Page 1

AMTROL PRESSURISER

®

WATER PRESSURE BOOSTER SYSTEM

WITH GUARDIAN CP™ CONTROL

INSTALLATION & OPERATION INSTRUCTIONS

Models RP-10HP, RP-15HP and RP-25HP

NOTE: Inspect for shipping damage. Notify freight carrier or store where purchased immediately if damage is present. To avoid risk of personal injury

and property damage, if the product appears to be malfunctioning or shows signs of corrosion, call a qualified professional immediately. Current copies

of the product manual can be viewed at www.amtrol.com. Use proper safety equipment when installing.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL PERSONAL INJURY AND OTHER

HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO REDUCE THE RISK OF PERSONAL

INJURY AS WELL AS PROPERTY DAMAGE.

USE ONLY WITH POTABLE WATER SYSTEMS.

Do not operate in a setting with freezing

temperatures or where the temperature can exceed 200°F and do not

exceed the maximum working pressure specified for this Product.

READ CAREFULLY THE PRODUCT

INSTALLATION & OPERATION INSTRUCTIONS.

FAILURE TO FOLLOW THE INSTRUCTIONS AND WARNINGS MAY

RESULT IN SERIOUS OR FATAL INJURY AND/OR PROPERTY

DAMAGE, AND WILL VOID THE PRODUCT WARRANTY. THIS

PRODUCT MUST BE INSTALLED BY A QUALIFIED PROFESSIONAL.

FOLLOW ALL APPLICABLE LOCAL AND STATE CODES AND

REGULATIONS. IN THE ABSENCE OF SUCH CODES, FOLLOW THE

CURRENT EDITIONS OF THE NATIONAL PLUMBING CODE AND

NATIONAL ELECTRIC CODE, AS APPLICABLE.

This Product, like most Products under pressure,

may over time corrode, weaken and burst or

explode, causing serious or fatal injury, leaking or flooding and/or

property damage. To minimize risk, a licensed professional must install

and periodically inspect and service the Product. A drip pan connected to

an adequate drain must be installed if leaking or flooding could cause

property damage. Do not locate in an area where leaking could cause

property damage to the area adjacent to the appliance or to lower floors

of the structure.

CALIFORNIA PROPOSITION 65 WARNING! This product contains a

chemical known by the State of California to cause cancer and to cause

birth defects or other reproductive harm. (California Installer/Contractor

- California law requires that this notice be given to consumer/end user

of this product.) For more information: www.amtrol.com/prop65.html

temperatures in excess of 200°F. Do not adjust the pre-charge or

re-pressure this Product except during installation or regular inspection.

Replace the Product and do not adjust the precharge if corroded,

damaged or with diminished integrity. Adjustments to pre-charge must be

done at ambient temperature only. Failure to properly size the Product or

follow these instructions may result in excessive strain on the system and

may lead to Product failure, serious or fatal personal injury, leakage and/

or property damage.

working pressure designated in the Product Manual, whichever is less.

At least once every 3 years or if discharge is present, a licensed

contractor should inspect the temperature and pressure relief valve and

replace if corrosion is evident or the valve does not function. FAILURE

TO INSPECT THIS VALVE AS DIRECTED COULD RESULT IN

UNSAFE TEMPERATURE OR PRESSURE BUILD-UP WHICH CAN

RESULT IN PRODUCT FAILURE, SERIOUS INJURY OR DEATH AND/

OR SEVERE PROPERTY DAMAGE AND VOID THE PRODUCT

WARRANTY.

You should test for corrosive elements, acidity, total solids and other

relevant contaminants, including chlorine and treat your water appropriately

to insure satisfactory performance and prevent premature failure.

RUPTURE OR EXPLOSION HAZARD. Do not

expose Product to freezing temperatures or

A relief valve must be installed to prevent pressure

in excess of local code requirement or maximum

Chlorine & Aggressive Water: The water quality

can significantly influence the life of this Product.

Page 2

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION -

ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.

If the control is set too high or the pump is running

demand on the system, the pump will run continuously, can overheat

and become damaged, potentially resulting in product failure, leaking

and/or rupture.

codes, and in their absence, national codes must be followed to minimize

the risk of electric shock, property damage or personal injury.

will cause damage to the motor. The pump models RP-10HP, RP-15HP

and RP25-HP are pre-wired for 115 vac; however, they can be rewired to

be used with 230 vac. Consult motor nameplate for the wiring diagram.

visible and near the pump. Use a 20 amp circuit.

when the water supply is shut off and there is no

All wire and fuse sizings are preliminary

recommendations only. For your safety, local

The pump motor is designed for use with single

phase, 60Hz ac. Use with any other type of power

The power for your pump must be on a dedicated

circuit. In addition, a shut off switch should be

Sizing Chart

Amtrol

Pressuriser

Flow Rate

®

From City

Minimum

Supply

RP-10HP 10 gpm 10 psig

RP-15HP 15 gpm 10 psig 1" 1"

RP-25HP 25 gpm 10 psig 1 1/4" 1 1/4"

Metal piping must be used for all inlet and outlet lines to the unit.

Do not oversize pump. Inadequate water supply will result in

poor performance and pump damages.

Minimum

Flow Pressure

From City

Supply

Minimum

Incoming

Pipe Size

3

/4"

Water

Meter

3

/4"

Pre-Installation

• DONOTUSEFORPRE-HEATEDWATERSUPPLIES;

• DO NOT USE FOR ANYTHING EXCEPT COLD WATER

(AMBIENTTEMPERATURENOTTOEXCEED100°F);

• DO NOT USE IN SYSTEMS WHERE LOW PRESSURE IS

DUE TO LEAKS OR WHERE LEAKS IN THE PLUMBING

SYSTEMMAYEXIST;

• DONOTUSEINSYSTEMSWHERETHEWATERSUPPLY

CANDROPBELOW10PSIG;

• DO NOT USE IN SERIES WITH ANOTHER PUMP (SUCH

ASINPRIVATEWELLWATERSYSTEMS);

• DO NOT RE-PRESSURIZED TANK AFTER INITIAL

INSTALLATION;

• DO NOT PIPE EXCEPT WITH METAL PIPING AT INLET

AND OUTLETS.

The system must be placed indoors only on a solid level

surface with a drip pan piped to a drain with adequate capacity

for large volumes of water in the event the system ruptures or

fails. Consider the risks posed by tanks under pressure and the

potential for leaking and/or flooding damage in selecting the

location. The unit must not be placed in an environment that would

expose the water in the tank to temperatures below freezing or in

excess of 100° F.

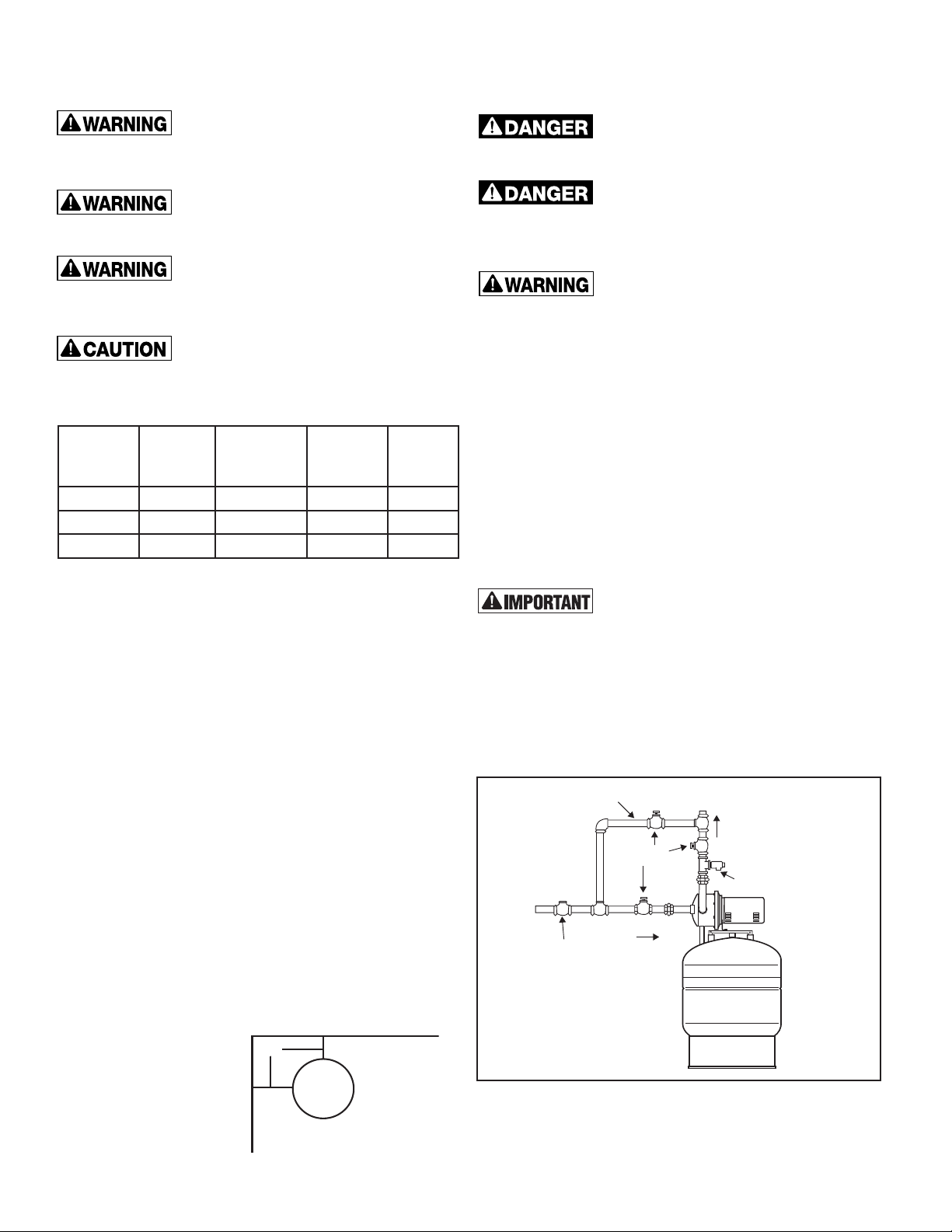

Be sure to leave a minimal

clearance of 12” around

the unit for access should

field adjustments be

necessary in the future

and to permit maintenance

and inspection (Figure 1).

Figure 1

12"

Amtrol Pressuriser

®

Before attempting any service and disassembly,

disconnected prior to removing motor. Ensure power is disconnected

before cleaning is attempted.

should be completed by a licensed electrician, and in accordance with

local codes or in their absence, the National Electrical Code. Before

starting the wiring installation, disconnect all power to the circuit to be

used for the AMTROL Pressuriser®.

systems with a minimum pressure of 10 psig at all times, measured under

flow at the tap closest to the location of the AMTROL Pressuriser®

installation.

shut off power to the pump. Ensure power is

Grounding of the pump is essential for your

protection and the protection of the motor. All wiring

The AMTROL Pressuriser® should only be

connected to a municipal, cold water supply, and in

Installation

1. Remove protective air valve cap.

2. Check pre-charge pressure (pressure should be + or – 10% of

the factory setting). Factory pre-charge is 38 psig.

3. Release or add air as necessary to make the pre-charge

pressure 2 psig below the pressure switch pump cut-in setting.

4. Replace protective air valve cap. (Remove air valve label,

replace protective air valve cap, peel off backing of label and

apply on air valve cap.)

MINIMUM SUPPLY LINE AND METER SIZE FOR

THE RP-25HP IS 11/4". THIS APPLIES TO ALL LINES INCLUDING

THOSE USED WITH THE WATER METER OR FITTINGS BEFORE THE

PUMP. CONTACT FACTORY IF MINIMUM FITTING/LINE SIZE IS

BELOW THE ABOVE NUMBERS.

5. Install a SPRING LOADED CHECK VALVE in the city supply

line on the suction side of the pump along with a shut-off valve.

Failure to do so will result in premature failure of the AMTROL

Pressuriser due to excessive pump cycling.

6. Install a by-pass loop (Figure 2).

Figure 2

CITY

WATER

SUPPLY

SPRING

CHECK VALV E

7. Pipe the city supply after the shut-off valve to the suction side

of the pump, as shown.

8. Connect the house supply line using a 100 psig maximum relief

valve as shown (Figure 2). It is important that the pressure

relief valve be installed on the pump discharge prior to any

shut off valves.

THE RP-10HP IS 3/4", THE RP-15HP IS 1" AND

BYPASS

LOOP

SHUT-OFF

VALVES

FLOW

TO SYSTEM

FLOW

PRESSURE

RELIEF

VALV E

RP-10HP

RP-15HP

RP-25HP

Page 3

ELECTROCUTION HAZARD. DISCONNECT

SERVICING. THE GUARDIAN CP™ MUST BE ELECTRICALLY

GROUNDED.

ALL ELECTRICAL POWER BEFORE

The Guardian CP™ will operate on 115 vac & 230 vac systems.

9. Disconnect power and verify with a volt meter.

10. Determine the pump electrical requirements. If unknown,

contact the pump manufacturer.

11. Select the appropriate wire gauge per local codes and the

pump manufacturer’s recommendation. All pumps are 1/2

horsepower and are rated at 10.6 amps for 115 volts and 5.3

amps for 230 volts.

12. Loosen the captive fastener on the top of the controller and

remove the plastic cover, exposing the wire leads. (When

reassembling cover, do not over-tighten fastener.)

13. Following all electrical codes, wire the Guardian CP™ (Figure 3.)

The Guardian CP™ has openings to accept standard conduit

terminations.

DO NOT INSTALL ON ELECTRICAL SERVICE

RATED ABOVE 20 AMPS.

14. Close the bypass valve.

Figure 3

BASIC

GUARDIAN CP™

WIRING

Factory wiring to pump

Programming the Guardian CP

™

Differential pressure should be adjusted to no greater than

35 psi nor lower than 10 psi. The 20 psi factory differential is

recommended.

1. Press and hold . When LO appears, release. This will

determine the pressure at which the pump activates.

2. When number appears, tap or to change cut-in setting.

3. Press again. When HI appears, tap or to change cut-

out setting. This will determine the pressure at which the pump

shuts off.

4. Press a third time. The last Error Code in memory will

display (see Error Code table in Troubleshooting section). If

no errors have occurred, the display will show - -

5. After approximately 10 seconds Pr will appear, indicating the

settings are programmed. Display will then revert to the line

pressure.

NOTE: The settings will now be stored until changed manually,

even in the event of power failure.

NOTE: If pump cannot reach cut-out setting within 5 minutes with

no water running, lower the pressure settings to fall within the

pump’s pressure capabilities

Operation

ENSURE THE SWITCH IS OPERATING PROPERLY. AFTER MAKING

ANY ADJUSTMENTS, OBSERVE AT LEAST ONE PUMP CYCLE TO

VERIFY PROPER PUMP SHUT-OFF.

Please contact AMTROL Technical Support at 401-535-1216 or

an AMTROL representative if further assistance is required.

Winterizing: To drain, disconnect the pump from power and open

a faucet to bleed off water pressure. Lay the tank on its side to

disconnect the piping between the pump and tank to completely drain

the unit. Ensure exposed piping conected to unit is also drained.

White

White

L2

w/Black

P2

Black

L1

Blue

P1

15. Open the city water supply line valve and a faucet and check

the system for leaks, repair any leaks before proceeding.

16. Shut off the faucet and check the system for leaks. Repair any

leaks before proceeding.

IF THE CONTROL SWITCH IS SET TOO HIGH OR

SUPPLY IS SHUT OFF AND THERE IS NO DEMAND ON THE SYSTEM,

THE PUMP WILL POTENTIALLY RUN CONTINUOUSLY, CAN

OVERHEAT AND CAUSE DAMAGE; RESULTING IN PRODUCT

FAILURE, LEAKING AND/OR RUPTURE. TO REDUCE THIS RISK,

NEVER EXCEED 80 PSIG CUTOUT.

THE PUMP IS RUNNING WHEN THE WATER

Start-Up

BEFORE CONTINUING, ENSURE THAT ALL

GROUNDED. CHECK FOR OPEN DRAIN VALVES OR OTHER

SOURCES OF FLOODING BEFORE STARTING UNIT.

1. Prime pump if necessary and adjust tank precharge to

manufacturer’s recommendation for intended pressure range.

The factory Guardian CP setting is 40 psi cut-in and 60 psi

cut-out.

2. Turn on power and ensure Guardian CP display illuminates.

Display will blank momentarily and the pump will start. If not,

check installation.

3. The display will now read the current line pressure.

4. Allow the pump to reach the factory cut-off setting of 60 psi. IF

THE PUMP CANNOT REACH THIS SETTING, DISCONNECT

POWER AND SEE THE TROUBLESHOOTING SECTION.

5. Check for leaks and repair as necessary.

WIRING IS COMPLETED AND THE UNIT IS

DO NOT ADJUST PRESSURE OR

RE-PRESSURIZE THIS PRODUCT EXCEPT

FOR ANY ADJUSTMENTS MADE AT THE TIME OF INITIAL

INSTALLATION WHEN THE UNIT IS NEW. RE-PRESSURIZATION OF

A WEAKENED, DAMAGED, OR CORRODED UNIT CAN CAUSE AN

EXPLOSION, POSSIBLY CAUSING SERIOUS OR FATAL PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

If pressure adjustments are necessary because of changes in

inlet pressure, check the condition of the unit first to make sure

there is no corrosion of the tank or any connected lines or fittings.

Take appropriate precautions. Never adjust the pressure if water

is leaking from the air stem. Replace any damaged or corroded

tank. Also, air loss is an indication that damage, corrosion or

weakening of the unit may have occurred and it should not be

re-pressurized.

Maintenance

Your AMTROL Pressuriser unit, including the pump, must be

periodically inspected by an experienced professional for signs of

damage, corrosion and leaking. The pump should be checked to

ensure it is turning on and off at the appropriate cut-in and cut-out

points. At a minimum, after installation, a thorough inspection of

all components should take place annually. However, note that

units in settings with frequent use, where corrosion, high humidity

or aggressive water is more likely to occur, and as the unit ages,

should be inspected more frequently.

Warranty

Two (2) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.

Page 4

Troubleshooting

The Guardian CP™ incorporates built-in diagnostics. If the AMTROL Pressuriser® is not functioning properly or is inoperable, look for

a error code (example E1) on the digital readout before proceeding. Error codes are listed in the table at the bottom of this page.

PROBLEM CAUSE SOLUTION

Pump will not start.

Pump runs but will

not build pressure.

Pump builds

pressure but will not

shut off.

Pump starts too often

(cycles under 30

sec.).

1. No Power.

2. Faulty wiring.

3. Damaged motor.

4. Damaged control.

1. Supply closed/blocked.

2. Bypass loop open.

3. Pump plumbed backwards.

4. Bad internal parts.

1. Operating pressure set too high.

2. Bad internal parts.

3. Control line blocked.

1. Control differential too narrow.

2. Tank precharge incorrect.

3. Waterlogged pressure tank.

1. Check circuit breaker and fuses, tighten connections.

2. Check wiring per installation diagram in this booklet. If pump hums,

but will not start, check pump motor wiring (115/230V).

3. If display illuminates with no error code, but pump will not start,

replace pump.

4. If power is present at L1/L2 but display is blank, replace control.

1. Open all supply valves, ensure check valve is not sticking, clean

any filters.

2. Close bypass valve.

3. Reverse inlet/outlet.

4. Check for bad seals or broken impeller. Repair or replace as

necessary.

1. Reduce control setting as necessary.

2. Check for bad seals or broken impeller. Repair or replace as

necessary.

3. Remove control line and blow compressed air to clear.

1. Set cut-in and cut-out 20 psi apart.

2. Set air pressure 2 psi below cut-in while pump is off and gauge

pressure is zero.

3. If water emerges from tank air stem when depressed, replace tank.

To reset control at any time, press buttons simultaneously for 5 seconds.

To "invert" the display for easier viewing, press together for 3 seconds.

CODE REASON ACTION CAUSE & REMEDY

E1

Rapid cycle

Excessive amp draw

E2 Low-suction

(running pressure)

below 10 PSI

Switch continues to operate.

Shuts off pump. Auto restart

after 60 min.

See “Pump Starts Too Often” above.

Have pump checked for proper operation.

1. Determine cause of low-suction.

2. Check Wiring.

3. Inspect pump.

E3 Improper voltage Shuts off pump. Restore voltage to proper range. Pump automatically

restarts with proper voltage.

THE GUARDIAN CP CONTROL CONTAINS NO SERVICEABLE PARTS. REMOVAL OF MAIN CIRCUIT BOARD COVER WILL

VOID WARRANTY.

LOW-LEAD

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 F: 800.293.1519

www.amtrol.com

© 2014 AMTROL Inc. Part #: 9040B140 (07/14)

Mark of the

Originator

Loading...

Loading...