Analog Devices AD9660 Datasheet

200 MHz Laser Diode Driver

a

FEATURES

1.5 ns Rise/2.0 ns Fall Times

Output Current: 180 mA @ 3 V, 200 mA @ 2.5 V

Bias Current: 90 mA @ 3 V

Modulation Current: 60 mA @ 3 V

Offset Current: 30 mA @ 3 V

Single +5 V Power Supply

Switching Rate: 200 MHz

Onboard Light Power Control Loops

APPLICATIONS

Laser Printers and Copiers

Optical Disk Drives

FO Datacomm

GENERAL DESCRIPTION

The AD9660 is a highly integrated driver for laser diode applications such as optical disk drives, printers, and copiers. The

AD9660 gets feedback from an external photo detector and includes two analog feedback loops to allow users to set “bias”

and “write” (for optical disk drives) power levels of the laser,

and switch between the two power levels at up to 200 MHz.

Output rise and fall times are typically 1.5 ns and 2.0 ns to

complement printer applications that use image enhancing techniques such as pulse width modulation to achieve gray scale,

and allow disk drive applications to improve density and take

advantage of pulsed write formats. Control signals are TTL/

CMOS compatible.

with Light Power Control

AD9660

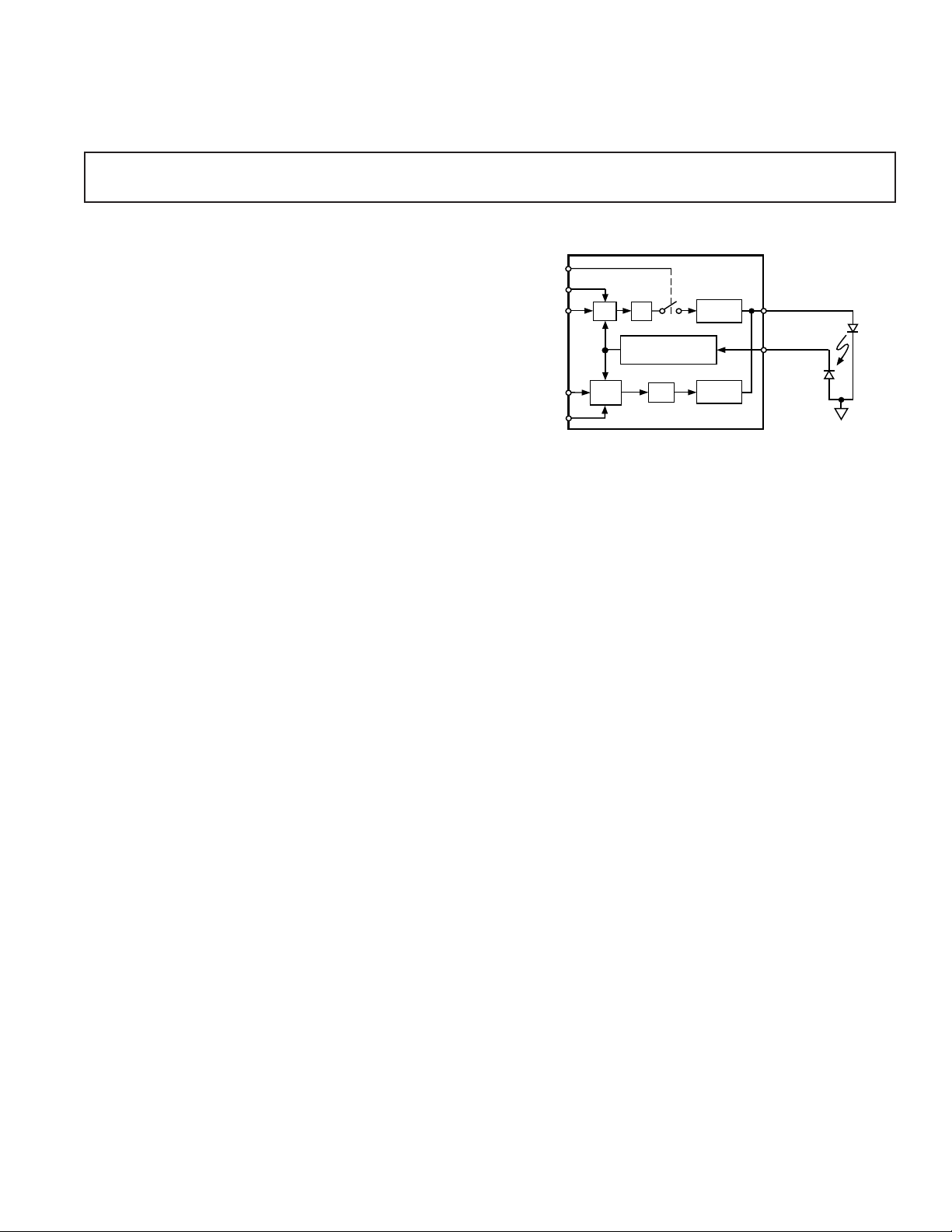

FUNCTIONAL BLOCK DIAGRAM

WRITE

PULSE

WRITE

CALIBRATE

WRITE

LEVEL

BIAS

LEVEL

BIAS

CAL

TRANSIMPEDANCE

BIAS

T/H

V:1T/H

AMPLIFIER

V:1

OUTPUT

DRIVER

OUTPUT

DRIVER

AD9660

The driver output provides up to 180 mA of current @ 3 V,

90 mA of BIAS current, 60 mA of modulation current, and

30 mA of offset current. The onboard disable circuit turns off

the output drivers and returns the light power control loops to a

safe state.

The AD9660 can also be used in closed loop applications in

which the output power level follows an analog WRITE LEVEL

voltage input. By optimizing the external hold capacitor, and

the photo detector, the write loop can achieve bandwidths as

high as 25 MHz.

The AD9660 is offered in a 28-pin plastic SOIC for operation

over the commercial temperature range (0°C to +70°C).

OUTPUT

SENSE

INPUT

PHOTO

DETECTOR

DIODE

LASER

DIODE

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1995

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

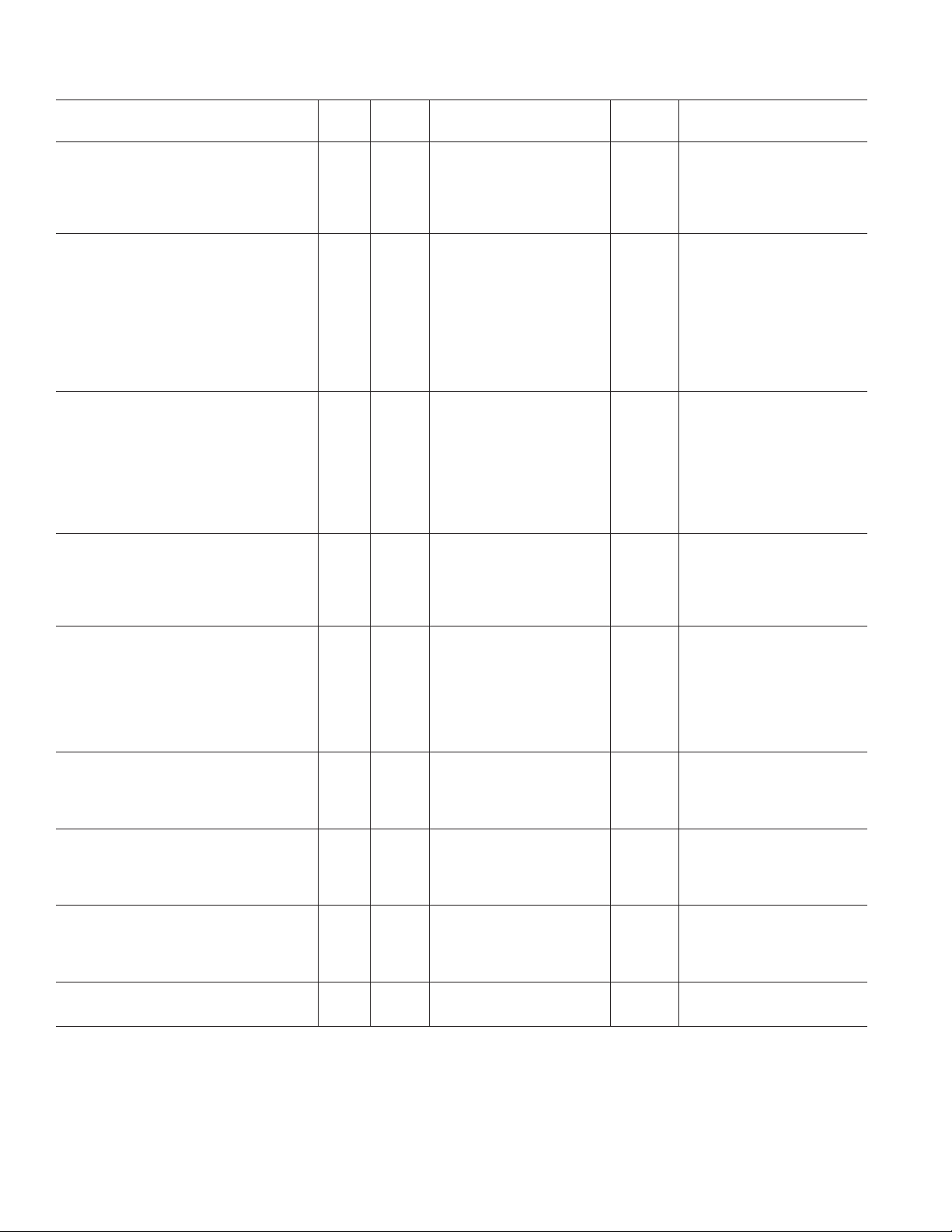

(+V

= +5 V, Temperature = +25°C unless otherwise noted. Sourced currents defined

S

AD9660–SPECIFICATIONS

as positive.)

Test AD9660KR

Parameter Level Temp Min Typ Max Units Conditions

ANALOG INPUTS

(WRITE LEVEL, BIAS LEVEL)

Input Voltage Range IV Full V

REF

V

REF

+ 1.6 V

Input Bias Current I +25°C –50 +50 µA

Analog Bandwidth V Full 25 MHz External Hold Cap = 20 pF

OUTPUTS

Maximum Output Current, I

I

OUT

Bias Current, I

BIAS

Modulation Current, I

Offset Current, I

OFFSET

OUT

MODULATION

I +25°C 200 mA V

I +25°C 180 mA V

I +25°C90 mA V

I +25°C60 mA V

I +25°C30 mA V

OUT

OUT

OUT

OUT

OUT

= 2.5 V

= 3.0 V

= 3.0 V

= 3.0 V

= 3.0 V

Output Compliance Range I +25°C 0 3.0 V

Idle Current I +25°C 3 13 mA WRITE PULSE = LOW,

DISABLE = HIGH

SWITCHING PERFORMANCE

Maximum Pulse Rate IV +25°C 200 250 MHz 3 dB Reduction in I

OUT

Output Propagation Delay (tPD), Rising1IV Full 1.6 3.0 ns

Output Propagation Delay (t

Output Current Rise Time

Output Current Fall Time

WRITE CAL Aperture Delay

Disable Time

5

), Falling1IV Full 1.6 2.5 ns

PD

2

3

4

IV Full 1.1 1.5 1.7 ns

IV Full 1.4 2.0 2.8 ns

V +25°C13 ns

V +25°C5 ns

HOLD NODES

(WRITE HOLD, BIAS HOLD)

Input Bias Current I +25°C –200 200 nA V

Input Voltage Range IV Full V

REF

V

+ 1.6 V Open Loop Application Only

REF

HOLD

= 2.5 V

Minimum External Hold Cap V Full 20 pF

TTL INPUTS

6

Logic “1” Voltage I +25°C 2.0 V DISABLE = LOW

Logic “1” Voltage IV Full 2.0 V While Other

Logic “0” Voltage I +25°C 0.8 V TTL Inputs Are

Logic “0” Voltage IV Full 0.8 V Tested

Logic “1” Current I +25°C –10 20 10 µA

Logic “0” Current I +25°C –1.5 mA

BANDGAP REFERENCE

Output Voltage V

REF

I +25°C 1.55 1.75 1.90 V

Temperature Coefficient V –0.2 mV/°C

Output Current V +25°C –0.5 1.0 mA

SENSE IN

Current Gain V +25°C 1.85 mA/mA

Voltage I +25°C 3.7 4.0 4.3 V I

MONITOR

= 2 mA

Input Resistance V +25°C <150 Ω

POWER SUPPLY (DISABLE = HIGH)

+V

Voltage I +25°C 4.75 5.00 5.25 V DISABLE = HIGH

S

Current I +25°C 75 110 150 mA

+V

S

Power Dissipation I +25°C 550 mW

OFFSET CURRENT

OFFSET SET Voltage I +25°C 1.1 1.4 1.7 V I

NOTES

1

Propagation delay measured from the 50% of the rising/falling transition of WRITE PULSE to 50% point of the rising/falling edge of the output modulation current.

2

Rise time measured between the 10% and 90% points of the rising transition of the modulation current.

3

Fall time measured between the 10% and 90% points of the falling transition of the modulation current.

4

Aperture Delay is measured from the 50% point of the rising edge of WRITE PULSE to the time when the output modulation begins to recalibrate, WRITE CAL is

held during this test.

5

Disable Time is measured from the 50% point of the rising edge of DISABLE to the 50% point of the falling transition of the output current. Fall time during disable

is similar to fall time during normal operation.

6

WRITE PULSE, WRITE CAL, BIAS CAL, OFFSET PULSE are TTL compatible inputs.

Specifications subject to change without notice.

MONITOR

= 4.0 mA

–2–

REV. 0

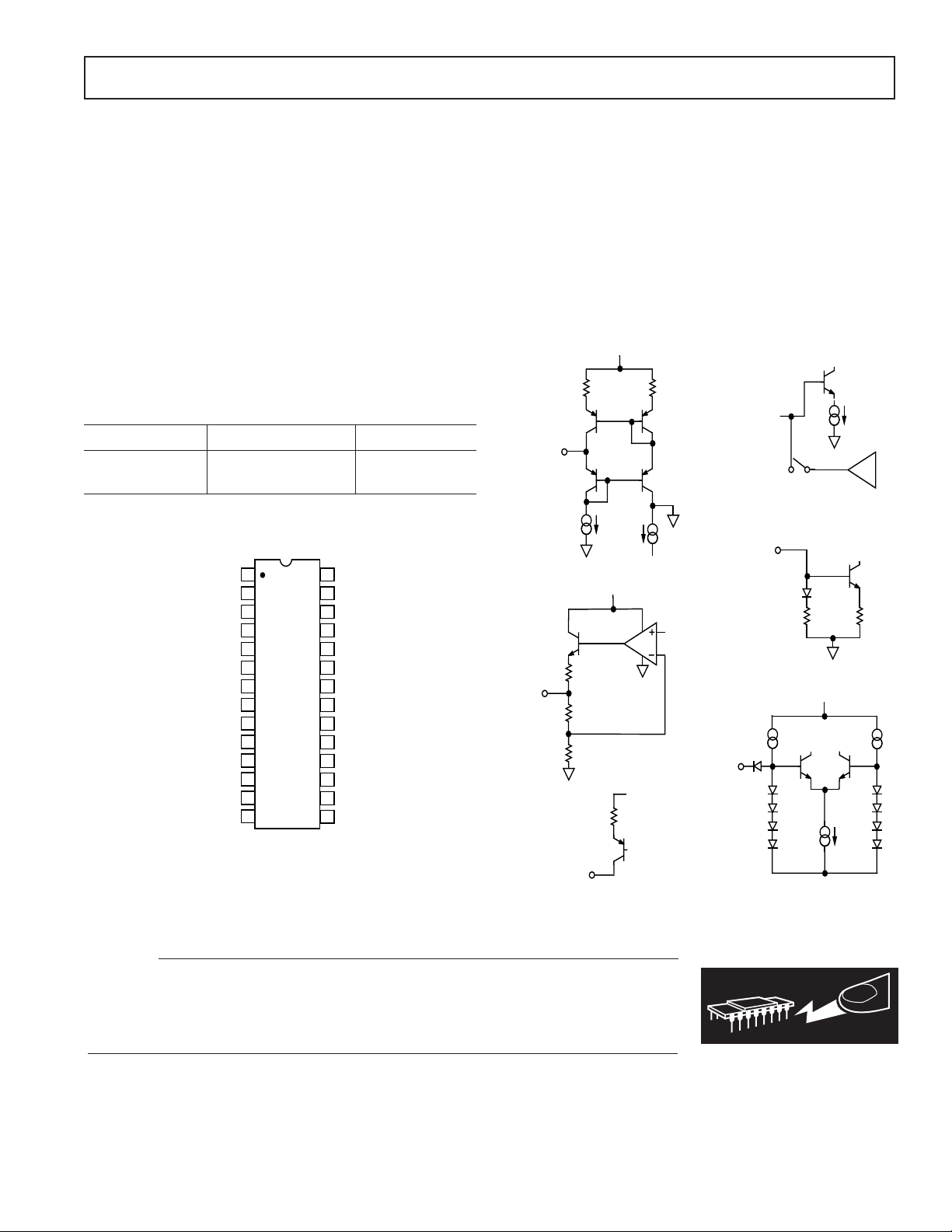

AD9660

100Ω

450Ω

1250Ω

V

BANDGAP

V

REF

+V

S

1mA

+V

S

50Ω 50Ω

SENSE

IN

T/H

WRITE

HOLD

BIAS

HOLD

OUTPUT

+V

S

OFFSET

SET

TTL

INPUT

+V

S

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

+VS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +6 V

V

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 mA

REF

WRITE LEVEL, BIAS LEVEL . . . . . . . . . . . . . –0.5 V to +V

TTL INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to +V

S

S

Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 mA

Operating Temperature

AD9660KR . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature

2

. . . . . . . . . . . . . . . . +150°C

Lead Soldering Temp (10 sec) . . . . . . . . . . . . . . . . . . . +300°C

1

Absolute maximum ratings are limiting values, to be applied individually, and

beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied. Exposure of

absolute maximum rating conditions for extended periods of time may affect

device reliability.

2

Typical thermal impedance is θJA = 45°C/W, θJC = 41°C/W.

ORDERING GUIDE

Model Temperature Range Package Option

AD9660KR 0°C to +70°C R-28

AD9660KR-REEL 0°C to +70°C R-28 (1000/reel)

PIN ASSIGNMENTS

EXPLANATION OF TEST LEVELS

Test Level

I. 100% Production Tested.

II. 100% production tested at +25°C, and sample tested at

specified temperatures. AC testing done on sample basis.

III. Sample Tested Only.

IV. Parameter is guaranteed by design and characterization

testing.

V. Parameter is a typical value only.

VI. All devices are 100% production tested at +25°C, sample

tested at temperature extremes.

WRITE CAL

WRITE PULSE

WRITE LEVEL

V

REF

WRITE HOLD

GROUND

+V

SENSE IN

GAIN

POWER MONITOR

+V

GROUND

BIAS HOLD

BIAS LEVEL

S

S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AD9660KR

TOP VIEW

(Not to Scale)

28

OFFSET PULSE

27

OFFSET SET

26

GROUND

25

+V

S

24

OUTPUT

23

+V

S

22

OUTPUT

21

+V

S

20

OUTPUT

+V

19

S

OUTPUT

18

17

GROUND

DISABLE

16

15

BIAS CAL

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9660 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

Equivalent Circuits

REV. 0

–3–

AD9660

PIN DESCRIPTIONS

Pin Function

OUTPUT Analog laser diode current output. Connect to anode of laser diode, cathode connected to GROUND externally.

BIAS LEVEL Analog voltage input, V

tion as follows:

BIAS CAL TTL/CMOS compatible, Bias loop T/H control signal. Logic HIGH enables calibration mode, and the bias loop

T/H immediately goes into track mode. Logic LOW disables the bias loop T/H and immediately places it in hold

mode. WRITE PULSE should be held logic LOW while calibrating. Floats logic HIGH.

BIAS HOLD External hold capacitor for the bias loop T/H. Approximate droop in the bias current while BIAS CAL is logic

LOW is:

±∆I

BIAS

=

WRITE PULSE TTL/CMOS compatible, current control signal. Logic HIGH supplies I

LOW turns I

MODULATION

WRITE CAL TTL/CMOS compatible, write loop T/H control signal. Logic HIGH enables calibration mode; before enabling

calibration the bias loop should be calibrated and OFFSET PULSE driven to an appropriate state. In calibration

mode, 13 ns after the WRITE PULSE goes logic HIGH, the write loop T/H goes into track mode (there is no delay if WRITE PULSE is HIGH before WRITE CAL transitions to a HIGH level). The write loop T/H immediately goes into hold mode when the WRITE PULSE goes Logic LOW. WRITE CAL LOW disables the write

loop T/H and places it in hold mode. Floats logic HIGH.

WRITE LEVEL Analog voltage input, V

I

tion as follows:

MONITOR

REF

18 ×10

C

to V

+ 1.6 V. Bias current is set proportional to the BIAS LEVEL during calibra-

REF

I

MONITOR

–9

t

BIAS HOLD

BIAS HOLD

off. Floats logic HIGH.

REF

to V

=

+1.6 V. Write current is set proportional to the input voltage during calibra-

REF

V

WRITE LEVEL−VREF

1. 85 ×(R

GAIN

V

BIAS LEVEL−VREF

=

1. 85 × R

+50 Ω

()

GAIN

. Bandwidth of the loop is:

+ 50 Ω)

BW =

2π (550 Ω)C

MODULATION

1

BIAS HOLD

to the laser diode. Logic

WRITE HOLD External hold capacitor for the write loop T/H. Approximate droop in I

−9

±∆I

logic LOW is:

MODULATED

BW =

2π (550 Ω) C

1

BIAS HOLD

SENSE IN Analog current input, I

MONITOR

18 ×10

=

, from PIN photo detector diode. SENSE IN should be connected to the cathode

t

WRITE HOLD

C

WRITE HOLD

. Bandwidth of the loop is:

MODULATION

current while WRITE CAL is

of the PIN diode, with the PIN anode connected to GROUND or a negative voltage. Voltage at SENSE IN varies slightly with temperature and current, but is typically 4.0 V.

GAIN External connection for the feedback network of the transimpedance amplifier. External feedback network, R

and C

, should be connected between GAIN and POWER MONITOR. See text for choosing values.

GAIN

GAIN

POWER Output voltage monitor of the internal feedback loop. Voltage is proportional to feedback current from photo

MONITOR diode.

OFFSET Set resistor connection for the offset current source. Resistor between OFFSET CURRENT SET and +V

S

CURRENT SET determines offset current level. The input voltage at this node varies slightly with temperature and current, but is

typically 1.4 V. See curves. Can also be driven with a current out DAC.

OFFSET TTL/CMOS compatible, OFFSET current control signal. Logic HIGH adds I

PULSE turns off I

. Floats logic HIGH.

OFFSET

OFFSET

to I

. Logic LOW

OUT

DISABLE TTL/CMOS compatible, current output disable circuit. Logic LOW for normal operation; logic HIGH disables

the current outputs to the laser diode, and drives the voltage on the hold capacitors close to V

(minimizes the

REF

output current when the device is re-enabled). DISABLE floats logic HIGH.

V

+V

REF

S

Analog Voltage Output, internal bandgap voltage reference, ~1.75 V, provided to user for power level offset.

Positive Power Supply. Nominally +5 V, pin connections should be tied together externally.

GROUND Ground Reference. All grounds should be tied together externally.

–4–

REV. 0

Loading...

Loading...