Page 1

Reference Guide

THERMAL EXPANSION

AND CROSS

-

CONNECTION

CONTROL SOLUTIONS

As Seen On

Page 2

2 3

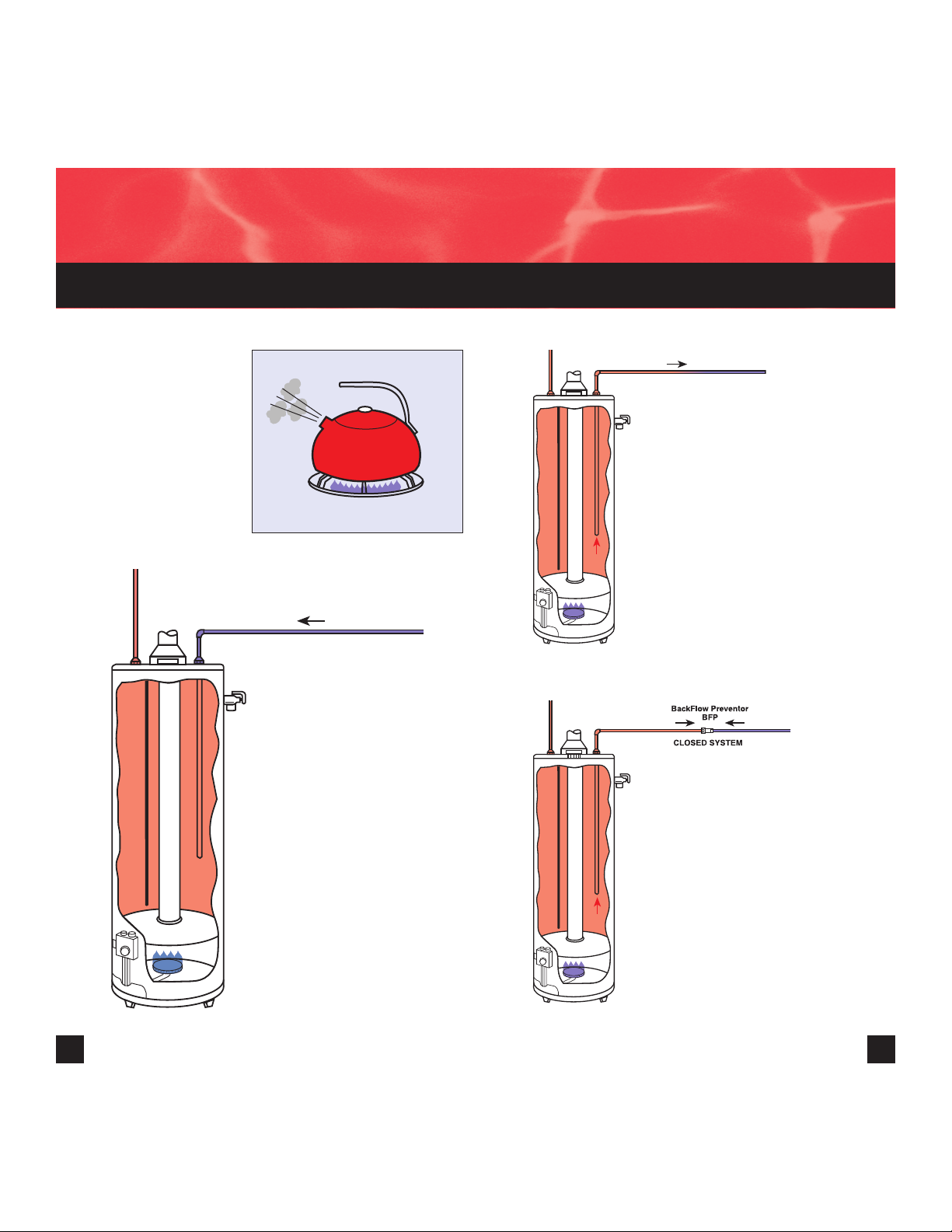

In a 40-gallon water heater,

for example, water being

heated to recover after

usage will expand to about

40.60 gallons when the

desired temperature is

reached.

It expands! Reacting

to physical law, water

expands in volume as

its temperature rises.

In the "Good Old" days

Before the advent of

cross-connection control,

expanded water that

exceeded the capacity of

the water heater flowed

back to the city main,

where it easily dissipated.

It was "open" at the city

supply side of the system,

even though it was

"closed" on the system

side.

Cross connection

means "no return"

Today, with back flow

preventers, water meters

with check valves, and/or

pressure-reducing valves

without a bypass being

installed, expanded water

from a water heater

cannot return to the city

supply. It is now a closed

system, and expanded

water has no place to go.

When water is heated...

OPEN SYSTEM

COLD

WATER

SUPPLY

Page 3

4 5

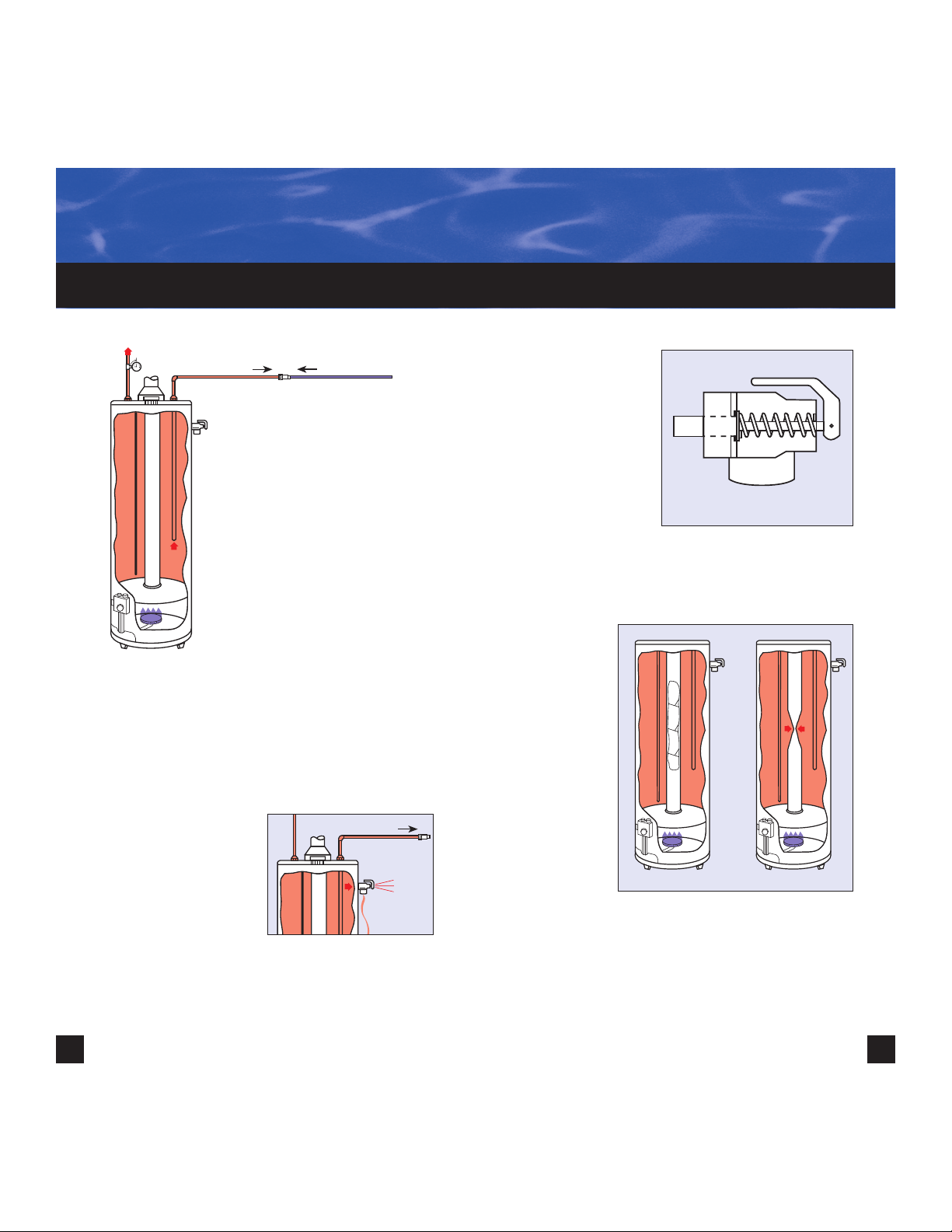

Water is not

compressible

Since water completely

fills the water heater

and system piping before

recovery starts, and since

it can't be compressed,

the expanded volume,

even though small, has no

place to go.

As a result, the expanding

water creates a rapid

and dangerous pressure

increase in the water

heater and system piping,

much like the action of a

hydraulic ram.

So "pop" goes the relief valve

The setting on a temperature & pressure safety

relief is quickly reached,

and the relief valve

opens, losing heater

water down the drain or,

more often than not, all

over the floor.

The illogical practice of operating your safety valve

once or twice a day is not only wasteful (you paid to

heat the water that went down the drain), it's also

dangerous.

First of all, the T & P

relief valve you

installed serves as

an emergency control only. It was never

designed as an

operating control.

Once a safety valve

is used on a daily

basis, it isn't that

safe.

Deposits on the seat... deteriorating springs... wearand-tear erosion can wear out a relief valve in no time

at all.

Dangerous

pressures

before relief

What most

people don't

realize is that

dangerous

conditions can exist during thermal expansion long

before the relief valve operates.

Internal pressures repeatedly occurring during recovery

periods can collapse the center flue of a gas-fired water

heater, creating a hazardous presence of deadly carbon

monoxide gas, or even a water-heater explosion.

DANGER!

BACK FLOW PREVENTER

BFP

LOST

BTUs

Page 4

6 7

Even though the relief valve operates during each

recovery period, high internal pressures occurring over

and over again can accelerate tank leakage and shorten water-heater life, no matter how it is fired.

Controlled Pressure Rise

During Thermal Expansion

The best solution to thermal expansion is to control

the pressure it generates within a safe operating

range, well below the emergency setting of a relief

valve. This allows thermal expansion to occur without

causing a dangerous increase in pressure.

Solution

SAFE

RANGE

150 PSIG

Page 5

8

9

AIR

This is easily accomplished by adding an

expansion tank with a

sealed-in, compressible

air cushion, which will

compress as thermal

expansion occurs, providing the place for the

expanded volume of

water to go during

recovery.

By sizing the air cushion

according to Boyle's

Law, we can select

the maximum pressure

on the system when

the total amount of

expanded water has

been generated.

When hot water is used

in the system, the pressurized air cushion

forces hot water back

into the system for use,

not waste.

The thermal expansion tank features the sealed-in air

cushion, pre-charged to the minimum system pressure before recovery is started. A rugged butyl

diaphragm seals in the air cushion and also separates

air from hot domestic water to prevent air from being

dissolved by hot system water.

Finally, on the water side of the expansion tank is a

separate, rigid polypropylene liner so fresh, corrosive,

domestic hot water can be handled without fear of

corrosion and leaks.

1. System

Connection

2. Separate, rigid

polypropylenelined water

reservoir (NSF

listed)

3. Heavy-duty

butyl diaphragm

4. Sealed-in,

permanent air

charge

5. Welded steel

pressure support domes

6. Air charging

valve

CUSHION

EXPANDED WATER

AIR

CUSHION

AIR

CUSHION

Page 6

10 11

Sizing charts based on:

• Precharge matched to incoming supply

pressure prior to installation

• Incoming water temperature 40°F

• 150psi T & P safety relief valve

AMTROL’s Therm-X-Trol

®

brochure MC#4090

contains precise sizing guidelines for sytems not

covered in the above charts.

The thermal-expansion tank for domestic water

heaters, sized right, is the only logical answer to the

growing problem of thermal expansion in water

heaters protected by BFP, check valves or pressurereducing valves. A simple installation to the supply

side on the water heater, this small tank will eliminate

the dangerous condition so that the relief valve will not

open during normal heating cycles.

Water Heater*

Size (gals.)

Static Supply Pressure (psi)

40

60

**

80

40 ST-5 ST-5 ST-5

50 ST-5 ST-5 ST-5

60 ST-5 ST-5 ST-8

80 ST-8 ST-8 ST-12

120 ST-12 ST-12 ST-25V

Max. Temp. Setting 140°F

BACK FLOW PREVENTER

BFP

Water Heater*

Size (gals.)

Static Supply Pressure (psi)

40

60

**

80

40 ST-5 ST-5 ST-5

50 ST-5 ST-5 ST-8

60 ST-8 ST-8 ST-8

80 ST-8 ST-8 ST-12

120 ST-12 ST-12 ST-25V

Max. Temp. Setting 150°F

Water Heater*

Size (gals.)

Static Supply Pressure (psi)

40

60

**

80

40 ST-8 ST-8 ST-8

50 ST-8 ST-8 ST-12

60 ST-8 ST-12 ST-25V

80 ST-12 ST-25V ST-25V

120 ST-25V ST-25V ST-25V

Max. Temp. Setting 180°F

Page 7

MC# 8550 PN: 9015-612 (06/07)

®

Corporate Headquarters

1400 Division Road

West Warwick, RI 02893

Telephone: 401-884-6300

Fax: 401-884-5276

AMTROL Canada, Ltd.

275 Shoemaker Street

Kitchener, Ontario N2E 3B3

Telephone: 519-478-1138

Fax: 519-748-1138

www.amtrol.com

12

Loading...

Loading...