Page 1

Quick Start Guide

NI-4000 NetLinx Integrated Controller

For more detailed installation, configuration, programming, file transfer, and

operating instructions, refer to the NetLinx Integrated Controllers (NI-2000,

NI-3000, NI-4000) Instruction Manual, available online at www.amx.com.

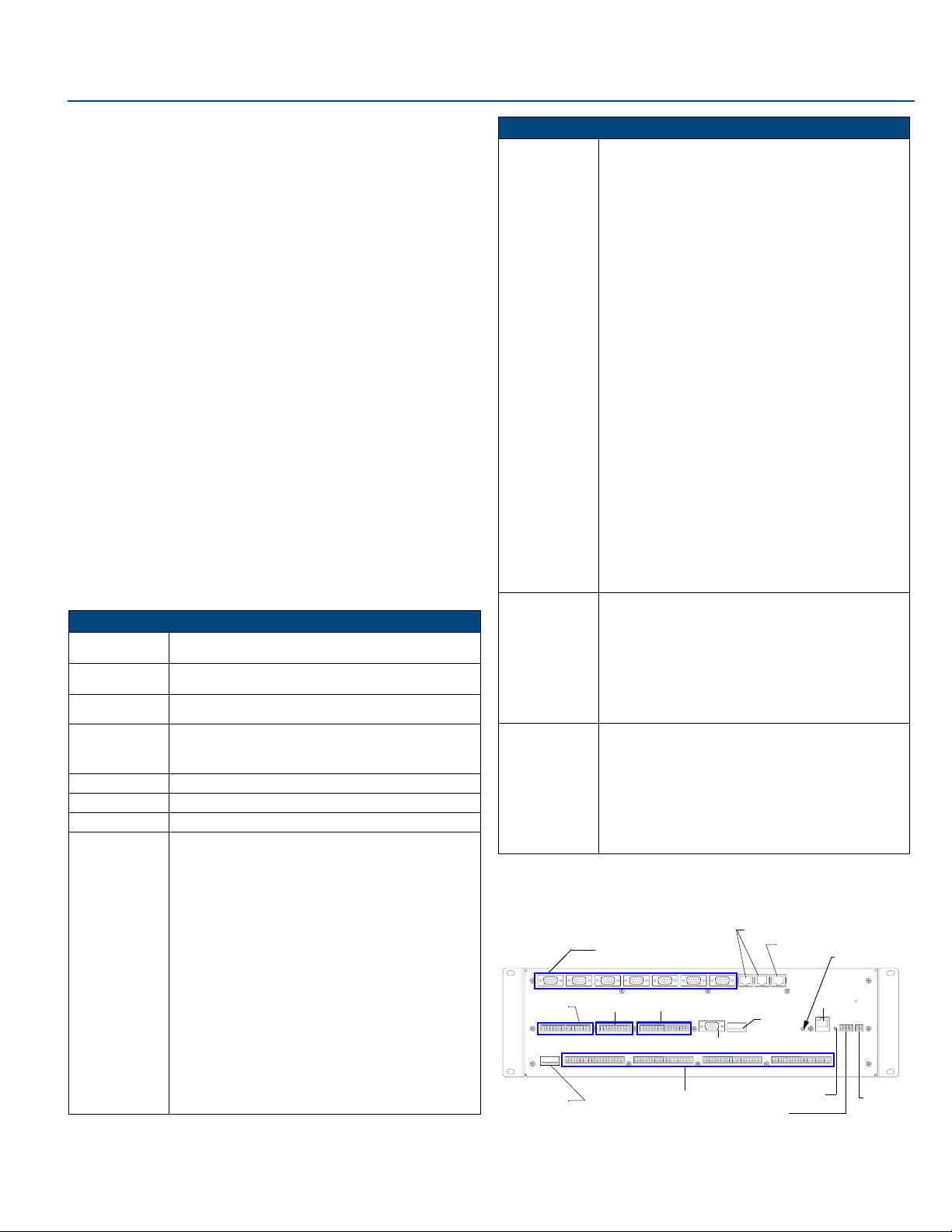

NI-4000 NetLinx Integrated Controller (front view)

FIG. 1

Overview

The NI-4000 unit (FG2105) is geared toward those advanced control and

automation requirements associated with most complex commercial and

residential installations. The NI-4000 provides support for up to 4 NetLinx

control cards (such as NXC-COM2, NXC-IRS4, etc.),

7 RS-232/RS-422/RS-485 Ports, 8 IR/Serial Output ports,

8 Digital Input/Output ports, and 8 Relays. The NI-4000’s on-board Master

also provides the ability to update installed control card firmware.

ATTENTION!

To utilize the latest security firmware features, verify you are using the latest

NI firmware for the on-board Master. Verify you are using the latest version of

NetLinx Studio (available for download from www.amx.com). After the

installation of build 130 (or higher) to the on-board Master, Telnet security

configuration access becomes disabled.

Specifications

NI-4000 Specifications

Dimensions

(HWD):

Power

Requirement:

Memory: • 32 MB SDRAM

Compact Flash: • 32 MB Card (upgradeable) (refer to the Other AMX Equipment

Weight: • 9.15 lbs (4.15 kg)

Enclosure: • Metal with black matte finish

Certifications: • FCC Part 15 Class B and CE

Front Panel

Components:

• 5.21" x 17.00" x 9.60" (13.23 cm x 43.18 cm x 24.27 cm)

• 3 rack units high

• 900 mA @ 12 VDC

• 1 MB Non-volatile Flash

section)

• Refer to the NetLinx Integrated Controllers (NI-2000, NI-3000,

and NI-4000 Series) Instruction Manual for more information.

• LINK/ACT: Green LED blinks when the Ethernet cables are

connected and terminated correctly. Also blinks when receiving

Ethernet data packets.

• Status: Green LED blinks to indicate that the system is

programmed and communicating properly.

• Output: Red LED blinks when the Controller transmits data, sets

channels On and Off, sends data strings, etc.

• Input: Yellow LED blinks when the Controller receives data from

button pushes, strings, commands, channel levels, etc.

• RS-232/422/485 LEDs: Seven sets of red and yellow LEDs light to

indicate the rear DB9 Ports 1-7 are transmitting or receiving

RS-232, 422, or 485 data

• Relay LEDs: Eight red LEDs light to indicate the rear relay

channels 1 - 8 are active (closed). These LEDs reflect the state of

the relay on Port 8.

• IR/Serial LEDs: Eight red LEDs light to indicate the rear IR/Serial

channels 1 - 8 are transmitting control data on Ports 9 - 16. LED

indictor for each IR port remains lit for the length of time that

IR/Serial data is being generated.

• I/O LEDs: Eight yellow LEDs light when the rear I/O channels 1 - 8

are active. LED indicator for each I/O port reflects the state of that

particular port.

• NetLinx Control Card Slot 1- 4: Accepts up to 4 compatible

NetLinx Cards: such as the NXC-COM2, NXC-I/O10, etc.

• Rack-mount brackets: Provides an installation option for the

Integrated Controller to be mounted into an equipment rack,

when used with the Installation Kit (KA2105-01).

NI-4000 Specifications (Cont.)

Rear Panel

Connectors:

Included

Accessories:

Other AMX

Equipment:

• RS-232/422/485 (Ports 1 - 7): Seven RS-232/422/485 control

ports using DB9 (male) connectors with XON/XOFF (transmit

on/transmit off), CTS/RTS (clear to send/ready to send), and

300-115,200 baud.

• ICSNet: Two RJ-45 connectors for ICSNet interface.

• ICSHub Out: RJ-45 connector provides data to a Hub connected

to the Controller.

•Relay (Port 8 ): 8-channel single-pole single throw relay ports with

each relay being independently controlled and supporting up to

8 independent external relay devices.

• Digital I/O (Port 17): 8-channel binary I/O port for contact closure

with each input being capable of voltage sensing. Input format is

software selectable with interactive power sensing for IR ports.

•IR/Serial (Ports 9 - 16): Eight IR/Serial control ports support

high-frequency carriers of up to 1.142 MHz with each output

being capable of two electrical formats: IR or Serial. Eight IR/

Serial data signals can be generated simultaneously. IR ports

support data mode (at limited baud rates and wiring distances).

• Program Port: RS-232 DB9 connector (male) can be connected to

a DB9 port on a PC. This connector can be used with serial and

NetLinx programming commands, as well as other DB9 capable

devices, to both upload/download information from the NetLinx

Studio program.

• Configuration DIP Switch: Sets the communication parameters for

the Program port.

• ID Pushbutton: Sets the NetLinx ID (Device only) assignment for

the device.

• Ethernet Port: LEDs show communication activity, connection

status, speeds, and mode information:

SPD (speed) - Yellow LED lights On when the connection speed

is 100 Mbps and turns Off when the speed is 10 Mbps.

L/A (link/activity) - Green LED lights On when the Ethernet cables

are connected and terminated correctly, and blinks when

receiving Ethernet data packets.

• AXlink LED: Green LED indicates the state of the AXlink port.

• AXlink Port: 4-pin 3.5 mm mini-Phoenix (male) connector that

provides data and power to external control devices.

• Power Port: 2-pin 3.5 mm mini-Phoenix (male) connector.

• CardFrame Number DIP Switch: Sets the starting address for the

Control Cards in the CardFrame. (Factory default CardFrame

DIP switch value = 0). The Control Card address range is 1-3064.

• Control Card Connectors (1 - 4): 20-pin (male) connectors that

connect the Control Cards and external equipment to the

CardFrame.

• 2-pin 3.5 mm mini-Phoenix (female) PWR connector (41-5025)

• 4-pin 3.5 mm mini-Phoenix (female) AXlink connector (41-5047)

• 10-pin 3.5 mm mini-Phoenix (female) I/O connector (41-5107)

• Installation Kit (KA2105-01):

8-pin Relay Common Strip

Four rack mount screws

Four washers

• Quick Start Guide

• Two 8-pin 3.5 mm mini-Phoenix (female) Relay connectors

(41-5083)

• Two CC-NIRC IR Emitters

• Two removable rack ears (62-2105-07)

• 2-pin 3.5 mm mini-Phoenix male connector (41-5026)

• CSB Cable Support Bracket (FG517)

• CC-NIRC IR cables (FG10-000-11)

• CC-NSER IR/Serial cables (FG10-007-10)

• NCK, NetLinx Connector Kit (FG2902)

• STS, Serial To Screw Terminal (FG959)

• Upgrade Compact Flash (factory programmed with firmware):

NXA-CFNI64M - 64 MB compact flash card (FG2116-31)

NXA-CFNI128M - 128 MB compact flash card (FG2116-32)

NXA-CFNI256M - 256 MB compact flash card (FG2116-33)

NXA-CFNI512M - 512 MB compact flash card (FG2116-34)

NXA-CFNI1G - 1 GB compact flash card (FG2116-35)

Connections and Wiring

FIG. 2 shows the layout of the connectors and components located on the

rear of the NI-4000 NetLinx Integrated Controller.

Rear

RS-232/422/485 (Ports 1-7)

Relays

(Port 8)

CardFrame DIP

switc h

I/O (Port 17)

IR/Serial (Ports 9-16)

Program port

Slot 1-4 connectors

FIG. 2 NI-4000 rear connectors and components

ICSNet (2)

DIP

switc h

AXlink port

ICSHub Out

AXlink LED

(green)

ID Pushbutton

Ethernet

PWR

Page 2

Wiring a power connection

Use a 12 VDC-compliant power supply to provide power to the Integrated

Controller through the rear 2-pin 3.5 mm mini-Phoenix. Use the power

requirements information listed in the Specifications table to determine the

power draw.

The incoming PWR and GND cable from the PSN power supply must be

connected to their corresponding locations within the PWR connector.

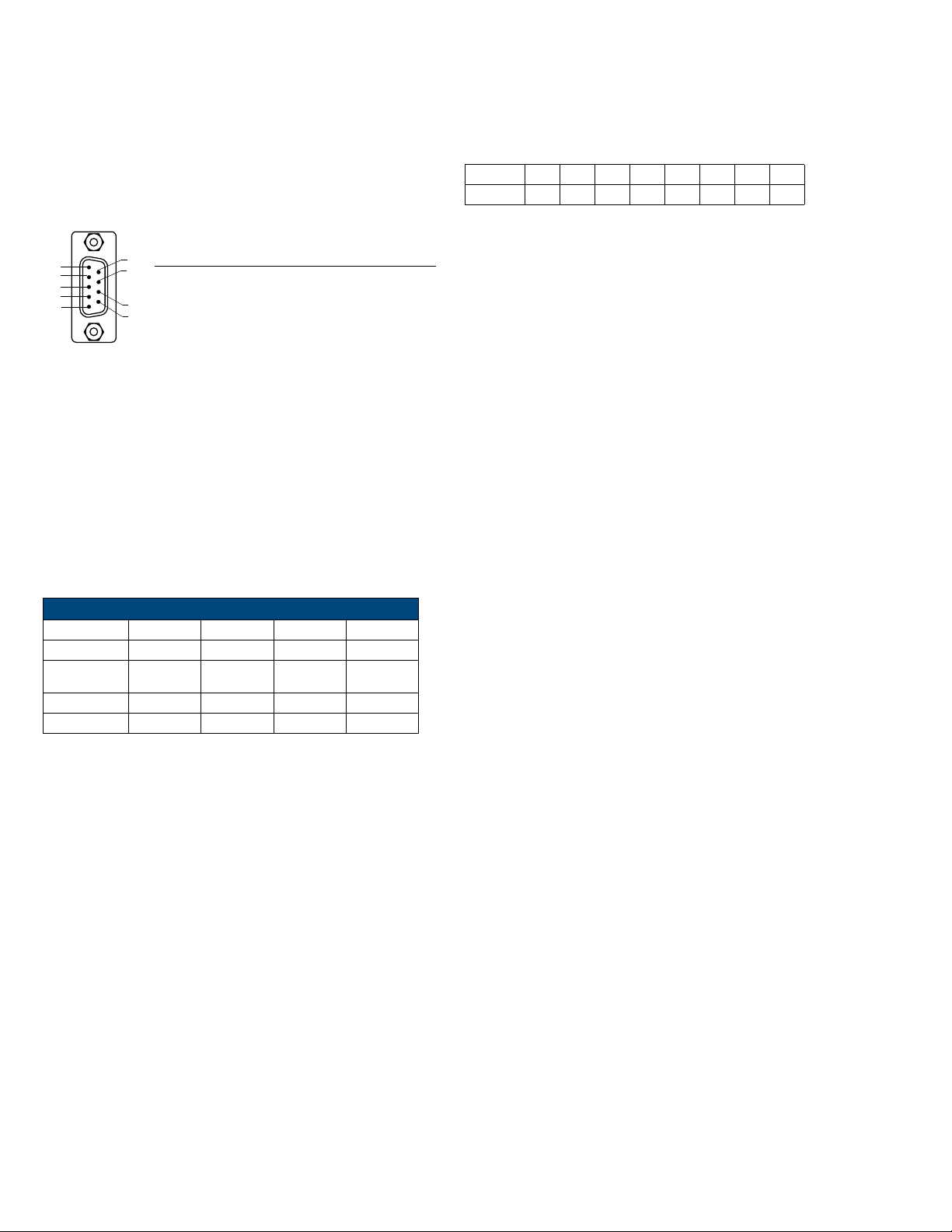

RS-232/422/485 wiring connector information

FIG. 3 shows the pinout and wiring specification information for the rear

RS-232/RS-422/RS-485 (DB9) Device Ports. These ports support most

standard serial mouse control devices and RS-232 communication protocols

for PC data transmission (NI-4000 uses Ports 1 - 7).

DB9 Serial Port pinouts (male connector)

RS-232

Male

9

8

Pin 2: RX signal

Pin 3: TX signal

PIN 5: GND

7

6

Pin 7: RTS

Pin 8: CTS

5

4

3

2

1

RS-422

Pin 1: RX Pin 4: TX +

PIN 5: GND

Pin 6: RX +

Pin 9: TX -

RS-485

Pin 1: A (strap to 9)

Pin 4: B (strap to 6)

PIN 5: GND

Pin 6: B (strap to 4)

Pin 9: A (strap to 1)

FIG. 3 RS-232/422/485 DB9 (male) connector pinouts

RJ-45 Connections

Use a standard CAT5 Ethernet cable to provide communication between the

Integrated Controller and external NetLinx devices.

Ethernet 10/100 Base-T Connector

The Ethernet cable provides 10/100 network connectivity between the panel

and the NetLinx Master.

Baud Rate Settings

The Program Port DIP switch is located on the rear of the device. Use this

DIP switch to set the baud rate for the Program Port, according to the

settings shown in the following table. Make sure the baud rate you set

matches the baud rate on your PC's NetLinx COM Settings before

programming the unit. By default, the baud rate is set to 38,400 (bps).

Baud Rate Settings

Baud Rate Position 5 Position 6 Position 7 Position 8

9600 bps OFF ON OFF ON

38,400 bps

(default)

57,600 bps ON OFF OFF OFF

115,200 bps ON ON ON ON

OFFONONON

Note: DIP switch 1 activates/deactivates the Program Run Disable

Mode. DIP Switches 2,3, and 4 must remain OFF at all times.

Inserting NetLinx Cards into the NetLinx Control Card Slots

NetLinx Cards can be installed into the front card slots. The cards mount

horizontally through the card slot openings on the front panel of the

enclosure. To install a NetLinx Card:

1. Discharge the static electricity from your body by touching a grounded

metal object and unplug all the connectors from the unit.

2. Remove the three screws by turning them in a counter-clockwise

direction and remove the front faceplate.

3. Align the edges of the card with the internal guide slots and gently slide

it in all the way until the rear edge of the card snap into place.

4. Re-secure the faceplate by inserting the three screws by turning them

in a clockwise direction and securing the front faceplate to the

Integrated Controller.

5. Re-apply power and other connections as necessary.

Setting the Integrated Controllers’ starting Card Address

The rear 8-position CardFrame Number DIP switch, lower-left rear of the

Integrated Controller, sets the starting address (the device number in the

D:P:S specification) for the Control Cards installed in the controller.

The Control Card address range is 1 - 3064.

For full warranty information, refer to the AMX Instruction Manual(s) associated with your Product(s).

©2006 AMX. All rights reserved. AMX and the AMX logo are registered trademarks of AMX.

AMX reserves the right to alter specifications without notice at any time.

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 • 800.222.0193 • fax 469.624.7153 • technical support 800.932.6993 • www.amx.com

060-004-2692 05/06

The factory default CardFrame DIP switch value = 0 (All CardFrame DIP

switches in the OFF position).

The formula for setting the starting address is:

(DIP switch value) + Card slot Number (1 - 4) = Card Address

For example:

A DIP switch setting of 00010101: (0 + 0 + 0 + 96 + 0 + 384 + 1536) +

SLOT #(ex:1) = 2017. A card in slot number 1 = device address 2017.

Set the CardFrame Number DIP switch value is based on the table below.

Posi tion

Value

12345678

12 24 48 96 192 384 768 1536

ON position

Cycle power to the unit for approximately 5 seconds. This allows the

unit to read the new device number settings.

Preparing the NI-4000 for Serial Communication

1. Launch NetLinx Studio 2.x (default location is Start > Programs >

AMX Control Disc > NetLinx Studio 2 > NetLinx Studio 2).

2. Select Settings > Master Communication Settings, from the Main

menu, to open the Master Communication Settings dialog box.

3. Click the Communications Settings button to open the

Communications Settings dialog.

4. Click the NetLinx Master radio button (from the Platform Selection

section) to indicate you are working with a NetLinx Master.

5. Click the Serial radio button (from the Transport Connection Option

section) to indicate you are connecting to the Master via a COM port.

6. Click the Edit Settings button (on the Communications Settings

dialog) to open the Serial Settings dialog and set the COM port

parameters (used to communicate to the NetLinx Master).

7. Click the OK button three times to return to the main application.

8. Right-click the Online Tree tab entry and select Refresh System.

9. Assign a System Value by using Diagnostics > Device Addressing

from the Main menu.

10. Enable the Change System selection by clicking on it and then enter

the current and new System values.

11. Click the Change Device/System Number button and when finished

click Done.

12. Select Too ls > Reboot the Master Controller to access the Reboot

the Master dialog, then click Reboot to restart the Master and

incorporate any changes.

13. Once the dialog replies with "Reboot of system complete", click Done

and then click the OnLine Tree tab in the Workspace window to view

the devices on the System.The default System value is one.

14. Right-click on the Empty Device Tree/System entry and select Refresh

System to re-populate the list.

Configuring the NI-4000 for Ethernet Communication

Before continuing, complete the COM port steps above.

1. Connect an Ethernet cable to the unit’s rear Ethernet connector.

2. Select Diagnostics > Network Address from the Main menu and

enter the System, Device (0 for a Master), and Host Name information.

3. To configure the Address:

• Use a DHCP Address by selecting the Use DHCP radio button, then

click the GET IP button (to obtain a DHCP Address from the DHCP

Server), click the SET IP Information button (to retain the new

address), and then finish the process by clicking the Reboot Master >

OK buttons.

• Use a Static IP Address by selecting the Specify IP Address radio

button, enter the IP parameters into the available fields, then click the

SET IP Information button (to retain the pre-reserved IP Address to

the Master), and then click the Reboot Master > OK buttons to finish

the process.

4. Repeat steps 1 - 5 from the previous section but rather than selecting

the Serial option, choose TCP/IP and edit the settings to match the IP

Address you are using (whether Static or IP).

5. Click on the Authentication Required radio box (if the Master is

secured) and press the User Name and Password button to enter a

valid username and password being used by the secured Master.

6. Click the OK button three times to return to the main application.

93-2105

REV: R

Loading...

Loading...