AMS Wireless Vibration Monitor

User Guide

User Guide

MHM-97927-PBF, Rev 1

August 2020

Copyright

©

2020 by Emerson. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of Emerson.

Disclaimer

This manual is provided for informational purposes. EMERSON MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Emerson shall not be liable for errors, omissions, or inconsistencies that may be contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. Information in this document is

subject to change without notice and does not represent a commitment on the part of Emerson. The information in this manual is

not all-inclusive and cannot cover all unique situations.

Patents

The product(s) described in this manual are covered under existing and pending patents.

Where to get help

Software Registration

Phone:

Toll free 888.367.3774, option 2 (U.S. and Canada)

+63.2.702.1111 (Rest of world)

Email:

Web:

wwcs.custserv@emerson.com

http://www.emerson.com/machineryhealthreg

Product Support

Emerson provides a variety of ways to reach your Product Support team to get the answers you need when you need them:

Phone

Toll free 800.833.8314 (U.S. and Canada)

+1.512.832.3774 (Latin America)

+63.2 702.1111 (Asia Pacific, Europe, and Middle East)

Email

Web

ap-sms@emerson.com

http://www.emerson.com/en-us/contact-us

To search for documentation, visit http://www.emerson.com.

To view toll free numbers for specific countries, visit http://www.emerson.com/technicalsupport.

2

User Guide Contents

MHM-97927-PBF August 2020

Contents

Chapter 1 Introduction.................................................................................................................. 5

1.1 Safety messages...............................................................................................................................5

1.2 Symbols............................................................................................................................................5

1.3 Considerations................................................................................................................................. 7

1.4 Return of materials...........................................................................................................................7

1.5 Overview.......................................................................................................................................... 9

1.6 Device variables..............................................................................................................................13

1.7 Variable mappings..........................................................................................................................14

Chapter 2 Configuration...............................................................................................................15

2.1 Setup overview...............................................................................................................................15

2.2 Pre-configuration........................................................................................................................... 16

2.3 Configuration overview.................................................................................................................. 17

2.4 Configuration with AMS Device Manager........................................................................................20

2.5 Configure with Trex Communicator................................................................................................37

2.6 Configuration options.................................................................................................................... 38

Chapter 3 Installation...................................................................................................................43

3.1 Device handling..............................................................................................................................43

3.2 Mounting tools and supplies...........................................................................................................43

3.3 Mounting mechanisms...................................................................................................................44

3.4 Mount the device........................................................................................................................... 48

3.5 Change the battery.........................................................................................................................49

Chapter 4 Operation.................................................................................................................... 51

4.1 Verify the device is operational.......................................................................................................51

4.2 Verify operation with Emerson Wireless Gateway...........................................................................51

4.3 Verify operation with AMS Trex Communicator..............................................................................52

4.4 Check device status........................................................................................................................53

4.5 Device variable ranges....................................................................................................................54

4.6 Device operating limits...................................................................................................................54

4.7 Clean the device............................................................................................................................. 54

Chapter 5 Overall Velocity, PeakVue, and temperature................................................................ 55

5.1 Overall Velocity.............................................................................................................................. 55

5.2 PeakVue......................................................................................................................................... 58

5.3 Temperature.................................................................................................................................. 62

Appendix A Specifications and reference data.................................................................................65

A.1 Functional specifications................................................................................................................ 65

A.2 Physical specifications.................................................................................................................... 66

A.3 Performance specifications............................................................................................................ 66

MHM-97927-PBF, Rev 1 iii

Contents User Guide

August 2020 MHM-97927-PBF

A.4 Radio specifications........................................................................................................................67

A.5 Device variable alert limits..............................................................................................................67

Appendix B Product certifications................................................................................................... 73

B.1 Approved manufacturing locations................................................................................................ 73

B.2 Wireless certifications.................................................................................................................... 73

B.3 Ordinary location certification (CSA)...............................................................................................75

B.4 CE mark..........................................................................................................................................75

B.5 Hazardous locations certifications.................................................................................................. 77

B.6 Waste Electrical and Electronic Equipment..................................................................................... 79

Appendix C Third-party licenses......................................................................................................81

C.1 Dust SmartMeshSDK C Library........................................................................................................81

Index .................................................................................................................................... 83

iv MHM-97927-PBF, Rev 1

User Guide Introduction

MHM-97927-PBF August 2020

1 Introduction

1.1 Safety messages

Instructions in this manual may require special precautions to ensure the safety of the

personnel performing the operations.

The AMS Wireless Vibration Monitor complies with Part 15 of the FCC Rules. Operation is

subject to the following conditions:

This device may not cause harmful interference, this device must accept any interference

received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum separation of 20 cm from all persons.

Refer to the following safety messages before performing an operation preceded by the

warning symbol:

WARNING

Failure to follow these installation guidelines can result in death or serious injury. Only

qualified personnel should install the AMS Wireless Vibration Monitor.

Explosions could result in death or serious injury:

• Before connecting a Field Communicator in an explosive environment, make sure the

instruments are installed in accordance with applicable field wiring practices.

• Verify that the operating environment of the AMS Wireless Vibration Monitor is

consistent with the appropriate hazardous locations certifications.

1.2 Symbols

Note

This symbol marks passages that contain important information.

CAUTION

This symbol marks operations that can lead to malfunctions or faulty measurements, but

will not damage the device.

DANGER

This symbol indicates actions that can lead to property damage or personal injury.

The symbols on the device signify compliance to the following:

Ukraine Restriction of Hazardous Substances (RoHS)

MHM-97927-PBF, Rev 1 5

Introduction User Guide

August 2020 MHM-97927-PBF

Regulatory Compliance Mark Australia

China Restriction of Hazardous Substances (RoHS)

Lithium-ion cell recyclable

The documentation must be completely read and understood before installing and

commissioning the device. Observe all safety-related instructions in this document.

Waste Electronic and Electrical Equipment Directive

6 MHM-97927-PBF, Rev 1

User Guide Introduction

MHM-97927-PBF August 2020

1.3 Considerations

General

Electrical vibration sensors, such as accelerometers, produce low-level signals proportional

to their sensed vibration. With simple HART configuration, the monitor converts the lowlevel sensor signal to a wireless-enabled signal.

Commissioning

The monitor can be commissioned before or after installation. You can commission it on

the bench before installation to ensure proper operation and to be familiar with its

functions.

Make sure the instruments are installed in accordance with applicable field wiring

practices.

The AMS Wireless Vibration Monitor is powered whenever the battery is installed.

Installation

When choosing an installation location and position, provide ample access to the monitor.

The device should be mounted vertically, perpendicular to the shaft and on the bearing

case. Horizontal mounting is also an option. For more information, see Installation.

Battery

The AMS Wireless Vibration Monitor uses an off-the-shelf Tadiran TL-4920/VE battery.

The battery comes with the device but it is not connected when the device is shipped. You

need to connect the battery before configuring and installing the device.

Environmental

The monitor operates within specifications for ambient temperatures between –40°F and

185°F (–40°C and 85°C).

Verify that the operating environment of the monitor is consistent with the appropriate

hazardous location certifications.

1.4 Return of materials

You may need to ship the device to an Emerson Product Service Center for return or

replacement in case of warranty issues. Before shipping, contact Emerson Product Support

to obtain a Return Materials Authorization (RMA) number and receive additional

instructions.

Emerson Product Support contact information:

Phone

Email

Web

Toll free 800.833.8314 (U.S. and Canada)

+1.512.832.3774 (Latin America)

+63.2 702.1111 (Asia Pacific, Europe, and Middle East)

ap-sms@emerson.com

http://www.emerson.com/en-us/contact-us

MHM-97927-PBF, Rev 1 7

Introduction User Guide

August 2020 MHM-97927-PBF

Note

If the monitor has been exposed to hazardous substances, a Material Safety Data Sheet

(MSDS) must be included with the returned materials. An MSDS is required by law to be

available to people exposed to specific hazardous substances.

Shipping considerations for wireless products (Lithium Batteries)

• The unit was shipped to you with the battery inside but disconnected. Connect the

battery for proper operation.

• Primary lithium batteries are regulated in transportation by the U.S. Department of

Transportation, and are also covered by IATA (International Air Transport Association),

ICAO (International Civil Aviation Organization), and ADR (European Ground

Transportation of Dangerous Goods).

• It is the responsibility of the shipper to ensure compliance with these or any other local

requirements. Please consult current regulations and requirements before shipping.

8 MHM-97927-PBF, Rev 1

User Guide Introduction

MHM-97927-PBF August 2020

1.5 Overview

The manual

This User Guide applies to the AMS Wireless Vibration Monitor, a triaxial vibration

measurement device designed for use on a WirelessHART network.

Use this manual to install, operate, and maintain the device.

The monitor

The AMS Wireless Vibration Monitor is an installation-ready solution that monitors

vibration and temperature in rotating equipment in hard-to-reach locations.

The AMS Wireless Vibration Monitor also provides a variety of monitor and sensor

configurations. It has built-in radio and four integral sensors:

• X and Y MEMS

• Z MEMS High Sensitivity, High Bandwidth (Vibration & PeakVue)

• Temperature sensor

The Z accelerometer has the highest bandwidth and is considered the primary sensor. The

temperature sensor is designed to measure the temperature near the mounting point

(that is, the machine surface).

Other features include:

• Support for up to 13 device variables with up to three user-configurable alerts for each

process variable. Any device variable can be configured as any process variable (PV, SV,

TV, QV).

• Support for storage of Waveform/Spectrum directly in AMS Machine Works

• Wireless output with >99% data reliability, delivering rich HART data, protected by

industry leading security (when operated as part of a well-formed network)

The device uses an off-the-shelf battery contained in the device which is easily removable

for device installation and replacement.

MHM-97927-PBF, Rev 1 9

Introduction User Guide

August 2020 MHM-97927-PBF

Parts of the monitor

A. Chassis

B. HART Terminals

C. Orientation hole

D. Mounting screw

10 MHM-97927-PBF, Rev 1

User Guide Introduction

MHM-97927-PBF August 2020

A. Cover

B. Battery clamp

C. Battery

D. Battery pull tab

E. Base O-ring

MHM-97927-PBF, Rev 1 11

Introduction User Guide

August 2020 MHM-97927-PBF

Device revision information

Revision Current level Description

Universal 7 This is the HART version the monitor supports.

Field device

Software 56 This is the current software version.

Hardware 2 This is the hardware revision.

1

If you have an older device revision, a factory upgrade may be possible in some cases. Contact

Product Support for more information.

1

DD 1 This is the Device Descriptor (DD) revision.

1 This is the major revision of the monitor and corresponds with a

major interface release.

When using AMS Device Manager, this revision can be found on

the screen title.

The software may be occasionally modified to refine

functionality. When major functionality is added, the device

revision increases.

The device descriptor is primarily used for configuring devices in

the field.

You can also view the revision information in AMS Device Manager and Trex

Communicator.

Figure 1-1: Revision numbers in AMS Device Manager

12 MHM-97927-PBF, Rev 1

User Guide Introduction

MHM-97927-PBF August 2020

1.6 Device variables

The device supports the following measurements.

Device

variable index

0 Z-Velocity

1 Z-Peakvue

2 Machine Temperature

3 Supply Voltage

4 X-Velocity (Triax Mode license required)

5 Y-Velocity (Triax Mode license required)

6 IB1 (Velocity) (Advanced Diagnostics license required)

7 IB2 (Velocity) (Advanced Diagnostics license required)

8 IB3 (Acceleration) (Advanced Diagnostics license required)

9 IB4 (Accleration) (Advanced Diagnostics license required)

10 Speed Estimate (Advanced Diagnostics license and valid speed required)

11 Mechanical Condition (Advanced Diagnostics license and valid speed required

12 Lubrication Condition (Advanced Diagnostics license and valid speed required

Device variables

MHM-97927-PBF, Rev 1 13

Introduction User Guide

August 2020 MHM-97927-PBF

1.7 Variable mappings

Any of the device variables can be configured as a process variable.

The process variables and their default values are as follows.

Table 1-1: Process Variables

Process Variable Default

PV Z-axis Overall

SV X-axis Overall

TV Y-axis Overall

QV Z-axis PeakVue

Table 1-2: Device Variables

Device Variables Process Variables

X-axis Overall Any of the 13 Device Variables

Y-axis Overall SV

Z-axis Overall TV

Z-axis PeakVue QV

Velocity Parameter 1

Velocity Parameter 2

Acceleration Parameter 1

Acceleration Parameter 2

Bearing/Mechanical Severity

Lubrication Severity

Calculated Speed

Skin Temperature

Supply Voltage

can be configured as a Process

Variable

PV

14 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

Configuration

2 Configuration

2.1 Setup overview

Unless the AMS Wireless Vibration Monitor is purchased pre-configured from the factory,

it needs to be configured prior to installation at the facility or measurement location.

There are three possible setups to configure the device:

1. Connect the device to a field communicator, and then configure the device using

the field communicator.

Note

This setup is recommended if you are in a hazardous area.

2. Connect the device to a computer through a HART modem, and then configure the

device using AMS Device Manager.

Note

The HART modem is purchased separately.

3. Connect the device to a computer through a wireless gateway and then configure

the device using AMS Device Manager.

MHM-97927-PBF, Rev 1 15

Configuration User Guide

August 2020 MHM-97927-PBF

Note

This setup is recommended for standard device configuration.

2.2 Pre-configuration

The AMS Wireless Vibration Monitor is shipped with the battery disconnected from the

device to comply with safety requirements. You need to connect the battery before you

can configure the device. Remove the battery after configuration to avoid depleting it.

Procedure

1. Use your hands to unscrew and remove the blue cover.

This exposes the HART ports.

Use an Allen wrench or a small screwdriver and put it through the Orientation hole

to use as leverage while loosening the cover.

CAUTION

Exercise caution when using your bare hands to remove the cover.

2. Remove the battery with the pull tab.

3. Locate the battery connector and plug it into the socket on the device as shown.

16 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

Configuration

4. Replace the battery. Tuck the wires against the battery and lock them into place.

5. Mount the cover and then tighten it.

Note

To avoid depleting the battery, disconnect it when the device is not in use. If you

have configured the device and network but are not ready to commission it,

remove the battery to extend its operating life. Reconnect the battery when you are

ready to install the device.

2.3 Configuration overview

Configure the device to control the following operations:

• How measurement results are reported and how often are they reported

• How and when alerts are generated

• Set the upper and lower limits of the alerts

• Set the units of measurement for the parameters

• Set the primary variable, secondary variable, tertiary variable, and quarternary variable

You can change these configurations from AMS Device Manager or from a field

communicator such as Trex Communicator.

To view the default values, see Configuration defaults.

Note

The specific user interface for performing the configuration varies depending on the host

used.

MHM-97927-PBF, Rev 1 17

Configuration User Guide

August 2020 MHM-97927-PBF

Procedure

1. Connect to a computer or field communicator.

You need to connect to a wired connection to set the wireless credentials.

For more information, see Connect to a wired HART interface.

2. Set the wireless network credentials (Network ID and Join Key) using wired

connection.

The monitor has a default Network ID and Join Key. You can change the network

credentials in the gateway that you used for configuration. All devices should join

the network once the battery is connected.

For more information, see Set the wireless network configuration.

After the device has joined the network, you can complete the rest of the

configuration steps over a wireless connection.

3.

(Optional)

Name the device (Tag and Device Description).

By default, the tag is VXAABBCC, where AABBCC: is the unique device ID. The device

joins the network and operates correctly even if no changes are made, but it is

recommended to name the device something meaningful for the specific

application.

4. Specify the units (English or metric) that will be used for each parameter.

By default, units are set to English.

5. Specify which measurements (velocity, temperature, etc.) correspond to the

process variables PV, SV, TV, and QV. Specify the units (English or metric) for

each parameter.

By default, PV corresponds to Z-axis overall, SV is X-axis overall, TV is Y-axis overall,

and QV is Z-axis PeakVue.

6. Specify alert levels.

Determine the thresholds at which measurement alerts will display and determine

the behavior of device alerts. See the alert limits in Device variable alert limits.

7. Specify the update rate.

The default update rate is once every 60 minutes. A faster update rate is not

recommended as it significantly reduces battery life.

8. Configure trending of parameters.

You can trend parameters in multiple locations such as in a plant historian, in AMS

Machine Works, and in a DCS control system.

18 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

Configuration

2.3.1 Connect to a wired HART interface

You need to initially connect the device to a wired HART interface to define the credentials

that allow it to communicate on a wireless network. You can also define other device

configurations such as sensor type and alert thresholds at this time.

Notes

Use the wired HART interface only for configuration. Dynamic variables (such as measured

vibration parameters) are not updated when communicating on the wired interface.

Procedure

1. Locate the terminals for the communication port on the opposite side of the device.

2. Connect a configuration device to the terminals such as a computer running AMS

Device Manager with a HART™ modem or an AMS Trex Communicator.

3. Configure the device.

• To configure the device using AMS Device Manager, see Configuration with AMS

Device Manager.

2.3.2

• To configure the device using AMS Trex Communicator, see Configure with Trex

Communicator.

Press Send to send configuration changes to the monitor.

Set the wireless network configuration

This enables the monitor to communicate with the Emerson Wireless Gateway and with

other systems. This is the wireless equivalent of connecting wires from a transmitter to a

control system input.

Procedure

1. From the Emerson Wireless Gateway, click System Settings → Network →

Network Settings to obtain the Network ID and Join Key.

MHM-97927-PBF, Rev 1 19

Configuration User Guide

August 2020 MHM-97927-PBF

2. Using a field communicator or AMS Device Manager with a wired modem, enter the

Network ID and Join Key so that they match the Network ID and Join Key from the

Emerson Wireless Gateway.

Note

If the Network ID and Join Key are not identical to the gateway settings, the AMS

Wireless Vibration Monitor will not communicate with the network.

2.4 Configuration with AMS Device Manager

2.4.1 Configure wireless network credentials

Prerequisites

Before performing operations in AMS Device Manager, first scan the AMS Wireless

Vibration Monitor with a wired HART modem. Right-click the HART Modem icon

Device Explorer and select Scan All Devices.

in

Note

Configuring the wireless network is only applicable using a wired HART modem and

cannot be done using WirelessHART devices.

Procedure

1. In AMS Device Manager, right-click AMS Wireless Vibration Monitor and then select

Methods → Join Network.

2. Enter the network ID for the wireless network in the Join Device to Network screen

and click Next.

You can obtain the network ID from the Emerson Wireless Gateway web server.

Click Setup → Network → Settings.

3. Enter the Join Key in the screens that follow, and click Next.

4. Select the Accept new join key option, and click Next.

5. Click Finish when done.

20 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

2.4.2 Main navigation

The main navigation page provides quick links to the Overview, Configure, and Service

Tools menus, as well as to other context menus available for the device.

In the Device Explorer view, select the wireless network where the transmitter is

connected and right-click the transmitter to display the context menus.

Figure 2-1: AMS Wireless Vibration Monitor Main Navigation

MHM-97927-PBF, Rev 1 21

Configuration User Guide

August 2020 MHM-97927-PBF

2.4.3 Overview menu

The Overview menu provides a glimpse of the status of the AMS Wireless Vibration

Monitor, including the status of the connection to the wireless network, and a summary of

the primary variables, machine temperature, battery voltage, and update rate.

From this menu, you can access the Configure menu and the Service Tools.

You can also access these shortcuts:

• Device Information

• Perform Acquisition

• Join Device to Network

22 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

Configuration

2.4.4 Configure menu

Use this menu to configure sensors, variable mappings, units and alert limits.

There are two options to configure the device It is advisable to use Guided Setup.

Important

To be able to edit configuration settings, select Current in the Time drop-down menu at

the bottom of the screen.

Guided setup

This option lets you configure device settings in a guided step-by-step process. Click each

of the buttons under Initial Setup to complete the guided setup.

Click Configure Variable Mapping to display or specify which measurements are reported

as the Primary, Secondary, Tertiary, and Quaternary variables.

Click Configure Device Variable Units to configure the units for device variables.

Click Configure Alert Limits to define the lower range and upper range values and alert

limits for Advisory, Maintenance, and Failure for each of the process variables. You can also

configure alert reporting from here.

Click Configure Acquisition Settings to set the acquisiton settings.

Click Join Device to Network to enter network identifiers and join keys that will enable the

device to join a wireless network.

Click Configure Update Rate to set how often the device acquires and reports new

measurements (update rate) and to specify the number of times the transmitter skips data

acquisitions between updates to the gateway.

MHM-97927-PBF, Rev 1 23

Configuration User Guide

August 2020 MHM-97927-PBF

Manual setup

In this option, you have to define the settings in several tabs as shown below.

Wireless tab

Click Join Device to Network to enter network identifiers and join keys that will enable the

monitor to join a wireless network.

Click Configure Update Rate to set how often the device acquires and reports new

measurements (update rate) and to specify the number of times the monitor skips data

acquisitions between updates to the gateway.

Click Apply Default Burst Configuration to reset the burst configuration to default values.

Note

The burst messages are not individually controllable via the DD.

24 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

Machine tab

Click Configure Acquisiton Settings to configure the parameters for the specific sensor.

Click Refresh Acquisition Time to reset the parameters to default values.

MHM-97927-PBF, Rev 1 25

Configuration User Guide

August 2020 MHM-97927-PBF

Z Axis tab

Click Configure Acquisiton Settings to configure the parameters for the specific sensor.

Click Refresh Acquisition Time to reset the parameters to default values.

When configured with speed (which requires the Advanced Diagnostics License), the

optimal and minimum values are displayed.

26 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

X-Y Axis tab

Click Configure Acquisiton Settings to configure the parameters for the specific sensor.

Click Refresh Acquisition Time to reset the parameters to default values.

When configured with speed (which requires the Advanced Diagnostics License), the

optimal and minimum values are displayed.

MHM-97927-PBF, Rev 1 27

Configuration User Guide

August 2020 MHM-97927-PBF

Interval Bands tab

This tab shows the measurement ranges for the Z PeakVue, Z Velocity, and X-Y Velocity

and effectively bound FMin and FMax for the selected source.

The device enforces these ranges and forces them to the bounded values. This was

designed to never allow bad configuration.

28 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

General tab

Write Protect—Allow or block an application from modifying the device parameters.

SW Configuration—Allow or block software applications to modify the device parameters.

Configure Device Variable Units—Specify the units of measurement for acceleration,

velocity, and temperature.

Localization—Set the country and timezone where the device is located.

MHM-97927-PBF, Rev 1 29

Configuration User Guide

August 2020 MHM-97927-PBF

Mapping tab

Use this menu to set the PV, SV, TV, and QV.

30 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

Device Information tab

This window shows relevant device information such as the serial number, device

identifier, and revision numbers.

Identification—displays the device tag, long tag, device type, serial number, device

identifier, date, and device description.

Revision Numbers—displays the universal, field device, software, hardware, and DD

revision numbers.

MHM-97927-PBF, Rev 1 31

Configuration User Guide

August 2020 MHM-97927-PBF

License tab

Change License—This option lets you upgrade the device license. Downgrading is not

allowed. When the device is fully licensed, this option is not visible to the user.

Installed Features

The device has 2 license options. Triax Mode and Advanced Diagnostic.

• Triax Mode—Enabling this mode allows the device to collect vibration data in all axis (X,

Y, and Z).

• Advanced Diagnostic—Enabling this mode lets you edit acquisition parameters,

acquire four additional vibration parameters, acquire spectra and waveform, access

advanced prescriptive analytics.

32 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

Alert setup

Use this menu to configure the alert limits of the device variables. Each tab lets you

configure the units of each variable or set it back to the default values. All alerts are

configured from highest value to lowest value. Depending on the alert type, this may

mean the fail or the advise follows the range upper.

MHM-97927-PBF, Rev 1 33

Configuration User Guide

August 2020 MHM-97927-PBF

2.4.5 Service Tools

Alerts

This menu displays alert conditions. These include hardware and software malfunctions or

parameters with values beyond specifications. Only active alerts are visible.

34 MHM-97927-PBF, Rev 1

User Guide Configuration

MHM-97927-PBF August 2020

Variables

This tab lets you see the graphical gauge for each device variable.

Click Mapped Variables to display graphical gauges of the PV, SV, TV, and QV.

Click the tabs for each parameter to view graphical gauges for each of the parameters.

MHM-97927-PBF, Rev 1 35

Configuration User Guide

August 2020 MHM-97927-PBF

Spectra

This tab allows you to retrieve spectral data from the device. It is only visible if the

Advanced Diagnostics license is enabled

Communications tab

36 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

This tab shows the status and details of the device joining a network.

Maintenance tab

Use this tab to manage the device maintenance and log settings.

Configuration

Click Routine Maintenance to view device statistics and restore the device to default

settings.

Log to display events such as measurements, HART transmissions, and wake actions.

Click Log Configuration to configure event logging options. Data from event logs are

useful during a debug process.

Click Device Statistics to display statistics related to radio transmission operation such as

communication interval between data requests.

Click Reset/Restore to reset the device or to restore factory default settings.

2.5 Configure with Trex Communicator

You can configure the monitor using a field communicator such as the AMS Trex

Communicator. For instructions on using the AMS Trex, refer to the AMS Trex Device

Communicator User Guide.

A Rev 1 DD is required when using a field communicator to configure the AMS Wireless

Vibration Monitor. Refer to the Field Communicator User’s Manual for more details on DDs

or go to https://www.emerson.com/en-us/catalog/ams-trex-device-communicator for

instructions on adding a DD for AMS Wireless Vibration Monitor.

MHM-97927-PBF, Rev 1 37

Configuration User Guide

August 2020 MHM-97927-PBF

2.6 Configuration options

2.6.1 Measurement parameter units

The table below shows the measurement parameters and units that can be configured for

each parameter.

Table 2-1: Measurement parameter units

Parameter Units

Acceleration m/s

m/s

Velocity

mm/s

in/s

Temperature

Speed rpm

Supply Voltage V

2.6.2 Configuration defaults

Table 2-2: Configuration Values

Configuration option Default value

Network ID 1234

Join Key 12340000 00000000 00000000 00000000

Message WIRELESS VIBRATION TRANSMITTER

Description ASSET NAME

Default Long Tag Format VX WWYYTTTTTTT

Default Short Tag Format VXAABBCC

Update Rate 60 minutes

Mounting Method Not Set

Motor Type Not Set

°C

°F

Line Frequency Not Set

VFD Not Set

Machine Noise Threshold 0.05 in/sec

Nameplate Speed RPM 0 rpm

Driver/Driven Ratio 1

X_YLOR 1600 lines

X_YFMIN 2 Hz

38 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

Configuration

Table 2-2: Configuration Values

Configuration option Default value

X_YFMAX 1000 Hz

Z LOR 1600 lines

Z FMIN 1000 Hz

Z FMAX 1000 Hz

Z Peakvue LOR Z velocity spectrum

Z Peakvue HP Filter 2

Z Peakvue FMAX 65

Velocity Band 1 Source Z velocity spectrum

Velocity Band 1 Start 2

Velocity Band 1 Stop 65

Velocity Band 2 Source Z velocity spectrum

Velocity Band 2 Start 65

Velocity Band 2 Stop 300

Acceleration Band 1 Source Z acceleration spectrum

Acceleration Band 1 Start 10

(continued)

Acceleration Band 1 Stop 500

Acceleration Band 2 Source Z acceleration spectrum

Acceleration Band 2 Start 500

Acceleration Band 2 Stop 1000

2.6.3 Publish mode

The device publishes all device variables and status in three bursts. In cases where a third

party host or other control system configures the burst configuration in a custom mode,

the DD allows the user to reset the burst configuration to the default burst mode.

However, it is strongly recommended that the device bursting not be manipulated as it

has been optimized to provide all device variables and status bytes, hence allowing any

potential data from the device to be cached in the gateway, minimizing opportunity for

errant communication from a 3rd party host or other control system to wake the device

due to burst misconfiguration.

2.6.4

Update rate

The default update rate is 60 minutes. This is the maximum (fastest) recommended

update rate. You can change this at commissioning or at any time through AMS Device

Manager, the AMS Trex Communicator, or the Smart Wireless gateway web server.

The update rate can be set from 1 minute to 60 minutes (with 1-second resolution) and

from 1 hour to 24 hours (with 1-hour resolution, always rounding to the next hour).

MHM-97927-PBF, Rev 1 39

Configuration

August 2020 MHM-97927-PBF

When the update rate is greater than 1 hour, the device will publish the last measurement

every hour (meeting the HART requirement to at least publish data once / hour) and will

publish the new data set on the update rate.

Reducing the update rate minimizes power consumption and extends the life of the

battery.

Note

If the device is configured to publish at the fastest allowable update rate (once per

minute), the battery is expected to last only about 2-3 months.

User Guide

2.6.5 Alert levels

The AMS Wireless Vibration Monitor sets HART status bits to indicate when measured

values exceed the configured thresholds. Measured values have six levels: Saturated,

Sensor, Range, Advisory, Maintenance, and Failed.

The level at which these thresholds should be set depends on the type of equipment being

monitored and on your specific process.

Check the alert thresholds in Device variable alert limits.

One rule of thumb for vibration is to examine the current level at which the equipment is

operating. Assuming the equipment is in good working condition, set the Advisory level at

2x the current value (or at a minimum of 0.05 in/s RMS, whichever is greater), set the

Maintenance level at 4x the current value, and set the Failed level at 8x the current value.

For example, if the current value for Overall Velocity is 0.1 in/s, set the Advisory threshold

at 0.2 in/s, the Maintenance threshold at 0.4 in/s and the Failed threshold at 0.8 in/s. While

this type of vibration program is not recommended, it can provide a starting point when

no other information is available.

A good rule of thumb for establishing the PeakVue alert levels is to use the rule of 10's. This

applies for most rolling element bearing equipment with a turning speed between 900

and 4000 CPM. Using this approach, the Advisory alert would be set at 10 g's, the

Maintenance alert at 20 g's, and the Failed alert at 40 g's. In general, PeakVue alert levels

can then be interpreted as follows:

10 g's

20 g's Serious Abnormal Situation - Maintenance Plan Required

40 g's Critical Abnormal Situation - Implement Maintenance Plan

For more information on PeakVue, see PeakVue.

Notes

When any measured process parameter (Velocity, PeakVue, or Temperature) exceeds the

configured Advisory, Maintenance, or Failed threshold, this causes an alert indication that

you can view from AMS Device Manager (or in another graphical host). This indicator itself

does not set a status bit.

Indication of Abnormal Situation

2.6.6

40 MHM-97927-PBF, Rev 1

Trend parameters

You can trend parameters in multiple locations such as in a plant historian or in AMS

Machine Works. The method for configuring this functionality is contained in the

User Guide Configuration

MHM-97927-PBF August 2020

associated software and the details of all the possibilities are beyond the scope of this

manual. This manual only indicates some of the general capabilities and version

requirements.

You can trend values in essentially any host that accepts Modbus or OPC inputs. Configure

OPC tags and Modbus registers for wireless devices in the Smart Wireless Gateway web

interface. Refer to the Smart Wireless Gateway User Manual for additional information.

The settings in the gateway and the host must be consistent and entered in both locations

(for example, Modbus register definitions).

Also, with AMS Machine Works and AMS Wireless Vibration Monitor devices (that are

licensed for the Advanced Diagnostics application), you can trend Energy Band parameters

and collect spectrum and waveform information.

MHM-97927-PBF, Rev 1 41

Configuration User Guide

August 2020 MHM-97927-PBF

42 MHM-97927-PBF, Rev 1

User Guide Installation

MHM-97927-PBF August 2020

3 Installation

3.1 Device handling

Before beginning the installation process:

Install the Emerson Wireless Gateway and ensure it functions properly before you activate

the AMS Wireless Vibration Monitor or any other wireless devices. Power up wireless

devices in order of proximity from the Emerson Wireless Gateway, beginning with the

closest. This will result in a simpler and faster network installation.

Note

The device requires a standard 1/4–28-inch mounting location.

CAUTION

Do not drop, hammer, or impact the device housing before, during, or after installation.

CAUTION

When installing the device in hazardous locations, ensure that the device is grounded to

the machine case.

CAUTION

If the equipment is used in a manner not specified by the manufacturer or contrary to the

instructions in this manual, the protection provided by the equipment may be impaired.

3.2 Mounting tools and supplies

Mounting tools

• Drill

• Spot face or end mill tool

The spot face tool attaches to a standard electric drill and provides a machined surface

that is at least 1.1 times greater than the diameter of the sensor. The spot face tool also

drills a pilot hole that can then be tapped for a stud mounted sensor.

You can purchase the spot face tool from Emerson (MHM P/N 88101), or you can

substitute a spot face tool with similar characteristics as required. Contact your local sales

representative for assistance.

MHM-97927-PBF, Rev 1 43

Installation

August 2020 MHM-97927-PBF

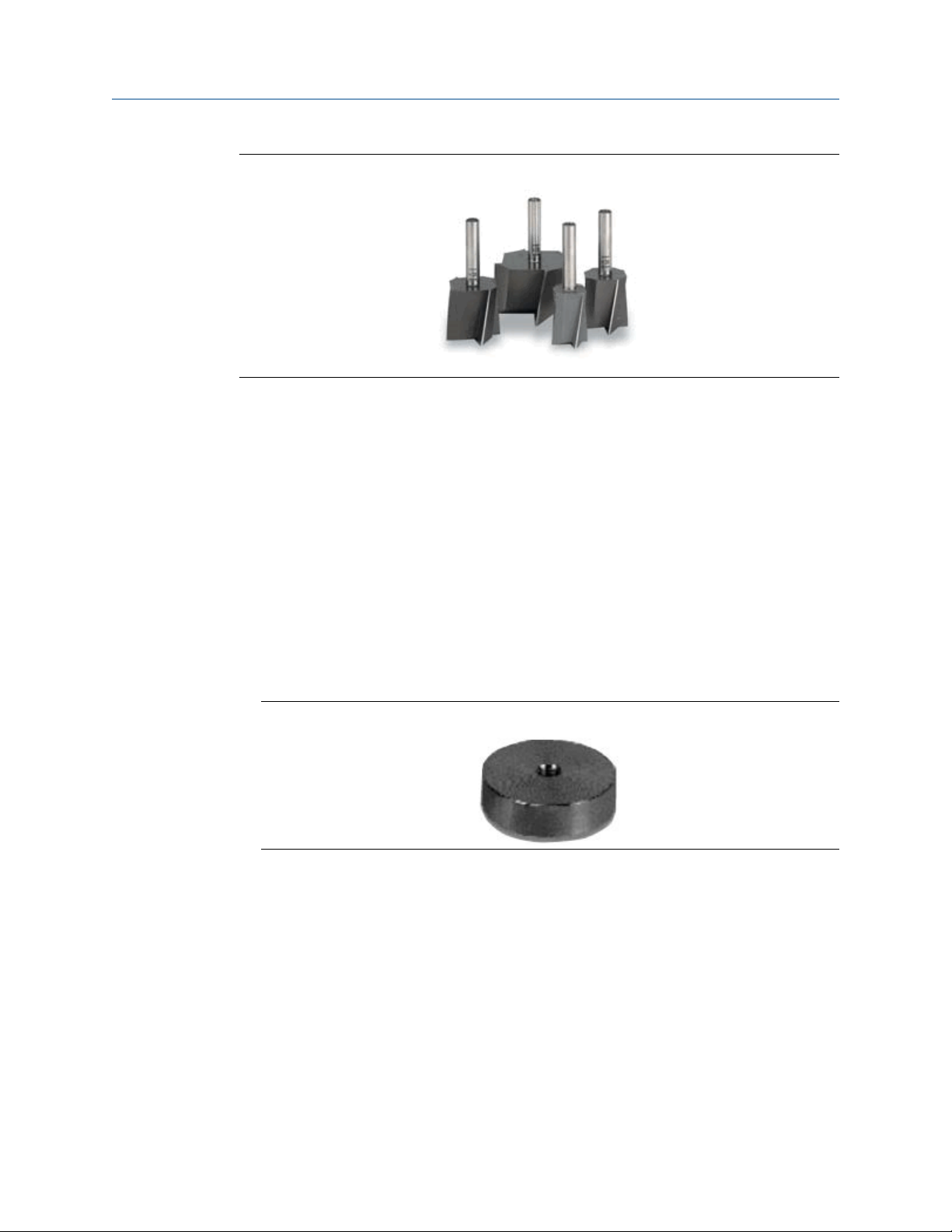

Figure 3-1: Spot face or end mill tool

Attachment tools and supplies

• 1/4-28" taps and tap handle

• 9/16" open-end wrench

• 1/8" hex Allen key

• 3/16" ball-end hex wrench

User Guide

• Wire brush

• Plant-approved cleaner/degreaser

• Plant-approved semi-permanent thread locker (e.g. Loctite)

For epoxy mount, you also need the following:

• 2-part epoxy

• A212 Mounting Pads

Figure 3-2: A212 mounting pad

• (Optional) Grinder – to create a sufficiently flat mounting surface

For motor fin mount, you also need the following:

• Motor Fin Mount Probe

• Epoxy

3.3 Mounting mechanisms

The device may be mounted using any of the mechanisms listed below. Stud mounting is

preferred. The mounts are listed according to our recommendation. Temporary mounting

should be a last resort.

• Stud mounting (preferred)

44 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

• Epoxy mounting (alternative)

• Triaxial quick connection

• Motor fin mounting

• Temporary mounting

Installation

3.3.1 Stud mounting (preferred)

Prerequisites

The mounting location must provide a flat surface of at least 1.1 in (27.94mm) in diameter

and a case thickness exceeding 0.4 in. (10.2 mm). If this is not possible, use the epoxy

mount method instead.

Stud mount provides increased reliability, improved frequency response, and increased

signal sensitivity.

CAUTION

Do not exceed the specified torque when tightening a stud-mounted device. Overtightening the device will damage the sensing element and void the manufacturer’s

warranty.

3.3.2

Procedure

1. Prepare the spot face or end mill tool by setting the drill bit depth to a minimum of

0.325 in. (8.255 mm).

2. Using a wire brush and plant-approved cleaner, clean and degrease the surface

area.

3. Keeping the spot face and end mill tool perpendicular to the machine surface, drill

into the mounting location until the surface is smooth to the touch with no

noticeable irregularities. This may require the spot face tool to remove as much as

0.04 in. (1.016 mm) or more from the surface.

Note

If the spot face is not uniform on all sides, it indicates that the spot face tool is not

perpendicular to the mounting surface, and the resulting surface will not allow the

sensor to be mounted properly.

4. Using 1/4-28 in. tap set, tap a pilot hole to a minimum depth of 0.25 in. (6.35 mm).

Epoxy mounting (alternative)

If it is not practical to drill into the machine casing, then the epoxy mount method is

acceptable.

CAUTION

When installing in a hazardous location, all efforts must be made to ensure that the device

is grounded to the machine case.

MHM-97927-PBF, Rev 1 45

Installation

August 2020 MHM-97927-PBF

Procedure

1. If the equipment surface has a radius of curvature that is less than 4 in. (100 mm),

grind a flat surface approximately 0.5 in. (12.7 mm) in diameter.

2. Using a wire brush and plant-approved cleaner, clean and degrease the surface

area.

3. Using a two-part epoxy (such as Emerson P/N A92106)), spray the activator onto

the mounting surface. Place a light coat of epoxy on the surface of the mounting

pad and hold firmly against the machine spot face surface for one minute.

Note

If the adhesive does not set within 1 minute, it indicates that too much epoxy is

applied or that the mounting surface is not prepared properly. Repeat steps 2–3.

4. Ensure that the mounting pad / base of the device is grounded to the machine case.

Use a two-part conductive epoxy (such as Loctite Ablestik 2902) and make a bead

that bridges the mounting pad to the machine case.

5. Use a multimeter to check conductivity between the mounting pad and machine

surface.

User Guide

3.3.3

3.3.4

Triaxial quick connection

Use this mount in scenarios where there is a need to remove the monitor from the

machine but you also need a more permanent type of installation. This mounting

mechanism has two components: the receptacle that attaches to the device and the base

that attaches to the machine. The base itself comes in two options: epoxy mounted, or

stud mounted.

Procedure

1. Find the right location for the base. Make sure that the base notch is oriented with

either the X or the Y axis of the device.

2. Install the device on the receptacle and orientate the whole assembly together.

3. Install the base on the machine using either Stud mounting (preferred) or Epoxy

mounting (alternative).

4. Align the notch on the receptacle with the notch on the base and give it a ¼ turn. It

will lock in the same place every single time.

Motor fin mounting

Procedure

1. Prepare cooling fins on motor for mounting by scraping or grinding any paint or

debris between cooling fins.

2. Clean mounting area with a spray degreaser that will not leave a thin fil lubricating

residue.

3. Mix adhesive.

4. Apply adhesive to the sides and the bottom of the probe portion of the motor fin

mount probe/pad (the area is roughened to enhance the bonding area).

46 MHM-97927-PBF, Rev 1

User Guide

MHM-97927-PBF August 2020

5. Place the motor fin mount probe/pad between the motor fins at the location

desired.

• Correct motor fin mount selection is important. The probe must fit in between

the motor fins, and the bottom of the probe must contact the motor casing.

• For motors that have a space greater than ½” between each fin, motor fin

mount probe pads with a thickness of ½” are available and will reduce the

amount of adhesive needed.

6. Firmly press the motor fin mount probe/pad into place, ensuring the bottom of the

motor fin mount probe/pad is touching the motor casing (this contact area is where

the vibration is transferred from the motor to the sensor).

• The tip of the motor fin mount probe/pad should be as flat against the motor

casing as possible.

• The motor fin mount probe/pad should not be resting on the top of the fins – if it

does, then the bottom of the probe may not be in direct contact with the motor

casing.

7. Use a spatula to redirect any epoxy that has been displaced from the mounting area

when pushing the fin mount probe/pad into place.

8. Fill in any remaining voids with the adhesive to ensure the motor fin mount will be

fixed in place.

9. Allow full cure for the adhesive prior to installing sensor.

Installation

3.3.5

Temporary mounting

Temporary mounting may be required to perform field testing. This allows for testing the

location and orientation of each sensor to get the best possible coverage. A magnetic

mount is the best solution in this case. Once the optimum location is determined, the

device shall be permanently mounted using one of the methods outlined above.

CAUTION

The recommended magnets have a pull force of 40lb-60lb and are very strong. Handle

with care when working with multiple units or near metal structures.

Procedure

1. Prepare the surface. Use a rag or wire brush to remove any loose debris, grease, dirt,

or rust.

2. Attach the device on the magnetic base with a ¼”-28 threaded hole.

3. Position the magnetic base on a ferrous surface, making sure that the device is

properly oriented.

4. Check to see that the device is properly and firmly attached. Wriggle the device

with your hand. It should not wobble or rotate.

MHM-97927-PBF, Rev 1 47

Installation

August 2020 MHM-97927-PBF

User Guide

3.4 Mount the device

Prerequisites

Prepare the surface according to your mounting method. The mounting location is the

machine surface when using stud mount and the mounting pad when using epoxy mount.

The mounting location should be prepared according to best practices.

Procedure

1. To stud mount the device (recommended), prepare the machine surface using a

spot face tool. Then drill and tap a ¼-28” hole 0.25” (6.35mm) deep. Alternately, a

mounting pad with ¼-28” thread can be glued in place using epoxy.

2. With the cover still on the device, use your hand to loosely screw the device into the

threaded hole. Do not tighten.

3. Using your hand, loosely screw device into the mounting location.

4. Remove the cover and battery.

5. Set the device in the proper orientation. Insert a small screwdriver through the

guide hole in the base of the unit (shown below) and use this to hold the device in

the desired orientation.

Make sure that your planes are in the right direction. The Z plane should be vertical.

The orientation of the X and Y axis depends on how you configured your device.

To make sure that your X and Y axis stay where they are, use an allen wrench or a

small screwdriver while you torque down the device to make sure that everything

stays in the correct position. You can also hold the device while you torque it down.

6. While maintaining the device orientation, use a 3/16” ball driver to tighten the

captive screw in the center of the base (shown above) to 2-5 ft-lb.

The mounting screw must be tightened firmly but carefully to prevent stripping out

the mounting thread, typically 1/8 turn past finger tight for steel and slightly less for

aluminum or brass. For high-frequency applications above 7kHz and all PeakVue

48 MHM-97927-PBF, Rev 1

User Guide Installation

MHM-97927-PBF August 2020

measurements, a good quality silicon grease (Dow #4) should be used as a coupling

agent on the mounting ring on the bottom of the device. Only a small amount is

needed.

7. Insert and connect the battery.

8. Mount the cover and then tighten it. Tighten the cover all the way down until the

bottom of the cover touches the base.

Ensure that the base does not turn while tightening the cover. Turning of the base

causes misalignment of the measuring directions.

Always ensure a proper seal when screwing the cover. The cover should be

tightened all the way down to the base to keep the device watertight and free from

the elements.

3.5 Change the battery

The battery that comes with the device is replaceable. The battery may last without need

of replacement or recharge for a minimum of 3 years up to 5 years, if used at room

temperature while collecting and reporting with default collection parameters.

Note

While the device is approved for battery replacement in hazardous locations, always check

with your local Safety Officer before replacing the battery in a hazardous location.

Procedure

1. Using an allen wrench, hold the metal base.

2. Unscrew the device cover and then remove it.

3. Release the holding latch, and then carefully pull the battery tab to take the battery

out of the compartment.

4. Use your finger to release the bottom latch on the battery connect by lifting the tab

and then gently pull it until the connector is released.

5. Plug the battery wire into the connector and position the wire so that it is held by

the battery clamp.

6. Place the battery into the compartment.

7. Snap the battery clamp back into place to secure the battery and wire.

8. Mount the cover and then tighten it. Tighten the cover all the way down until the

bottom of the cover touches the base.

Ensure that the base does not turn while tightening the cover. Turning of the base

causes misalignment of the measuring directions.

Always ensure a proper seal when screwing the cover. The cover should be

tightened all the way down to the base to keep the device watertight and free from

the elements.

MHM-97927-PBF, Rev 1 49

Installation User Guide

August 2020 MHM-97927-PBF

50 MHM-97927-PBF, Rev 1

User Guide Operation

MHM-97927-PBF August 2020

4 Operation

4.1 Verify the device is operational

You can verify the device operates properly using the following methods:

• Field Communicator

• Emerson Wireless Gateway web interface

4.2 Verify operation with Emerson Wireless Gateway

If the device is configured with the Network ID and Join Key, and sufficient time for

network polling has passed, the monitor will be connected to the network.

Note

The time to join a new device to the network is dependent upon the number of devices

being joined and the number of devices in the current network. For one device joining an

existing network with multiple devices, it may take up to five minutes. It may take up to 60

minutes for multiple new devices to join the existing network.

Procedure

1. From the Emerson Wireless Gateway Home page, navigate to the Devices page.

The Devices page shows if the device has joined the network and if it is

communicating properly. It also displays the transmitter tag name, PV, SV, TV, QV,

time of last update. A checkmark in a green box means that the device is working

properly. A red indicator means there is a problem with either the device or its

communication path.

Note

It is normal for the AMS Wireless Vibration Monitor to have a red “X”, on the screen

until the sensor is installed and configured.

Figure 4-1: Emerson Wireless Gateway Devices page

MHM-97927-PBF, Rev 1 51

Operation User Guide

August 2020 MHM-97927-PBF

2. On the Devices page, click + beside a tag name to display more information about

the device.

3. Verify the Network ID and Join Key in the device match those found on the Emerson

Wireless Gateway:

a. From the Emerson Wireless Gateway, click System Settings → Network →

Network Settings.

b. Verify Show join key has a check mark.

Note

The most common cause of incorrect operation is that the Network ID or Join Key

are not set correctly in the device.

4.3 Verify operation with AMS Trex Communicator

You can verify the status of the AMS Wireless Vibration Monitor and configure it using an

AMS Trex Communicator. For instructions on using the AMS Trex unit, see the User Guide.

Note

HART Wireless transmitter communication requires a AMS Wireless Vibration Monitor

Device Descriptor file (DD). Refer to the Field Communicator User's Manual for more

details on DDs or go to http://www2.emersonprocess.com/en-US/brands/Field-

Communicator/Pages/SysSoftDDs.aspxhttps://www.emerson.com/en-us/catalog/amstrex-device-communicator for instructions on adding a DD for AMS Wireless Vibration

Monitor.

Table 4-1: Field Communicator menu

Menu Submenu

Guided Setup Configure Variable Mapping

Configure Device Variable Units

Configure Alert Limits

Configure Acquisition Settings

Join Device to Network

Configure Update Rate

Manual Setup Wireless

Machine

Z Axis

X-Y Axis

Interval Bands

General

Mapping

Device Information

License

52 MHM-97927-PBF, Rev 1

User Guide Operation

MHM-97927-PBF August 2020

Table 4-1: Field Communicator menu

Menu Submenu

Alert Setup Z Axis

Note

Disconnect the leads when you are finished configuring or troubleshooting. The AMS

Wireless Vibration Monitor does not publish any new vibration data to the gateway while

connected to an AMS Trex Device Communicator or HART modem. It can take up to three

minutes for the leads connection to time out; after which, the AMS Wireless Vibration

Monitor resumes reporting new readings to the gateway.

4.4 Check device status

You can check the device status from the AMS Device Manager or the AMS Trex

Communicator.

(continued)

X-Y Axis

Temperature

Battery

IB1-2 (Velocity)

IB3-4 (Accel)

Machine Conditions (PVP)

The images below show the status of the device and what it means.

The device status is dependent upon individual device variable evaluation, system activity,

and operating parameters.

The out-of-the box overall status should always be Good.

The highest level severity is always be asserted, even if there are underlying lower level

alerts.

MHM-97927-PBF, Rev 1 53

Operation User Guide

August 2020 MHM-97927-PBF

4.5 Device variable ranges

The device variables have the following ranges:

1. Saturated – Indicates the saturation point of the transducer. In this device, this

level is not settable by the end user. When this range is violated, the device variable

status is Bad. This is referred to as “Upper Saturated” and “Lower Saturated”.

2. Sensor – Indicates the sensor point of the transducer. In this device, this level is not

settable by the end user. When this range is violated, the device variable status is

Degraded. This is referred to as “Upper Sensor” and “Lower Sensor”.

3. Range – Indicates the user-defined process range. This is referred to as “Upper

Range” and “Lower Range”.

4. Fail – The user-defined fail level(s)

5. Maint – The user-defined maintenance levels.

6. Advise – The user-defined fail levels.

4.6 Device operating limits

Table 4-2: Operational ranges

Sensor Range Frequency Response

Vibration Overall X 16 g's 1 KHz

Vibration Overall Y 16 g's 1 KHz

Vibration Overall Z 80 g's 20 KHz

PeakVue Z 80 g's 20 KHz

Temperature -40⁰C to 85⁰C N/A

4.7 Clean the device

Use a soft towel or paper towel to wipe any excess grime.

If necessary, use a cloth dampened with a mixture of water and mild detergent (similar to

cleaning household dishes).

Do not use solvents to clean the device.

54 MHM-97927-PBF, Rev 1

User Guide Overall Velocity, PeakVue, and temperature

MHM-97927-PBF August 2020

5 Overall Velocity, PeakVue, and

temperature

5.1 Overall Velocity

The Overall Velocity measurement provides a summation of the low-frequency vibration

energy, which indicates fault conditions such as imbalance, misalignment, looseness, and

late-stage bearing problems.

The AMS Wireless Vibration Monitor uses (lower-frequency) Overall Velocity in

conjunction with (higher-frequency) PeakVue to provide a holistic solution across all

frequencies while optimizing the usage of the limited power and bandwidth available in a

wireless device. The majority of developing fault conditions manifest in one or both of

these key parameters.

The difference between the standard vibration waveform and the associated PeakVue

waveform is shown in Figure 5-1 and Figure 5-2. Overall Vibration indicates energy from

shaft rotation, expressed in units of RMS velocity per the ISO 10816 standard. PeakVue, on

the other hand, filters out the rotational energy to focus on impacting. Impacting is

expressed in units of Peak acceleration. This indicates key mechanical problems such as

rolling element bearing faults, gear defects, and under-lubrication.

Figure 5-1: Velocity waveform

MHM-97927-PBF, Rev 1 55

Overall Velocity, PeakVue, and temperature User Guide

August 2020 MHM-97927-PBF

Figure 5-2: PeakVue waveform

While PeakVue is very useful for providing an early indication of impact-related faults in

rolling-element bearings, there are many general applications where a lower-frequency

measurement is more appropriate. Also, virtually all vibration analysts are very familiar

with the Overall Velocity measurement and use it as part of their existing vibration

programs. While it may not be possible to obtain a measurement result comparable to the

PeakVue value reported by the AMS Wireless Vibration Monitor with a non-Emerson unit,

the Overall Velocity measurement is common throughout the industry and should be easy

to correlate with results from handheld instruments.

There are, however, a number of different methods for measuring and reporting Overall

Velocity, so ensure that the measurement conditions are similar when trying to duplicate

the value reported by the AMS Wireless Vibration Monitor with a handheld. The AMS

Wireless Vibration Monitor uses ISO 10816, which defines a measurement bandwidth of 2

Hz to 1 kHz. The ISO 10816 general fault levels at various turning speeds are shown in

Figure 5-3.

56 MHM-97927-PBF, Rev 1

User Guide Overall Velocity, PeakVue, and temperature

MHM-97927-PBF August 2020

Figure 5-3: General fault levels

Depending on the type of machine being monitored, the values shown in this graph

should be multiplied by the service factors given in Table 5-1.

Table 5-1: Service factor multiplier

Machinery type Service factor

Single-stage Centrifugal Pump, Electric Motors, Fans 1.0

Non-critical Chemical Processing Equipment 1.0

Turbine, Turbine Generator, Centrifugal Compressor 1.6

Miscellaneous Equipment 2.0

Figure 5-3 shows the Overall Velocity thresholds for root-mean-square (RMS) velocity in

units of inches per second. Particularly, in digital acquisition systems, it is customary to

measure and calculate with RMS quantities. While it is accepted practice in the industry to

convert between RMS and peak values using the 1.4142 conversion factor, it is not

technically correct to do so except for a pure sinusoidal waveform. For this reason, the

AMS Wireless Vibration Monitor measures, calculates, and reports Overall Velocity in RMS,

and it is necessary to multiply by 1.4142 to get the corresponding peak levels if this is the

preferred format.

Table 5-2: Default velocity levels in AMS Wireless Vibration Monitor

Alert level Velocity (in RMS)

Advise 0.14 in/s

MHM-97927-PBF, Rev 1 57

Overall Velocity, PeakVue, and temperature User Guide

August 2020 MHM-97927-PBF

Table 5-2: Default velocity levels in AMS Wireless Vibration Monitor

Alert level Velocity (in RMS)

Maintenance 0.35 in/s

Failed 1.0 in/s

5.2 PeakVue

™

PeakVue

frequency phenomena associated with developing faults, especially in rolling-element

bearings.

The premise for PeakVue is that the high-frequency components are not readily detected

with more conventional measurements such as Overall Velocity, low-frequency energy

(LFE), or digital overall. This is because the low-frequency measurements either average

the energy or provide an energy summation over a relatively large frequency band, and

the relative amount of energy that is typically contributed by the high-frequency

components is quite small. As a result, even large "spikes" are difficult to detect with classic

techniques.

The difference in the vibration waveform and the associated measurement for overall

vibration versus PeakVue is shown in Figure 5-5 and Figure 5-6. The overall vibration is well

below the established advisory and maintenance alert levels indicating that the machine is

running well. In contrast, the PeakVue graph shows that the values have increased from

zero, and that they are already crossing the advisory alert level and approaching the

maintenance alert level. This early warning about impending defects is key to maintaining

good machine health.

is a patented Emerson technology that is very useful for isolating high-

(continued)

The PeakVue algorithm isolates the peak energy of interest to provide early indications of

developing bearing faults such as inner and outer race defects, ball defects, and

lubrication problems. Any type of "impacting" fault, where metal is contacting metal, is

readily visible with PeakVue long before there is any significant increase in Overall

Vibration. PeakVue is especially useful for monitoring rolling-element bearings.

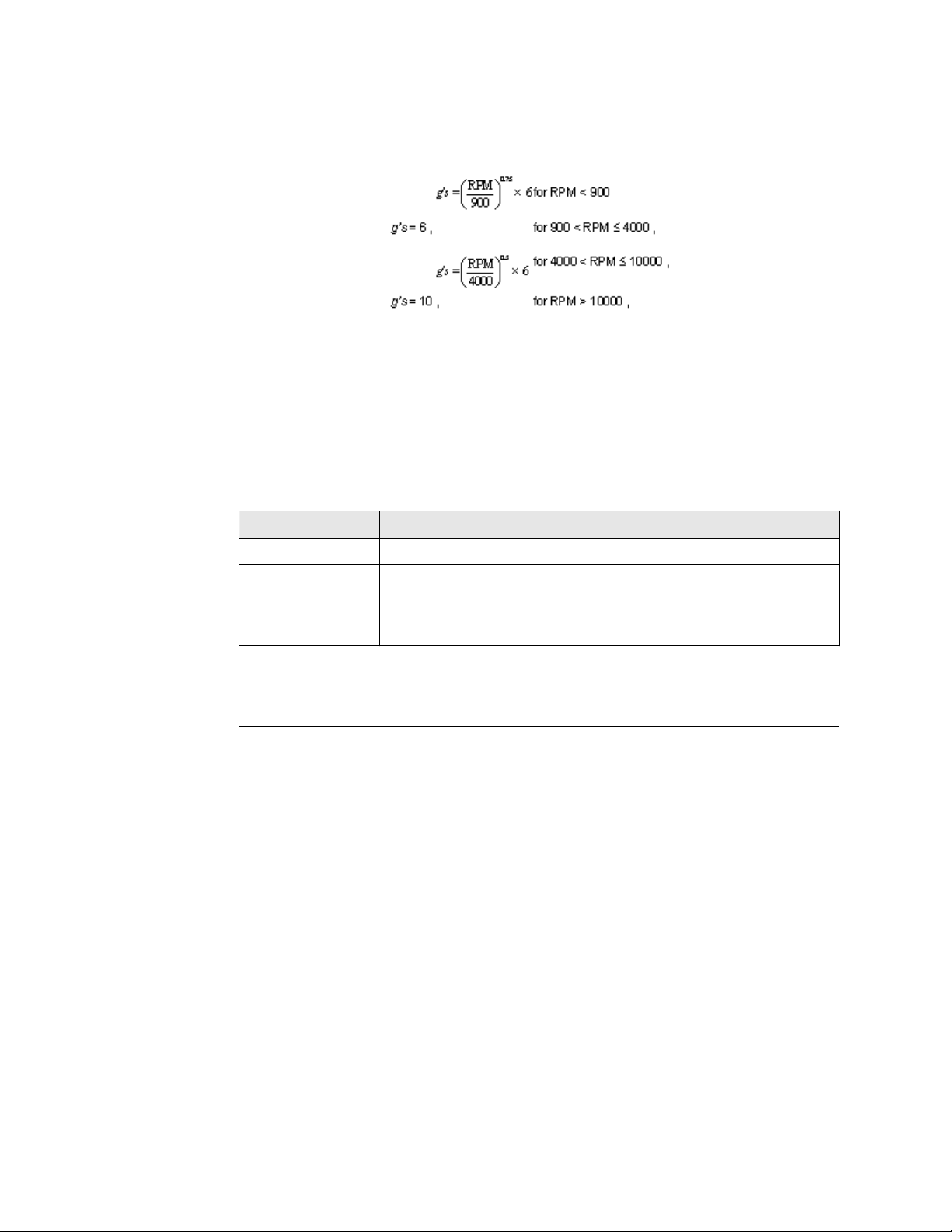

Figure 5-4 shows an example of a typical formula for calculating the advisory alert level for

PeakVue.

Figure 5-4: PeakVue advisory levels

58 MHM-97927-PBF, Rev 1

User Guide Overall Velocity, PeakVue, and temperature

MHM-97927-PBF August 2020

These are the equations that govern this curve:

These, however, are generic limits. They are provided as a starting point and these values

(for a 3600 RPM machine) are used as the default alert thresholds by the vibration

transmitter.

These levels were devised for periodic data collection with a portable vibration analyzer

and are set relatively low. For frequent automated monitoring, such as that offered by the

AMS Wireless Vibration Monitor, the levels can be increased for most balance of plant

equipment running between 900 and 4000 RPM. You can use the "rule of tens" as a simple

but effective approach to monitoring PeakVue on most rolling element bearing machines.

Using this guideline, we can assume the following:

Level Interpretation

0 Machine is in good condition

10 Some problem is developing on the machine

20 The problem has become serious

40 Problem is critical

Note

The appropriate alerts for a given machine will be a function of its design, service, and

turning speed.

Utilizing the embedded PeakVue technology, the AMS Wireless Vibration Monitor

identified developing problems at a couple of test sites during early field trials. In both

cases, the problem was not visible with conventional low-frequency analysis. The following

examples provide sample data from one of the sites. Notice in the example that the

velocity measurement is indicating less than 0.1 in/s. The PeakVue trend, however,

indicates high-frequency vibration that is regularly in excess of 6 g's.

MHM-97927-PBF, Rev 1 59

Overall Velocity, PeakVue, and temperature User Guide

August 2020 MHM-97927-PBF

Figure 5-5: Example 1: 4600 HP fan motor - OH (Overall)

Figure 5-6: Example 2: 4600 fan motor - OH (PeakVue)

The defective bearing was removed and Figure 5-7 shows the developing problem that

was the source of the impacting. After replacing the bearing, the PeakVue vibration is

significantly reduced, as shown in Figure 5-8, indicating that the problem has been

resolved.

60 MHM-97927-PBF, Rev 1

User Guide Overall Velocity, PeakVue, and temperature

MHM-97927-PBF August 2020

Figure 5-7: Defective bearing

MHM-97927-PBF, Rev 1 61

Overall Velocity, PeakVue, and temperature User Guide

August 2020 MHM-97927-PBF

Figure 5-8: Motor - OH after the bearing is replaced (PeakVue)

5.3 Temperature

The levels at which to set temperature alerts depend on a number of factors including the

specific process, the operating environment, and the characteristics of the equipment

being monitored. This section provides some generic guidelines, given some knowledge

of the variables involved, for setting the thresholds for your specific AMS Wireless

Vibration Monitor installation. However, the generic methodologies described here are no

substitute for first-hand knowledge of your plant. If, for example, you know that you have

problems when a temperature exceeds a particular value, then set your thresholds

accordingly rather than following these generic guidelines.

In general, the best way to detect a developing fault related to temperature is to look for

an increase in temperature, relative to ambient, over time. This implies that, for reliable

alerting, the thresholds should change as ambient temperature changes. In practice, this

can be difficult to do because it requires the operator to constantly monitor the ambient

temperature and adjust the alert levels accordingly. It is customary, therefore, to pick an

"average" ambient temperature (that is generally seasonal for outdoor installations) and

choose fixed thresholds based on this average. Also, there are issues with this

methodology (such that it does not work well) in areas with large variations in ambient

temperature.

You can select thresholds based on some absolute temperature limit. In practice, this is

much easier to maintain but is not as effective at detecting early failures as relative

monitoring.

62 MHM-97927-PBF, Rev 1

User Guide Overall Velocity, PeakVue, and temperature

MHM-97927-PBF August 2020

5.3.1 Relative temperature monitoring

The recommended generic guidelines for setting the thresholds based on the relative

change are:

T

= 10°C increase

Advise

T

Maintenance

T

Failed

Assuming that the ambient temperature is 25°C, when operating at steady-state, you have

determined that the normal temperature at this point on your equipment is 55°C. Your

"baseline" relative difference is 30°C. Using these guidelines, you should choose the Advise,

Maintenance, and Failed levels for a difference of 40°C, 45°C, and 50°C, respectively.

Assuming the ambient temperature is constant at 25°C, this means the thresholds

become 65°C, 70°C, and 75°C for Advise, Maintenance, and Failed, respectively. Then, as

the ambient temperature changes, the thresholds should be changed accordingly (e.g., a

5°C increase in ambient temperature raises the alert thresholds by 5°C).

= 15°C increase

= 20°C increase

5.3.2

Absolute temperature monitoring

For monitoring a driven component (such as a pump or fan), there are no generic rules to

determine the default levels without some prior knowledge of the steady-state baseline

(good) value. In general, the Advise level should be set about 10°C to 20°C above this

baseline, with the Maintenance level about 10°C above Advise and the Failed level about

10°C above Maintenance.

There are equations that define the suggested generic thresholds for monitoring motor

(driver) temperature. These are based on characteristics of the motor as well as

knowledge of the ambient temperature.

The first step is to determine the estimated winding temperature, which is dependent on

the following variables:

• Insulation type

• Motor type

• Ambient temperature

• Altitude

The estimated winding temperature, TW, is the rise in temperature, T

appropriate type of motor adjusted for high ambient temperature (Ta) effects.

T

=

rise

• 65°C + serv_fact_temp; for class A insulation

, for the

rise

• 85°C + serv_fact_temp; for class B insulation

• 110°C + serv_fact_temp; for class F insulation

• 130°C + serv_fact_temp; for class H insulation

• 150°C + serv_fact_temp; for class N insulation

where serv_fact_temp =

MHM-97927-PBF, Rev 1 63

Overall Velocity, PeakVue, and temperature User Guide

August 2020 MHM-97927-PBF

• 5 for service factor of 1.15 or greater

• -5 for either open or totally enclosed fan cooled (TEFC) motors, and service factor of

1.0

• 0 for either totally enclosed non-ventilated (TENV) motors or motors with

encapsulated windings, and service factor of 1.0