Page 1

INSTRUCTION MANUAL

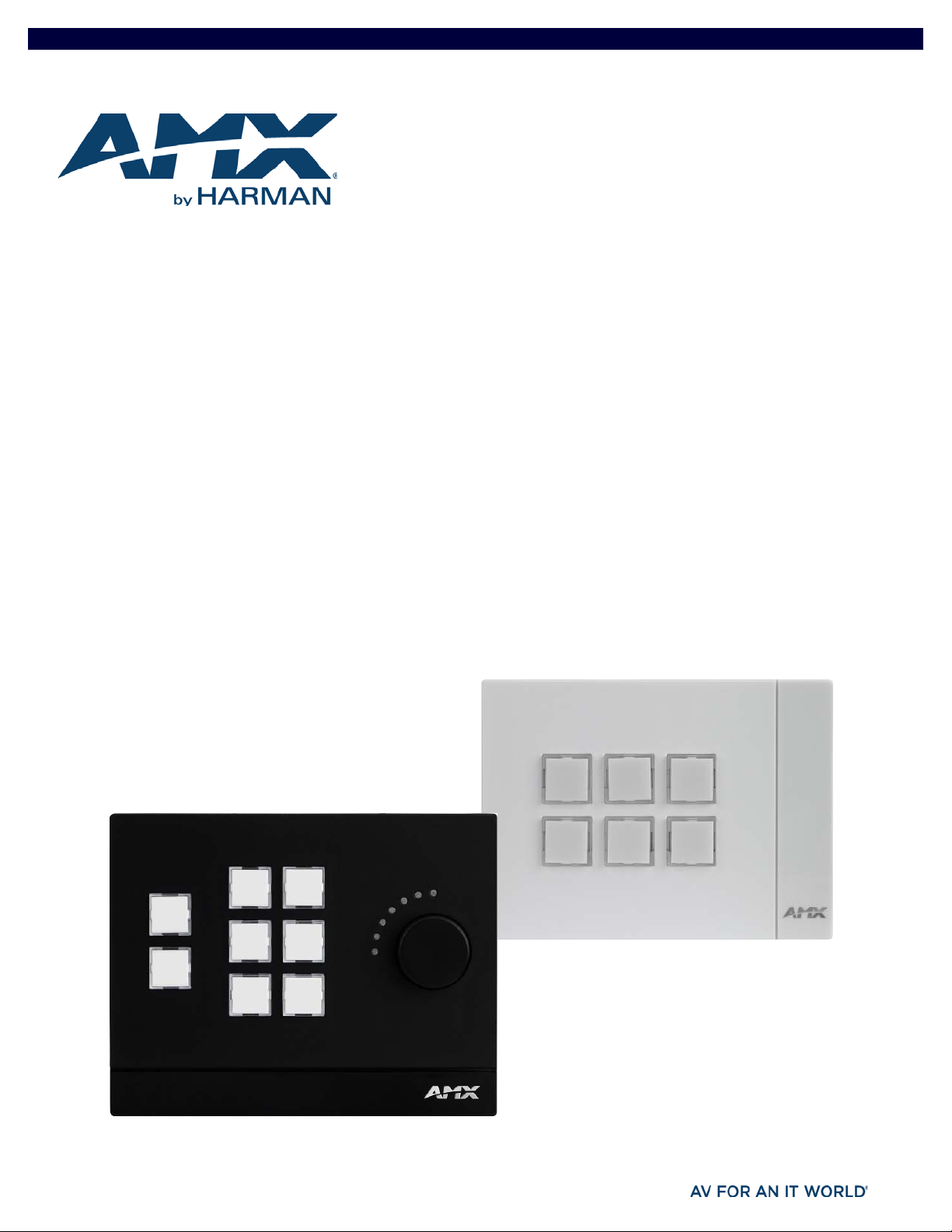

MASSIO CONTROLPADS AND KEYPADS

MCP-106, MCP-108, MKP-106, MKP-108

Page 2

IMPORTANT SAFETY INSTRUCTIONS

1. READ these instructions.

2. KEEP these instructions.

3. HEED all warnings.

4. FOLLOW all instructions.

5. DO NOT use this apparatus near water.

6. CLEAN ONLY with dry cloth.

7. DO NOT block any ventilation openings. Install in accordance with the manufacturer's instructions.

8. DO NOT install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that

produce heat.

9. DO NOT defeat the safety purpose of the polarized or grounding type plug. A polarized plug has two blades with one wider than the

other. A grounding type plug has two blades and a third grounding prong. The wider blade or the third prong are provided for your

safety. If the provided plug does not fit into your outlet, consult an electrician for replacement of the obsolete outlet.

10. PROTECT the power cord from being walked on or pinched, particularly at plugs, convenience receptacles, and the point where

they exit from the apparatus.

11. ONLY USE attachments/accessories specified by the manufacturer.

12. USE ONLY with a cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the apparatus. When a cart is

used, use caution when moving the cart/apparatus combination to avoid injury from tip-over.

13. UNPLUG this apparatus during lightning storms or when unused for long periods of time.

14. REFER all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as

power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

15. DO NOT expose this apparatus to dripping or splashing and ensure that no objects filled with liquids, such as vases, are placed on

the apparatus.

16. To completely disconnect this apparatus from the AC Mains, disconnect the power supply cord plug from the AC receptacle.

17. Where the m ains plug or an appliance coupler is used as the disco nnect device, the disconnect device shal l remain readily operable.

18. DO NOT overload wall outlets or extension cords beyond their rated capacity as this can cause electric shock or fire.

The exclamation point, within an equilateral triangle, is intended to alert the user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the product.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the presence of uninsulated "dangerous

voltage" within the product's enclosure that may be of suff icient magnitude to constitute a risk of electrical shock to persons.

ESD Warning: The icon to the left indicates text regarding potential danger associated with the discharge of static electricity from an outside

source (such as human hands) into an integrated circuit, often resulting in damage to the circuit.

WARNING: To reduce the risk of f ire or electrical shock, do not expose this apparatus to rain or moisture.

WARNING: No naked flame sources - such as candles - should be placed on the product.

WARNING: Equipment shall be connected to a MAINS socket outlet with a protective earthing connection.

COPYRIGHT NOTICE

AMX© 2015, all rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of AMX. Copyright protection claimed

extends to AMX hardware and software and includes all forms and matters copyrightable material and information now allowed by statutory or judicial

law or herein after granted, including without limitation, material generated from the software programs which are displayed on the screen such as

icons, screen display looks, etc. Reproduction or disassembly of embodied computer programs or algorithms is expressly prohibited.

LIABILITY NOTICE

No patent liability is assumed with respect to the use of information contained herein. While every precaution has been taken in the preparation of this

publication, AMX assumes no responsibility for error or omissions. No liability is assumed for damages resulting from the use of the information

contained herein. Further, this publication and features described herein are subject to change without notice.

AMX WARRANTY AND RETURN POLICY

The AMX Warranty and Return Policy and related documents can be viewed/downloaded at www.amx.com.

Page 3

3

Instruction Manual - Massio ControlPads and Keypads

ESD WARNING

To avoid ESD (Electrostatic Discharge) damage to sensitive components, make sure you are properly grounded before

touching any internal materials.

When working with any equipment manufactured with electronic devices, proper ESD grounding procedures must be

followed to make sure people, products, and tools are as free of static charges as possible. Grounding straps, conductive

smocks, and conductive work mats are specifically designed for this purpose. These items should not be manufactured

locally, since they are generally composed of highly resistive conductive materials to safely drain static discharges, without

increasing an electrocution risk in the event of an accident.

Anyone performing f ield maintenance on AMX equipment should use an appropriate ESD f ield service kit complete with at

least a dissipative work mat with a ground cord and a UL listed adjustable wrist strap with another ground cord

WARNING: Do Not Open! Risk of Electrical Shock. Voltages in this equipment are

hazardous to life. No user-serviceable parts inside. Refer all servicing to qualified

service personnel.

Place the equipment near a main power supply ou tlet and make sure that you can

easily access the power breaker switch.

WARNING: This product is intended to be operated ONLY from the voltages listed on the back panel or the recommended, or

included, power supply of the product. Operation from other voltages other than those indicated may cause irreversible

damage to the product and void the products warranty. The use of AC Plug Adapters is cautioned because it can allow the

product to be plugged into voltages in which the product was not designed to operate. If the product is equipped with a

detachable power cord, use only the type provided with your product or by your local distributor and/or retailer. If you are

unsure of the correct operational voltage, please contact your local distributor and/or retailer.

FCC AND CANADA EMC COMPLIANCE INFORMATION:

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

Approved under the verification provision of FCC Part 15 as a Class B Digital Device.

Caution: Changes or modifications not expressly approved by the manufacturer could void the user's authority to operate this

devi ce.

CAN ICES-3 (B)/NMB-3(B)

EU COMPLIANCE INFORMATION:

Eligible to bear the CE mark; Conforms to European Union Low Voltage Directive 2006/95/EC; European Union EMC Directive

2004/108/EC; European Union Restriction of Hazardous Substances Recast (RoHS2) Directive 2011/65/EU; European Union

WEEE (recast) Directive 2012/19/EU.

You may obtain a free copy of the Declaration of Conformity by visiting http://www.amx.com/techcenter/certifications.asp.

WEEE NOTICE:

This appliance is labeled in accordance with European Directive 2012/19/EU concerning waste of electrical and electronic

equipment (WEEE). This label indicates that this product should not be disposed of with household waste. It should be

deposited at an appropriate facility to enable recovery and recycling.

Page 4

Table o f C o n t e n ts

4

Instruction Manual - Massio ControlPads and Keypads

Table of Contents

Overview - Massio ControlPads .........................................................................7

Features .................................................................................................................................................. 7

Port Assignments by Massio ControlPad ............................................................................................... 7

Specifications .................................................................................................................... 8

MCP-106 ................................................................................................................................................. 8

MCP-108 ................................................................................................................................................. 9

Overview - Massio Keypads .............................................................................10

Specifications ................................................................................................................. 10

MKP-106 ............................................................................................................................................... 10

MKP-108 ............................................................................................................................................... 11

Wiring and Device Connections ......................................................................12

Overview ......................................................................................................................... 12

Control Ports and Indicators.......................................................................................... 13

RS-232 .................................................................................................................................................. 13

RELAYS .................................................................................................................................................. 13

I/O......................................................................................................................................................... 14

IR/Serial ............................................................................................................................................... 14

LAN (RJ-45)........................................................................................................................................... 15

Applying Power................................................................................................................................................... 15

ID Pushbutton....................................................................................................................................... 16

Installation ......................................................................................................18

Overview ......................................................................................................................... 18

Mounting Procedures ..................................................................................................... 18

Wallbox Mounting ................................................................................................................................. 18

Button Labeling ...............................................................................................20

Overview ......................................................................................................................... 20

Installing Acetate Button Labels.................................................................................... 20

Disassembling the Massio Device................................................................................... 21

Re-Assembling the Massio Device................................................................................... 22

Initial Configuration ........................................................................................23

Massio ControlPads......................................................................................................... 23

Before You Start.................................................................................................................................... 23

Obtaining the ControlPad’s IP Address ................................................................................................ 23

Changing the ControlPad’s Network Address Information.................................................................. 24

Connecting to the ControlPad via USB ................................................................................................. 25

Toggling Between IP Addressing Modes: DHCP and Static IP ............................................................. 26

Configuration and Programming .......................................................................................................... 26

Programming...................................................................................................................................................... 26

Page 5

Table o f C o n t e n ts

5

Instruction Manual - Massio ControlPads and Keypads

WebConsole........................................................................................................................................................ 26

Accessing the WebConsole ................................................................................................................................ 26

Default User Names and Passwords................................................................................................................... 27

Massio Keypads.............................................................................................................. 27

Locating the IP Address of the Keypad ................................................................................................ 27

Toggling Between IP Addressing Modes: DHCP and Static IP ............................................................. 27

Upgrading Firmware .......................................................................................28

Overview .......................................................................................................................... 28

Massio ControlPads - Firmware Files ................................................................................................... 28

Master Firmware..................................................................................................................................................................... 28

Device Controller Firmware.................................................................................................................................................... 28

Before You Start .............................................................................................................. 28

Verifying the Current Firmware Version ......................................................................... 28

Downloading the Latest Firmware Files from www.amx.com ......................................... 29

NetLinx Controllers ............................................................................................................................... 29

Master and Device Firmware Kit Files for Massio ControlPads .......................................................................... 29

Downloading Massio ControlPad Firmware Files on www.amx.com.................................................................. 29

Required Order of Firmware Updates ............................................................................. 29

Upgrading Firmware via NetLinx Studio ........................................................................ 30

Resetting the Factory Default System and Device Values............................................... 32

Programming ..................................................................................................33

Programming the Massio ControlPads and Keypads...................................................... 33

Button Layouts...................................................................................................................................... 33

Channels ............................................................................................................................................... 33

Port Assignments by Massio ControlPad ............................................................................................. 33

Port Numbers and Levels (ControlPads) .............................................................................................. 34

Port Numbers and Levels (Keypads) .................................................................................................... 34

Programming the Knob and LED Bargraph (MCP/MKP-108)............................................................... 34

Knob - Button 11................................................................................................................................... 34

Knob - Buttons 12-13 ........................................................................................................................... 34

Navigation Wheel - Level Control ......................................................................................................... 34

Display Bargraph .................................................................................................................................. 34

Supported SEND_LEVELs ...................................................................................................................... 34

SEND_LEVEL........................................................................................................................................................................... 34

Supported SEND_COMMANDs............................................................................................................... 35

@BRT ...................................................................................................................................................................................... 35

BMODE .................................................................................................................................................................................... 35

?EXPANSION........................................................................................................................................................................... 35

LED-DIS................................................................................................................................................................................... 35

Terminal (Telnet) Commands ......................................................................................... 36

Establishing a Terminal Connection via Telnet .................................................................................... 36

LED-EN .................................................................................................................................................................................... 36

REBOOT................................................................................................................................................................................... 36

SET_NDX_DESC....................................................................................................................................................................... 36

Telnet User Name and Password.......................................................................................................... 37

Page 6

Table o f C o n t e n ts

6

Instruction Manual - Massio ControlPads and Keypads

Additional Notes ................................................................................................................................... 37

Setting a Telnet User Name and Password .......................................................................................... 37

Telnet Commands ........................................................................................................... 38

? or Help.................................................................................................................................................................................. 38

DEVICE STATUS ...................................................................................................................................................................... 38

EXIT ........................................................................................................................................................................................ 38

FACTORYFWIMAGE................................................................................................................................................................. 38

GET CONFIG............................................................................................................................................................................ 38

GET CONNECTION................................................................................................................................................................... 38

GET DEVICE............................................................................................................................................................................. 38

GET DNS .................................................................................................................................................................................. 39

GET ETHERNET MODE ............................................................................................................................................................. 39

GET FRIENDLY <name>.......................................................................................................................................................... 39

GET IP ..................................................................................................................................................................................... 39

GET LOCATION........................................................................................................................................................................ 39

GET SN .................................................................................................................................................................................... 39

INFO........................................................................................................................................................................................ 39

MSG [ON|OFF] ......................................................................................................................................................................... 39

NDP UNBIND ........................................................................................................................................................................... 39

PING [ADDRESS]..................................................................................................................................................................... 39

REBOOT................................................................................................................................................................................... 39

RENEW DHCP ......................................................................................................................................................................... 40

RESET FACTORY..................................................................................................................................................................... 40

SET CONNECTION .................................................................................................................................................................. 40

SET DEVICE ............................................................................................................................................................................ 40

SET DNS ................................................................................................................................................................................. 40

SET ETHERNET MODE............................................................................................................................................................. 40

SET FRIENDLY ........................................................................................................................................................................ 41

SET IP .................................................................................................................................................................................... 41

SET LOCATION ....................................................................................................................................................................... 41

SET TELNET PORT .................................................................................................................................................................. 41

SET TELNET USERNAME......................................................................................................................................................... 41

SET TELNET PASSWORD ........................................................................................................................................................ 41

SHOW CONNECTION LOG....................................................................................................................................................... 41

Notes on Specific Telnet Clients..................................................................................... 42

Windows Client Programs .................................................................................................................... 42

Linux Telnet Client ................................................................................................................................ 42

Enabling/Disabling Telnet on the Keypad...................................................................... 42

SHOW CONNECTION STATS................................................................................................................................................... 42

SHOW LOG.............................................................................................................................................................................. 42

Page 7

7

Instruction Manual - Massio ControlPads and Keypads

Overview - Massio ControlPads

MCP-108

MCP-106 (Landscape)

The Massio MCP-106 (FG2102-06) and MCP-108 (FG2102-08) ControlPads each feature built-in Ethernet ports and combine a

controller with a 6- or 8-button keypad. The 6-Button Massio ControlPad mounts into a standard 1 gang US, UK, or EU back box.

The 8-Button Massio ControlPad mounts into a standard 2 gang US, UK, or EU back box.

FIG. 1 displays the Massio ControlPads.

FIG. 1

Massio ControlPads

Features

All-in-one Keypad/Controller – Combines a user interface with an on-board controller

Includes AMX Control – Controls all the same devices as NetLinx Integrated Controllers, with the same capabilities and

macro functions

Simple to Program with RPM – Uses AMX’s Rapid Project Maker (RPM) software to quickly configure and program a system

Simple Integration with RMS – Using RPM, easily integrate AMX’s Resource Management Suite (RMS) with a Massio

ControlPad to provide a platform for real-time performance monitoring and maintenance

Display Monitoring – Use the ControlPad with RMS to monitor power status, input status, lamp hours and filter hours

Web-based Control – Remotely login to ControlPads and execu te button presses

Inactivity Timer – Turn off equipment after lack of activity (timeouts) to save energy

Built In Control Ports – Serial and IR ports available to communicate and control common presentation equipment

Backlit Buttons – Can flash or turn on/off when pressed

Execute Multiple Functions at Once – Macros can be written to trigger multiple functions through a single button press

Works with AMX IR Files – Leverage thousands of pre-existing AMX IR files on AMX.com

Standard Enclosures – Standard back box mounting options for US, UK and EU

Native Direct Connection to RMS – No proxy required

Master-to-Master Communication – The ControlPads support AMX Master-to-Master communication when paired with

another AMX Master

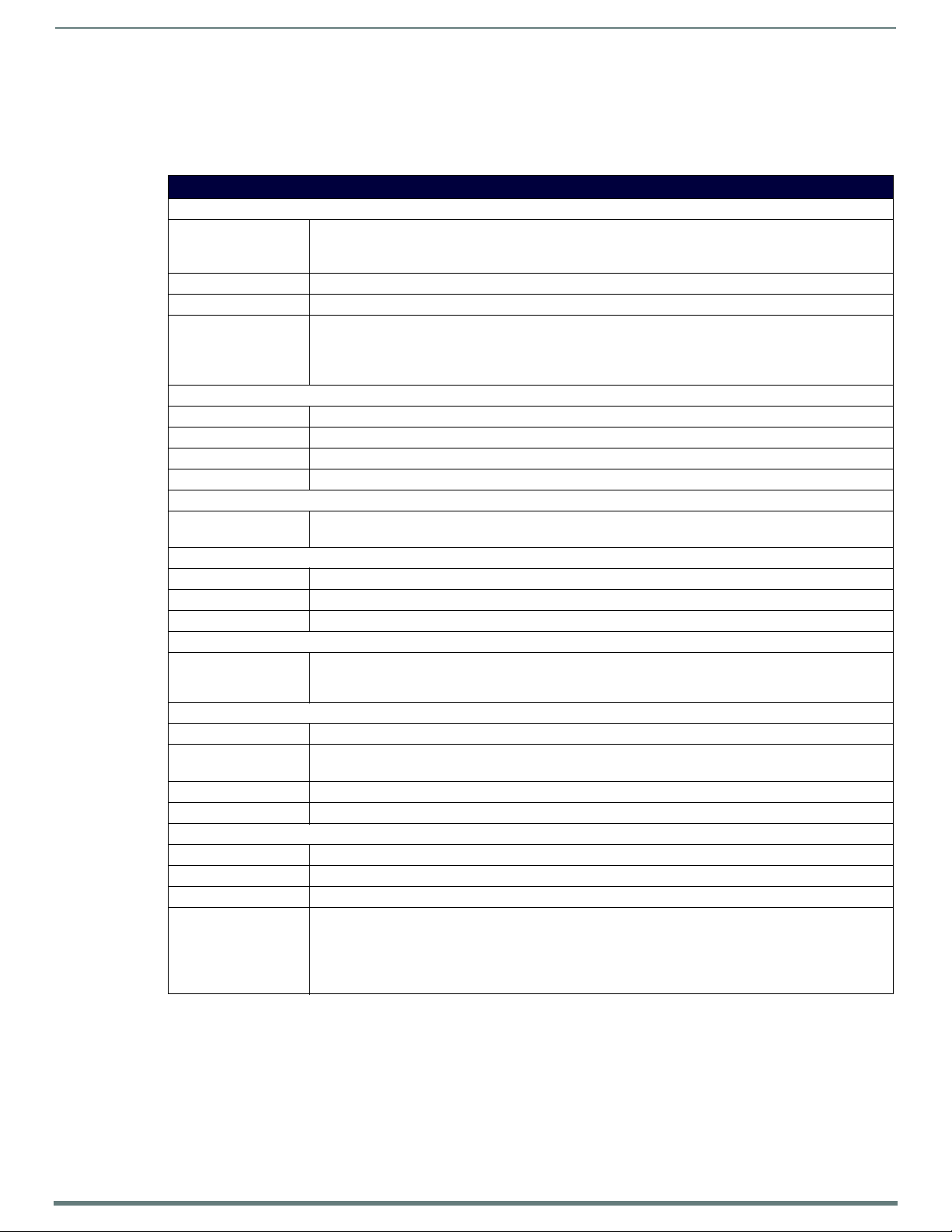

Port Assignments by Massio ControlPad

The following table lists the port assignments for Massio ControlPads:

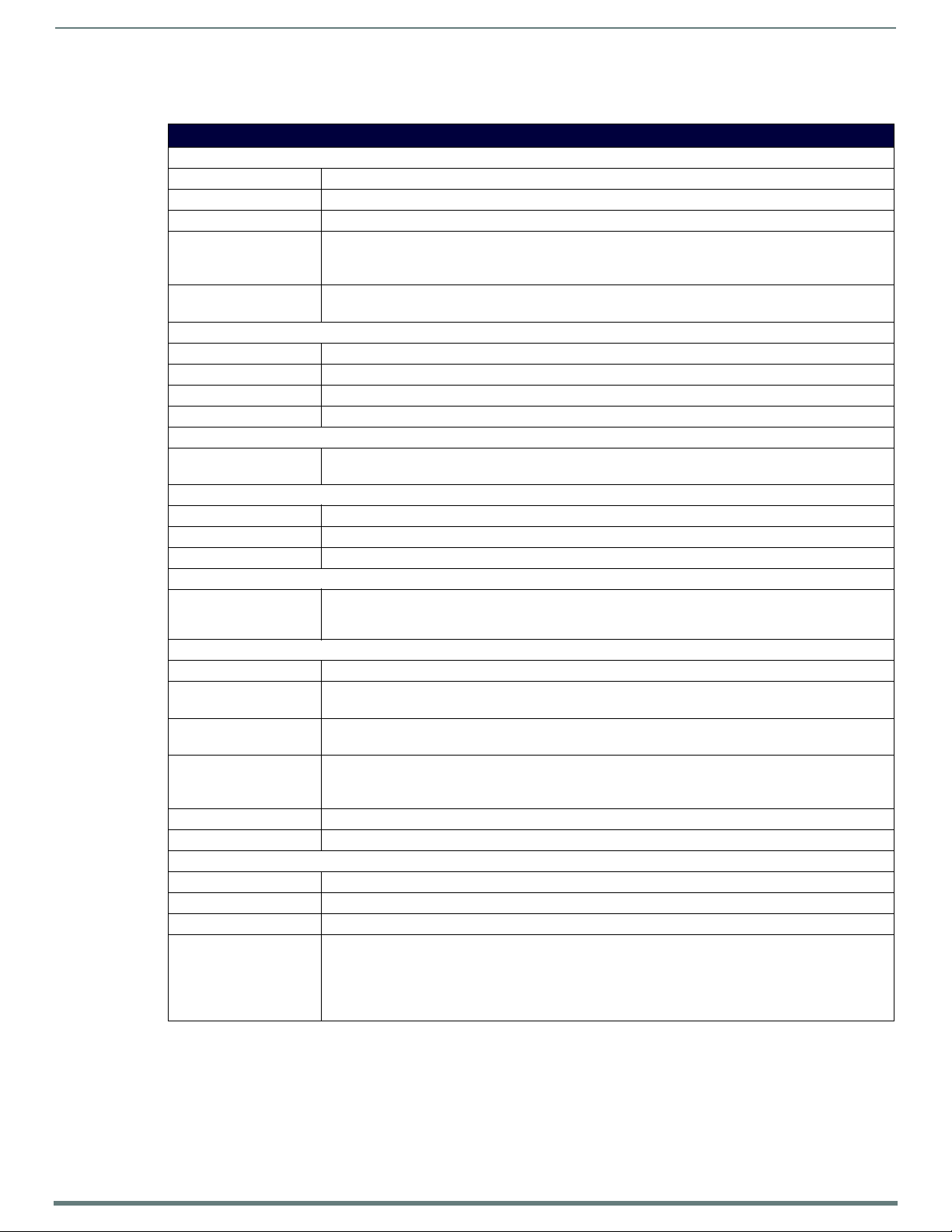

Port Assignments By ControlPad

ControlPad RS-232 IR/Serial Relays I/O Keypad

MCP-106 Port 1 Port 11 N/A N/A Port 28

MCP-108 Ports 1-2 Ports 11-12 Port 21 Port 22 Port 28

Overview - Massio ControlPads

Page 8

Overview - Massio ControlPads

8

Instruction Manual - Massio ControlPads and Keypads

Specifications

The following sections list the specifications for the Massio ControlPads.

MCP-106

The following table lists the specifications for the MCP-106:

MCP-106 Specifications

Ge n er al :

Dimensions (HWD): Portrait: 4 11/16" x 3 7/16" x 9/16" (119 mm x 87.5 mm x 13.9 mm)

Landscape: 3 7/16" x 4 11/16" x 9/16" (87.5 mm x 119 mm x 13.9 mm)

Mount onto standard 1 gang US, UK, or EU back boxes

Weight: Approximately 0.25 lb (0.11 kg)

Front Panel Com ponents: 6 buttons

Colors/Styles Available: • Portrait, Black: MCP-106P-BL (FG2102-06P-BL)

• Portrait, White: MCP-106P-WH (FG2102-06P-W)

• Landscape, Black: MCP-106L-BL (FG2102-06L-BL)

• Landscape, White: MCP-106L-WH (FG2102-06L-W)

Active Power Requirements:

Voltage, DC (Typical): PoE (37V-57V)

Voltage DC Range: 37V-57V per 802.3af specification

Power Connector: (1) RJ-45 Ethernet

Maximum Power Draw: 4.5W

Power Supply:

External, Required: Any POE injector or switch, conforming to the 802.3af standard including AMX’s PS-POE-AF-TC (FG423-83),

Environmental:

Temperature (Operating): 32º F to 104º F (0º C to 40º C)

Temperature (Storage): 14º F to 140º F (-10º C to 60º C)

Humidity (Operating): 5% to 85% RH

Ethernet:

Ethernet Connection: (1) 10/100; Port provides TCP/IP communication. This is an Auto MDI/MDI-X enabled port, which allows you

Control Ports and Indicators:

RS-232 Port: (1) 3-position 3.5mm Screw Terminal; 300 - 115,200 baud

IR/Serial Port: (1) 2-position 3.5mm Screw Terminal; IR Transmit / 1-way Serial ports

Program Port: (1) USB Mini-B, USB

ID Pushbutton Reset factory settings, reset factory image, toggle between DHCP or static IP addressing mode

Memory:

Flash: 4 GB

Memory Card: 4 GB SD

DDRAM: 256 MB

Certifications: • FCC Class B

not included

to use either straight-through or crossover Ethernet cables. The Ethernet Port LEDs show communication

activity, connection status, speeds, and mode information.

Support high-frequency carriers up to 1.142 MHz

• CE EN 55022

•EN 55024

• IEC/EN-60950-1

•UL 60950-1

Page 9

Overview - Massio ControlPads

9

Instruction Manual - Massio ControlPads and Keypads

MCP-108

The following table lists the specifications for the MCP-108:

MCP-108 Specifications

Ge n er al :

Dimensions (HWD): 4 11/16" x 6" x 1" (119 mm x 152.5 mm x 26 mm)

Weight: Approximately 0.41 lb (0.19 kg)

Mounting Options: Mount onto standard 2 gang US, UK, or EU back boxes

Front Panel Components: • 8 Buttons

• 1 Volume Knob with Push Mute

• 7 LED Bar Graph Indicator

Colors Ava ilable: • Blac k: MCP -108-BL (FG2102-08-BL)

• White: MCP-108-WH (FG2102-08-W)

Active Power Requirements:

Voltage, DC (Typical): PoE (37V-57V)

Voltage DC Range: 37V-57V per 802.3af specification

Power Connector: (1) RJ-45 Ethernet

Maximum Power Draw: 5.0W, plus any power used by the I/O port, which can draw up to an additional 6.0W.

Power Supply:

External, Required: Any POE injector or switch, conforming to the 802.3af standard including AMX’s PS-POE-AF-TC (FG423-83),

Environmental:

Temperature (Operating): 32º F to 104º F (0º C to 40º C)

Temperature (Storage): 14º F to 140º F (-10º C to 60º C)

Humidity (Operating): 5% to 85% RH

Ethernet:

Ethernet Connection: (1) 10/100; Port provides TCP/IP communication. This is an Auto MDI/MDI-X enabled port, which allows

Control Ports and Indicators:

RS-232 Port: (2) 3-position 3.5mm Screw Terminals; 300 - 115,200 baud

IR/Serial Port: (2) 2-position 3.5mm Screw Terminals; IR Transmit / 1-way Serial ports

I/O Channels: (1) 4-position 3.5 mm Screw Terminal; 2-channel binary I/O port for contact closure with each input being

Relay Connection: (1) 4-position 3.5mm Screw Terminal; (2) single-pole, single-throw relays

Program Port: (1) USB Mini-B, USB

ID Pushbutton Reset factory settings, reset factory image, toggle between DHCP or static IP addressing mode

Memory:

Flash: 4 GB

Memory Card: 4 GB SD

DDRAM: 256 MB

Certifications: • FCC Class B

not included

you to use either straight-through or crossover Ethernet cables. The Ethernet Port LEDs show

communication activity, connection status, speeds, and mode information.

Support high-frequency carriers up to 1.142 MHz

capable of voltage sensing

Each relay can switch up to 24 V

Each relay is independently controlled

• CE EN 55022

•EN 55024

•IEC/EN-60950-1

• UL 60950-1

or 28 VAC @ 1 A

DC

Page 10

10

Instruction Manual - Massio ControlPads and Keypads

Overview - Massio Keypads

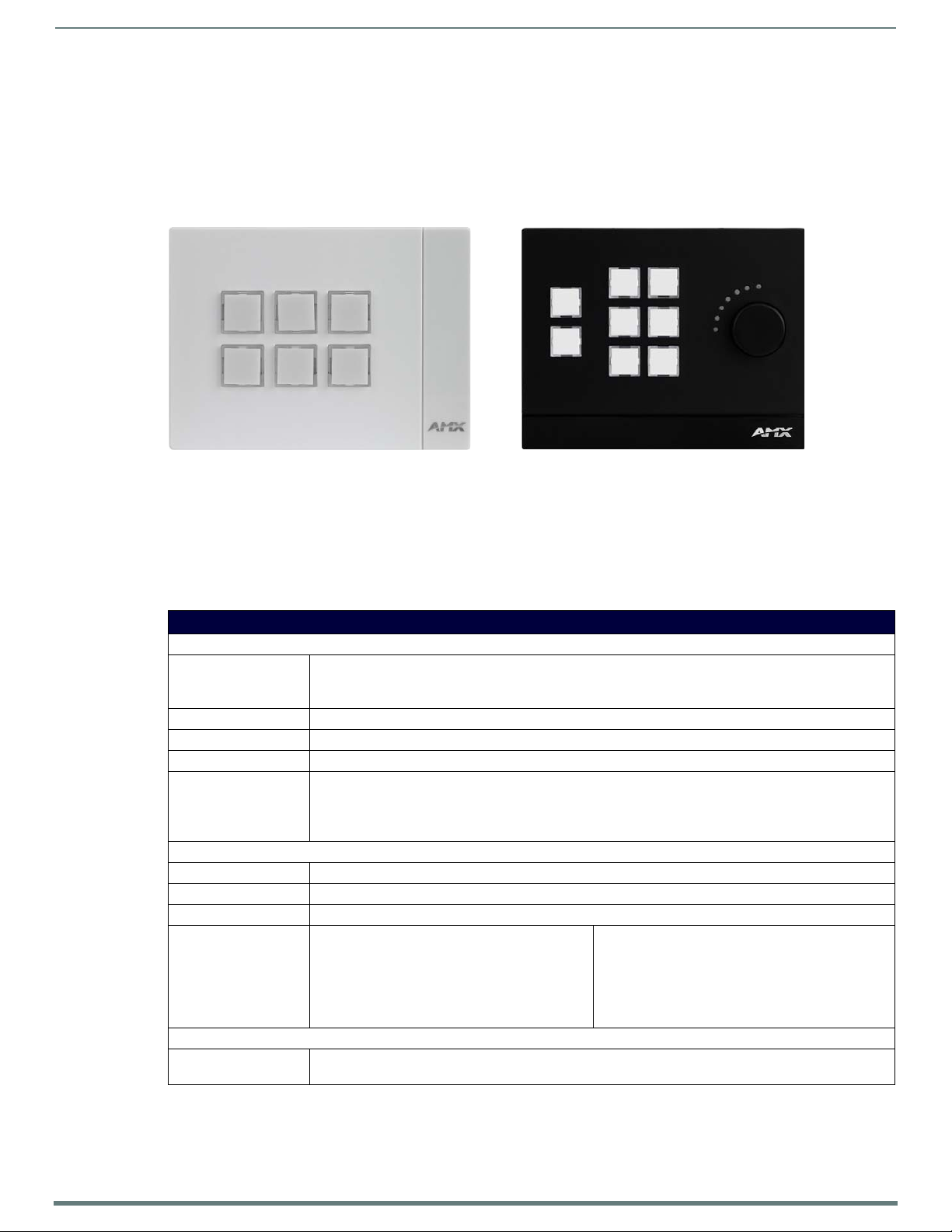

MKP-108

MKP-106 (Landscape)

The Massio MKP-106 (FG5793-06) and MKP-108 (FG5793-08) Keypads are keypad-only versions of the Massio ControlPad. The

keypads can serve as second user interfaces or as primary UI in spaces that already contain a separate controller. Massio Keypads

connect to a controller via Ethernet. The 6-Button Massio Keypad mounts into a standard 1 gang US, UK, or EU back box. The

8-Button Massio Keypad mounts into a standard 2 gang US, UK, or EU back box.

FIG. 2 displays the Massio ControlPads.

Overview - Massio Keypads

FIG. 2

Massio Keypads

Specifications

The following sections list the specifications for the Massio Keypads.

MKP-106

The following table lists the specifications for the MKP-106:

MKP-106 Specifications

Ge n er al :

Dimensions (HWD): Portrait: 4 11/16" x 3 7/16" x 9/16" (119 mm x 87.5 mm x 13.9 mm)

Landscape: 3 7/16" x 4 11/16" x 9/16" (87.5 mm x 119 mm x 13.9 mm)

Mount onto standard 1 gang US, UK, or EU back boxes

Weight: Approximately 0.25 lb (0.11 kg)

Front Panel Com ponents: 6 buttons

ID Pushbutton Reset factory settings, reset factory image, toggle between DHCP or static IP addressing mode

Colors/Styles Available: • Portrait, Black: MKP-106P-BL (FG5793-06P-BL)

• Portrait, White: MKP-106P-WH (FG5793-06P-W)

• Landscape, Black: MKP-106L-BL (FG5793-06L-BL)

• Landscape, White: MKP-106L-WH (FG5793-06L-W)

Active Power Requirements:

Voltage, DC (Typical): PoE (37V-57V)

Voltage DC Range: 37V-57V per 802.3af specification

Power Connector: (1) RJ-45 Ethernet

Regulatory Compliance: • FCC CFR Title 47 Part 15

• CE EN 55022

• CE EN 55024

• CE EN 60950-1

• IEC-60950-1

•UL 60950-1

Power Supply:

External, Required: Any POE injector or switch, conforming to the 802.3af standard including AMX’s PS-POE-AF-TC (FG423-83),

not included.

•C-Tick CISPR 22

• IC CISPR 22

• VCCI CISPR 22

•RoHS

•WEEE

Page 11

Overview - Massio Keypads

11

Instruction Manual - Massio ControlPads and Keypads

MKP-106 Specifications (Cont.)

Environmental:

Temperature (Operating): 32º F to 122º F (0º C to 50º C)

Temperature (Storage): 14º F to 140º F (-10º C to 60º C)

Humidity (Operating): 5% to 85% RH

Ethernet:

Ethernet Connection: (1) 10/100; Port provides TCP/IP communication. This is an Auto MDI/MDI-X enabled port, which allows you

Memory:

Flash: 4 GB

Memory Card: 4 GB SD

DDRAM: 256 MB

to use either straight-through or crossover Ethernet cables. The Ethernet Port LEDs show communication

activity, connection status, speeds, and mode information.

MKP-108

The following table lists the specifications for the MKP-108:

MKP-108 Specifications

Ge n er al :

Dimensions (HWD): 4 11/16" x 6" x 1" (119 mm x 152.5 mm x 26 mm)

Weight: Approximately 0.41 lb (0.19 kg)

Mounting Options: Mount onto standard 2 gang US, UK, or EU back boxes

Front Panel Components: • 8 Buttons

• 1 Volume Knob with Push Mute

• 7 LED Bar Graph Indicator

ID Pushbutton Reset factory settings, reset factory image, toggle between DHCP or static IP addressing mode

Colors Ava ilable: • Blac k: MKP -108L -BL (FG5793-08L-BL)

• White: MKP-108L-WH (FG5793-08L-W)

Active Power Requirements:

Voltage, DC (Typical): PoE (37V-57V)

Voltage DC Range: 37V-57V per 802.3af specification

Power Connector: (1) RJ-45 Ethernet

Regulatory Compliance: • FCC CFR Title 47 Part 15

• CE EN 55022

• CE EN 55024

• CE EN 60950-1

• IEC-60950-1

•UL 60950-1

Power Supply:

External, Required: Any POE injector or switch, conforming to the 802.3af standard including AMX’s PS-POE-AF-TC (FG423-83),

not included

Environmental:

Temperature (Operating): 32º F to 122º F (0º C to 50º C)

Temperature (Storage): 14º F to 140º F (-10º C to 60º C)

Humidity (Operating): 5% to 85% RH

Ethernet:

Ethernet Connection: (1) 10/100; Port provides TCP/IP communication. This is an Auto MDI/MDI-X enabled port, which allows you

to use either straight-through or crossover Ethernet cables. The Ethernet Port LEDs show communication

activity, connection status, speeds, and mode information.

Memory:

Flash: 4 GB

Memory Card: 4 GB SD

DDRAM: 256 MB

•C-Tick CISPR 22

•IC CISPR 22

•VCCI CISPR 22

•RoHS

• WEEE

Page 12

12

Instruction Manual - Massio ControlPads and Keypads

Wiring and Device Connections

Ethernet port

Program port

RS-232 port

IR/Serial port

RS-232 ports

Ethernet port

Program port

IR/Serial ports

I/O port

Relay ports

Overview

This section describes the device connectors and ports available on each type of Massio ControlPad. Here you can find wiring and

electrical capacities for each type of connector.

FIG. 3 displays the rear panel of the MCP-106.

Wiring and Device Connections

FIG. 3

MCP-106 rear panel

FIG. 4 displays the rear panel of the MCP-108.

FIG. 4

MCP-108 rear panel

Page 13

Wiring and Device Connections

13

Instruction Manual - Massio ControlPads and Keypads

RX

ControlPad

TX

GNDGND

RX

TX

External Device

Control Ports and Indicators

The following sub-sections describe each control port on the Massio ControlPads. Refer to Overview section on page 12 for the

component layout of the rear panels of each type of Massio ControlPad.

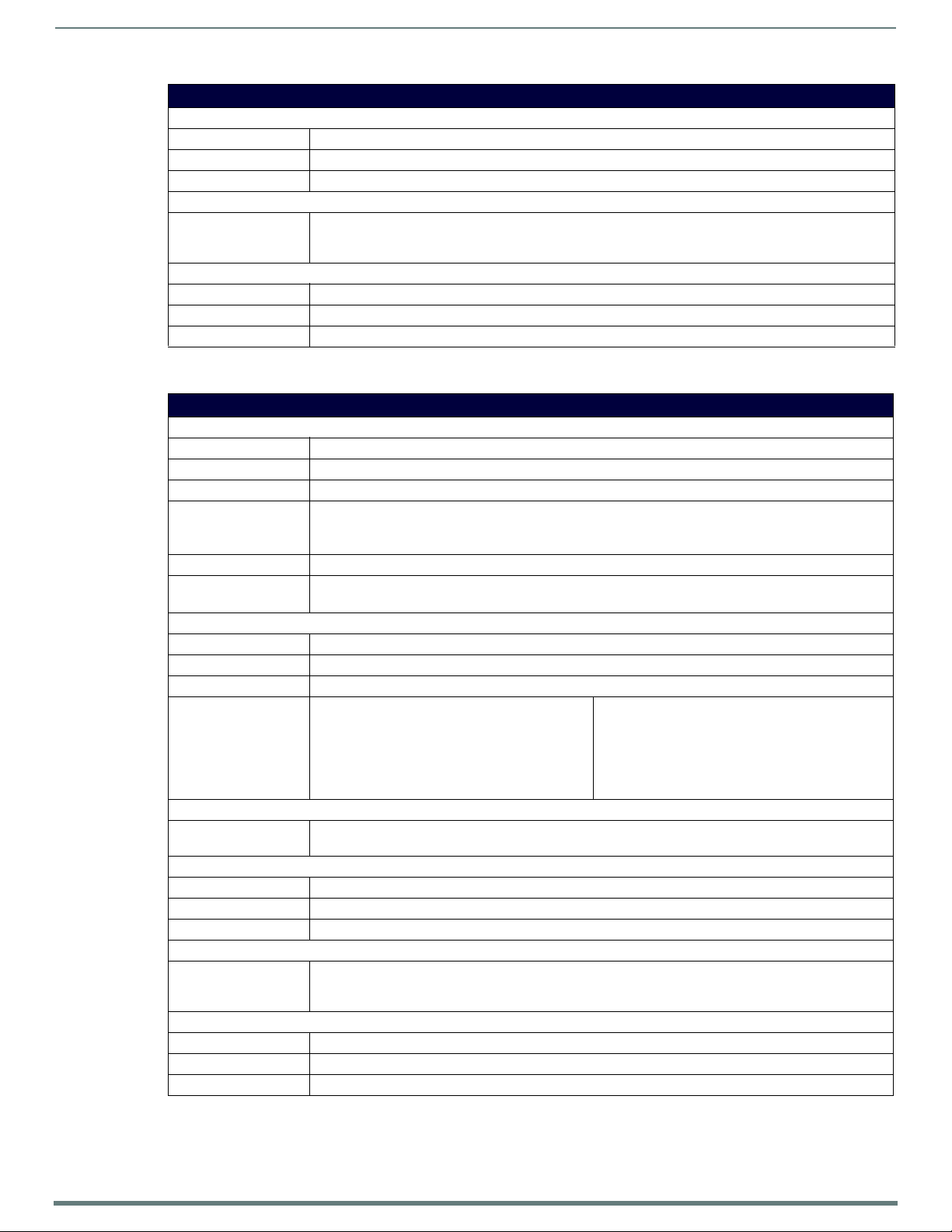

RS-232

The Massio ControlPads features up to two RS-232 300-115,200 baud connector ports so you can connect up to two serial devices

to the ControlPad. The MCP-106 features one RS-232 connector; the MCP-108 features two connectors. The serial connectors

comply with EIA-232-F signal levels. The RX line supports polling for RS-232 devices for statuses such as power status, input

status, and lamp hours, so that this information can be provided to RMS.

NOTE: Massio ControlPads do not support RS-422 or RS-485 communications to devices.

FIG. 5 displays the RS-232 ports on the MCP-108.

FIG. 5

RS-232 Serial Ports (MCP-108)

FIG. 6 displays the wiring for the RS-232 connector.

FIG. 6

RS-232 connector wiring

RELAYS

You can connect up to two independent external relay devices to the Relay connectors on the ControlPad. The relay port is only

available on the MCP-108.

FIG. 7 displays the RELAYS connector.

FIG. 7

RELAYS connector

Each relay is isolated and normally open.

@ 1 A maximum

24 V

DC

@ 1 A maximum

28 V

AC

Page 14

Wiring and Device Connections

14

Instruction Manual - Massio ControlPads and Keypads

+ - + -

I/O

The I/O port (available only on the MCP-108) responds to switch closures and voltage level (high/low) changes, or can be used for

logic-level outputs. The +12 pin provides +12 V

Sensors, VSS2 Video Sync Sensors (or equivalent). The GND connector is a common ground and is shared by all I/O ports. A

common ground is shared with I/O ports 1 - 2.

FIG. 8 displays the I/O connector.

FIG. 8

I/O port

CAUTION:

Improper wiring could damage your ControlPad. The CP-3008 ControlPad has the ground and power signals in swapped

positions on the I/O port. If you are replacing a CP-3008 ControlPad with the MCP-108, you may need to make a wiring change in

your I/O connector to avoid damaging the MCP-108.

A contact closure between the GND and an I/O port is detected as a Push.

When used for voltage inputs, the I/O port detects a low signal (0 - 1.5 V

(3.5 - 5 V

) as a Release. (This I/O port uses 5V logic but can handle up to 12V without harm.)

DC

The following table provides wiring requirements for the I/O port:

I/O Port Wiring Specifications

Signal Function

GND: Signal GND

1: Output

2: Output

+12 V: PWR

@ 200 mA and is designed as a power output for the PCS Power Current

DC

) as a Push, and a high signal

DC

IR/Serial

You can connect up to two IR-controllable devices to the IR connectors to the Massio ControlPads. The MCP-106 features only one

IR connector; the MCP-108 features two connectors.

The IR connectors support generating carriers up to 1.142 MHz. The IR connectors accept an IR Emitter (CC-NIRC) that mounts

onto the device's IR window, or a mini-plug (CC-NSER) that connects to the device's control jack.

You can also connect a data (0 - 5 V

FIG. 9 displays the IR/SERIAL connector.

IR/SERIAL connector

FIG. 9

The IR/Serial connector wiring specif ications are listed in the following table.

IR Connector Wiring Specifications (per Port)

IR connections Signal Function

1Signal 1 (+)

GND (-)

2 (MCP-108 only) Signal 2 (+)

GND (-)

CAUTION:

IMPORTANT: The IR positive (+) and negative (-) connections are positioned from left to right. The signal connector is located on the

left side of the IR connection while the ground connector is located on the right side.

Do NOT connect a power connector to either IR port. Doing so may damage the ControlPad.

) device.

DC

IR data

Signal GND

IR data

Signal GND

Page 15

Wiring and Device Connections

15

Instruction Manual - Massio ControlPads and Keypads

Data & Power

Out

Data In

Category cable to ControlPad

Cat5 cable from

the network

or Keypad

LAN (RJ-45)

The LAN RJ-45 port provides 10/100 Mbps communication via Cat5/5e/6 network cable. The LAN port automatically negotiates

the connection speed (10 Mbps or 100 Mbps), and whether to use half duplex or full duplex mode. The LAN port is best used for

connecting to a network switch. This is an Auto MDI/MDI-X enabled port, which allows you to use either straight-through or

crossover Ethernet cables. The port LEDs show communication activity, connection status, speeds, and mode information.

The LAN port also receives its power via the LAN port and Power-over-Ethernet (PoE) when you connect this port to a PoE switch

which conforms to the 802.3af standard. See the Applying Power section on page 15 for information on PoE setup.

FIG. 10 displays the LAN port.

FIG. 10

FIG. 11 provides the pinouts and signals for the LAN connector and cable.

FIG. 11

NOTE: If Ethernet connectivity is lost on any ControlPad, and then re-established, connectivity may take some time to resume. You

will be unable to program the ControlPad until it is fully online.

LAN port

RJ-45 wiring diagram

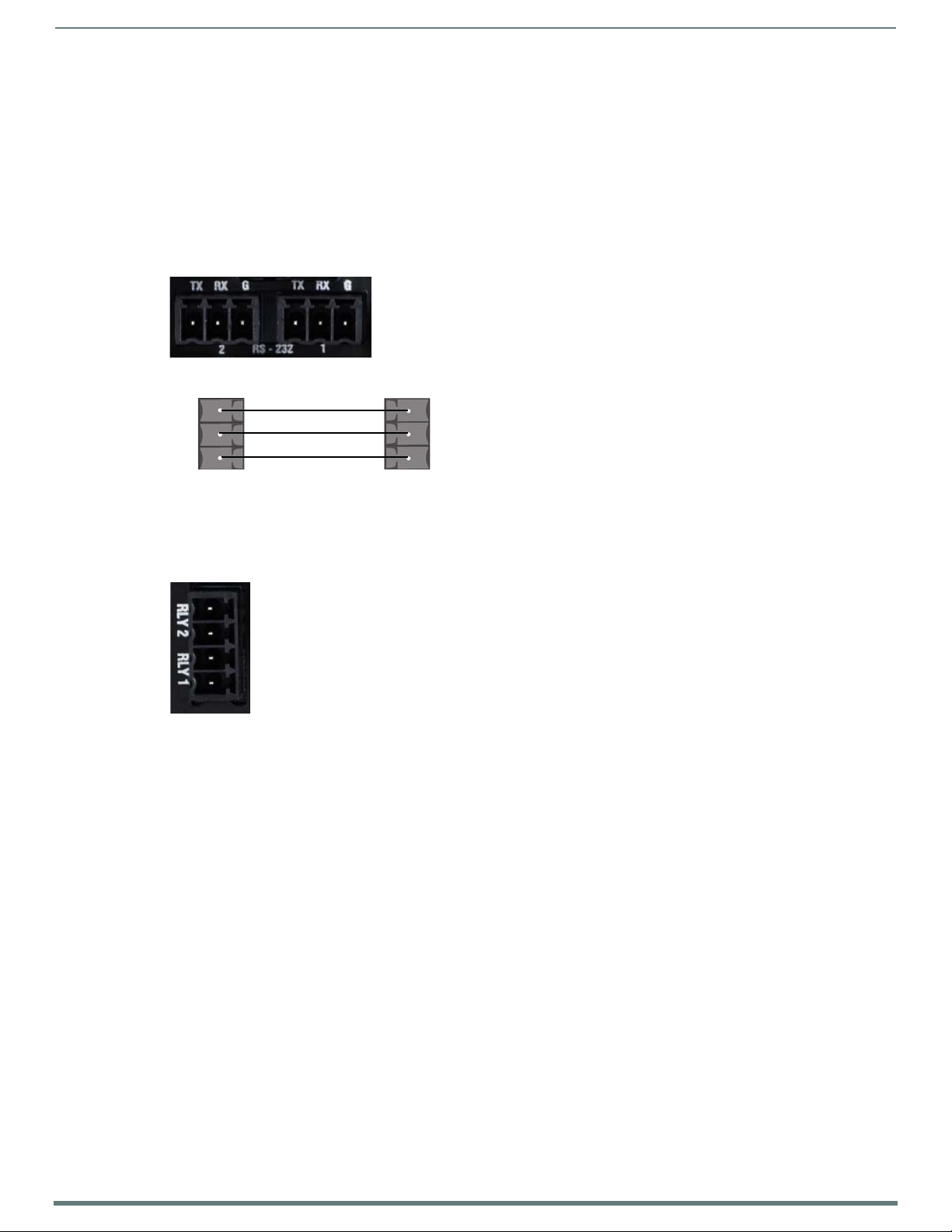

Applying Power

Applying power to Massio ControlPads and Keypads requires Cat5 cable and a PoE injector, such as the PS-POE-AF-TC (FG423-83)

available from AMX, or a PoE-capable Ethernet switch which conforms to the 802.3af standard. The network must be connected

through the PoE injector to send power to the ControlPad.

1. Connect the PoE injector to an AC outlet (~100-240V) using a standard power cord.

2. Connect the switch category cable to the Data In port on the PoE injector (FIG. 12).

FIG. 12

3. Using a separate category cable, connect the Data & Power Out port on the PoE injector to LAN Port on the ControlPad or

Connecting to a PoE Injector

keypad.

Page 16

Wiring and Device Connections

16

Instruction Manual - Massio ControlPads and Keypads

6-button

ID pushbutton

8-button

6-button (portrait)

8-button

1

2

1

2

3

4

56

34

5

6

7

8

11

13

12

Rotate counter-clockwise

= Button #13

Rotate clockwise

= Button #12

ID Pushbutton

Each Massio ControlPad and Keypad features a pinhole reset pushbutton located on the bottom of the device.

FIG. 13 displays the lo cation of the res et pushbutton on each ControlPad or keypad.

FIG. 13

Location of the ID Pushbuttons on each ControlPad

You can use the ID pushbutton to perform the following procedures:

Perform a factory reset of the ControlPad or Keypad: Press the ID pushbutton for approximately 10 seconds during the

boot process. While pressing the ID pushbutton, disconnect and reconnect the cable from the LAN port on the rear panel

of the ControlPad to reset the ControlPad’s factory defaults. During factory reset, the backlight turns off for all buttons,

but all buttons should be back online after 1-2 minutes. If you do not hold in the ID pushbutton for the full 10 seconds,

the reset does not occur. (There is no soft reboot with the ID pushbutton, but you can perform a soft reboot from the

web pages.)

On Massio ControlPads and Keypads, the LEDs on buttons 1 and 2 blink while you keep them pressed. Hold them until the

LEDs begin blinking at double the rate (approximately10 seconds.) Release the buttons and the keypad will reset.

NOTE: When you reset a ControlPad or Keypad, the device is restored to the factory default, so you will lose any scripts, IRL f iles,

Device Interrogation settings, or RMS server information loaded on the system.

Restore the factory image on the ControlPad or Keypad: Press the ID pushbutton for approximately 20 seconds or longer

during the boot process. While pressing the ID pushbutton, disconnect and reconnect the cable from the LAN port on the

rear panel of the device to restore the factory image firmware on the ControlPad.

Toggle between a DHCP or static IP address. See the Toggling Between IP Addressing Modes: DHCP and Static IP section on

page 26 for more information.

In place of using the ID pushbutton, you can press buttons 1 and 2 simultaneously on the ControlPad or keypad to simulate the

functions of the ID pushbutton. You must keep both buttons pressed for approximately 10 or 20 seconds as you would with the ID

pushbutton to perform a factory reset or restore the factory firmware image on the device. You must also disconnect and

reconnect the cable from the LAN port while pressing the buttons. FIG. 14 displays the locations of buttons 1 and 2 on each Massio

devi ce.

FIG. 14

NOTE: RPM applies a different numbering scheme in its background for the ControlPads. Disregard any button pushes you see in

NetLinx Studio.

Button layout for Massio ControlPads and Keypads

Page 17

Wiring and Device Connections

17

Instruction Manual - Massio ControlPads and Keypads

6-button (landscape)

6

4

2

5

3

1

6-button (portrait)

8-button

X

X

X

X

X

X

6-button (landscape)

X

X

X

The button assignments are the same on the portrait and landscape versions of the MCP-106 and MKP-106. On a landscape

installation, bu tto n 1 is in the low er left corner of the device (see FIG. 15).

FIG. 15

Button layout (6-button landscape)

You can also simultaneously press buttons 4, 5, and 6 to power cycle the device. Press all three buttons simultaneously and hold

them for 20 seconds to power cycle the device (see FIG. 16).

FIG. 16

Press buttons marked with X to power cycle the device

On a landscape installation, consult FIG. 17 for the locations o f the button to press for a power cycle.

FIG. 17

Press buttons marked with X to power cycle the device

Page 18

18

Instruction Manual - Massio ControlPads and Keypads

Installation

MCP-106

MCP-108

Overview

This chapter describes installing Massio ControlPads and Keypads. The MCP-106 and MKP-106 mount onto standard 1 gang US,

UK, or EU back boxes. The MCP-108 and MKP-108 mount onto standard 2 gang US, UK, or EU back boxes.

NOTE: Before touching the device, discharge the static electricity from your body by touching a grounded metal object.

NOTE: It is best to install button labels before mounting the device. Doing so keeps you from disassembling the ControlPad after

mounting it. For instructions on installing button labels, see the Button Labeling section on page 20.

Mounting Procedures

AMX recommends mounting each type of ControlPad or Keypad in standard a conduit box per NEC specs section 370. You can

mount the MCP-108 and MKP-108 to a podium using the provided metal mounting bracket.

NOTE: Before installing and mounting the device, you should test it to see that it can receive power. See the Applying Power section

on page 15 for more information.

Wallbox Mounting

Perform these steps to mount the device into a back box:

1. Install the back box into the surface o f the desired location for the device. Be sure to thread any appropriate wiring through

the back box.

IMPORTANT: Leave 3/8" (9.52mm) of space between the top of the mounting bracket and any overhanging or otherwise obstructing

surface. The extra space is required for attaching the device frame to the mounting bracket.

2. Once the back box is installed and secured, secure the metal mounting bracket to the back box using the provided screws.

FIG. 18 displays the location of the screw holes for the metal mounting brackets for each type of Massio device.

Installation

FIG. 18

3. Peel the plastic covering off of the insulator on the rear panel of the device. You can discard the plastic covering after removing

4. Make all necessary connections to the ports on the rear panel of the ControlPad. Be sure to connect category cable to the LAN

5. Attach the device frame to the mounting bracket by hooking the top of the device frame onto the extended lip at the top of the

Location of screw holes on metal mounting brackets.

it.

port to supply power to the device. See the Applying Power section on page 15 for more information.

mounting bracket.

Page 19

19

Instruction Manual - Massio ControlPads and Keypads

FIG. 19 illustrates how to connect the device frame to the mounting bracket.

Hook top of frame onto the lip

of the mounting bracket

Metal clip from mounting bracket

Metal clips from mounting bracket

Installation

FIG. 19

Attaching the frame to the mounting bracket (MCP-106 displayed)

6. Press the sides of the device frame to snap them into place.

7. Press the bottom corners of the device frame to snap them into place. The metal clip on the mounting bracket should align

with the open spaces located at the bottom of the device frame. The clip should fit inside this space and lock the device frame

into position on the mounting bracket. There are two metal clips on the 8-button Massio devices. There is only one on the

6-button devices.

FIG. 20 displays the location of the metal clip on the 6-button devices.

FIG. 20

Metal clip from mounting bracket locking device frame onto bracket

FIG. 21 displays the locations of the metal clips on the 8-button devices.

FIG. 21

Metal clips from mounting bracket locking device frame onto bracket

8. Connect the faceplate to the device frame by snapping the top corners of the faceplate into place on the device frame. If

connected properly, the faceplate should hold itself in place against the device frame.

NOTE: If you need to label the buttons on the device or replace any key caps, it is best to do so before attaching the faceplate. Consult

the Button Labeling section on page 20 for instructions.

9. Press the bottom corners of the faceplate until each corner snaps into place with the device frame.

Page 20

20

Instruction Manual - Massio ControlPads and Keypads

Button Labeling

Overview

Massio ControlPads and Keypads come with a set of clear plastic Button Caps which are designed to fit tightly over the

pushbuttons, and allow you to place a label on each button according to the requirements of your particular installation.

Massio devices also come with a pre-printed acetate sheet with a range of 70 (pre-cut) button label inserts. The button labels

provided will accommodate most installations, but it is also possible to print your own button labels on acetate for custom button

labe ling.

Button Labeling

FIG. 22

Acetate sheet of 70 standard button labels (pre-cut)

Installing Acetate Button Labels

Follow these instructions to install the acetate button labels and Button Caps:

1. Remove the faceplate from the device.

2. Remove the cone and diffuser from the button. The cone and diffuser are adhered together and should not be separated.

3. Peel off the desired Button Label from the included acetate sheet. If you have printed your own custom button labels on

acetate, cut each button label to fit inside the Button Caps.

Custom button labels must be cut to a 14mm (0.55") square to fit securely inside the Button Caps.

The thickness of the acetate used must not exceed .004” (0.10 mm).

4. Place the Button Cap face-down, and insert the Button Label into the bo ttom o f the Bu tton Cap (FIG. 23).

Orient the Bu tton Label inside the Bu tton Cap so that the two clips are located on the top and bottom sides of the readable

text on the Button Label, as indicated in FIG. 23.

Be sure to place the Button Label face-down inside the Button Cap, otherwise the label will be seen in reverse.

Page 21

Button Labeling

21

Instruction Manual - Massio ControlPads and Keypads

Cone and Diffuser

Acetate Button Label (face down)

ridges

6-button

ridges

8-button

FIG. 23 Placing a Button Label inside a Button Cap

5. Place the cone and diffuser back over the button and snap the cone into place on the faceplate.

6. Repeat steps 2-5 for any additional buttons. When finished, mount the faceplate back onto the device.

Disassembling the Massio Device

If you are replacing button labels after you have already installed and mounted the Massio device, follow these steps to disassemble

the device.

NOTE: Remove power from the Massio device, and discharge any static electricity from your body by touching a grounded metal

object before performing the following steps.

This procedure requires a flat-head screwdriver.

1. Use the flat-head screwdriver to locate the two small ridges at the bottom of the faceplate and gently pry the faceplate away

from the device frame. The two ridges are located toward the center of the faceplate on the 6-button Massio devices. They are

located toward the sides of the device on the 8-button Massio devices (see FIG. 24).

FIG. 24

2. Lift the faceplate away from the rear panel to expose the device frame.

3. Remove device frame from the mounting bracket by inserting the flat-head screwdriver below the metal clip located at the

Location of the ridges on the bottom of each Massio device

bottom center of the device frame and lifting the clip upward to unlock the device frame from the mounting bracket (see

FIG. 25).

Page 22

Button Labeling

22

Instruction Manual - Massio ControlPads and Keypads

Metal clips from mounting bracket

Metal clip from mounting bracket

FIG. 25 illustrates using a flat-head screwdriver to unlock the device frame of an MCP-106 from the metal clip on the mounting

bracket.

FIG. 25

4. When the device frame is unlocked from the mounting bracket, lift the device frame upward and away from the top lip of the

Unlocking the device frame from the mounting bracket

mounting bracket.

Re-Assembling the Massio Device

Follow these steps to re-assemble the Massio device.

1. Make all necessary connections to the ports on the rear panel of the device. Be sure to connect category cable to the LAN port

to supply power to the device. See the Applying Power section on page 15 for more information.

2. Attach the device frame to the mounting bracket by hooking the top of the device frame under the extended lip(s) at the top of

the mounting bracket.

3. Press the sides of the device frame to snap them into place.

4. Press the bottom corners of the device frame to snap them into place. The metal clips on the mounting bracket should align

with the open spaces located at the bottom of the device frame. The clips should fit inside these spaces and lock the device

frame into position on the mounting bracket. There are two metal clips on the 8-button Massio devices. There is only one on

the 6-button Massio devices.

FIG. 26 displays the locations of the metal clips on the 8-button Massio devices.

FIG. 26

FIG. 27 displays the lo cation of the me tal clip on the 6-button Massio devices.

Metal clips from mounting bracket locking device frame onto bracket

FIG. 27

5. Connect the faceplate to the device frame by pressing the top corners of the faceplate until they snap into place on the device

6. Press the bottom corners of the faceplate until each corner snaps into place with the device frame.

Metal clip from mounting bracket locking device frame onto bracket

frame. If connected properly, the faceplate should hold itself in place against the device frame.

Page 23

23

Instruction Manual - Massio ControlPads and Keypads

Initial Conf iguration

Massio ControlPads

This section describes using the NetLinx Studio software application to perform the initial configuration of the Massio ControlPad.

You can use NetLinx Studio to perform the following conf iguration options on a Massio ControlPad:

Set up a System number

Obtain/assign the IP/URL for the ControlPad

Transfer firmware Kit files to the ControlPad - see the Upgrading Firmware section on page 28

You can perform other conf iguration and programming options on Massio ControlPads by using Rapid Project Maker (RPM)

available at www.amx.com.

For information on configuring the Massio Keypad, see the Massio Keypads section on page 27.

NOTE: You can also configure the ControlPad using the NetLinx Diagnostics 3 application, which is a companion application for RPM

for configuration and management of Massio ControlPads. It is a lightweight application that does not include the integrated

development environment for NetLinx code. It may be a more suitable and recommended application, although in larger sites where

both NX controllers and Massio ControlPads are being installed, NetLinx Studio is the preferable application.

Before You Start

1. Verify you have the latest version of the NetLinx Studio application version 4.0 installed on your PC.

NetLinx Studio is available to download from www.amx.com. Login to download the latest version. Alternatively, if it is already

installed, use the Web Update option in NetLinx Studio’s Help menu to obtain the latest version.

The default location for the NetLinx Studio application is Star t > Programs > AMX Control Disc > NetLinx Studio > NetLinx

Studi o.

2. Verify that a LAN cable is connected from the ControlPad to a PoE injector or a PoE-capable Ethernet switch, and the PoE

switch is connected to the LAN Hub. If connected correctly, the ControlPad should receive power.

Obtaining the ControlPad’s IP Address

Rapid Project Maker (RPM) requires the IP address of the ControlPad for conf iguration. Perform the following steps to retrieve the

IP address of the ControlPad. To assign a static IP address to the ControlPad, see the Changing the ControlPad’s Network Address

Information section on page 24 for more information.

NOTE: Massio ControlPads use DHCP addressing by default.

NOTE: Verify there is an active LAN connection on the ControlPad’s LAN port before beginning these procedures.

1. Open RPMLoader and click Communications Settings to open the Connect to Master dialog (FIG. 28).

Initial Configuration

FIG. 28

2. Under Connection to Master, select Network Connection.

Communications Settings dialog

Page 24

Initial Configuration

24

Instruction Manual - Massio ControlPads and Keypads

3. Click Search For Masters to search the network for online Masters in the Search for Masters dialog (FIG. 29).

FIG. 29

Search for Masters dialog

4. Click Start Searchi ng to begin listening for "blink" (UDP) messages from NetLinx Masters on the subnet.

5. When you see the IP Address for the ControlPad in the List of Active NetLinx Master Controllers, click Stop L istenin g. The IP

address of the ControlPad is listed in the TCP/IP column of the dialog.

Changing the ControlPad’s Network Address Information

1. Select Options > Master's Network Address to open the Master Controller's Network Address dialog (FIG. 30):

FIG. 30 Master Controller's Network Address dialog

2. Edit the IP Address fields as necessary:

• Host Name: Use this f ield to view/edit the ControlPad’s current Host Name.

NOTE: Host names may contain only the ASCII letters 'a' through 'z' (in a case-insensitive manner),

the digits '0' through '9', and the hyphen ('-').

•Use DHCP/

Specify IP Add ress:

• IP Address: Use this field to view/edit the ControlPad’s current IP Address.

• Subnet Mask: Use this field to view/edit the ControlPad’s current Subnet Mask assignment. Click the help icon to open

• Gateway: Use this field to view/edit the ControlPad’s current Gateway assignment.

• Set IP Information: Sets the new IP information, as indicated in this dialog.

Use these radio buttons to specify whether to use DHCP, or to Specify an IP Add ress for the ControlPad.

DHCP is selected by default.

NOTE: If you select DHCP, the IP Address and Subnet Mask fields (below) are disabled for editing.

the Vali d Subn et Masks h elp topic, which lists valid subnet masks, and the maximum number of IP hosts

allowed for each.

NOTE: RPMLoader will reboot the ControlPad when the Set IP Information button is clicked.

Page 25

Initial Configuration

25

Instruction Manual - Massio ControlPads and Keypads

3. Click the Set IP Information button to set the new IP address information on the ControlPad. The program will prompt you

that the Master Controller will be rebooted when this button is pressed (click OK to proceed).

4. Edit the DNS Address fields as necessary:

• Domain Suff ix: Use this field to view/edit the target master's current Domain Suff ix.

• DNS IP #1, #2, #3: Use these f ields to view/edit the target master's current DNS IP address(es).

• Set DNS Information: Sets new DNS IP information, as indicated in this dialog.

Note: The Master Controller does not require a reboot if only changing DNS information.

5. Click the Set DNS Information button to set the new IP address information on the ControlPad. It is not necessary to reboot

the ControlPad if only the DNS Address information is changed.

6. Click Done to close this dialog.

Connecting to the ControlPad via USB

If you do not have a DHCP server or if the ControlPad has an unknown static IP address, you can obtain the IP address of the

controller via USB.

1. Using a standard Micro-USB cable, connect the Program Port on the rear panel of the ControlPad to your PC.

2. In NetLinx Studio, select Settings > Workspace Communications Settings to open the Workspace Communication Settings

dialo g.

FIG. 31 Workspace Communication Settings dialog

3. Click System Settings to open the Communication Settings dialog.

FIG. 32 Communication Settings dialog - Recent tab

Page 26

Initial Configuration

26

Instruction Manual - Massio ControlPads and Keypads

4. Select the USB tab. The USB tab features a list of devices connected to your PC via USB. The IP address of the ControlPad

appears in the IPv4 Address column.

FIG. 33

5. Highlight your ControlPad and click Select to connect to it.

Communications Settings dialog - USB tab

Toggling Between IP Addressing Modes: DHCP and Static IP

Massio ControlPads support both DHCP and static IP addresses. You can use a static IP address which you can set via a Telnet

command (SET IP), or you can use the factory default static IP address (192.168.1.3). The default static IP address can be recalled

at any time by resetting the unit to its factory default configuration.

You can toggle between the DHCP and Static IP modes by pressing the ID Pushbutton located on the bottom of the ControlPad.

After the ControlPad boots, press and hold the ID Pushbutton for 10 seconds. While pressing the ID pushbutton, disconnect and

reconnect the cable from the LAN port on the rear panel of the ControlPad to toggle between IP addressing modes.

NOTE: You must wait until the ControlPad is finished booting before toggling the IP address. Pressing the pushbutton while booting

will cause the ControlPad to restore its factory default settings.

When you release the Pushbutton, the switcher toggles either from static to dynamic (DHCP) IP addressing or vice versa and

remains in that mode until the you use ID Pushbutton to toggle the IP mode again or you perform a factory reset. The switcher

automatically reboots to complete the process.

In place of using the ID pushbutton, you can press buttons 1 and 2 simultaneously on the ControlPad to simulate the functions of

the ID pushbutton. You must keep both buttons pressed for 10 seconds as you would with the ID pushbutton to toggle between IP

address mo des. See the ID Pushbutton section on page 16 for the button locations for each type of ControlPad.

Conf iguration and Programming

You can configure Massio ControlPads with RPM. RPM is a cloud-based configuration tool that allows you to easily configure an

AMX system by using a step-by-step wizard-based approach. You can get started using RPM by accessing it via the AMX Services

Home page at https://my.amx.com.

For more information on using RPM, see the RPM Instruction Manual available at www.amx.com.

Programming

You can program ControlPads and Keypads using NetLinx Studio, available at www.amx.com. You can also send NetLinx commands

to a Massio ControlPad through a Terminal (Telnet) window (see the Terminal (Telnet) Commands section on page 36 for more

information.)

See the Programming section on page 33 for a list of programming commands unique to Massio ControlPads and Keypads. You can

find additional NetLinx Programming and Terminal (Telnet) commands in the NX-Series WebConsole and Programming Guide

available at www.amx.com.

WebConsole

Massio ControlPads have a built-in WebConsole that allows you to make various configuration settings via a web browser on any

PC that has access to the ControlPad. These pages are available by accessing the ControlPad via NetLinx Studio or any compatible

web browser.

Accessing the WebConsole

From any PC that has access to the LAN on which the target ControlPad resides:

1. Open a web browser and type the IP address of the target ControlPad in the Address Bar.

2. Press Enter to access WebConsole for that ControlPad. The initial view is the Web Control page.

Page 27

Initial Configuration

27

Instruction Manual - Massio ControlPads and Keypads

Default User Names and Passwords

The following table lists the default user names and passwords for accessing the Massio ControlPads through NetLinx Studio or the

WebConsole.

Default User Names and Passwords

User Name Password

NetLinx Studio netlinx password

WebConsole administrator password

For more information about navigating and the features of the WebConsole, see the NX-Series WebConsole and Programming

Guide available at www.amx.com.

Massio Keypads

The following sections provide instructions on accessing and configuring the keypad.

Locating the IP Address of the Keypad

The MKP-106 is configured for DHCP addressing by default. The keypad uses link local addressing as a backup in case the DHCP

server is inaccessible. See the Toggling Between IP Addressing Modes: DHCP and Static IP section for information on setting a static

IP address. Verify there is an active LAN connection on the controller’s LAN port before beginning this procedure.

1. Using category cable, connect the LAN port on the keypad to your external network.

2. In NetLinx Studio, select the OnLine Tree tab. You should see the Keypad listed among the Unbound Devices.

3. Right-click the Keypad and select Network Bind/Unbind Device from the menu that appears. The Bind/Unbind Device dialog

opens.

4. By default, the selected keypad appears in the Device to Bind/Unbind menu at the top of the dialog. If there is more than one

Unbound device in the system, click the down arrow to select which device you want to bind.

5. Select the check box next to the Master to which you want to bind the keypad. If there is more than one Master in the system,

check the specific Master to which you want to bind the keypad.

6. Click OK to save changes and close this dialog.

7. Select Refresh System (in the Online Tree context menu). The device should now appear in the Bound Devices folder.

Toggling Between IP Addressing Modes: DHCP and Static IP

Massio Keypads support both DHCP and static IP addresses. You can use a static IP address which you can set via a Telnet

command (SET IP), or you can use the factory default static IP address (192.168.1.2).

With the keypad powered and booted up (or in ID Mode), you can toggle between the DHCP and Static IP modes by pressing and

holding buttons 1 and 2. The LEDs on buttons 1 and 2 blink while you keep them pressed. Hold them until the LEDs begin blinking

at double the rate (approximately10 seconds), then release the buttons.

When you release the buttons, the keypad toggles either from static to dynamic (DHCP) IP addressing or vice versa and remains in

that mode until the you use the buttons to toggle the IP mode again or you perform a factory reset. The keypad automatically

reboots to complete the process.

NOTE: You must wait until the keypad is finished booting before toggling the IP address. Pressing the buttons while booting will cause

the keypad to restore its factory default settings.

Page 28

28

Instruction Manual - Massio ControlPads and Keypads

Upgrading Firmware

Overview

The basic process of upgrading firmware on Massio ControlPads involves downloading the latest firmware f iles from www.amx.com

and using NetLinx Studio to transfer the files to a target ControlPad.

Use the OnLine Device tree in NetLinx Studio to view the firmware f iles currently loaded on the device. FIG. 34 shows an example

OnLine Tree indicating an MCP-108:

Upgrading Firmware

FIG. 34

While the method of upgrading firmware f iles is the same for all Massio ControlPads, there are some specific points relative to the

specific model and type of controller that must be noted:

NetLinx Studio - Sample OnLine Tree

Massio ControlPads - Firmware Files

Massio ControlPads contain two devices (Master and Device Controller), each of which require a separate firmware (*.kit) file.

The ControlPad firmware file is not the same as the Device Controller firmware file. These two devices must be kept at compatible

firmware versions for proper operation. Therefore, both f iles should be used when upgrading any firmware associated with the

Integrated Controllers.

Massio ControlPads - Firmware Files

Master Firmware The on-board Master is listed first in the OnLine Tree as

Device Controller Firmware The Device Controller is listed next as "05001 MCP-10x (<firmware version>)"

"00000 MCP-10x Master (<firmware version>)"

For example, the Master in FIG. 34 above is "00000 - MCP-108 Master (v1.3.23)".

•"00000" represents Device ID 0, which is reserved for the Master.

• The number in parenthesis (in this case "v1.3.23") is the current Master firmware version.

For example, the Device Controller in FIG. 34 above is "05001 - MCP-108 (v1.1.18)".

•"05001" represents Device ID 5001, which is reserved for the Device Control ports.

• The number in parenthesis (in this case "v1.1.18") is the current Device Controller firmware version.

Before You Start

1. Verify you have the latest version of the NetLinx Studio application installed on your PC.

NetLinx Studio is available to download from www.amx.com. Login to do wnload th e latest version. Alternatively, if it is already

installed, use the Web Update option in NetLinx Studio’s Help menu to obtain the latest version.

The default location for the NetLinx Studio application is Star t > Programs > AMX Control Disc > NetLinx Studio > NetLinx

Studi o.

2. Verify that a LAN cable is connected from the controller to the LAN Hub.

3. Verify that the controller is powered on.

4. Connect to the controller via IP address.

5. Establish what version of f irmware is currently loaded on the controller (see Verifying the Current Firmware Version below).

Verifying the Current Firmware Version