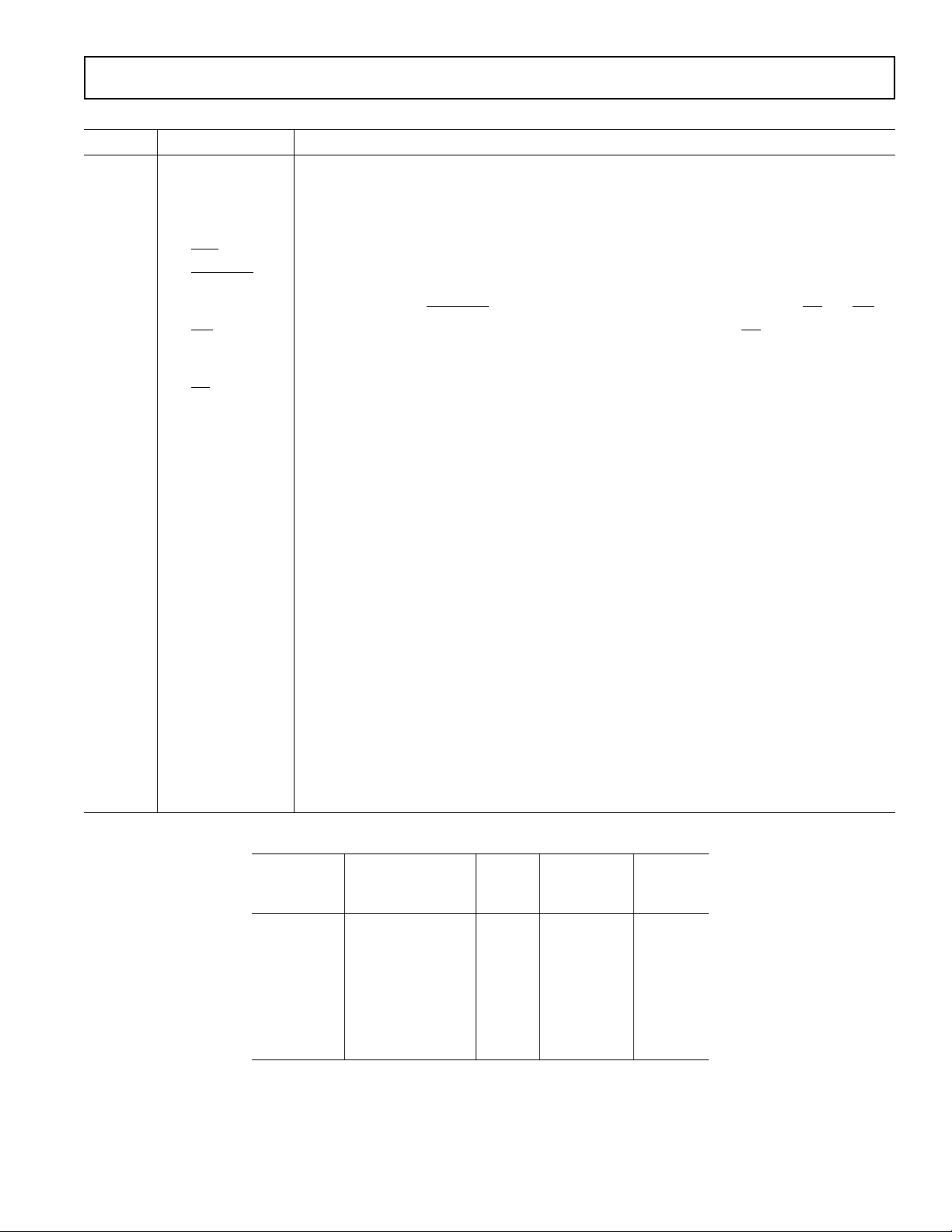

LC2MOS 4-Channel, 12-Bit Simultaneous

AGND

CLK

DGND

DB11

DB0

V

SS

CS

12-BIT

DAC

V

IN1

V

IN2

V

IN3

V

IN4

COMP

REFERENCE

BUFFER

INT

RD

AD7874

CONVST

VDDV

DD

REF IN

REF OUT

3V

REFERENCE

DATA

REGISTERS

SAR

MUX

CONTROL LOGIC

INTERNAL

CLOCK

TRACK/

HOLD 3

TRACK/

HOLD 4

TRACK/

HOLD 2

TRACK/

HOLD 1

a

Sampling Data Acquisition System

AD7874

FEATURES

Four On-Chip Track/Hold Amplifiers

Simultaneous Sampling of 4 Channels

Fast 12-Bit ADC with 8 ms Conversion Time/Channel

29 kHz Sample Rate for All Four Channels

On-Chip Reference

610 V Input Range

65 V Supplies

APPLICATIONS

Sonar

Motor Controllers

Adaptive Filters

Digital Signal Processing

GENERAL DESCRIPTION

The AD7874 is a four-channel simultaneous sampling, 12-bit

data acquisition system. The part contains a high speed 12-bit

ADC, on-chip reference, on-chip clock and four track/hold amplifiers. This latter feature allows the four input channels to be

sampled simultaneously, thus preserving the relative phase

information of the four input channels, which is not possible if

all four channels share a single track/hold amplifier. This makes

the AD7874 ideal for applications such as phased-array sonar

and ac motor controllers where the relative phase information is

important.

The aperture delay of the four track/hold amplifiers is small and

specified with minimum and maximum limits. This allows several AD7874s to sample multiple input channels simultaneously

without incurring phase errors between signals connected to

several devices. A reference output/reference input facility also

allows several AD7874s to be driven from the same reference

source.

In addition to the traditional dc accuracy specifications such as

linearity, full-scale and offset errors, the AD7874 is also fully

specified for dynamic performance parameters including distortion and signal-to-noise ratio.

The AD7874 is fabricated in Analog Devices’ Linear Compatible CMOS (LC

that combines precision bipolar circuits with low-power CMOS

logic. The part is available in a 28-pin, 0.6" wide, plastic or hermetic dual-in-line package (DIP), in a 28-terminal leadless ceramic chip carrier (LCCC) and in a 28-pin SOIC.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

2

MOS) process, a mixed technology process

PRODUCT HIGHLIGHTS

1. Simultaneous Sampling of Four Input Channels.

Four input channels, each with its own track/hold amplifier,

allow simultaneous sampling of input signals. Track/hold acquisition time is 2 µs, and the conversion time per channel is

8 µs, allowing 29 kHz sample rate for all four channels.

2. Tight Aperture Delay Matching.

The aperture delay for each channel is small and the aperture

delay matching between the four channels is less than 4 ns.

Additionally, the aperture delay specification has upper and

lower limits allowing multiple AD7874s to sample more than

four channels.

3. Fast Microprocessor Interface.

The high speed digital interface of the AD7874 allows direct

connection to all modern 16-bit microprocessors and digital

signal processors.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

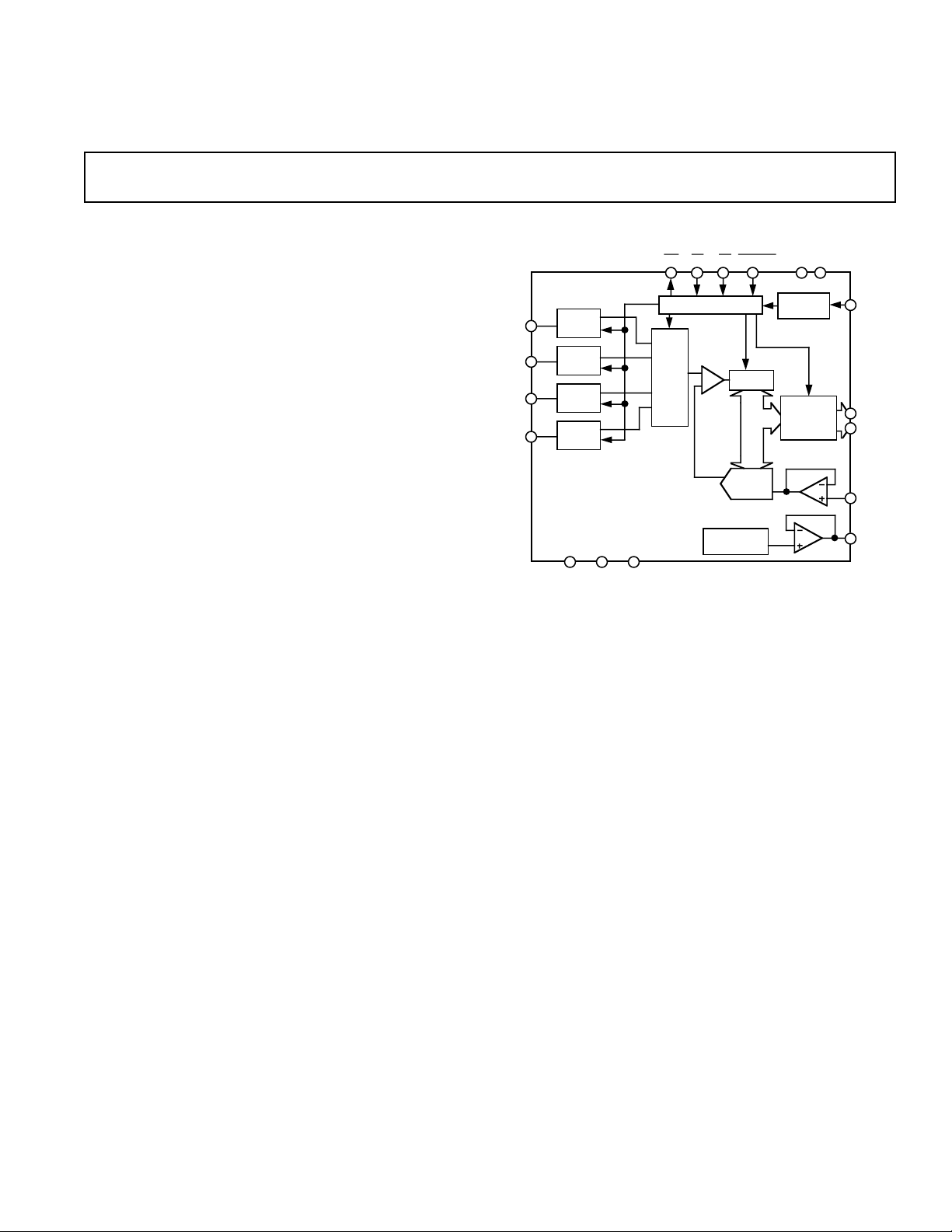

FUNCTIONAL BLOCK DIAGRAM

AD7874–SPECIFICA TIONS

(VDD = +5 V, VSS = –5 V, AGND = DGND = 0 V, REF IN = +3 V, f

external. All specifications T

MIN

to T

unless otherwise noted.)

MAX

= 2.5 MHz

CLK

Parameter A Version B Version S Version Units Test Conditions/Comments

SAMPLE-AND-HOLD

Acquisition Time2 to 0.01% 2 2 2 µs max

Droop Rate

–3 dB Small Signal Bandwidth

Aperture Delay

Aperture Jitter

Aperture Delay Matching

2, 3

2, 3

2

3

1 1 2 mV/ms max

500 500 500 kHz typ VIN = 500 mV p-p

0 0 0 ns min

40 40 40 ns max

2

200 200 200 ps typ

4 4 4 ns max

SAMPLE-AND-HOLD AND ADC

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio 70 71 70 dB min fIN = 10 kHz Sine Wave, f

Total Harmonic Distortion –78 –80 –78 dB max fIN = 10 kHz Sine Wave, f

Peak Harmonic or Spurious Noise –78 –80 –78 dB max fIN = 10 kHz Sine Wave, f

Intermodulation Distortion fa = 9 kHz, fb = 9.5 kHz, f

SAMPLE

SAMPLE

SAMPLE

SAMPLE

= 29 kHz

= 29 kHz

= 29 kHz

= 29 kHz

2nd Order Terms –80 –80 –80 dB max

3rd Order Terms –80 –80 –80 dB max

Channel-to-Channel Isolation

2

–80 –80 –80 dB max

DC ACCURACY

Resolution 12 12 12 Bits

Relative Accuracy ± 1 ±1/2 ± 1 LSB max

Differential Nonlinearity ± 1 ±1 ±1 LSB max No Missing Codes Guaranteed

Positive Full-Scale Error

Negative Full-Scale Error

4

4

± 5 ± 5 ±5 LSB max Any Channel

±5 ±5 ±5 LSB max Any Channel

Full-Scale Error Match 5 5 5 LSB max Between Channels

Bipolar Zero Error ±5 ±5 ±5 LSB max Any Channel

Bipolar Zero Error Match 4 4 4 LSB max Between Channels

ANALOG INPUTS

Input Voltage Range ±10 ±10 ±10 Volts

Input Current ± 600 ±600 ± 600 µA max

REFERENCE OUTPUTS

REF OUT 333V nom

REF OUT Error @ +25°C ±0.33 ±0.33 ±0.33 % max

T

MIN

to T

MAX

±1 ±1 ±1 % max

REF OUT Temperature Coefficient ±35 ±35 ± 35 ppm/°C typ

Reference Load Change ±1 ±1 ±2 mV max Reference Load Current Change (0–500 µA)

Reference Load Should Not Be Changed During Conversion

REFERENCE INPUT

Input Voltage Range 2.85/3.15 2.85/3.15 2.85/3.15 V min/V max 3 V ± 5%

Input Current ± 1 ±1 ±1 µA max

Input Capacitance

3

10 10 10 pF max

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

IN

IN

INH

INL

3

2.4 2.4 2.4 V min VDD = 5 V ± 5%

0.8 0.8 0.8 V max VDD = 5 V ± 5%

±10 ±10 ±10 µA max VIN = 0 V to V

10 10 10 pF max

DD

LOGIC OUTPUTS

Output High Voltage, V

Output Low Voltage, V

OL

OH

4.0 4.0 4.0 V min VDD = 5 V ± 5%; I

0.4 0.4 0.4 V max VDD = 5 V ± 5%; I

SOURCE

= 1–6 mA

SINK

= 40 µA

DB0–DB11

Floating-State Leakage Current ±10 ±10 ±10 µA max VIN = 0 V to V

DD

Floating-State Output Capacitance 10 10 10 pF max

Output Coding 2s COMPLEMENT

POWER REQUIREMENTS

V

DD

V

SS

I

DD

I

SS

+5 +5 +5 V nom ± 5% for Specified Performance

–5 –5 –5 V nom ±5% for Specified Performance

18 18 18 mA max CS = RD = CONVST = +5 V; Typically 12 mA

12 12 12 mA max CS = RD = CONVST = +5 V; Typically 8 mA

Power Dissipation 150 150 150 mW max CS = RD = CONVST = +5 V; Typically 100 mW

NOTES

1

Temperature ranges are as follows: A, B Versions: –40°C to +85°C; S Version: –55°C to +125°C.

2

See Terminology.

3

Sample tested @ +25°C to ensure compliance.

4

Measured with respect to the REF IN voltage and includes bipolar offset error.

5

For capacitive loads greater than 50 pF a series resistor is required.

Specifications subject to change without notice.

–2–

REV. C

AD7874

TIMING CHARACTERISTICS

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, AGND = DGND = O V, t

1

otherwise noted.)

= 2.5 MHz external unless

CLK

Parameter A, B Versions S Version Units Conditions/Comments

t

1

t

2

t

3

t

4

t

5

2

t

6

3

t

7

50 50 ns min CONVST Pulse Width

0 0 ns min CS to RD Setup Time

60 70 ns min RD Pulse Width

0 0 ns min CS to RD Hold Time

60 60 ns max RD to INT Delay

57 70 ns max Data Access Time after RD

55ns min Bus Relinquish Time after RD

45 50 ns max

t

8

t

CONV

t

CLK

NOTES

1

Timing Specifications in bold print are 100% production tested. All other times are sample tested at +25°C to ensure compliance. All input signals are specified with

tr = tf = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

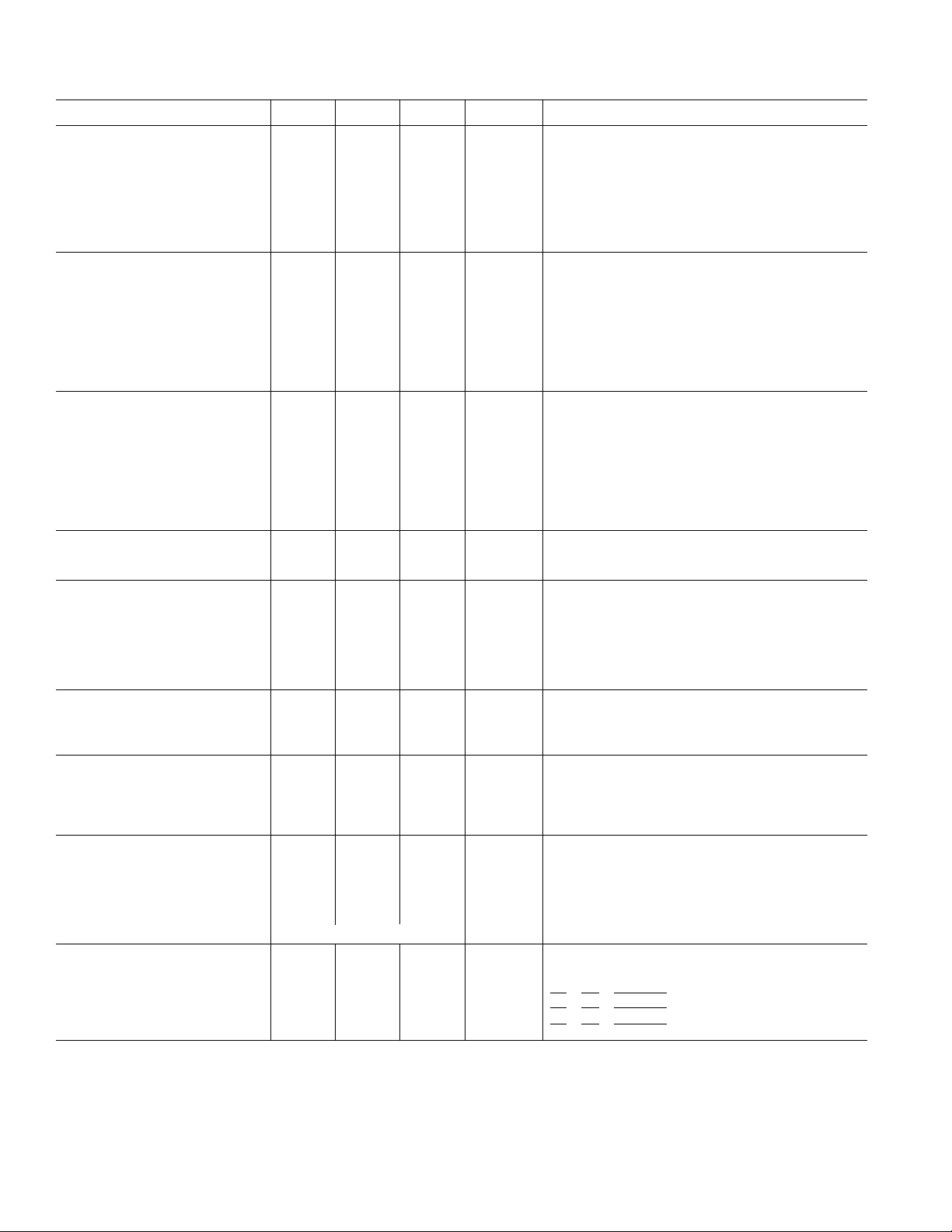

2

t6 is measured with the load circuit of Figure 1 and defined as the time required for an output to cross 0.8 V or 2.4 V.

3

t7 is derived from the measured time taken by the data outputs to change 0.5 V when loaded with the circuit of Figure 2. The measured number is then extrapolated

back to remove the effects of charging or discharging the 50 pF capacitor. This means that the time, t

time of the part and as such is independent of external bus loading capacitances.

Specifications subject to change without notice.

130 150 ns min Delay Time between Reads

31 31 µs min CONVST to INT, External Clock

32.5 32.5 µs max

31 31 µs min

35 35 µs max

CONVST to INT, External Clock

CONVST to INT, Internal Clock

CONVST to INT, Internal Clock

10 10 µs max Minimum Input Clock Period

, quoted in the timing characteristics is the true bus relinquish

7

1.6mA

ABSOLUTE MAXIMUM RATINGS*

(TA = +25°C unless otherwise noted)

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

DD

V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V to –7 V

SS

AGND to DGND . . . . . . . . . . . . . . . . –0.3 V to V

V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . .–15 V to +15 V

IN

REF OUT to AGND . . . . . . . . . . . . . . . . . . . . . . . 0 V to V

DD

+ 0.3 V

DD

TO OUTPUT

PIN

50pF

2.1V+

200µA

Digital Inputs to DGND . . . . . . . . . . . –0.3 V to VDD + 0.3 V

Digital Outputs to DGND . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

Figure 1. Load Circuit for Access Time

Operating Temperature Range

Commercial (A, B Versions) . . . . . . . . . . . –40°C to +85°C

1.6mA

Extended (S Version) . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . +300°C

Power Dissipation (Any Package) to +75°C . . . . . . 1,000 mW

Derates above +75°C by . . . . . . . . . . . . . . . . . . . . 10 mW/°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those listed in the

operational sections of this specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

TO OUTPUT

PIN

50pF

200µA

2.1V+

Figure 2. Load Circuit for Bus Relinquish Time

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7874 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. C

–3–

WARNING!

ESD SENSITIVE DEVICE

AD7874

V

IN1

V

IN2

V

IN4

V

IN3

REF IN

AGND

DB0 (LSB)

V

DD

V

SS

REF OUT

CLK DB1

V

DD

DB2

DB11 (MSB) DB3

DB10 DB4

DB9 DB5

DB8 DB6

DGND DB7

13

18

1

2

28

27

5

6

7

24

23

22

3

4

26

25

821

920

10

19

1111

12

17

16

14

15

TOP VIEW

(Not to Scale)

AD7874

INT

CONVST

RD

CS

V

DD

CLK

V

DD

V

IN4

V

IN2

V

IN1

DB9

DB8

DB6

DGND

DB7

REF OUT

REF IN

DB1

AGND

DB0 (LSB)

DB10

DB11 (MSB)

DB4

DB5

V

SS

V

IN3

DB3

DB2

AD7874

2712822634

25

22

24

23

21

19

20

181712 13 1614 15

11

10

9

8

7

6

5

TOP VIEW

(Not to Scale)

CONVST

RD

CS

INT

TERMINOLOGY

ACQUISITION TIME

Acquisition Time is the time required for the output of the

track/hold amplifiers to reach their final values, within ±1/2

LSB, after the falling edge of

holds return to track mode). This includes switch delay time,

slewing time and settling time for a full-scale voltage change.

APERTURE DELAY

Aperture Delay is defined as the time required by the internal

switches to disconnect the hold capacitors from the inputs. This

produces an effective delay in sample timing. It is measured by

applying a step input and adjusting the

until the output code follows the step input change.

APERTURE DELAY MATCHING

Aperture Delay Matching is the maximum deviation in aperture

delays across the four on-chip track/hold amplifiers.

APERTURE JITTER

Aperture Jitter is the uncertainty in aperture delay caused by

internal noise and variation of switching thresholds with signal

level.

DROOP RATE

Droop Rate is the change in the held analog voltage resulting

from leakage currents.

INT (the point at which the track/

CONVST input position

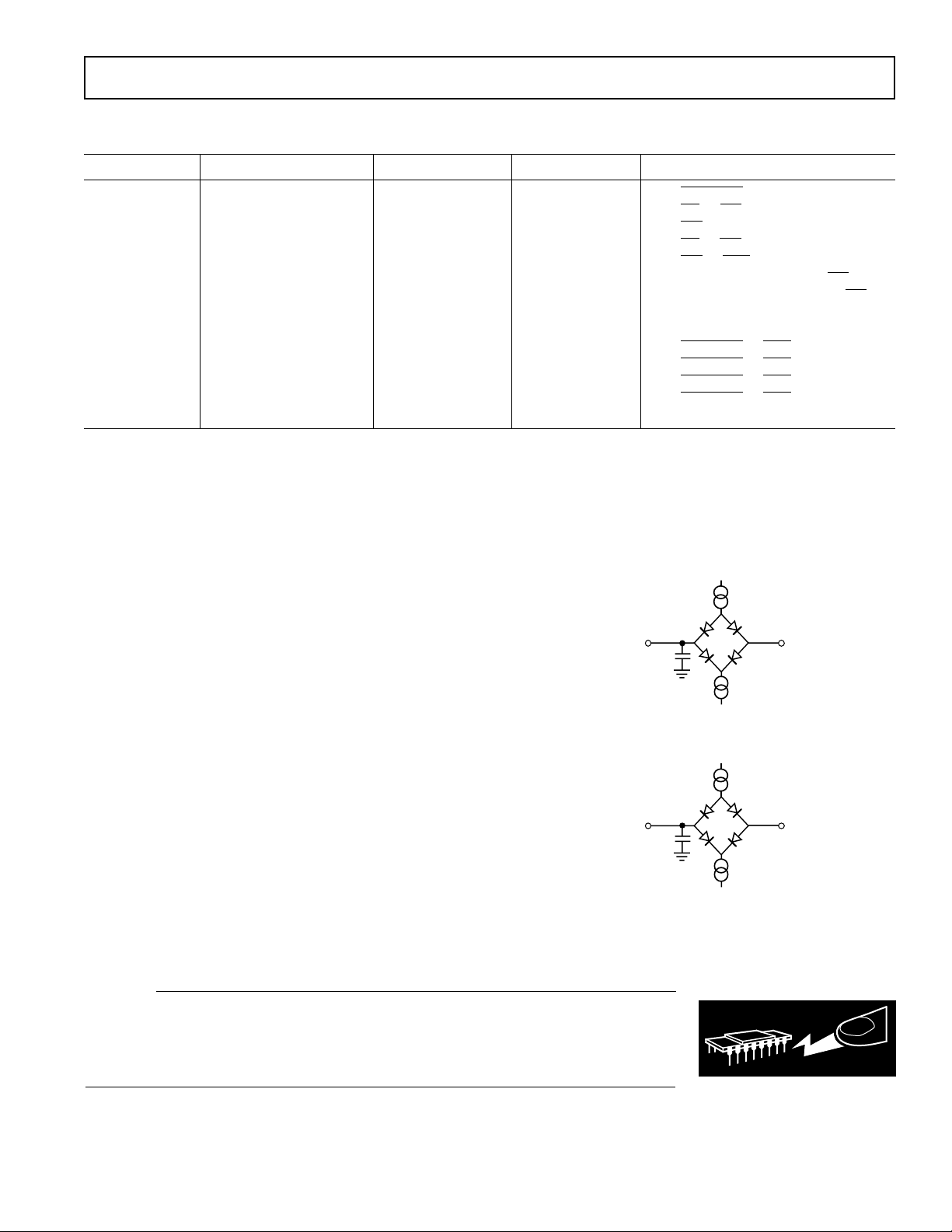

PIN CONFIGURATIONS

DIP and SOIC

LCCC

CHANNEL-TO-CHANNEL ISOLATION

Channel-to-Channel Isolation is a measure of the level of

crosstalk between channels. It is measured by applying a fullscale 1 kHz signal to the other three inputs. The figure given is

the worst case across all four channels.

SNR, THD, IMD

See DYNAMIC SPECIFICATIONS section.

–4–

REV. C

PIN FUNCTION DESCRIPTION

Pin Mnemonic Description

AD7874

1V

IN1

Analog Input Channel 1. This is the first of the four input channels to be converted in a con-

version cycle. Analog input voltage range is ± 10 V.

2V

3V

4

5

IN2

DD

INT Interrupt. Active low logic output indicating converter status. See Figure 7.

CONVST Convert Start. Logic Input. A low to high transition on this input puts the track/hold into its

Analog Input Channel 2. Analog input voltage range is ±10 V.

Positive supply voltage, +5 V ± 5%. This pin should be decoupled to AGND.

hold mode and starts conversion. The four channels are converted sequentially, Channel 1 to

Channel 4. The

6

RD Read. Active low logic input. This input is used in conjunction with CS low to enable the

CONVST input is asynchronous to CLK and independent of CS and RD.

data outputs. Four successive reads after a conversion will read the data from the four chan-

nels in the sequence, Channel 1, 2, 3, 4.

7

CS Chip Select. Active low logic input. The device is selected when this input is active.

8 CLK Clock Input. An external TTL-compatible clock may be applied to this input pin. Alterna-

9V

DD

tively, tying this pin to V

Positive Supply Voltage, +5 V ± 5%. Same as Pin 3; both pins must be tied together at the

enables the internal laser trimmed clock oscillator.

SS

package. This pin should be decoupled to DGND.

10 DB11 Data Bit 11 (MSB). Three-state TTL output. Output coding is 2s complement.

11–13 DB10–DB8 Data Bit 10 to Data Bit 8. Three-state TTL outputs.

14 DGND Digital Ground. Ground reference for digital circuitry.

15–21 DB7–DB1 Data Bit 7 to Data Bit 1. Three-state TTL outputs.

22 DB0 Data Bit 0 (LSB). Three-state TTL output.

23 AGND Analog Ground. Ground reference for track/hold, reference and DAC.

24 REF IN Voltage Reference Input. The reference voltage for the part is applied to this pin. It is inter-

nally buffered, requiring an input current of only ±1 µA. The nominal reference voltage for

correct operation of the AD7874 is 3 V.

25 REF OUT Voltage Reference Output. The internal 3 V analog reference is provided at this pin. To oper-

ate the AD7874 with internal reference, REF OUT is connected to REF IN. The external

load capability of the reference is 500 µA.

26 V

27 V

28 V

SS

IN3

IN4

Negative Supply Voltage, –5 V ± 5%.

Analog Input Channel 3. Analog input voltage range is ±10 V.

Analog Input Channel 4. Analog input voltage range is ±10 V.

REV. C

ORDERING GUIDE

Relative

Temperature SNR Accuracy Package

Range (dBs) (LSB) Option

Model

1

AD7874AN –40°C to +85°C 70 min ±1 max N-28

AD7874BN –40°C to +85°C 72 min ±1/2 max N-28

AD7874AR –40°C to +85°C 70 min ±1 max R-28

AD7874BR –40°C to +85°C 72 min ±1/2 max R-28

AD7874AQ –40°C to +85°C 70 min ±1 max Q-28

AD7874BQ –40°C to +85°C 72 min ±1/2 max Q-28

AD7874SQ

AD7874SE

NOTES

1

To order MIL-STD-883, Class B processed parts, add /883B to part number. Contact

1

our local sales office for military data sheet and availability.

2

E = Leaded Ceramic Chip Carrier; N = Plastic DIP; Q = Cerdip; R = SOIC.

3

Available to /883B processing only.

3

–55°C to +125°C 70 min ±1 max Q-28

3

–55°C to +125°C 70 min ±1 max E-28A

–5–

2

AD7874

CONVERTER DETAILS

The AD7874 is a complete 12-bit, 4-channel data acquisition

system. It is comprised of a 12-bit successive approximation

ADC, four high speed track/hold circuits, a four-channel analog

multiplexer and a 3 V Zener reference. The ADC uses a successive approximation technique and is based on a fast-settling,

voltage switching DAC, a high speed comparator, a fast CMOS

SAR and high speed logic.

Conversion is initiated on the rising edge of

CONVST. All four

input track/holds go from track to hold on this edge. Conversion

is first performed on the Channel 1 input voltage, then Channel

2 is converted and so on. The four results are stored in on-chip

registers. When all four conversions have been completed,

INT

goes low indicating that data can be read from these locations.

The conversion sequence takes either 78 or 79 rising clock edges

depending on the synchronization of

CONVST with CLK. Internal delays and reset times bring the total conversion time

from

CONVST going high to INT going low to 32.5 µs maxi-

mum for a 2.5 MHz external clock. The AD7874 uses an implicit addressing scheme whereby four successive reads to the

same memory location access the four data words sequentially.

The first read accesses Channel 1 data, the second read accesses

Channel 2 data and so on. Individual data registers cannot be

accessed independently.

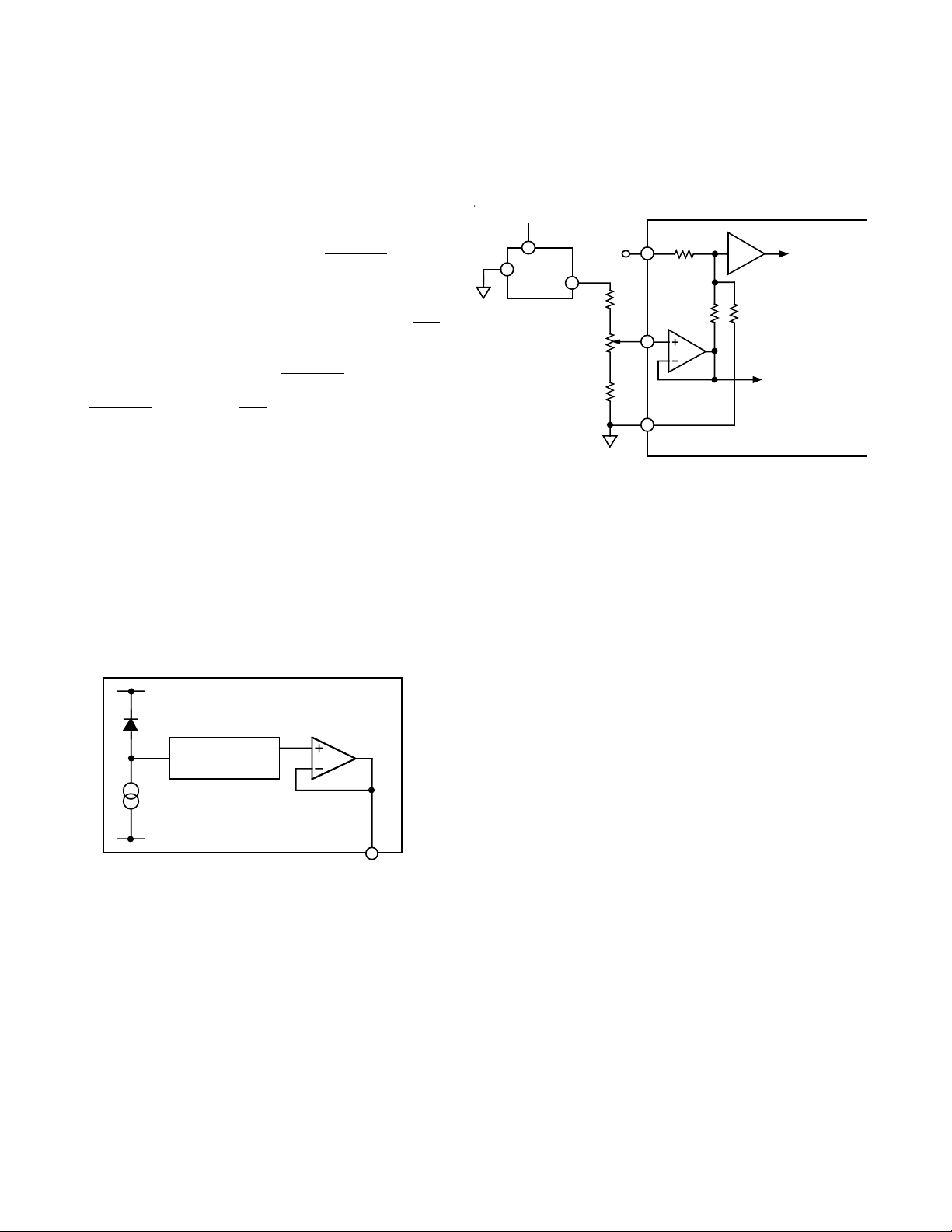

INTERNAL REFERENCE

The AD7874 has an on-chip temperature compensated buried

Zener reference which is factory trimmed to 3 V ± 10 mV (see

Figure 3). The reference voltage is provided at the REF OUT

pin. This reference can be used to provide both the reference

voltage for the ADC and the bipolar bias circuitry. This is

achieved by connecting REF OUT to REF IN.

V

DD

TEMPERATURE

COMPENSATION

V

SS

AD7874

REF OUT

Figure 3. AD7874 Internal Reference

The reference can also be used as a reference for other components and is capable of providing up to 500 µA to an external

load. In systems using several AD7874s, using the REF OUT of

one device to provide the REF IN for the other devices ensures

good full-scale tracking between all the AD7874s. Because the

AD7874 REF IN is buffered, each AD7874 presents a high impedance to the reference so one AD7874 REF OUT can drive

several AD7874 REF INs.

The maximum recommended capacitance on REF OUT for

normal operation is 50 pF. If the reference is required for other

system uses, it should be decoupled to AGND with a 200 Ω resistor in series with a parallel combination of a 10 µF tantalum

capacitor and a 0.1 µF ceramic capacitor.

EXTERNAL REFERENCE

In some applications, the user may require a system reference or

some other external reference to drive the AD7874 reference input. Figure 4 shows how the AD586 5 V reference can be used

to provide the 3 V reference required by the AD7874 REF IN.

+

15V

+V

GND

IN

V

AD586

OUT

10kΩ

1kΩ

15kΩ

V

REF

AGND

7R*

IN1

TRACK/HOLD 1

2.1R* 3R*

IN

TO ADC

REFERENCE

CIRCUITRY

*R = 3.6kΩ TYP

**ADDITIONAL PINS OMITTED FOR CLARITY

TO INTERNAL

COMPARATOR

AD7874**

Figure 4. AD586 Driving AD7874 REF IN

TRACK-AND-HOLD AMPLIFIER

The track-and-hold amplifier on each analog input of the

AD7874 allows the ADC to accurately convert an input sine

wave of 20 V p-p amplitude to 12-bit accuracy. The input bandwidth of the track/hold amplifier is greater than the Nyquist rate

of the ADC even when the ADC is operated at its maximum

throughput rate. The small signal 3 dB cutoff frequency occurs

typically at 500 kHz.

The four track/hold amplifiers sample their respective input

channels simultaneously. The aperture delay of the track/hold

circuits is small and, more importantly, is well matched across

the four track/holds on one device and also well matched from

device to device. This allows the relative phase information between different input channels to be accurately preserved. It also

allows multiple AD7874s to sample more than four channels

simultaneously.

The operation of the track/hold amplifiers is essentially transparent to the user. Once conversion is initiated, the four channels

are automatically converted and there is no need to select which

channel is to be digitized.

ANALOG INPUT

The analog input of Channel 1 of the AD7874 is as shown in

Figure 4. The analog input range is ±10 V into an input resistance of typically 30 kΩ. The designed code transitions occur

midway between successive integer LSB values (i.e., 1/2 LSB,

3/2 LSBs, 5/2 LSBs, . . . FS – 3/2 LSBs). The output code is

2s complement binary with 1 LSB = FS/4096 = 20 V/4096 =

4.88 mV. The ideal input/output transfer function is shown in

Figure 5.

–6–

REV. C

AD7874

OUTPUT

CODE

011...111

011...110

000...010

–

000...001

000...000

111...111

111...110

100...001

100...000

FS

2

+

FS

1LSB–

2

FS=20V

FS

1LSB =

4096

0V

INPUT VOLTAGE

Figure 5. Input/Output Transfer Function

OFFSET AND FULL-SCALE ADJUSTMENT

In most Digital Signal Processing (DSP) applications, offset and

full-scale errors have little or no effect on system performance.

Offset error can always be eliminated in the analog domain by

ac coupling. Full-scale error effect is linear and does not cause

problems as long as the input signal is within the full dynamic

range of the ADC. Invariably, some applications will require

that the input signal span the full analog input dynamic range.

In such applications, offset and full-scale error will have to be

adjusted to zero.

Figure 6 shows a circuit which can be used to adjust the offset

and full-scale errors on the AD7874 (Channel 1 is shown for example purposes only). Where adjustment is required, offset error must be adjusted before full-scale error. This is achieved by

trimming the offset of the op amp driving the analog input of

the AD7874 while the input voltage is a 1/2 LSB below analog

ground. The trim procedure is as follows: apply a voltage of

–2.44 mV (–1/2 LSB) at V

in Figure 6 and adjust the op amp

1

offset voltage until the ADC output code flickers between 1111

1111 1111 and 0000 0000 0000.

INPUT

RANGE = ±10V

V

1

R1

10kΩ

R2

500Ω

R4

10kΩ

R5

R3

10kΩ

10kΩ

*ADDITIONAL PINS OMITTED FOR CLARITY

V

IN1

AD7874*

AGND

Figure 6. AD7874 Full-Scale Adjust Circuit

Gain error can be adjusted at either the first code transition

(ADC negative full scale) or the last code transition (ADC positive full scale). The trim procedures for both cases are as

follows:

Positive Full-Scale Adjust

Apply a voltage of +9.9927 V (FS/2 – 3/2 LSBs) at V1. Adjust

R2 until the ADC output code flickers between 0111 1111 1110

and 0111 1111 1111.

Negative Full-Scale Adjust

Apply a voltage of –9.9976 V ( –FS + 1/2 LSB) at V1 and adjust

R2 until the ADC output code flickers between 1000 0000 0000

and 1000 0000 0001.

An alternative scheme for adjusting full-scale error in systems

which use an external reference is to adjust the voltage at the

REF IN pin until the full-scale error for any of the channels is

adjusted out. The good full-scale matching of the channels will

ensure small full-scale errors on the other channels.

TIMING AND CONTROL

Conversion is initiated on the AD7874 by asserting the

CONVST input. This CONVST input is an asynchronous input

which is independent of the ADC clock. This is essential for

applications where precise sampling in time is important. In

these applications, the signal sampling must occur at exactly

equal intervals to minimize errors due to sampling uncertainty

or jitter. In these cases, the

CONVST input is driven from a

timer or precise clock source. Once conversion is started,

CONVST should not be asserted again until conversion is complete on all four channels.

In applications where precise time interval sampling is not critical, the

CONVST pulse can be generated from a microprocessor WRITE or READ line gated with a decoded address

(different to the AD7874

CS address). CONVST should not be

derived from a decoded address alone because very short

CONVST pulses (which may occur in some microprocessor systems as the address bus is changing at the start of an instruction

cycle) could initiate a conversion.

All four track/hold amplifiers go from track to hold on the rising

edge of the

CONVST pulse. The four track/hold amplifiers remain in their hold mode while all four channels are converted.

The rising edge of

Channel 1 input voltage (V

CONVST also initiates a conversion on the

). When conversion is complete

IN1

on Channel 1, its result is stored in Data Register 1, one of four

on-chip registers used to store the conversion results. When the

result from the first conversion is stored, conversion is initiated

on the voltage held by track/hold 2. When conversion has been

completed on the voltage held by track/hold 4 and its result is

stored in Data Register 4,

INT goes low to indicate that the

conversion process is complete.

The sequence in which the channel conversions takes place is

automatically taken care of by the AD7874. This means that the

user does not have to provide address lines to the AD7874 or

worry about selecting which channel is to be digitized.

Reading data from the device consists of four read operations to

the same microprocessor address. Addressing of the four

on-chip data registers is again automatically taken care of by the

AD7874.

REV. C

–7–

AD7874

z

The first read operation to the AD7874 after conversion always

accesses data from Data Register 1 (i.e., the conversion result

from the V

RD during this first read operation. The second read always accesses data from Data Register 2 and so on. The address pointer

is reset to point to Data Register 1 on the rising edge of

CONVST. A read operation to the AD7874 should not be attempted during conversion. The timing diagram for the

AD7874 conversion sequence is shown in Figure 7.

CONVST

INT

CS

RD

DATA

TIMES t2, t3, t4, t6, t7, AND t8 ARE THE SAME FOR ALL FOUR READ OPERATIONS.

AD7874 DYNAMIC SPECIFICATIONS

The AD7874 is specified and 100% tested for dynamic performance specifications as well as traditional dc specifications such

as Integral and Differential Nonlinearity. These ac specifications

are required for the signal processing applications such as

phased array sonar, adaptive filters and spectrum analysis.

These applications require information on the ADC’s effect on

the spectral content of the input signal. Hence, the parameters

for which the AD7874 is specified include SNR, harmonic distortion, intermodulation distortion and peak harmonics. These

terms are discussed in more detail in the following sections.

Signal-to-Noise Ratio (SNR)

SNR is the measured signal to noise ratio at the output of the

ADC. The signal is the rms magnitude of the fundamental.

Noise is the rms sum of all the nonfundamental signals up to

half the sampling frequency (fs/2) excluding dc. SNR is dependent upon the number of quantization levels used in the digitization process; the more levels, the smaller the quantization

noise. The theoretical signal to noise ratio for a sine wave input

is given by

where N is the number of bits.

Thus for an ideal 12-bit converter, SNR = 74 dB.

The output spectrum from the ADC is evaluated by applying a

sine wave signal of very low distortion to the V

sampled at a 29 kHz sampling rate. A Fast Fourier Transform

(FFT) plot is generated from which the SNR data can be obtained. Figure 8 shows a typical 2048 point FFT plot of the

AD7874BN with an input signal of 10 kHz and a sampling

frequency of 29 kHz. The SNR obtained from this graph is

73.2 dB. It should be noted that the harmonics are taken into

account when calculating the SNR.

input). INT is reset high on the falling edge of

IN1

TRACK/HOLDS GO

INTO HOLD

t

1

t

HIGH-IMPEDANCE

CONV

t

2

t

3

t

6

CH1

DATA

t

5

t

8

HIGH-

t

4

t

7

Z

t

ACQUISITION

CH2

HIGH-

DATA

CH4

HIGH-

CH3

DATA

Z

Z

DATA

HIGH-Z

Figure 7. AD7874 Timing Diagram

SNR = (6.02N + 1.76) dB (1)

input which is

IN

Figure 8. AD7874 FFT Plot

Effective Number of Bits

The formula given in Equation 1 relates the SNR to the number

of bits. Rewriting the formula, as in Equation 2, it is possible to

get a measure of performance expressed in effective number of

bits (N).

SNR −1.76

N =

6.02

(2)

The effective number of bits for a device can be calculated directly from its measured SNR.

Figure 9 shows a typical plot of effective number of bits versus

frequency for an AD7874BN with a sampling frequency of

29 kHz. The effective number of bits typically falls between

11.75 and 11.87 corresponding to SNR figures of 72.5 dB and

73.2 dB.

Figure 9. Effective Numbers of Bits vs. Frequency

–8–

REV. C

AD7874

Total Harmonic Distortion (THD)

Total Harmonic Distortion (THD) is the ratio of the rms sum

of harmonics to the rms value of the fundamental. For the

AD7874, THD is defined as

2

2

2

2

2

+V

5

6

THD = 20log

+V

+V

V

2

3

+V

4

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

V

, V5 and V6 are the rms amplitudes of the second through the

4

sixth harmonic. The THD is also derived from the FFT plot of

the ADC output spectrum.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products at sum and difference frequencies of mfa ± nfb where

m, n = 0, 1, 2, 3 . . ., etc. Intermodulation terms are those for

which neither m or n are equal to zero. For example, the second

order terms include (fa + fb) and (fa – fb) while the third order

terms include (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb).

Using the CCIF standard where two input frequencies near the

top end of the input bandwidth are used, the second and third

order terms are of different significance. The second order terms

are usually distanced in frequency from the original sine waves

while the third order terms are usually at a frequency close to

the input frequencies. As a result, the second and third order

terms are specified separately. The calculation of the intermodulation distortion is as per the THD specification where it is the

ratio of the rms sum of the individual distortion products to the

rms amplitude of the fundamental expressed in dBs. In this case,

the input consists of two, equal amplitude, low distortion sine

waves. Figure 10 shows a typical IMD plot for the AD7874.

Peak Harmonic or Spurious Noise

Harmonic or Spurious Noise is defined as the ratio of the rms

value of the next largest component in the ADC output spectrum (up to fs/2 and excluding dc) to the rms value of the fundamental. Normally, the value of this specification will be

determined by the largest harmonic in the spectrum, but for

parts where the harmonics are buried in the noise floor the peak

will be a noise peak.

AC Linearity Plot

When a sine wave of specified frequency is applied to the VIN input of the AD7874 and several million samples are taken, a histogram showing the frequency of occurrence of each of the 4096

ADC codes can be generated. From this histogram data it is

possible to generate an ac integral linearity plot as shown in Figure 11. This shows very good integral linearity performance

from the AD7874 at an input frequency of 10 kHz. The absence

of large spikes in the plot shows good differential linearity. Simplified versions of the formulae used are outlined below.

INL(i) =

(V(i) −V(o))⋅4096

V( fs)−V(o)

− i

where INL(i) is the integral linearity at code i. V(fs) and V(o) are

the estimated full-scale and offset transitions, and V(i) is the estimated transition for the i

th

code.

V(i), the estimated code transition point is derived as follows:

π⋅cum(i)

V(i)=−A⋅Cos

[]

N

where A is the peak signal amplitude, N is the number of histogram samples

i

and cum(i) =

V(n)occurrences

∑

n=o

REV. C

Figure 11. AD7874 AC INL Plot

Figure 10. AD7874 IMD Plot

–9–

AD7874

A0

A15

D15

D0

IS

EN

ADDR

DECODE

ADDRESS BUS

TIMER

DATA BUS

CONVST

CS

DB11

DB0

RD

INT

AD7874*

TMS320C25

*ADDITIONAL PINS OMITTED FOR CLARITY

INTn

R/W

STRB

MSC

READY

MICROPROCESSOR INTERFACING

The AD7874 high speed bus timing allows direct interfacing to

DSP processors as well as modern 16-bit microprocessors.

Suitable microprocessor interfaces are shown in Figures 12

through 16.

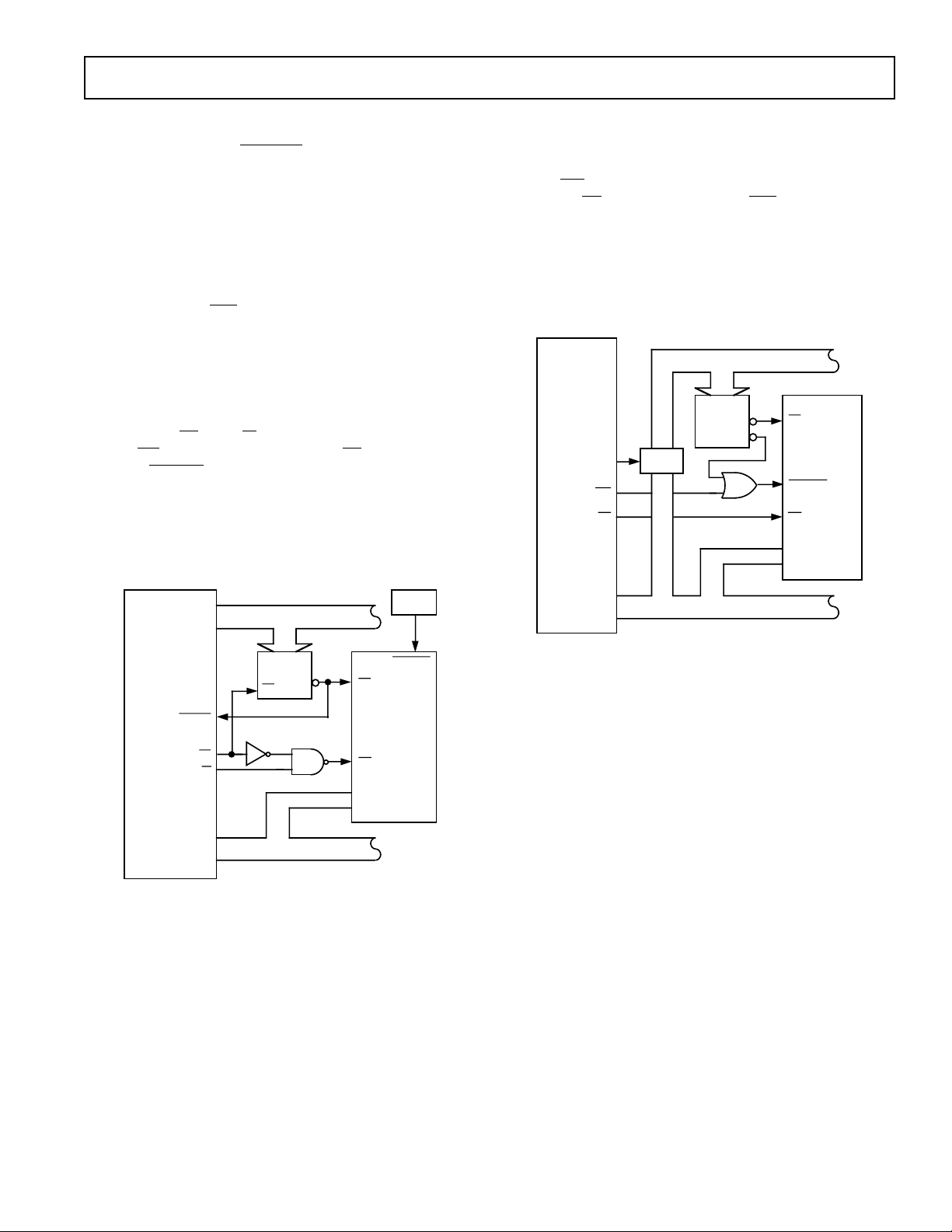

AD7874–ADSP-2100 Interface

Figure 12 shows an interface between the AD7874 and the

ADSP-2100. Conversion is initiated using a timer which allows

very accurate control of the sampling instant on all four channels. The AD7874

INT line provides an interrupt to the ADSP2100 when conversion is completed on all four channels. The

four conversion results can then be read from the AD7874 using

four successive reads to the same memory address. The following instruction reads one of the four results (this instruction is

repeated four times to read all four results in sequence):

MR0 = DM(ADC)

where MR0 is the ADSP-2100 MR0 register and

ADC is the AD7874 address.

DMA13

DMA0

ADSP-2100

(ADSP-2101/

ADSP-2102)

IRQn

DMRD (RD)

DMD15

DMD0

ADDRESS BUS

ADDR

DECODE

DMS

EN

DATA BUS

* ADDITIONAL PINS OMITTED FOR CLARITY

CS

INT

RD

DB11

DB0

TIMER

CONVST

AD7874*

TIMER

PA2

ADDRESS BUS

PA0

TMS32010

ADDR

DECODE

MEN

INT

DEN

D15

EN

DATA BUS

D0

*ADDITIONAL PINS OMITTED FOR CLARITY

CONVST

CS

AD7874*

INT

RD

DB11

DB0

Figure 13. AD7874–TMS32010 Interface

AD7874–TMS320C25 Interface

Figure 14 shows an interface between the AD7874 and the

TMS320C25. As with the two previous interfaces, conversion is

initiated with a timer and the processor is interrupted when the

conversion sequence is completed. The TMS320C25 does not

have a separate

RD output to drive the AD7874 RD input directly. This has to be generated from the processor STRB and

R/

W outputs with the addition of some logic gates. The RD sig-

nal is OR-gated with the MSC signal to provide the one WAIT

state required in the read cycle for correct interface timing.

Conversion results are read from the AD7874 using the following instruction:

IN D,ADC

where D is Data Memory address and

ADC is the AD7874 address.

Figure 12. AD7874–ADSP-2100 Interface

AD7874–ADSP-2101/ADSP-2102 Interface

The interface outlined in Figure 12 also forms the basis for an

interface between the AD7874 and the ADSP-2101/ADSP-2102.

The READ line of the ADSP-2101/ADSP-2102 is labeled

In this interface, the

programmed using the Data Memory Wait State Control Register. The instruction used to read one of the four results is as

outlined for the ADSP-2100.

AD7874–TMS32010 Interface

An interface between the AD7874 and the TMS32010 is shown

in Figure 13. Once again the conversion is initiated using an ex-

RD pulse width of the processor can be

ternal timer and the TMS32010 is interrupted when all four

conversions have been completed. The following instruction is

used to read the conversion results from the AD7874:

where D is Data Memory address and

IN D,ADC

ADC is the AD7874 address.

RD.

–10–

Figure 14. AD7874–TMS320C25 Interface

REV. C

AD7874

ALE

AD15

AD0

ADDR

DECODE

ADDRESS BUS

ADDRESS/DATA BUS

CONVST

CS

DB11

DB0

RD

AD7874*

8086

*ADDITIONAL PINS OMITTED FOR CLARITY

WR

RD

LATCH

Some applications may require that the conversion is initiated

by the microprocessor rather than an external timer. One option

is to decode the AD7874

CONVST from the address bus so

that a write operation starts a conversion. Data is read at the

end of the conversion sequence as before. Figure 16 shows an

example of initiating conversion using this method. Note that

for all interfaces, a read operation should not be attempted during conversion.

AD7874–MC68000 Interface

An interface between the AD7874 and the MC68000 is shown

in Figure 15. As before, conversion is initiated using an external

timer. The AD7874

INT line can be used to interrupt the processor or, alternatively, software delays can ensure that conversion has been completed before a read to the AD7874 is

attempted. Because of the nature of its interrupts, the 68000

requires additional logic (not shown in Figure 15) to allow it to

be interrupted correctly. For further information on 68000 interrupts, consult the 68000 users manual.

The MC68000

separate

the 68000

AS and R/W outputs are used to generate a

RD input signal for the AD7874. CS is used to drive

DTACK input to allow the processor to execute a

normal read operation to the AD7874. The conversion results

are read using the following 68000 instruction:

MOVE.W ADC,D0

where D0 is the 68000 D0 register and

ADC is the AD7874 address.

AD7874–8086 Interface

Figure 16 shows an interface between the AD7874 and the 8086

microprocessor. Unlike the previous interface examples, the

microprocessor initiates conversion. This is achieved by gating

the 8086

the AD7874

WR signal with a decoded address output (different to

CS address). The AD7874 INT line is used to in-

terrupt the microprocessor when the conversion sequence is

completed. Data is read from the AD7874 using the following

instruction:

MOV AX,ADC

where AX is the 8086 accumulator and

ADC is the AD7874 address.

A15

A0

MC68000

DTACK

AS

R/W

D15

D0

ADDRESS BUS

ADDR

DECODE

EN

DATA BUS

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 15. AD7874–MC68000 Interface

CS

AD7874*

RD

DB11

DB0

TIMER

CONVST

Figure 16. AD7874–8086 Interface

REV. C

–11–

AD7874

APPLICATIONS

Vector Motor Control

The current drawn by a motor can be split into two components: one produces torque and the other produces magnetic

flux. For optimal performance of the motor, these two components should be controlled independently. In conventional

methods of controlling a three-phase motor, the current (or

voltage) supplied to the motor and the frequency of the drive are

the basic control variables. However, both the torque and flux

are functions of current (or voltage) and frequency. This coupling effect can reduce the performance of the motor because,

for example, if the torque is increased by increasing the frequency, the flux tends to decrease.

Vector control of an ac motor involves controlling phase in addition to drive and current frequency. Controlling the phase of the

motor requires feedback information on the position of the rotor

relative to the rotating magnetic field in the motor. Using this

information, a vector controller mathematically transforms the

three phase drive currents into separate torque and flux components. The AD7874, with its four-channel simultaneous sampling capability, is ideally suited for use in vector motor control

applications.

DSP

MICROPROCESSOR

TORQUE & FLUX

CONTROL LOOP

CALCULATIONS &

TWO TO THREE

PHASE

INFORMATION

DAC

DAC

DAC

A block diagram of a vector motor control application using the

AD7874 is shown in Figure 17. The position of the field is derived by determining the current in each phase of the motor.

Only two phase currents need to be measured because the third

can be calculated if two phases are known. Channel 1 and

Channel 2 of the AD7874 are used to digitize this information.

Simultaneous sampling is critical to maintain the relative phase

information between the two channels. A current sensing isolation amplifier, transformer or Hall effect sensor is used between

the motor and the AD7874. Rotor information is obtained by

measuring the voltage from two of the inputs to the motor.

Channel 3 and Channel 4 of the AD7874 are used to obtain this

information. Once again the relative phase of the two channels

is important. A DSP microprocessor is used to perform the

mathematical transformations and control loop calculations on

the information fed back by the AD7874.

I

C

DRIVE

CIRCUITRY

I

B

I

A

V

3

B

PHASE

MOTOR

V

A

TORQUE

SETPOINT

FLUX

SETPOINT

TRANSFORMATION

TO TORQUE &

FLUX CURRENT

COMPONENTS

*ADDITIONAL PINS OMITTED FOR CLARITY

AD7874*

V

IN1

V

IN2

V

IN3

V

IN4

ISOLATION

AMPLIFIERS

ATTENUATORS

Figure 17. Vector Motor Control Using the AD7874

VOLTAGE

–12–

REV. C

AD7874

MULTIPLE AD7874s

Figure 18 shows a system where a number of AD7874s can be

configured to handle multiple input channels. This type of configuration is common in applications such as sonar, radar, etc.

The AD7874 is specified with maximum and minimum limits on

aperture delay. This means that the user knows the maximum

difference in the sampling instant between all channels. This allows the user to maintain relative phase information between the

different channels.

A common read signal from the microprocessor drives the

RD

input of all AD7874s. Each AD7874 is designated a unique address selected by the address decoder. The reference output of

AD7874 number 1 is used to drive the reference input of all

other AD7874s in the circuit shown in Figure 18. One REF

OUT pin can drive several AD7874 REF IN pins. Alternatively,

an external or system reference can be used to drive all REF IN

inputs. A common reference ensures good full-scale tracking between all channels.

V

CH1

V

V

V

V

CH2

V

CH3

V

CH4

V

CH5

V

CH6

V

CH7

V

CH8

V

CHm

CHm+1

CHm+2

CHm+3

RD

AD7874(1)

CS

REF OUT

RD

AD7874(2)

CS

REF IN

REF IN

RD

AD7874(n)

CS

ADDRESS

DECODE

RD

ADDRESS

the input signal connects to the buffer amplifier driving the analog input of the ADC. If the shorting plug is omitted, a wire link

can be used to connect the input signal to the PCB component

grid.

Microprocessor connections to the board are made via a 26contact IDC connector, SKT8, the pinout for which is shown in

Figure 19. This connector contains all data, control and status

signals of the AD7874 (with the exception of the CLK input

and the

SKT7, respectively). It also contains decoded R/

CONVST input which are provided via SKT5 and

W and STRB

inputs which are necessary for TMS32020 interfacing (and also

for 68000 interfacing although pin labels on the 68000 are different). Note that the AD7874

CS input must be decoded prior

to the AD7874 evaluation board.

SKT1, SKT2, SKT3 and SKT4 provide the inputs for V

V

, V

, V

IN2

IN3

respectively. Assuming LK1 to LK4 are in

IN4

IN1

,

place, these input signals are fed to four buffer amplifiers, IC1,

before being applied to the AD7874. The use of an external

clock source is optional; there is a shorting plug (LK5) on the

AD7874 CLK input which must be connected to either –5 V

(for the ADCs own internal clock) or to SKT5. SKT6 and

SKT7 provide the reference and

CONVST inputs respectively.

Shorting plug LK6 provides the option of using the external reference or the ADCs own internal reference.

1

2

R/W

N/C

N/C

DB10

DB8

DB6

DB4

DB2

DB0

+

GND

RD

CS

3

5

7

9

11

13

15

17

19

21

23

5V

25

STRB

4

N/C

6

N/C

8

INT

10

N/C

12

DB11

14

DB9

16

DB7

18

DB5

20

DB3

22

DB1

24

+

5V

26

GND

Figure 18. Multiple AD7874s in Multichannel System

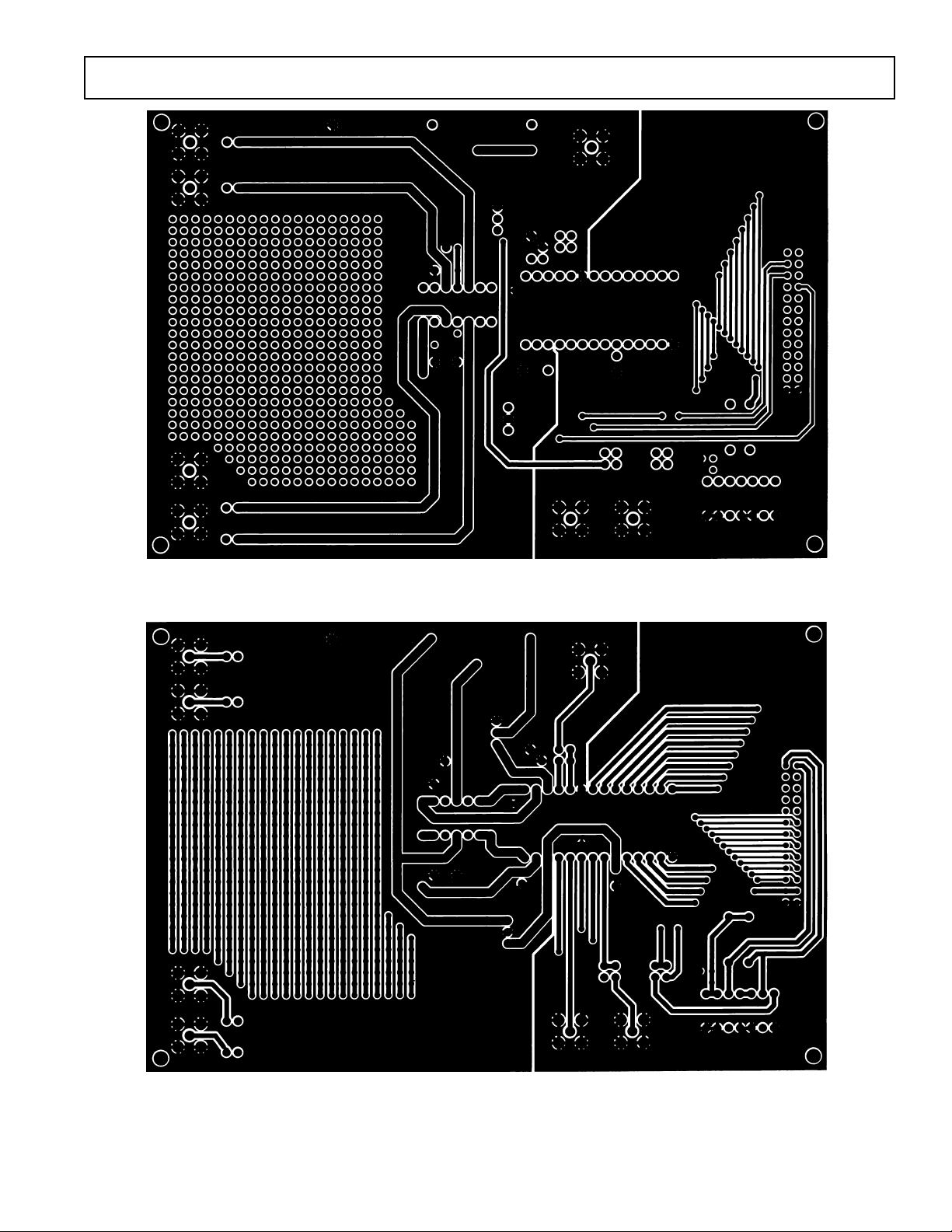

DATA ACQUISITION BOARD

Figure 20 shows the AD7874 in a data acquisition circuit. The

corresponding printed circuit board (PCB) layout and silkscreen

are shown in Figures 21 to 23. A 26-contact IDC connector provides for a microprocessor connection to the board.

A component grid is provided near the analog inputs on the

PCB which may be used to provide antialiasing filters for the

analog input channels or to provide signal conditioning circuitry.

To facilitate this option, four shorting plugs (labeled LK1 to

LK4 on the PCB) are provided on the analog inputs, one plug

per input. If the shorting plug for a particular channel is used,

REV. C

–13–

Figure 19. SKT8, IDC Connector Pinout

POWER SUPPLY CONNECTIONS

The PCB requires two analog power supplies and one 5 V digital supply. The analog supplies are labeled V+ and V– and the

range for both supplies is 12 V to 15 V (see silkscreen in Figure

23). Connection to the 5 V digital supply is made via SKT8.

The +5 V supply and the –5 V supply required by the AD7874

are generated from voltage regulators (IC3 and IC4) on the V+

and V– supplies.

AD7874

SKT1

SKT2

SKT3

SKT4

C4

C2

78L05

V

DD

IN

IC3

IC1

AD713

79L05

IC4

C7

V

IN1

V

IN2

V

IN3

V

IN4

AGND

DGND

OUT

C5

C8

V

DD

CONVST

DB11

DB0

INT

IC2

AD7874

REF IN

REF

OUT

V

CLK

SS

C6

CONVST

SKT6

CS

RD

LK5

AB

CLK

SKT5

DATA BUS

A

IC5

B

A

B

REFERENCE

SKT6

IC5

+

5V

R1R2

DGND

SKT8

11

22

8

5

23, 24

2

1

3

25, 26

+

V

C3

LK1

LK2

LK3

LK4

V

SS

C1

V–

Figure 20. Data Acquisition Circuit Using the AD7874

Figure 21. PCB Silkscreen for Figure 20

–14–

REV. C

AD7874

Figure 22. PCB Component Side Layout for the Circuit of Figure 20

REV. C

Figure 23. PCB Solder Side Layout for the Circuit of Figure 20

–15–

AD7874

SHORTING PLUG OPTIONS

There are seven shorting plug options which must be set before

using the board. These are outlined below:

LK1–LK4 Connects the analog inputs to the buffer amplifi-

ers. The analog inputs may also be connected to a

component grid for signal conditioning.

LK5 Selects either the AD7874 internal clock or an ex-

ternal clock source.

LK6 Selects either the AD7874 internal reference or an

external reference source.

LK7 Connects the AD7874

RD input directly to the

RD input of SKT8 or to a decoded STRB and

R/

W input. This shorting plug setting depends on

the microprocessor, e.g., the TMS32020 and

68000 require a decoded

RD signal.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Plastic (N-28)

COMPONENT LIST

IC1 AD713 Quad Op Amp

IC2 AD7874 Analog-to-Digital Converter

IC3 MC78L05 +5 V Regulator

IC4 MC79L05 –5 V Regulator

IC5 74HC00 Quad NAND Gate

C1, C3, C5, C7, C9 10 µF Capacitors

C2, C4, C6, C8, C10 0.1 µF Capacitors

R1, R2 10 kΩ Pull-Up Resistors

LK1, LK2, LK3 Shorting Plugs

LK4, LK5, LK6

LK7

SKT1, SKT2, SKT3, BNC Sockets

SKT4, SKT5, SKT6,

SKT7

SKT8 26-Contact (2-Row) IDC Connector

SOIC (R-28)

C1388a–5–5/91

Cerdip (Q-28)

–16–

0.100 (2.54)

0.064 (1.63)

1

0.050 ± 0.005

(1.27 ± 0.13)

0.040 x 45°

(1.02 x 45°)

REF 3 PLCS

0.055 (1.40)

0.045 (1.14)

LCCC (E-28A)

0.075

(1.91)

REF

0.028 (0.71)

0.022 (0.56)

28

NO. 1 PIN INDEX

BOTTOM VIEW

0.020 x 45°

0.458 (11.63)

NOTES

1. THIS DIMENSION CONTROLS THE OVERALL PACKAGE

THICKNESS.

2. APPLIES TO ALL FOUR SIDES.

3. ALL TERMINALS ARE GOLD PLATED.

0.442 (11.23)

2

(0.51 x 45°) REF

PRINTED IN U.S.A.

REV. C

Loading...

Loading...