Page 1

Cabling for Success with DXLink

Author: Curry Kinyon

Co-Author: Jeff Howes

Co-Author: Ann Yanecek

CABLING F O R SUCC E SS WI TH DX L I NK

White Paper

TM

Page 1 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 2

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

Table of Contents

EXECUTIVE SUMMARY .................................................................................................................... 3

INTRODUCTION ............................................................................................................................... 4

Overview ................................................................................................................................................... 4

DXLINK PERFORMANCE .................................................................................................................. 5

Basic Cable Information ............................................................................................................................ 5

Installed Cable Channel Performance ...................................................................................................... 6

Enova DGX Link Quality Reporting ........................................................................................................... 6

CABLE QUALITY ............................................................................................................................... 6

Cable Type ................................................................................................................................................ 6

Internal Channel Parameters .................................................................................................................... 6

External Channel Parameters ................................................................................................................... 7

Cable Shielding ......................................................................................................................................... 7

Cable End Termination ............................................................................................................................. 8

Bandwidth Performance ........................................................................................................................... 9

CABLE TOPOLOGY ........................................................................................................................... 9

Cable Length ............................................................................................................................................. 9

Cable Management ................................................................................................................................ 10

Patch Panels ............................................................................................................................................ 11

Patch Cables............................................................................................................................................ 11

ENVIRONMENT ............................................................................................................................. 12

Grounding ............................................................................................................................................... 12

Electrostatic Discharge (ESD) .................................................................................................................. 13

Electromagnetic Interference (EMI) ....................................................................................................... 14

Electrical Motors ..................................................................................................................................... 14

Proximity ESD Events .............................................................................................................................. 14

Ambient Operating Conditions ............................................................................................................... 15

CONCLUSION ................................................................................................................................. 15

Appendix A .................................................................................................................................... 16

Page 2 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 3

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

EXECUTIVE SUMMARY

Cabling For Success with DXLinkTM

After a full year of supporting deployments of DXLink solutions, it has become clear that using

unshielded cable is problematic. Installations with unshielded cable often have reliability issues with

the DXLink connection caused by changing environmental conditions. Therefore, our revised minimum

required cable type for DXLink systems is shielded CAT6 and that it’s installation follow the

recommended guidelines in this document.

DXLink™ delivers 10.2 Gb/s throughput over shielded category cable. It accomplishes this by leveraging

the transport layer of HDBaseT technology.

audio / video content at distances up to 100 meters when properly deployed and configured. The

following white paper provides detailed information on how cable quality, cable topology and the

environment affect the performance of DXLink systems. In summary, suffice it to say that looping, poor

cable end termination, using patch blocks, inadequate grounding of the cable/rack/building and

running cables near noisy devices will negatively affect the quality of the signal path and cause issues

such as offline events and blinking of video. Below are some helpful guidelines to follow when deploying

your DXLink system.

Best Practices

For best “it just works” results shielded Cat6A cable is recommended

If you have a cable deployment scheme running many cables in a bundled structure through

conduit or cable trays and have runs that traverse near large EMI or ESD generators you should

use shielded Cat6A cable to achieve reliable 100 meter performance

For optimal performance:

Keep the cable runs as short as possible

Follow cable shielding and termination techniques defined in this document

Follow Equipment and Building Ground requirements defined in this document

DXLink twisted pair cable runs for DXLink equipment shall only be run within a common building

Keep the DXLink cables as isolated as possible from noisy power cables

Avoid running cables in parallel with power runs, try to cross at 90 degree angles

Avoid running near noisy devices (motors) or inductive loads

Avoid tie wrapping and/or tightly bundling DXLink cables together

Avoid making sharp corners/bends in cable runs

Minimize “coiling” of the cables

Minimize patch panels & patch cables (every connection introduces losses)

Make sure connectors are properly terminated, higher quality shielded cables require

more intricate terminations

DXLink is state of the art technology capable of delivering

Page 3 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 4

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

INTRODUCTION

A multitude of aspects contribute to the overall system performance of DXLink products when installing

structured cabling solutions. The capabilities of this solution to pass Uncompressed HDMI Video,

Uncompressed HD Audio, Ethernet, Serial, IR and Power require a cable bandwidth of 250 MHz or

greater and cabling infrastructure performance that supports throughput of 10 Gb/s. Based on the

bandwidth required to transmit this amount of information we recommend following industry standard

practices designed for 10 Gigabit Ethernet. In order to perform at its best, the HDBaseT transport layer

utilized in DXLink requires specific rules which include management of not only to the cabling system

back-bone but also the patch locations and end-point runs. The primary focus of this paper is to review

the key challenges and solutions facing the structured copper cabling media required to properly

support the DXLink technology.

OVERVIEW

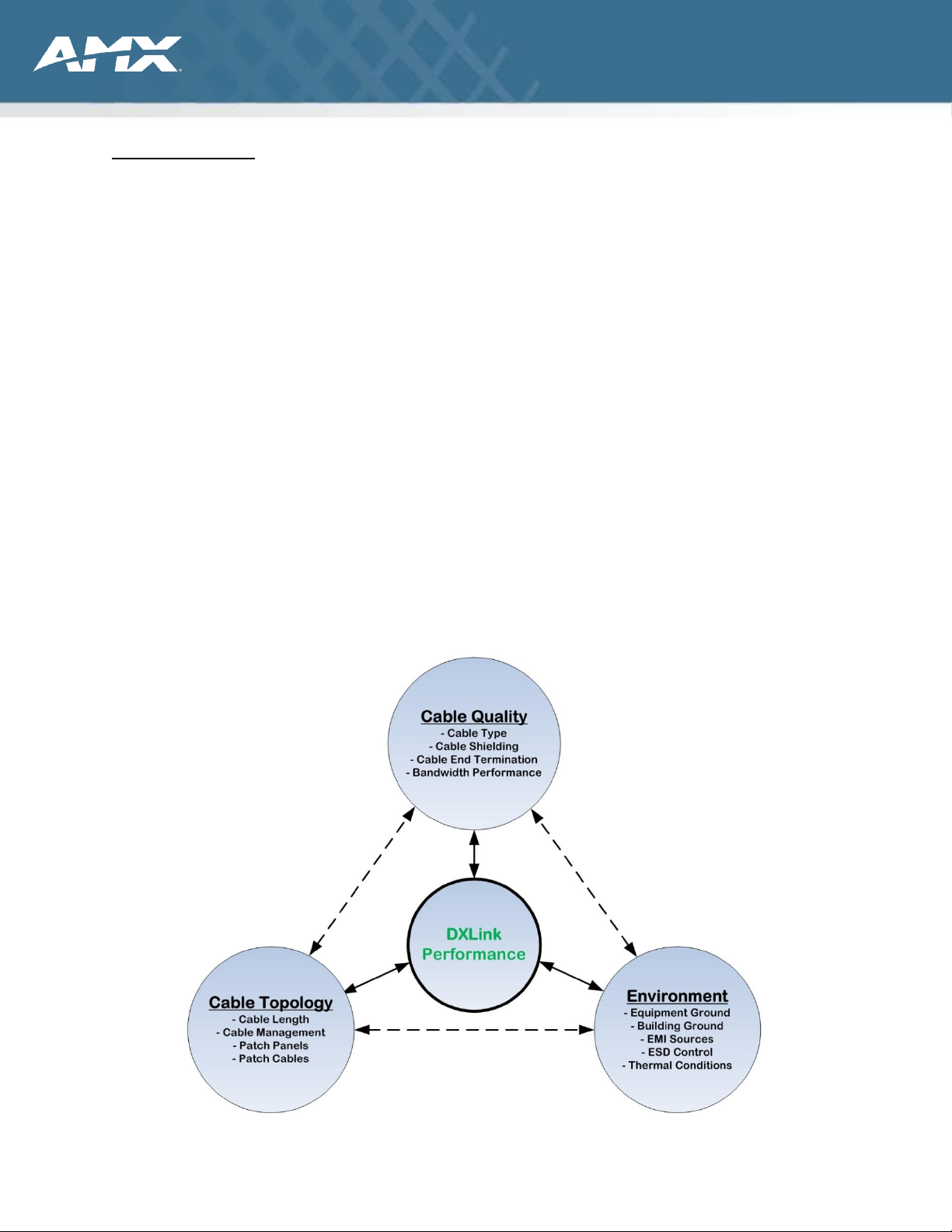

To achieve a high performing and reliable installation, several key factors need to be considered and

managed which all have a combined impact. When any one of these factors is not adhered to the

likelihood of inconsistent performance or sporadic video, audio and network drop-outs increase, to the

point where the products can fail to function at all if faced with several conditions not being met.

Three main areas need to be addressed in order to optimize the performance of DXLink installations.

They all have a direct impact on the performance of the overall DXLink system and also have relational

impact on each other, such that improving in one area can often provide ability to overcome

shortcomings in one of the other areas. A balancing of these three roles will allow for a successful and

robust DXLink system.

Page 4 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 5

Cat6A F/UTP (shielded and bonded)

Belden 10GX 10GX62F (Riser)

Belden 10GX 10GX63F (Plenum)

Cat6 F/UTP (shielded cable)

Belden 2412F DataTwist (Riser)

Belden 2413F DataTwist (Plenum)

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

DXLINK PERFORMANCE

Depending on the link quality between DXLink devices over structured cabling, the product performance

can vary from a solid and reliable system to a system which may have intermittent problems or links

that fail to function altogether. The most common symptom of poor link quality due to deficiencies in

the structured cabling is intermittent momentary dropping of video and audio but can also degrade to

the point that end-points fall offline and can even cause a link not to function at all, incurring a failure to

link.

This section touches on specific guidelines which can be referenced to ensure success from the

beginning of the project all the way through installation providing validation of link quality after the job

has been completed.

BASIC CABLE INFORMATION

Pre-installation cable selection should be the first order of business when designing the overall

installation. The cable selection should be determined by the combination of these factors: the

environment, the length of DXLink cable runs and the planned cable topology. As shown in this

document they all play a role in overall system performance.

The primary goal is to negate any of the external environmental factors that can impact performance

while ensuring a quality transport path from end-point to end-point. The minimum required cable to

provide a successful system installation is a shielded Cat6 cable. To ensure robust performance in

installations with unmanaged environmental factors, stepping up to Cat6A STP or Cat7 is recommended.

STP is used in this document to cover the wide range of Shielded Twisted Pair implementations listed

below; the severity of environmental factors should be considered when selecting between them:

SF/FTP, S/FTP, F/FTP, SF/UTP, U/FTP and F/UTP

‘S’ represents Screened braid shielding (also sometimes referenced as ‘Sc’)

‘F’ represents Foil shielding

‘U’ represents Unshielded

‘TP’ represents Twisted Pair

And notations left of the ‘/’ defines outer cable shielding while right of the ‘/’ defines shielding of the

individual wire pairs. Some graphical examples are shown on page 8 of this document.

Note: Not all cable manufacturers use the same definitions regarding shielding nomenclature.

For best performance a shielded Cat6A cable is suggested, we recommend the following (or equivalent)

to provide a good price vs. performance point while minimizing environmental impact.

When using a Cat6 F/UTP cable we recommend the following (or equivalent).

A complete Belden shielded Cat6A cable and cable management solution is available here:

http://www.belden.com/docs/upload/CheatSheet_10GX_FT_Shielded_Systems.pdf

Page 5 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 6

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

INSTALLED CABLE CHANNEL PERFORMANCE

Once cable is installed there are generally several factors that can affect link quality such as cable

quality, cable termination, grounding techniques, building ground differences, cable length, cable

topology, service loops, patch panel quality and quantity, cable kinks, etc… In order to understand how

the overall cable paths perform from one end of DXLink to the other end of DXLink, you can utilize tools

such as the Fluke DTX 1800 to characterize a number of specifications defined by TIA-568-C.2. Any cable

type chosen should have its end-to-end performance meet the installed Channel Requirements specified

by TIA-568-C.2.

ENOVA DGX LINK QUALITY REPORTING

Another method for determining the link integrity for a given DXLink path is provided if it is connected

to an Enova DGX populated with DXLink Input/Output boards. The Enova DGX 64, 32, 16 and 8

Enclosures can report measured link integrity values which are useful in qualifying the overall system or

troubleshooting paths that are presenting problems. When connected to the Enova DGX Enclosure,

reporting of each DXLink Input/Output port can be captured which presents a decibel value for each of

the four twisted pairs on a given port. If any of these MSE values reports >= -15dB (i.e. -13dB) the link

quality is in a range that can affect performance. See Appendix A for instructions and examples of how

link quality reporting through the Enova DGX Enclosure can be acquired.

CABLE QUALITY

CABLE TYPE

AMX requires as a minimum using CAT6 shielded cable installed per the recommended guidelines in

this document.

As you might expect, the higher the quality of the category cable the more robust the DXLink system will

perform. The gains to be made in this area are improved bandwidth, improved internal channel

parameters, improved external channel parameters and reduced susceptibility to environmental EMI

and ESD events.

When using Cat6 STP, Cat6A STP and Cat7 which meet their correlating TIA-568-C.2 performance

requirements, the DXLink runs can fully reach the 100m specification when bundled in groups of 6+1

(TIA-568 Alien Crosstalk Bundle). Using the heavier shielded versions of them, such as S/FTP, provide

improved resistance to uncontrolled environmental EMI and ESD events.

The benefits of these increasing grades of cable type provide significant improvement in both internal

and external channel parameters. Specifically of note are:

INTERNAL CHANNEL PARAMETERS

Insertion Loss / Max Attenuation: The measure of signal loss that occurs from transmitter to

receiver.

o

Often referred to as the cable bandwidth, typical factors that affect insertion loss include

conductor size, insulation and jacket material type, frequency bandwidth, number of patch

connections and cable length.

Return Loss: The measure of how much signal gets reflected back to the source due to impedance

variations in the Channel.

Page 6 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 7

CAB LING F O R SUCC E SS WI TH DX L I NK

o

Typical factors that affect Return Loss include variations in twist rates and discontinuities in

impedance.

Near End Crosstalk (NEXT): The measure of unwanted signal coupling between pairs in the same

cable.

o

Power Sum NEXT (PSNEXT) is the sum of unwanted signal coupling between multiple pairs in

the same cable.

Equal Level Far End Crosstalk / Attenuation to Crosstalk Ratio, Far End (ELFEXT/ACRF): The

measurement of unwanted signal coupling between pairs in the same cable when a disturbing

signal is sent from one end and received by the transceiver on the opposite end, including

attenuation loss due to insertion loss.

o

Power Sum ELFEXT / Power Sum Attenuation to Crosstalk Ratio, Far End (PSELFEXT/PSACRF)

is the sum of unwanted signal coupling between multiple pairs in the same cable when the

disturbing signals are sent from one end and received by the transceiver on the opposite

end..

o

Typical factors in the severity of these internal crosstalk measurements are the cable

internal insulation and pair to pair separation.

White Paper

EXTERNAL CHANNEL PARAMETERS

Alien Crosstalk is the most significant external parameter that affects signal and channel

performance. Both near end and far end crosstalk can detract from robust functionality and

specifically include the Power Sum scenarios described above where multiple cables contribute

crosstalk to the channel under evaluation.

o

Power Sum Alien NEXT (PSANEXT) is the effect of multiple Alien/External cable channels

injecting NEXT on a given cable.

o

Power Sum Alien ELFEXT / Power Sum Alien ACRF (PSAELFEXT/PSAACRF) is the effect of

multiple Alien/External cable channels injecting ELFEXT/ACRF on a given cable.

Alien Crosstalk can significantly be reduced or mitigated by:

o

The use of higher grade cables such as Cat6A STP and Cat7 cabling, while some

improvements can still be achieved through the use of shielded or foiled Cat6 (F/UTP).

o

Separating the cables from each other for portions or the entire cable run.

CABLE SHIELDING

Properly managed STP cable will provide numerous benefits, with the double shielded version such as

S/FTP and F/FTP giving even greater protection against unmanaged environmental disturbances. When

utilizing shielded cable, the entire system and building ground should be managed to ensure end-to-end

common ground reference levels. Some specific benefits of STP include:

It will provide shielding from Alien forms of crosstalk, as covered in the cable type section, which

reduce or eliminate noise from adjacent or bundled cables.

It will provide a significant improvement in immunity to environmental EMI and ESD events that

might be occurring in the area of the DXLink TX, DXLink cable runs, DXLink Enclosure or DXLink RX.

o

This added immunity will generally eliminate possible video or network drops due to events

of this nature by the virtue of keeping the large area events that are radiated through the air

from coupling onto the high-speed DXLink signals and circuitry.

Page 7 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 8

F/UTP: Foil shielding that

encompasses the cable while

leaving individual pairs

unshielded.

S/FTP: Foil shielding or screened

braid that encompasses the cable

while including additional foil

shielding around each of the four

differential pairs.

U/FTP: No shielding or screening

around the cable, but including

individual foil shielded pairs

inside the cable.

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

CABLE END TERMINATION

Termination techniques for using shielded cable need to be applied correctly for STP cable benefits to be

realized and keep from introducing negative effects. Not only do the cables include shielding

components which need to be terminated correctly, but the diameter of the cable itself will be larger

and in some cases require the use of shielded punch-down connectors to properly terminate.

Bonding to ground at both ends of the cable is required.

o

Bonding throughout the run, including patch panels and patch cables to achieve a true end

to end ground connection is necessary.

o

A full 360 degree shielding termination is required to ensure ground connection is robust

and will not make intermittent contact when stresses are applied to the cable once

installed. We recommend use of a copper tape to be wrapped around the cable end with

the grounded drain wire and possibly foil shielding placed underneath the copper tape as

shown below. The copper tape used here is a ¾” wide 3M 1181 brand, part number

80011181049. This will ensure a low impedance connection at each interconnect point. The

series of pictures below show the recommended termination process with the final picture

showing that even when the cable has stresses applied; the 360 degree shielding will ensure

contact between the cable shielding and the shielded RJ-45 plug.

o

A low impedance connection at the equipment rack ensuring a solid tie between equipment

and the rack itself as well as between rack and the buildings main ground buss bar is

needed.

Shielded or screened cable can reduce the effects of EMI and ESD on DXLink transmission, but

they require equal grounding of the screen at both ends of the cable. A difference in ground

potential between the termination points of the cable could cause the cable to act as an

antenna, virtually negating all benefits hoped to be gained. But with good grounding techniques

applied to all components of the DXLink system, including the cable drain wires, lost packets and

dropped video can be kept to a minimum.

Source: http://en.wikipedia.org/wiki/Twisted_pair

Page 8 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 9

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

BANDWIDTH PERFORMANCE

The published specification minimum requirement for supporting proper functionality is based on a

controlled environment with quality cable and meets the horizontal cable specifications for Cat6 defined

by TIA-568-C.2 at 250 MHz.

The indicator of a cable’s bandwidth performance is the Insertion Loss specification, also referred to as

Max Attenuation. We recommend a cable rating of no more than 32.8dB of attenuation at 250 MHz over

100m.

Source: www.belden.com/techdatas/english/2412F.pdf

Note: The bandwidth of the cable alone will not guarantee robust performance in any installation as the

overall performance is a factor of the three main categories referenced in this document as Cable

Quality, Cable Topology and Environmental Factors.

CABLE TOPOLOGY

CABLE LENGTH

DXLink maximum cable length is specified at 100m. Many contributing factors can impact the DXLink

signal performance over that length of category cable. Conduit density, loops, bends, kinks, patch panels

and patch cables are the areas addressed in the following section.

A standard 10G Base-T Ethernet cabling topology of 5m (patch) 90m (Horizontal cabling) 5m

(patch) is recommended. Better signal performance can be achieved if the DXLink system cabling does

not include patch cords, panels, or couplers which will degrade the signal.

Page 9 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 10

Shielded Cat6, Cat6A or Cat7

# of Cables bundled together

Total length of cable run

supported

>=1

100m

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

Figure 1, in conjunction with its table depict the ability to achieve a full 100m distance run

when using Shielded Cat6, Cat6A and Cat7 cables. There are no restrictions on the number of

cables bundled together up to 100m.

Figure 1 - Bundling topology, shielded cabling

Figure 1 Table – Bundling lengths for shielded Cat6, Cat6A or Cat7 category cables.

CABLE MANAGEMENT

Cable management solutions

o There are several off-the-shelf cable management systems which provide a full offering

of compatible components to help ensure appropriate installation and management of

category cable infrastructures. These will provide solutions to cable routing, cable end

termination, punch down connectors, patch panels, patch cables and even preterminated horizontal back-bone cables among other items.

o One such offering that has been shown effective for both performance and installation

practices is offered here by Leviton:

http://www.leviton.com/OA_HTML/ibcGetAttachment.jsp?cItemId=80036&labe

l=IBE&appName=IBE&minisite=10251

Specifications for shielded category cables

Definition: Shield – A metallic layer placed around a conductor or group of conductors.

These specifications apply to F/UTP, U/FTP, S/FTP plus other shielded cable types in a bundle:

o Maximum conduit fill density will be no more than 60%.

Page 10 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 11

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

o At all termination points along the shielded cable’s path, the copper tape or foil must

make 360 degree contact with the shielded connector’s housing (e.g., RJ-45 conductive

housing).

o All patch cords, panels, and couplers must be shielded in the cable run.

o A low impedance connection must be maintained over the full length of the shielded

cable run.

o DXLink twisted pair cable runs for DXLink equipment shall only be run within a common

building.

Common building is defined as: Where the walls of the structure(s) are

physically connected and the structure(s) share a single ground reference.

o Additional care must be taken during installation not to kink the cable which can deform

the conductors, thereby degrading the cable’s performance.

o Avoid tie wraps. If tie wrap use is absolutely necessary, then they should only loosely

surround the cables. Cinching the tie wraps around a bundle will deform the cable

conductors and negatively affect performance.

o Use loose Velcro™ wraps to bundle cable, only if it is necessary.

o Use 10G Base-T horizontal wire management techniques.

o Service loops are sometimes required as a means to store excess cabling. We do not

recommend service loops as they increase the total length of the cable run, and the loop

will wrap the cable back on itself which will increase crosstalk. If you must store excess

DXLink system cabling do not use a loop, but instead use an “S” pattern.

o Bend radiuses tighter than the manufacturer’s recommendations and kinks (even

straightened out kinks) created during installation will have a negative impact on the

cable’s performance.

Excessive bends or kinks can deform the cable’s conductors, which will degrade

the cable’s performance.

Excessive bends or kinks can deform the cable, which can alter the cable’s pair

balance leading to noise immunity performance losses.

Kinked cable (even straightened out kinks) might perform adequately for

Ethernet applications, but will have a much larger effect on DXLink system

cabling.

It is our recommendation that any category cables with an excessive bend radius or kinks are

treated as a damage cable. Deformed category cables will limit the cable’s ability to properly

pass a 10 Gb/s signal.

PATCH PANELS

Recommended panel practices:

Utilize patch panel designed for the shielded cable class you are installing.

Ensure the patch panel itself is well grounded to the buildings ground bus.

Use proper strain relief to keep from damaging cable terminations.

o Cable management combs may be desirable.

Do not place patch panels near large EMI or ESD generators.

PATCH CABLES

Recommended Patch cable/cord practices:

As defined by the TIA standard, patch cables are intended to be relatively short cables.

Ensure the patch cable is the same cable type or better than the horizontal back-bone cabling.

Page 11 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 12

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

Do not install low quality patch cables as they will become the weakest link and negate the

integrity and quality of the rest of the installation and horizontal cabling infrastructure.

o Patch cables must also be shielded and properly terminated.

5 Meters is the maximum recommended length for the patch cables.

ENVIRONMENT

Environmental factors play an important role in determining the success of a DXLink installation,

especially when the cable runs are over 30 meters. Some factors could result in an installation suffering

intermittent failures or being inoperable if not carefully considered during the project development

phase. Factors could include:

Grounding

o Equipment Grounding

o Building Ground Integrity

Electrostatic discharge (ESD) of excess static in the category cable jacket or when excess static

electricity is discharged by a human hand through one of the DXLink components.

Electromagnetic interference (EMI) generated by proximity electrostatic discharges, or by

operating electrical motors.

Ambient operating conditions surrounding the system installation.

Note: EMI and ESD, can be greatly reduced through the use of well balanced, shielded cables with

grounded connectors, and keeping the cable runs as short as possible. Internal testing has shown that

unbalanced and improperly grounded or terminated cable runs and equipment will lead to erratic

behavior including network, audio and video losses.

GROUNDING

Transmission of DXLink data over twisted pair copper wire (differential mode) requires well balanced

cable and terminations at both ends of the twisted pair to minimize the effects of the common mode

hostile sources described in the EMI and ESD sections of this paper. Obtaining perfect balance becomes

increasingly difficult as the length of the cable increases, making the cable less immune to EMI and ESD

sources. Shielded or screened cable will reduce the effects of EMI and ESD on DXLink transmission, but

they require equal grounding of the screen at both ends of the cable. A difference in ground potential

between the termination points of the cable will cause the cable to act as an antenna, virtually negating

all benefits hoped to be gained. But with good grounding techniques applied to all components of the

DXLink system, including the cable drain wires, lost packets and dropped video can be overcome.

The following two sub-sections are discussed thoroughly and practically inside of the document link

provided below from Amp Netconnect and Tyco Electronics which when understood and followed will

provide a quality installation and robust DXLink performance. It incorporates practices defined in the

National Electric Code (NEC) NFPA 70 which defines grounding and bonding as well as providing

requirements of the grounding of a building’s electrical system. The linked document also incorporates

practices defined in the TIA J-STD-607 Commercial Building Grounding (Earthing) and Bonding

Requirements for Telecommunications.

http://www.ampnetconnect.com/documents/Grounding_and_Bonding_White_Paper_%5B0901%5D.pdf

Equipment Grounding

o Follow requirements defined in TIA STD-607.

The standard can be purchased through IHS here.

o The grounding of ALL equipment used in a DXLink installation is required.

Page 12 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 13

Examples of Static Generation

Typical Voltage Levels

Means of Generation

10-25% RH

65-90% RH

Walking across carpet

35,000V

1,500V

Walking across vinyl tile

12,000V

250V

Worker at bench

6,000V

100V

Poly bag picked up from bench

20,000V

1,200V

Chair with urethane foam

18,000V

1,500V

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

o Grounding is recommended to be provided through a low impedance connection to

equipment racks which in-turn should be heavily tied into the buildings electrical ground

system.

Building Ground Integrity

o Follow requirements defined in NEC NFPA 70.

The standard can be accessed free through NFPA here.

o The entire building should have a common ground potential.

Siemon has provided an informative discussion of the benefits of shielded cable:

http://www.siemon.com/us/standards/Screened_and_Shielded_Guide_1_Overview_and_History.asp.

DXLink signals can be carried over long distances; equipment connected to AC power at one end of the

system may not be at the same ground potential as equipment at the other end of the system if

guidelines provided by NEC (National Electrical Code) and TIA-607 (Generic Telecommunications

Bonding and Grounding/Earthing for Customer Premises) are not followed.

ELECTROSTATIC DISCHARGE (ESD)

ESD is a type of EMI, but in this paper we are treating indirect ESD and direct ESD events separately.

Direct ESD events refer to any electrostatic discharge that takes place directly to the DXLink system,

where the system includes all components: DXLink receivers and transmitters, cables, and racks.

ESD is defined as the transfer of excess electrons (charge) from one surface at some electrical potential

to another surface at a different potential. The most common method of generating a charge is when

different materials are rubbed against each other, transferring electrons; this is known as triboelectric

generation. An example of triboelectric generation occurs when a person walks across a carpeted floor

wearing shoes with soles made of a different material than the carpet.

An example of the voltage potential created by various activities under two ranges of relative humidity is

provided in the following table by the Electrostatic Discharge Association, North Central Regional

Tutorial Program (http://www.esda.org/fundamentalsP1.html):

As this table indicates, the relative humidity of the air surrounding the activity can affect the amount of

potential; the drier the air the greater the potential. Note that the materials indicated in this table have

insulative properties, meaning they do not permit the flow of electrons. The potential on insulative

materials can exist for a long time if not placed in contact with a material having a different potential.

When a material with high potential created during these activities contacts a material that has very low

potential, such as when a person walking across a carpeted floor touches a metal door knob, the

Page 13 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 14

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

potential is rapidly dissipated causing an electromagnetic pulse and possibly the familiar spark (shock!).

This occurs regularly during the installation of a DXLink system:

Triboelectric generation of potential on cable outer jackets when they are installed may be

dissipated when the jacket comes in contact with a metal surface, such as a cable raceway.

Potential on the cable jackets may also be dissipated when the cable’s terminated ends are

connected to the DXLink receivers/transmitters.

An installer touches the metal frame of a DXLink system component, dissipating any charge built

up while walking across the floor.

When a potential is dissipated directly to the system, the path it takes varies so it is difficult to predict

exactly what effect it will have on the DXLink transmission. AMX has conducted experiments which show

static discharges with voltage potential of ±3.5kV and greater applied directly to system components

cause sufficient disruption to the transmission that result in momentary lost video. This is probably due

in part to EMI (discussed below) and to propagation of the voltage throughout the component being

discharged to.

Note: AMX equipment used in DXLink installations is protected against damage from ESD events.

ELECTROMAGNETIC INTERFERENCE (EMI)

Of the many forms of EMI, the greatest disruption to a DXLink installation is generated by

1) Electrical motors 2) Proximity ESD events and 3) Alien crosstalk from adjacent cables. The third form

is covered in another section of this paper and will not be discussed here.

ELECTRICAL MOTORS

The second form, EMI generated by electrical motors operating in proximity to a DXLink system cable

run, is greatly reduced by the use of twisted wire pairs provided the twisted pairs are well balanced.

However, EMI transients generated when cycling power to the motor could propagate quickly through

cable located nearby causing momentary loss of data, ultimately resulting in loss of video, audio or

network connection. The good news here is these EMI sources have fixed locations and their operation

is well understood; avoid placement of DXLink system cable runs close to large motors (e.g. heat pumps,

elevators, lifts) and keep the runs perpendicular to power line cables.

PROXIMITY ESD EVENTS

Proximity ESD events are severe EMI occurrences produced when static electricity is discharged close to

a DXLink system cable run – no direct contact with the cable is made, but the resulting electrostatic field

can induce voltages in the category cable and cause momentary interference with transmission of the

DXLink stream. In a typical Ethernet installation lost packets are simply retransmitted, but in an DXLink

installation the lost packets are perceived by the user as dropped video, audio or network connection. In

the real world, certain DXLink installations can be prone to the effects of proximity ESD events;

examples are casinos where electrostatic air cleaners are used, and carpeted conference centers.

AMX has conducted testing to empirically quantify the effect of real-world ESD events on transmission

of DXLink data: the test configuration is shown in Figure 2. In this testing a Schaffner ESD generator was

used to apply controlled static discharges to various locations around the DXLink switcher, and to

locations connected to ground along the length of the cable run. Various cable types (shielded,

unshielded, Cat5e, Cat6) and cable configurations (straight one-way run, straight two-way run, loosely

coiled, with and without patch cables) were tested using discharge voltages between +/-2kV and +/-8kV.

Page 14 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 15

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

Results from this testing showed that discharge voltages as low as 4kV at a distance of ~4 meters from

the cable run were responsible for causing video to drop.

Figure 2 - Proximity ESD Event Test Diagram

Conclusions from this testing are that DXLink system susceptibility to EMI generated by proximity ESD

events is related to the length of the cable run (shorter runs are less susceptible), the distance from the

event to the cable, and the type of cable (properly terminated and bonded shielded cable is least

susceptible).

AMBIENT OPERATING CONDITIONS

Temperature - Cable manufacturers specify their cables in different ways, but most will provide

specifications for both installation temperature and operating temperature. To minimize damage to the

cables, these specifications should be well understood before attempting to install a DXLink system

cable run.

Humidity - As was demonstrated above, relative humidity has a distinct effect on the voltage generated

during an ESD event which in turn can have an effect on the quality of the transmitted DXLink signal

when the event occurs in proximity to an unshielded cable.

CONCLUSION

DXLink products can provide a wealth of features and benefits for your installation. Ensuring a properly

shielded and terminated transmission medium plus a well-grounded system for distribution of signals

will allow for a successful and robust solution.

For more information on DXLink products, contact your AMX Representative or visit www.amx.com.

Page 15 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 16

MSE Value

Cable Quality

Unlinked

No cable connected

0dB to -8dB

Unusable – Likely no link made

-9dB to -11dB

Bad – Likely no video

-12dB to -14dB

Poor – Frequent video drops

-15dB to -17dB

OK – Rare video drops

-18dB to -20dB

Good – Stable

-21dB to -23dB

Ideal – Very robust

CAB LING F O R SUCC E SS WI TH DX L I NK

White Paper

APPENDIX A

Enova DGX Link Quality Reporting

Link quality measurements can be reported by the Enova DGX DXLink Input and Output boards to help

determine the quality of the link established between a DXLink Input board and connected TX or a

DXLink Output board and connected RX. The reporting information can potentially identify cable runs

that will cause performance issues due to items such as poor cable quality, excessive length or patch

cables discussed in this White Paper.

Link Quality Reporting over Enova DGX Serial or USB Port

If your system has DXLink Input with FW v1.0.3.1 or higher and DXLink Output with FW v1.0.4.1 or

higher, which are included in the Enova DGX FW KIT upgrade v 1.2.5.1 or higher (released on 8/21/2012)

you will have access to the individual input & output port statistical reporting from the CPU’s Serial or

USB port. With this capability you will be able to view the link quality of a given cable run and determine

if there are potential cabling issues which could cause performance issues. Another metric which can be

viewed in this reporting is the cable length which has a +/-10% tolerance and is reliable at 25 meters and

above.

The reporting is gathered and presented by the Enova DGX’s CPU and accessed using the SHELL

command mode over the DB-9 serial port or mini-USB port using a terminal program.

To gain access to the SHELL you should follow the instructions in the Enova DGX product manual under

the Installation and Setup Chapter – Attaching an External Serial Controller section to establish

communication with the CPU. Once in communication, the commands shown below with values

reported will guide you into the SHELL and show examples of how to get the MSE Link Quality reporting.

1. After establishing CPU communication with a terminal program:

a. Press “CTL+C” (Control and C) to enter the command SHELL, you should see a prompt of

‘DGX_SHELL>’.

i. Note: The SHELL interface will time-out after a brief period and return to the

BCS interface so if you don’t enter the commands before the time-out you’ll

need to re-enter the SHELL with the “CTL+C” key combination.

b. Type “show stats” followed by <Enter>, you should get a statistic report for all DXLink

Input and Output boards in the enclosure.

c. The MSE (Mean Square Error) value is included in this information and BOLDED below.

The data for all 4 twisted pairs of each cable/port are displayed with the dB values

below. The BER and DSP Reset reporting that is presented with the MSE is not currently

meaningful for diagnostic purposes.

d. The following table shows the -dB value ranges and their typical performance levels.

Page 16 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Page 17

CAB LING F O R SUCC E SS WI TH DX L I NK

DGX_SHELL>show stats

MCPU:

i2c failure count: 2

reboot count: 10

BCPU1:

Ch1-[DxLink In] BER Video:10^(-0), Audio:10^(-0), Blank:10^(-0), Ctrl:10^(-10)

Ch1-[TX] Cable Length: 90 (Meters), 295 (Feet)

Ch1-[DxLink In] MSE Chan A:-19db, Chan B:-18db, Chan C:-18db, Chan D:-20db

Ch1-[DxLink In] DSP Reset Count: 0

Ch2-[DxLink In] BER Video:10^(-0), Audio:10^(-0), Blank:10^(-0), Ctrl:10^(-10)

Ch2-[TX] Cable Length: 80 (Meters), 262 (Feet)

Ch2-[DxLink In] MSE Chan A:-20db, Chan B:-20db, Chan C:-20db, Chan D:-21db

Ch2-[DxLink In] DSP Reset Count: 0

Ch3-[DxLink In] BER Video:10^(-0), Audio:10^(-0), Blank:10^(-0), Ctrl:10^(-10)

Ch3-[TX] Cable Length: 33 (Meters), 108 (Feet)

Ch3-[DxLink In] MSE Chan A:-21db, Chan B:-21db, Chan C:-22db, Chan D:-22db

Ch3-[DxLink In] DSP Reset Count: 0

Ch4-Unlinked.

Ch4-Unlinked.

Ch4-Unlinked.

Ch4-Unlinked.

White Paper

Page 17 AMX White Paper | Cabling for Success with DXLinkTM | V 3.1 6.2013

Loading...

Loading...