Page 1

INSTALLATION, OPERATION

West Warwick, Rhode Island 02893

& MAINTENANCE

INSTRUCTIONS

TM

BOILER MATE

INDIRECT-FIRED WATER HEATERS WITH

TOP-MOUNTED COIL

TOP-DOWN

MODELS: TD-7Z

TD-41Z

TD-7ZDW

TD-41ZDW

The heat transfer medium should be water. If any product other than water is used, it must be a

non-toxic fluid suitable for human ingestion as determined by the FDA

WARNING: REVIEW ALL GENERAL SAFETY INFORMATION ON PAGE 3 PRIOR TO INSTALLATION.

Your AMTROL BOILER MATE™ has been carefully assembled and factory tested. To enjoy the full service your BOILER

TE™ can pr

MA

been completed, make sur

AMTROL product. You should also read carefully the sections describing proper product maintenance, and follow the

ed procedures as you use your BOILER MATE™. Return this booklet to its original envelope, and keep it with the

equir

r

BOILER MA

www.amtrol.com or ask your AMTROL supplier for any updates relating to your product.

Our goal is to ensure you are fully satisfied with your new BOILER MATE™. If any questions or concerns arise, call

Technical Service at 401-535-1216.

Part #: 9040-628 REV

ovide, you should r

e you also follow the enclosed post-installation and start-up checklists befor

TE™.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL PERSONAL

INJUR

SYMBOL TO REDUCE THE RISK OF POSSIBLE INJUR

This manual may become out-of-date by later amendments. Check our web site,

Y AND OTHER HAZARDS. OBEY ALL SAFETY MESSAGES THA

B (7/04)

ead and follow all of the instructions in this manual. When all installation steps have

e using your

T FOLLOW THIS

Y AS WELL AS PROPER

-1-

TY DAMAGE.

Page 2

TABLE OF CONTENTS

1. GENERAL SAFETY INFORMATION......................................................................................3

2. PRE-INSTALLATION CHECKLIST

Important Steps and Decisions Required Before Installation

3. REQUIRED COMPONENTS AND ACCESSORIES CHECKLIST .......................................5

........................................................................................4

FORCED HOT WATER, CLOSED HYDRONIC HEATING SYSTEMS

4. INSTALLATION - Forced Hot Water, Closed Hydronic Heating System .........................6

A. General Installation Requirements ..................................................................................6

B. Piping .................................................................................................................................7

C. Electrical Wiring ................................................................................................................8

D. Post-Installation and Start-up Check List.......................................................................9

ALL SYSTEMS

6. OPERATION AND MAINTENANCE.....................................................................................11

7. REPLACEMENT PARTS.......................................................................................................12

8. TROUBLESHOOTING CHECKLIST ....................................................................................13

9. SERVICE RECORD...............................................................................................................14

10. AMTROL LIMITED PRODUCT WARRANTY......................................................................15

-2-

Page 3

1. GENERAL SAFETY INFORMATION

IMPOR

TANT GENERAL SAFETY INFORMATION - ADDITIONAL SPECIFIC SAFETY ALERTS

APPEAR IN THE FOLLOWING INSTRUCTIONS

EXPLOSION HAZARD: DO NOT INSTALL TO A HIGH PRESSURE STEAM BOILER (greater than 15

psig). AN EXPLOSION COULD OCCUR.

EXPLOSION HAZARD. THE PRESSURE OF THE HEAT TRANSFER MEDIUM MUST BE LIMITED TO

A MAXIMUM OF 30 PSIG BY AN APPROVED SAFETY OR RELIEF VALVE ON YOUR BOILER. THE

TEMPERATURE AND PRESSURE RELIEF VALVE (INCLUDED).

EXCESSIVE LEVELS THAT MAY CAUSE SERIOUS SCALDING, EVEN IF THE TEMPERATURE SETTING IS CORRECT.

AFTER INSTALLATION AND ANY SERVICING OF THE UNIT, VERIFY THAT THE THERMOSTAT IS WORKING AND FIRMLY

INSERTED IN THE THERMOSTAT WELL BY FOLLOWING THE THERMOSTAT TESTING INSTRUCTIONS IN THE MANUAL

AFTER INSTALLATION AND ANY SERVICING OF THE UNIT.

TANK PRESSURE MUST BE LIMITED TO 150 PSIG MAXIMUM BY THE INSTALLATION OF A

SCALDING HAZARD: IF THE WATER TEMPERATURE IS OVER 120° F, HOUSEHOLD MEMBERS

CAN SUFFER SERIOUS OR FATAL SCALDING AND PAINFUL AND PERMANENT INJURY.

THE CONSUMER PRODUCTS SAFETY COMMISSION RECOMMENDS AN INITIAL SETTING

•

OF 120° F, BUT NOTES A SLOWER RESPONSE TIME OF INFANTS, AGED, DISABLED AND

OTHER PERSONS INCREASES THE HAZARD TO THEM AND MAY REQUIRE LOWER

SETTINGS.

• ALWAYS CHECK THE WATER TEMPERATURE BEFORE USE, INCLUDING WASHING,

BATHING OR SHOWERING.

• TEMPERATURE LIMITING VALVES ARE AVAILABLE FROM YOUR PLUMBING SUPPLIER.

SCALDING HAZARD: IF THE THERMOSTAT IS NOT WORKING PROPERLY OR IF THIS PRODUCT

IS NOT INSTALLED IN ACCORDANCE WITH THE MANUAL, WATER TEMPERATURE CAN REACH

SCALDING HAZARD: A CHECK VALVE MUST BE INSTALLED IN THE BOILER RETURN LINE TO

PREVENT GRAVITY FLOW THROUGH THE HEAT EXCHANGER. THIS CAN CAUSE OVER HEATING

AND RESULT IN SERIOUS SCALDING.

IF NOT INSTALLED BY THE BOILER MANUFACTURER, INSTALL A LOW WATER CUT-OFF OR

PRESSURE REDUCING VALVES MUST BE INSTALLED ON YOUR BOILER SO THAT LEAKING FROM

FIRE, AN EXPLOSION HAZARD EXISTS.

LICENSED PROFESSIONAL MUST INSTALL AND PERIODICALLY INSPECT AND SERVICE THE UNIT. A DRIP PAN,

CONNECTED TO AN ADEQUATE DRAIN MUST BE INSTALLED IF LEAKING OR FLOODING CAN CAUSE PROPERTY

DAMAGE.

YOUR HOME’S PLUMBING SYSTEM.

SATISFACTORY PERFORMANCE AND PREVENT PREMATURE FAILURE.

ANY PLUMBING FIXTURE WILL NOT RESULT IN A DRY BOILER; IF THE BOILER CONTINUES TO

THIS UNIT MUST BE INSTALLED AS A SEPARATE HEATING ZONE. DO NOT CONNECT THIS UNIT

TO AN EXISTING HEATING ZONE OR FEED BOILER WATER DIRECTLY THROUGH THE COIL AS

DANGEROUS OVER-HEATING WILL RESULT.

DO NOT DRAIN THIS APPLIANCE BEFORE SHUTTING OFF THE SUPPLY VALVE AND OPENING

THE RELIEF VALVE OR ANOTHER DOWNSTREAM FIXTURE, AS IT WILL DAMAGE THIS UNIT.

ALSO, MAKE SURE A VACUUM BREAKER IS IN PLACE TO AVOID DAMAGING THE LINER.

VOID RISK OF INGESTING A TOXIC FLUID. THE HEAT TRANSFER MEDIUM SHOULD BE WATER.

A

YCOL MUST BE USED, IT SHOULD ONL

IF GL

EXCHANGERS.

ANK, LIKE MOST T

THIS T

MAY BURST AND/OR LEAK OR FLOOD (AND IN RARE CASES EXPLODE) WHICH CAN CAUSE

SERIOUS OR FATAL PERSONAL INJURY AND PROPERTY DAMAGE. TO MINIMIZE RISK, A

AS IN ALL PLUMBING PRODUCTS AND W

YOUR BOILER MATE

PLUMBING OFFICIAL REGARDING ANY STEPS YOU MAY WISH TO TAKE TO SAFELY DISINFECT

TER QUALITY CAN SIGNIFICANTL

A

W

TEST FOR CORROSIVE ELEMENTS, ACIDITY

CONTAMINANTS, INCLUDING CHLORINE AND TREAT YOUR WATER APPROPRIATELY TO INSURE

ANKS UNDER PRESSURE, WILL OVER TIME CORRODE OR F

TM

, ESPECIALLY DURING TIMES OF NON-USE. CONSULT YOUR LOCAL

A

Y INFLUENCE THE LIFE OF YOUR PRODUCT

Y BE USED WITH DOUBLE-W

TER STORAGE VESSELS, BACTERIA CAN GROW IN

AL SOLIDS, AND OTHER RELEV

, TOT

ALLED HEA

AIL AND/OR

, YOU SHOULD

ANT

T

FOLLOW ALL OF THE INSTRUCTIONS AND RECOMMENDATIONS CONTAINED IN THIS MANUAL,

AND THE FOLLOWING ADDITIONAL SPECIFIC WARNINGS. FAILURE TO DO SO IS UNSAFE

PROPER

AILURE TO FOLLOW THE ABOVE W

F

AND/OR PROPERTY DAMAGE, AND WILL VOID THE WARRANTY.

TY DAMAGE.

CAN CAUSE SERIOUS SCALDING, EXPLOSION, SERIOUS OR FATAL PERSONAL INJURY AND

ARNINGS MAY RESULT IN SERIOUS OR FATAL PERSONAL INJURY

-3-

AND

Page 4

2. PRE-INSTALLATION CHECKLIST

IMPORTANT STEPS AND DECISIONS REQUIRED BEFORE INSTALLATION

j

MAINTAINED BY A LICENSED PROFESSIONAL. IN ADDITION

TO THE INSTRUCTIONS IN THIS MANUAL, FOLLOW ALL

APPLICABLE LOCAL AND STATE CODES OR IN THE

ABSENCE OF SUCH CODES, THE CURRENT EDITIONS OF

THE NATIONAL PLUMBING CODE AND THE NATIONAL

ELECTRIC CODE.

j

j

THIS PRODUCT MUST BE INSTALLED AND

DRIP P

property damage, install with a drip pan connected to

an adequate working drain kept clear at all times.

CAUTION: Determine whether your water is corrosive

or acidic, and that there are no suspended solids, toxic

or other substances or abnormally high chlorine levels

in the water that could damage or af

MATE™ or the rest of your plumbing system.

damage to surrounding property.

MODELS. Glycol is a hazardous substance. To avoid

seepage or leakage of glycol to surfaces where children or

animals can ingest it, use glycol only in double-walled

units, so that any leaks will most likely be released to the

atmosphere. However, a leak to a surface area may still

occur, so any use of glycol must be monitored closely and

children and animals should be protected from contact

with the unit.

other space heating units or elements. Any contaminants

in the baseboard units will contaminate the potable water

in the BOILER MATE™ and also adversely affect its

performance.

AN AND DRAIN: To avoid leaking and/or

fect the BOILER

Do not locate this product where

leaking and flooding could cause

USE GLYCOL ONLY WITH DOUBLEWALLED HEAT EXCHANGER

Do not connect the BOILER MATE™

domestic supply with baseboard or

2. Priority System - Under this wiring option the

BOILER MATE™ will be supplied before space

heating.

In limited cir

heating can be lost in the home in

this priority mode. Any demand for space heating is

postponed until the BOILER MATE™ has reached its set

temperatur

zones is usually not noticed by the inhabitants of the living

spaces. However, in the event of certain malfunctions

such as circulator or thermostat failure, space heating

could be delayed indefinitely. If undetected and

uncorrected, freezing damage to piping could result.

Select Circulator versus Zone Valve

j

The flow of hot boiler water to the BOILER MATE™ can be

controlled with either a motorized zone valve or a

circulator.

1. Zone valve (system flow of 4-8 gpm). If a zone valve is to

be used, a minimum flow rate of 4 gpm with all zones in

use is required with a maximum of 8 gpm with only the

BOILER MATE™ in use. Be sure the zone valve chosen has

a maximum pressure drop (Cv = 4) when fully opened.

2. Separate circulator. The recommended way to provide

adequate flow through the BOILER MATE™ heat

exchanger is to use a separate dedicated circulator with a

minimum flow rate of 4 gpm (10 feet of head minimum) and

maximum flow rate of 8 gpm. This option may be used

even though the heating system utilizes zone valves.

j

j

e. This delay in supplying the space heating

All installations require a low-water cut-off or automatic

fill valve on your boiler system to reduce the risk of

boiler water loss.

Steam boiler installations r

which is also required by most codes.

cumstances, space

e a low-water cut-of

equir

f

Wiring Options. Select either a Non-Priority or Priority

j

System:

Two options are available when wiring the controls of the

BOILER MA

distribution elements).

1. Non-Priority System - The controls of the BOILER

MATE™ must be wired as a separate heating zone with

a standard zone valve or a separate circulator

dedicated to the BOILER MA

NOTICE: In this non-priority option, the BOILER MATE™ will

be supplied just as another zone. This means that if all space

heating zones call for hot boiler water at the same time, the

BOILER MA

water to "r

water will be diminished. In many, but not all cases, this is not

a problem because the routine oversizing of boiler output is

adequate for both loads.

TE™ in the space heating system (boiler and

TE™ "zone".

TE™ may not be supplied with enough hot boiler

ecover" adequately

. The delivery of domestic hot

-4-

Installation of a vacuum br

j

damage to the BOILER MATE™ when drained.

eaker is r

equired to prevent

Page 5

3. REQUIRED COMPONENTS AND

ACCESSORIES CHECKLIST

TD-7Z, TD-41Z, TD-7ZDW, TD-41ZDW

COMPONENTS CHECKLIST

The following is a checklist of components required for proper installation of these

A. Separate circulator

1 each - circulator (4-8 gpm)

•

• 1 each - positive shut-off weighted check valve

B. Use of heating system zone circulator

1 each - zone valve

•

C. Also Required:

• 4 each - unions

• 4 each - shut off valve

• 1 each - vacuum breaker

• 1 each - T & P relief valve (included)

• 1 each - A THERM-X-TROL®expansion tank - REQUIRED IF a Back flow preventer, check

valve or pressure reducing valve is installed anywhere between the BOILER MATE™ and

the city main.

• As needed - pipe dope or Teflon tape

• Do not forget an EXTROL

side of your system.

BOILER MATE™ models, both Priority and Non-Priority:

®

and thermal expansion - an expansion tank is required on the boiler

If a steel hydropneumatic tank is in place, AMTROL recommends

replacing it with a properly sized EXTROL®expansion tank. Otherwise,

significant heat transfer problems can occur by causing air to be trapped in the heat

exchanger. If the boiler system has an EXTROL®expansion tank and the boiler

temperatures are being changed, resize the EXTROL®expansion tank.

-5-

Page 6

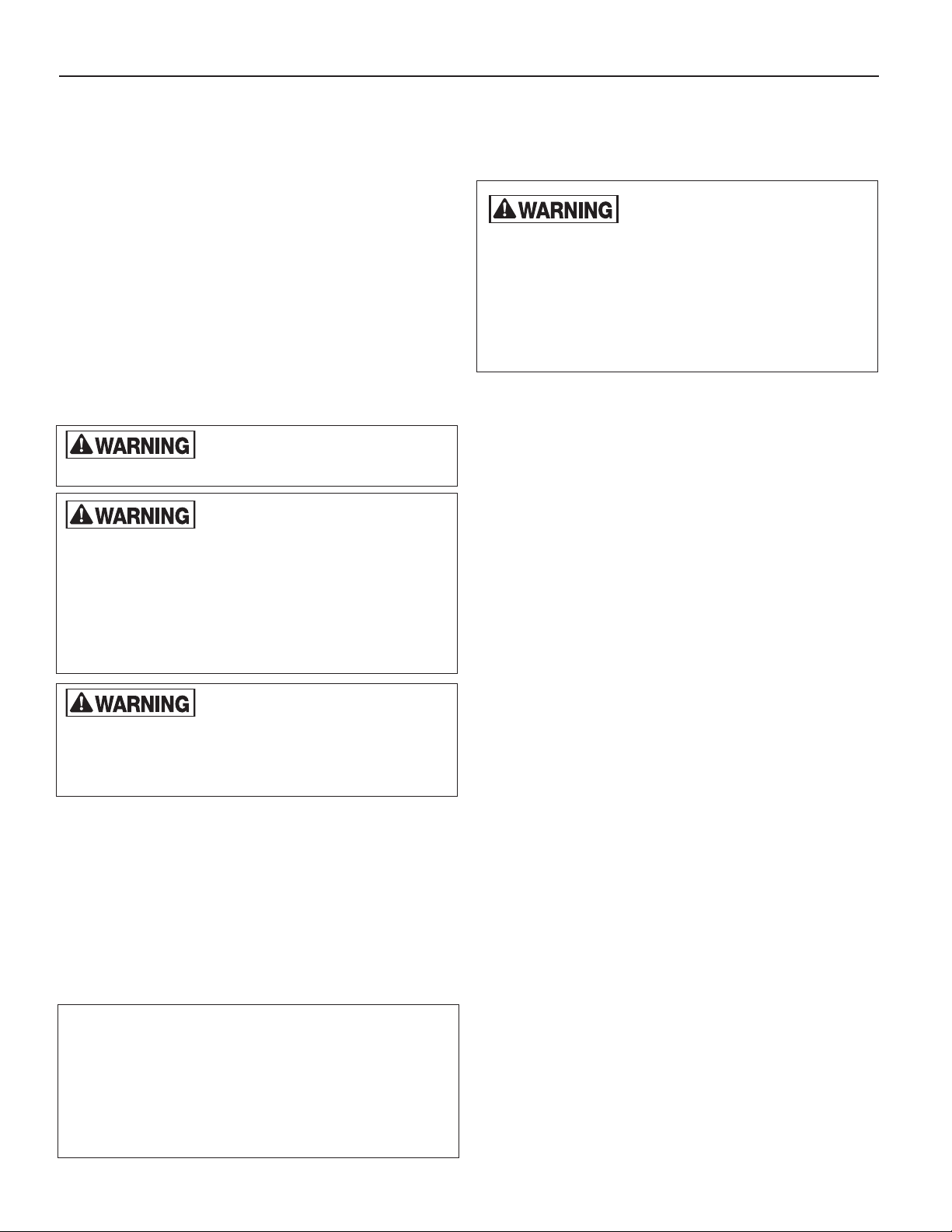

4. INSTALLATION INSTRUCTIONS FOR

TYPICAL INSTALLATION

FIGURE 1

BOILER

HEATING ZONES

HEATING

SYSTEM

RETURN

ZONE VALVES

CONTROLLED BY

THERMOSTAT

HEATING

CIRCULATOR

CIRCULATOR

BOILER

MATE™

DRAIN

VAL VE

THERMAL

LOOP

DOMESTIC

HOT W ATE R

VAC UUM

BREAKER

DRAIN VAL VE

FLOW CHECK

VAL VE

THERM-X-TR OL

®

DOMESTIC

COLD WA TER

SUPPLY

PRV

SHUT-OFF

VAL VE

SHUT-OFF

VAL VE

SHUT-OFF

VAL VE

BOILER

SUPPLY

RELIEF VAL VE

BLOW -DOWN TUBE

BOILER

RETURN

FORCED HOT WATER, CLOSED HYDRONIC HEATING SYSTEMS

A. General Installation Requirements

1. Do not "short circuit" the boiler

Do not connect boiler supply and return lines to the same

section or in the same flow circuit in a boiler, because the

boiler water returning from the BOILER MATE™ will "short

circuit" and exit the boiler too cold for proper heat transfer.

2. Avoid high flow domestic water

recirculating loops

If a recirculating loop is necessary consult applicable Code

requirements. A flow of no more than 1/2 gpm is all that is

generally needed for temperature maintenance at the furthest

hot water fixture. Any flow greater than 1/2 gpm will result in

excessive heat loss and reduction in performance.

3. Locating Unit

Do not locate this product where

leaking and flooding could cause

damage to surrounding property.

The BOILER MATE™ should be located in an area where

water leakage from the tank or connections will not result

in damage to areas adjacent to the application or to lower

floors of the structure. When such a location cannot be

avoided, a suitable drain pan must be installed. The pan

must be connected to a drain. The installation location for

this unit should also be chosen to comply with the following required and recommended dimensions for clearance

and accessibility:

Clearance from Combustible Surfaces

This unit is design certified by the C.S.A. for installation on

combustible flooring and in alcoves, closets, etc. The minimum clearance dimensions from combustible material is

as follows: (See dimensions given facing units)

Clearance From Combustible Surfaces

LEFT SIDE ...........10" REAR .....................1"

RIGHT SIDE.........10" FLOOR ..................0"

TOP......................30" FRONT ..................1"

Recommended Clearance for Servicing

....................10" HEAD ROOM ........30"

LEFT

..................10" REAR.....................1"

RIGHT

.................30"

FRONT

4. Instructions for reversing unit:

The unit is designed to be reversible, i.e. depending on the

particular installation area, the BOILER MATE™ can be

rotated 180° for easier connection to the boiler and cold

water supply. All units are shipped "left-handed" with all

connections (boiler, cold water supply) on the left side of

the unit. If, for ease of installation, it is necessary to have

the connections on the right, the following steps should be

taken:

1. Carefully remove the front panel (remove top screw

and unhook from stand).

2. Move the access panel/electronic control assembly to the opposite side of the BOILER MATE™.

3. Remove the ground screw from the BOILER

MATE™ stand and save.

4. Proceed with electrical installation

5. Reassemble the access panel/electronic control to

the BOILER MATE™.

6. Confirm that the temperature sensor is firmly

inserted into the thermostat well.

7. Proceed with the installation.

-6-

Page 7

B. PIPING

PLUG HERE

DO NO

T PLUG

INTERNAL

TA NKLESS

COILS

EXTERNAL

TA NKLESS

HEATER

X

PIPING SHOULD BE ACCOMPLISHED WITH UNIONS.

Step 1 - Locate the BOILER MATE™ near boiler.

Step 2 - Connect the cold water piping.

a. Shut off the cold water supply at the main shut-off

valve.

b. Drain existing domestic water system. Open 1 or

more system faucets to prevent vacuum.

c. When the system is drained, for boilers that have an

external or internal tankless heater, disconnect the

tankless heater from the domestic hot water piping.

EXTERNAL TANKLESS HEATERS

Disconnect all the lines to the boiler and plug the boiler tappings. Disconnect the external heater from the domestic system piping and discard appropriately.

INTERNAL TANKLESS COILS

PREVENT PRESSURE BUILD-UP IN

LESS COIL. Do not plug incoming or outgoing tappings in

the internal tankless coil plate. Leave the coil in the boiler

and leave system connections open, to prevent pressure

build-up. (Figure 3)

Install a shut-off valve in the existing cold water line.

d.

e. Run 3/4" or 1/2" tube and fittings from the city main,

as required, to the BOILER MATE™

f. If a backflow preventer, pressure reducing valve or

check valve is installed anywhere between the

BOILER MATE™ and the city main, install a properly

sized Therm-X-Trol

thermal expansion tank. See the water supplier or

local plumbing inspector for more information

ANY EXISTING INTERNAL TANK-

®

pre-pressurized diaphragm-type

BOILER

RETURN

COLD

ATER

W

SUPPL

Y

DOMESTIC

ATER

HOT W

OUTLET

FIGURE 2

BOILER SUPPL

T & P

OUTLET

Y

Step 3 - Connect domestic hot water piping Figure 5.

EXPLOSION HAZARD. THE

MEDIUM MUST BE LIMITED TO A MAXIMUM OF 30 PSIG

BY AN APPROVED SAFETY OR RELIEF V

BOILER. THE TANK PRESSURE MUST BE LIMITED TO 150

PSIG MAXIMUM BY THE INSTALLATION OF A

TEMPERATURE AND PRESSURE RELIEF VALVE

(INCLUDED).

RETURN LINE TO PREVENT GRA

THE HEAT EXCHANGER. THIS CAN CAUSE OVER HEATING

AND RESUL

a.

b. Install a union, shut-of

T IN SERIOUS SCALDING.

Attach the blow-down tube from the T & P valve

outlet. Install the blow-down tube to within 6" of the

floor. The blow-down tube should be placed so that it

will discharge to a drain with adequate capacity. No

reducing couplings, valves, or any other type of

restriction is to be installed in this line. The blow-down

tube must be installed to allow free and complete

drainage of both the valve and the blow-down tube.

the hot water outlet.

PRESSURE OF THE HEAT TRANSFER

VE ON YOUR

AL

SCALDING HAZARD: A CHECK VALVE

MUST BE INSTALLED IN THE BOILER

f valve and vacuum br

VITY FLOW THROUGH

eaker on

FIGURE 3

DAMAGE TO THE UNIT AND

VACUUM BREAKER IS NOT INSTALLED.

c.

To minimize piping heat loss during non-draw periods,

a thermal trap can be installed in the hot water line as

shown in Figure 1.

Step 4 - Fill the BOILER MA

a. Open a hot water faucet in the house to allow any air

in the BOILER MATE™ and in the piping to escape.

b. Open the shut-of

c. Open the shut-of

d. When water dischar

Check for system leaks and r

LEAKAGE CAN OCCUR IF A

TE™.

f valve in the cold water line.

f valve(s) in the hot water supply line.

om the faucet, close it.

ges fr

epair if necessary.

-7-

Page 8

Step 5 - Connect boiler supply pipe. Figure 1.

a. Shut off the cold water supply valve to the boiler, and

drain it using a hose attached to the drain valve at the

boiler.

b. When the boiler system piping is drained, cut the

piping to accommodate the supply line tee. Install the

tee between the boiler supply outlet and any system

zone valve or flow check.

c. Connect the circulator flange and mount the

circulator to the boiler supply.

arrow points towards the BOILER MATE™

the second flange to the circulator.

d. Connect a 3/4" NPTM to a 3/4" sweat adapter to the

second circulator flange.

e. Using short lengths of tubing, connect the 3/4"shut-

off valve.

f. Run the 3/4"copper tubing with necessary fittings to

the point of connection to the boiler supply tee.

Be sure the flow

Step 6 - Connect boiler return pipe. Figure 1.

a. Connect the 3/4" NPT, boiler return fitting and

connect the drain valve and union.

b. Sweat a short length of tubing to the adapter and

connect the weighted check valve with the flow

towards the boiler (preventing flow towards the

BOILER MATE™). Failure to do so will result in the

BOILER MATE™ overheating.

c. Run the 3/4" tubing and fittings as required to the

point of connection to the boiler return.

NOTE: This point must be between the boiler return

tapping and any system circulator(s). Failure to do so

will result in the BOILER MATE™ overheating.

Step 7 - Refill the boiler system

a. Open the cold water supply valve to the boiler.

b. Check for system leaks.

c. Close the weighted check valve on the boiler return

piping of the BOILER MATE™

d. Open the drain valve on the boiler return line to

release entrapped system air.

e. Close the drain valve

f. Open the weighted check valve.

. Mount

SEPARATE CIRCULATOR

BOILER MATE™ as Separate Zone - Non-Priority

I.

A. Use of separate

Step 1 - Disconnect electrical power.

Step 2 - Remove electrical box cover on Thermostat.

Step 3 - Wire BOILER MATE™ using

Step 4 - T

Note: Some boilers require minimum setting of low limit.

BOILER MATE™ ZONE CIRCULATOR

urn off the boiler service switch.

a. T

b. Turn off the safety switch (if separate from

the service switch).

c. Switch off the branch circuit breaker.

Schematic #1 or #2.

a. Install BX connector

b. Insert outside wiring to BOILER MATE™

through electrical conduit opening on

thermostat.

c. Complete exterior electrical wiring per

Schematic #1 or #2.

urn boiler low-limit control (it is part of the

boiler control) to the off position.

.

SEPARATE CIRCULATOR

C. ELECTRICAL WIRING

All wiring must be in accordance with local codes, regulations,

and ordinances or, in the absence of such codes, the National

Electrical Code ANSI/NFP

The BOILER MATE™ thermostat can be used for either 24 or

120V AC. The thermostat is packaged separately and is installed

by sliding the capillary tube into the thermostat well.

A No. 70, latest edition.

ocution hazar

Electr

dis-connect all electrical power

e doing any electrical work.

befor

ocution hazar

Electr

TE™ must be electrically

MA

grounded.

Electrical supply must come from the

boiler side of boiler’

shut-of

unsafe boiler operation.

f switch in or

d. First

d. The BOILER

s emergency

der to prevent

Step 5 - Adjust boiler high-limit control to the desired

Step 6 - Re-assemble electrical box cover

Step 7 - Re-connect electrical power

B. Use of only the heating system circulator.

When wiring a separate zone valve, follow all steps in 1A

except for Step 3c. Use Schematic #3(A, B or C)

depending upon the type of zone valve. (Zone valve

sizing per pg. 5)

BOILER MA

II.

Hot W

A.

Use of separate BOILER MATE™ zone.

A DPDT relay is to be used. Refer to Schematic #4.

Step 1 - Disconnect electrical power.

setting. In most cases 180

is acceptable.

TE™ - Priority Wiring

ater Befor

e Space Heating

a. Turn off the boiler service switch.

b. Turn off the safety switch (if separate from

F to 200° F

°

.

-8-

.

Page 9

the service switch).

c. Switch of

Step 2 - Remove electrical box cover

Step 3 - Remove existing wir

terminal C1 and connect to terminal #2 on

DPDT relay.

Step 4 - Install wire from DPDT relay terminal #1 to boiler

aquastat terminal C1.

Step 5 - Connect terminals of 4 and 6 of DPDT relay "T-

T" terminals of boiler aquastat relay.

Step 6 - Connect BOILER MATE™ thermostat to L1,

BOILER MATE™ and DPDT relay as shown

in Schematic #4.

Step 7 - Connect L2 to BOILER MATE™ circulator

and DPDT relay as shown in Schematic #4.

B. Use only the heating system circulator.

When wiring a separate, full-flow 3-way zone valve, follow

steps in 1B. above.

Note: Priority comes from the valve operation and not the

wiring.

f the branch circuit breaker.

.

e from boiler aquastat

SEPARATE CIRCULATOR

lowest temperatur

ovide the lowest operating costs.

also pr

In conjunction with a Consumer Product Safety Commission

ecommendation, an initial setting of 120° F is recommended.

r

This may or may not be suitable for your needs. Check the

temperature at a hot water faucet soon after the burner has

completed the first heating. Adjust as needed. Note that

adjusting to a lower setting will not have an immediate effect. The

ed hot water will first have to be used. Additional checks of

stor

the water temperature should follow completion of a cycle.

Further adjustments may be necessary as you use your BOILER

MATE™ and water piping system.

NOTE: V

TEMPERATURE BY MIXING COLD AND HOT WATER ARE

AVAILABLE. CONSULT A LICENSED PLUMBER OR THE

LOCAL PLUMBING AUTHORITY.

e which satisfies your hot water needs. This will

ALVES FOR REDUCING POINT OF USE

ZONE VALVES - SCHEMATIC 3

D. POST-INSTALLATION and

START-UP CHECKLIST

After the BOILER MATE™ has been plumbed and wired, it is now

eady to be set for automatic operation. Turn on the boiler and

r

safety switches.

TEMPERATURE ADJUSTMENT

PAINFUL SCALDING WITH POSSIBLE

CAN OCCUR IF THE TEMPERATURE IS SET TOO HIGH OR

THE THERMOSTAT IS NOT FUNCTIONING PROPERLY.

The thermostat controls the maximum water temperature in the

BOILER MATE™.

cause painful scalding with possible serious and permanent

injury.

person’

The slower response time of infants, aged or handicapped

persons incr

It is recommended that the temperature control be set for the

The temperature at which this occurs varies with a

s age and the length of time in contact with the water.

eases the hazar

SERIOUS AND PERMANENT INJURY

If set too high, the resulting hot water can

d to them.

3-WIRE ZONE VALVES

VES

4-WIRE ZONE V

AL

PRIORITY W/CIRCULATORS - SCHEMATIC 4

-9-

Page 10

-10-

Page 11

6. OPERATION/MAINTENANCE.

FOR FORCED HOT WATER, CLOSED HYDRONIC HEATING SYSTEMS

AND LOW PRESSURE STEAM BOILER.

The BOILER MATE™ is intended to provide a tank service life of

many years. Components, however

that require service. Failure to use the correct procedures or parts

in these circumstances may make the unit unsafe.

• DO NOT OPEN DOWN-STREAM FIXTURE IF YOU

HAVE LOOSENED THE TOP CONNECTIONS.

• DO NOT OVER-DRAIN THE TANK - THE HEAT

EXCHANGER MUST REMAIN COVERED BY WATER TO

AVOID DAMAGE TO THE LINER.

The owner should arrange to have the following inspections

and simple maintenance pr

frequencies suggested.

a. Domestic Water Piping - Yearly Visual Inspection Check

all piping for a signs of leakage at joints, unions and shutoff valves. Remedy as needed.

b. Boiler Water Piping - yearly Visual Inspection Check all

piping for signs of leakage at joints, unions and shut-off

valves. remedy as needed.

c. T & P Relief Valve - Yearly Inspection

d. Sediment - Monthly Inspection - depending on water

conditions

Depending on water conditions, a varying amount of

sediment may collect in the tank. This is normal. Levels

requiring service are indicated by a small temperature

difference in the supply and return lines. (See also "Scale"

below.) Repeated flushing usually clears such material. As

a preventive measure, each month water should be drawn

from the tank at the drain valve until it runs clear.

e. Scale - Monthly Inspection

A small temperature difference between the water entering

and leaving the coil may indicate a scale build-up. A water

softener will prevent this problem. (See also "Sediment"

above.) Repeated flushing should also resolve the

problem. If not, proceed as follows:

o avoid water damage to nearby areas in subsequent

1. T

steps, shut off the cold water supply to the BOILER

MATE™.

2. Make a note of the temperatur

BOILER MATE™, then turn the unit off by depressing

the key switch on the Smart Contr

reads "OFF".

3. Relieve the water pressure in the tank by opening a

hot water faucet. This will reduce the risk of scalding

.

injury

4. Remove the relief valve from the top of the BOILER

MATE™, taking care to avoid contact with the hot

water which may drain out of the lines leading to the

domestic uses.

5. Drain the BOILER MATE™ until the water within the

tank is even with the top of the heat exchanger -

oughly 15 gallons for 41-gallon units and 5 gallons for

r

26-gallon units.

, may be subject to failures

ocedures done at the

ol setting on the

e contr

ol™ until the unit

Do not over-drain the tank. Improper

during Step 6 and lead to damage to the BOILER MA

6.

Using a funnel, pour one gallon of commercial

phosphoric acid solution (commercial icemaker

cleaning solution) into the water tank through the top

opening. Be sure that the manufacturer’s directions,

cautions, and warning on the container are followed:

7. Set the temperatur

operate the system until the control is satisfied.

Boiler may cycle on its high limit several times during

this period. If the tank temperature setting has not

been satisfied after 45 minutes of boiler operation,

turn it to its lowest setting to stop boiler operation.

8. Allow heated solution to set in tank for 30 minutes.

then drain tank completely using fitting and hose, as

required, to reach a floor drain.

9. Fill water tank with fresh, cold, conditioned water and

drain completely at least two time to flush all

phosphoric acid mixture from the tank.

10.Reinstall the temperature pressure relief valve, being

sure the (1) the temperature pressure relief valve

temperature probe reaches into the top portion of the

tank and (2) the top half union fitting is firmly in place.

11.Open the cold water supply and fill the tank with

water. Then purge air from lines and tank by operating

hot and cold water faucets in the house.

12.Return the Smart Control™to the setting noted in Step

2 and verify it is working properly as described on

page 17.

As an alternative to the above, the heat exchanger may be

removed from the BOILER MATE™, cleaned, and reinstalled (with

a new gasket); or, in some cases, a simple high velocity washing

by water from a wand may be used in place of Steps 5-9. The

chemical cleaning pr

properly.

thermostatic contr

e control to its highest setting and

ocess, however

, is the most effective if done

ol could result

TE™.

Note:

-11-

Page 12

7. REPLACEMENT PARTS

6

1

3

4

2

5

RESIDENTIAL

BOILER MATE™ CLASSIC

(TD-7Z and TD-41Z)

ELECTROCUTION HAZARD.

THE BOILER MA

BE ELECTRICALLY GROUNDED.

NOTES:

1. THE BOILER MATE™ MUST BE ELECTRICALLY GROUNDED AND INSTALLED IN

ACCORDANCE WITH LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH

THE NATIONAL ELECTRIC CODE.

2. HEAT EXCHANGER PACKAGE INCLUDE

ITEMS 5-11

3. TORQUE NUTS 12 TO 14 FT. LBS.

FAILURE TO USE THE

CORRECT REPLACEMENT

PARTS MAY MAKE YOUR UNIT UNSAFE.

TE™ MUST

ITEM DESCRIPTION

T CONTROL

1

2

3 GASKET ONLY 2704-403

4

5

6 DRAIN VALVE 9340-087

AQUAST

T EXCHANGER - COMPLETE

HEA

THERMISTOR DR

A

Y WELL

TOP COVER

PART

NUMBER

2704-093

2700-5004

2700-924

20-0001

-12-

Page 13

8. TROUBLE SHOOTING CHECKLIST

PROBLEM CAUSE SOLUTION

1. No hot water at faucet. 1.Boiler does not operate. 1.a.

2.Circulator does not operate. 2.a.Check power supply.

3.Improper BOILER MATE™ 3.Set BOILER MATE™ temperature to

setting or calibration.

4.Zone valve does not open. 4.Check power supply.

5.Electrical pr

fuse, low voltage, brown-outs, etc.) b.Check circuit breaker and

6.BOILER MATE™ scale 6.If boiler, circulator, and BOILER MATE™

build-up. temperature controls are operating

7.Clogged filter (if used) or clogged 7. Clean and replace filter.

strainer in steam boiler systems.

oblems (relay, wiring,

2. Insufficient or runs out of 1.BOILER MATE™ 1.Set BOILER MATE™

hot water at faucet. temperature setting too low. temperature control to a higher setting.

2.Undersized boiler with no 2.Rewire for priority.

priority to domestic hot water.

3.Peak use of hot water is greater 3.Determine peak usage and compare tank

e contr

TE™ storage.

TE™

ol.

than BOILER MA

4.BOILER MATE™ scale 4.Clean coil according to instructions.

build-up.

5.Faulty BOILER MA

temperatur

3. Water at faucet too hot. 1.BOILER MATE™ temperature is 1.Lower BOILER MATE™

set too high. temperature.

2.Improper system plumbing. 2.Compare plumbing to installation guide.

3.Improper system wiring. 3.Compare wiring to installation guide.

4.Probe out of thermostat well. 4.Check to make sure Probe is properly inserted,

4. Boiler cycles more than 5 1.Excessive demand. 1.Reduce demand or consider larger

times per day in summer. BOILER MATE™.

Boiler runs for longer 2.Damaged or broken BOILER MATE™ 2.Replace BOILER MATE™

Periods of time . temperatur

3.Boiler hi-limit set too low. 3.Increase boiler hi-limit.

4.BOILER MATE™ scale build-up. 4.Clean coil according to instructions.

e control. temperature control.

Press reset button on boiler.

b.Check main cut-off switch.

Check fuse.

c.

Check shaft coupling.

b.

c. Check impeller for locking.

a higher setting. Call boiler service.

Check fuse and replace.

5.a.

reset (if applicable).

c. Check power supply.

d.Low voltage or brown-out conditions

can make the boiler control inoperative;

engage the boiler reset button.

satisfactorily, the BOILER MATE™ coil

may have scale coating. Remove coil and

clean or keep coil in tank and treat with

a phosphoric acid product (e.g. NuCalgon -

1-800-554-5499) (Refer to page 20)

volume.

5.Replace contr

see Figure 2 Page 8.

ol.

-13-

Page 14

9. SERVICE RECORD

DA

TE SERVICE PERFORMED COMMENTS CONTRACTOR

-14-

Page 15

AMTROL®BOILERMATE™CLASSIC AND TOP-DOWN™ LIMITED PRODUCT WARRANTY

This W

arranty cannot be transferred - it is extended only to the original Purchaser or First User of the Product. By accepting and keeping this Product you

agree to all of the warranty terms and limitations of liability described below.

IMPORTANT WARNING: READ CAREFULLY THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL (“MANUAL”) to avoid

serious personal injury and/or property damage and to ensure safe use and proper care of this product.

Mail Your Product Registration Card Within 30 Days of Purchase to Ensure Your Warranty Coverage or Proof of Purchase Will Be Required for All Warranty

Claims.

WH and TD Model Numbers Covered: WH-7Z, WH7-ZDW, WH7-P, WH7-L, WH7-LDW, WH-9L, WH-9LDW, TD-7L, TD-7Z,TD-7P, TD-7LDW, TD-7ZDW

*FOR AS LONG AS YOU OWN AND LIVE IN YOUR SINGLE FAMILY HOME, this Warranty covers the tank assembly and heat exchanger, if you are the first

user or original owner of this BoilerMate™ Classic and Top-Down™ and purchased it for single family home use – subject to all of the conditions, limitations and exclusions listed below. Purchasers who buy the BoilerMate™ Classic and Top-Down™ for other purposes, and other component parts are subject

to more limited warranties and you should read all of the terms included in this form to make sure you understand your Warranty.

LIMITED WARRANTY ON BOILERMATE™ CLASSIC AND TOP-DOWN™ TANK ASSEMBLY AND HEAT EXCHANGER

AMTROL Inc. (“AMTROL”) warrants that at the time of manufacture, the BoilerMate™ Classic and Top-Down™ heat exchanger and tank assembly shall be free

from defects in material and workmanship for one of two time periods as follows:

Period 1 – Single Home Use. If you are the first user or original owner of the BoilerMate™, for as long as you own and occupy the single-family home

in which the BoilerMate™ Classic and Top-Down™ has been properly installed.

Period 2 - ** Commercial and Other Uses. For five years from the date of purchase if you are the first user or original owner first using the new BoilerMate™

Classic and Top-Down™ (except for the model numbers listed above that are transferable), and you are not a homeowner-purchaser as described in Period 1

(for example, if you purchased the Product for re-sale, or a commercial, industrial, non-residential, multi-unit or rental property application).

LIMITED ONE YEAR W

AMTROL warrants to the first user or original owner using the new BoilerMate™, that at the time of manufacture, except for the tank assembly and the heat

exchanger referenced above, all other AMTROL supplied components or parts of the BoilerMate™ are warranted to be free from defects in material or

workmanship for one year from the date of purchase.

What AMTROL Will Do If You Have a Covered Warranty Claim

In the event of a breach of the foregoing warranty, AMTROL will at its option either make repairs to correct any defect in material or workmanship or supply

and ship either new or used replacement parts or products. AMTROL will not accept any claims for labor, property damage or other costs.

What This Warranty Does Not Cover - Exclusions and Limitations

This Warranty does not cover any claim unless it was caused by a defect in material or workmanship during the warranty periods specified above. In addition,

this Warranty shall not apply:

• if the Product is not correctly installed, operated, repaired or maintained as described in the Manual provided with the Product;

• to any failure or malfunction resulting from abuse (including freezing); improper or negligent: handling, shipping (by anyone other than AMTROL), storage,

• to any failure or problem resulting from the use of the Product for any purpose other than those specified in the accompanying Manual or alteration of any

• if the Product is used anywhere except the United States, its territories or possessions, or Canada;

• this Warranty does not cover labor costs, shipping charges, service charges, delivery expenses, administrative fees or any costs incurred in removing or

• this Warranty does not cover any claims submitted to AMTROL or an AMTROL-authorized distributor or retailer more than 30 days after expiration of the

• this Warranty also does not cover repair or replacement costs not authorized in advance by AMTROL.

• if the unit has not always been operated within the factory calibrated temperature limits, and at a water pressure not exceeding 150 psi or it is subjected to

Additional Warranty Limitations

ALL IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

SPECIFICALLY DISCLAIMED.

Limitations of Remedies

THE REMEDIES CONT

WILL AMTROL BE LIABLE FOR MORE THAN, AND PURCHASER-FIRST USER’S REMEDIES SHALL NOT EXCEED, THE PRICE PAID FOR THE

PRODUCT. IN NO CASE SHALL AMTROL BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER

RESUL

OR FROM AMTROL’S OWN NEGLIGENCE OR OTHER TORT.

breach of contract, negligence, strict liability, in tort or under any other legal theory. Such damages include, but are not limited to, inconvenience, loss or

damage to property, mold, loss of profits, loss of savings or revenue, loss of use of the Products or any associated equipment, facilities, buildings or services,

downtime, and the claims of third parties including customers. Some states do not allow the exclusion or the limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

What T

Any covered W

from an AMTROL distributor or AMTROL. If you do not receive a prompt response, call AMTROL directly at 401-535-1216. Notice of a Warranty claim should

be submitted by the authorized distributor to AMTROL at the following address:

Before AMTROL determines to provide any replacement part or Product, it may as a pre-condition to making such a determination require that the warranty

claimant ship the Product, postage prepaid to an authorized AMTROL distributor, or to AMTROL and provide proof of purchase evidenced by the original

sales receipt or Product registration.

Replacement Product Warranty

In case of replacement of a Product or any component part, AMTROL reserves the right to make changes in the design, construction, or material of the

substitute

be reduced by the amount of time the warranty claimant owned the product prior to submitting notification of the warranty claim.

LIMITED LIFETIME WARRANTY* Tank Assembly and Heat Exchanger (To Original Product Owner, Single Family Residence)

LIMITED FIVE YEAR COMMERCIAL WARRANTY**

Model Numbers Covered: WH7C, WH7CDW

Model Numbers Covered: WH-41Z, WH-41L, TD-41L, TD-41Z, TD-41LDW and TD-41ZDW only

Warranty for these models only runs from date of manufacture and are transferable

ARRANTY ON ALL BOILERMATE™ CLASSIC AND TOP-DOWN™ COMPONENT PARTS

use, operation, accident; or alteration, lightning, flood or any other environmental condition;

part of the product;

reinstalling the Product;

applicable warranty time period described in this Warranty;

concentrations in excess of 5 ppm;

chlorine

Some states do not allow limitations on how long an implied Warranty lasts, so the above limitation may not apply to you.

AINED IN THIS W

TING FROM NONDELIVER

o Do If You Have a Problem Covered By This Warranty

arranty service must be authorized by

components or products, which shall be subject to all of the terms and limitations of this Warranty, except that the applicable warranty periods shall

Y OR FROM THE USE, MISUSE, OR INABILITY TO USE THE PRODUCT OR FROM DEFECTS IN THE PRODUCT

LIMITED FIVE YEAR TRANSFERRABLE WARRANTY**

ARRANTY ARE THE PURCHASER’S OR FIRST USER’S EXCLUSIVE REMEDIES. IN NO CIRCUMST

This exclusion applies regardless of whether such damages are sought for breach of warranty,

AMTROL. Contact the person from whom you purchased the Product, who

AMTROL Inc., Warranty Claim Dept.

1400 Division Rd., West Warwick, RI 02893

must receive authorization

ANCES

-15-

Page 16

Part #: 9040-628 REV B (7/04)

West Warwick, Rhode Island 02893

-16-

Loading...

Loading...