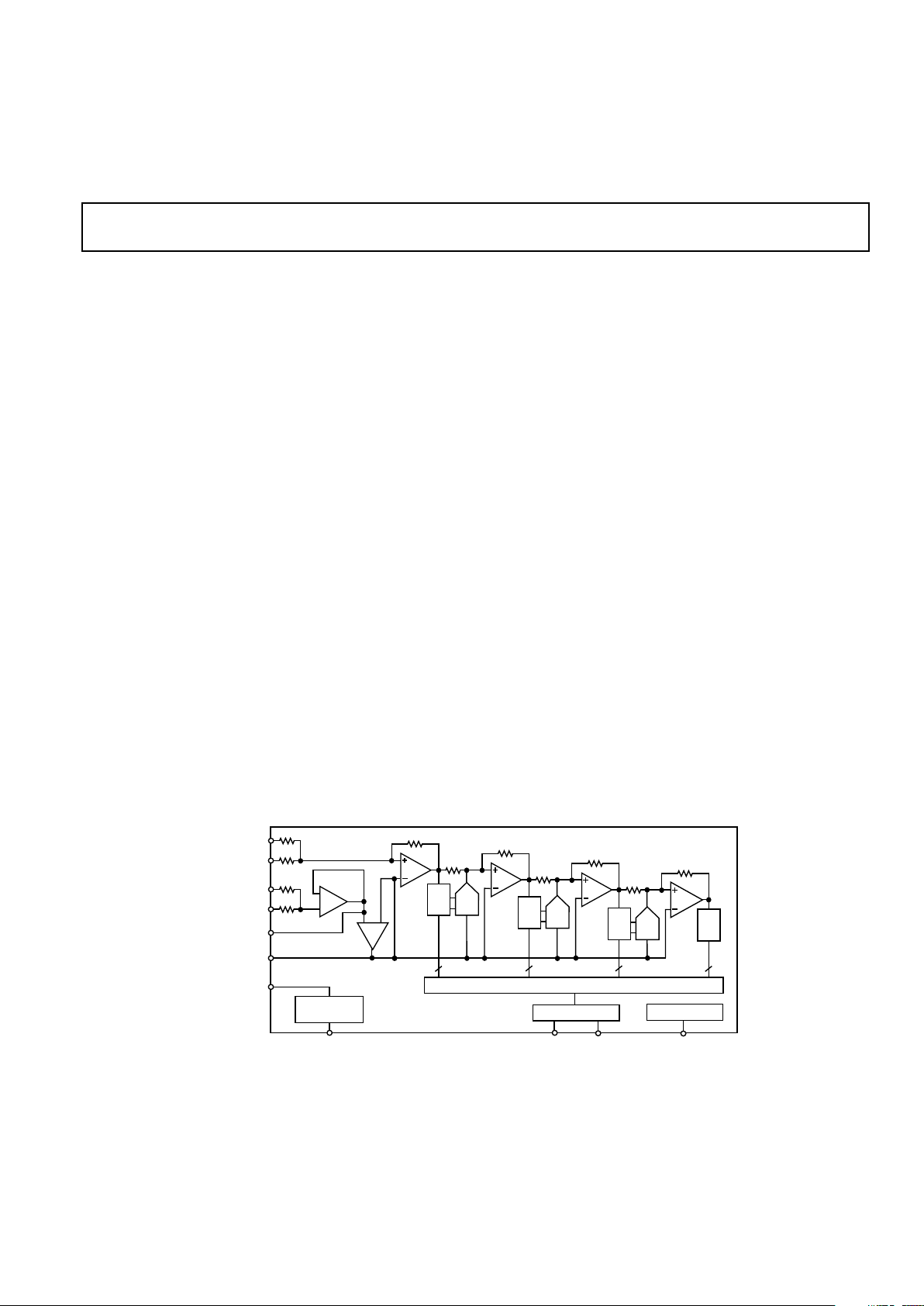

FUNCTIONAL BLOCK DIAGRAM

THA

THA

DAC

AMP

REF

AMP

4

4

3

4

CORRECTION LOGIC

2.5V REF

OUTPUT

REFCOM

OUTPUT DATA

12 BITS

CLOCK INPUT

ADC

DAC

ADC

BANDGAP

REFERENCE

LATCHES

CLOCK TIMER

NOISE

REDUCTION

AIN1 & 2

REF IN

AD1672

THA

THA

REFCOM

ADC

DAC

ADC

DAC

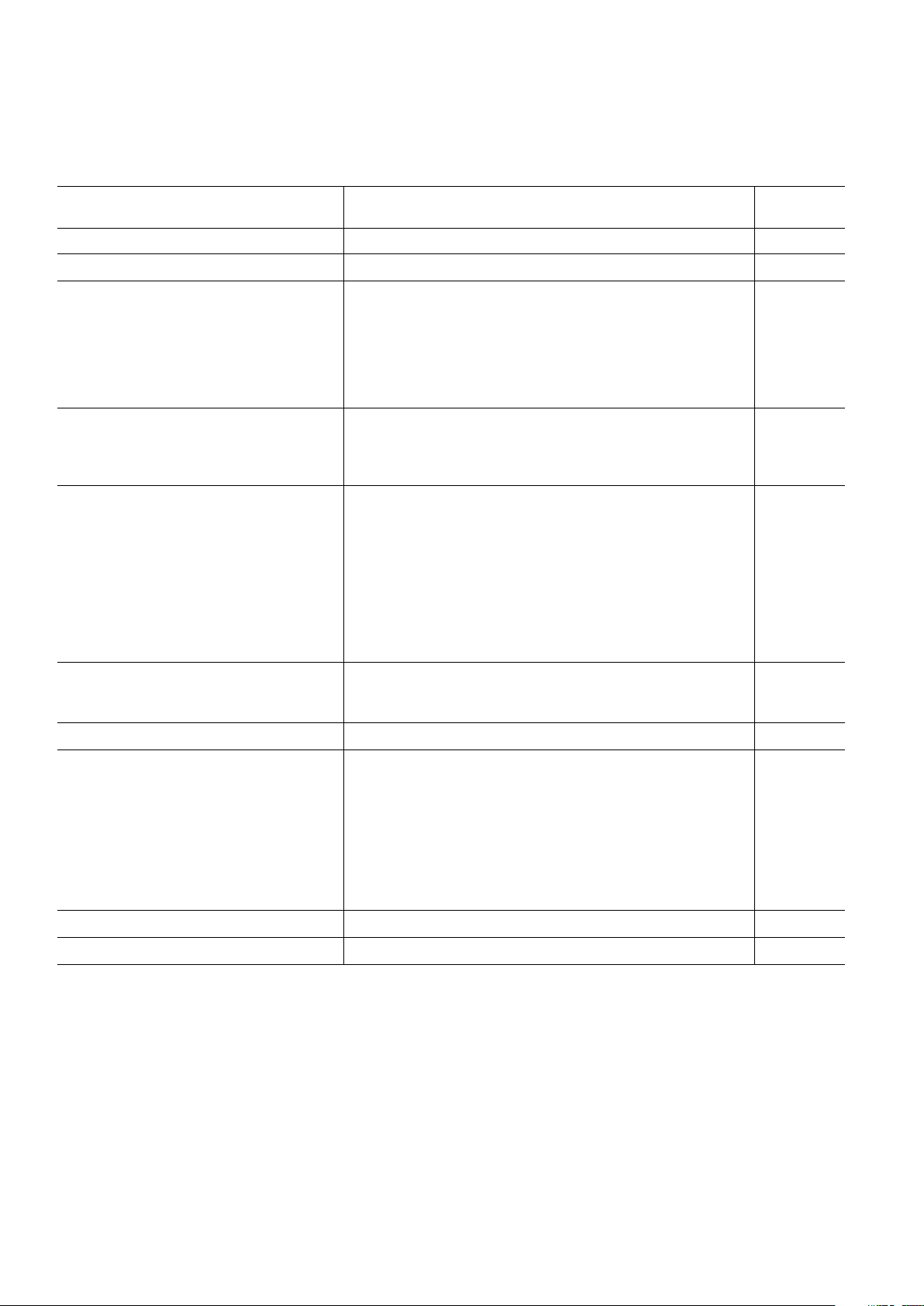

AD1672–SPECIFICATIONS

DC SPECIFICATIONS

REV. 0

–2–

(T

MIN

to T

MAX

with VCC = +5.0 V, VDD = +5.0 V, DRVDD = +5.0 V, f

SAMPLE

= 3 MHz unless otherwise noted)

AD1672AP

Parameter Min Typ Max Units

RESOLUTION 12 Bits

MAX CONVERSION RATE 3 MHz

ACCURACY

Integral Nonlinearity (INL) –2.5 ±1.0 2.5 LSB

Differential Nonlinearity (DNL) –1.0 ±0.5 1.5 LSB

No Missing Codes 12 Bits Guaranteed

Offset Error –0.75 ±0.20 0.75 % FSR

Zero Error

1

–0.75 ±0.20 0.75 % FSR

Gain Error

2

–1.50 ±0.30 1.50 % FSR

POWER SUPPLY REJECTION

3

VCC (5.0 V ± 0.25 V) –0.30 0.30 % FSR

V

DD

(5.0 V ± 0.25 V) –0.30 0.30 % FSR

V

DRDD

(3.0 V to 5.25 V) –0.10 0.10 % FSR

ANALOG INPUT

Input Ranges

2.5 V Range Unipolar 0.0 2.5 Volts

5.0 V Range Unipolar 0.0 5.0 Volts

5.0 V Bipolar –2.5 2.5 Volts

Input Resistance

2.5 V Input Range 1.5 2.0 2.5 kΩ

5.0 V Input Ranges 3.0 4.0 5.0 kΩ

Input Capacitance 10 pF

INTERNAL VOLTAGE REFERENCE

Output Voltage 2.475 2.5 2.525 Volts

Output Current

4

0.5 mA

REFERENCE INPUT RESISTANCE 6.0 8.0 10.0 kΩ

POWER SUPPLIES

Supply Voltages

V

CC

4.75 5.0 5.25 Volts

V

DD

4.75 5.0 5.25 Volts

DRV

DD

3.00 5.0 5.25 Volts

Supply Current

I

VCC

46 65 mA

I

VDD

1.0 2.0 mA

I

DRVDD

0.2 2.0 mA

POWER CONSUMPTION 240 363 mW

TEMPERATURE RANGE –40 25 85 °C

NOTES

1

Bipolar Mode.

2

Includes internal reference error.

3

Change in full scale as a function of the dc supply voltage.

4

Current available for external loads. External load should not change during conversion.

Specification subject to change without notice.

AC SPECIFICATIONS

AD1672AP

Parameter Min Typ Max Units

SIGNAL-TO-NOISE AND DISTORTION RATIO (S/(N+D))

f

INPUT

= 100 kHz 68 dB

f

INPUT

= 500 kHz 63 68 dB

f

INPUT

= 1.5 MHz 60 dB

SIGNAL-TO-NOISE RATIO (SNR)

f

INPUT

= 100 kHz 70 dB

f

INPUT

= 500 kHz 66 70 dB

f

INPUT

= 1.5 MHz 67 dB

TOTAL HARMONIC DISTORTION (THD)

f

INPUT

= 100 kHz –74 dB

f

INPUT

= 500 kHz –74 –64 dB

f

INPUT

= 1.5 MHz –60 dB

SPURIOUS FREE DYNAMIC RANGE (SFDR)

f

INPUT

= 100 kHz –77 dB

f

INPUT

= 500 kHz –77 –65 dB

f

INPUT

= 1.5 MHz –61 dB

INTERMODULATION DISTORTION (IMD)

1

65 dB

FULL POWER BANDWIDTH 5 MHz

SMALL SIGNAL BANDWIDTH (–20 dB FSR) 20 MHz

CODE TRANSITION NOISE 1/4 LSB rms

APERTURE DELAY 9 ns

APERTURE JITTER 10 ps rms

ACQUISITION TO FULL-SCALE STEP 150 ns

OVERVOLTAGE RECOVERY TIME 150 ns

NOTES

1

fs = 490 kHz; fb = 510 kHz typical value for third order products.

Specifications subject to change without notice.

DIGITAL SPECIFICATION

AD1672AP

Parameter Symbol Min Typ Max Units

LOGIC INPUTS

High Level Input Voltage V

IH

3.5 Volts

Low Level Input Voltage V

IL

1.0 Volts

High Level Input Current (V

IN

= VDD)IIH–10 10 µA

Low Level Input Current (V

IN

= 0 V) I

IL

–10 10 µA

Input Capacitance C

IN

10 pF

LOGIC OUTPUTS

High Level Output Voltage (I

OH

= 0.5 mA) V

OH

2.4 Volts

Low Level Output Voltage (I

OL

= 1.6 mA) V

OL

0.4 Volts

Output Capacitance C

OUT

5pF

Specifications subject to change without notice.

(T

MIN

to T

MAX

with VCC = +5 .0 V, VDD = +5.0 V, DRVDD = +5.0 V, f

SAMPLE

= 3 MHz, AIN = 0.5 dB in bipolar

–2.5 V to +2.5 V configuration unless otherwise noted)

AD1672

REV. 0

–3–

(T

MIN

to T

MAX

with VCC = +5 .0 V, VDD = +5.0 V, V

DRVDD

= +5.0 V unless otherwise noted)

AD1672

REV. 0

–4–

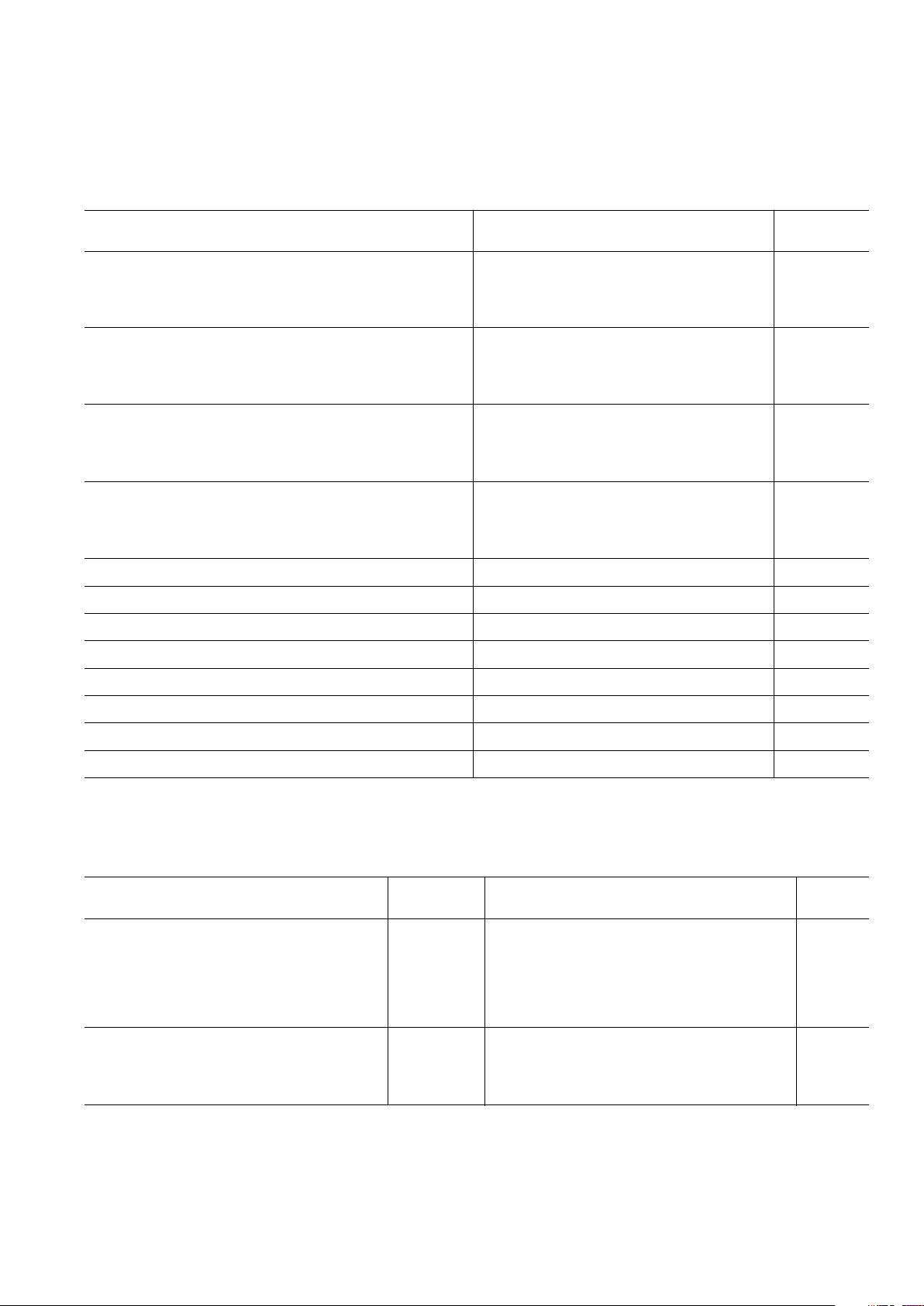

t

OD

S1

S1

S2

S2

S3

S3

DATA 1

DATA 2

ANALOG

INPUT

INPUT

CLOCK

DATA

OUTPUT

OTR

t

C

t

CL

t

CH

Figure 1. Timing Diagram

SWITCHING SPECIFICATIONS

Parameter Symbol Value Units

Clock Period t

C

334 ns min

Clock

Pulse Width High t

CH

167 ns min

Pulse Width Low t

CL

167 ns min

Output Delay t

OD

15 ns min

30 ns typ

Pipeline Delay (Latency) 2.5 Clock Cycles

ABSOLUTE MAXIMUM RATINGS*

Parameter With Respect to Min Max Units

V

CC

ACOM –0 5 +6.5 Volts

V

DD

DCOM –0.5 +6.5 Volts

DRV

DD

DRCOM –0.5 +6.5 Volts

ACOM DCOM, DRCOM –0.5 +0.5 Volts

CLOCK DCOM –0.5 V

DD

+ 0.5 Volts

Digital Outputs DCOM –0.5 DRV

DD

+ 0.5 Volts

AIN ACOM –6.5 +6.5 Volts

REFIN ACOM –0.5 V

CC

+ 0.5 Volts

Junction Temperature +150 °C

Storage Temperature –65 +150 °C

Lead Temperature (10 sec) +300 °C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum ratings for extended periods may effect device reliability.

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD1672 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

AD1672

REV. 0

–5–

PIN DESCRIPTION

Pin

Symbol No. Type Name and Function

DRCOM 1 P Digital Output Driver Ground.

BIT 12 2 DO Data Bit (LSB).

BIT 2–11 3–12 DO Data Bits.

BIT 1 13 DO Data Bit (MSB).

DRV

DD

14 P +5 V Digital Output Driver Sup-

ply.

OTR 15 DO Out of Range is Active High on

the leading edge of Code 0 or the

trailing edge of Code 4096. See

Output Data Format Table V.

CLOCK 16 DI Sample Clock.

V

DD

17 P +5 V Digital Supply.

DCOM 18 P Digital Ground.

REFCOM 19, 24 P Analog Ground.

REFOUT 20 AO 2.5 V Reference Output

(Decouple with 1 µF ceramic

capacitor to REFCOM).

AIN1 21 AI Analog Input.

AIN2 22 AI Analog Input.

REFIN 23 AI Reference Input.

NCOMP2 25 AO Noise Compensation (Decouple

with 1 µF ceramic capacitor to

ACOM).

NCOMP1 26 AO Noise Compensation (Decouple

with 1 µF ceramic capacitor to

ACOM).

ACOM 27 P Analog Ground.

V

CC

28 P +5 V Analog Supply.

TYPE: AI = Analog Input; DI = Digital Input; P = Power;

AO = Analog Output; DO = Digital Output.

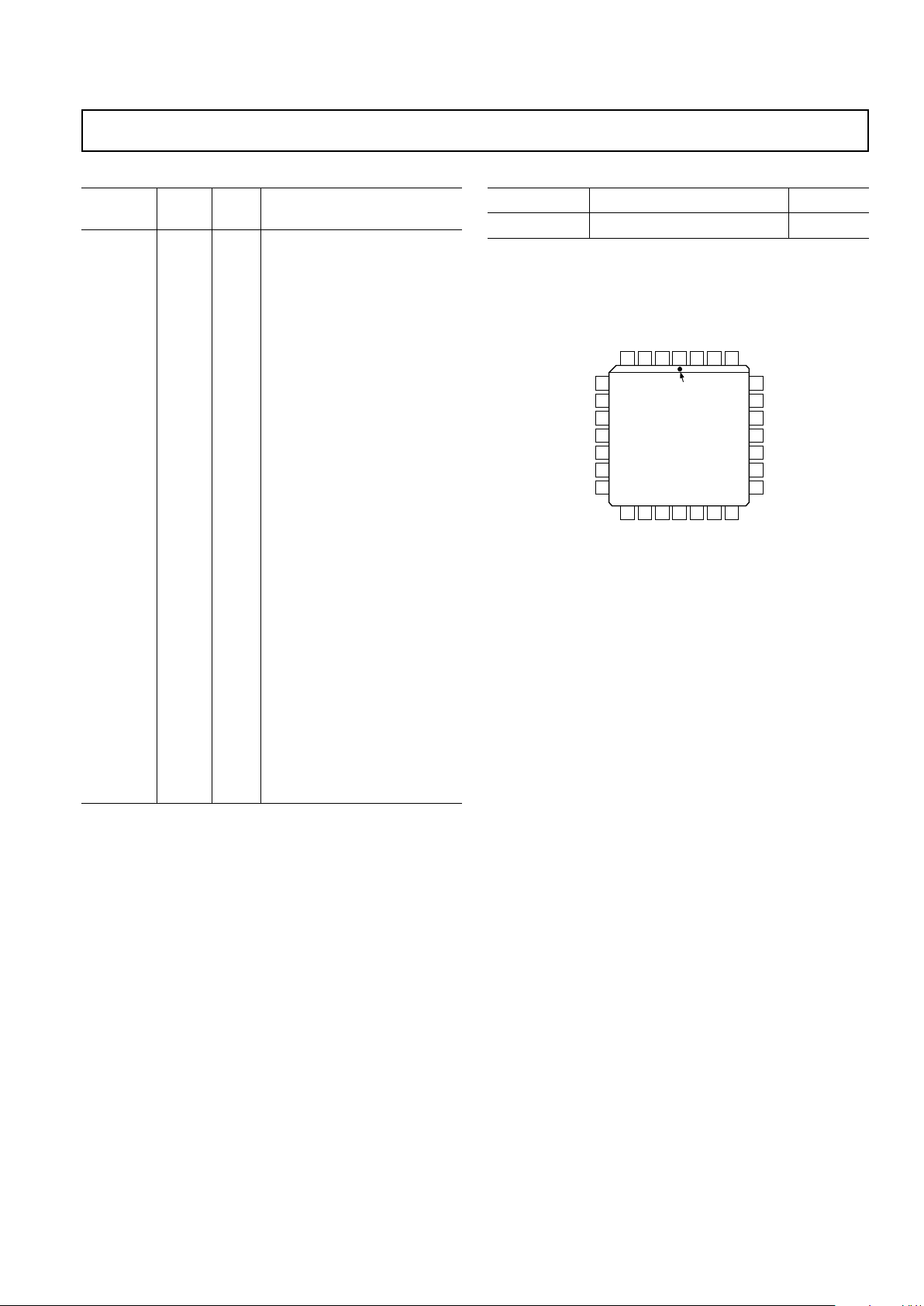

ORDERING GUIDE

Model Temperature Range Package

AD1672AP –40°C to +85°C P-28A

PIN CONFIGURATION

7

8

9

10

11

5

6

28 27 261234

21

22

23

24

25

19

20

121314 15 16 17 18

TOP VIEW

(Not to Scale)

PIN 1

IDENTIFIER

BIT 9

BIT 8

BIT 7

BIT 6

BIT 5

NCOMP2

REFCOM

REFIN

AIN2

AIN1

AD1672

BIT 4

BIT 3

REFOUT

REFCOM

ACOM

BIT 10

BIT 11

BIT 12 (LSB)

DRCOM

V

CC

(MSB) BIT 1

NCOMP1

BIT 2

DRV

DD

OTR

CLOCK

V

DD

DCOM

AD1672

REV. 0

–6–

DEFINITIONS OF SPECIFICATIONS

INTEGRAL NONLINEARITY ERROR (INL)

Integral nonlinearity error refers to the deviation of each individual

code from a line drawn from “negative full scale” through

“positive full scale.” The point used as “negative full scale”

occurs 1/2 LSB before the first code transition (all zeros to only

the LSB on). “Positive full scale” is defined as a level 1 1/2 LSB

beyond the last code transition (to all ones). The deviation is

measured from the middle of each particular code to the true

straight line.

DIFFERENTIAL LINEARITY ERROR (DNL, NO MISSING

CODES)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. Thus every

code must have a finite width. Guaranteed no missing codes to

12-bit resolution indicates that all 4096 codes must be present

over all operating ranges.

UNIPOLAR OFFSET ERROR

In the unipolar mode, the first transition should occur at a level

1/2 LSB above analog common. Unipolar offset is defines as

the deviation of the actual from that point.

BIPOLAR ZERO ERROR

In the bipolar mode, the major carry transition should occur for

an analog value 1/2 LSB below analog common. Zero error is

defined as the deviation of the actual transition from that point.

GAIN ERROR

The first transition should occur for an analog value 1/2 LSB

above nominal negative full scale. The last transition should

occur for an analog value 1 1/2 LSB below the nominal full

scale. Gain error is the deviation of the actual difference

between first and last code transitions and the ideal difference

between first and last code transitions.

POWER SUPPLY REJECTION

One of the effects of power supply error on the performance of

the device will be a small change in gain. The specifications

show the maximum change in the converter’s full scale as the

supplies are varied from minimum to maximum values.

APERTURE JITTER

Aperture jitter is the variation in aperture delay for successive

samples and is manifested as noise on the input to the A/D.

CODE TRANSITION NOISE

The effects of noise are to introduce an uncertainty in the precise determination of the analog input values at which the output code transitions take place, and, in effect, to increase or

reduce the quantization band. Code transition noise describes

the quantization band variation resulting from noise in terms of

rms LSBs.

APERTURE DELAY

Aperture delay is a measure of the Sample-and-Hold (SHA)

performance and is measured from the rising edge of the clock

input to when the input signal is held for conversion.

OVERVOLTAGE RECOVERY TIME

Overvoltage recovery time is defined as that amount of time

required for the ADC to achieve a specified accuracy after an

overvoltage (50% greater than full-scale range), measured from

the time the overvoltage signal reenters the converter’s range.

DYNAMIC SPECIFICATIONS

SIGNAL-TO-NOISE AND DISTORTION (S/N+D) RATIO

S/N+D is the ratio of the rms value of the measured input signal

to the rms sum of all other spectral components below the

Nyquist frequency, including harmonics but excluding dc. The

value for S/N+D is expressed in decibels.

TOTAL HARMONIC DISTORTION (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of the measured input signal and is

expressed as a percentage or in decibels.

INTERMODULATION DISTORTION (IMD)

With inputs consisting of sine waves at two frequencies, fa and

fb, any device with nonlinearities will create distortion products,

of order (m + n), at sum and difference frequencies of

mfa ± nfb, where m, n = 0, 1, 2, 3. . . . Intermodulation terms

are those for which m or n is not equal to zero. For example,

the second order terms are (fa + fb) and (fa – fb) and the third

order terms are (2 fa + fb), (2 fa – fb), (fa + 2fb) and (2 fb – fa).

The IMD products are expressed as the decibel ratio of the rms

sum of the measured input signals to the rms sum of the distortion terms. The two signals are of equal amplitude and the peak

value of their sums is –0.5 dB from full-scale. The IMD products are normalized to a 0 dB input signal.

FULL-POWER BANDWIDTH

The full-power bandwidth is that input frequency at which the

amplitude of the reconstructed fundamental is reduced by 3 dB

for a full-scale input.

SPURIOUS FREE DYNAMIC RANGE

The difference, in dB, between the rms amplitude of the input

signal and the peak spurious signal.

AD1672

REV. 0

–7–

Sample Rate: 3 MSPS and AIN = –0.5 dB

CODE

1.0

–1.0

0 4000500

DNL ERROR – LSB

1000 1500 2000 2500 3000 3500

0.8

0.2

–0.2

–0.6

-0.8

0.6

0.4

0.0

–0.4

Figure 2. Typical DNL Performance

INPUT FREQUENCY – Hz

S/(N+D) – dB

80

40

10

5

10

7

10

6

75

70

–0.5dB

– 6.0dB

60

55

50

45

65

– 20.0dB

Figure 3. S/(N+D) vs. Input Frequency

INL ERROR – LSB

CODE

2.5

–2.5

0 4000500 1000 1500 2000 2500 3000 3500

2.0

0.5

–0.5

–1.5

–2.0

1.5

1.0

0.0

–1.0

Figure 4. Typical INL Performance

AMPLITUDE – dB

70

58

–10 0–7

68

60

–5

62

64

66

S/(N+D) – dB

–9 –8 –6 –4 –3 –2 –1

500kHz

1.5MHz

1MHz

Figure 5. S/(N+D) vs. Amplitude

INPUT FREQUENCY – Hz

AMPLITUDE – dB

–40

–50

–90

10

5

10

7

10

6

–60

–70

–80

THD

2nd HARM

3rd HARM

Figure 6. Distortion vs. Input Frequency, Full-Scale Input

Typical Performance Characteristics–AD1672

REV. 0

–7–

Sample Rate: 3 MSPS and AIN = –0.5 dB

15dB/DIV

1

3

4

5

78

9

6

2

THD = –74.42dB

S/(N+D) = 68.83dB

SFDR = –78.79dB

HARMONICS – dB

2ND –79 6TH –86

3RD –86 7TH –93

4TH –78 8TH –95

5TH –81 9TH –96

Figure 7. Typical FFT, fIN = 525 kHz

AD1672–Dynamic Characteristics

REV. 0

–8–

15dB/DIV

1

3

4

5

7

8

9

6

THD = –60.12dB

S/(N+D) = 59.70dB

SFDR = –61.09dB

HARMONICS – dB

2ND –61 6TH –79

3RD –67 7TH –91

4TH –98 8TH –93

5TH –78 9TH –87

2

Figure 8. Typical FFT, fIN = 1.450 MHz

THEORY OF OPERATION

The AD1672 is implemented using a 4-stage pipelined multiple

flash architecture. The flash resolution for the stages is 4-4-3-4

with one-bit of overlap used between stages for error correction.

A low noise sample-and-hold amplifier (SHA) acquires a fullscale, single-ended input to 12-bit accuracy within 167 ns. A

4-bit approximation of the input is made by the first flash converter, and an accurate analog representation of this four-bit estimate is generated by a digital-to-analog (DAC) converter.

This approximation is subtracted from the SHA output to produce a remainder, or residue. This residue is then sampled and

held by the second SHA, and a 4-bit approximation is generated

and subtracted by the second stage. Once the second SHA goes

into hold, the first stage goes back into sample mode to acquire a

new input signal.

The third stage which has 3 bits of resolution is similar to the

first and second stage in that each stage consists of a SHA, flash

ADC, and a DAC. Each stage preforms a 4- (or 3-) bit approximation/subtraction operation with the residue of each stage

being passed on to the next stage. The fourth or last stage consists only of a 4-bit flash ADC which converts the final residue.

The 15 output bits from the 4 flash converters are accumulated

in the correction logic block, which adds the bits together using

the appropriate correction algorithm, to produce the 12 bit

output word. The digital output, together with the overrange

indicator (OTR), is latched into an output buffer to drive the

output pins.

The additional SHA inserted in each stage of the AD1672 architecture allows pipelining of the conversion. In essence, the converter is converting multiple inputs simultaneously, processing

them through the converter chain serially. This means that

while the converter is capable of capturing a new input sample

every clock cycle, it actually takes 2 1/2 clock cycles for the conversion to be fully processed and appear at the output. This

“pipeline delay” is often referred to as latency, and is not a concern in most applications, however there are some cases where it

may be a consideration. For example, some applications call for

the A/D converter to be placed in a high speed feedback loop,

where its input is servoed to provide a desired result at the digital output (e.g., offset calibration or zero restoration in video

applications). In these cases the clock cycle delay through the

pipeline must be accounted for in the loop stability calculations.

Also, because the converter is working on three conversions simultaneously major disruptions to the part (such as a large

glitch on the supplies or reference) may corrupt three data

samples. Finally, there will be a minimum clock rate below

which the SHA droop corrupts the signal in the pipeline. In the

case of the AD1672, this minimum clock rate is 20 kHz at

25°C.

The AD1672 clock circuitry uses both edges of the clock in its

internal timing circuitry (see specification page for exact timing

requirements). The AD1672 samples the analog input on the

rising edge of the clock input. During the clock low time (between the falling edge and rising edge of the clock), the input

SHA is in sample mode; during the clock high time it is in hold.

System disturbances just prior to the rising edge of the clock

may cause the part to acquire the wrong value, and should be

minimized. While the part uses both clock edges for its timing,

jitter is only a significant issue for the rising edge of the clock

(see CLOCK INPUT section).

AD1672

REV. 0

–9–

APPLYING THE AD1672

ANALOG INPUTS

Figure 9 shows the equivalent analog input of the AD1672. The

input SHA and associated resistor network topology can be easily configured for either unipolar (0 V to 2.5 V, 0 V to 5.0 V) or

bipolar (–2.5 V to 2.5 V) input signals as shown in Figure 10.

The nominal input resistance, R

IN

, of the AD1672 is 2 kΩ for a

2.5 V span and 4 kΩ for a 5 V span. The circuit topology both

level shifts and inverts the analog input for the various input

spans.

SHA

OUT

AIN 1

4kΩ

2kΩ

V

BIAS

1.25V

4kΩ

AIN 2

2kΩ

Figure 9. Equivalent Analog Input Circuit

21

22

20

23

1µF

AIN1

AIN2

REFOUT

REFIN

AD1672

V

IN

21

22

20

23

1µF

AIN1

AIN2

REFOUT

REFIN

AD1672

V

IN

21

22

20

23

1µF

AIN1

AIN2

REFOUT

REFIN

AD1672

V

IN

a. 0 to +2.5 V Input Range b. 0 to +5.0 V Input Range

c. –2.5 to +2.5 V Input Range

Figure 10. Input Range Connections

In applications where ac coupling of the analog input signal is

appropriate such as in a single supply system, the user can

capacitively couple the input signal for a 2.5 V or 5 V span thus

removing any preceding system dc offsets. Figure 11 shows the

proper configurations of the AD1672 for ac coupling. Maintaining the specifications outlined in the data sheet requires careful selection of the component values. The most important

concern is that the f

–3 dB

high pass corner is a function of C1 and

C2 in parallel with R

IN

. The f

-3 dB

point can be approximated

by the equation

/

f

–3 dB

=1/(2×π×RIN×C

EQ

)

where CEQ is the parallel combination of C1 and C2. Note that

C1 is typically a large electrolytic or tantalum capacitor that becomes inductive at high frequencies. Adding a small ceramic

capacitor on the order of 0.1 µF that does not become inductive

until negligibly higher frequencies maintains a low impedance

over a wide frequency range.

21

22

25

20

23

C1

10µF

C2

1.0µF

10µF

1.0µF

ANALOG

INPUT

AIN1

AIN2

NCOMP2

REF

OUT

REFIN

AD1672

21

22

25

20

23

C1

10µF

C2

1.0µF

10µF

1.0µF

ANALOG

INPUT

AIN1

AIN2

NCOMP2

REF

OUT

REFIN

AD1672

2.5V Span 5.0V Span

Figure 11. AC Coupled Inputs

In applications requiring dc coupling, a buffer amplifier is recommended for driving the AD1672 input. Any source resistance will contribute to both gain and offset error due to its

interaction with the AD1672’s input resistance. The particular

application and signal input range will determine how the buffer

amplifier is configured. For example, in dc precision applications, the buffer amplifier can be configured for convenient gain

and offset adjustment as shown in Figure 12. In spectral

analysis/signal processing applications, the buffer amplifier can

be configured as a 2nd order antialiasing filter in a Sallen-Key

or Multiple-Feedback topology as shown in Figure 13.

V

CC

500Ω 50Ω 500Ω

5kΩ

50Ω

5kΩ

0.1µF

V

EE

ANALOG

INPUT

OFFSET

ADJUSTMENTS

GAIN

ADJUSTMENT

AD1672

AIN

Figure 12. Offset and Gain Adjustment

V

IN

V

OUT

C2

R4

C1

R2R1

R3

V

IN

V

OUT

C2

C1

R2R1

R3

Figure 13. Sallen-Key and Multiple-Feedback

Antialiasing Filter Topologies

In imaging and multiplexed data acquisition applications, the

AD1672’s wide input bandwidth facilitates rapid acquisition of

transient input signals: the input SHA can typically settle to 12bit accuracy from a full scale input step in less than 150 ns. Figure 14 illustrates the typical acquisition of a full scale input step.

For amplifiers that are powered by supplies greater than

6.5 V, it is recommended that a clamping circuit be included at

the input of AD1672. This circuit limits the input voltage to

6.5 V under a fault condition.

AD1672

REV. 0

–10–

The selection of the buffer is of particular concern in preserving

the performance of the AD1672. The total output referrednoise contribution of the selected amplifier should be less than

200 µV rms to preserve the AD1672’s noise performance. The

amplifiers harmonic distortion should be 12 dB or better in performance than the AD1672 over the bandwidth and signal level

range of the particular application. The selected amplifier

should settle to 0.01% within 70 ns.

Table I lists the performance of various suitable amplifiers when

configured for a gain of +1 or –1 with the AD1672 configured

for ±2.5 V bipolar operation and f

CLOCK

= 3 MHz. The AD80xx

family of high speed amplifiers are only suitable for ±2.5 V

bipolar and 0 V–2.5 V unipolar operation due to their powersupply range and voltage output swing constraints. Note that

the SNR, THD, and SFDR results in Tables I, II and III are for

a 750 kHz full-scale (–0.5 dB) input signal. These results were

determined experimentally using the AD1672 evaluation board,

and hence the stated amplifier’s performance is inclusive of the

AD1672.

Table I. –2.5 V to +2.5 V Range

ADI

Part # SNR THD SFDR Gain

AD8047 70.5 –67.5 –68.4 +1

AD8041 70.0 –67.3 –68.2 +1

AD8011 70.5 –67.0 –67.8 +1

AD817 70.4 –62.1 –62.9 +1

AD818 70.3 –65.0 –68.0 –1

AD811 70.3 –61.9 –63.4 +1

w/o Op Amp 70.5 –67.5 –68.4

Table II lists the performance of three high speed amplifiers

which are configured for a gain of +1 or –1 with the AD1672

configured for 0 V to 5 V unipolar operation and f

CLOCK

= 3 MHz.

Note that these amplifiers may operate at the higher power supply range to achieve the 0 V to 5 V output swing.

Table II. 0 V to +5 V Range

Settling

ADI Time (ns)

Part # SNR THD to 0.01% Gain

AD811 70.1 –67.6 65 +1

AD817 70.1 –68.9 70 +1

AD818 70.0 –67.4 80 –1

Table III lists the performance of two high speed amplifiers

specified for single supply operation. They are configured for

a gain of +1 with the AD1672 configured for 0 V to 2.5 V

unipolar operation and f

CLOCK

= 3 MHz. The output of these

amplifiers are ac coupled to the AD1672.

Table III. AC Coupled 0 V to 2.5 V Range

ADI

Part # SNR THD SFDR

AD8011 70.1 –70.0 –71.6

AD8041 69.7 –71.3 –73.4

nsec

0 16020 40 60 80 100 120 140

4500

4000

0

2000

1500

1000

500

3000

2500

3500

CODE OUT

Figure 14. Typical AD1672 Settling Time

The AD1672 will contribute its own wideband thermal noise.

As a result of the integrated wideband noise (1/4 LSB rms,

referred-to-input), applying a dc analog input produces more

than one code at the output. A histogram analysis of the

AD1672 with a dc input is shown in Figure 15. It shows a bell

shaped curve consistent with the Gaussian nature of the thermal

noise. This histogram will be approximately 3 codes wide,

depending on how well the input is centered on a given code

and how many samples are taken. Figure 16 illustrates the

AD1672’s transition noise.

DEVIATION FROM CORRECT CODE – LSB

2100000

1800000

0

1200000

900000

600000

300000

1500000

+1–1 0

# CODE HITS

2015807

13639

67324

Figure 15. Typical Grounded Histogram

100

90

0

60

30

20

10

80

70

40

50

100 x p (≥ CODE X + 1)

σ = 0.25 LSB RMS

CODE X CODE X ÷ 1

Figure 16. Code Probability at a Transition

AD1672

REV. 0

–11–

REFERENCE INPUT

The nominal reference input is 2.5 V, taken with respect to

REFCOM. The reference input pin (REFIN) can be connected

to the reference output pin (REFOUT) or a standard external

+2.5 Volt reference can be selected to meet specific system requirements. Figure 17 shows the AD1672’s REFIN being

driven from an external precision voltage reference such as the

REF192. If an external reference is used, REFOUT can be effectively disabled by tying it directly to the positive supply voltage V

CC

. Note that if the reference is changed during a conversion,

all three conversions in the pipeline will be invalidated.

The nominal 2.5 V reference input is rescaled to 1.25 V via a

resistor divider network as shown in Figure 18. The nominal

resistance of this resistor network is 8 kΩ. Table IV summarizes various 2.5 V references for use with the AD1672 (see

REFERENCE OUTPUT section).

Table IV. Suitable 2.5 Volt References

Drift Initial Accuracy

(ppm/8C) %

REF43B 10 (max) 0.1

REF192E 5 (max) 0.08

AD780B 3 (max) 0.04

0.1µF10µF

+V

CC

+V

CC

AD780

OUTPUTGND

V

S

1µF

AD1672

REFIN

REFOUT

Figure 17. Circuit using AD780 Optional +2.5 V

Reference Input Circuit

REFERENCE NOISE REDUCTION

Figure 18 shows the proper connection of two external 1 µF

capacitors, C

NR1

and C

NR2

, associated with the two noise re-

duction nodes NCOMP1 and NCOMP2 (Pins 25 and 26) of

the AD1672. Although these noise reduction capacitors, CNR, are

not required for stability, the most optimum noise and distortion performance will be attained with a 1

µ

F ceramic capacitor connected

from each Noise Reduction node to ACOM. C

NR1

is associated with

the output of the DAC amp and is required for optimum distortion performance and SHA settling time. It provides a low

source impedance for signal-dependent, transient currents associated with this node. C

NR2

reduces the noise contribution from

the reference buffer amplifier.

CNR2

1µF

1µF

CNR1

1µF

NCOMP2

REFOUT

REFIN

AD1672

REFCOM

NCOMP1

DAC

AMP

REF

AMP

4kΩ

4kΩ

20

23

24

25

26

Figure 18. Reference Noise Reduction

REFERENCE OUTPUT

The AD1672 includes an onboard +2.5 V curvature compensated bandgap reference that has been laser trimmed for both

absolute value and temperature drift. The reference must be

externally compensated with a capacitor of 1 µF or greater from

REFOUT to REFCOM.

The reference is specified to provide an additional load current

up to 500 µA. For large dynamic loads and/or external loads

greater than 500 µA, an external buffer amplifier or pull-up re-

sistor is required. If a pull-up resistor is used, its value should

be selected such that REFOUT will not be required to sink any

current under all operating conditions. Figure 19 illustrates the

load regulation of the reference. The power supply rejection of

the reference is better than 0.2 % of FSR at dc.

LOAD CURRENT – µA

REFERENCE VOLTAGE – Volts

2.500

2.493

2.490

0 100 200 300 400 500 600 700 800 900 1000

2.499

2.494

2.492

2.491

2.498

2.496

2.497

2.495

Figure 19. Reference Output Voltage vs. Load Current

DIGITAL OUTPUTS

The AD1672 output data is presented in positive true straight

binary for both the 0 V to 2.5 V and 0 V to 5 V unipolar input

ranges and positive true offset binary for the ± 2.5 V bipolar

range. Table V indicates the output data formats for the three

analog input ranges. Users requiring twos complement encoding

for the ±2.5 V range may simply invert the MSB (Pin 13).

Table V. Output Data Format

Input Voltage Range +FS (V) –FS (V) LSB (mV)

0 to +2.5 +2.5 0.0 0.610

0 to +5.0 +5.0 0.0 1.22

–2.5 to +2.5 +2.5 –2.5 1.22

–FS+1/2 LSB

–FS

–FS –1/2 LSB

+FS

+FS –1/2 LSB

OTR

+FS –1 1/2 LSB

OTR DATA OUTPUTS

1 1111 111 1111

0 1111 1111 1111

0 1111 1111 1110

0 0000 0000 0001

0 0000 0000 0000

1 0000 0000 0000

Figure 20. Output Data Format

AD1672

REV. 0

–12–

The AD1672’s CMOS digital output drivers can be configured

to interface with +5 V or +3.3 V logic families by setting

DRV

DD

to +5 V or +3.3 V respectively . They are also sized to

provide sufficient output current to drive a wide variety of logic

families. However, large drive currents tend to cause glitches

on the supplies and may effect S/(N+D) performance. Applications requiring the AD1672 to drive large capacitive loads or

large fanout may require additional decoupling capacitors on

DRV

DD

and DVDD. In extreme cases, external buffers or

latches may be required.

OUT OF RANGE

An out-of-range condition exists when the analog input voltage

is beyond the input range (0 V to +2.5 V, 0 V to +5.0 V, ±2.5 V)

of the converter. OTR (Pin 15) is a digital output which is updated along with the data output pertaining to the particular

sampled analog input voltage. Hence, OTR has the same pipeline delay (latency) as the digital data. It is set low when the

analog input voltage is within the analog input range. It is set

HIGH and will remain HIGH when the analog input voltage

exceeds the input range by typically 1/2 LSB from the center of

the ±full-scale output codes. OTR will remain HIGH until the

analog input is within the input range and another conversion is

completed. By logical ANDing OTR with the MSB and its

complement, overrange high or underrange low conditions can

be detected. Table IV is a truth table for the over/under range

circuit in Figure 20 which uses NAND gates. Systems requiring programmable gain conditioning prior to the AD1672 can

immediately detect an out-of-range condition, thus eliminating

gain selection iterations. Also, OTR can be used for digital offset and gain calibration (see Gain and Offset Adjustment).

Table VI. Out-of-Range Truth Table

OTR MSB Analog Input Is

0 0 In Range

0 1 In Range

1 0 Underrange

1 1 Overrange

OVER = “1”

UNDER = “1”

MSB

OTR

LSB

Figure 21. Overrange or Underrange Logic

CLOCK INPUT

The AD1672 internal timing control uses the two edges of the

clock input to generate a variety of internal timing signals. The

clock input must meet or exceed the minimum specified pulse

width high and low (t

CH

and tCL) specifications of 167 ns to

maintain the AD1672’s rated performance. At a clock rate of

3 MSPS, the clock input must have a 50% duty cycle to meet

this timing requirement. For clock rates below 3 MSPS, the

duty cycle may deviate from 50% to the extent that both tch and

tcl are satisfied. One way to minimize the tolerance of a 50%

duty cycle clock is to divide down a clock of higher frequency,

as shown in Figure 22.

6MHz

CLK

3MHz

+5V

R

Q

Q

D

S

+5V

Figure 22. Divide-by-Two Clock Circuit

In this case, a 6 MHz clock is divided by 2 to produce the 3 MHz

clock input for the AD1672. In this configuration, the duty

cycle of the 6 MHz clock is irrelevant.

The input circuitry for the CLOCK pin is designed to accommodate CMOS inputs. The quality of the logic input, particularly the rising edge, is critical in realizing the best possible jitter

performance for the part: the faster the rising edge, the better

the jitter performance.

The offset of the AD1672 is sensitive to the rising edge (i.e.,

dV/dt) seen at CLOCK due to clock feedthrough. An additional offset component becomes noticeable for rise times below

10 ns and causes an additional few LSBs of offset. The amount

of additional offset is dependent on dV/dt of the rising edge and

hence will remain constant for nonvarying rising edges. For

applications which are sensitive to a change in offset due to a

variation in the rise edge, the CLOCK rise time may be reduced

by selecting a slower logic family or installing a 1 kΩ resistor between the clock driver and CLOCK of the AD1672.

As a result, careful selection of the logic family for the clock

driver, as well as the fanout and capacitive load on the clock

line, is important. Jitter-induced errors become more predominant at higher frequency, large amplitude inputs, where the

input slew rate is greatest.

Although the AD1672 is designed to support a sampling rate of

3 MSPS, operating at slightly faster or slower clock rates may be

possible with a minimum degradation in performance levels. Figure 23 is a plot of the S/(N+D) vs. clock frequency for a 500 kHz

analog input. In fact, the AD1672 is capable of operating with

a clock frequency as low as 20 kHz

FREQUENCY – MHz

75

70

50

050.5

S/(N+D) – dB

1 1.5 2 2.5 3 3.5 4 4.5

65

60

55

Figure 23. Typical S/(N+D) vs. Clock Frequency;

f

IN

= 500 kHz, Full-Scale Input

AD1672

REV. 0

–13–

The power dissipated by the correction logic and output buffers

is largely proportional to the clock frequency; running at reduced

clock rates provides a slight reduction in power consumption.

Figure 24 illustrates this tradeoff.

FREQUENCY – MHz

260

252

244

250

248

246

258

256

254

050.5

POWER – mW

1 1.5 2 2.5 3 3.5 4 4.5

Figure 24. Typical Power Dissipation vs. Clock Frequency

GROUNDING AND POWER SUPPLY DECOUPLING

RULES

Proper grounding and decoupling should be a primary design

objective in any high speed, high resolution system. The AD1672

features separate analog and digital supply and ground pins to

optimize the management of analog and digital ground currents

in a system. In general, V

CC

, the analog supply, should be decoupled to ACOM, the analog common, as close to the chip as

physically possible. Similarly, V

DD

, the digital supply, should be

decoupled to DCOM as close to the chip as physically as possible. DRV

DD

, the digital supply for the output drivers should

be decoupled to DRCOM which is also connected to the digital

ground plane.

Figure 31, the AD1672/EB evaluation board schematic, demonstrates the recommended decoupling strategy for the supply

pins. Note that in extremely noisy environments, a more elaborate supply filtering scheme may be necessary. Figure 25 shows

the power supply rejection ratio vs. frequency for 100 mV of

FREQUENCY – MHz

1100.2

SUPPLY REJECTION – dB

2

–30

–120

–40

–50

–60

–70

V

CC

V

DD

DRV

DD

–80

–90

–100

–110

0.1 0.5

5

Figure 25. Power Supply Rejection vs. Frequency,

100 mV p-p Signal on Power Supplies

FREQUENCY – MHz

0.1 100.2 2

75

65

60

55

40

50

45

70

DRV

DD

V

CC

V

DD

510.5

S/(N+D) – dB

Figure 26. S/(N+D) vs. Supply Noise Frequency

power supply ripple at various frequencies. Figure 26 shows the

degradation in S/(N+D) ratio resulting from this 100 mV power

supply ripple for a full-scale analog input at 500 kHz. The

AD1672/EB evaluation board was used to generate these graphs

The AD1672 is designed to minimize the code dependent current at REFCOM, therefore reducing input dependent analog

ground voltage drops and errors. The majority of code dependent ground current is diverted to ACOM.

The digital activity on the AD1672 chip falls into two general

categories: CMOS correction logic, and CMOS output drivers.

The internal correction logic draws relatively small surges of

current which flow through V

DD

and DCOM. The output

drivers draw large current impulses while the output bits are

changing. The size and duration of these currents is a function

of the load on the output bits: large capacitive loads are to be

avoided. The output drivers are supplied through DRV

DD

and

DRCOM. A 0.1 µF ceramic capacitor for decoupling the driver

supply, DRV

DD

, is appropriate for a reasonable capacitive load

on the digital outputs (typically 20 pF on each pin). Applications involving greater digital loads should consider increasing

the digital decoupling proportionately.

For those applications that require a single +5 V supply for both

the analog and digital supply, a clean analog supply may be

generated using the circuit shown in Figure 27. The circuit

consists of a differential LC filter with separate power supply

and return lines. Lower noise can be attained using low ESR

(Equivalent Series Resistance) type electrolytic and tantalum

capacitors.

FERRITE

BEADS

100µF

ELECT.

10–20µF

TANT.

0.1µF

CER.

+5V

AGND

+5V DGND

+5V

POWER SUPPLY

TTL/CMOS

LOGIC

CIRCUITS

Figure 27. Differential LC Filter for Single +5 V Applications

AD1672

REV. 0

–14–

GAIN AND OFFSET ADJUSTMENT

The AD1672 is factory trimmed to minimize gain, offset and

linearity errors. In some applications, the gain and offset errors

need to be externally trimmed to zero. Since the gain and offset

errors of the AD1672 are interdependent, an iterative process is

required to trim both errors. The OTR pin can be monitored to

trim the offset and gain errors to within 1/2 LSB of negative and

positive full-scale (i.e., –FS and +FS) respectively. In this case,

the calibration procedure would be to iterate between –FS and

+FS voltage levels which are applied to the input of the AD1672

and adjust the offset and gain until OTR toggles at both –FS

and +FS.

Both gain and offset errors may be trimmed with external calibration circuits based on a potentiometer or a DAC. Digital

calibration circuits using a DAC offers greater flexibility and

can be programmed for various operating conditions. The following digital calibration circuits are based on the DAC08

which is a low cost, 8-bit current output DAC with 85 ns settling time performance. Different adjustment spans and resolution may be achieved by judicious selection of the resistors in

the circuit.

Figure 28 shows an offset correction circuit for the unipolar

input ranges of 0 V to 2.5 V and 0 V to 5.0 V. The complementary current outputs of the DAC08 provide a bipolar adjustment

range at the output of the op amp if R

S

is made equal to RF/G.

G is the noninverting gain of the op amp and is equal to

1 + R

F/RA

. REFOUT divided by RIN sets the full-scale current

output, I

FS

, for the DAC08 Note, RP is a pull-up resistor used

to source additional current if I

FS

is greater than 500 µA. The

bipolar voltage adjustment span at the output of the op amp is

equal to I

FS

× RF. RI isolates the op amp from the DAC08

output capacitance. Note, that the values of these resistors can

be optimized for any circuit requirement or adjustment span

since they are not uniquely defined for any given voltage span.

R

F

R

A

R

I

R

I

V

REF(+)

V

REF(–)

DAC08

I

O

I

O

R

IN

RIN1µF

R

P

AD1672

AIN

REFOUT

+V

CC

Figure 28. Unipolar Offset Correction Using the DAC08

Figure 29 shows an offset correction circuit for the bipolar input

range of –2.5 to +2.5 V. This circuit is similar to the circuit

shown in Figure 28 except that the op amp is configured in an

inverting topology so that the voltage compliance of the DAC08

is not exceeded.

R

F

R

A

R

I

R

I

V

REF(+)

V

REF(–)

DAC08

I

O

I

O

R

IN

RIN1µF

R

P

+V

CC

R

S

AD1672

AIN

REFOUT

Figure 29. Bipolar Offset Correction Using the DAC08

Figure 30 shows a gain correction circuit which is also similar to

the circuit shown in Figure 28. The circuit consists of a unity

gain amplifier in which R

S

and RF are equal to 158 Ω. In this

case, the full-scale output current of the DAC08, I

FS

, is set at

500 µA to minimize the load to the AD1672 REFOUT. The

output of the op amp can be varied over a ±78 mV range

around the midscale voltage of REFOUT. Also, R

S

and RF are

selected such that 1 LSB of the DAC08 corresponds to 1 LSB

of the AD1672.

500Ω

5kΩ

5kΩ

1µF

4.7kΩ

+V

CC

AD1672

REFIN

REFOUT

2.5V

V

REF(+)

V

REF(–)

DAC08

I

O

I

O

500Ω

158Ω

158Ω

2.5 ±0.078V

Figure 30. Gain Correction Using the DAC08

OUTPUT LATCHES

The AD1672/EB evaluation board schematic in Figure 31

shows the AD1672 connected to the 74HC541 octal/buffer line

drivers with three-state outputs. The latch can drive highly capacitive loads (i.e., bus lines, I/O ports) while maintaining the

data signal integrity.

AD1672 EVALUATION BOARD GENERAL DESCRIPTION

The AD1672/EB is an evaluation board for the AD1672 12-bit

3 MSPS analog-to-digital converter (ADC). Figure 31 shows the

schematic for the AD1672/EB evaluation board. Careful attention

to layout and circuit design combined with analog and digital prototyping areas allows the user to easily and effectively evaluate the

AD1672 in any application requiring high resolution, high speed

conversion.

The analog input to the AD1672/EB may be driven directly or

via an onboard buffer amplifier. The AD1672/EB contains an

8-bit DAC which can be easily configured for input offset adjustment or for reconstruction of the digital output. An optional

external voltage reference is included for greater dc precision

AD1672

REV. 0

–15–

and/or offset adjustment purposes. Onboard data buffers are

also included. The AD1672/EB requires an external clock

which is applied from a user’s bench or generated from a circuit

built on the prototyping area. A standard 40-pin IDC-connector

provides access for the digital outputs from the AD1672/EB. The

user must also provide a digital +5 V power supply and analog

±5 V supplies to operate the AD1672/EB.

OPERATING PROCEDURE AND FUNCTIONAL

DESCRIPTION

Power

Apply power to the AD1672/EB by attaching banana plugs to

the appropriate banana jacks on the printed circuit board (Figure 31). The +V

CC

analog supply should be +5 V (± 5%) and

be capable of supplying 70 mA. The –V

EE

analog supply should

be –5 V (±5%) and be capable of supplying 20 mA. The +V

DD

digital supply should be +5 V (± 5%) and be capable of supplying 12 mA (not including any additional current required by the

digital load).

The power supply pin for the onboard output drivers internal to

the AD1672 (DRV

DD

–Pin 14) can be driven directly by the

digital supply, +V

DD

, by installing JP10 or may be driven via a

separate supply by removing JP10 and driving the test point,

TP5. The separate supply option allows the user to interface

with +5 V or +3.3 V (±5%) logic families.

JP1 To provide +V

CC

supply to both U3 (DAC08) and U1

(op amp), attach jumper JP1.

JP10 To provide +5 V (+/-5%) supply to DRV

DD

pin of

AD1672 via +V

DD

or separate supply. To provide power

to DRV

DD

pin via +VDD, install JP10. To provide power

to DRV

DD

pin via separate supply, remove JP10 and con-

nect external supply to test point TP5.

Analog Inputs

The BNC jack, AIN (J1), accepts voltage inputs that comply

with the analog input requirements of the AD1672. It is terminated with a 49.9 Ω resistor (R1) located on the componentside of the evaluation board. Remove and/or replace this

resistor with other values in order to match different cable impedances. The AD1672 analog input can be directly driven via

AIN (J1) by installing JP2 and removing JP3 or it can be driven

via an amplifier (U1) by installing JP3 and removing JP2. The

amplifier (U1) may be configured in the inverting or noninverting mode with a gain of one by configuring S4.

JP2 Installing JP2 and removing JP3, directly dc couples AIN

(J1) to the AD1672 analog input.

JP3 Installing JP3 and removing JP2, indirectly dc couples

AIN (J1) to the AD1672 analog input via the inverting

op amp U1.

S4 Selects inverting or noninverting gain of one for the am-

plifier U1. When S4 is in position A, the noninverting

mode is selected. When S1 is in position B, the inverting

mode is selected.

The AD1672’s analog input range can be configured for

0 V–2.5 V, 0 V–5 V, or ± 2.5 V by installing only one of the four

jumpers, JP5–JP7, as outline in Table VII.

JP5 Installing only jumper JP5, the 0 V–2.5 V range of the

AD1672 is selected.

JP6 Installing only jumper JP6, the 0 V–5 V range of the

AD1672 is selected.

JP7 Installing only jumper JP7, the ±2.5 V range of the

AD1672 is selected.

Table VII. Analog Input Range Selection

Analog Input Range

(Volts) JP5 JP6 JP7

0 to 2.5 ON OFF OFF

0 to 5.0 OFF ON OFF

±2.5 OFF OFF ON

Reference

An external 2.5 V voltage reference, U2, is also included on the

AD1672/EB to provide the option for greater dc precision than

the AD1672’s internal reference. The external reference also

provides the proper biasing currents for the offset adjustment

circuitry consisting of U3. To use the external voltage reference

for the AD1672, install JP9 and remove JP4. To use the AD1672’s

internal voltage reference, install JP4 and remove JP9.

JP4 Installing JP4 and removing JP9 selects the AD1672’s

internal reference.

JP9 Installing JP9 and removing JP4 selects the external

reference, U2.

Offset Adjustment/Reconstruction DAC

An 8-bit complementary current output DAC08, U3, allows for

either offset adjustment of the analog input or reconstruction of

the AD1672 digital output for simple evaluation purposes. The

offset adjustment option is implemented by installing both JP3

and JP8. Note that JP5, JP6 and JP7 should be removed so

that the AD1672 is configured for a 0 V–5 V range.

The DAC08 can also be configured to reconstruct the digital

output of the AD1672 using its digital output for the DAC08’s

digital input. The output of the user supplied ribbon cable used

to interface with the 40-pin IDC connector (E1) can be connected directly to the connector U8, hence recirculating the

eight most significant digital output bits of the AD1672. In this

configuration, JP8 would be removed and the reconstructed

waveform (±50 mV p-p) can be monitored via test point TP4.

JP8 Installing JP8 and removing JP5, JP6 and JP7 selects the

offset adjustment option. Removing JP8 and connecting

E1 to U8 via an external user-supplied ribbon cable

selects the reconstruction option.

AD1672

REV. 0

–16–

Clock Input

A 49.9 Ω resistor (R9) terminates this input. Remove and/or

replace this resistor with other values in order to match different

cable impedances. An external sample clock must be provided

to the BNC connector labeled CLK (J5). The rising or falling

edge of CLK can be selected to trigger a conversion and is available to the user via the connector E1 by configuring S1 and S3.

The CLK INPUT has two modes of operation which is

determined by the position of S5. When S5 is in Position B, the

CLK is directly coupled to U5, a Hex inverter with Schmitt trigger inputs. The requisite input levels are CMOS-compatible in

this mode. When S5 is in Position A, the CLK is ac coupled via

C23 and level shifted via R10, R12, and R13. This mode is

used to generate a low jitter clock input for the AD1672 with a

tunable duty cycle. The input to CLK (J5) is a filtered 5 V p-p

sine wave at the desired sampling frequency. The duty cycle

may be adjusted via R10.

S1 Selects the rising or falling edge of CLK to initiate a con-

version. When S1 is in Position A, the falling edge of

CLK is selected. When S1 is in Position B, the rising

edge of CLK is selected.

S3 Selects the rising or falling edge of CLK made available to

the user via the connector via E1, Pin 33. When S3 is in

Position A, the rising edge of CLK is selected. When S1

is in Position B, the falling edge of CLK is selected.

S5 Selects CLK INPUT mode of operation. If S5 is in Posi-

tion A, the low jitter, ac coupled mode of operation is selected. If S5 is Position B, the dc coupled mode

of operation is selected.

Digital Inputs/Outputs

The digital outputs of the AD1672 are buffered and connected

to a 40-pin IDC connector (E1). The digital output can be either in a straight binary or twos complement format by configuring S2. S2 selects the MSB output or its complement. The

Out-of-Range (OTR) output is available on test point, OTR.

S2 Selects either the MSB or its complement for either

straight binary or twos complement digital output data

formatting, respectively. When S2 is in Position A, the

straight binary format is selected. When S2 is in Position

B, the twos complement format is selected.

Layout Considerations

Figure 31 to 34 show the schematic diagram, component layout,

trace routing, and silk screening for the AD1672 4-layer

evaluation board. Figure 35 and 36 show the AD1672 ground

and power plane layouts.

The AD1672-EB is a 4-layer evaluation board consisting of

separate ground and power plane layouts. Separate ground and

power planes have several advantages for high speed layouts.

(For further information outlining these advantages, see the

application note “Design and Layout of a Video Graphics System for Reduced EMI” [E1309] available from Analog Devices

[(617) 461-3392].) The ground planes are separated into analog and digital planes that are joined together under the AD1672.

The AD1672 should be treated as an analog component and a

common ground connection should be made underneath the

AD1672 despite some pins being labeled “digital” and some as

“analog” ground plane.

A summary of the test point designators and a parts list is given

in Table VIII and IX.

Table VIII. Summary of Test Point Designators

Test Point Description

TP1 AGND

TP2 AIN

TP3 V

CC

for U1 and U3

TP4 DAC08 (U3) V

OUT

TP5 DRV

DD

TP6 DGND

TP7 CLK

Table IX. AD1672 EB Parts List

Reference Value/Part Type Package Qty/Bd

U1 AD8047 8-Pin DIP 1

U2 REF192 8-Pin DIP 1

U3 DAC08 16-Pin DIP 1

U4 AD1672 28-Pin PLCC 1

U5 74HC14N 14-Pin DIP 1

U6, U7 74HC541N 20-Pin DIP 2

AIN, CLK BNC JACKs Small, Vertical 2

JP1–10 Headers/Shunts 2-Pin 10

S1-S5 SPDT, Secme 0.1" × 0.3" 5

E1 40-Pin IDC R.A., Male 1

Connector w/Latches

R1, R9 50 Ω 1%, 1/4 Ω 2

R2–R4 499 Ω 1%, 1/4 Ω 6

R11–R13

R5 4.99 kΩ 1%, 1/4 Ω 1

R6 100 Ω 1%, 1/4 Ω 1

R7, R8 2.49 kΩ 1%, 1/4 Ω 2

R10 2.0 kΩ POT 1%, 1/4 Ω 2

C1, C2, C4, 0.1 µF Ceramic, SMT 11

C12–C16,

C18–C20

C3, C6–C9, 1.0 µF Ceramic, 8

C11, C22, C23 Throughhole

C5, C17, C21 10 µF Tantanlum 3

Throughhole

C10 0.01 µF Ceramic 1

C24 47 µF Alum. Elect. 1

AD1672

REV. 0

–17–

S3

A

B

246

8

101214

16

182022

24

26

28

30

32

36

38

40

34

E1E1E1E1E1E1E1E1E1E1E1E1E1E1E1E1E1E1E1

E1

A

TP9

AGND

AGND

A

TP12

+V

DD

C21

10µF

16V

TP11

DGND

DGND

+V

DD

A

TP10

+V

CC

C17

10µF

16V

+V

CC

TP8

–V

EE

C5

10µF

16V

–V

EE

C1

1µF

J3

J7

J6

J4

J2

56789

101112

13

2

A

A

C15

0.1µF

13579

111315

U8U8U8U8U8U8U8

U8

246

8

101214

16

U8U8U8U8U8U8U8

U8

A

R7

2.5kΩ

15

A

16

1

4

C10

0.1µF

A1A2A3A4A5A6A7A8V

CC

GND

V

REF(–)

COMP

NC

IO–

DAC08

U3

V

REF(+)

–V

EE

C16

0.1µF

14

R8

2.5kΩ

R6

100Ω

R5

5kΩ

TP4

A

REF192

4

62

+V

CC

C4

0.1µF

S5

A

B

9

8

U5

74HC14

C18

0.1µF

+V

DD

11 10

U5

74HC14

13

12

U5

74HC14

V

IN

V

OUT

GND

U2

A

C22

1µF

3

2

4

7

6

U1

AD8047

A

R4

500Ω

A

S4

A

B

EREF

JP9

A

C2

0.1µF

–V

EE

R3

500Ω

TP2

R1

50Ω

A

AIN

TP1

J1

JP1

+V

CC

A

C1

0.1µF

TP3

R2

500Ω

JP3

JP2

A

C8

1µF

JP4

A

A

C6

1µF

JP5

JP7

JP8

JP6

A

3

V

EE

A

A

C7

1µF

+V

DD

C11

1µF

C12

0.1µF

+V

CC

C9

1µF

C14

0.1µF

A

S2

A

B

3

4

U5

74HC14

JP10

TP5

C13

0.1µF

+V

DD

OTR

181716151413121120

74HC541N

C19

0.1µF

+V

DD

1192345678109

G1G2A0A1A2A3A4A5A6A7GND

Y0Y1Y2Y3Y4Y5Y6

Y7

+5VD

U6

TP7

R9

50Ω

CLK

J5

CW

C23

1µF

R10

2kΩ

R13

500Ω

181716151413121120

74HC541N

C20

0.1µF

+V

DD

1

19

2

34567

8109

G1G2A0A1A2A3A4A5A6A7GND

Y0Y1Y2Y3Y4Y5Y6

Y7

+5VD

U7

S1

A

B

5

6

U5

74HC14

C24

47µF

R12

500Ω

+V

DD

1

2

U5

74HC14

R11

500Ω

3

252729

31

35

37

39

1

7

9

11

5

33

23

21

13

15

17

19

E1

E1

E1

E1

E1

E1

E1

E1

E1

E1

E1

E1

E1E1E1

E1

E1

E1

E1

E1

19

26

23

20

21

22

24

17

18

27

28

25

16

8

9

10

11

12

U4

AD1672

15

14

13

6

7

1

2

3

4

5

TP6

Figure 31. Evaluation Board Schematic

AD1672

REV. 0

–18–

Figure 32. PCB Component Side Layout for Evaluation Board

Figure 33. PCB Solder Side Layout for Evaluation Board

AD1672

REV. 0

–19–

Figure 34. PCB Component Side Silkscreen

Figure 35. PCB Ground Plane Layout for AD1672

AD1672

REV. 0

–20–

Figure 36. PCB Power Plane Layout for AD1672

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead PLCC

(P-28A)

4

PIN 1

IDENTIFIER

5

26

25

11

12

19

18

TOP VIEW

(PINS DOWN)

0.495 (12.57)

0.485 (12.32)

SQ

0.456 (11.58)

0.450 (11.43)

SQ

0.048 (1.21)

0.042 (1.07)

0.048 (1.21)

0.042 (1.07)

0.020

(0.50)

R

0.050

(1.27)

BSC

0.021 (0.53)

0.013 (0.33)

0.430 (10.92)

0.390 (9.91)

0.032 (0.81)

0.026 (0.66)

0.180 (4.57)

0.165 (4.19)

0.040 (1.01)

0.025 (0.64)

0.056 (1.42)

0.042 (1.07)

0.025 (0.63)

0.015 (0.38)

0.110 (2.79)

0.085 (2.16)

C2049–10–7/95

PRINTED IN U.S.A.

Loading...

Loading...