Page 1

1.2 GHz Clock Distribution IC, 1.6 GHz Inputs,

FEATURES

Two 1.6 GHz, differential clock inputs

5 programmable dividers, 1 to 32, all integers

Phase select for output-to-output coarse delay adjust

3 independent 1.2 GHz LVPECL outputs

Additive output jitter 225 fs rms

2 independent 800 MHz/250 MHz LVDS/CMOS clock outputs

Additive output jitter 275 fs rms

Fine delay adjust on 1 LVDS/CMOS output

Serial control port

Space-saving 48-lead LFCSP

APPLICATIONS

Low jitter, low phase noise clock distribution

Clocking high speed ADCs, DACs, DDSs, DDCs, DUCs, MxFEs

High performance wireless transceivers

High performance instrumentation

Broadband infrastructure

Dividers, Delay Adjust, Five Outputs

AD9512

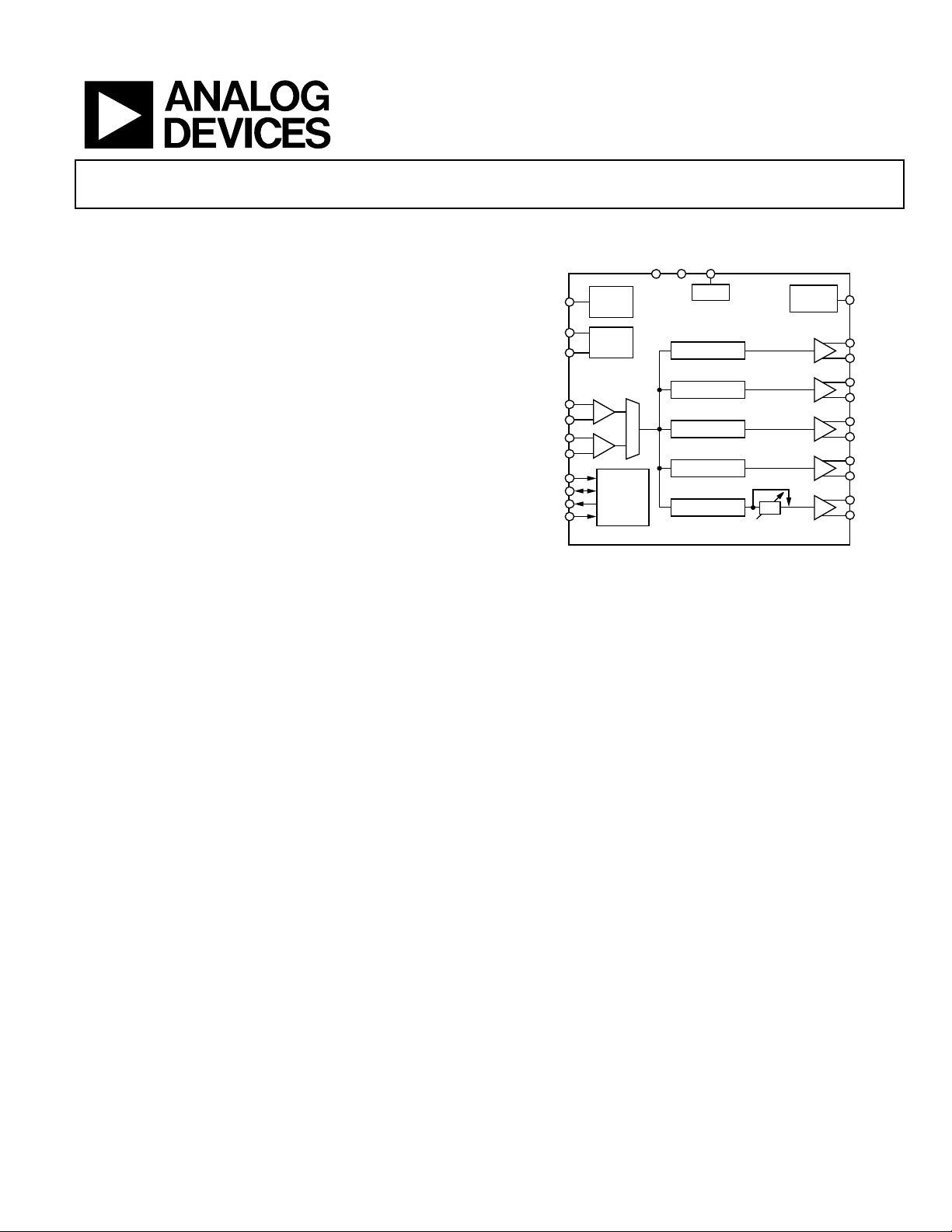

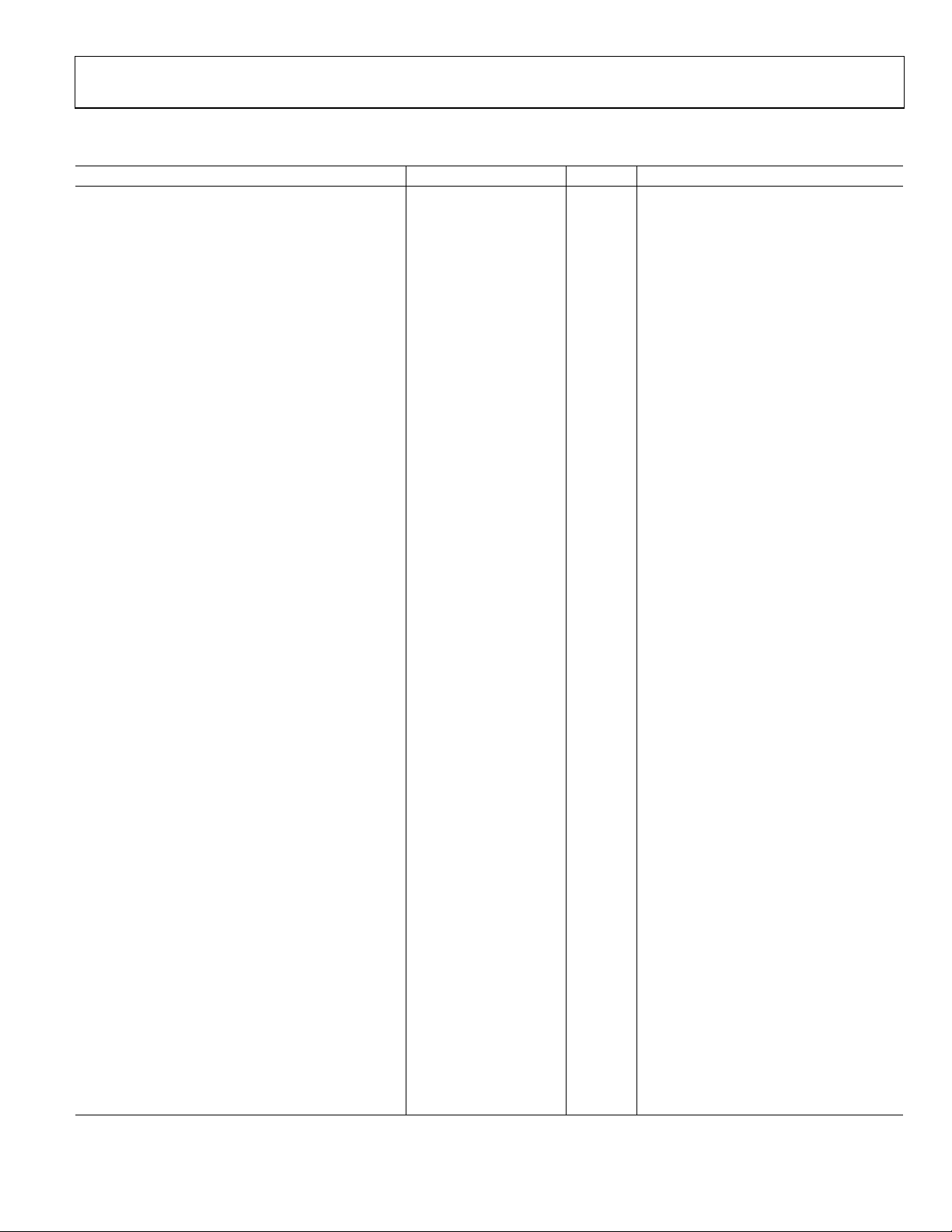

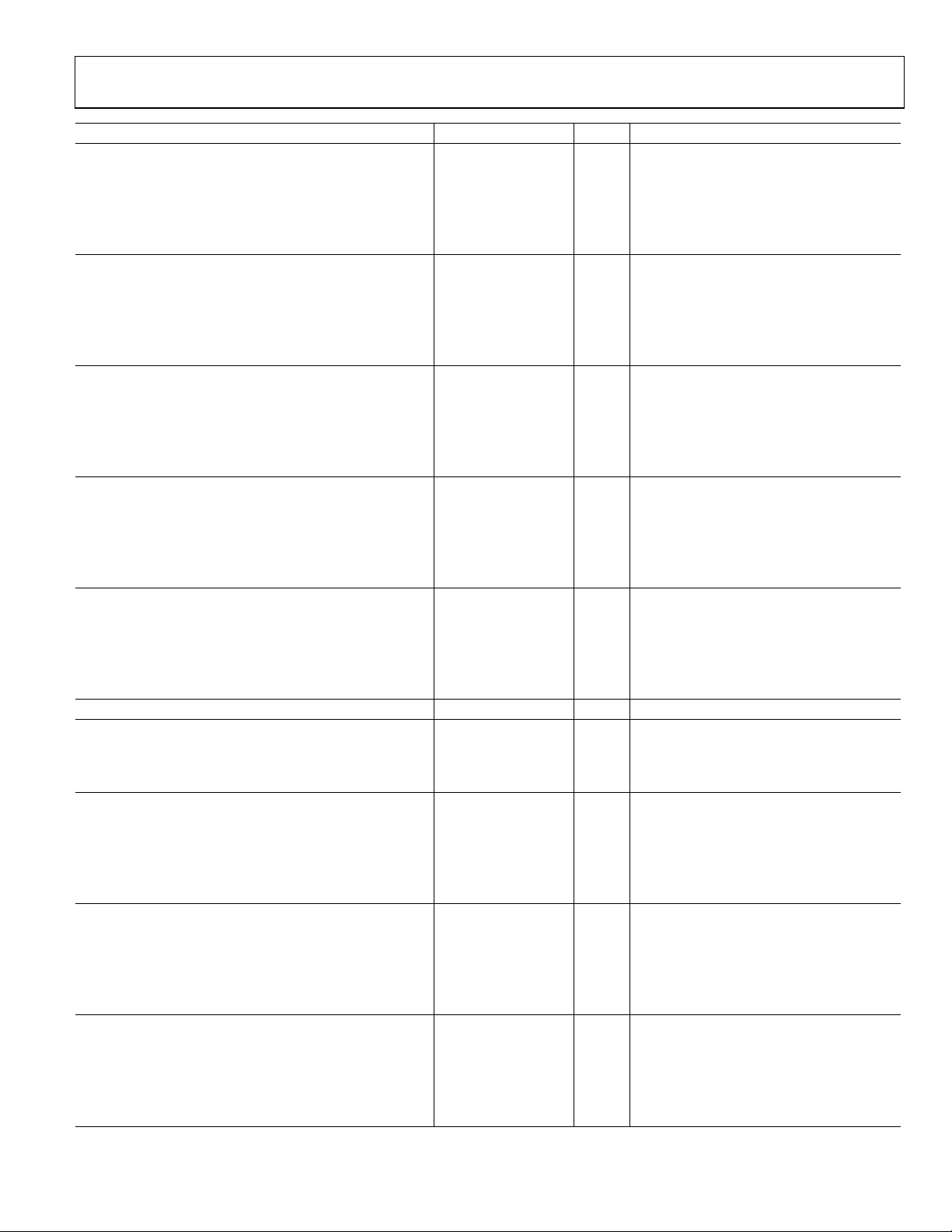

FUNCTIONAL BLOCK DIAGRAM

GNDVS

RSET

FUNCTION

DSYNC

DSYNCB

CLK1

CLK1B

CLK2

CLK2B

SCLK

SDIO

SDO

CSB

SYNCB,

RESETB

PDB

DETECT

SYNC

SERIAL

CONTROL

PORT

VREF

PROGRAMMABLE

DIVIDERS AND

PHASE ADJUST

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

Figure 1.

AD9512

DELAY

ADJUST

Δ

T

SYNC

STATUS

LVPECL

LVPECL

LVPECL

LVDS/CMOS

LVDS/CMOS

SYNC

STATUS

OUT0

OUT0B

OUT1

OUT1B

OUT2

OUT2B

OUT3

OUT3B

OUT4

OUT4B

05287-001

GENERAL DESCRIPTION

The AD9512 provides a multi-output clock distribution in a

design that emphasizes low jitter and low phase noise to

maximize data converter performance. Other applications with

demanding phase noise and jitter requirements can also benefit

from this part.

There are five independent clock outputs. Three outputs are

LVPECL (1.2 GHz), and two are selectable as either LVDS

(800 MHz) or CMOS (250 MHz) levels.

Each output has a programmable divider that may be bypassed

or set to divide by any integer up to 32. The phase of one clock

output relative to another clock output may be varied by means

of a divider phase select function that serves as a coarse timing

adjustment.

One of the LVDS/CMOS outputs features a programmable

delay element with a range of up to 10 ns of delay. This fine

tuning delay block has 5-bit resolution, giving 32 possible delays

from which to choose.

The AD9512 is ideally suited for data converter clocking

applications where maximum converter performance is

achieved by encode signals with subpicosecond jitter.

The AD9512 is available in a 48-lead LFCSP and can be

operated from a single 3.3 V supply. The temperature range is

−40°C to +85°C.

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2005 Analog Devices, Inc. All rights reserved.

Page 2

AD9512

TABLE OF CONTENTS

Specifications..................................................................................... 4

Outputs ........................................................................................ 30

Clock Inputs.................................................................................. 4

Clock Outputs............................................................................... 4

Timing Characteristics ................................................................ 5

Clock Output Phase Noise .......................................................... 7

Clock Output Additive Time Jitter........................................... 10

Serial Control Port ..................................................................... 12

FUNCTION Pin ......................................................................... 13

SYNC Status Pin ......................................................................... 13

Power ............................................................................................14

Timing Diagrams............................................................................ 15

Absolute Maximum Ratings.......................................................... 16

Thermal Characteristics ............................................................ 16

ESD Caution................................................................................ 16

Pin Configuration and Function Descriptions........................... 17

Te r mi n ol o g y .................................................................................... 19

Typical Performance Characteristics ........................................... 20

Functional Description .................................................................. 24

Overall.......................................................................................... 24

FUNCTION Pin ......................................................................... 24

RESETB: 58h<6:5> = 00b (Default)..................................... 24

SYNCB: 58h<6:5> = 01b .......................................................24

PDB: 58h<6:5> = 11b............................................................. 24

DSYNC and DSYNCB Pins....................................................... 24

Clock Inputs................................................................................ 24

Dividers........................................................................................ 25

Setting the Divide Ratio ........................................................ 25

Setting the Duty Cycle........................................................... 25

Divider Phase Offset .............................................................. 29

Delay Block.................................................................................. 30

Calculating the Delay............................................................. 30

Power-Down Modes .................................................................. 31

Chip Power-Down or Sleep Mode—PDB........................... 31

Distribution Power-Down .................................................... 31

Individual Clock Output Power-Down............................... 31

Individual Circuit Block Power-Down................................ 31

Reset Modes ................................................................................ 31

Power-On Reset—Start-Up Conditions when

VS is Applied........................................................................... 31

Asynchronous Reset via the FUNCTION Pin ................... 31

Soft Reset via the Serial Port................................................. 31

Single-Chip Synchronization.................................................... 32

SYNCB—Hardware SYNC ................................................... 32

Soft SYNC—Register 58h<2>............................................... 32

Multichip Synchronization ....................................................... 32

Serial Control Port ......................................................................... 33

Serial Control Port Pin Descriptions....................................... 33

General Operation of Serial Control Port............................... 33

Framing a Communication Cycle with CSB ...................... 33

Communication Cycle—Instruction Plus Data................. 33

Wr it e ........................................................................................ 33

Read ......................................................................................... 34

The Instruction Word (16 Bits)................................................ 34

MSB/LSB First Transfers ........................................................... 34

Register Map and Description...................................................... 37

Summary Table........................................................................... 37

Register Map Description ......................................................... 39

Power Supply................................................................................... 43

Power Management ................................................................... 43

Applications..................................................................................... 44

Using the AD9512 Outputs for ADC Clock Applications.... 44

CMOS Clock Distribution ........................................................ 44

Rev. A | Page 2 of 48

Page 3

AD9512

LVPECL Clock D i s t r ib ut i o n ......................................................45

LVDS Clock Distribution...........................................................45

Power and Grounding Considerations and Power Supply

Rejection.......................................................................................45

Outline Dimensions ........................................................................46

Ordering Guide ...........................................................................46

REVISION HISTORY

6/05—Rev. 0 to Rev. A

Changes to Features..........................................................................1

Changes to General Description .....................................................1

Changes to Table 1 ............................................................................4

Changes to Table 3 ............................................................................5

Changes to Table 4 ............................................................................7

Changes to Table 5 and Table 6 .....................................................12

Changes to Table 7 ..........................................................................13

Changes to Figure 12 and Figure 14 to Figure 16 .......................21

Changes to Figure 17 Caption .......................................................22

Changes to Figure 23 ......................................................................23

Changes to Divider Phase Offset Section ....................................29

Changes to Chip Power-Down or Sleep Mode—PDB Section .31

Changes to Distribution Power-Down Section...........................31

Changes to Individual Clock Output Power-Down Section .....31

Changes to Individual Circuit Block Power-Down Section ......31

Changes to Soft Reset via the Serial Port Section .......................31

Changes to SYNCB—Hardware SYNC Section..........................32

Changes to Soft SYNC Register 58h<2> Section ........................32

Changes to Multichip Synchronization Section..........................32

Changes to Serial Control Port Section .......................................33

Changes to Serial Control Port Pin Descriptions Section.........33

Changes to General Operation of Serial

Control Port Section.......................................................................33

Added Framing a Communication Cycle with CSB Section ....33

Added Communication Cycle—Instruction Plus

Data Section.....................................................................................33

Changes to Write Section ............................................................... 33

Changes to Read Section................................................................34

Changes to Instruction Word (16 Bits) Section ..........................34

Changes to MSB/LSB First Transfers Section..............................34

Changes to Figure 32 and Figure 36 .............................................35

Added Figure 38; Renumbered Sequentially...............................36

Changes to Table 17 ........................................................................37

Changes to Table 18 ........................................................................39

Changes to Power Supply Section.................................................43

Changes to Power Management Section......................................43

4/05—Revision 0: Initial Version

Rev. A | Page 3 of 48

Page 4

AD9512

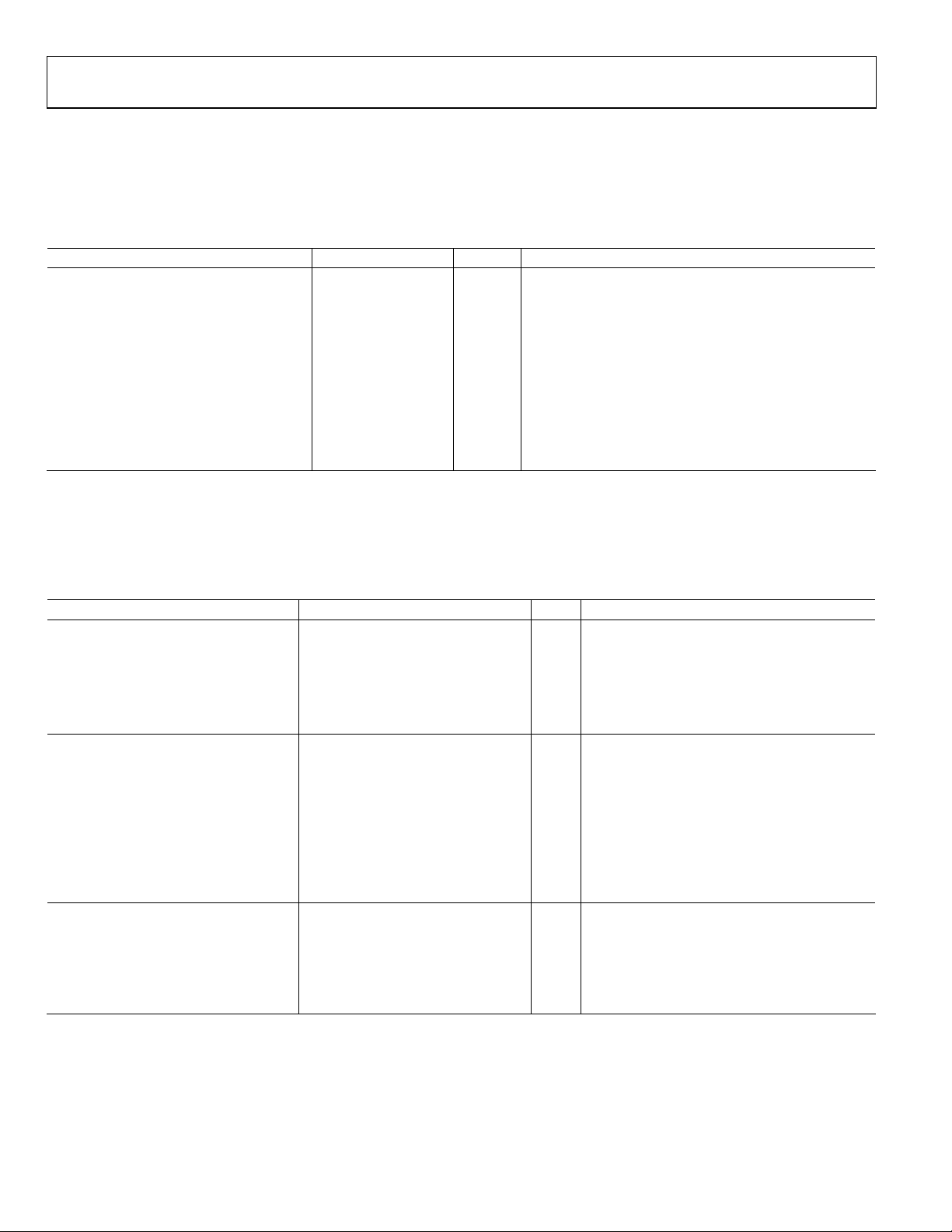

SPECIFICATIONS

Typical ( Ty p ) i s g iv e n f o r VS = 3.3 V ± 5%; TA = 25°C, R

values are given over full V

and TA (−40°C to +85°C) variation.

S

CLOCK INPUTS

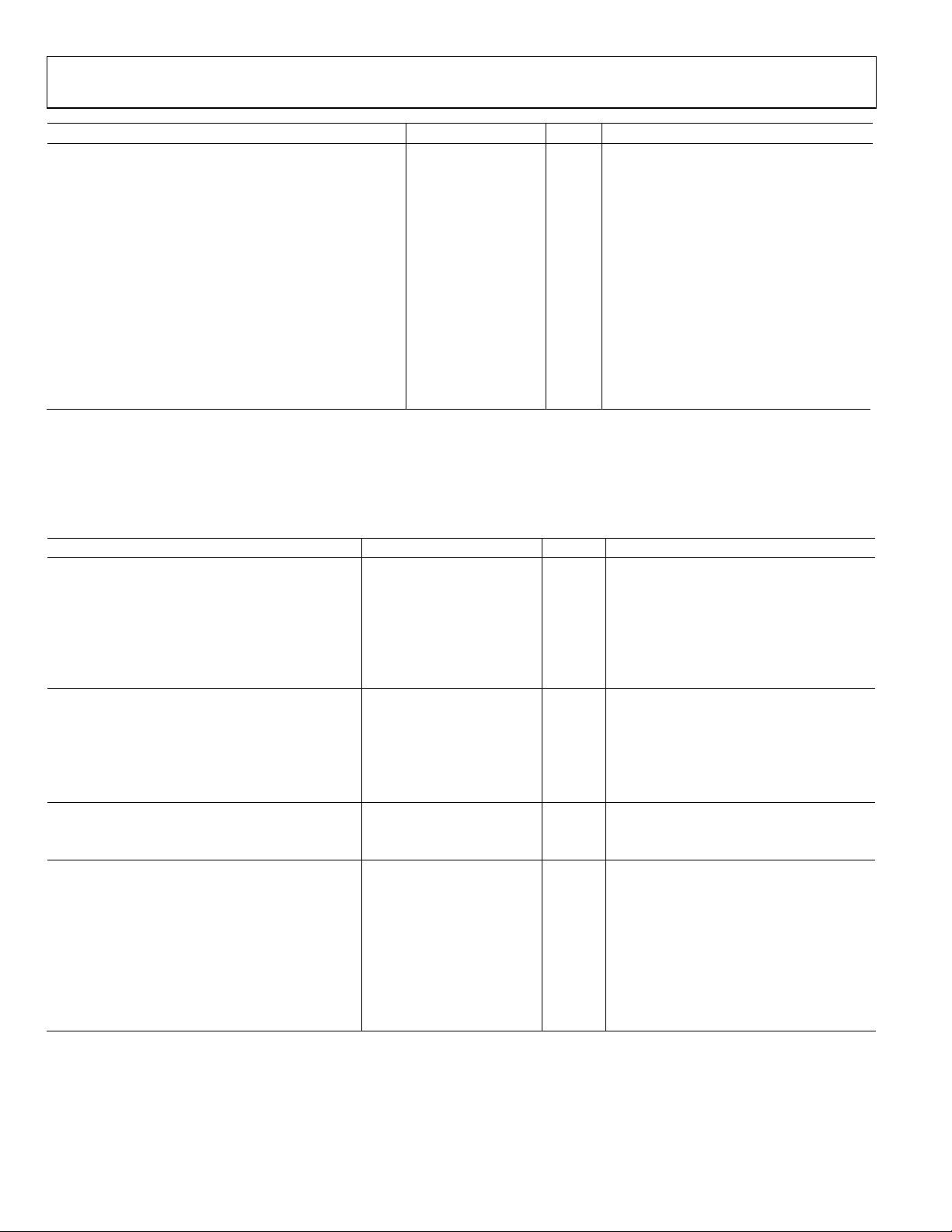

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

CLOCK INPUTS (CLK1, CLK2)

Input Frequency 0 1.6 GHz

Input Sensitivity 1502 mV p-p

Input Level 2

Input Common-Mode Voltage, V

Input Common-Mode Range, V

Input Sensitivity, Single-Ended 150 mV p-p CLK2 ac-coupled; CLK2B ac bypassed to RF ground.

Input Resistance 4.0 4.8 5.6 kΩ Self-biased.

Input Capacitance 2 pF

1

CLK1 and CLK2 are electrically identical; each can be used as either differential or single-ended input.

2

With a 50 Ω termination, this is −12.5 dBm.

3

With a 50 Ω termination, this is +10 dBm.

1

CM

CMR

1.5 1.6 1.7 V Self-biased; enables ac coupling.

1.3 1.8 V With 200 mV p-p signal applied; dc-coupled.

= 4.12 kΩ, unless otherwise noted. Minimum (Min) and Maximum (Max)

SET

Jitter performance can be improved with higher slew

rates (greater swing).

3

V p-p

Larger swings turn on the protection diodes and can

degrade jitter performance.

CLOCK OUTPUTS

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL CLOCK OUTPUTS Termination = 50 Ω to VS − 2 V

OUT0, OUT1, OUT2; Differential Output level 3Dh (3Eh) (3Fh)<3:2> = 10b

Output Frequency 1200 MHz See Figure 14

Output High Voltage (VOH) VS − 1.22 VS − 0.98 VS − 0.93 V

Output Low Voltage (VOL) VS − 2.10 VS − 1.80 VS − 1.67 V

Output Differential Voltage (VOD) 660 810 965 mV

LVDS CLOCK OUTPUTS Termination = 100 Ω differential; default

OUT3, OUT4; Differential

Output Frequency 800 MHz See Figure 15

Differential Output Voltage (VOD) 250 360 450 mV

Delta V

OD

25 mV

Output Offset Voltage (VOS) 1.125 1.23 1.375 V

Delta V

OS

25 mV

Short-Circuit Current (ISA, ISB) 14 24 mA Output shorted to GND

CMOS CLOCK OUTPUTS

OUT3, OUT4

Output Frequency 250 MHz With 5 pF load each output; see Figure 16

Output Voltage High (VOH) VS − 0.1 V @ 1 mA load

Output Voltage Low (VOL) 0.1 V @ 1 mA load

Output level 40h (41h)<2:1> = 01b

3.5 mA termination current

Single-ended measurements;

B outputs: inverted, termination open

Rev. A | Page 4 of 48

Page 5

AD9512

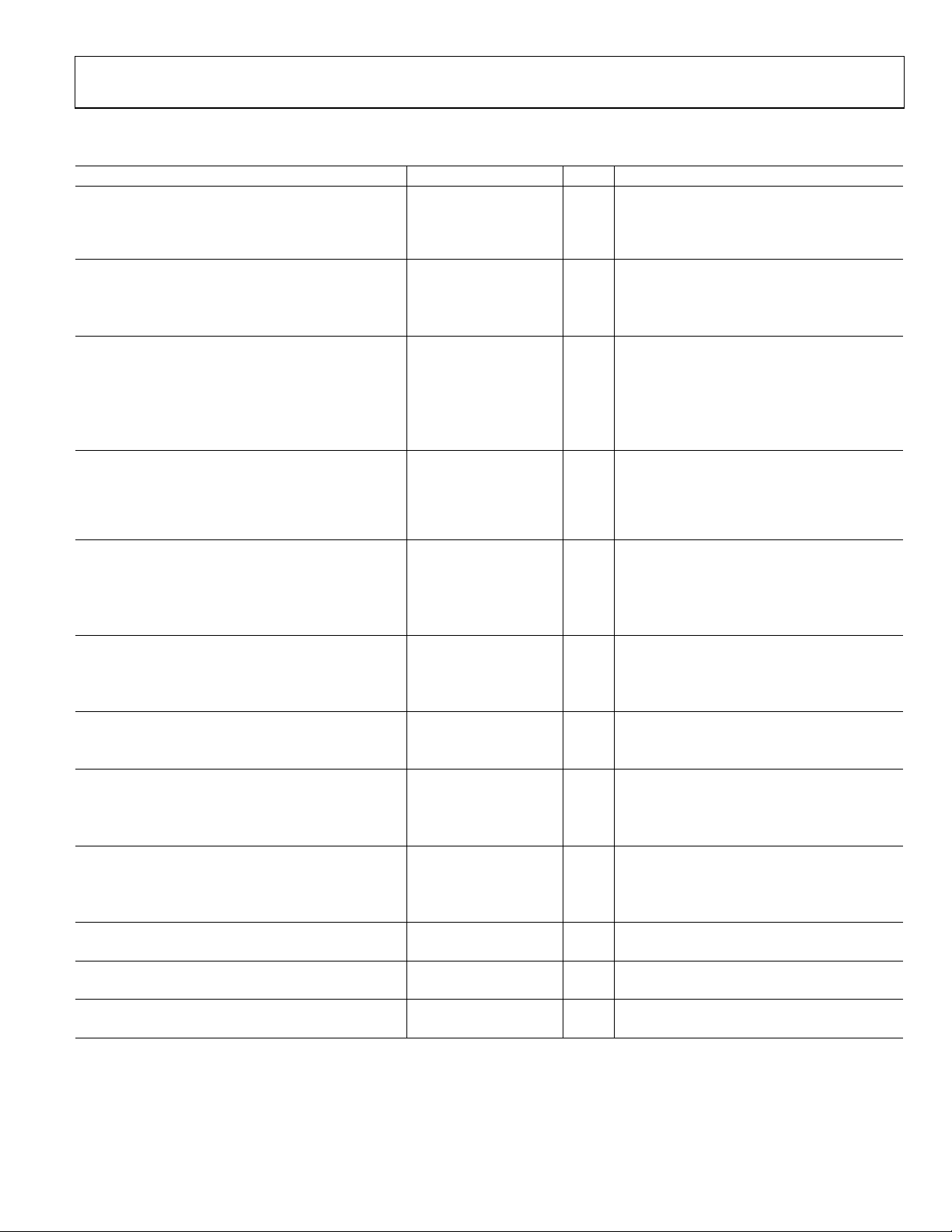

TIMING CHARACTERISTICS

Table 3.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL

Termination = 50 Ω to V

Output level 3Dh (3Eh) (3Fh)<3:2> = 10b

Output Rise Time, t

Output Fall Time, t

RP

FP

PROPAGATION DELAY, t

, CLK-TO-LVPECL OUT

PECL

1

130 180 ps 20% to 80%, measured differentially

130 180 ps 80% to 20%, measured differentially

Divide = Bypass 335 490 635 ps

Divide = 2 − 32 375 545 695 ps

Variation with Temperature 0.5 ps/°C

OUTPUT SKEW, LVPECL OUTPUTS

OUT1 to OUT0 on Same Part, t

OUT1 to OUT2 on Same Part, t

OUT0 to OUT2 on Same Part, t

All LVPECL OUT Across Multiple Parts, t

Same LVPECL OUT Across Multiple Parts, t

LVDS

SKP

SKP

SKP

2

2

2

3

SKP_AB

3

SKP_AB

70 100 140 ps

15 45 80 ps

45 65 90 Ps

275 ps

130 ps

Termination = 100 Ω differential

Output level 40h (41h) <2:1> = 01b

3.5 mA termination current

Output Rise Time, t

Output Fall Time, t

RL

FL

PROPAGATION DELAY, t

, CLK-TO-LVDS OUT

LVDS

1

200 350 ps 20% to 80%, measured differentially

210 350 ps 80% to 20%, measured differentially

Delay off on OUT4

OUT3 to OUT4

Divide = Bypass 0.99 1.33 1.59 ns

Divide = 2 − 32 1.04 1.38 1.64 ns

Variation with Temperature 0.9 ps/°C

OUTPUT SKEW, LVDS OUTPUTS Delay off on OUT4

OUT3 to OUT4 on Same Part, t

All LVDS OUTs Across Multiple Parts, t

Same LVDS OUT Across Multiple Parts, t

SKV

2

3

SKV_AB

3

SKV_AB

−85 +270 ps

450 ps

325 ps

CMOS B outputs are inverted; termination = open

Output Rise Time, t

Output Fall Time, t

RC

FC

PROPAGATION DELAY, t

, CLK-TO-CMOS OUT

CMOS

1

681 865 ps 20% to 80%; C

646 992 ps 80% to 20%; C

LOAD

LOAD

Delay off on OUT4

Divide = Bypass 1.02 1.39 1.71 ns

Divide = 2 − 32 1.07 1.44 1.76 ns

Variation with Temperature 1 ps/°C

OUTPUT SKEW, CMOS OUTPUTS Delay off on OUT4

OUT3 to OUT4 on Same Part, t

All CMOS OUT Across Multiple Parts, t

Same CMOS OUT Across Multiple Parts, t

SKC

2

3

SKC_AB

3

SKC_AB

−140 +145 +300

650 ps

500 ps

LVPECL-TO-LVDS OUT Everything the same; different logic type

Output Skew, t

SKP_V

0.74 0.92 1.14 ns LVPECL to LVDS on same part

LVPECL-TO-CMOS OUT Everything the same; different logic type

Output Skew, t

SKP_C

0.88 1.14 1.43 ns LVPECL to CMOS on same part

LVDS-TO-CMOS OUT Everything the same; different logic type

Output Skew, t

SKV_C

158 353 506 ps LVDS to CMOS on same part

= 3 pF

= 3 pF

− 2 V

S

Rev. A | Page 5 of 48

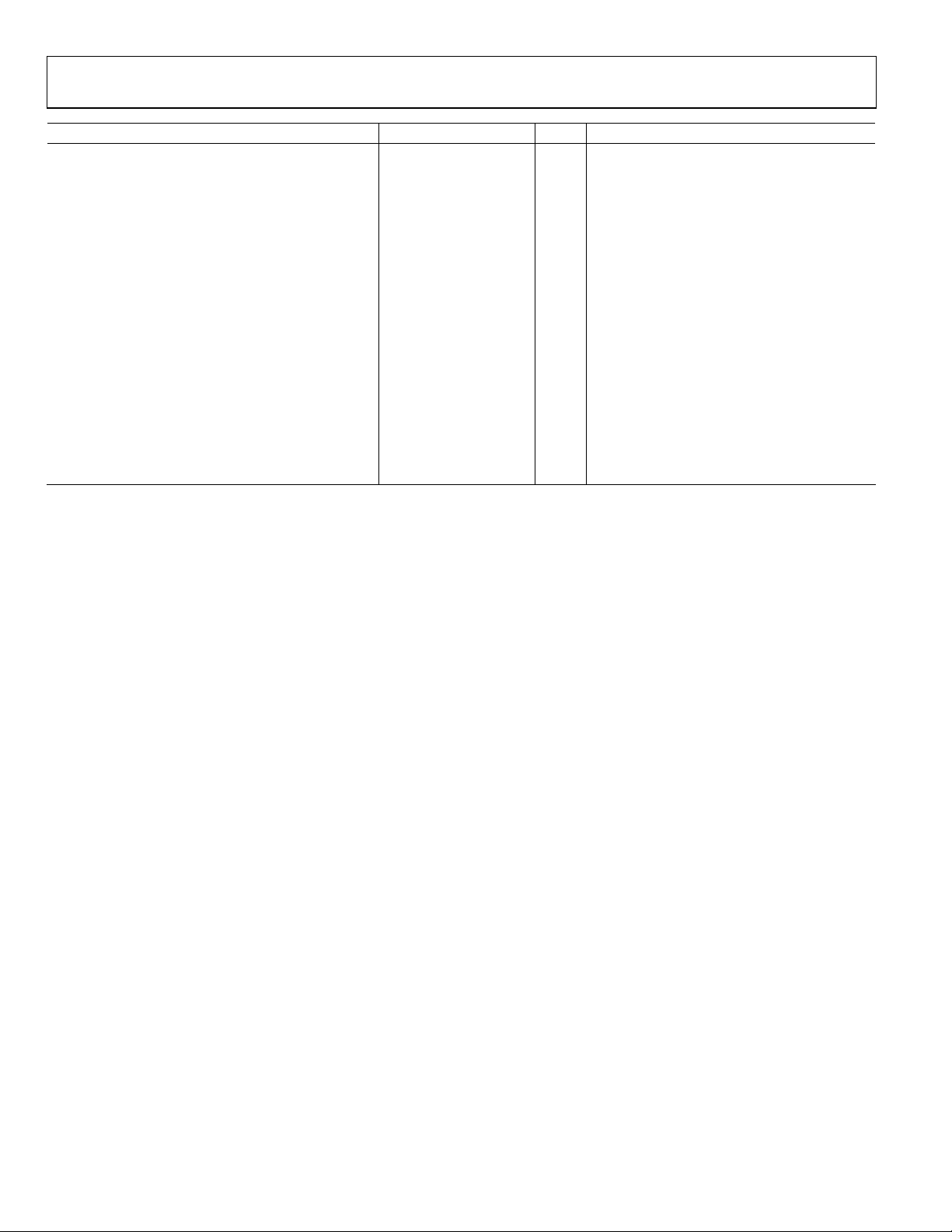

Page 6

AD9512

Parameter Min Typ Max Unit Test Conditions/Comments

DELAY ADJUST OUT4; LVDS and CMOS

Shortest Delay Range

Zero Scale 0.05 0.36 0.68 ns 36h <5:1> 00000b

Full Scale 0.72 1.12 1.51 ns 36h <5:1> 11111b

Linearity, DNL 0.5 LSB

Linearity, INL 0.8 LSB

Longest Delay Range

Zero Scale 0.20 0.57 0.95 ns 36h <5:1> 00000b

Full Scale 9.0 10.2 11.6 ns 36h <5:1> 11111b

Linearity, DNL 0.3 LSB

Linearity, INL 0.6 LSB

Delay Variation with Temperature

Long Delay Range, 10 ns

Zero Scale 0.35 ps/°C

Full Scale −0.14 ps/°C

Short Delay Range, 1 ns

Zero Scale 0.51 ps/°C

Full Scale 0.67 ps/°C

1

The measurements are for CLK1. For CLK2, add approximately 25 ps.

2

This is the difference between any two similar delay paths within a single device operating at the same voltage and temperature.

3

This is the difference between any two similar delay paths across multiple devices operating at the same voltage and temperature.

4

Incremental delay; does not include propagation delay.

5

All delays between the zero scale and full scale can be estimated by linear interpolation.

4

4

5

5

35h <5:1> 11111b

35h <5:1> 00000b

Rev. A | Page 6 of 48

Page 7

AD9512

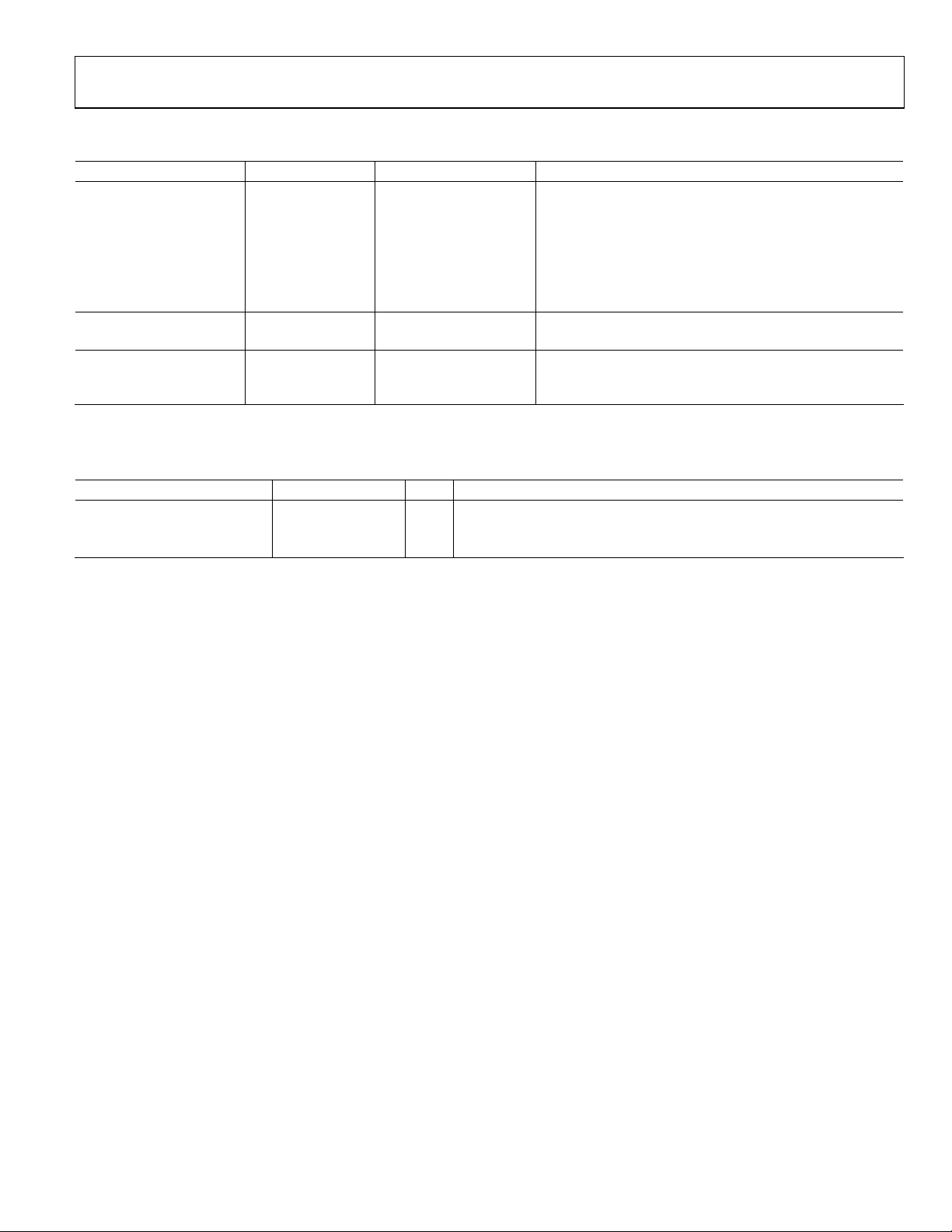

CLOCK OUTPUT PHASE NOISE

Table 4.

Parameter Min Typ Max Unit Test Conditions/Comments

CLK1-TO-LVPECL ADDITIVE PHASE NOISE

CLK1 = 622.08 MHz, OUT = 622.08 MHz Input slew rate > 1 V/ns

Divide Ratio = 1

@ 10 Hz Offset −125 dBc/Hz

@ 100 Hz Offset −132 dBc/Hz

@ 1 kHz Offset −140 dBc/Hz

@ 10 kHz Offset −148 dBc/Hz

@ 100 kHz Offset −153 dBc/Hz

>1 MHz Offset −154 dBc/Hz

CLK1 = 622.08 MHz, OUT = 155.52 MHz

Divide Ratio = 4

@ 10 Hz Offset −128 dBc/Hz

@ 100 Hz Offset −140 dBc/Hz

@ 1 kHz Offset −148 dBc/Hz

@ 10 kHz Offset −155 dBc/Hz

@ 100 kHz Offset −161 dBc/Hz

>1 MHz Offset −161 dBc/Hz

CLK1 = 622.08 MHz, OUT = 38.88 MHz

Divide Ratio = 16

@ 10 Hz Offset −135 dBc/Hz

@ 100 Hz Offset −145 dBc/Hz

@ 1 kHz Offset −158 dBc/Hz

@ 10 kHz Offset −165 dBc/Hz

@ 100 kHz Offset −165 dBc/Hz

>1 MHz Offset −166 dBc/Hz

CLK1 = 491.52 MHz, OUT = 61.44 MHz

Divide Ratio = 8

@ 10 Hz Offset −131 dBc/Hz

@ 100 Hz Offset −142 dBc/Hz

@ 1 kHz Offset −153 dBc/Hz

@ 10 kHz Offset −160 dBc/Hz

@ 100 kHz Offset −165 dBc/Hz

>1 MHz Offset −165 dBc/Hz

CLK1 = 491.52 MHz, OUT = 245.76 MHz

Divide Ratio = 2

@ 10 Hz Offset −125 dBc/Hz

@ 100 Hz Offset −132 dBc/Hz

@ 1 kHz Offset −140 dBc/Hz

@ 10 kHz Offset −151 dBc/Hz

@ 100 kHz Offset −157 dBc/Hz

>1 MHz Offset −158 dBc/Hz

CLK1 = 245.76 MHz, OUT = 61.44 MHz

Divide Ratio = 4

@ 10 Hz Offset −138 dBc/Hz

@ 100 Hz Offset −144 dBc/Hz

@ 1 kHz Offset −154 dBc/Hz

@ 10 kHz Offset −163 dBc/Hz

@ 100 kHz Offset −164 dBc/Hz

>1 MHz Offset −165 dBc/Hz

Rev. A | Page 7 of 48

Page 8

AD9512

Parameter Min Typ Max Unit Test Conditions/Comments

CLK1-TO-LVDS ADDITIVE PHASE NOISE

CLK1 = 622.08 MHz, OUT = 622.08 MHz

Divide Ratio = 1

@ 10 Hz Offset −100 dBc/Hz

@ 100 Hz Offset −110 dBc/Hz

@ 1 kHz Offset −118 dBc/Hz

@ 10 kHz Offset −129 dBc/Hz

@ 100 kHz Offset −135 dBc/Hz

@ 1 MHz Offset −140 dBc/Hz

>10 MHz Offset −148 dBc/Hz

CLK1 = 622.08 MHz, OUT = 155.52 MHz

Divide Ratio = 4

@ 10 Hz Offset −112 dBc/Hz

@ 100 Hz Offset −122 dBc/Hz

@ 1 kHz Offset −132 dBc/Hz

@ 10 kHz Offset −142 dBc/Hz

@ 100 kHz Offset −148 dBc/Hz

@ 1 MHz Offset −152 dBc/Hz

>10 MHz Offset −155 dBc/Hz

CLK1 = 491.52 MHz, OUT = 245.76 MHz

Divide Ratio = 2

@ 10 Hz Offset −108 dBc/Hz

@ 100 Hz Offset −118 dBc/Hz

@ 1 kHz Offset −128 dBc/Hz

@ 10 kHz Offset −138 dBc/Hz

@ 100 kHz Offset −145 dBc/Hz

@ 1 MHz Offset −148 dBc/Hz

>10 MHz Offset −154 dBc/Hz

CLK1 = 491.52 MHz, OUT = 122.88 MHz

Divide Ratio = 4

@ 10 Hz Offset −118 dBc/Hz

@ 100 Hz Offset −129 dBc/Hz

@ 1 kHz Offset −136 dBc/Hz

@ 10 kHz Offset −147 dBc/Hz

@ 100 kHz Offset −153 dBc/Hz

@ 1 MHz Offset −156 dBc/Hz

>10 MHz Offset −158 dBc/Hz

CLK1 = 245.76 MHz, OUT = 245.76 MHz

Divide Ratio = 1

@ 10 Hz Offset −108 dBc/Hz

@ 100 Hz Offset −118 dBc/Hz

@ 1 kHz Offset −128 dBc/Hz

@ 10 kHz Offset −138 dBc/Hz

@ 100 kHz Offset −145 dBc/Hz

@ 1 MHz Offset −148 dBc/Hz

>10 MHz Offset −155 dBc/Hz

Rev. A | Page 8 of 48

Page 9

AD9512

Parameter Min Typ Max Unit Test Conditions/Comments

CLK1 = 245.76 MHz, OUT = 122.88 MHz

Divide Ratio = 2

@ 10 Hz Offset −118 dBc/Hz

@ 100 Hz Offset −127 dBc/Hz

@ 1 kHz Offset −137 dBc/Hz

@ 10 kHz Offset −147 dBc/Hz

@ 100 kHz Offset −154 dBc/Hz

@ 1 MHz Offset −156 dBc/Hz

>10 MHz Offset −158 dBc/Hz

CLK1-TO-CMOS ADDITIVE PHASE NOISE

CLK1 = 245.76 MHz, OUT = 245.76 MHz

Divide Ratio = 1

@ 10 Hz Offset −110 dBc/Hz

@ 100 Hz Offset −121 dBc/Hz

@ 1 kHz Offset −130 dBc/Hz

@ 10 kHz Offset −140 dBc/Hz

@ 100 kHz Offset −145 dBc/Hz

@ 1 MHz Offset −149 dBc/Hz

> 10 MHz Offset −156 dBc/Hz

CLK1 = 245.76 MHz, OUT = 61.44 MHz

Divide Ratio = 4

@ 10 Hz Offset −122 dBc/Hz

@ 100 Hz Offset −132 dBc/Hz

@ 1 kHz Offset −143 dBc/Hz

@ 10 kHz Offset −152 dBc/Hz

@ 100 kHz Offset −158 dBc/Hz

@ 1 MHz Offset −160 dBc/Hz

>10 MHz Offset −162 dBc/Hz

CLK1 = 78.6432 MHz, OUT = 78.6432 MHz

Divide Ratio = 1

@ 10 Hz Offset −122 dBc/Hz

@ 100 Hz Offset −132 dBc/Hz

@ 1 kHz Offset −140 dBc/Hz

@ 10 kHz Offset −150 dBc/Hz

@ 100 kHz Offset −155 dBc/Hz

@ 1 MHz Offset −158 dBc/Hz

>10 MHz Offset −160 dBc/Hz

CLK1 = 78.6432 MHz, OUT = 39.3216 MHz

Divide Ratio = 2

@ 10 Hz Offset −128 dBc/Hz

@ 100 Hz Offset −136 dBc/Hz

@ 1 kHz Offset −146 dBc/Hz

@ 10 kHz Offset −155 dBc/Hz

@ 100 kHz Offset −161 dBc/Hz

>1 MHz Offset −162 dBc/Hz

Rev. A | Page 9 of 48

Page 10

AD9512

CLOCK OUTPUT ADDITIVE TIME JITTER

Table 5.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL OUTPUT ADDITIVE TIME JITTER

CLK1 = 622.08 MHz 40 fs rms BW = 12 kHz − 20 MHz (OC-12)

Any LVPECL (OUT0 to OUT2) = 622.08 MHz

Divide Ratio = 1

CLK1 = 622.08 MHz 55 fs rms BW = 12 kHz − 20 MHz (OC-3)

Any LVPECL (OUT0 to OUT2) = 155.52 MHz

Divide Ratio = 4

CLK1 = 400 MHz 215 fs rms

Any LVPECL (OUT0 to OUT2) = 100 MHz

Divide Ratio = 4

CLK1 = 400 MHz 215 fs rms

Any LVPECL (OUT0 to OUT2) = 100 MHz

Divide Ratio = 4

Other LVPECL = 100 MHz Interferer(s)

Both LVDS (OUT3, OUT4) = 100 MHz Interferer(s)

CLK1 = 400 MHz 222 fs rms

Any LVPECL (OUT0 to OUT2) = 100 MHz

Divide Ratio = 4

Other LVPECL = 50 MHz Interferer(s)

Both LVDS (OUT3, OUT4) = 50 MHz Interferer(s)

CLK1 = 400 MHz 225 fs rms

Any LVPECL (OUT0 to OUT2) = 100 MHz

Divide Ratio = 4

Other LVPECL = 50 MHz Interferer(s)

Both CMOS (OUT3, OUT4) = 50 MHz (B Outputs Off) Interferer(s)

CLK1 = 400 MHz 225 fs rms

Any LVPECL (OUT0 to OUT2) = 100 MHz

Divide Ratio = 4

Other LVPECL = 50 MHz Interferer(s)

Both CMOS (OUT3, OUT4) = 50 MHz (B Outputs On) Interferer(s)

LVDS OUTPUT ADDITIVE TIME JITTER

CLK1 = 400 MHz 264 fs rms

LVDS (OUT3) = 100 MHz

Divide Ratio = 4

CLK1 = 400 MHz 319 fs rms

LVDS (OUT4) = 100 MHz

Divide Ratio = 4

CLK1 = 400 MHz 395 fs rms

LVDS (OUT3) = 100 MHz

Divide Ratio = 4

LVDS (OUT4) = 50 MHz Interferer(s)

All LVPECL = 50 MHz Interferer(s)

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Rev. A | Page 10 of 48

Page 11

AD9512

Parameter Min Typ Max Unit Test Conditions/Comments

CLK1 = 400 MHz 395 fs rms

LVDS (OUT4) = 100 MHz

Divide Ratio = 4

LVDS (OUT3) = 50 MHz Interferer(s)

All LVPECL = 50 MHz Interferer(s)

CLK1 = 400 MHz 367 fs rms

LVDS (OUT3) = 100 MHz

Divide Ratio = 4

CMOS (OUT4) = 50 MHz (B Outputs Off) Interferer(s)

All LVPECL = 50 MHz Interferer(s)

CLK1 = 400 MHz 367 fs rms

LVDS (OUT4) = 100 MHz

Divide Ratio = 4

CMOS (OUT3) = 50 MHz (B Outputs Off) Interferer(s)

All LVPECL = 50 MHz Interferer(s)

CLK1 = 400 MHz 548 fs rms

LVDS (OUT3) = 100 MHz

Divide Ratio = 4

CMOS (OUT4) = 50 MHz (B Outputs On) Interferer(s)

All LVPECL = 50 MHz Interferer(s)

CLK1 = 400 MHz 548 fs rms

LVDS (OUT4) = 100 MHz

Divide Ratio = 4

CMOS (OUT3) = 50 MHz (B Outputs On) Interferer(s)

All LVPECL = 50 MHz Interferer(s)

CMOS OUTPUT ADDITIVE TIME JITTER

CLK1 = 400 MHz 275 fs rms

Both CMOS (OUT3, OUT4) = 100 MHz (B Output On)

Divide Ratio = 4

CLK1 = 400 MHz 400 fs rms

CMOS (OUT3) = 100 MHz (B Output On)

Divide Ratio = 4

All LVPECL = 50 MHz Interferer(s)

LVDS (OUT4) = 50 MHz Interferer(s)

CLK1 = 400 MHz 374 fs rms

CMOS (OUT3) = 100 MHz (B Output On)

Divide Ratio = 4

All LVPECL = 50 MHz Interferer(s)

CMOS (OUT4) = 50 MHz (B Output Off) Interferer(s)

CLK1 = 400 MHz 555 fs rms

CMOS (OUT3) = 100 MHz (B Output On)

Divide Ratio = 4

All LVPECL = 50 MHz Interferer(s)

CMOS (OUT4) = 50 MHz (B Output On) Interferer(s)

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

F

= 100 MHz with AIN = 170 MHz

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Calculated from SNR of ADC method;

= 100 MHz with AIN = 170 MHz

F

C

Rev. A | Page 11 of 48

Page 12

AD9512

Parameter Min Typ Max Unit Test Conditions/Comments

DELAY BLOCK ADDITIVE TIME JITTER

100 MHz Output

Delay FS = 1 ns (1600 A, 1C) Fine Adj. 00000 0.61 ps

Delay FS = 1 ns (1600 A, 1C) Fine Adj. 11111 0.73 ps

Delay FS = 2 ns (800 A, 1C) Fine Adj. 00000 0.71 ps

Delay FS = 2 ns (800 A, 1C) Fine Adj. 11111 1.2 ps

Delay FS = 3 ns (800 A, 4C) Fine Adj. 00000 0.86 ps

Delay FS = 3 ns (800 A, 4C) Fine Adj. 11111 1.8 ps

Delay FS = 4 ns (400 A, 4C) Fine Adj. 00000 1.2 ps

Delay FS = 4 ns (400 A, 4C) Fine Adj. 11111 2.1 ps

Delay FS = 5 ns (200 A, 1C) Fine Adj. 00000 1.3 ps

Delay FS = 5 ns (200 A, 1C) Fine Adj. 11111 2.7 ps

Delay FS = 11 ns (200 A, 4C) Fine Adj. 00000 2.0 ps

Delay FS = 11 ns (200 A, 4C) Fine Adj. 00100 2.8 ps

1

This value is incremental. That is, it is in addition to the jitter of the LVDS or CMOS output without the delay. To estimate the total jitter, the LVDS or CMOS output jitter

should be added to this value using the root sum of the squares (RSS) method.

SERIAL CONTROL PORT

Table 6.

Parameter Min Typ Max Unit Test Conditions/Comments

CSB, SCLK (INPUTS)

Input Logic 1 Voltage 2.0 V

Input Logic 0 Voltage 0.8 V

Input Logic 1 Current 110 µA

Input Logic 0 Current 1 µA

Input Capacitance 2 pF

SDIO (WHEN INPUT)

Input Logic 1 Voltage 2.0 V

Input Logic 0 Voltage 0.8 V

Input Logic 1 Current 10 nA

Input Logic 0 Current 10 nA

Input Capacitance 2 pF

SDIO, SDO (OUTPUTS)

Output Logic 1 Voltage 2.7 V

Output Logic 0 Voltage 0.4 V

TIMING

Clock Rate (SCLK, 1/t

Pulse Width High, t

Pulse Width Low, t

SDIO to SCLK Setup, t

SCLK to SDIO Hold, t

SCLK to Valid SDIO and SDO, t

CSB to SCLK Setup and Hold, tS, t

CSB Minimum Pulse Width High, t

) 25 MHz

SCLK

PWH

PWL

DS

DH

1

Incremental additive jitter

1

CSB and SCLK have 30 kΩ

internal pull-down resistors

16 ns

16 ns

2 ns

1 ns

DV

H

PWH

6 ns

2 ns

3 ns

Rev. A | Page 12 of 48

Page 13

AD9512

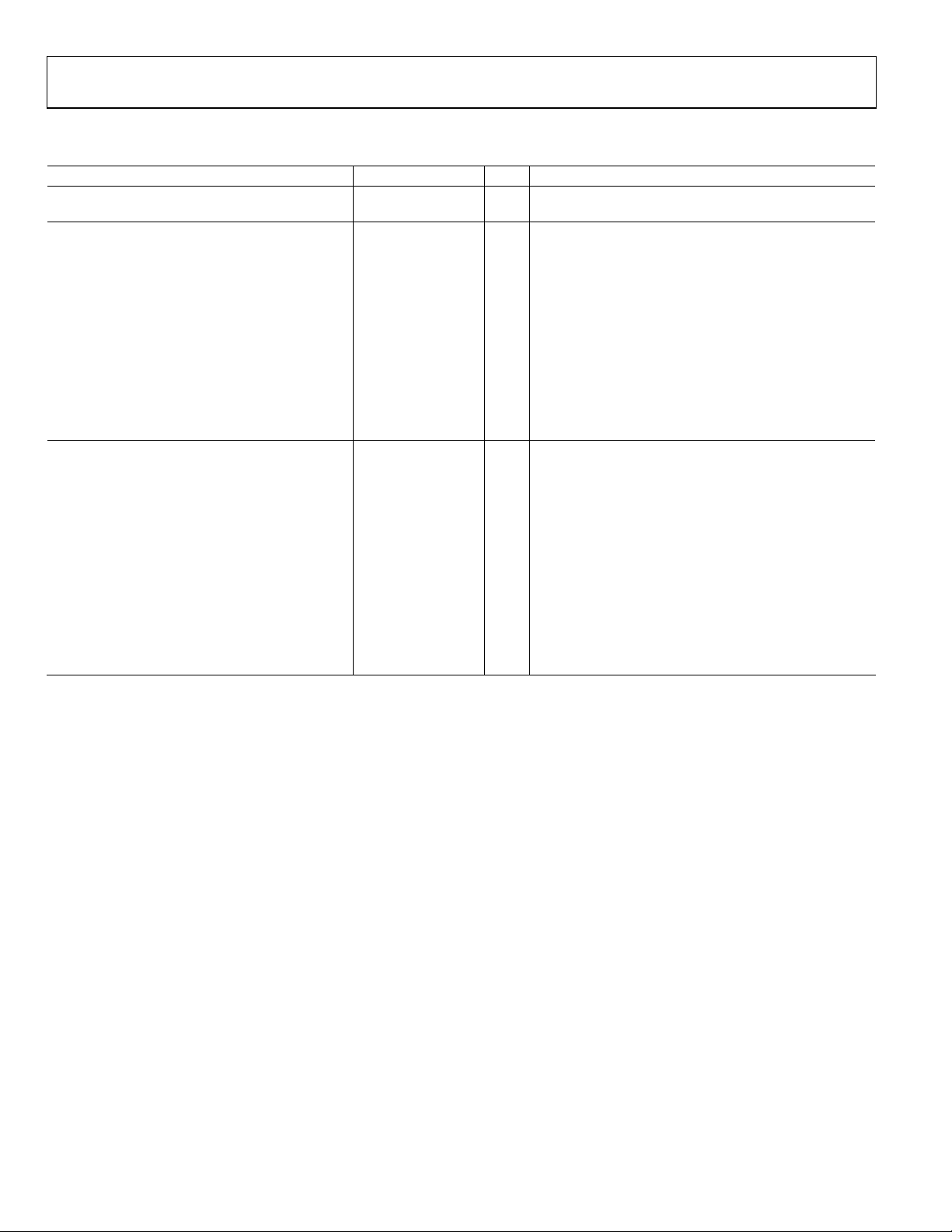

FUNCTION PIN

Table 7.

Parameter Min Typ Max Unit Test Conditions/Comments

INPUT CHARACTERISTICS

Logic 1 Voltage 2.0 V

Logic 0 Voltage 0.8 V

Logic 1 Current 110 µA

Logic 0 Current 1 µA

Capacitance 2 pF

RESET TIMING

Pulse Width Low 50 ns

SYNC TIMING

Pulse Width Low 1.5 High speed clock cycles

SYNC STATUS PIN

Table 8.

Parameter Min Typ Max Unit Test Conditions/Comments

OUTPUT CHARACTERISTICS

Output Voltage High (VOH) 2.7 V

Output Voltage Low (VOL) 0.4 V

The FUNCTION pin has a 30 kΩ internal pull-down resistor.

This pin should normally be held high. Do not leave NC.

High speed clock is CLK1 or CLK2, whichever is being used

for distribution.

Rev. A | Page 13 of 48

Page 14

AD9512

POWER

Table 9.

Parameter Min Typ Max Unit Test Conditions/Comments

POWER-UP DEFAULT MODE POWER DISSIPATION 550 600 mW

POWER DISSIPATION 800 mW

850 mW

Full Sleep Power-Down 35 60 mW

Power-Down (PDB) 60 80 mW

POWER DELTA

CLK1, CLK2 Power-Down 10 15 25 mW

Divider, DIV 2 − 32 to Bypass 23 27 33 mW For each divider.

LVPECL Output Power-Down (PD2, PD3) 50 65 75 mW

LVDS Output Power-Down 80 92 110 mW For each output.

CMOS Output Power-Down (Static) 56 70 85 mW For each output. Static (no clock).

CMOS Output Power-Down (Dynamic) 115 150 190 mW

CMOS Output Power-Down (Dynamic) 125 165 210 mW

Delay Block Bypass 20 24 60 mW

Power-up default state; does not include power

dissipated in output load resistors. No clock.

All outputs on. Three LVPECL outputs @ 800 MHz,

two CMOS out @ 62 MHz (5 pF load). Does not include

power dissipated in external resistors.

All outputs on. Three LVPECL outputs @ 800 MHz,

two CMOS out @ 125 MHz (5 pF load). Does not include

power dissipated in external resistors.

Maximum sleep is entered by setting 0Ah<1:0> = 01b

and 58h<4> = 1b. This powers off all band gap

references. Does not include power dissipated in

terminations.

Set FUNCTION pin for PDB operation by setting

58h<6:5> = 11b. Pull PDB low. Does not include

power dissipated in terminations.

For each output. Does not include dissipation

in termination (PD2 only).

For each CMOS output, single-ended. Clocking at

62 MHz with 5 pF load.

For each CMOS output, single-ended. Clocking at

125 MHz with 5 pF load.

Vs. delay block operation at 1 ns fs with maximum

delay; output clocking at 25 MHz.

Rev. A | Page 14 of 48

Page 15

AD9512

C

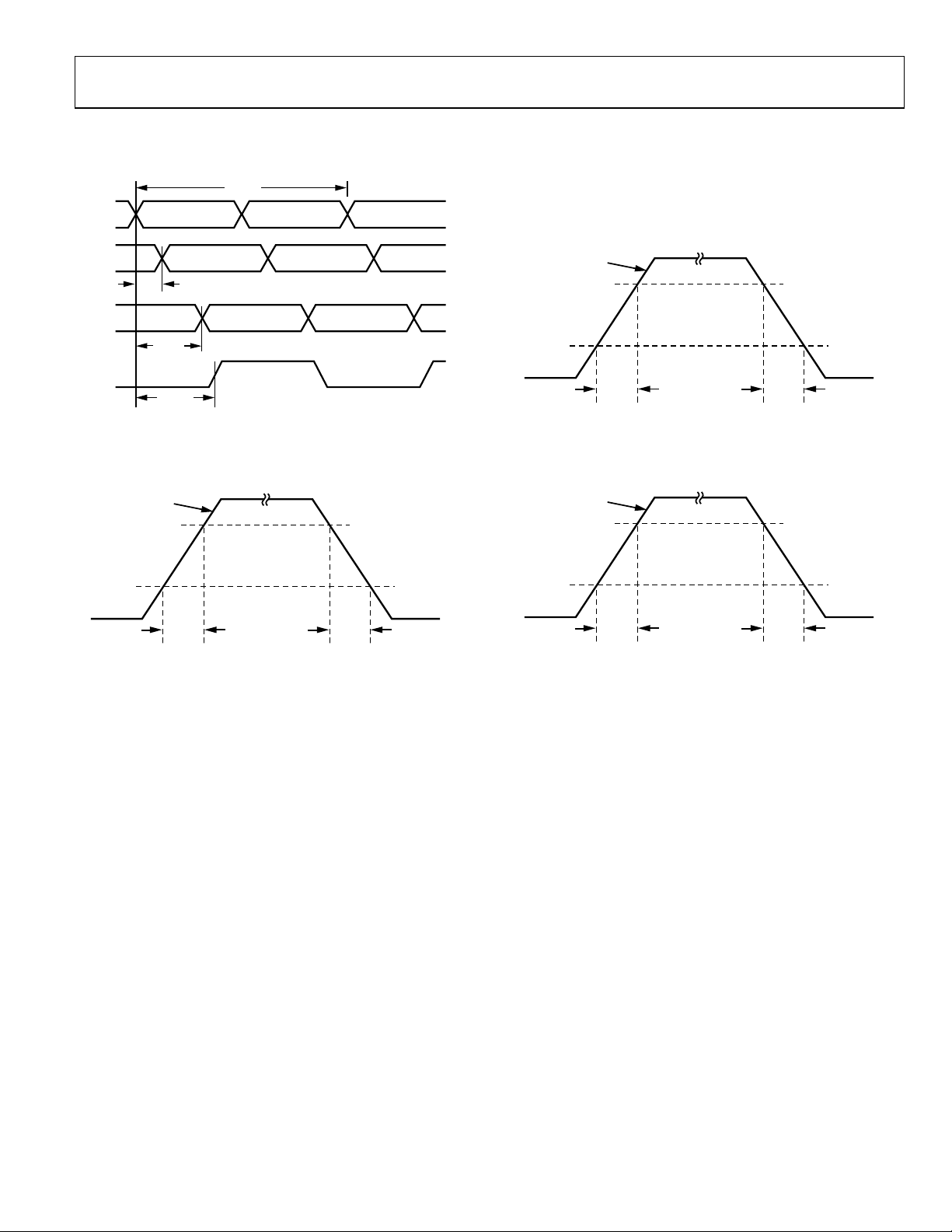

TIMING DIAGRAMS

LK1

t

CLK1

DIFFERENTIAL

t

PECL

t

LVDS

t

CMOS

Figure 2. CLK1/CLK1B to Clock Output Timing, DIV = 1 Mode

DIFFERENTIAL

80%

LVPECL

20%

t

RP

Figure 3. LVPECL Timing, Differential

80%

LVDS

20%

t

05287-002

RL

t

FL

05287-065

Figure 4. LVDS Timing, Differential

SINGLE-ENDED

80%

CMOS

3pF LOAD

20%

t

FP

05287-064

t

RC

t

FC

05287-066

Figure 5. CMOS Timing, Single-Ended, 3 pF Load

Rev. A | Page 15 of 48

Page 16

AD9512

ABSOLUTE MAXIMUM RATINGS

Table 10.

With

Respect

Parameter or Pin

VS GND −0.3 +3.6 V

DSYNC/DSYNCB GND −0.3 VS + 0.3 V

RSET GND −0.3 VS + 0.3 V

CLK1, CLK1B, CLK2, CLK2B GND −0.3 VS + 0.3 V

CLK1 CLK1B −1.2 +1.2 V

CLK2 CLK2B −1.2 +1.2 V

SCLK, SDIO, SDO, CSB GND −0.3 VS + 0.3 V

OUT0, OUT1,

OUT2, OUT3, OUT4

FUNCTION GND −0.3 VS + 0.3 V

SYNC STATUS GND −0.3 VS + 0.3 V

Junction Temperature 150 °C

Storage Temperature −65 +150 °C

Lead Temperature (10 sec) 300 °C

to

GND −0.3 V

Min Max Unit

+ 0.3 V

S

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to

absolute maximum ratings for extended periods may affect

device reliability.

THERMAL CHARACTERISTICS

Thermal Resistance

48-Lead LFCSP

θ

= 28.5°C/W

JA

1

Thermal impedance measurements were taken on a 4-layer board in still air,

in accordance with EIA/JESD51-7.

1

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. A | Page 16 of 48

Page 17

AD9512

B

T

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VS

OUT0

OUT0

GND

OUT2B

VSVSGND

24

VS

VS

GND

OUT2

37 GND

36

VS

35

OUT3

34

OUT3B

33

VS

32

VS

31

OUT4

30

OUT4B

29

VS

28

VS

27

OUT1

26

OUT1B

25

VS

05287-003

DSYNC

DSYNCB

CLK2B

CLK1B

FUNCTION

DNC = DO NO CONNEC

VS

VS

DNC

VS

CLK2

VS

CLK1

1

2

3

4

5

6

7

8

9

10

11

12

VSVSGND

RSETVSGND

4847464544434241403938

PIN 1

INDICATOR

AD9512

TOP VIEW

(Not to Scale)

1314151617181920212223

CSB

SDO

SDIO

SCLK

STATUS

Figure 6. 48-Lead LFCSP Pin Configuration

Note that the exposed paddle on this package is an electrical connection as well as a thermal enhancement. For the device to

function properly, the paddle must be attached to ground, GND.

Rev. A | Page 17 of 48

Page 18

AD9512

Table 11. Pin Function Descriptions

Pin No. Mnemonic Description

1 DSYNC Detect Sync. Used for multichip synchronization.

2 DSYNCB Detect Sync Complement. Used for multichip synchronization.

3, 4, 6, 9, 18,

22, 23, 25, 28,

29, 32, 33, 36,

39, 40, 44, 47, 48

5 DNC Do Not Connect.

7 CLK2 Clock Input.

8 CLK2B Complementary Clock Input. Used in conjunction with CLK2.

10 CLK1 Clock Input.

11 CLK1B Complementary Clock Input. Used in conjunction with CLK1.

12 FUNCTION Multipurpose Input. Can be programmed as a reset (RESETB), sync (SYNCB), or power-down (PDB) pin.

13 STATUS Output Used to Monitor the Status of Multichip Synchronization.

14 SCLK Serial Data Clock.

15 SDIO Serial Data I/O.

16 SDO Serial Data Output.

17 CSB Serial Port Chip Select.

19, 24, 37,

38, 43, 46

20 OUT2B Complementary LVPECL Output.

21 OUT2 LVPECL Output.

26 OUT1B Complementary LVPECL Output.

27 OUT1 LVPECL Output.

30 OUT4B Complementary LVDS/Inverted CMOS Output. OUT4 includes a delay block.

31 OUT4 LVDS/CMOS Output. OUT4 includes a delay block.

34 OUT3B Complementary LVDS/Inverted CMOS Output.

35 OUT3 LVDS/CMOS Output.

41 OUT0B Complementary LVPECL Output.

42 OUT0 LVPECL Output.

45 RSET Current Set Resistor to Ground. Nominal value = 4.12 kΩ.

VS Power Supply (3.3 V).

GND Ground.

Note that the exposed paddle on this package is an electrical connection as well as a thermal enhancement. For the device to

function properly, the paddle must be attached to ground, GND.

Rev. A | Page 18 of 48

Page 19

AD9512

TERMINOLOGY

Phase Jitter and Phase Noise

An ideal sine wave can be thought of as having a continuous

and even progression of phase with time from 0 degrees to

360 degrees for each cycle. Actual signals, however, display a

certain amount of variation from ideal phase progression over

time. This phenomenon is called phase jitter. Although many

causes can contribute to phase jitter, one major cause is random

noise, which is characterized statistically as being Gaussian

(normal) in distribution.

This phase jitter leads to a spreading out of the energy of the

sine wave in the frequency domain, producing a continuous

power spectrum. This power spectrum is usually reported as a

series of values whose units are dBc/Hz at a given offset in

frequency from the sine wave (carrier). The value is a ratio

(expressed in dB) of the power contained within a 1 Hz

bandwidth with respect to the power at the carrier frequency.

For each measurement, the offset from the carrier frequency is

also given.

It is meaningful to integrate the total power contained within

some interval of offset frequencies (for example, 10 kHz to

10 MHz). This is called the integrated phase noise over that

frequency offset interval and can be readily related to the time

jitter due to the phase noise within that offset frequency

interval.

Phase noise has a detrimental effect on the performance of

ADCs, DACs, and RF mixers. It lowers the achievable dynamic

range of the converters and mixers, although they are affected

in somewhat different ways.

Time Jitter

Phase noise is a frequency domain phenomenon. In the time

domain, the same effect is exhibited as time jitter. When

observing a sine wave, the time of successive zero crossings is

seen to vary. In a square wave, the time jitter is seen as a

displacement of the edges from their ideal (regular) times of

occurrence. In both cases, the variations in timing from the

ideal are the time jitter. Since these variations are random in

nature, the time jitter is specified in units of seconds root mean

square (rms) or 1 sigma of the Gaussian distribution.

Time jitter that occurs on a sampling clock for a DAC or an

ADC decreases the SNR and dynamic range of the converter.

A sampling clock with the lowest possible jitter provides the

highest performance from a given converter.

Additive Phase Noise

It is the amount of phase noise that is attributable to the device

or subsystem being measured. The phase noise of any external

oscillators or clock sources has been subtracted. This makes it

possible to predict the degree to which the device impacts the

total system phase noise when used in conjunction with the

various oscillators and clock sources, each of which contribute

their own phase noise to the total. In many cases, the phase

noise of one element dominates the system phase noise.

Additive Time Jitter

It is the amount of time jitter that is attributable to the device

or subsystem being measured. The time jitter of any external

oscillators or clock sources has been subtracted. This makes it

possible to predict the degree to which the device will impact

the total system time jitter when used in conjunction with the

various oscillators and clock sources, each of which contribute

their own time jitter to the total. In many cases, the time jitter of

the external oscillators and clock sources dominates the system

time jitter.

Rev. A | Page 19 of 48

Page 20

AD9512

TYPICAL PERFORMANCE CHARACTERISTICS

0.6

DEFAULT – 3 LVPECL + 2 LVDS (DIV ON)

0.7

0.5

POWER (W)

3 LVPECL + 2 LVDS (DIV BYPASSED)

0.4

3 LVPECL (DIV ON) 2 LVDS (DIV ON)

0.3

0 800400

OUTPUT FREQUENCY (MHz)

Figure 7. Power vs. Frequency—LVPECL, LVDS

3GHz

CLK1 (EVAL BOARD)

5MHz

05287-080

0.6

POWER (W)

0.5

0.4

0 12010080604020

3GHz

3 LVPECL + 2 CMOS (DIV ON)

OUTPUT FREQUENCY (MHz)

Figure 9. Power vs. Frequency—LVPECL, CMOS

CLK2 (EVAL BOARD)

5MHz

05287-081

Figure 8. CLK1 Smith Chart (Evaluation Board)

05287-043

Figure 10. CLK2 Smith Chart (Evaluation Board)

05287-044

Rev. A | Page 20 of 48

Page 21

AD9512

1.8

1.7

1.6

1.5

1.4

DIFFERENTIAL SWING (V p-p)

1.3

VERT 500mV/DIV HORIZ 500ps/DI V

Figure 11. LVPECL Differential Output @ 800 MHz

VERT 100mV/DIV HORIZ 500ps/ DIV

Figure 12. LVDS Differential Output @ 800 MHz

05287-053

1.2

100 16001100600

OUTPUT FREQUENCY (MHz)

05287-056

Figure 14. LVPECL Differential Output Swing vs. Frequency

750

700

650

600

550

DIFFERENTIAL SWING (mV p-p)

05287-054

500

100 900700500300

OUTPUT FREQUENCY (MHz)

05287-050

Figure 15. LVDS Differential Output Swing vs. Frequency

3.5

2pF

3.0

VERT 500mV/DIV HORIZ 1n s/ DIV

Figure 13. CMOS Single-Ended Output @ 250 MHz with 10 pF Load

)

OUTPUT (V

05287-055

Rev. A | Page 21 of 48

2.5

PK

2.0

1.5

1.0

0.5

0

0 600500400300200100

OUTPUT F REQUENCY (MHz)

10pF

20pF

Figure 16. CMOS Single-Ended Output Swing vs. Frequency and Load

05287-047

Page 22

AD9512

–

–

–

–

–

110

110

–120

–130

–140

L(f) (dBc/Hz)

–150

–160

–170

10 10M1M100k10k1k100

OFFSET (Hz)

Figure 17. Additive Phase Noise—LVPECL DIV1, 245.76 MHz

Distribution Section Only

80

–90

–100

–110

–120

–130

L(f) (dBc/Hz)

–140

–120

–130

–140

L(f) (dBc/Hz)

–150

–160

05287-051

–170

10 10M1M100k10k1k100

OFFSET (Hz)

05287-052

Figure 20. Additive Phase Noise—LVPECL DIV1, 622.08 MHz

80

–90

–100

–110

–120

–130

L(f) (dBc/Hz)

–140

–150

–160

–170

10 10M1M100k10k1k100

OFFSET (Hz)

Figure 18. Additive Phase Noise—LVDS DIV1, 245.76 MHz

100

–110

–120

–130

–140

L(f) (dBc/Hz)

–150

–160

–170

10 10M1M100k10k1k100

OFFSET (Hz)

Figure 19. Additive Phase Noise—CMOS DIV1, 245.76 MHz

–150

–160

05287-048

–170

10 10M1M100k10k1k100

OFFSET (Hz)

05287-049

Figure 21. Additive Phase Noise—LVDS DIV2, 122.88 MHz

–100

–110

–120

–130

–140

L(f) (dBc/Hz)

–150

–160

05287-045

–170

10 10M1M100k10k1k100

OFFSET (Hz)

05287-046

Figure 22. Additive Phase Noise—CMOS DIV4, 61.44 MHz

Rev. A | Page 22 of 48

Page 23

AD9512

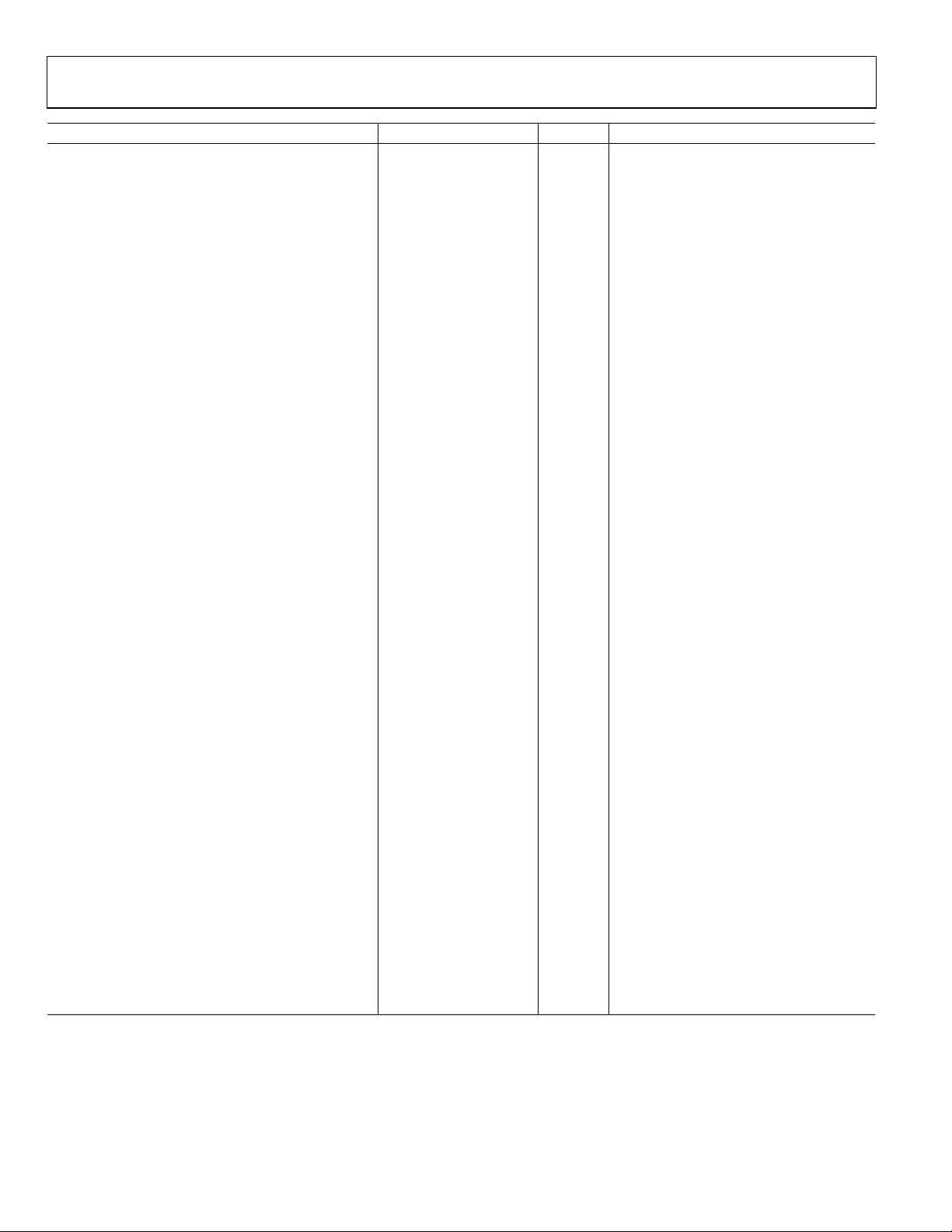

V

RSET

GND

S

FUNCTION

DSYNC

DSYNCB

CLK1

CLK1B

CLK2

CLK2B

SCLK

SDIO

SDO

CSB

SYNCB,

RESETB

PDB

DETECT

SYNC

SERIAL

CONTROL

PORT

VREF

PROGRAMMABLE

DIVIDERS AND

PHASE ADJUST

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

/1, /2, /3... /31, /32

AD9512

Δ

DELAY

ADJUST

T

SYNC

STATUS

LVPECL

LVPECL

LVPECL

LVDS/CMOS

LVDS/CMOS

SYNC

STATUS

OUT0

OUT0B

OUT1

OUT1B

OUT2

OUT2B

OUT3

OUT3B

OUT4

OUT4B

05287-090

Figure 23. Functional Block Diagram Showing Maximum Frequencies

Rev. A | Page 23 of 48

Page 24

AD9512

FUNCTIONAL DESCRIPTION

OVERALL

Figure 23 shows a block diagram of the AD9512. The AD9512

accepts inputs on either of two clock inputs (CLK1 or CLK2).

This clock can be divided by any integer value from 1 to 32.

The duty cycle and relative phase of the outputs can be selected.

There are three LVPECL outputs (OUT0, OUT1, OUT2) and

two outputs that can be either LVDS or CMOS level outputs

(OUT3, OUT4). OUT4 can also make use of a variable

delay block.

The AD9512 provides clock distribution function only; there is

no clock clean-up. The jitter of the input clock signal is passed

along directly to the distribution section and can dominate at

the clock outputs.

Figure 24 for the equivalent circuit of CLK1 and CLK2.

See

CLOCK INPUT

V

S

CLK

CLKB

2.5kΩ 2.5kΩ

5kΩ

5kΩ

Figure 24. CLK1, CLK2 Equivalent Input Circuit

FUNCTION PIN

The FUNCTION pin (Pin 12) has three functions that are

selected by the value in Register 58h<6:5>. There is an internal

30 kΩ pull-down resistor on this pin.

RESETB: 58h<6:5> = 00b (Default)

In its default mode, the FUNCTION pin acts as RESETB, which

generates an asynchronous reset or hard reset when pulled low.

The resulting reset writes the default values into the serial

control port buffer registers as well as loading them into the

chip control registers. The AD9512 immediately resumes

operation according to the default values. When the pin is taken

high again, an asynchronous sync is issued (see the

58h<6:5> = 01b

section).

STAGE

05287-016

SYNCB:

SYNCB: 58h<6:5> = 01b

The FUNCTION pin can be used to cause a synchronization

or alignment of phase among the various clock outputs.

The synchronization applies only to clock outputs that:

• are not powered down

• the divider is not masked (no sync = 0)

• are not bypassed (bypass = 0)

SYNCB is level and rising edge sensitive. When SYNCB is low,

the set of affected outputs are held in a predetermined state,

defined by each divider’s start high bit. On a rising edge, the

dividers begin after a predefined number of fast clock cycles

(fast clock is the selected clock input, CLK1 or CLK2) as

determined by the values in the divider’s phase offset bits.

The SYNCB application of the FUNCTION pin is always active,

regardless of whether the pin is also assigned to perform reset

or power-down. When the SYNCB function is selected, the

FUNCTION pin does not act as either RESETB or PDB.

PDB: 58h<6:5> = 11b

The FUNCTION pin can also be programmed to work as an

asynchronous full power-down, PDB. Even in this full powerdown mode, there is still some residual V

current because

S

some on-chip references continue to operate. In PDB mode, the

FUNCTION pin is active low. The chip remains in a powerdown state until PDB is returned to logic high. The chip returns

to the settings programmed prior to the power-down.

Chip Power-Down or Sleep Mode—PDB section for more

See the

details on what occurs during a PDB initiated power-down.

DSYNC AND DSYNCB PINS

The DSYNC and DSYNCB pins (Pin 1 and Pin 2) are used

when the AD9512 is used in a multichip synchronized

configuration (see the

Multichip Synchronization section).

CLOCK INPUTS

Two clock inputs (CLK1, CLK2) are available for use on the

AD9512. CLK1 and CLK2 can accept inputs up to 1600 MHz.

Figure 24 for the CLK1 and CLK2 equivalent input circuit.

See

The clock inputs are fully differential and self-biased. The signal

should be ac-coupled using capacitors. If a single-ended input

must be used, this can be accommodated by ac coupling to one

side of the differential input only. The other side of the input

should be bypassed to a quiet ac ground by a capacitor.

The unselected clock input (either CLK1 or CLK2) should be

powered down to eliminate any possibility of unwanted

crosstalk between the selected clock input and the unselected

clock input.

Rev. A | Page 24 of 48

Page 25

AD9512

DIVIDERS

Each of the five clock outputs of the AD9512 has its own

divider. The divider can be bypassed to get an output at the

same frequency as the input (1×). When a divider is bypassed, it

is powered down to save power.

All integer divide ratios from 1 to 32 may be selected. A divide

ratio of 1 is selected by bypassing the divider.

Example 2:

Set Divide Ratio = 8

high_cycles = 3

low_cycles = 3

Divide Ratio = (3 + 1) + (3 + 1) = 8

Each divider can be configured for divide ratio, phase, and duty

cycle. The phase and duty cycle values that can be selected

depend on the divide ratio that is chosen.

Setting the Divide Ratio

The divide ratio is determined by the values written via the SCP

to the registers that control each individual output, OUT0 to

OUT4. These are the even numbered registers beginning at 4Ah

and going through 52h. Each of these registers is divided into

bits that control the number of clock cycles the divider output

stays high (high_cycles <3:0>) and the number of clock cycles

the divider output stays low (low_cycles <7:4>). Each value is 4

bits and has the range of 0 to 15.

The divide ratio is set by

Divide Ratio = (high_cycles + 1) + (low_cycles + 1)

Example 1:

Set the Divide Ratio = 2

high_cycles = 0

low_cycles = 0

Divide Ratio = (0 + 1) + (0 + 1) = 2

Note that a Divide Ratio of 8 may also be obtained by setting:

high_cycles = 2

low_cycles = 4

Divide Ratio = (2 + 1) + (4 + 1) = 8

Although the second set of settings produces the same divide

ratio, the resulting duty cycle is not the same.

Setting the Duty Cycle

The duty cycle and the divide ratio are related. Different divide

ratios have different duty cycle options. For example, if Divide

Ratio = 2, the only duty cycle possible is 50%. If the Divide

Ratio = 4, the duty cycle can be 25%, 50%, or 75%.

The duty cycle is set by

Duty Cycle = (high_cycles + 1)/[(high_cycles + 1) + (low_cycles + 1)]

Tabl e 12 for the values of the available duty cycles for each

See

divide ratio.

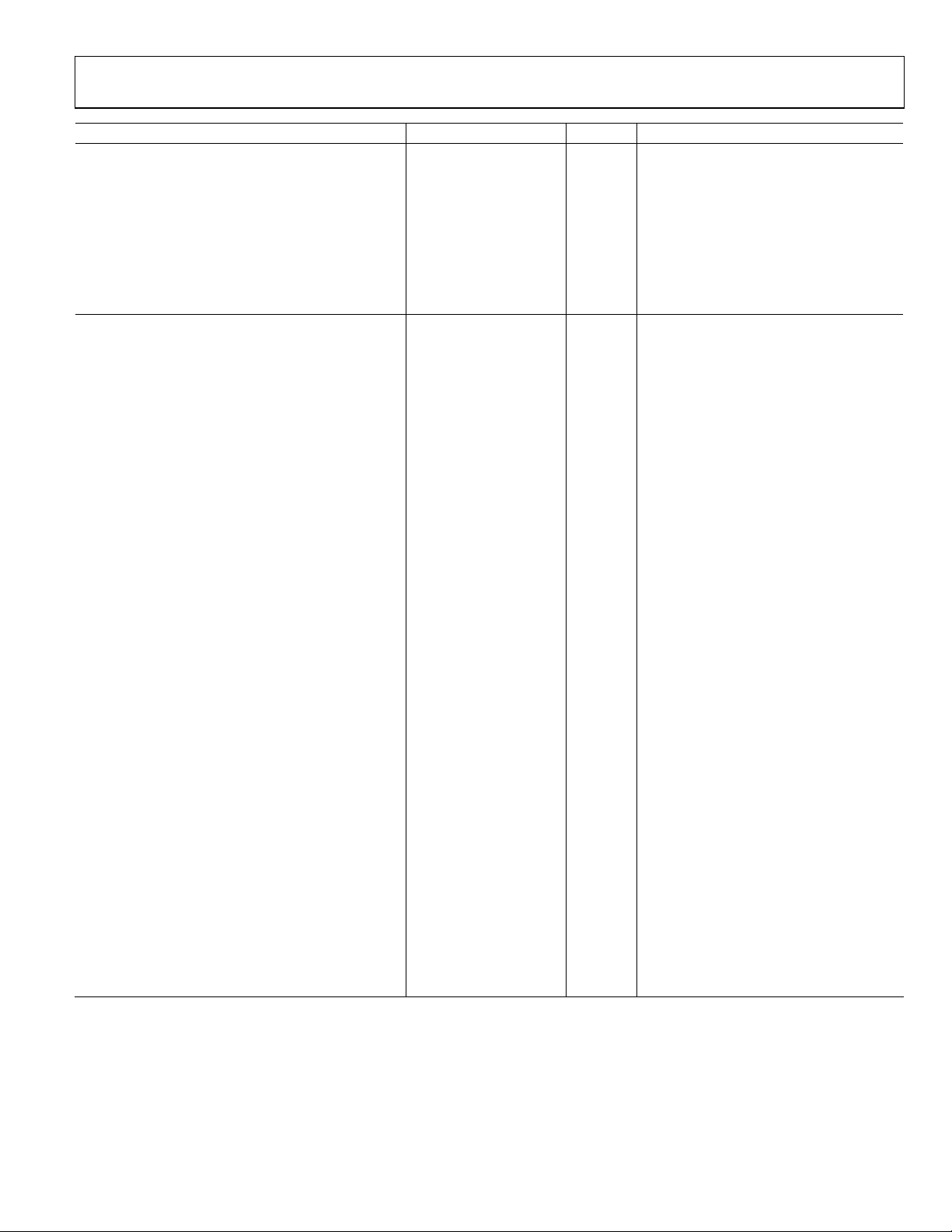

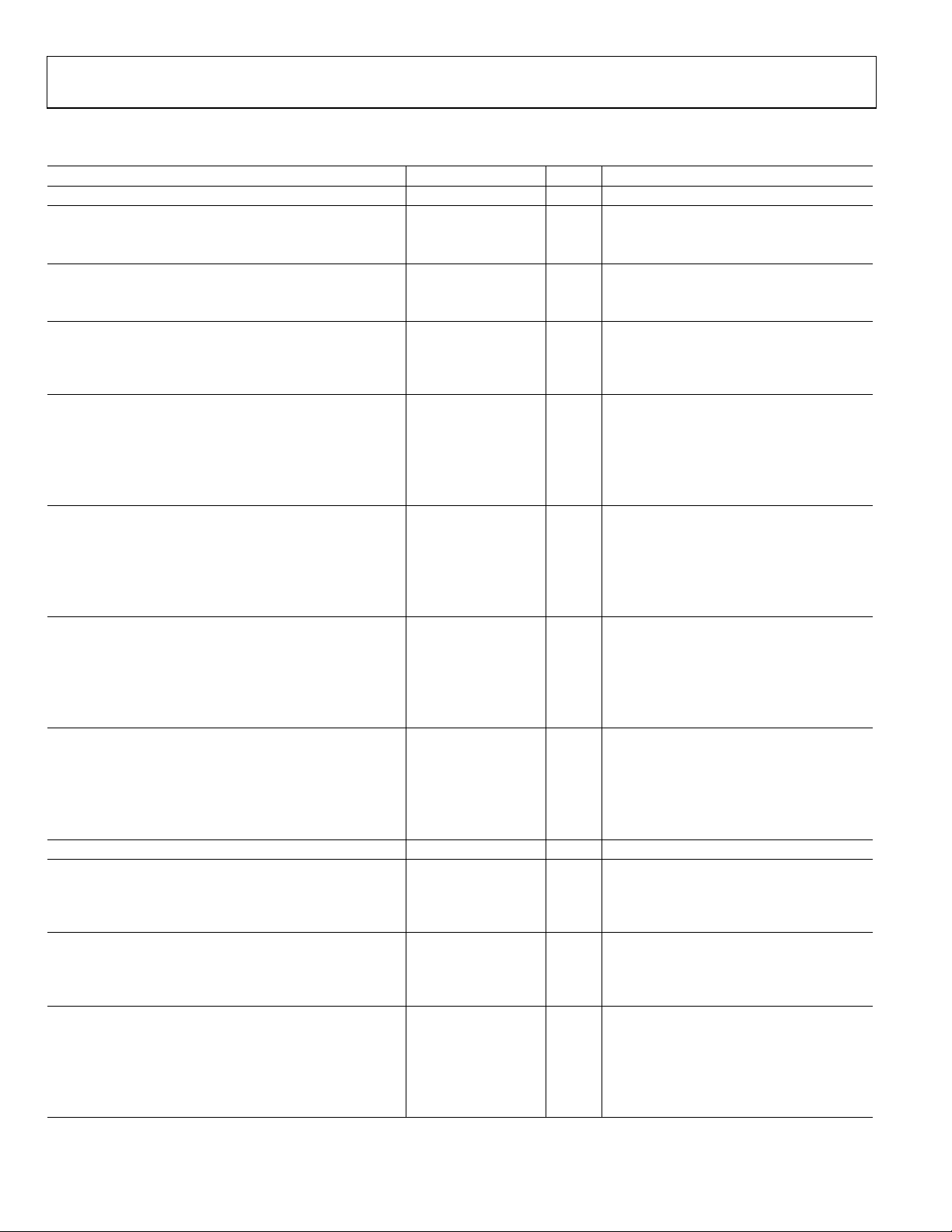

Table 12. Duty Cycle and Divide Ratio

4Ah to 52h

Divide Ratio Duty Cycle (%)

2 50 0 0

3 67 0 1

3 33 1 0

4 50 1 1

4 75 0 2

4 25 2 0

5 60 1 2

5 40 2 1

5 80 0 3

5 20 3 0

6 50 2 2

6 67 1 3

6 33 3 1

6 83 0 4

6 17 4 0

LO<7:4> HI<3:0>

Rev. A | Page 25 of 48

4Ah to 52h

Divide Ratio Duty Cycle (%)

7 57 2 3

7 43 3 2

7 71 1 4

7 29 4 1

7 86 0 5

7 14 5 0

8 50 3 3

8 63 2 4

8 38 4 2

8 75 1 5

8 25 5 1

8 88 0 6

8 13 6 0

9 56 3 4

9 44 4 3

LO<7:4> HI<3:0>

Page 26

AD9512

4Ah to 52h

Divide Ratio Duty Cycle (%)

9 67 2 5

9 33 5 2

9 78 1 6

9 22 6 1

9 89 0 7

9 11 7 0

10 50 4 4

10 60 3 5

10 40 5 3

10 70 2 6

10 30 6 2

10 80 1 7

10 20 7 1

10 90 0 8

10 10 8 0

11 55 4 5

11 45 5 4

11 64 3 6

11 36 6 3

11 73 2 7

11 27 7 2

11 82 1 8

11 18 8 1

11 91 0 9

11 9 9 0

12 50 5 5

12 58 4 6

12 42 6 4

12 67 3 7

12 33 7 3

12 75 2 8

12 25 8 2

12 83 1 9

12 17 9 1

12 92 0 A

12 8 A 0

13 54 5 6

13 46 6 5

13 62 4 7

13 38 7 4

13 69 3 8

13 31 8 3

13 77 2 9

13 23 9 2

13 85 1 A

13 15 A 1

13 92 0 B

13 8 B 0

14 50 6 6

14 57 5 7

14 43 7 5

LO<7:4> HI<3:0>

4Ah to 52h

Divide Ratio Duty Cycle (%)

14 64 4 8

14 36 8 4

14 71 3 9

14 29 9 3

14 79 2 A

14 21 A 2

14 86 1 B

14 14 B 1

14 93 0 C

14 7 C 0

15 53 6 7

15 47 7 6

15 60 5 8

15 40 8 5

15 67 4 9

15 33 9 4

15 73 3 A

15 27 A 3

15 80 2 B

15 20 B 2

15 87 1 C

15 13 C 1

15 93 0 D

15 7 D 0

16 50 7 7

16 56 6 8

16 44 8 6

16 63 5 9

16 38 9 5

16 69 4 A

16 31 A 4

16 75 3 B

16 25 B 3

16 81 2 C

16 19 C 2

16 88 1 D

16 13 D 1

16 94 0 E

16 6 E 0

17 53 7 8

17 47 8 7

17 59 6 9

17 41 9 6

17 65 5 A

17 35 A 5

17 71 4 B

17 29 B 4

17 76 3 C

17 24 C 3

17 82 2 D

17 18 D 2

LO<7:4> HI<3:0>

Rev. A | Page 26 of 48

Page 27

AD9512

4Ah to 52h

Divide Ratio Duty Cycle (%)

17 88 1 E

17 12 E 1

17 94 0 F

17 6 F 0

18 50 8 8

18 56 7 9

18 44 9 7

18 61 6 A

18 39 A 6

18 67 5 B

18 33 B 5

18 72 4 C

18 28 C 4

18 78 3 D

18 22 D 3

18 83 2 E

18 17 E 2

18 89 1 F

18 11 F 1

19 53 8 9

19 47 9 8

19 58 7 A

19 42 A 7

19 63 6 B

19 37 B 6

19 68 5 C

19 32 C 5

19 74 4 D

19 26 D 4

19 79 3 E

19 21 E 3

19 84 2 F

19 16 F 2

20 50 9 9

20 55 8 A

20 45 A 8

20 60 7 B

20 40 B 7

20 65 6 C

20 35 C 6

20 70 5 D

20 30 D 5

20 75 4 E

20 25 E 4

20 80 3 F

20 20 F 3

21 52 9 A

21 48 A 9

21 57 8 B

21 43 B 8

21 62 7 C

LO<7:4> HI<3:0>

Divide Ratio Duty Cycle (%)

21 38 C 7

21 67 6 D

21 33 D 6

21 71 5 E

21 29 E 5

21 76 4 F

21 24 F 4

22 50 A A

22 55 9 B

22 45 B 9

22 59 8 C

22 41 C 8

22 64 7 D

22 36 D 7

22 68 6 E

22 32 E 6

22 73 5 F

22 27 F 5

23 52 A B

23 48 B A

23 57 9 C

23 43 C 9

23 61 8 D

23 39 D 8

23 65 7 E

23 35 E 7

23 70 6 F

23 30 F 6

24 50 B B

24 54 A C

24 46 C A

24 58 9 D

24 42 D 9

24 63 8 E

24 38 E 8

24 67 7 F

24 33 F 7

25 52 B C

25 48 C B

25 56 A D

25 44 D A

25 60 9 E

25 40 E 9

25 64 8 F

25 36 F 8

26 50 C C

26 54 B D

26 46 D B

26 58 A E

26 42 E A

26 62 9 F

4Ah to 52h

LO<7:4> HI<3:0>

Rev. A | Page 27 of 48

Page 28

AD9512

4Ah to 52h

Divide Ratio Duty Cycle (%)

26 38 F 9

27 52 C D

27 48 D C

27 56 B E

27 44 E B

27 59 A F

27 41 F A

28 50 D D

28 54 C E

28 46 E C

28 57 B F

28 43 F B

LO<7:4> HI<3:0>

4Ah to 52h

Divide Ratio Duty Cycle (%)

29 52 D E

29 48 E D

29 55 C F

29 45 F C

30 50 E E

30 53 D F

30 47 F D

31 52 E F

31 48 F E

32 50 F F

LO<7:4> HI<3:0>

Rev. A | Page 28 of 48

Page 29

AD9512

Divider Phase Offset

The phase of each output may be selected, depending on the

divide ratio chosen. This is selected by writing the appropriate

values to the registers, which set the phase and start high/low

bit for each output. These are the odd numbered registers from

4Bh to 53h. Each divider has a 4-bit phase offset <3:0> and a

start high or low bit <4>.

Following a sync pulse, the phase offset word determines how

many fast clock (CLK1 or CLK2) cycles to wait before initiating

a clock output edge. The Start H/L bit determines if the divider

output starts low or high. By giving each divider a different

phase offset, output-to-output delays can be set in increments of

the fast clock period, t

CLK

.

Figure 25 shows three dividers, each set for DIV = 4, 50% duty

cycle. By incrementing the phase offset from 0 to 2, each output

is offset from the initial edge by a multiple of t

123456789101112131415

0

CLOCK INPUT

CLK

DIVIDER OUTPUTS

DIV = 4, DUTY = 50%

START = 0,

PHASE = 0

START = 0,

PHASE = 1

START = 0,

PHASE = 2

Figure 25. Phase Offset—All Dividers Set for DIV = 4, Phase Set from 0 to 2

t

CLK

t

CLK

2 ×

t

CLK

CLK

.

For example:

CLK1 = 491.52 MHz

t

= 1/491.52 = 2.0345 ns

CLK1

For DIV = 4

Phase Offset 0 = 0 ns

Phase Offset 1 = 2.0345 ns

Phase Offset 2 = 4.069 ns

The three outputs may also be described as:

OUT1 = 0°

OUT2 = 90°

OUT3 = 180°

Setting the phase offset to Phase = 4 results in the same relative

phase as the first channel, Phase = 0° or 360°.

05287-091

In general, by combining the 4-bit phase offset and the Start

H/L bit, there are 32 possible phase offset states (see Tab le 1 3 ).

Table 13. Phase Offset—Start H/L Bit

Phase Offset

(Fast Clock

Rising Edges)

Phase Offset <3:0> Start H/L <4>

4Bh to 53h

0 0 0

1 1 0

2 2 0

3 3 0

4 4 0

5 5 0

6 6 0

7 7 0

8 8 0

9 9 0

10 10 0

11 11 0

12 12 0

13 13 0

14 14 0

15 15 0

16 0 1

17 1 1

18 2 1

19 3 1

20 4 1

21 5 1

22 6 1

23 7 1

24 8 1

25 9 1

26 10 1

27 11 1

28 12 1

29 13 1

30 14 1

31 15 1

The resolution of the phase offset is set by the fast clock period

) at CLK1 or CLK2. As a result, every divide ratio does not

(t

CLK

have 32 unique phase offsets available. For any divide ratio, the

number of unique phase offsets is numerically equal to the

divide ratio (see Tab l e

13 ):

DIV = 4

Unique Phase Offsets Are Phase = 0, 1, 2, 3

DIV= 7

Unique Phase Offsets Are Phase = 0, 1, 2, 3, 4, 5, 6

Rev. A | Page 29 of 48

Page 30

AD9512

DIV = 18

Unique Phase Offsets Are Phase = 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10,

11, 12, 13, 14, 15, 16, 17

Phase offsets may be related to degrees by calculating the phase

step for a particular divide ratio:

Phase Step = 360°/(Divide Ratio) = 360°/DIV

Using some of the same examples,

DIV = 4

Phase Step = 360°/4 = 90°

Unique Phase Offsets in Degrees Are Phase = 0°, 90°,

180°, 270°

DIV = 7

Phase Step = 360°/7 = 51.43°

This path adds some jitter greater than that specified for the

nondelay outputs. This means that the delay function should be

used primarily for clocking digital chips, such as FPGA, ASIC,

DUC, and DDC, rather than for data converters. The jitter is

higher for long full scales (~10 ns). This is because the delay

block uses a ramp and trip points to create the variable delay. A

longer ramp means more noise might be introduced.

Calculating the Delay

The following values and equations are used to calculate the

delay of the delay block.

Value of Ramp Current Control Bits (Register 35h or Register 39h

<2:0>) = Iramp_bits

(µA) = 200 × (Iramp_bits + 1)

I

RAMP

No. of Caps = No. of 0s + 1 in Ramp Control Capacitor

(Register 35h or Register 39h <5:3>), that is, 101 = 1 + 1 = 2;

110 = 2; 100 = 2 + 1 = 3; 001 = 2 + 1 = 3; 111 = 0 + 1 = 1)

Unique Phase Offsets in Degrees Are Phase = 0°, 51.43°,

102.86°, 154.29°, 205.71°, 257.15°, 308.57°

DELAY BLOCK

OUT4 (LVDS/CMOS) includes an analog delay element that

can be programmed (Register 34h to Register 36h) to give

variable time delays (T) in the clock signal passing through

that output.

CLOCK INPUT

OUT4 ONLY

÷N

∅SELECT

ΔT

FINE DELAYADJUST

(32 STEPS)

FULL-SCALE: 1ns TO 10ns

Figure 26. Analog Delay (OUT4)

The amount of delay that can be used is determined by the

frequency of the clock being delayed. The amount of delay can

approach one-half cycle of the clock period. For example, for a

10 MHz clock, the delay can extend to the full 10 ns maximum

of which the delay element is capable. However, for a 100 MHz

clock (with 50% duty cycle), the maximum delay is less than

5 ns (or half of the period).

OUT4 allows a full-scale delay in the range 1 ns to 10 ns. The

full-scale delay is selected by choosing a combination of ramp

current and the number of capacitors by writing the appropriate

values into Register 35h. There are 32 fine delay settings for

each full scale, set by Register 36h.

MUX

LVDS

CMOS

OUTPUT

DRIVER

Delay_Range (ns) = 200 × [(No. of Caps + 3)/(I

⎛

4

−

()

()

IOffset

RAMP

⎜

1016000.34ns

+×−+=

⎜

⎝

)] × 1.3286

RAMP

CapsofNo.

I

RAMP

⎞

1

−

⎟

6

×

⎟

⎠

Delay_Full_Scale (ns) = Delay_Range + Offset

Fine_Adj = Value of Delay Fine Adjust (Register 36h or

Register 3Ah <5:1>), that is, 11111 = 31

Delay (ns) = Offset + Delay_Range × Fine_adj × (1/31)

OUTPUTS

The AD9512 offers three different output level choices:

LVPECL, LVDS, and CMOS . O U T 0 to O U T 2 are LV P E C L o n l y.

OUT3 and OUT4 can be selected as either LVDS or CMOS.

Each output can be enabled or turned off as needed to save

05287-092

power.

The simplified equivalent circuit of the LVPECL outputs is

shown in Figure 27.

3.3V

OUT

OUTB

GND

Figure 27. LVPECL Output Simplified Equivalent Circuit

05287-037

Rev. A | Page 30 of 48

Page 31

AD9512

3

A

3

A

.5m

the LVPECL power-down mode is set to <11b>, the LVPECL

output is not protected from reverse bias and can be damaged

under certain termination conditions.

OUT

OUTB

.5m

05287-038

Figure 28. LVDS Output Simplified Equivalent Circuit

POWER-DOWN MODES

Chip Power-Down or Sleep Mode—PDB

The PDB chip power-down turns off most of the functions and

currents in the AD9512. When the PDB mode is enabled, a chip

power-down is activated by taking the FUNCTION pin to a

logic low level. The chip remains in this power-down state until

PDB is brought back to logic high. When woken up, the

AD9512 returns to the settings programmed into its registers

prior to the power-down, unless the registers are changed by

new programming while the PDB mode is active.

The PDB power-down mode shuts down the currents on the

chip, except the bias current necessary to maintain the LVPECL

outputs in a safe shutdown mode. This is needed to protect the

LVPECL output circuitry from damage that could be caused by

certain termination and load configurations when tri-stated.

Because this is not a complete power-down, it can be called

sleep mode.

When the AD9512 is in a PDB power-down or sleep mode, the

chip is in the following state:

• All clocks and sync circuits are off.

• All dividers are off.

• All LVDS/CMOS outputs are off.

• All LVPECL outputs are in safe off mode.

• The serial control port is active, and the chip responds to

commands.

If the AD9512 clock outputs must be synchronized to each

other, a SYNC (see the Single-Chip Synchronization section) is

required when exiting power-down mode.

Distribution Power-Down

The distribution section can be powered down by writing 1 to

Register 58h<3>. This turns off the bias to the distribution

section. If the LVPECL power-down mode is normal operation

<00>, it is possible for a low impedance load on that LVPECL

output to draw significant current during this power-down. If

Individual Clock Output Power-Down

Any of the five clock distribution outputs may be powered

down individually by writing to the appropriate registers via the

SCP. The register map details the individual power-down

settings for each output. The LVDS/CMOS outputs may be

powered down, regardless of their output load configuration.

The LVPECL outputs have multiple power-down modes

(see Register 3Dh, Register 3Eh, and Register 3Fh in Tab le 18 ).

These give some flexibility in dealing with various output

termination conditions. When the mode is set to <10b>, the

LVPECL output is protected from reverse bias to 2 V

+ 1 V. If

BE

the mode is set to <11b>, the LVPECL output is not protected

from reverse bias and can be damaged under certain

termination conditions. This setting also affects the operation

when the distribution block is powered down with Register

58h<3> = 1b (see the Distribution Power-Down section).

Individual Circuit Block Power-Down

Several of the AD9512 circuit blocks (such as CLK1 and CLK2)

can be powered down individually. This gives flexibility in

configuring the part for power savings when all chip

functionality is not needed.

RESET MODES

The AD9512 has several ways to force the chip into a reset

condition.

Power-On Reset—Start-Up Conditions when VS is Applied

A power-on reset (POR) is issued when the VS power supply is

turned on. This initializes the chip to the power-on conditions

that are determined by the default register settings. These are

indicated in the default value column of Tabl e 17 .

Asynchronous Reset via the FUNCTION Pin

As mentioned in the FUNCTION Pin section, a hard reset,

RESETB: 58h<6:5> = 00b (Default), restores the chip to the

default settings.

Soft Reset via the Serial Port

The serial control port allows a soft reset by writing to

Register 00h<5> = 1b. When this bit is set, the chip executes a

soft reset. This restores the default values to the internal

registers, except for Register 00h itself.

This bit is not self-clearing. The bit must be written to

00h<5> = 0b for the operation of the part to continue.

Rev. A | Page 31 of 48

Page 32

AD9512

SINGLE-CHIP SYNCHRONIZATION

SYNCB—Hardware SYNC

The AD9512 clocks can be synchronized to each other at any

time. The outputs of the clocks are forced into a known state

with respect to each other and then allowed to continue

clocking from that state in synchronicity. Before a

synchronization is done, the FUNCTION Pin must be set as the

input (58h<6:5> = 01b). Synchronization is done by forcing the

FUNCTION pin low, creating a SYNCB signal and then

releasing it.

See the SYNCB: 58h<6:5> = 01b section for a more detailed

description of what happens when the SYNCB: 58h<6:5> = 01b

signal is issued.

Soft SYNC—Register 58h<2>

A soft SYNC can be issued by means of a bit in

Register 58h<2>. This soft SYNC works the same as the

SYNCB, except that the polarity is reversed. A 1 written to this

bit forces the clock outputs into a known state with respect to

each other. When a 0 is subsequently written to this bit, the

clock outputs continue clocking from that state in

synchronicity.

slave must provide this same frequency back to the DSYNCB

input of the slave.

Multichip synchronization is enabled by writing to

Register 58h<0> = 1b on the slave AD9512. When this bit

is set, the STATUS pin becomes the output for the SYNC

signal. A low signal indicates an in-sync condition, and

a high indicates an out-of-sync condition.

Register 58h<1> selects the number of fast clock cycles that are

the maximum separation of the slow clock edges that are

considered synchronized. When 58h<1> = 0b (default), the

slow clock edges must be coincident within 1 to 1.5 high speed

clock cycles. If the coincidence of the slow clock edges is closer

than this amount, the SYNC flag stays low. If the coincidence of

the slow clock edges is greater than this amount, the SYNC flag

is set high. When Register 58h<1> = 1b, the amount of

coincidence required is 0.5 fast clock cycles to 1 fast clock

cycles.

Whenever the SYNC flag is set (high), indicating an out-of-sync

condition, a SYNCB signal applied simultaneously at the

FUNCTION pins of both AD9512s brings the slow clocks into

synchronization.

MULTICHIP SYNCHRONIZATION

The AD9512 provides a means of synchronizing two or more

AD9512s. This is not an active synchronization; it requires user

monitoring and action. The arrangement of two AD9512s to be

synchronized is shown in Figure 29.

Synchronization of two or more AD9512s requires a fast clock

and a slow clock. The fast clock can be up to 1 GHz and can be

the clock driving the master AD9512 CLK1 input or one of the

outputs of the master. The fast clock acts as the input to the

distribution section of the slave AD9512 and is connected to its

CLK1 input.

The slow clock is the clock that is synchronized across the two

chips. This clock must be no faster than one-fourth of the fast

clock, and no greater than 250 MHz. The slow clock is taken

from one of the outputs of the master AD9512 and acts as a

DSYNC input to the slave AD9512. One of the outputs of the

SYNCB

AD9512

MASTER

FUNCTION

(SYNCB)

DSYNC DSYNCB

AD9512

SLAVE

FAST CLOCK

<1GHz

CLK1

(SYNCB)

Figure 29. Multichip Synchronization

DETECT

FAST CLOCK

<1GHz

SLOW CLOCK

<250MHz

CLOCK

<250MHz

SYNC

SLOW

OUTN

OUTM

F

SYNC

OUTY

SYNCSTATUSFUNCTION

F

SYNC

05287-093

Rev. A | Page 32 of 48

Page 33

AD9512

SERIAL CONTROL PORT

The AD9512 serial control port is a flexible, synchronous, serial

communications port that allows an easy interface with many

industry-standard microcontrollers and microprocessors. The

AD9512 serial control port is compatible with most

synchronous transfer formats, including both the Motorola SPI®

and Intel® SSR protocols. The serial control port allows

read/write access to all registers that configure the AD9512.

Single or multiple byte transfers are supported, as well as MSB

first or LSB first transfer formats. The AD9512 serial control

port can be configured for a single bidirectional I/O pin (SDIO

only) or for two unidirectional I/O pins (SDIO/SDO).

SERIAL CONTROL PORT PIN DESCRIPTIONS

SCLK (serial clock) is the serial shift clock. This pin is an input.

SCLK is used to synchronize serial control port reads and

writes. Write data bits are registered on the rising edge of this

clock, and read data bits are registered on the falling edge. This

pin is internally pulled down by a 30 kΩ resistor to ground.

SDIO (serial data input/output) is a dual-purpose pin and acts

as either an input only or as both an input/output. The AD9512

defaults to two unidirectional pins for I/O, with SDIO used as

an input and SDO as an output. Alternatively, SDIO can be used

as a bidirectional I/O pin by writing to the SDO enable register

at 00h<7> = 1b.

SDO (serial data out) is used only in the unidirectional I/O

mode (00h<7> = 0b, default) as a separate output pin for

reading back data. The AD9512 defaults to this I/O mode.

Bidirectional I/O mode (using SDIO as both input and output)

may be enabled by writing to the SDO enable register at

00h<7> = 1b.

CSB (chip select bar) is an active low control that gates the read

and write cycles. When CSB is high, SDO and SDIO are in a

high impedance state. This pin is internally pulled down by a

30 kΩ resistor to ground. It should not be left NC or tied low.

See the Framing a Communication Cycle with CSB section on

the use of the CSB in a communication cycle.

SCLK (PIN 14)

SDIO (PIN 15)

SDO (PIN 16)

CSB (PIN 17)

Figure 30. Serial Control Port

AD9512

SERIAL

CONTROL

PORT

05287-094

GENERAL OPERATION OF SERIAL CONTROL PORT

Framing a Communication Cycle with CSB

Each communication cycle (a write or a read operation) is gated

by the CSB line. CSB must be brought low to initiate a

communication cycle. CSB must be brought high at the

completion of a communication cycle (see Figure 38). If CSB is

not brought high at the end of each write or read cycle (on a