Page 1

Operation/Reference Guide

NI-3101-SIG

Signature Series NetLinx

Integrated Controller

®

NetLinx Controllers

Latest Release: 4/14/2008

Page 2

AMX Limited Warranty and Disclaimer

AMX warrants its products to be free of defects in material and workmanship under normal use for three (3) years from

the date of purchase from AMX, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, and MX Series products are warranted for a period of one

(1) year.

• AMX Lighting products are guaranteed to switch on and off any load that is properly connected to our lighting

products, as long as the AMX Lighting products are under warranty. AMX does guarantee the control of dimmable

loads that are properly connected to our lighting products. The dimming performance or quality cannot be guaranteed due to the random combinations of dimmers, lamps and ballasts or transformers.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• AMX Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX or an Authorized AMX Dealer.

All products returned to AMX require a Return Material Authorization (RMA) number. The RMA number is obtained

from the AMX RMA Department. The RMA number must be clearly marked on the outside of each box. The RMA is

valid for a 30-day period. After the 30-day period the RMA will be cancelled. Any shipments received not consistent

with the RMA, or after the RMA is cancelled, will be refused. AMX is not responsible for products returned without a

valid RMA number.

AMX is not liable for any damages caused by its products or for the failure of its products to perform. This includes any

lost profits, lost savings, incidental damages, or consequential damages. AMX is not liable for any claim made by a

third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort claim

(including negligence and strict product liability), a contract claim, or any other claim. This limitation of liability cannot

be waived or amended by any person. This limitation of liability will be effective even if AMX or an authorized representative of AMX has been advised of the possibility of any such damages. This limitation of liability, however, will not

apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may also

have other rights that vary from state to state. The owner is advised to consult applicable state laws for full determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX MAKES NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. AMX EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED

WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF

THIS LIMITED WARRANTY.

Page 3

Introduction ........................................................................................................1

NI-3101-SIG Specifications........................................................................................ 2

Installation and Upgrading .................................................................................7

Device:Port:System (D:P:S) ....................................................................................... 7

Installation into an Equipment Rack.......................................................................... 8

Connections and Wiring .....................................................................................9

Setting the Configuration DIP Switch for the Configuration Port ............................. 9

Program Run Disable (PRD) mode................................................................................... 9

Working with the Configuration DIP switch .................................................................... 9

Configuration Port Connections and Wiring ........................................................... 10

Modes and Front Panel LED Blink Patterns ............................................................ 10

Port Assignments and Functionality........................................................................ 11

AXlink Port and LED ............................................................................................... 11

Wiring Guidelines ................................................................................................... 12

Wiring length guidelines ............................................................................................... 12

Preparing captive wires................................................................................................. 12

Wiring a power connection ........................................................................................... 13

Using the 4-pin mini-Phoenix connector for data and power ........................................ 13

Using the 4-pin mini-Phoenix connector for data with external power ......................... 14

DB9 Device Port: Connections and Wiring ............................................................. 15

Relay Port: Connections and Wiring ....................................................................... 15

Relay connections.......................................................................................................... 16

Input/Output (I/O) Port: Connections and Wiring ................................................... 16

IR/Serial Port: Connections and Wiring................................................................... 17

Ethernet/RJ-45 Port: Connections and Wiring ........................................................ 18

Ethernet ports used by the Integrated Controllers ....................................................... 19

Replacing the Timekeeper Battery ......................................................................... 20

Configuration and Firmware Update ................................................................21

Communicating with the Master via the Program Port........................................... 22

Setting the System Value........................................................................................ 23

Using multiple NetLinx Masters .................................................................................... 24

Changing the Device Address of a NetLinx Device ................................................ 25

Recommended NetLinx Device numbers ...................................................................... 26

Using the ID Button to Change the Controller’s Device Value ............................... 26

Resetting the Factory Default System and Device Values ...................................... 27

Obtaining the Master’s IP Address (using DHCP) ................................................... 28

Assigning a Static IP to the NetLinx Master............................................................ 30

Communicating with the NI Device via an IP .......................................................... 31

NI-3101-SIG Signature Series NetLinx Integrated Controller

i

Page 4

Verifying the current version of NetLinx Master Firmware ..................................... 34

Upgrading the On-board Master Firmware via an IP .............................................. 35

Upgrading the NI Controller Firmware via IP.......................................................... 37

NetLinx Security within the Web Server ...........................................................41

NetLinx Security Terms ........................................................................................... 42

Accessing an Unsecured Master via an HTTP Address ............................................ 43

Browser Application Frames ................................................................................... 44

Default Security Configuration ............................................................................... 44

Master Firmware Security Access Parameters ........................................................ 46

Web Control ........................................................................................................... 47

Managing WebControl Connections.............................................................................. 47

Security Features .................................................................................................... 48

Security - System Level Security page ........................................................................... 49

Setting the system security options for a NetLinx Master............................................. 52

ICSP Authentication ...................................................................................................... 54

Security - Group Level Security page ............................................................................ 54

Adding a new Group ..................................................................................................... 56

Modifying the properties of an existing Group............................................................. 56

Deleting an existing Group ........................................................................................... 57

Security - User Level Security page ............................................................................... 58

Adding a new User ........................................................................................................ 60

Modifying the properties of an existing User................................................................ 61

Deleting an existing User .............................................................................................. 62

System Settings ...................................................................................................... 62

System Settings - Manage System page........................................................................ 63

Manage System - System Menu Buttons................................................................. 66

System Menu - Modifying the Date/Time ...................................................................... 66

System Menu - Changing the System Number .............................................................. 67

System Menu - Rebooting the Master ........................................................................... 67

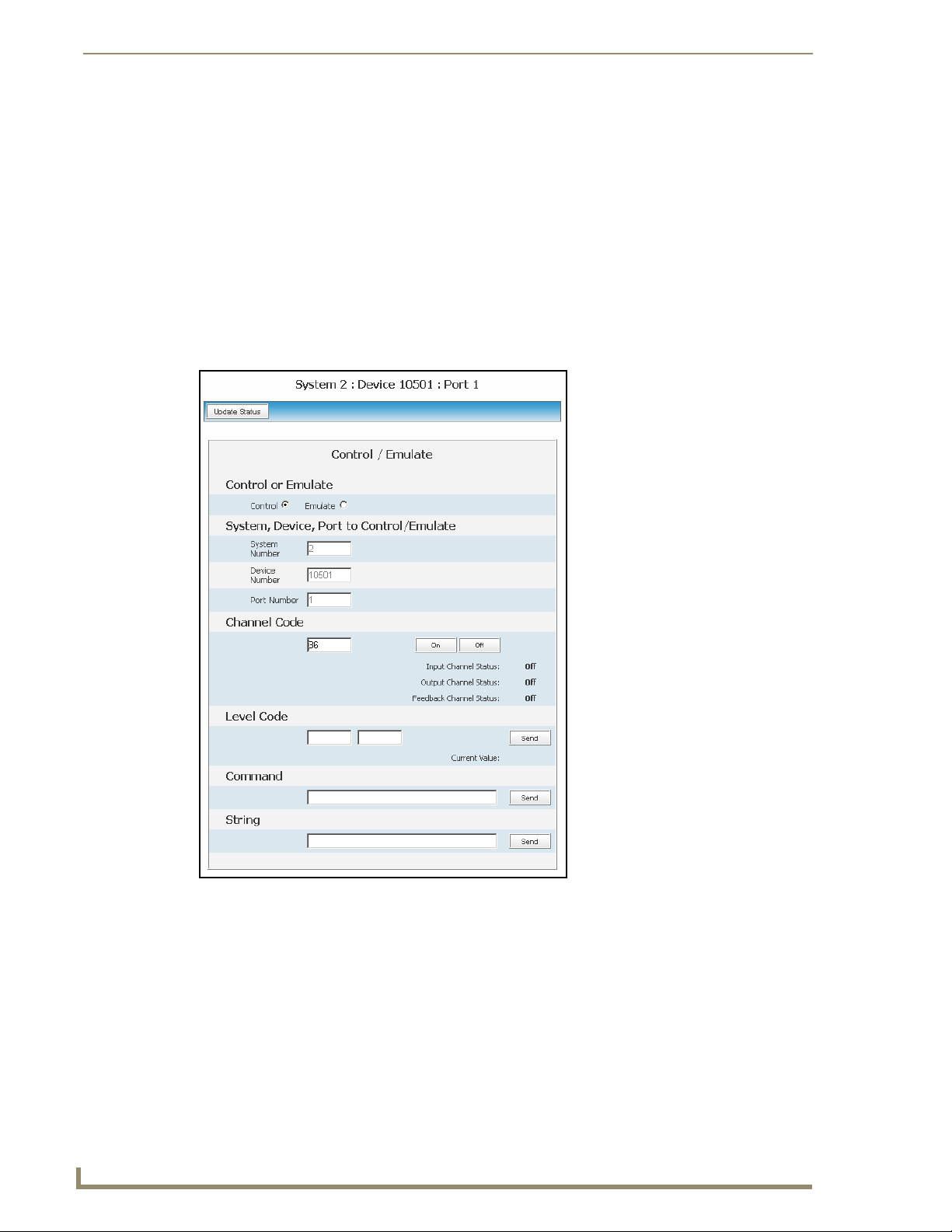

System Menu - Controlling/Emulating Devices on the Master ...................................... 67

Manage System - Diagnostics........................................................................................ 70

Setting up and removing a Diagnostic Filter ................................................................. 71

Setting the Master’s Port Configurations ............................................................... 74

Manage System - Server................................................................................................ 74

Modifying the Server Port Settings ............................................................................... 76

SSL Server Certificate Creation Procedures............................................................ 78

Server - Display SSL Server Certificate Information....................................................... 80

Server - Creating a self-generated SSL Certificate ........................................................ 80

Server - Regenerating an SSL Server Certificate Request ............................................. 81

ii

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 5

Server - Creating a Request for an SSL Certificate........................................................ 81

Common Steps for Requesting a Certificate from a CA.......................................... 83

Communicating with the CA ......................................................................................... 83

Server - Exporting an SSL Certificate Request .............................................................. 84

Server - Importing a CA created SSL Certificate ........................................................... 85

Manage System - Device Menu Buttons ................................................................. 86

Device Menu - Configuring the Network Settings......................................................... 86

Device Menu - Developing a URL List ........................................................................... 88

Device Menu - Changing the Device Number ............................................................... 89

Device Menu - Controlling or Emulating a device ......................................................... 90

Device Menu - Viewing the Log .................................................................................... 90

Device Menu - Running a Diagnostic Filter.................................................................... 90

System Settings - Manage License.......................................................................... 91

Adding a new license .................................................................................................... 91

Removing a license........................................................................................................ 92

System Settings - Manage NetLinx Devices............................................................ 93

Manage NetLinx Devices - Displaying NDP-capable devices......................................... 95

Manage NetLinx Devices - Binding/Unbinding - Explained ........................................... 95

Manage NetLinx Devices - Obtaining NetLinx Device information ............................... 96

System Settings - Manage Other Devices - Dynamic Device Discovery Pages........ 97

What is Dynamic Device Discovery? ............................................................................ 101

What is the difference between Program and Run-time defined binding? ................. 102

Manage Other Devices - Manage Device Bindings ............................................... 102

Configuring application-defined devices ..................................................................... 103

What are Application Devices and their association status? ....................................... 103

Manage Other Devices Menu - Viewing Discovered Devices ...................................... 106

Manage Other Devices Menu - Creating a new User-Defined Device ......................... 108

How do I write a program that uses Dynamic Device Discovery ................................. 109

How do I configure a Run-time installation ................................................................. 110

Accessing an SSL-Enabled Master via an IP Address ............................................ 111

Using your NetLinx Master to control the G4 panel.................................................... 114

What to do when a Certificate Expires ................................................................. 116

NetLinx Security with a Terminal Connection .................................................117

NetLinx Security Features..................................................................................... 117

Initial Setup via a Terminal Connection................................................................. 118

Establishing a Terminal connection via the RS-232/USB Configuration Port ............... 118

Accessing the Security configuration options ....................................................... 118

Option 1 - Set system security options for NetLinx Master (Security Options Menu) . 119

Option 2 - Display system security options for NetLinx Master .................................. 121

NI-3101-SIG Signature Series NetLinx Integrated Controller

iii

Page 6

Option 3 - Add user .................................................................................................... 121

Option 4 - Edit User .................................................................................................... 122

Option 5 - Delete user................................................................................................. 124

Option 6 - Show the list of authorized users ............................................................... 125

Option 7 - Add Group ................................................................................................. 125

Option 8 - Edit Group ................................................................................................. 127

Option 9 - Delete Group ............................................................................................. 128

Option 10 - Show List of Authorized Groups .............................................................. 128

Option 11 - Set Telnet Timeout in seconds ................................................................. 128

Option 12 - Display Telnet Timeout in seconds ........................................................... 129

Option 13 - Make changes permanent by saving to flash ........................................... 129

Main Security Menu .............................................................................................. 130

Default Security Configuration ............................................................................. 131

Help menu ................................................................................................................... 132

Logging Into a Session.......................................................................................... 134

Logout .................................................................................................................. 135

Help Security ............................................................................................................... 135

Setup Security ............................................................................................................. 135

Programming ..................................................................................................137

Converting Axcess Code to NetLinx Code............................................................ 137

Master Send_Commands ...................................................................................... 137

Master IP Local Port Send_Commands ................................................................. 139

Using the ID Button .............................................................................................. 139

Device:Port:System (D:P:S).......................................................................................... 140

Configuration Port Commands ............................................................................. 140

ESC Pass Codes .................................................................................................... 153

Notes on Specific Telnet/Terminal Clients ............................................................ 153

WindowsTM client programs....................................................................................... 153

Linux Telnet client ....................................................................................................... 153

LED Disable/Enable Send_Commands .................................................................. 154

RS232/422/485 Ports Channels ............................................................................ 154

RS-232/422/485 Send_Commands........................................................................ 155

RS-232/422/485 Send_String Escape Sequences.................................................. 158

IR / Serial Ports Channels ..................................................................................... 159

IR/Serial Send_Commands .................................................................................... 160

Input/Output Send_Commands ............................................................................ 166

Troubleshooting .............................................................................................167

iv

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 7

Introduction

The NI-3101-SIG Signature Series NetLinx Integrated Controller satisfies the control and automation

features common in a larger area or multiple rooms, which may include the integration of a larger

number of devices including VCR and DVD players, projectors, lighting, thermostats and other

electronic equipment. In technology-driven environments, this solution allows for the future addition of

more devices and control capabilities.

The NI-3101-SIG features an easy-to-install form factor that mounts into 1 unit of rack space and

provides extended rack depth to simplify rear connections. Its sleek, gloss black faceplate complements

the Tango Distributed Audio line and Metreau Keypads. For smaller business and home applications, the

NI-3101-SIG includes just the right mix of ports and features.

NetLinx Integrated Master Controller Features

NI-3101-SIG

(FG2105-08)

The NI-3101-SIG is Duet-compatible and can be upgraded via firmware. Duet is a dual-interpreter

firmware platform from AMX which combines the proven reliability and power of NetLinx with the

extensive capabilities of the Java

a system that includes third party devices by standardizing device and function definitions, defaulting

touch panel button assignments, and controlling feedback methods. Dynamic Device Discovery makes

integration even easier by automatically identifying and communicating with devices which support this

new beaconing technology. Refer to the System Settings - Manage Other Devices - Dynamic Device

Discovery Pages section on page 97 for more detailed information on the use of Dynamic Device

Discovery (DDD).

The NI-3101-SIG uses a combination lithium battery and clock crystal package called a Timekeeper.

Only one Tim ekee per unit is installed within a given NI-3101. The battery can be expected to have up to

3 years of usable life under very adverse conditions. Actual life is appreciably longer under normal

operating conditions. This calculation is based on storing the unit without power in 50° C (120° F)

temperature until battery levels are no longer acceptable. The part number for a replacement battery is

57-0032.

• 1 low-speed USB connection for configuration

• 6 RS-232/RS-422/RS-485 ports

• 8 IR/Serial Output ports

• 8 Digital Input/Output ports

•8 Relays

®

2 MicroEdition (J2ME) platform. Duet simplifies the programming of

Introduction

RISK OF EXPLOSION IF BATTERY IS REPLACED WITH AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO MANUFACTURER’S

INSTRUCTIONS.

NI-3101-SIG Signature Series NetLinx Integrated Controller

1

Page 8

Introduction

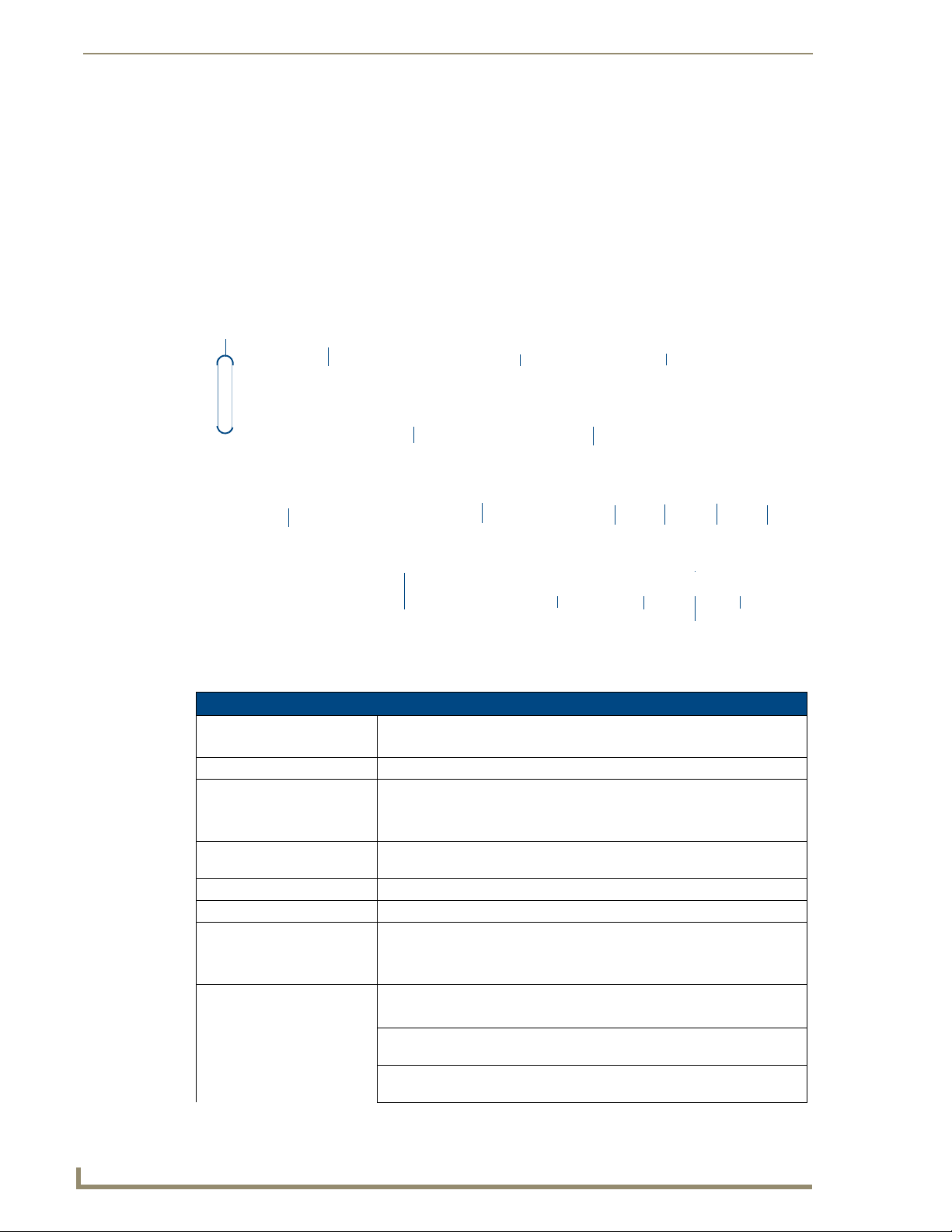

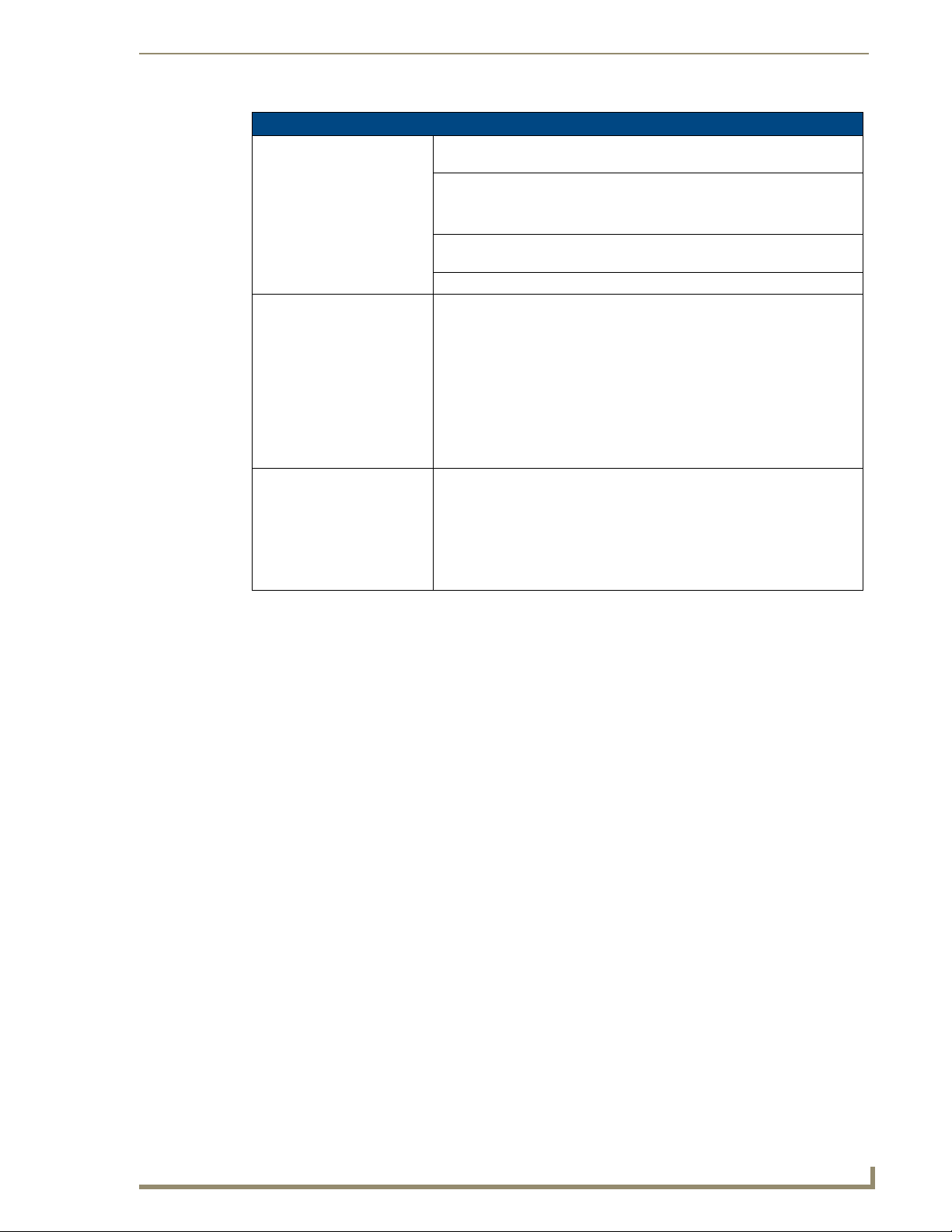

NI-3101-SIG Specifications

The NI-3101-SIG (FIG. 1) provides support for 6 configurable RS-232/RS-422/RS-485 Ports, 8 IR/

Serial Output ports, 8 Digital Input/Output ports, and 8 Relays.

FIG. 1 NI-3101 NetLinx Integrated Controller (front view)

Power

Front

Rear

Link/Active-Status-I/O

RS-232/422/485

Ports (1-6)

RS-232/422/485

TX/RX LEDs

Relays

(Port 8)

I/O

(Port 17)

Relay LEDs

(Ports 9-16)

IR/Serial LEDs

IR/Serial

Configuration

switches

Programming

I/O LEDs

switch

Port

ID

AXLink

LED

Ethernet

10/100

Port

12 VDC

AXLink

Port

Power

FIG. 2 NI-3101 front and rear panel connectors and components

NI-3101-SIG Specifications (Cont.)

Dimensions (HWD): • 2" (with feet) x 17" x 10" (5.1 cm x 43.2 cm x 26.35 cm)

• 1 RU (rack unit) high

Power Requirement: • 900 mA @ 12 VDC

Memory: • 64 MB SDRAM

• 256 MB Flash

• 1 MB Non-volatile (NV) SRAM

Compact Flash: • 128 MB Card (upgradeable) (refer to the Other AMX Equipment section for

more information)

Weight: • 6.95 lbs (3.15 kg)

Enclosure: • Metal with black matte finish and translucent polycarbonate faceplate

Certifications: • FCC Part 15 Class B

•CE

• IEC 60950

Front Panel Components:

POWER • Blue LED bar lights when powered up

LINK/ACTIVE • Blue LED blinks when the Ethernet cable is connected and an active link is

established. This LED also blinks when receiving Ethernet data packets.

Status • Blue LED blinks to indicate that the system is programmed and

communicating properly.

2

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 9

Introduction

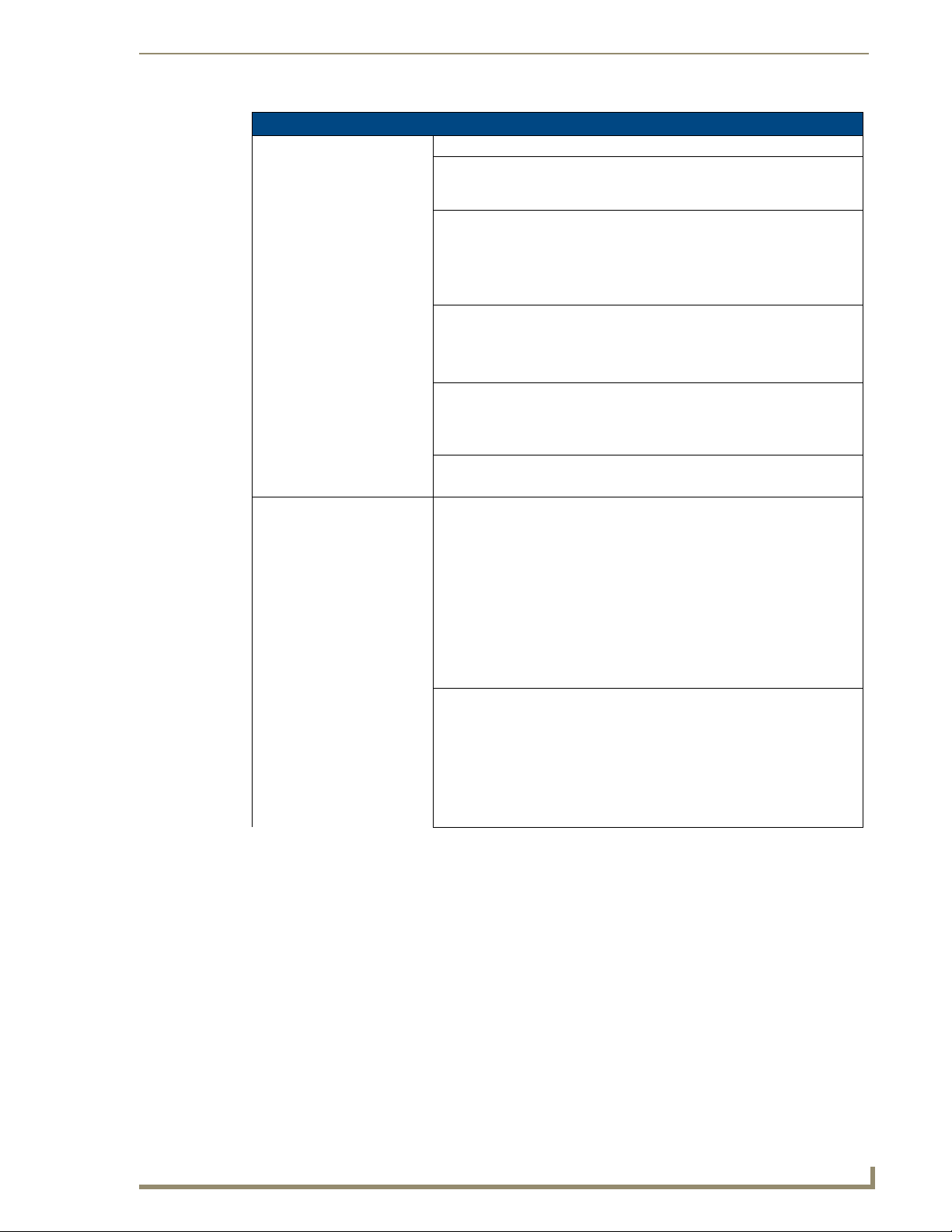

NI-3101-SIG Specifications (Cont.)

Front Panel Components:

Input/Output LEDs • White Output LED blinks when the Controller transmits data, sets channels

On/Off, sends data strings, etc. White Input LED blinks when it receives

data from button pushes, strings, commands, channel levels, etc.

RS-232/422/485 LEDs • Six sets of blue and white LEDs light to indicate the rear serial Ports 1 - 6

Relay LEDs • Eight blue LEDs light to indicate the rear relay channels 1 - 8 are active

IR/Serial LEDs • Eight blue LEDs light to indicate the rear IR/Serial channels 1 - 8 are

I/O LEDs • Eight white LEDs light when the rear I/O channels 1-8 are active

Rear Panel Connectors:

RS-232/422/485 (Ports 1 - 6)•Six RS-232/422/485 control ports using DB9 (male) connectors with XON/

Relay (Port 8) • Eight-channel single-pole single-throw relay ports

are transmitting or receiving RS-232, 422, or 485 data:

- TX LEDs (blue) light when transmitting data

- RX LEDs (white) light when receiving data

- LED activity reflects transmission and reception activity

(closed)

• These LEDs reflect the state of the relay on Port 8

• If the relay is engaged = LED On and if the relay is Off = LED Off

transmitting control data on Ports 9 - 16

• LED indictor for each IR port remains lit for the length of time that IR/Serial

data is being generated

• LED indicator for each I/O port reflects the state of that particular port

XOFF (transmit on/transmit off), CTS/RTS (clear to send/ready to send),

and 300-115,200 baud.

• Channel range = 1-255

• Channels 1-254 provide feedback

• Channel 255 (CTS Push channel): Reflects the state of the CTS Input if a

'CTSPSH' command was sent to the port

• Output data format for each port is selected via software

• Six DB9 connectors provide RS-232/422/485 termination

• Each relay is independently controlled.

• Supports up to 8 independent external relay devices

• Channel range = 1-8

• Each relay can switch up to 24 VDC or 28 VAC @ 1 A

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide relay

termination

NI-3101-SIG Signature Series NetLinx Integrated Controller

3

Page 10

Introduction

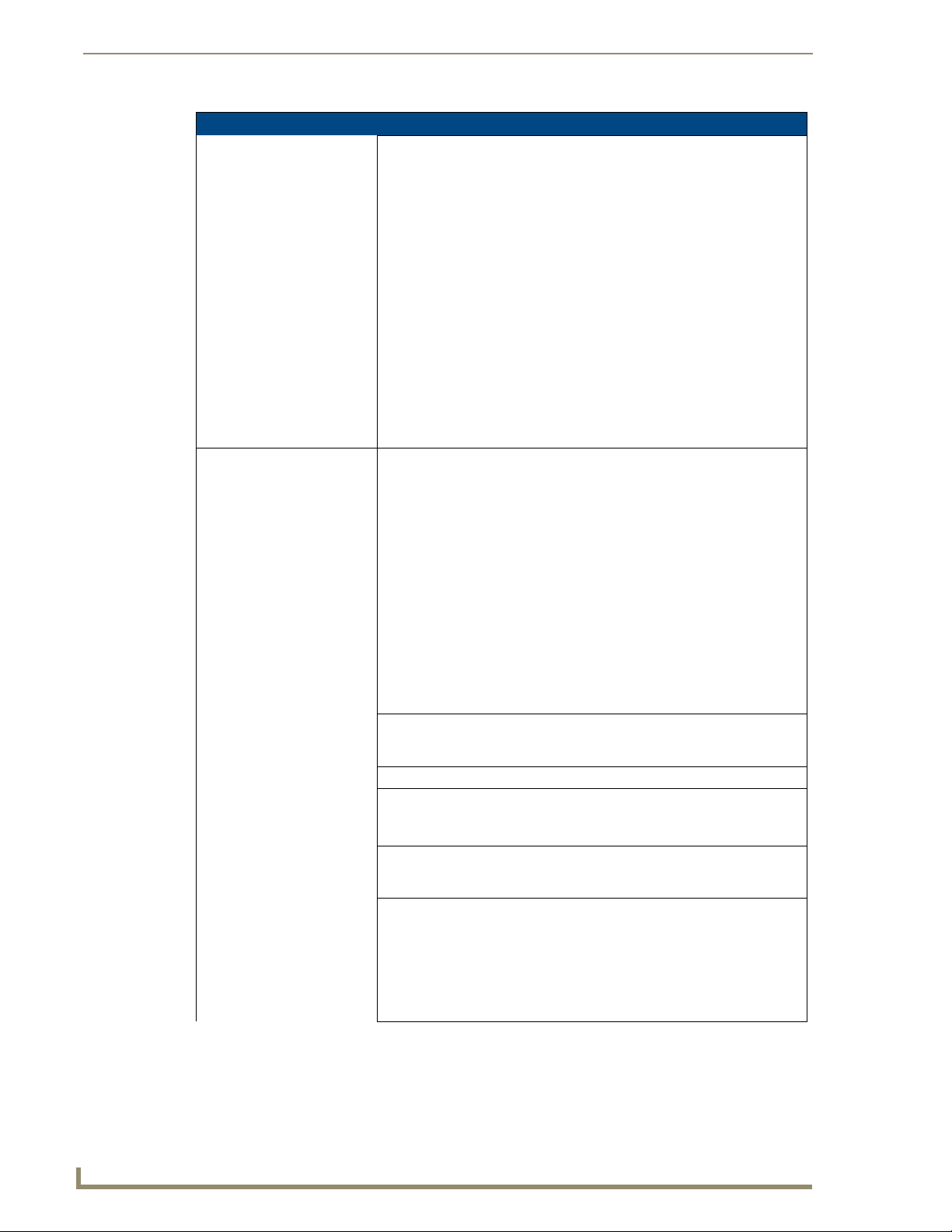

NI-3101-SIG Specifications (Cont.)

Digital I/O (Port 17) • Eight-channel binary I/O port for contact closure

• Each input is capable of voltage sensing. Input format is software

selectable.

• Interactive power sensing for IR ports

• Channel range = 1-8

• All inputs are assigned to respective IR/Serial ports for "automatic" power

control through the use of software commands. Power control is provided

via commands such as: ’PON’, ’POF’, ’POD’, ’DELAY’, I/O Link etc.).

• Contact closure between GND and an I/O port is detected as a PUSH

• When used as voltage input - I/O port detects a low signal (0- 1.5 VDC) as

a PUSH and a high signal (3.5 - 5 VDC) as a RELEASE

• When used as an output - each I/O port acts as a switch to GND and is

rated at 200 mA @ 12 VDC

• 10-pin 3.5 mm mini-Phoenix (female) connector provides I/O port

termination

Note: This IO port uses 5V logic, but can handle up to 12V on the input

without harm. Higher voltages run a higher risk of surge damage.

IR/Serial (Ports 9 - 16)•Eight IR/Serial control ports support high-frequency carriers up to

1.142 MHz

• Each output is capable of three electrical formats: IR, Serial, and Data

• Eight IR/Serial data signals can be generated simultaneously.

• Channel range = 1-32,767

• Channels 1-128 (output): IR commands

• Channels 129-253: used as reference channels

• Channel 254 (feedback): Power Fail (used with 'PON' and 'POF'

commands)

• Channel 255 (feedback): Power status (when IO Link is set)

• IR ports support data mode (at limited baud rates and wiring

distances).

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide IR/Serial port

termination

Configuration Port • USB connector (male) can be connected to a USB port on a computer.

This low-speed USB connection is used to configure system settings. Not

recommended for firmware updates or large file transfers.

Configuration DIP switch • Sets the onboard Master execution mode.

ID pushbutton • Provides the NetLinx ID (Device only) assignment for the device. Refer to

the Changing the Device Address of a NetLinx Device section on page 25.

• The D notation is used to represent a device number.

Ethernet port • RJ-45 port for 10/100 Mbps communication. This port automatically

negotiates the connection speed (10 Mbps or 100 Mbps) and whether to

use half duplex or full duplex mode.

Ethernet Link/Activity LED • LEDs show communication activity, connection status, speeds, and mode

information:

SPD (speed) - Yellow LED lights On when the connection speed is 100

Mbps and turns Off when the speed is 10 Mbps.

L/A (link/activity) - Green LED lights On when the Ethernet cables are

connected/terminated correctly, and blinks when receiving Ethernet data

packets.

4

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 11

Introduction

NI-3101-SIG Specifications (Cont.)

Rear Panel Connectors

(Cont.):

AXlink LED • Green LED indicates the state of the AXlink connector port.

• Normal AXlink activity = 1 blink/second

• Abnormal AXlink activity = cycle of 3 consecutive blinks and then Off

AXlink port • 4-pin 3.5 mm mini-Phoenix (male) connector provides data and power to

external control devices.

Power port • 2-pin 3.5 mm mini-Phoenix (male) connector

Included Accessories: • 2-pin 3.5 mm mini-Phoenix (female) PWR connector (41-5025)

• 4-pin 3.5 mm mini-Phoenix (female) AXlink connector (41-5047)

• 10-pin 3.5 mm mini-Phoenix (female) I/O connector (41-5107)

• Installation Kit (KA2105-02):

Two rack mount ears

Four #8-32 Phillips flat head screws

• NI-3101-SIG Quick Start Guide (93-2105-08)

• Two 8-pin 3.5 mm mini-Phoenix (female) Relay connectors (41-5083)

• Two CC-NIRC IR Emitters

Other AMX Equipment: • 2-pin 3.5 mm mini-Phoenix male connector (41-5026)

• CC-NIRC IR cables (FG10-000-11)

• CC-NSER IR/Serial cables (FG10-007-10)

• CSB Cable Support Bracket (FG517)

• NCK, NetLinx Connector Kit (FG2902)

• USB A to B cable (FG10-2105)

NI-3101-SIG Signature Series NetLinx Integrated Controller

5

Page 12

Introduction

6

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 13

Installation and Upgrading

Device:Port:System (D:P:S)

A device is any hardware component that can be connected to an AXlink bus. Each device must be

assigned a unique number to locate that device on the bus. Only the Device value can be set through

the DIP switch settings mentioned above.

NetLinx requires a Device:Port:System (D:P:S) specification. This D:P:S triplet can be expressed as a

series of constants, variables separated by colons, or a DEV structure. For example:

STRUCTURE DEV

{

INTEGER Number // Device number

INTEGER Port // Port on device

INTEGER System // System the device belongs to

}

The D:P:S notation is used to explicitly represent a device number, port and system. For example,

128:1:0 represents the first port on device 128 on this system.

If a device is declared in a NetLinx program with just the Device number (System and Port are

omitted), the NetLinx Compiler assumes it has a Port number of 1 and a System number of 0.

However, all existing device declarations should be converted using the D:P:S (Device:Port:System)

notation. This enables certain NetLinx specific debugging features and can help pinpoint other

potentially obscure errors.

The syntax is as follows:

NUMBER:PORT:SYSTEM

where:

NUMBER: 16-bit integer represents the device number

PORT: 16-bit integer represents the port number (in the range 1 through the number of

ports on the Controller or device)

SYSTEM: 16-bit integer represents the system number (0 = this system)

Installation and Upgrading

NI-3101-SIG Signature Series NetLinx Integrated Controller

7

Page 14

Installation and Upgrading

Installation into an Equipment Rack

Use the rack-mounting ears supplied with the NI-3101-SIG controller for equipment rack installations.

The device comes installed with four rubber feet for flat surface installations.

The maximum operating ambient temperature is 40°C.

Connect the unit only to a properly-rated supply circuit.

Never restrict the airflow through the devices’ fan or vents.

When installing equipment into a rack, distribute the units evenly. Otherwise,

hazardous conditions may be created by an uneven weight distribution.

Reliable earthing (grounding) of rack-mounted equipment should be maintained.

Before completing the install process, completing any firmware upgrade of the

NetLinx Control Cards is highly recommended. This upgrade involves physically

cycling power to the unit and can become cumbersome if the unit is already installed

into a rack.

1. Discharge the static electricity from your body by touching a grounded object.

2. Position and install the mounting ears, using the screws supplied with the unit. The mounting ears

may be rotated to accommodate your mounting needs.

3. Thread the cables through the opening in the equipment rack. Allow for enough slack in the cables

to accommodate for movement during the installation process.

4. Reconnect all cables to their appropriate source/terminal locations. Refer to theConnections and

Wiring section on page 9 for more detailed wiring and connection information.

Verify that the terminal end of the power cable is not connected to the a power supply before

plugging in the 2-pin power connector.

To prevent repetition of the installation, test the incoming wiring by connecting the

Controller’s connectors to their terminal locations and applying power. Verify that the

unit is receiving power and functioning properly. Disconnect the terminal end of the

power cable from the connected 12 VDC-compliant power supply.

5. Slide the device into the rack until the attachment holes, along both sides, align to their

corresponding locations on the mounting ears.

6. Secure the device to the rack by using the four flat-head Phillips screws supplied in the kit.

7. Apply power to the unit to complete the installation.

8

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 15

Connections and Wiring

Setting the Configuration DIP Switch for the Configuration Port

Prior to installing the Controller, use the Configuration DIP switch to set the information used by the

Configuration Port for communication. The DIP switchsets the starting address (the device number in

the D:P:S specification) for the Control Cards installed in the controller with a range of 1-1536. The

four-pin Configuration DIP switch is located on the rear of the device.

Program Run Disable (PRD) mode

The Configuration DIP switch is used to set the on-board Master to Program Run Disable (PRD) mode,

according to the settings listed in the table below.

PRD Mode Settings

PRD Mode Position 1

Normal mode (default) OFF

PRD Mode ON

Connections and Wiring

The PRD mode prevents the NetLinx program stored in the on-board Master from running during the

device’s power-up. This mode should only be used if the resident NetLinx program is causing

inadvertent communication and/or control problems. If necessary, place the on-board Master in PRD

mode and use the NetLinx Studio v 2.x program to resolve the communication and/or control problems

with the resident NetLinx program. After doing so, download the corrected program, reset the

configuration DIP switch to normal mode, recycle power, and try again.

Think of the PRD Mode (On) equating to a PC’s SAFE Mode setting. This mode

allows a user to continue powering a unit, update the firmware, and download a new

program while circumventing any problems with a currently downloaded program.

Power must be cycled to the unit after activating/deactivating this mode on the

Configuration Port DIP switch #1.

Working with the Configuration DIP switch

Disconnect the power supply from the 2-pin PWR (green) connector on the rear of the NetLinx

1.

Integrated Controller.

2. Set DIP switch positions according to the information listed in thePRD Mode Settings table.

3. Reconnect the 12 VDC power supply to the 2-pin 3.5 mm mini-Phoenix PWR connector.

NI-3101-SIG Signature Series NetLinx Integrated Controller

9

Page 16

Connections and Wiring

Configuration Port Connections and Wiring

The NI-3101 is equipped with a low-speed USB connection located on the rear of the unit. Use a

standard USB cable to establish a connection between the device and your PC's USB port. This

connection provides communication with the NetLinx Integrated Controller. From there, configure the

on-board Master as needed for your application.

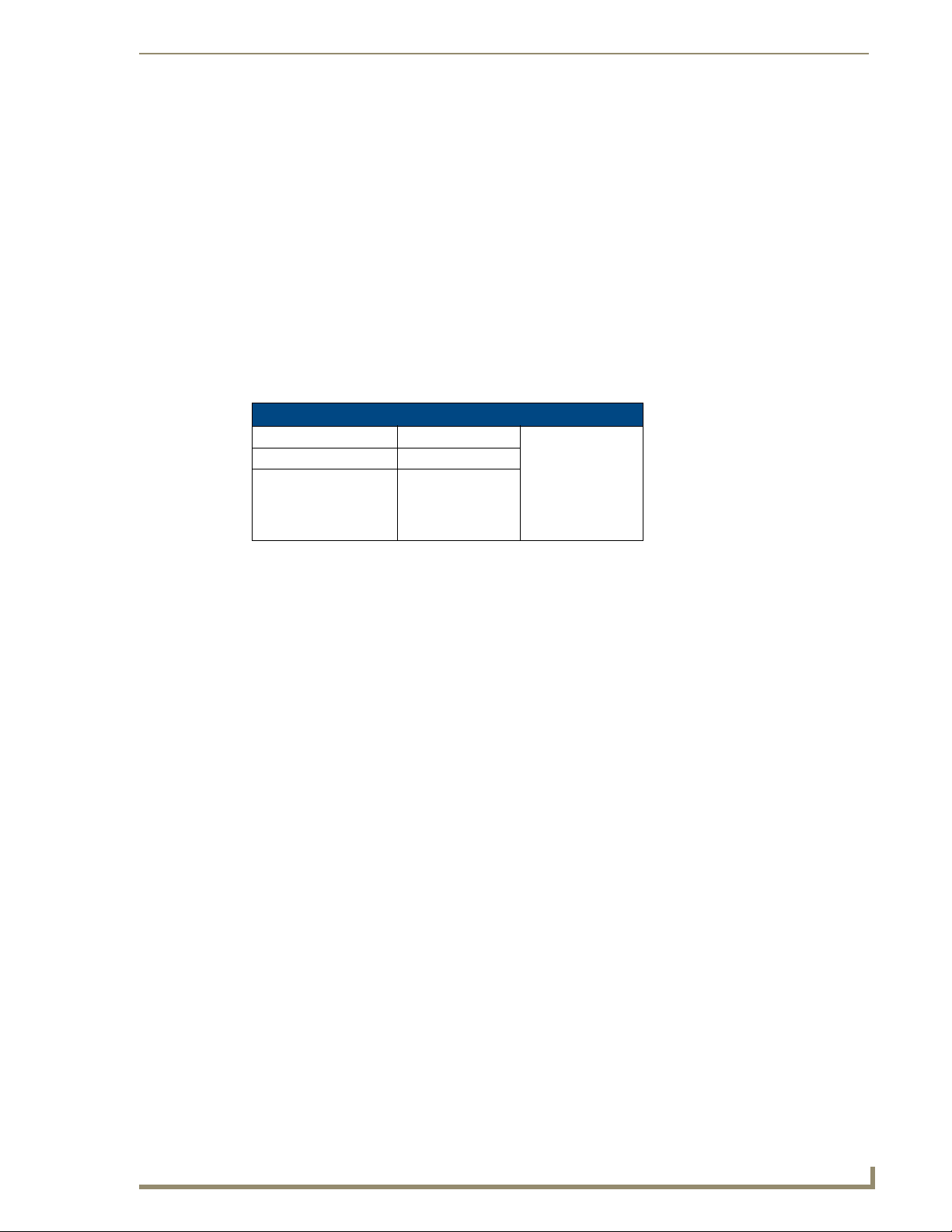

Modes and Front Panel LED Blink Patterns

The following table lists the modes and blink patterns for the front panel LEDs associated with each

mode. These patterns are not evident until after the unit is powered.

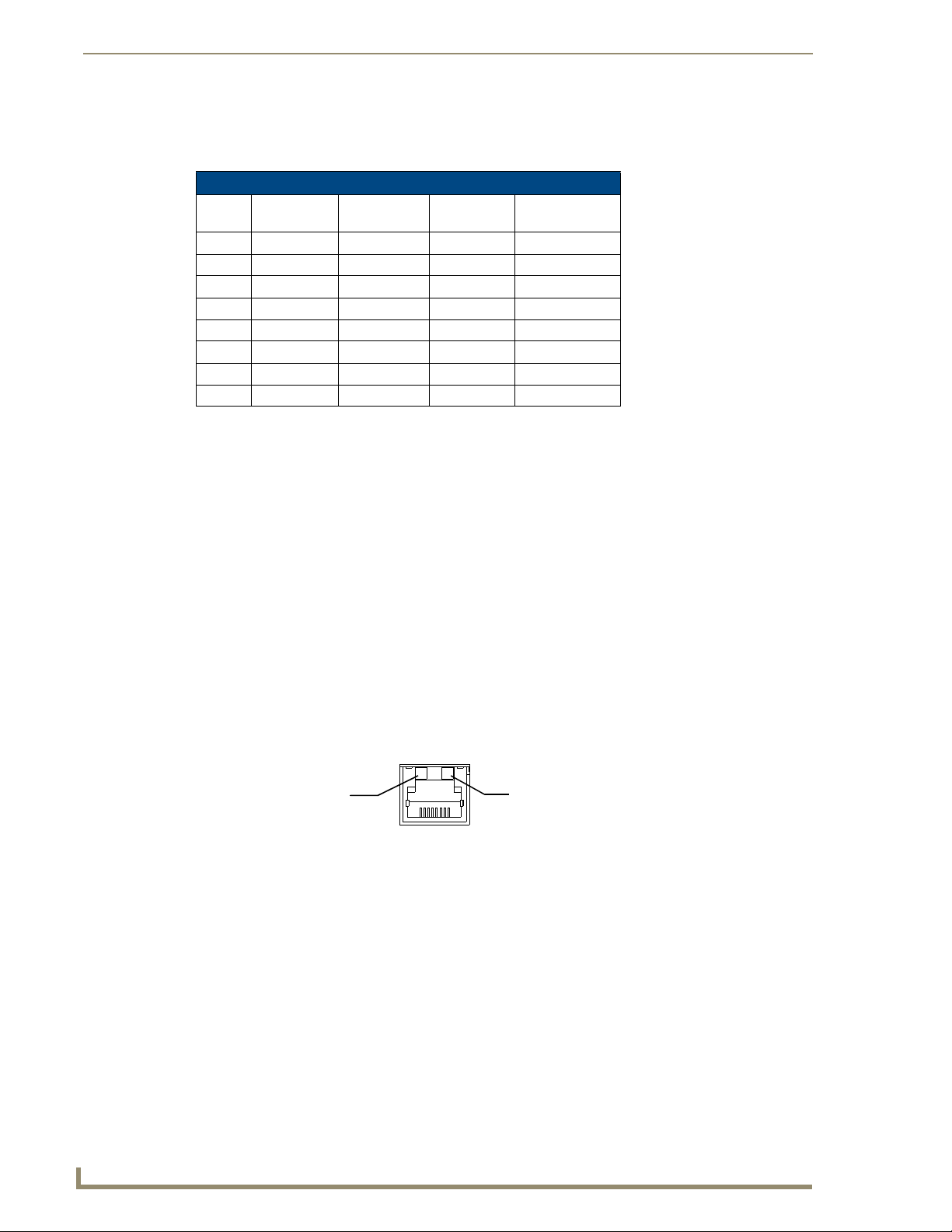

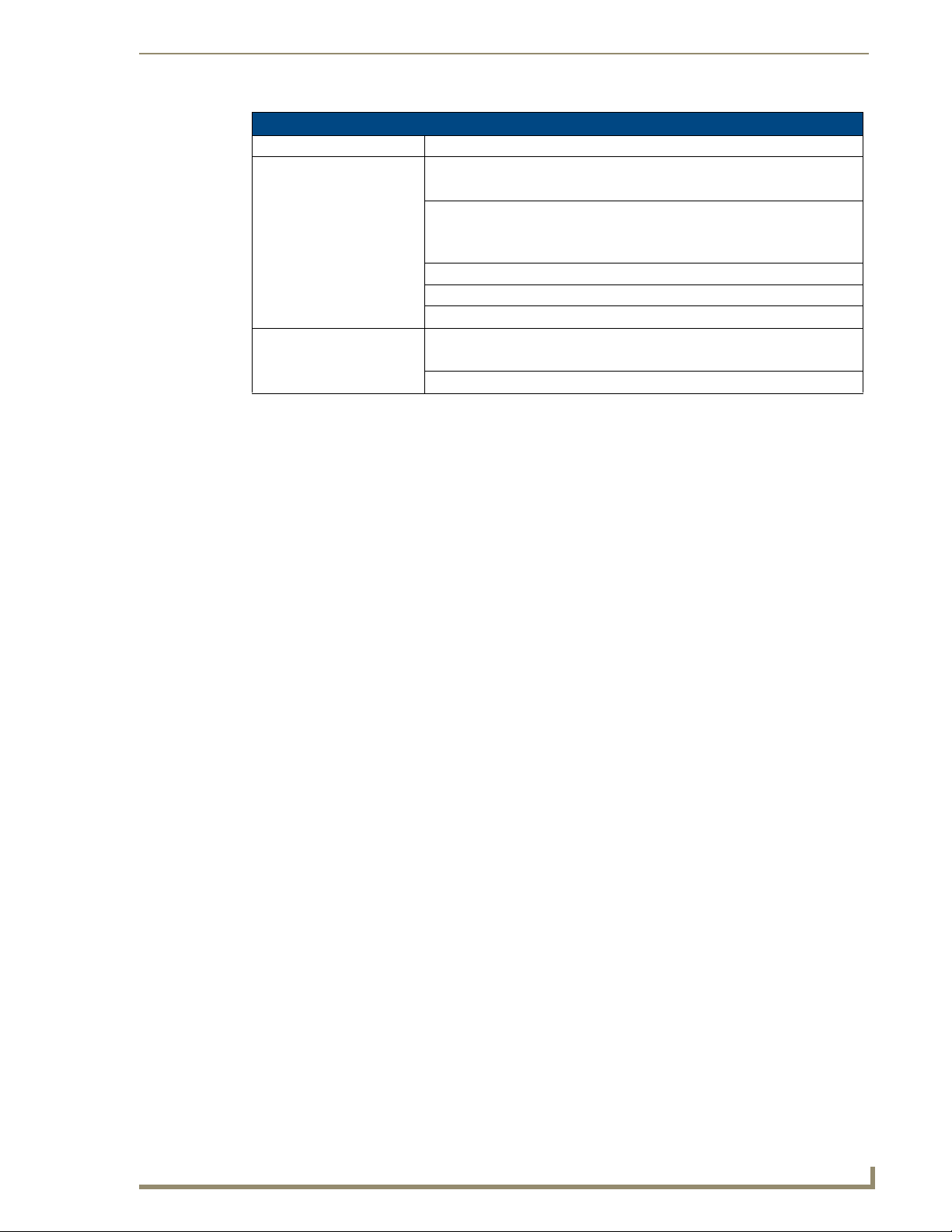

Modes and LED Blink Patterns

Mode Description

OS Start Starting the operating system (OS). On On On

Boot On-board Master is booting. On Off On

Contacting DHCP

server

Unknown DHCP

server

Downloading Boot

firmware

No program running Either no program is loaded, or the

Normal On-board Master is functioning normally. 1 blink per

On-board Master is contacting a DHCP

server for IP configuration information.

On-board Master could not find the DHCP

server.

Downloading Boot firmware to the Master’s

on-board flash memory.

Do not cycle power during this process!

program is disabled.

LEDs and Blink Patterns

STATUS

(blue)

On Off Fast Blink

Fast Blink Off Off

Fast Blink Fast Blink Fast Blink

On Normal Normal

second

OUTPUT

(white)

Indicates

activity

INPUT

(white)

Indicates

activity

10

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 17

Port Assignments and Functionality

The rear Port Assignments are as follows:

NI-3101 Port Assignments

Port ICSP Port #

Serial Port #1 1

Serial Port #2 2

Serial Port #3 3

Serial Port #4 4

Serial Port #5 5

Serial Port #6 6

Relays Ports (1-8) 8

IR Serial Port #1 9

IR Serial Port #2 10

IR Serial Port #3 11

IR Serial Port #4 12

IR Serial Port #5 13

IR Serial Port #6 14

IR Serial Port #7 15

IR Serial Port #8 16

I/O Port 17

Connections and Wiring

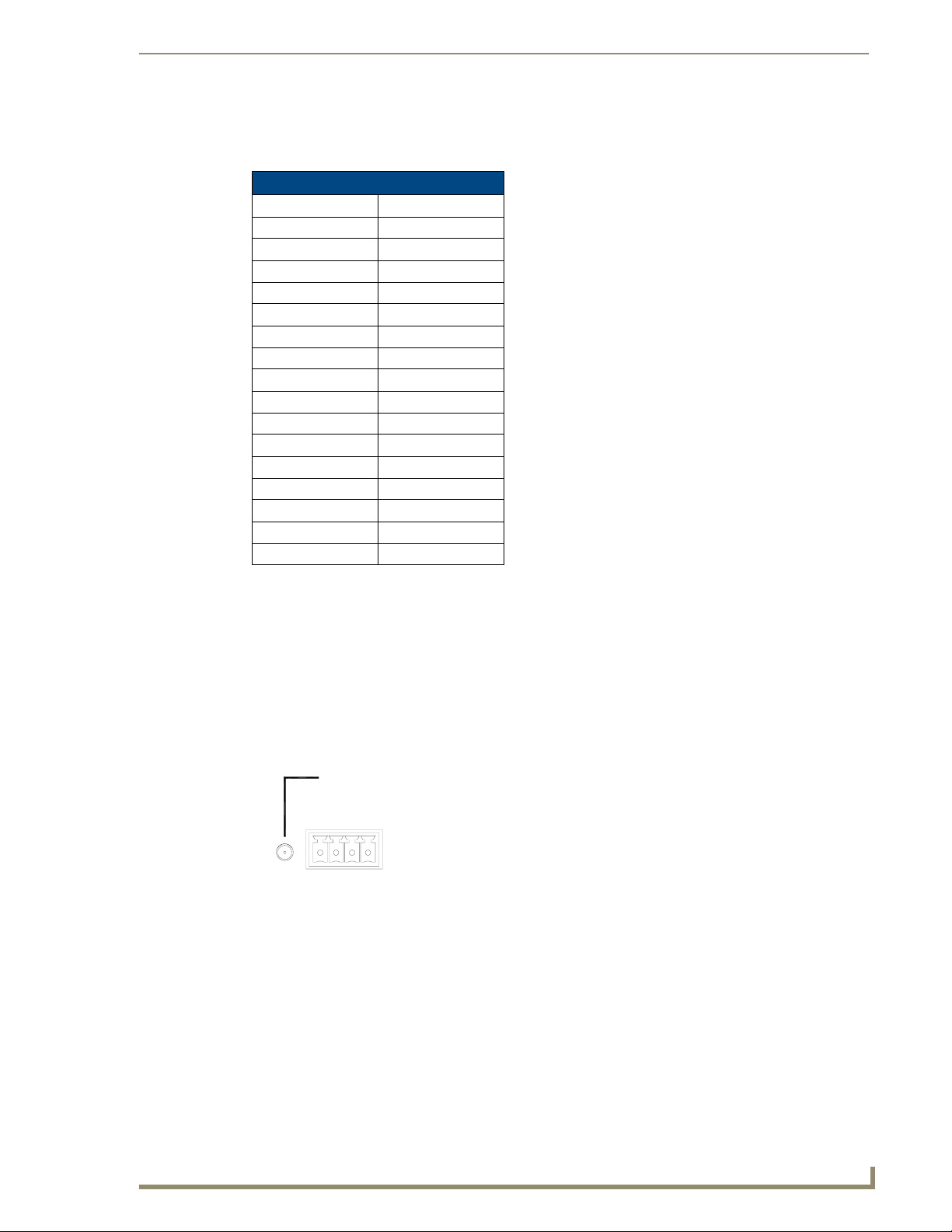

AXlink Port and LED

All NI units have an AXlink port and adjacent status LED (FIG. 3). This port allows the NI to support

AMX legacy AXlink devices such as G3 touch panels (ex: CP4/A) and PosiTrack Pilot devices. A green

LED shows AXlink data activity. When the AXlink port is operating normally, blink patterns include:

Off - No power, or the controller is not functioning properly.

1 blink per second - Normal operation.

3 blinks per second - AXlink bus error. Check all AXlink bus connections.

AXLink

AXP

AXM

GND

AXlink connector and LED

FIG. 3

The AXlink port can be used to supply power to downstream AXlink-compatible devices, so long as

both the power required is LESS THAN 2 Amps total and the external power supply feeding the device

has the necessary power capability.

PWR

NI AXlink connector

NI-3101-SIG Signature Series NetLinx Integrated Controller

11

Page 18

Connections and Wiring

Wiring Guidelines

The Integrated Controllers use a 12 VDC-compliant power supply to provide power through the rear

2-pin 3.5 mm mini-Phoenix PWR connector, or through the 4-pin 3.5 mm mini-Phoenix (female)

captive-wire connector used for data communication and power transfer. Use the power requirements

referenced in the product’s Specifications table to determine the power draw.

The incoming PWR and GND cable from the power supply must be connected to the corresponding

locations within the PWR connector.

Use only one power source for the device at a time. Using both the 2-pin miniPhoenix PWR connector and the 4-pin mini-Phoenix AXLink connector at the

same time may cause permanent damage to the device.

Apply power to the device only after installation is complete.

Wiring length guidelines

Refer to the following table for the wiring length information used with the NI-3101:

Wiring Guidelines - NI-3101 @ 900 mA

Wire size Maximum wiring length

18 AWG 120.41 feet (39.70 meters)

20 AWG 76.45 feet (23.30 meters)

22 AWG 49.36 feet (15.04meters)

24 AWG 30.08 feet (9.17 meters)

Preparing captive wires

You will need a wire stripper and flat-blade screwdriver to prepare and connect the captive wires.

Never pre-tin wires for compression-type connections.

1. Strip 0.25 inch (6.35 mm) of insulation off all wires.

2. Insert each wire into the appropriate opening on the connector (according to the wiring diagrams

and connector types described in this section).

3. Tighten the screws to secure the wire in the connector. Do not tighten the screws excessively. Doing

so may strip the threads and damage the connector.

12

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 19

Connections and Wiring

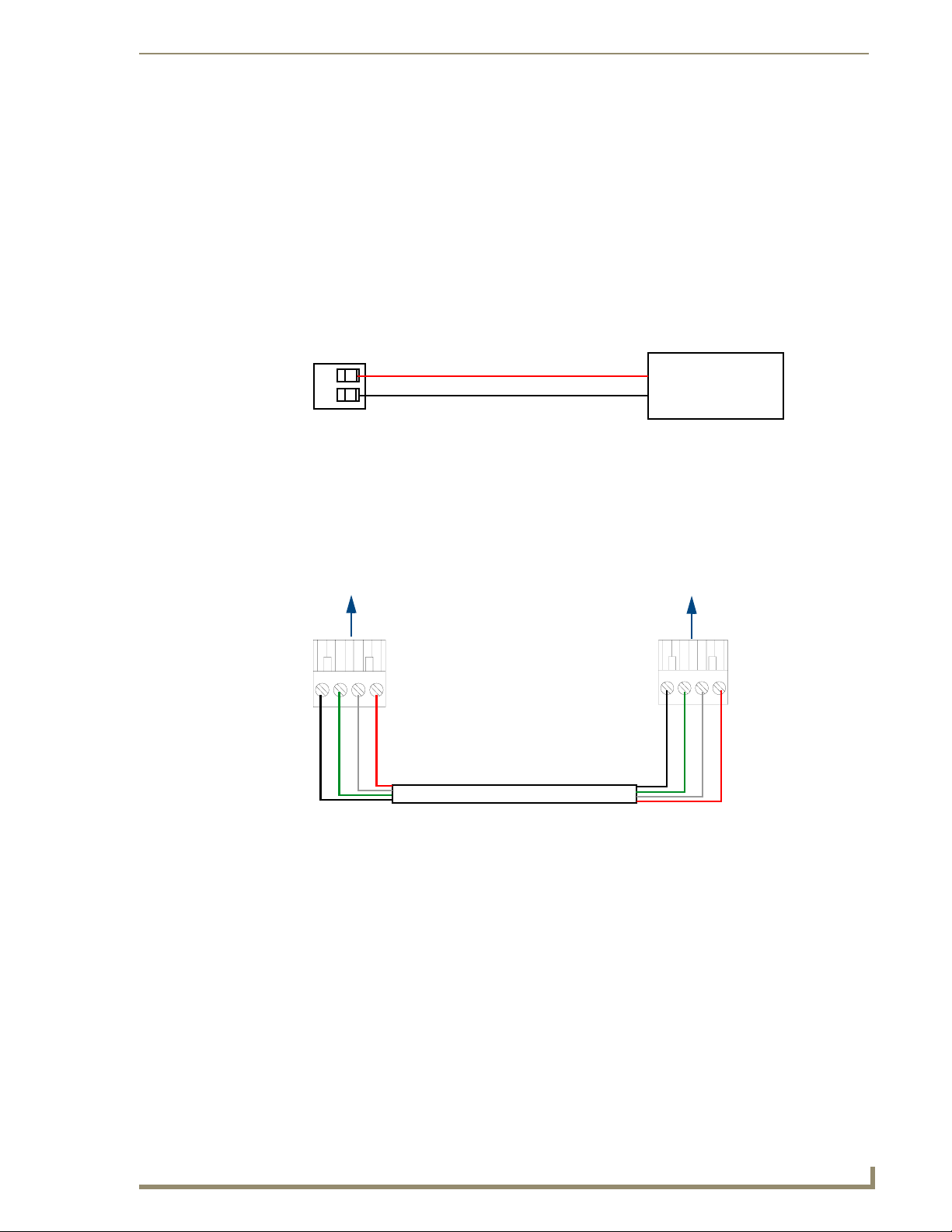

Wiring a power connection

To use the 2-pin 3.5 mm mini-Phoenix connector with a 12 VDC-compliant power supply, the incoming

PWR and GND cables from the external source must be connected to their corresponding locations on

the connector (FIG. 4).

1. Insert the PWR and GND wires on the terminal end of the 2-pin 3.5 mm mini-Phoenix cable. Match

the wiring locations of the +/- on both the power supply and the terminal connector.

2. Tighten the clamp to secure the two wires. Do not tighten the screws excessively; doing so may strip

the threads and damage the connector.

3. Verify the connection of the 2-pin 3.5 mm mini-Phoenix to the external 12 VDC-compliant power

supply.

PWR +

GND -

To the Integrated Controller

FIG. 4 2-pin mini-Phoenix connector wiring diagram (direct power)

Power Supply

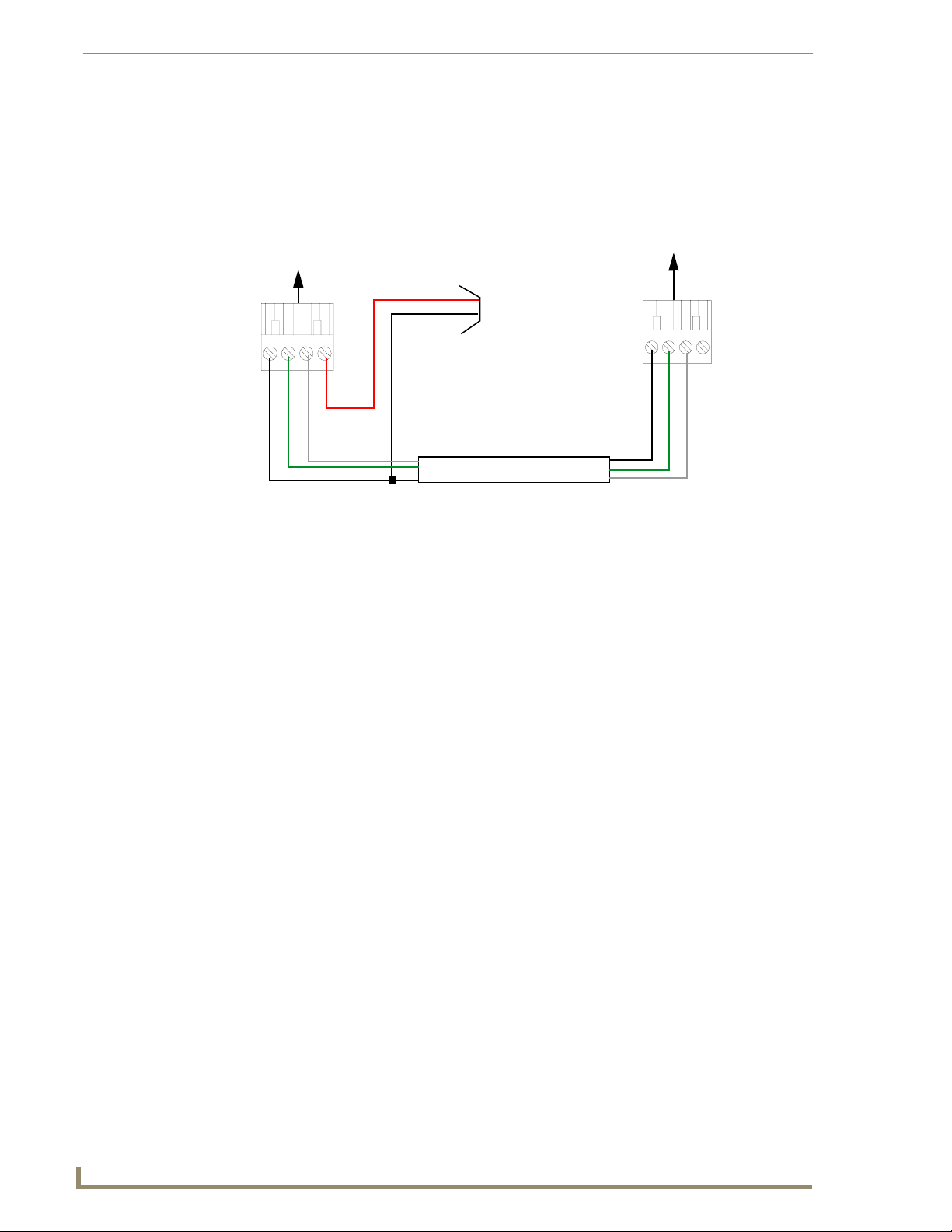

Using the 4-pin mini-Phoenix connector for data and power

Connect the 4-pin 3.5 mm mini-Phoenix (female) captive-wire connector to an external NetLinx device

as shown in FIG. 5.

To the Integrated Controller’s

AXlink/PWR connector

Top view

GND -

FIG. 5 Mini-Phoenix connector wiring diagram (direct data and power)

AXP/TX

AXM/RX

PWR +

To the external AXlink device

Top view

GND -

AXP/TX

AXM/RX

PWR +

NI-3101-SIG Signature Series NetLinx Integrated Controller

13

Page 20

Connections and Wiring

Using the 4-pin mini-Phoenix connector for data with external power

To use the 4-pin 3.5 mm mini-Phoenix (female) captive-wire connector for data communication and

power transfer, the incoming PWR and GND cable from the 12 VDC-compliant power supply must be

connected to the AXlink cable connector going to the device (FIG. 6). Always use a local power supply

to power the device.

To the Integrated Controller’s

AXlink/PWR connector

PWR (+)

GND (-)

Top view

GND -

AXM/RX

AXP/TX

FIG. 6 4-pin mini-Phoenix connector wiring diagram (using external power source)

Local +12 VDC

power supply

(coming from

an external

power supply)

To the external AXlink device

Top view

GND -

AXP/TX

AXM/RX

When you connect an external power supply, do not connect the wire from the PWR

terminal (coming from the external device) to the PWR terminal on the Phoenix

connector attached to the Controller unit. Make sure to connect only the AXM, AXP,

and GND wires to the Controller’s Phoenix connector when using an external power

supply.

Make sure to connect only the GND wire on the AXlink/PWR connector when using a separate

12 VDC power supply. Do not connect the PWR wire to the AXlink connector’s PWR (+) opening.

14

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 21

Connections and Wiring

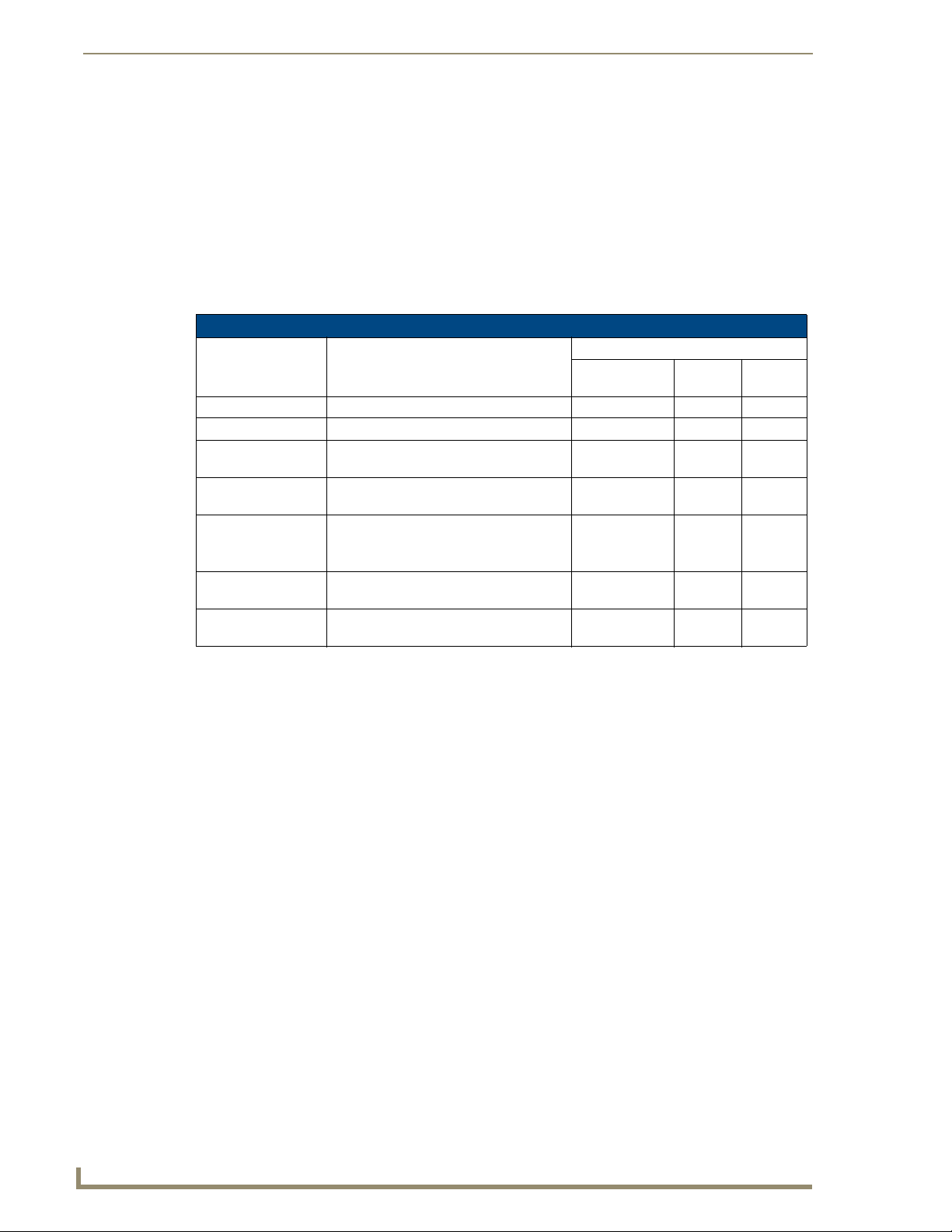

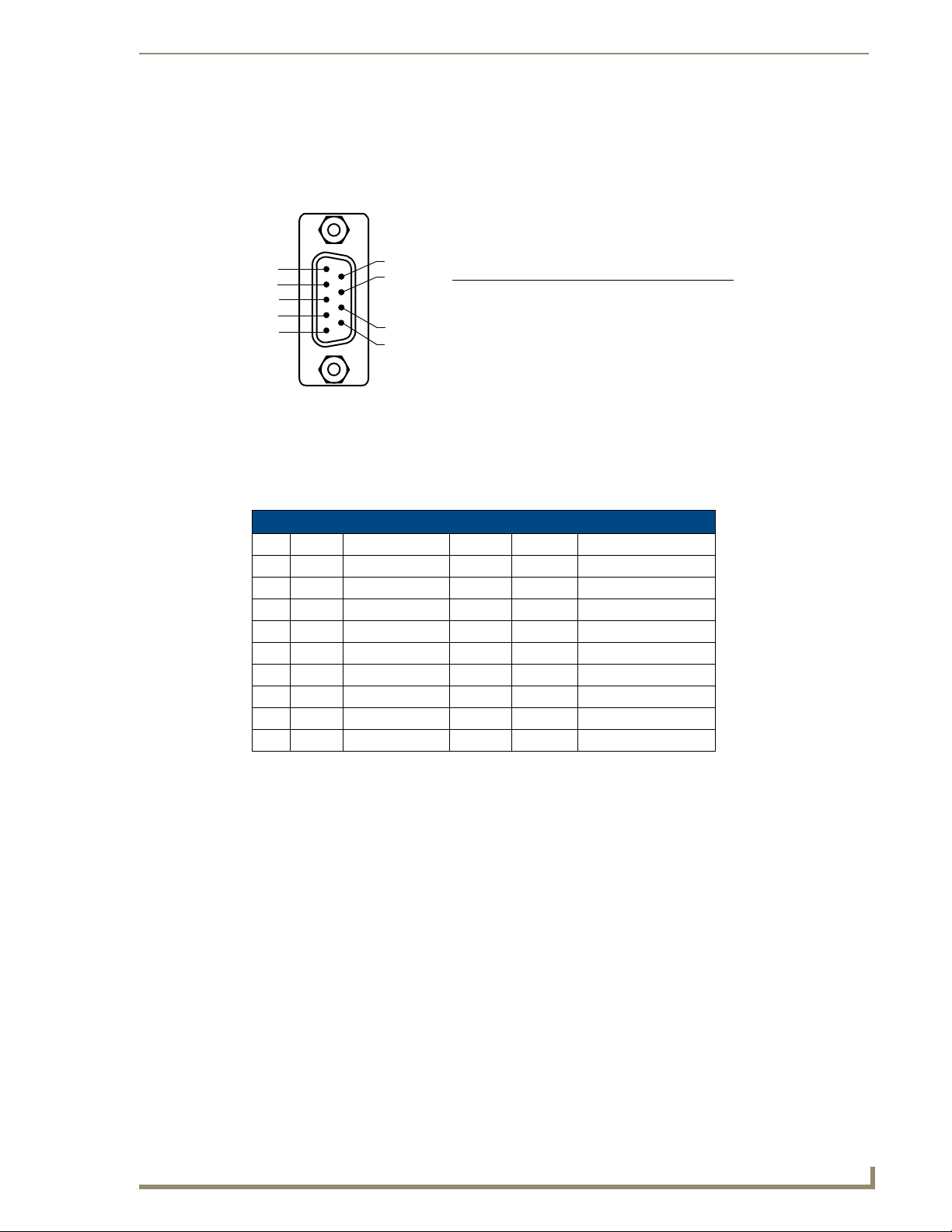

DB9 Device Port: Connections and Wiring

FIG. 7 shows the connector pinouts for the rear RS-232/RS-422/RS-485 (DB9) Device Ports. These

ports support most standard RS-232 communication protocols for data transmission. This figure gives a

visual representation of the wiring specifications for the RS-232/422/485 Device connectors.

DB9 Serial Port pinouts (male connector)

5

4

3

2

1

Male

FIG. 7 RS-232/422/485 DB9 (male) connector pinouts for the rear Device Ports

9

8

7

6

RS-232

Pin 2: RX signal

Pin 3: TX signal

Pin 5: GND

Pin 7: RTS

Pin 8: CTS

RS-422

Pin 1: RX Pin 4: TX +

Pin 5: GND

Pin 6: RX +

Pin 9: TX -

RS-485

Pin 1: A (strap to 9)

Pin 4: B (strap to 6)

Pin 5: GND

Pin 6: B (strap to 4)

Pin 9: A (strap to 1)

The table below provides information about the connector pins, signal types, and signal functions. This

table’s wiring specifications are applicable to the rear RS-232/422/485 Device Port connectors on the

NI-3101-SIG (Ports 1-6).

RS-232/422/485 Device Port Wiring Specifications

Pin Signal Function RS-232 RS-422 RS-485

1 RX- Receive data X X (strap to pin 9)

2 RXD Receive data X

3 TXD Transmit data X

4 TX+ Transmit data X X (strap to pin 6)

5 GND Signal ground X X

6 RX+ Receive data X X (strap to pin 4)

7 RTS Request to send X

8 CTS Clear to send X

9 TX- Transmit data X X (strap to pin 1)

Relay Port: Connections and Wiring

Up to 8 independent external relay devices may be connected to the Relay connectors on the device.

Connectors labeled A are for common; B are for output.

Each relay is isolated and normally open.

A metal commoning strip is supplied with each device to connect multiple relays.

NI-3101-SIG Signature Series NetLinx Integrated Controller

15

Page 22

Connections and Wiring

Relay connections

Use A for common and B for output (FIG. 8). Each relay is isolated and normally open. A metal

connector strip is also provided to common multiple relays.

RELAYS (Port 8)

6

5

3A2B1

A8B BB7A

NI-3101-SIG relay connector

FIG. 8 RELAY connector (male) NI-3101-SIG

BAA4BA

configuration (Port 8)

B

A

AB

Input/Output (I/O) Port: Connections and Wiring

The I/O port responds to either switch closures or voltage level (high/low) changes, or it can be used for

logic-level outputs.

I / O (Port 17)

78 65

+12V

NI-3101-SIG I/O connector

configuration (Port 17)

FIG. 9 INPUT/OUTPUT connector (male)

Up to eight devices may be connected to the I/O connectors on the NI-3101-SIG (FIG. 9). A contact

closure between the GND and an I/O port is detected as a Push.

When used for voltage inputs, the I/O port detects a low signal (0 - 1.5 VDC) as a Push, and a

high signal (3.5 - 5 VDC) as a Release (this IO port uses 5V logic but can handle up to 12V

without harm).

When used for outputs, the I/O port acts as a switch to GND and is rated for

200 mA @ 12 VDC. This device can use up to 8 I/O ports.

The PWR pin provides +12 VDC @ 200 mA and is designed as a power output for the PCS

Power Current Sensors, VSS2 Video Sync Sensors (or equivalent).

The GND connector is a common ground and is shared by all I/O ports. A common ground is

shared with I/O ports 1 - 8.

3

2

1

4

GND

16

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 23

Connections and Wiring

I/O Port Wiring Specifications - NI-3101-SIG

Pin Signal Function

1 GND Signal GND

2 I/O 1 Input/Output

3 I/O 2 Input/Output

4 I/O 3 Input/Output

5 I/O 4 Input/Output

6 I/O 5 Input/Output

7 I/O 6 Input/Output

8 I/O 7 Input/Output

9 I/O 8 Input/Output

10 12 VDC PWR

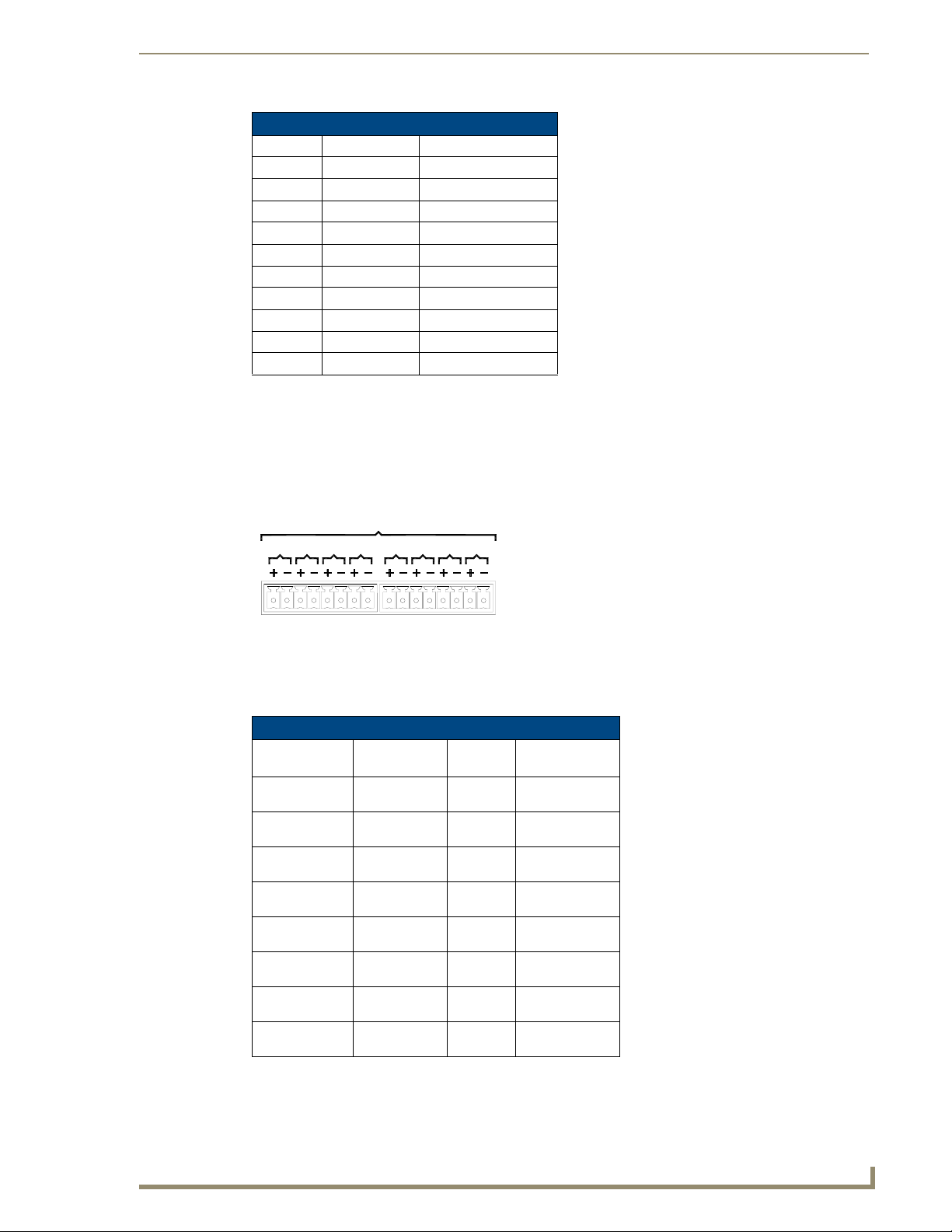

IR/Serial Port: Connections and Wiring

Up to eight IR- or Serial-controllable devices may be connected to the IR/Serial connectors on the rear

of the NI-3101 (FIG. 10). These connectors accept an IR Emitter (CC-NIRC) that mounts onto the

device's IR window, or a mini-plug (CC-NSER) that connects to the device's control jack. A data 0 - 5

VDC device may also be connected. These units come with two CC-NIRC IR Emitters (FG10-000-11).

IR / SERIAL (Ports 9-16)

8 76 45 321

NI-3101-SIG IR/Serial connector

configuration (Port 9-16)

FIG. 10

IR/SERIAL (male)

The IR/Serial connector wiring specifications are listed in the following table:

IR/Serial Connector Wiring Specifications (per Port)

Number of IR

connections

1 9 GND (-)

2 10 GND (-)

3 11 GND (-)

4 12 GND (-)

5 13 GND (-)

6 14 GND (-)

7 15 GND (-)

8 16 GND (-)

NI-3101-SIG

Port #

Signal Function

Signal 1 (+)

Signal 2 (+)

Signal 3 (+)

Signal 4 (+)

Signal 5 (+)

Signal 6 (+)

Signal 7 (+)

Signal 8 (+)

NI-3101-SIG Signature Series NetLinx Integrated Controller

17

Page 24

Connections and Wiring

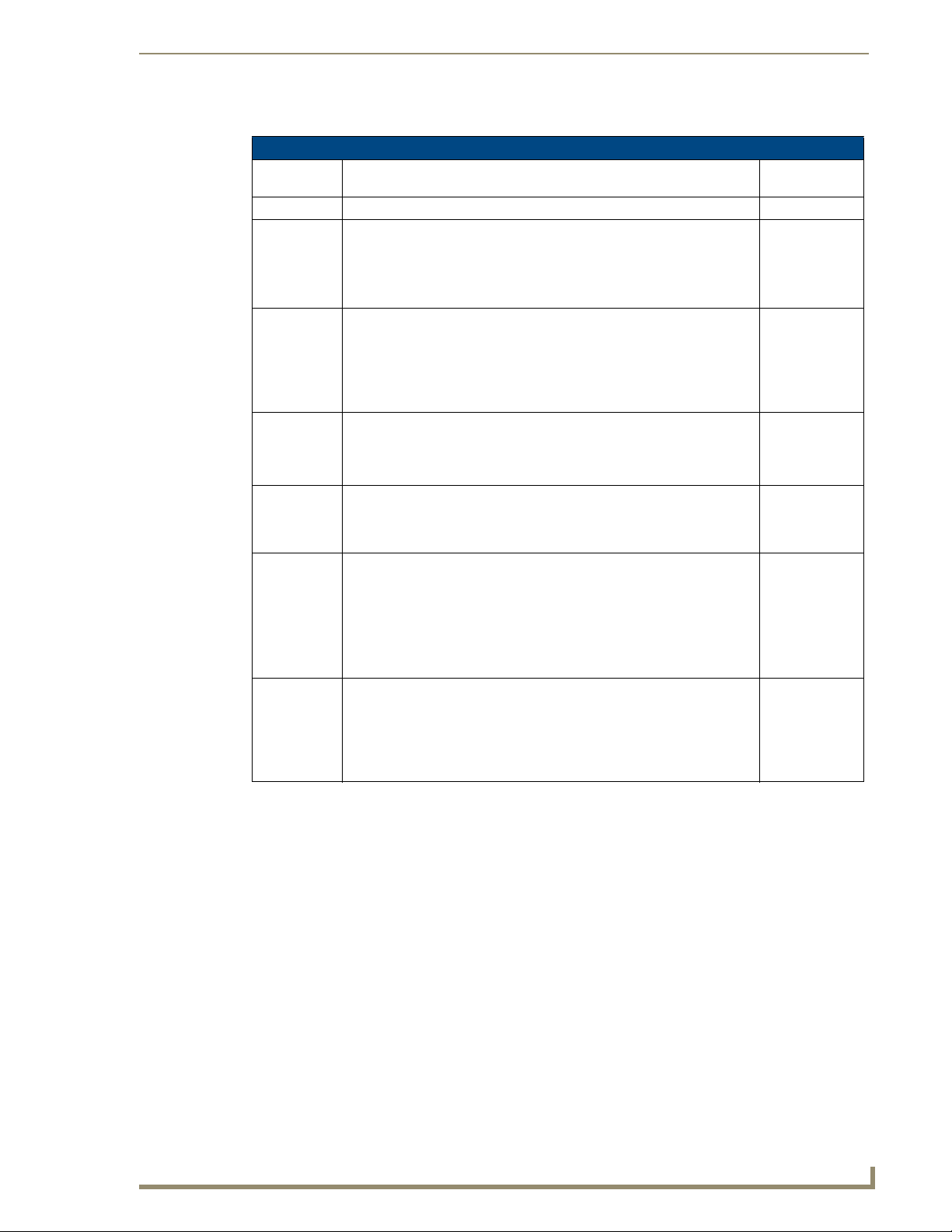

Ethernet/RJ-45 Port: Connections and Wiring

The following table lists the pinouts, signals, and pairing for the Ethernet connector.

Ethernet RJ-45 Pinouts and Signals

FIG. 11 diagrams the RJ-45 pinouts and signals for the Ethernet RJ-45 connector and cable.

Pin Signals ConnectionsPairing Color

1 TX + 1 --------- 1 1 --------- 2 Orange-White

2 TX - 2 --------- 2 Orange

3 RX + 3 --------- 3 3 --------- 6 Green-White

4 no connection 4 --------- 4 Blue

5 no connection 5 --------- 5 Blue-White

6 RX - 6 --------- 6 Green

7 no connection 7 --------- 7 Brown-White

8 no connection 8 --------- 8 Brown

12 3 45 6 78

12 3 45 6 78

FIG. 11

RJ-45 wiring diagram

Ethernet LEDs

L/A - Link/Activity LED

lights (green) when the

Ethernet cables are

connected and terminated

FIG. 12 Ethernet LEDs

correctly.

SPD - Speed LED

lights (yellow) when the

connection speed is 100 Mbps

and turns Off when speed is

10 Mbps.

ETHERNET

10/100

18

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 25

Connections and Wiring

Ethernet ports used by the Integrated Controllers

Ethernet Ports Used by the NetLinx Integrated Controllers

Port type Description Standard Port

#

FTP The on-board Master has a built-in FTP server. 21/20 (TCP)

SSH The SSH port functions using the same interface as Telnet but over a

Telnet The NetLinx Telnet server provides a mechanism to configure and

HTTP The Master has a built-in web server that complies with the HTTP 1.0

HTTPS/SSL This port is used by a web browser for secure communication between the

ICSP Peer-to-peer protocol used for both Master-to-Master and Master-to-

integration!

Solutions

secure shell where it uses SSL as a mechanism to configure and diagnose

a NetLinx system. This port value is used for secure Telnet

communication.

Note: only SSH version 2 is supported.

diagnose a NetLinx system.

For maximum flexibility, the Master can be configured to utilize a different

port than 23, or disable Telnet completely from either Telnet or the

Program port located on the rear of the Master itself. Once disabled, the

only way to enable Telnet again is from the Master’s Program port.

specification and supports all of the required features of HTTP v1.1.

This port is used for unsecure HTTP Internet communication between the

web browser’s UI and the target Master.

web server UI and the target Master. This port is also used for

simultaneous encryption of this data, using the SSL certificate information

on the Master as a key.

device communications.

For maximum flexibility, the Master can be configured to utilize a different

port than 1319, or disable ICSP over Ethernet completely from either

Telnet or the Program Port located on the rear of the Master itself.

This type of communication is used by the various AMX products for

communication amongst themselves.

This feature on the Master uses, by default, port 10500 for the XML based

communication protocol. This port is connected to by the client web

browser’s JVM when integration! Solutions control pages are retrieved

from the on-board Master’s web server.

For maximum flexibility, the on-board Master can be configured to utilize a

different port than 10500 or to disable integration! Solutions completely.

22 (TCP)

23 (TCP)

80 (TCP)

443 (TCP)

1319 (UDP/TCP)

10500 (TCP)

NI-3101-SIG Signature Series NetLinx Integrated Controller

19

Page 26

Connections and Wiring

Replacing the Timekeeper Battery

The NI-3101-SIG uses a combination lithium battery and clock crystal package called a Timekeeper.

Only one Timeke eper unit is installed within a given NI-3101-SIG. The battery can be expected to have

up to 3 years of usable life under very adverse conditions. Actual life is appreciably longer under normal

operating conditions. This calculation is based on storing the unit without power in 50° C (120° F)

temperature until battery levels are no longer acceptable. The part number for a replacement battery is

57-0032.

To replace the Timekeeper battery:

1. Discharge the static electricity from your body by touching a grounded metal object.

2. Unplug all the connectors from the device.

3. Remove the rear panel from the device, and then disconnect the NXI control cable and remove the

4. Locate the battery behind the Configuration Port on the circuit board.

5. Carefully slide the battery out of its socket and insert the new battery.

6. Plug the 2-pin 3.5 mm mini-Phoenix PWR (green) connector to reapply power. Wait approximately

7. Carefully slide the other battery out of its socket and insert the new battery

8. Re-connect the NXI control cable to the Master card.

9. Replace and secure the rear faceplate using the mounting screws and reconnect all communication

10. Reconnect the 12 VDC power supply to the respective PWR connector and apply power.

Master card.

1 minute, then remove the PWR connector again.

connectors.

20

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 27

Configuration and Firmware Update

Configuration and Firmware Update

This section refers to steps necessary to both communicate with and upgrade the NI-3101-SIG.

Before continuing, verify that you are using the latest version of NetLinx Studio

and the latest firmware Kit file (this file contains both the NI Integrated

Controller and on-board Master firmware).

The NI-3101-SIG Kit file begins with 2105_04_X100.

Before beginning:

1. Set up and configure the NI-3101-SIG. Refer to the previous Installation and Upgrading section.

2. Verify that the latest version of NetLinx Studio has been installed on the PC. If an update is

necessary, download the latest NetLinx Studio software from www.amx.com.

3. If the Ethernet port will be used for programming, verify that an Ethernet cable connects the

Controller to the PC being used for programming or to a network on the same subnet as the PC.

4. The low-speed USB connection is not recommended for firmware updates.

5. Verify that the NetLinx Master is receiving power and is turned ON. Refer to the previous

Connections and Wiring section on page 9 for more information.

If if communication has already been set up with the Controller via an IP Address,

continue with the firmware update procedures outlined in the Communicating with the

NI Device via an IP section on page 31.

NI-3101-SIG Signature Series NetLinx Integrated Controller

21

Page 28

Configuration and Firmware Update

Communicating with the Master via the Program Port

1. From your computer, launch NetLinx Studio 2.x.

2. Select Settings > Master Communication Settings, from the Main menu, to open the Master

Communication Settings dialog box (FIG. 13).

FIG. 13 Master Communication Settings dialog box

3. Click the Communications Settings button to open the Communications Settings dialog (FIG. 14).

FIG. 14 Communication Settings dialog box

4. Click the NetLinx Master radio button (from the Platform Selection section) to choose a NetLinx

Master such as the NI-3101-SIG.

5. Click the Serial radio button (from the Transport Connection Option section) to select

communication to the on-board Master via a (Serial) COM port.

6. Click the Edit Settings button to open the Serial Settings dialog (FIG. 15).

FIG. 15 Serial Settings dialog box

22

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 29

Configuration and Firmware Update

No authentication username or password information is required when selecting a

direct connection such as USB or Serial.

7. Set the COM port parameters for the selected COM port used for communication to the NetLinx

Master. Default parameters are:

COM1

115200

8 Data Bits

No Parity

1 Stop Bit

No Flow Control

If communication fails on a known COM port, change the baud rate to 115200 and try again.

8. Click OK three times to close the open dialogs and save the chosen settings.

If the connection fails to establish, select a different COM port, press the Retry button

to reconnect using the same communication parameters, or press the Change button

to alter your communication parameters and repeat steps 2 thru 8.

Setting the System Value

1. Access/open the Device Addressing dialog (FIG. 16) by either one of these two methods:

Right-click on any System item listed (such as the NI Master entry) in the OnLine Tree tab of

the Workspace and select Device Addressing (from the popup list).

Select Diagnostics > Device Addressing from the Main menu.

This process should be done while communicating to the Master via a Serial

connection.

System Address

(default for initial

system is 1)

Check-Off to

verify change

FIG. 16 Device Addressing tab (changing the system value)

NI-3101-SIG Signature Series NetLinx Integrated Controller

23

Page 30

Configuration and Firmware Update

This tab represents the only way to change the System Number associated to the

active on-board NI Master. The Master must have its power cycled to incorporate

the new System number, as often a simple reboot via Studio will not be enough

to incorporate this new number).

2. Select the Change System selection box from the System to Change section.

3. Enter both the current and new system address values.

4. Click the Change Device/System Number button. This configures the Master to accept the new

value and incorporate the information. The system information in the OnLine Tree tab of the

Workspace window refreshes and then displays the new information.

5. Click Done to close the Device Addressing dialog and return to the main program.

6. Click Reboot (from the Tools > Reboot the Master Controller dialog) and wait for the System

Master to reboot. The STATUS and OUTPUT LEDs should begin to alternately blink during the

incorporation. Wait until the STATUS LED is the only LED to blink.

7. Press Done once until the Master Reboot Status field reads *Reboot of System Complete*.

8. Click the OnLine Tree tab in the Workspace window to view the devices on the System. The

default System value is 1.

9. Right-click the associated System number (or anywhere within the tab itself) and select Refresh

System. This establishes a new connection to the specified System and populates the list with

devices on that system.

10. Use Ctrl+S to save your existing NetLinx Project with the new changes.

If the NetLinx device does not appear within the OnLine Tree tab, make sure that the

Integrated Controller’s on-board Master System Number (from within the Device

Addressing tab) is correctly assigned.

If there is a problem, use a system value of zero (0) on the NetLinx device.

The Master is set by default to DEVICE 0. Connected NetLinx device addresses

can only be changed through the Protected Setup page. The new address is

reflected within the OnLine Tree tab of the Workspace window only after the devices

are rebooted and the system is refreshed.

The system value on a Modero touch panel cannot be changed from the Device

Addressing dialog box and MUST be altered through the panel Protected Setup

page.

Using multiple NetLinx Masters

When using more than one Master, each unit must be assigned to a separate System value.

A Master’s System value can be changed but its device Address must always be set to zero (00000).

The Device Addressing dialog will not allow you to alter the NetLinx Master address value.

Example: Using NetLinx Studio v 2.x to work with an NXC-ME260/64 and NI-3101-SIG:

The NXC-ME260/64 could be assigned to System 1 (with a value of 00000).

The NI-3101-SIG could be assigned to System 2 (with a value of 00000).

24

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 31

Configuration and Firmware Update

Changing the Device Address of a NetLinx Device

1. Access the Device Addressing dialog (FIG. 17) by either one of these two methods:

Right-click on any system device (such as a Modero panel) listed in the OnLine Tree tab of

the Workspace and select Device Addressing (from the popup list).

Select Diagnostics > Device Addressing from the Main menu.

Device Address

(original device

FIG. 17 Device Addressing dialog (changing the device value)

value)

Check-Off to

verify change

Enter new

device value

This dialog represents the only way to change the device value of a selected NetLinx

device. Modero panels are one of the only devices that can have their Device values

changed within both this dialog and through the on-board firmware page.

2. Select the Change Device checkbox from the Device to Change section.

3. Ver i f y t h e Current value and enter the New Device value for the target NetLinx device.

4. Click the Change Device/System Number button. This configures the specified Master to accept

the new value for the NetLinx device and incorporate the information (the system information in the

Workspace window refreshes and then displays the new information).

5. Click Done to close the Device Addressing dialog.

6. Click Reboot (from the Tools > Reboot the Master Controller dialog) and wait for the System

Master to reboot. The STATUS and OUTPUT LEDs should begin to alternately blink during the

incorporation. Wait until the STATUS LED is the only LED to blink.

7. Press Done once until the Master Reboot Status field reads *Reboot of System Complete*.

8. Click the OnLine Tree tab in the Workspace window to view the devices on the System.

The default System value is one (1).

9. Right-click the associated System number (or anywhere within the tab itself) and select Refresh

System. This establishes a new connection to the specified System and populates the list with

devices on that system.

10. Use Ctrl+S to save your existing NetLinx Project with the new changes.

If the Master does not appear in the Workspace window, make sure that the Master’s

System Number (from within the Device Addressing tab) is correctly assigned. If this

issue persists, use a system value of zero (0) on the Master.

NI-3101-SIG Signature Series NetLinx Integrated Controller

25

Page 32

Configuration and Firmware Update

Recommended NetLinx Device numbers

• 1 - 255 • Axcess Devices use Axcess standards

• 301 - 3072 • NetLinx CardFrames start at frame number 25 - (frame# * 12) + Card #

• 5001 - 5999 • ICSNet NetLinx devices: NXI, NXM-COM2, NXM-IRS4, etc.

• 6001 - 6999 • ICSNet Landmark devices: PLH-VS8, PLH-AS16, PLB-AS16

• 7001 - 7999 • InConcert Devices

• 8001 - 8999 • PCLink Device: PCLink devices are PC programs

• 10000 - 31999 • ICSNet Panels: DMS, IMS, and future panels

• 33001 - 36863 • Virtual devices: these start at 33001

• 32001 - 32767 • Dynamic devices: the actual range used by Master

• 32768 - 36863 • Virtual devices: the actual range used by Master

Using the ID Button to Change the Controller’s Device Value

1. Access the Device Addressing dialog (FIG. 18) by selecting Diagnostics > Device Addressing

from the Main menu.

Enter the new Controller value

Assign the

new value to

the Controller

FIG. 18

A

Device Addressing dialog (using the ID mode to set the NI Controller device value)

B

This dialog represents the another way to change the Device value of the NI

Controller. This ID mode section of the Device Addressing dialog can be used only by

Masters with an ID button (which apply to all NI-Series Masters).

2. Locate the Device field (A in FIG. 18) and enter the new value for the NI Controller. This value

must fall within a range of 0 - 32767.

3. Press the on-screen Start Identify Mode button.

This action causes a previously red *Not Active* field to now display a green Waiting...Press

Cancel to Quit field.

This green field indicates that Studio is waiting to detect the device value of the NI Controller

associated with the ID button on the target NI.

26

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 33

Configuration and Firmware Update

4. Press the target NI device’s ID button to begin process of reading the current device value of the NI

Controller and then assigning it to the new value entered in step 2.

Once the swap has been made, a red Successful Identification Made field appears.

The previous Device value and associated System number of the targeted NI Controller are

then displayed below the red field. For example, the display might show Previous

D:S=32002:1, where 32002 was the previous device value of the Controller (D) and 1 was the

on-board Master’s System value (S).

Resetting the Factory Default System and Device Values

1. Access the Device Addressing dialog (FIG. 17 on page 25) by either one of these two methods:

Right-click on any system device listed in the Workspace and select Device Addressing.

Select Diagnostics > Device Addressing from the Main menu.

2. Click the Set Device/System to Factory Default button. This resets both the system value and

device addresses (for definable devices) to their factory default settings. The system information (in

the OnLine Tree tab of the Workspace window) refreshes and then displays the new information.

By setting the system to its default value (#1), Modero panels that were set to

connect to the Master on another System value will not appear in the OnLine Tree

tab of the Workspace window.

For example: A Modero touch panel was previously set to System #2. The system is

then reset to its default setting of System #1 and then refreshed from within the

Workspace window. The panel will not reappear until the system is changed (from

within the System Connection page on the Modero) to match the new value and both

the Master and panel are rebooted.

3. Click Done to close the Device Addressing dialog.

4. Click Reboot (from the Tools > Reboot the Master Controller dialog) and wait for the System

Master to reboot. The STATUS and OUTPUT LEDs should begin to alternately blink during the

incorporation. Wait until the STATUS LED is the only LED to blink.

5. Press Done once until the Master Reboot Status field reads *Reboot of System Complete*.

6. Click the OnLine Tree tab in the Workspace window to view the devices on the System. The default

System value is one (1).

7. Right-click the associated System number (or anywhere within the tab itself) and select Refresh

System. This establishes a new connection to the specified System and populates the list with

devices on that system.

8. Use Ctrl+S to save the existing NetLinx Project with the new changes.

NI-3101-SIG Signature Series NetLinx Integrated Controller

27

Page 34

Configuration and Firmware Update

Obtaining the Master’s IP Address (using DHCP)

Verify there is an active Ethernet connection on the Ethernet port of the

NI-Series Controller before beginning these procedures.

1. Select Diagnostics > Network Addresses from the Main menu to access the Network Addresses

dialog (FIG. 19).

System Address

reflects the value

set in the Device

Addressing tab

Used to obtain a

Dynamic

IP Address

FIG. 19 Network Addresses dialog (for a DHCP IP Address)

2. Verify that both the System number corresponds to the System value previously assigned within the

Device Addressing tab and that zero (0) is entered into the Device field.

The system value must correspond to the Device Address entered in the Device

Addressing dialog. Refer to the Setting the System Value section on page 23 for

more detailed instructions on setting a system value.

3. Click the Get IP Information button to configure the on-board Master for DHCP usage and then

read the IP Address obtained from the DHCP Server.

DO NOT enter ANY IP information at this time; this step only gets the System Master

to recognize that it should begin using an obtained DHCP Address.

4. Note the obtained IP Address (greyed-out and read-only). This information is later entered into the

Master Communication Settings dialog and used by NetLinx Studio v 2.x to communicate to the

Master via an IP. This address is reserved by the DHCP server and then given to the Master.

If the IP Address field is empty, give the Master a few minutes to negotiate a

DHCP Address with the DHCP Server, and try again. The DHCP Server can take

anywhere from a few seconds to a few minutes to provide the Master with an IP

Address.

5. Ver i f y t h a t NetLinx appears in the Host Name field (if not, then enter it in at this time).

6. Click the Use DHCP radio button from the IP Address section (if not greyed-out).

7. Click the Set IP Information button to retain the IP Address from the DHCP server and assign it to

the on-board Master. A popup window then appears to notify you that Setting the IP information

was successful and it is recommended that the Master be rebooted.

8. Click OK to accept the change to the new IP/DNS information.

9. Click the Reboot Master button and select Ye s to close the Network Addresses dialog.

28

NI-3101-SIG Signature Series NetLinx Integrated Controller

Page 35

Configuration and Firmware Update

10. Click Reboot from the Tools > Reboot the Master Controller dialog, and wait for the System

Master to reboot and retain the newly obtained DHCP Address. The STATUS and OUTPUT LEDs

should begin to blink alternately during the incorporation. Wait until the STATUS LED is the only

LED blinking.

11. Press Done once until the Master Reboot Status field reads *Reboot of System Complete*.

Verify that these IP values are also entered into the related fields within either the

IP Settings section of the System Connection page (on the touch panel) or within the

Address field on the web browser.

12. Complete the communication process by continuing on to the Communicating with the NI Device

via an IP section on page 31.

NI-3101-SIG Signature Series NetLinx Integrated Controller

29

Page 36

Configuration and Firmware Update

Assigning a Static IP to the NetLinx Master

Verify that the Controller has an active Ethernet connection before beginning

these procedures.

1. Select Diagnostics > Network Addresses from the Main menu to access the Network Addresses

dialog (FIG. 20).

System Address

reflects the value

set in the Device

Addressing tab

Used to retain an

IP Address

FIG. 20 Network Addresses dialog (for a pre-obtained Static IP Address)

2. Verify that both the System number corresponds to the System value previously assigned within the

Device Addressing tab and that zero (0) is entered into the Device field.

The system value must correspond to the Device Address previously entered in the

Device Addressing tab. Refer to the Setting the System Value section on page 23 for

more detailed instructions on setting a system value.

3. Click the Get IP Information button to temporarily configure the on-board Master for DHCP usage

and then read the IP Address obtained from the DHCP Server.

4. Click the Specify IP Address radio button from the IP Address section. With this action, all IP

fields become editable.

5. Ver i f y t h a t NetLinx appears in the Host Name field. If not, then enter it in at this time.

6. Enter the IP Address, Subnet Mask, and Gateway information into their respective fields.

7. Click the Set IP Information button to cause the on-board Master to retain the new IP Address

pre-obtained from the System Administrator.

8. Click OK to accept the change to the new IP/DNS information.

9. Click the Reboot Master button and select Ye s to close the Network Addresses dialog.

10. Click Reboot from the Tools > Reboot the Master Controller dialog, and wait for the System

Master to reboot and retain the newly obtained DHCP Address. The STATUS and OUTPUT LEDs

should begin to blink alternately during the incorporation. Wait until the STATUS LED is the only

LED blinking.

11. Press Done once until the Master Reboot Status field reads *Reboot of System Complete*.

30

Verify that these IP values are also entered into the related fields within either the IP