Voltage Output Temperature Sensor

a

FEATURES

200°C Temperature Span

Accuracy Better than 62% of Full Scale

Linearity Better than 61% of Full Scale

Temperature Coefficient of 22.5 mV/8C

Output Proportional to Temperature 3 V+

Single Supply Operation

Reverse Voltage Protection

Minimal Self Heating

High Level, Low Impedance Output

APPLICATIONS

HVAC Systems

System Temperature Compensation

Board Level Temperature Sensing

Electronic Thermostats

MARKETS

Industrial Process Control

Instrumentation

Automotive

with Signal Conditioning

AD22100*

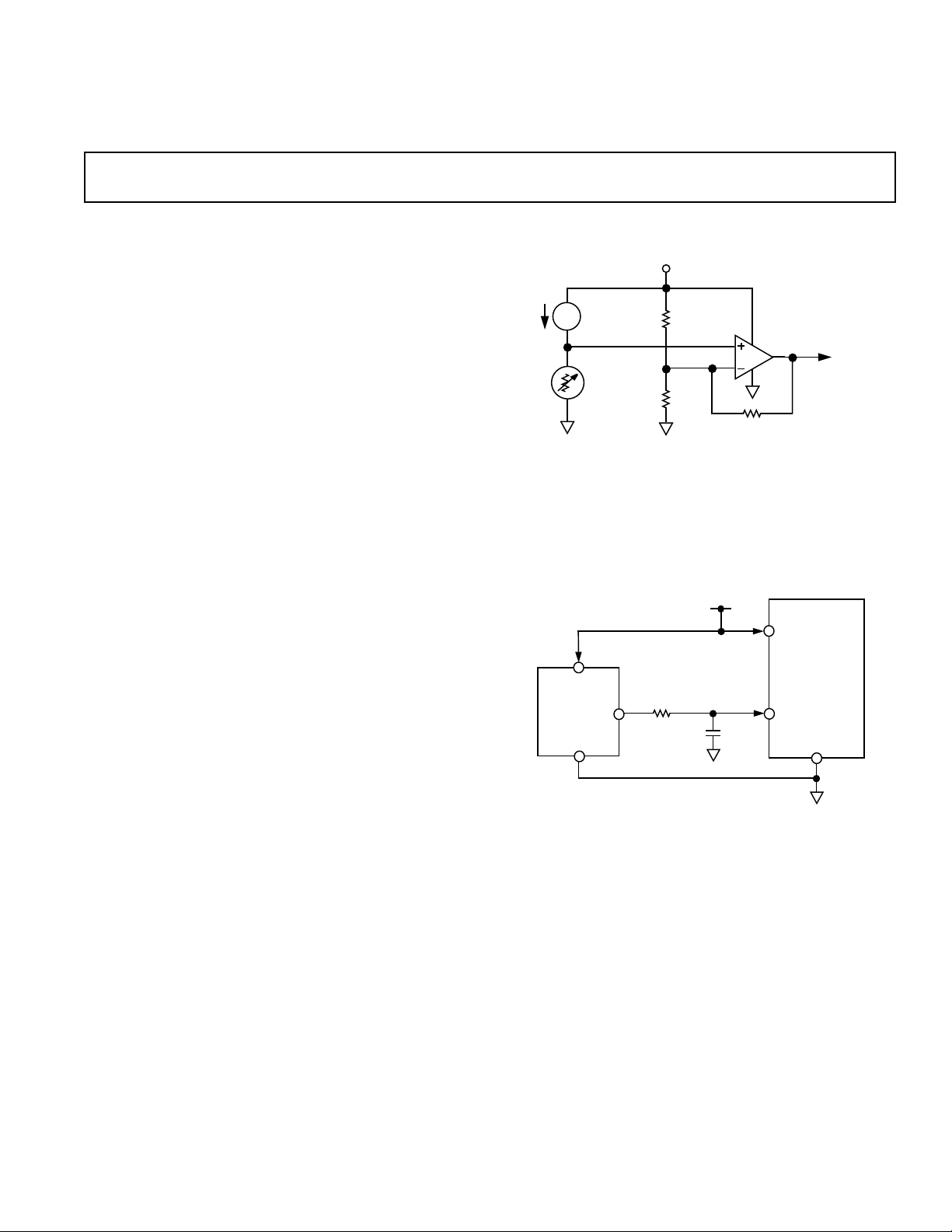

SIMPLIFIED BLOCK DIAGRAM

V+

Ι

R

T

V

OUT

GENERAL DESCRIPTION

The AD22100 is a monolithic temperature sensor with on-chip

signal conditioning. It can be operated over the temperature

range –50°C to +150°C, making it ideal for use in numerous

HVAC, instrumentation and automotive applications.

The signal conditioning eliminates the need for any trimming,

buffering or linearization circuitry, greatly simplifying the system

design and reducing the overall system cost.

The output voltage is proportional to the temperature times the

supply voltage (ratiometric). The output swings from 0.25V at

–50°C to +4.75 V at +150°C using a single +5.0V supply.

Due to its ratiometric nature, the AD22100 offers a cost effective solution when interfacing to an analog-to-digital converter.

This is accomplished by using the ADC’s +5V power supply as

a reference to both the ADC and the AD22100 (See Figure 1),

eliminating the need for and cost of a precision reference.

*

Protected by U.S. Patent Nos. 5030849 and 5243319

.

AD22100

–50°C TO +150°C

+5V

REFERENCE

SIGNAL OUTPUT

DIRECT TO ADC

V

O

1kΩ

Figure 1. Application Circuit

0.1µF

INPUT

ANALOG TO

DIGITAL

CONVERTER

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1994

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

AD22100

AD22100–SPECIFICATIONS

(TA = +25°C and V+ = +4 V to +6 V unless otherwise noted)

AD22100K AD22100A AD22100S

Parameter Min Typ Max Min Typ Max Min Typ Max Units

TRANSFER FUNCTION V

= (V+/5 V) × [1.375 V + (22.5 mV/°C) × TA]V

OUT

TEMPERATURE COEFFICIENT (V+/5 V) × 22.5 mV/°C

TOTAL ERROR

Initial Error

T

= +25°C ±0.5 ±2.0 ±1.0 ±2.0 ±1.0 ±2.0 °C

A

Error over Temperature

T

A = TMIN

T

A = TMAX

±0.75 ±2.0 ±2.0 ±3.7 ±3.0 ±4.0 °C

±0.75 ±2.0 ±2.0 ±3.0 ±3.0 ±4.0 °C

Nonlinearity

TA = T

MIN to TMAX

0.5 0.5 1.0 % FS

OUTPUT CHARACTERISTICS

Nominal Output Voltage

V+ = 5.0 V, T

V+ = 5.0 V, T

V+ = 5.0 V, T

V+ = 5.0 V, T

V+ = 5.0 V, T

= 0°C 1.375 V

A

= +100°C 3.625 V

A

= –40°C 0.475 V

A

= +85°C 3.288 V

A

= –50°C 0.250 V

A

V+ = 5.0 V, TA = +150°C 4.750 V

POWER SUPPLY

Operating Voltage +4.0 +5.0 +6.0 +4.0 +5.0 +6.0 +4.0 +5.0 +6.0 V

Quiescent Current 500 650 500 650 500 650 µA

TEMPERATURE RANGE

Guaranteed Temperature Range 0 +100 –40 +85 –50 +150 °C

Operating Temperature Range –50 +150 –50 +150 –50 +150 °C

1

PACKAGE TO-92 TO-92 TO-92

SOIC SOIC SOIC

Specifications subject to change without notice.

CHIP SPECIFICATIONS

(TA = +25°C and V+ = +5.0 V unless otherwise noted)

Parameter Min Typ Max Units

TRANSFER FUNCTION V

= (V+/5 V) × [1.375 + 22.5 mV/°C × TA]V

OUT

TEMPERATURE COEFFICIENT (V+/5V) × 22.5 mV/°C

OUTPUT CHARACTERISTICS

Error

T

= +25°C ±0.5 ±2.0 °C

A

Nominal Output Voltage

TA = +25°C 1.938 V

POWER SUPPLY

Operating Voltage +4.0 +5.0 +6.0 V

Quiescent Current 500 650 µA

TEMPERATURE RANGE

Guaranteed Temperature Range 25 °C

Operating Temperature Range –50 +150 °C

NOTES

1

FS (Full Scale) is defined as that of the operating temperature range, –50°C to +150°C. The listed max specification limit applies to the guaranteed temperature

range. For example, the AD22100K has a nonlinearity of (0.5%) × (200°C) = 1 °C over the guaranteed temperature range of 0°C to +100°C.

Specifications subject to change without notice.

–2–

–2–

REV. B

REV. B

AD22100

WARNING!

ESD SENSITIVE DEVICE

50

12000

100

150

200

800400

FLOW RATE – CFM

θ

JA

– °C/W

(SOIC)

250

(T0-92)

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +10 V

Reversed Continuous Supply Voltage . . . . . . . . . . . . . . –10 V

Operating Temperature . . . . . . . . . . . . . . . . –50°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +160°C

Output Short Circuit to V+ or Ground . . . . . . . . . . Indefinite

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . +300°C

1

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only; the functional

operation of the device at these or any other conditions above those indicated in the

operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

ORDERING GUIDE

Guaranteed

Temperature Package Package

Model/Grade Range Description* Option

AD22100 KT 0°C to 100°C TO-92 TO-92

AD22100 KR 0°C to 100°C SOIC SO-8

AD22100 AT –40°C to +85°C TO-92 TO-92

AD22100 AR –40°C to +85°C SOIC SO-8

AD22100 ST –50°C to +150°C TO-92 TO-92

AD22100 SR –50°C to +150°C SOIC SO-8

AD22100KChips +25°C N/A N/A

*Minimum purchase quantities of 100 pieces for all chip orders.

PIN DESCRIPTION

Mnemonic Function

V+ Power Supply Input

V

O

Device Output

GND Ground Pin must be connected to 0 V.

NC No Connect

PIN CONFIGURATIONS

TO-92

BOTTOM VIEW

(Not to Scale)

PIN 2 PIN 1

PIN 3

GND V

V+

O

SOIC

1

V+

V

2

O

3

NC

(Not to Scale)

GND

4

NC = NO CONNECT

AD22100

TOP VIEW

8

NC

7

NC

6

NC

5

NC

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD22100 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

Typical Performance Curves

16

14

12

T (T0-92)

8

6

T (SOIC)

4

2

0

FLOW RATE – CFM

800400

Figure 2. Thermal Response vs. Flow Rate

1200

Figure 3. Thermal Resistance vs. Flow Rate

10

– Sec

τ

REV. B

–3–

AD22100

THEORY OF OPERATION

The AD22100 is a ratiometric temperature sensor IC whose

output voltage is proportional to power supply voltage. The

heart of the sensor is a proprietary temperature-dependent resistor, similar to an RTD, which is built into the IC. Figure 4

shows a simplified block diagram of the AD22100.

V+

Ι

V

OUT

R

T

Figure 4. Simplified Block Diagram

The temperature-dependent resistor, labeled RT, exhibits a

change in resistance that is nearly linearly proportional to temperature. This resistor is excited with a current source that is

proportional to power supply voltage. The resulting voltage

across R

is therefore both supply voltage proportional and lin-

T

early varying with temperature. The remainder of the AD22100

consists of an op amp signal conditioning block that takes the

voltage across R

and applies the proper gain and offset to

T

achieve the following output voltage function:

V

= (V+/5 V) × [1.375 V + (22.5 mV/°C) × TA]

OUT

ABSOLUTE ACCURACY AND NONLINEARITY SPECIFICATIONS

Figure 5 graphically depicts the guaranteed limits of accuracy

for the AD22100 and shows the performance of a typical part.

As the output is very linear, the major sources of error are offset,

i.e., error at room temperature, and span error, i.e., deviation

from the theoretical 22.5 mV/°C. Demanding applications can

achieve improved performance by calibrating these offset and

gain errors so that only the residual nonlinearity remains as a

significant source of error.

OUTPUT STAGE CONSIDERATIONS

As previously stated, the AD22100 is a voltage output device. A

basic understanding of the nature of its output stage is useful for

proper application. Note that at the nominal supply voltage of

5.0 V, the output voltage extends from 0.25V at –50°C to

+4.75 V at +150°C. Furthermore, the AD22100 output pin is

capable of withstanding an indefinite short circuit to either

ground or the power supply. These characteristics are provided

by the output stage structure shown in Figure 6.

V+

V

OUT

Ι

Figure 6. Output Stage Structure

The active portion of the output stage is a PNP transistor with

its emitter connected to the V+ supply and collector connected

to the output node. This PNP transistor sources the required

amount of output current. A limited pull-down capability is

provided by a fixed current sink of about –80 µA. (Here,

“fixed” means the current sink is fairly insensitive to either supply voltage or output loading conditions. The current sink capability is a function of temperature, increasing its pull-down

capability at lower temperatures.)

Due to its limited current sinking ability, the AD22100 is incapable of driving loads to the V+ power supply and is instead intended to drive grounded loads. A typical value for short circuit

current limit is 7 mA, so devices can reliably source 1mA or

2 mA. However, for best output voltage accuracy and minimal

internal self-heating, output current should be kept below 1mA.

Loads connected to the V+ power supply should be avoided as

the current sinking capability of the AD22100 is fairly limited.

These considerations are typically not a problem when driving

a microcontroller analog to digital converter input pin (see

MICROPROCESSOR A/D INTERFACE ISSUES).

4

3

2

1

0

ERROR – °C

–1

–2

–3

–4

–50

TYPICAL ERROR

TEMPERATURE – °C

MAXIMUM ERROR

OVER TEMPERATURE

MAXIMUM ERROR

OVER TEMPERATURE

100500

Figure 5. Typical AD22100 Performance

150

RATIOMETRICITY CONSIDERATIONS

The AD22100 will operate with slightly better accuracy than

that listed in the data sheet specifications if the power supply is

held constant. This is because the AD22100’s output voltage

varies with both temperature and supply voltage, with some

errors. The ideal transfer function describing the output

voltage is:

(V+/5 V) × [1.375 V + (22.5 mV/°C) × T

]

A

The ratiometricity error is defined as the percent change away

from the ideal transfer function as the power supply voltage

changes within the operating range of +4V to +6V. For the

AD22100 this error is typically less than 1%. A movement from

the ideal transfer function by 1% at +25°C, with a supply voltage varying from 5.0 V to 5.50 V, results in a 1.94mV change in

output voltage or 0.08°C error. This error term is greater at

higher temperatures because the output (and error term) is directly proportional to temperature. At 150°C, the error in output voltage is 4.75 mV or 0.19°C.

–4–

REV. B

AD22100

100

0

100

30

10

10

20

0

60

40

50

70

80

90

9080706050403020

STILL AIR

TIME – sec

% OF FINAL VALUES

ALUMINUM

BLOCK

MOVING

AIR

For example, with VS = 5.0 V, and TA = +25°C, the nominal

output of the AD22100 will be 1.9375 V. At V

nominal output will be 2.1313 V, an increase of 193.75mV.

A proportionality error of 1% is applied to the 193.75mV,

yielding an error term of 1.9375 mV. This error term translates

to a variation in output voltage of 2.1293 V to 2.3332V. A

1.94 mV error at the output is equivalent to about 0.08°C error

in accuracy.

If we substitute 150°C for 25°C in the above example, then the

error term translates to a variation in output voltage of 5.2203V

to 5.2298 V. A 4.75 mV error at the output is equivalent to

about 0.19°C error in accuracy.

MOUNTING CONSIDERATIONS

If the AD22100 is thermally attached and properly protected, it

can be used in any measuring situation where the maximum

range of temperatures encountered is between –50°C and

+150°C. Because plastic IC packaging technology is employed,

excessive mechanical stress must be avoided when fastening the

device with a clamp or screw-on heat tab. Thermally conductive epoxy or glue is recommended for typical mounting conditions. In wet or corrosive environments, an electrically isolated

metal or ceramic well should be used to shield the AD22100.

Because the part has a voltage output (as opposed to current), it

offers modest immunity to leakage errors, such as those caused

by condensation at low temperatures.

THERMAL ENVIRONMENT EFFECTS

The thermal environment in which the AD22100 is used determines two performance traits: the effect of self-heating on accuracy and the response time of the sensor to rapid changes in

temperature. In the first case, a rise in the IC junction temperature above the ambient temperature is a function of two variables; the power consumption of the AD22100 and the thermal

resistance between the chip and the ambient environment θ

Self-heating error in °C can be derived by multiplying the power

dissipation by θ

for surroundings with different heat sinking capacities, it is necessary to specify θ

how the magnitude of self-heating error varies relative to the environment. A typical part will dissipate about 2.2mW at room

temperature with a 5 V supply and negligible output loading. In

still air, without a “heat sink,” the table below indicates a θ

190°C/W, yielding a temperature rise of 0.4°C. Thermal rise

will be considerably less in either moving air or with direct

physical connection to a solid (or liquid) body.

Medium θJA (°C/Watt) τ (sec) *

Aluminum Block 60 2

Moving Air**

Without Heat Sink 75 3.5

Still Air

Without Heat Sink 190 15

*The time constant τ is defined as the time to reach 63.2% of the final

**1200 CFM.

REV. B

Because errors of this type can vary widely

JA.

JA

Table I. Thermal Resistance (TO-92)

temperature change.

= 5.50 V, the

S

.

JA

under several conditions. Table I shows

of

JA

Response of the AD22100 output to abrupt changes in ambient

temperature can be modeled by a single time constant

τ

exponential function. Figure 7 shows typical response time plots for

a few media of interest.

Figure 7. Response Time

The time constant τ is dependent on θJA and the thermal

capacities of the chip and the package. Table I lists the effective

τ

(time to reach 63.2% of the final value) for a few different

media. Copper printed circuit board connections were

neglected in the analysis; however, they will sink or conduct

heat directly through the AD22100’s solder plated copper leads.

When faster response is required, a thermally conductive grease

or glue between the AD22100 and the surface temperature

being measured should be used.

MICROPROCESSOR A/D INTERFACE ISSUES

The AD22100 is especially well suited to providing a low cost

temperature measurement capability for microprocessor/

microcontroller based systems. Many inexpensive 8-bit microprocessors now offer an onboard 8-bit ADC capability at a modest cost premium. Total “cost of ownership” then becomes a

function of the voltage reference and analog signal conditioning

necessary to mate the analog sensor with the microprocessor

ADC. The AD22100 can provide an ideal low cost system by

eliminating the need for a precision voltage reference and any

additional active components. The ratiometric nature of the

AD22100 allows the microprocessor to use the same power supply as its ADC reference. Variations of hundreds of millivolts in

the supply voltage have little effect as both the AD22100 and

the ADC use the supply as their reference. The nominal

AD22100 signal range of 0.25 V to 4.75 V (–50°C to +150°C)

makes good use of the input range of a 0V to 5 V ADC. A

single resistor and capacitor are recommended to provide immunity to the high speed charge dump glitches seen at many

microprocessor ADC inputs (see Figure 1).

An 8-bit ADC with a reference of 5 V will have a least significant bit (LSB) size of 5 V/256 = 19.5 mV. This corresponds to

a nominal resolution of about 0.87°C.

–5–

AD22100

4

5

8

1

0.2440 (6.20)

0.2284 (5.80)

0.1574 (4.00)

0.1497 (3.80)

0.1968 (5.00)

0.1890 (4.80)

0.0500 (1.27)

0.0160 (0.41)

0°-8°

× 45°

0.0196 (0.50)

0.0099 (0.25)

0.0098 (0.25)

0.0075 (0.19)

SEATING

PLANE

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0040 (0.10)

USE WITH A PRECISION REFERENCE AS THE SUPPLY VOLTAGE

While the ratiometric nature of the AD22100 allows for system

operation without a precision voltage reference, it can still be

used in such systems. Overall system requirements involving

other sensors or signal inputs may dictate the need for a fixed

precision ADC reference. The AD22100 can be converted to

absolute voltage operation by using a precision reference as the

supply voltage. For example, a 5.00 V reference can be used to

power the AD22100 directly. Supply current will typically be

500 µA which is usually within the output capability of the refer-

ence. A large number of AD22100s may require an additional

op amp buffer, as would scaling down a 10.00V reference that

might be found in “instrumentation” ADCs typically operating

from ±15 V supplies.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

TO-92

0.135

(3.43)

MIN

SEATING PLANE

0.500

(12.70)

MIN

0.105 (2.66)

0.095 (2.42)

0.105 (2.66)

0.080 (2.42)

0.205 (5.20)

0.175 (4.96)

0.210 (5.33)

0.170 (4.58)

0.019 (0.482)

0.016 (0.407)

0.055 (1.39)

0.045 (1.15)

0.050

(1.27)

MAX

SQUARE

C1898b–9–12/94

0.105 (2.66)

0.080 (2.42)

0.165 (4.19)

0.125 (3.94)

SO-8 (SOIC)

PRINTED IN U.S.A.

–6–

REV. B

Loading...

Loading...