Reference Manual

MHM-97408, Rev 22

September 2020

AMS 9420 Wireless Vibration Transmitter

Reference Manual

Copyright

©

2020 by Emerson. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of Emerson.

Disclaimer

This manual is provided for informational purposes. EMERSON MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Emerson shall not be liable for errors, omissions, or inconsistencies that may be contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. Information in this document is

subject to change without notice and does not represent a commitment on the part of Emerson. The information in this manual is

not all-inclusive and cannot cover all unique situations.

Patents

The product(s) described in this manual are covered under existing and pending patents.

Where to get help

Software Registration

Phone:

Toll free 888.367.3774, option 2 (U.S. and Canada)

+63.2.702.1111 (Rest of world)

Email:

Web:

wwcs.custserv@emerson.com

http://www.emerson.com/machineryhealthreg

Product Support

Emerson provides a variety of ways to reach your Product Support team to get the answers you need when you need them:

Phone

Toll free 800.833.8314 (U.S. and Canada)

+1.512.832.3774 (Latin America)

+63.2 702.1111 (Asia Pacific, Europe, and Middle East)

Email

Web

ap-sms@emerson.com

http://www.emerson.com/en-us/contact-us

To search for documentation, visit http://www.emerson.com.

To view toll free numbers for specific countries, visit http://www.emerson.com/technicalsupport.

2

Reference Manual Contents

MHM-97408 September 2020

Contents

Chapter 1 Introduction.................................................................................................................. 6

1.1 Safety messages...............................................................................................................................6

1.2 Overview.......................................................................................................................................... 7

1.3 Considerations............................................................................................................................... 11

1.4 Return of materials.........................................................................................................................12

Chapter 2 Install the AMS 9420.....................................................................................................14

2.1 Sensors...........................................................................................................................................14

2.1.1 Sensor operating limits................................................................................................................14

2.1.2 Sensor handling...........................................................................................................................15

2.1.3 Sensor mounting/attachment tools and supplies........................................................................ 16

2.1.4 Prepare the sensor mount........................................................................................................... 17

2.1.5 Attach the sensors.......................................................................................................................18

2.1.6 Secure the sensor cables..............................................................................................................22

2.1.7 Conduit installation guidelines.................................................................................................... 23

2.1.8 Cable entry port installation guidelines........................................................................................24

2.1.9 Attach sensor wiring to the AMS 9420 terminals......................................................................... 27

2.2 Power the AMS 9420 with a power module.....................................................................................30

2.2.1 Power module installation and replacement................................................................................30

2.2.2 Physical installation..................................................................................................................... 32

2.3 Power the AMS 9420 with external DC power.................................................................................33

2.3.1 Emerson A9000P description of intended use..............................................................................33

2.3.2 Optional spacer........................................................................................................................... 33

2.3.3 Connect external DC power to Emerson wireless transmitters.....................................................34

2.3.4 Connect external DC power and ICP® accelerometer inputs to an AMS 9420............................... 36

2.4 Install the end cap.......................................................................................................................... 39

Position the antenna.......................................................................................................................40

2.5

2.6 Liquid Crystal Display (LCD)............................................................................................................ 42

2.6.1 Rotate the LCD............................................................................................................................ 42

2.6.2 Enable the LCD............................................................................................................................ 43

2.6.3 Turn on the LCD...........................................................................................................................44

2.7 Ground the transmitter.................................................................................................................. 45

Chapter 3 Configure the AMS 9420...............................................................................................46

3.1 Configuration overview.................................................................................................................. 46

3.1.1 Connect to a wired HART interface.............................................................................................. 48

3.1.2 Set the wireless network configuration........................................................................................50

3.1.3 Configuration options................................................................................................................. 52

3.1.4 Sensor configuration................................................................................................................... 53

MHM-97408, Rev 22 iii

Contents Reference Manual

September 2020 MHM-97408

3.1.5 Measurement parameter units.................................................................................................... 55

3.1.6 Alert levels...................................................................................................................................55

3.1.7 Publishing mode..........................................................................................................................57

3.1.8 Update rate................................................................................................................................. 58

3.1.9 Minimize power consumption..................................................................................................... 58

3.1.10 Trend parameters......................................................................................................................59

3.1.11 Remove the power module....................................................................................................... 60

3.2 Configuration with a Field Communicator...................................................................................... 60

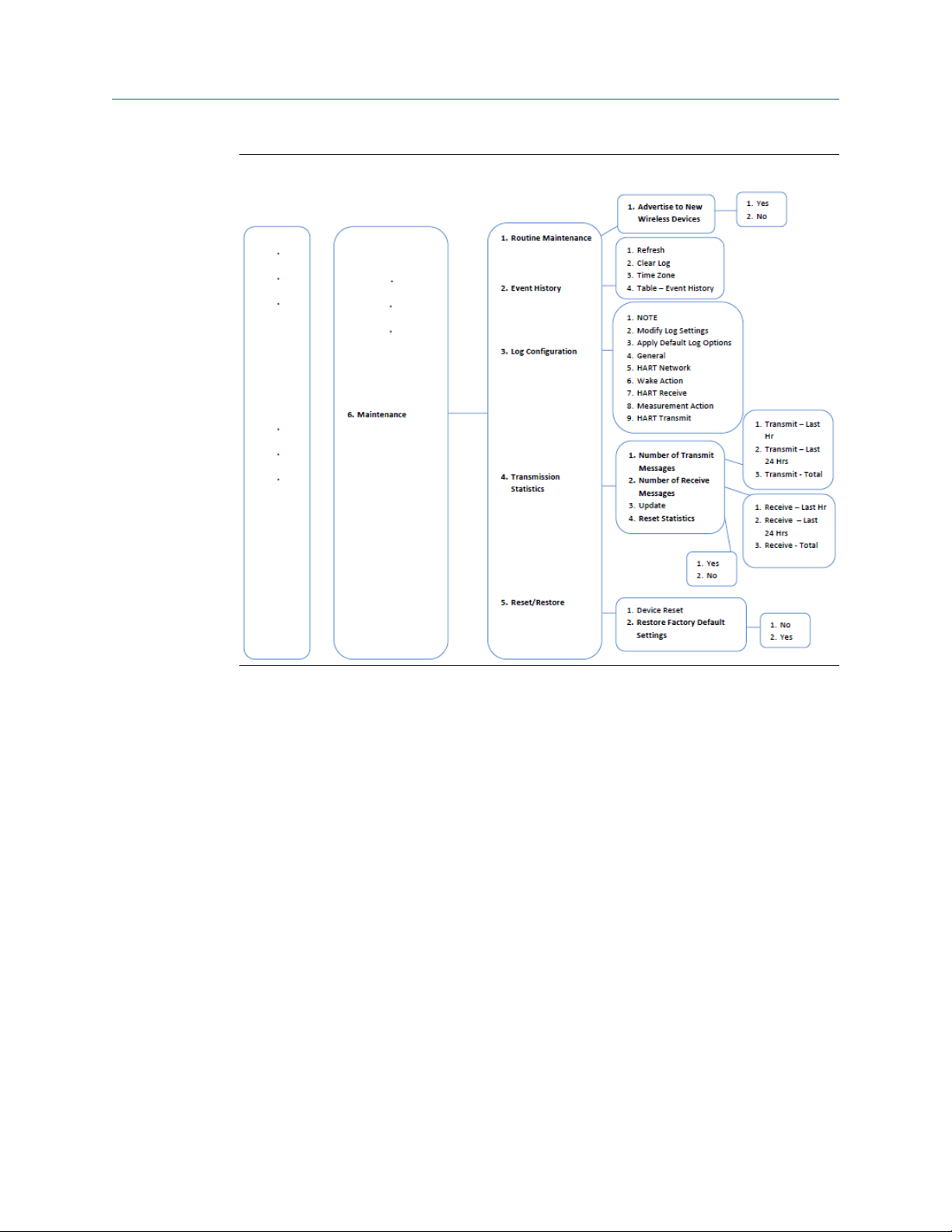

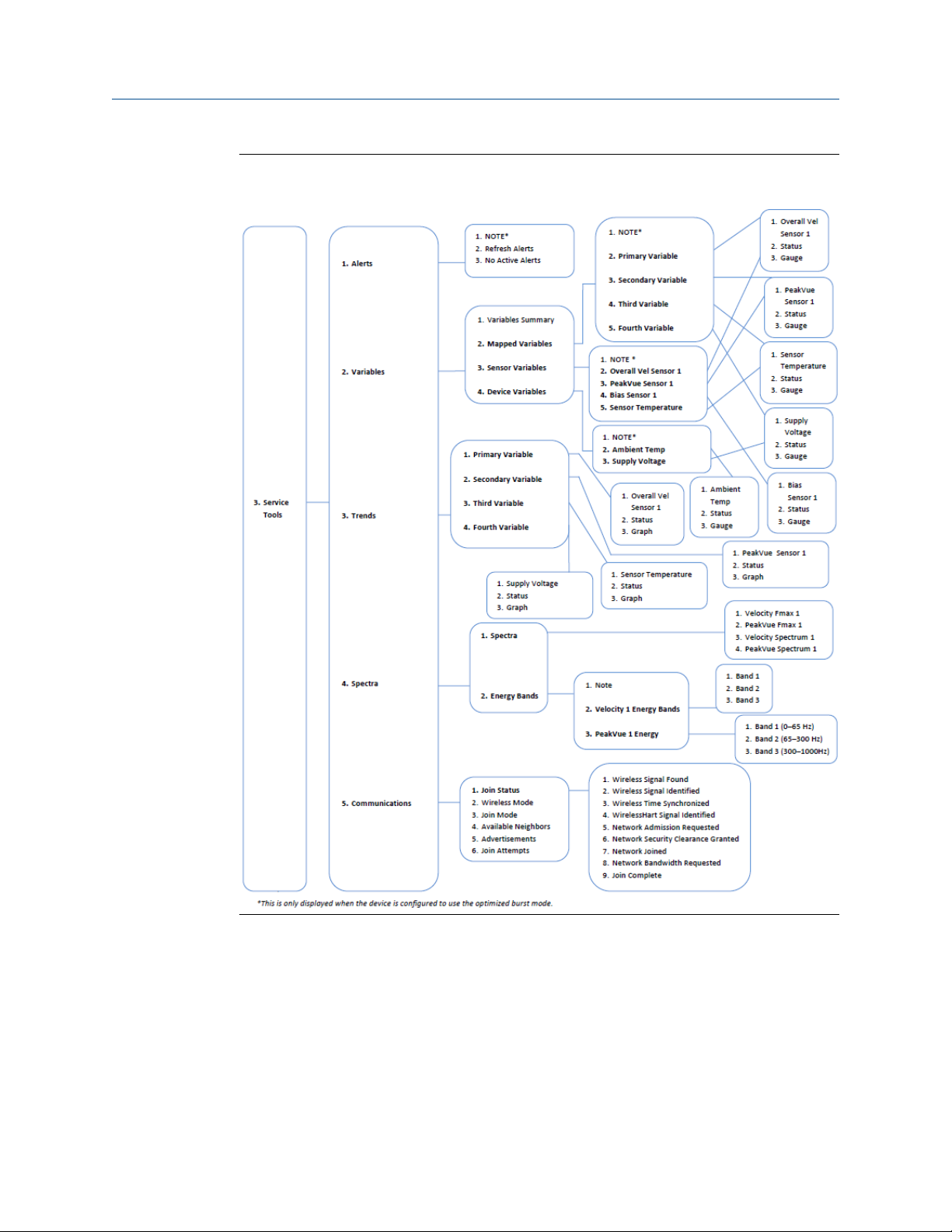

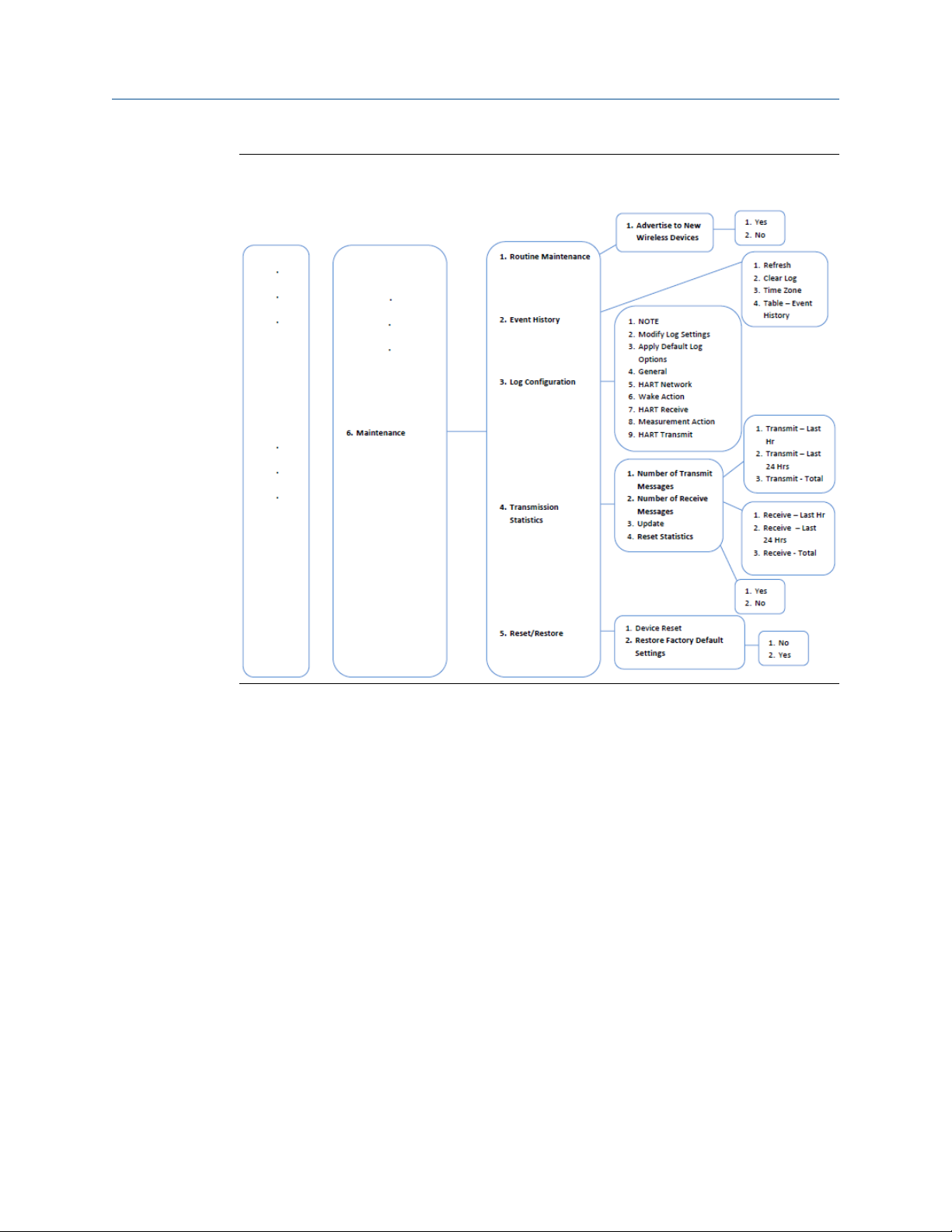

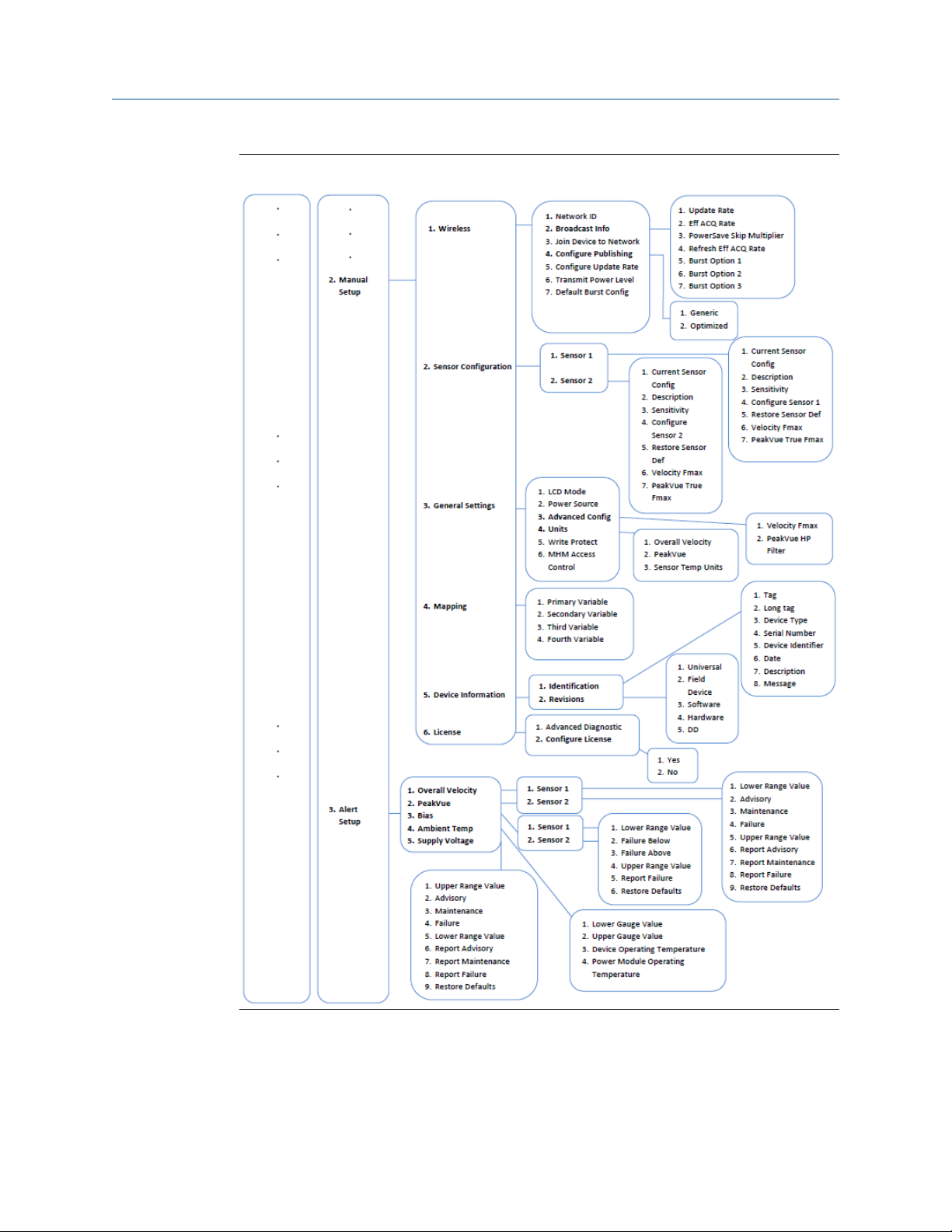

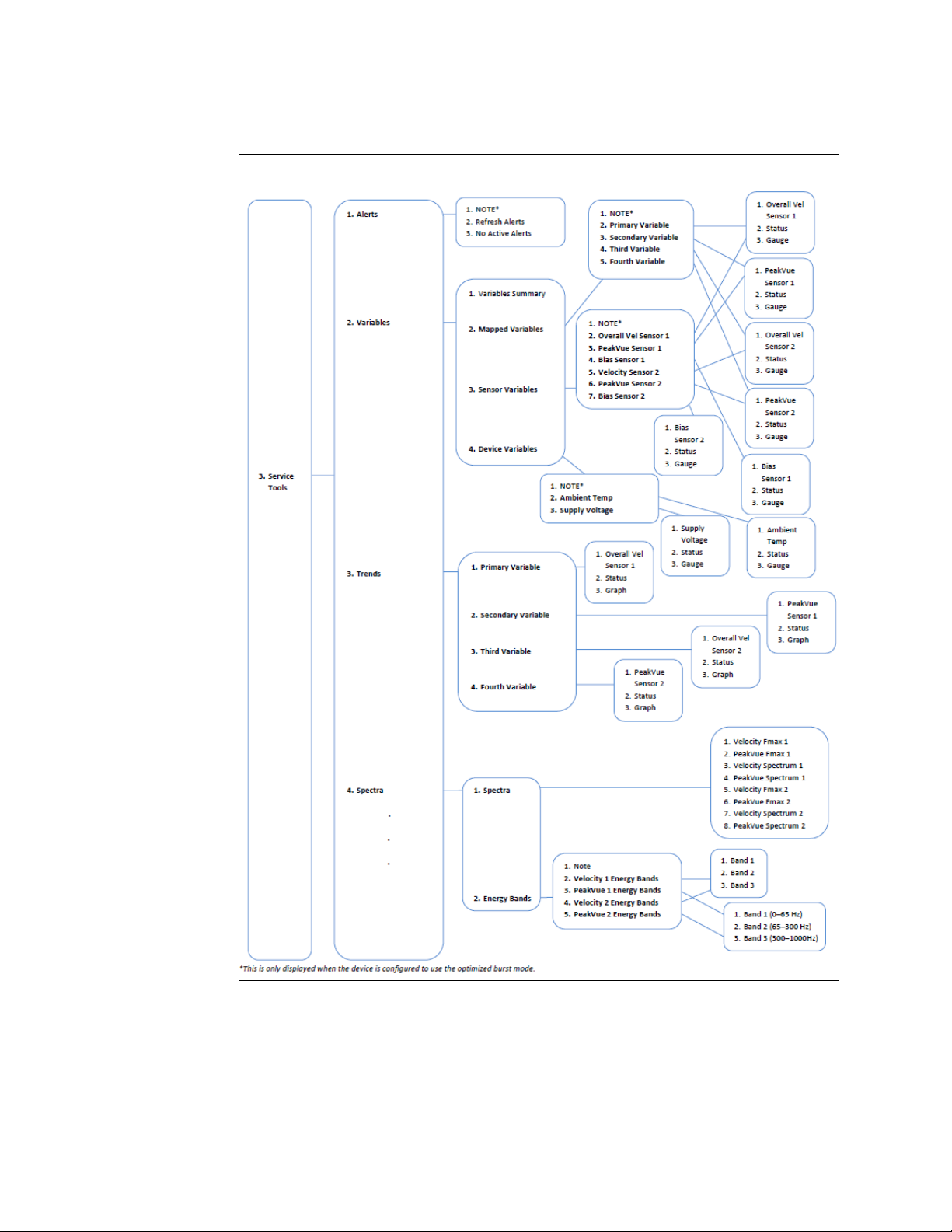

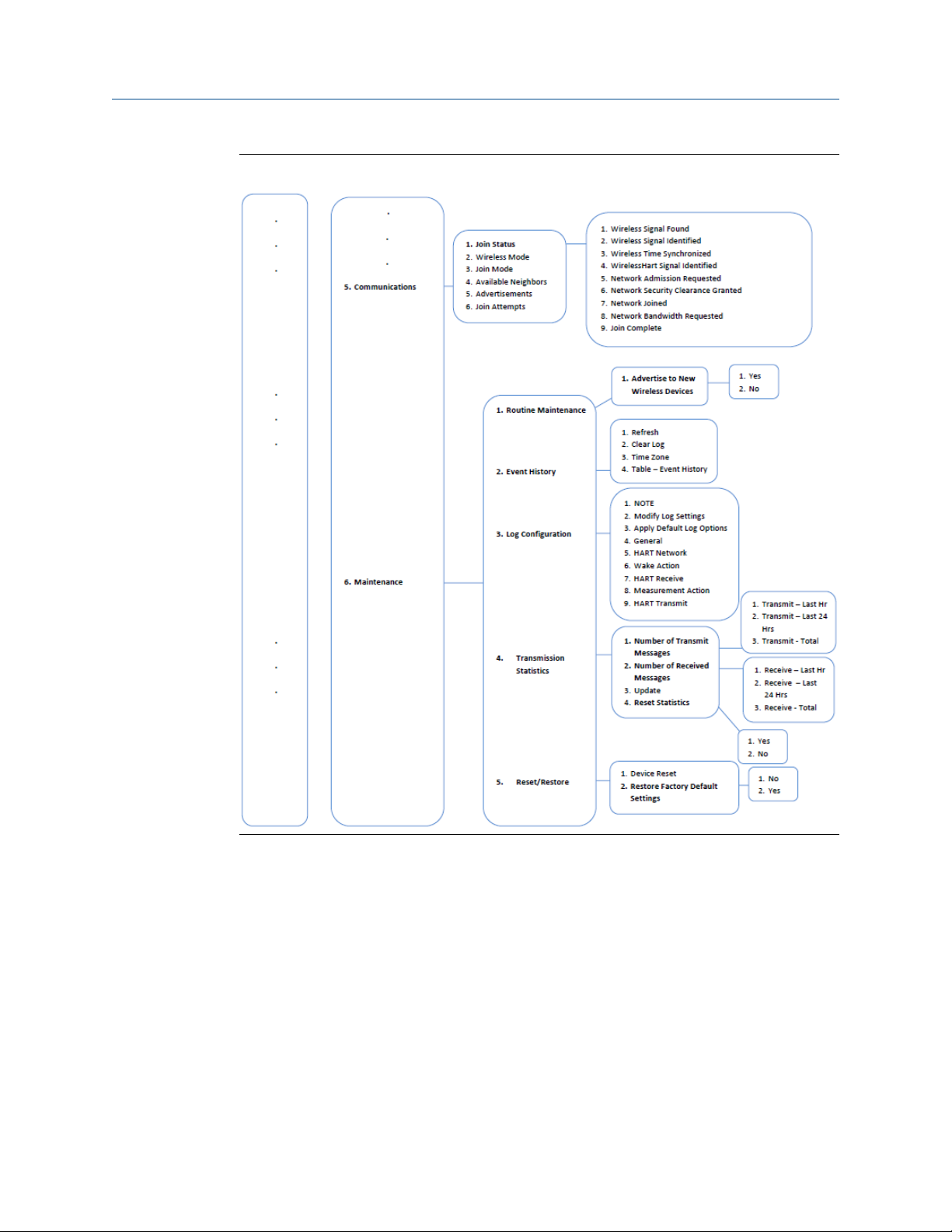

3.2.1 Field Communicator menu trees................................................................................................. 61

3.2.2 Field Communicator fast key sequences......................................................................................74

3.3 Configuration with AMS Device Manager........................................................................................76

3.3.1 Configure wireless network credentials in AMS Device Manager..................................................76

3.3.2 Right-click menu......................................................................................................................... 77

3.4 Configuration with AMS Machinery Manager................................................................................101

3.4.1 Advanced Diagnostics application.............................................................................................101

3.4.2 AMS 9420 Data Collection: Overview........................................................................................ 105

3.4.3 AMS 9420 publishing policy.......................................................................................................106

3.4.4 Maximum network size and publishing policy settings.............................................................. 108

3.4.5 Waveform or spectrum time..................................................................................................... 111

Chapter 4 Operation.................................................................................................................. 112

4.1 Verify the device is operational.....................................................................................................112

4.2 Verify operation with the integral LCD..........................................................................................112

4.3 Verify operation with a 475 Field Communicator..........................................................................112

4.4 Verify operation with Emerson Wireless Gateway.........................................................................113

Chapter 5 Overall Velocity, PeakVue, and temperature.............................................................. 115

5.1 Overall Velocity............................................................................................................................ 115

5.2 PeakVue....................................................................................................................................... 118

5.3 Temperature................................................................................................................................ 122

5.3.1 Relative temperature monitoring.............................................................................................. 123

5.3.2 Absolute temperature monitoring.............................................................................................123

Chapter 6 Mitigating EMI and RFI............................................................................................... 125

6.1 Accelerometer EMI and RFI considerations................................................................................... 125

6.2 Mitigate interference....................................................................................................................127

6.2.1 Use shorter cable lengths.......................................................................................................... 127

6.2.2 Use a conductive conduit.......................................................................................................... 127

6.2.3 Install ferrites.............................................................................................................................129

6.2.4 Reduce polarized interference...................................................................................................136

Appendix A Specifications and reference data............................................................................... 138

A.1 Functional specifications.............................................................................................................. 138

A.2 Physical specifications..................................................................................................................140

iv MHM-97408, Rev 22

Reference Manual Contents

MHM-97408 September 2020

A.3 Performance specifications.......................................................................................................... 141

A.4 Radio specifications......................................................................................................................141

A.5 Low-power sensor options........................................................................................................... 142

A.6 Dimensional drawings..................................................................................................................143

A.7 Device variable index....................................................................................................................144

Appendix B Product certifications................................................................................................. 145

B.1 Approved manufacturing locations.............................................................................................. 145

B.2 Wireless certifications.................................................................................................................. 145

B.3 Ordinary location certification (CSA)............................................................................................ 146

B.4 CE mark........................................................................................................................................146

B.5 Hazardous locations certifications................................................................................................ 147

B.6 RoHS 2 (2011/65/EU)................................................................................................................... 148

Appendix C LCD screen messages..................................................................................................149

Index .................................................................................................................................. 157

MHM-97408, Rev 22 v

Introduction Reference Manual

September 2020 MHM-97408

1 Introduction

Topics:

• 1.1

• 1.2 Overview

• 1.3

• 1.4 Return of materials

Safety messages

Considerations

1.1 Safety messages

Instructions in this manual may require special precautions to ensure the safety of the

personnel performing the operations.

This AMS 9420 device complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions: This device may not cause harmful interference, this device must

accept any interference received, including interference that may cause undesired

operation.

This device must be installed to ensure a minimum antenna separation of 20 cm from all

persons.

Refer to the following safety messages before performing an operation preceded by the

warning symbol:

WARNING

Failure to follow these installation guidelines can result in death or serious injury. Only

qualified personnel should install AMS 9420s.

Explosions could result in death or serious injury:

• Before connecting a Field Communicator in an explosive environment, make sure the

instruments are installed in accordance with applicable field wiring practices.

• Verify that the operating environment of the AMS 9420 is consistent with the

appropriate hazardous locations certifications.

• Do not remove the front electronics end cap or LCD cover while the device is in a

hazardous area.

Electrical shock can cause death or serious injury. Avoid contact with the leads and

terminals. High voltage that may be present on leads can cause electrical shock.

6 MHM-97408, Rev 22

Reference Manual Introduction

MHM-97408 September 2020

1.2 Overview

The manual

This Reference Manual applies to the 2.4 GHz WirelessHART version of the AMS 9420 for

use with the Smart Power Module unless otherwise specified.

Use this manual to install, operate, and maintain the AMS 9420 Wireless Vibration

Transmitter.

The transmitter

The AMS 9420 Wireless Vibration Transmitter is an installation-ready solution that

monitors vibration and temperature in hard-to-reach locations. It also provides a variety of

transmitter and sensor configurations.

Some of its features include:

• Support for up to 4 process variables with up to 3 user configurable alerts for each

process variable

• Support for storage of Waveform/Spectrum directly in AMS Machinery Manager

• Wireless output with >99% data reliability, delivering rich HART data, protected by

industry leading security (when operated as part of a well-formed network)

• Local operator interface with integral LCD that conveniently displays measured values

and diagnostics

• Simple and easy installation, used today for robust installations

Power options include two power modules and power adapter for external DC power.

The transmitter's main parts are shown in Figure 1-1 and are referenced in this document.

MHM-97408, Rev 22 7

Introduction Reference Manual

September 2020 MHM-97408

Figure 1-1: AMS 9420 overview

A. Antenna

B. Housing

C. Front electronics end cap or LCD cover

Mounting post

D.

E. Cable entry port (one on left and right)

F. Extended end cap or power module cover

Related documentation

Refer to the following related documents which are included with the products they

describe.

Table 1-1: Referenced documents for AMS 9420 power options

MHM-97913-CCPBF

00925-0100-4701 Quick Start Guide: Emerson™ SmartPower™ - Black Power Module 701PBK

MHM-97919-PBF Quick Start Guide: Emerson™ A9000Px Power Adapter

Quick Start Guide: Emerson™ SmartPower™ - Blue Power Module 701PBU

8 MHM-97408, Rev 22

Reference Manual Introduction

MHM-97408 September 2020

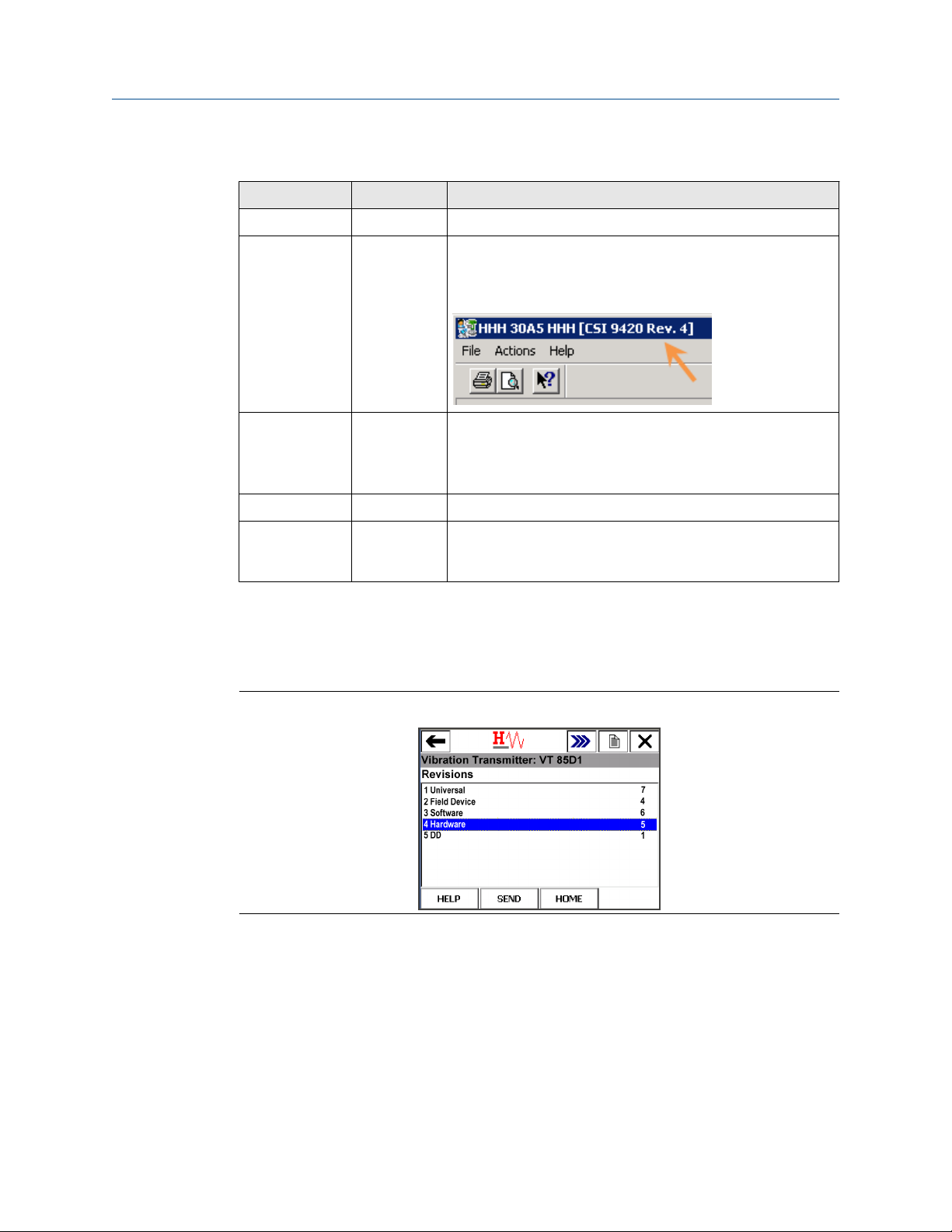

Device revision information

Revision Current level Description

Universal 7 This is the HART version the transmitter supports.

Field device

Software 8 This is the current software version.

Hardware 5 This is the hardware revision.

1

4 This is the major revision of the transmitter and corresponds

with a major interface release.

When using AMS Device Manager, this revision can be found on

the screen title.

The software may be occasionally modified to refine

functionality. When major functionality is added, the device

revision increases.

DD 1 This is the Device Descriptor (DD) revision.

The device descriptor is primarily used for configuring devices in

the field.

1

If you have an older device revision, a factory upgrade may be possible in some cases. Contact

Product Support for more information.

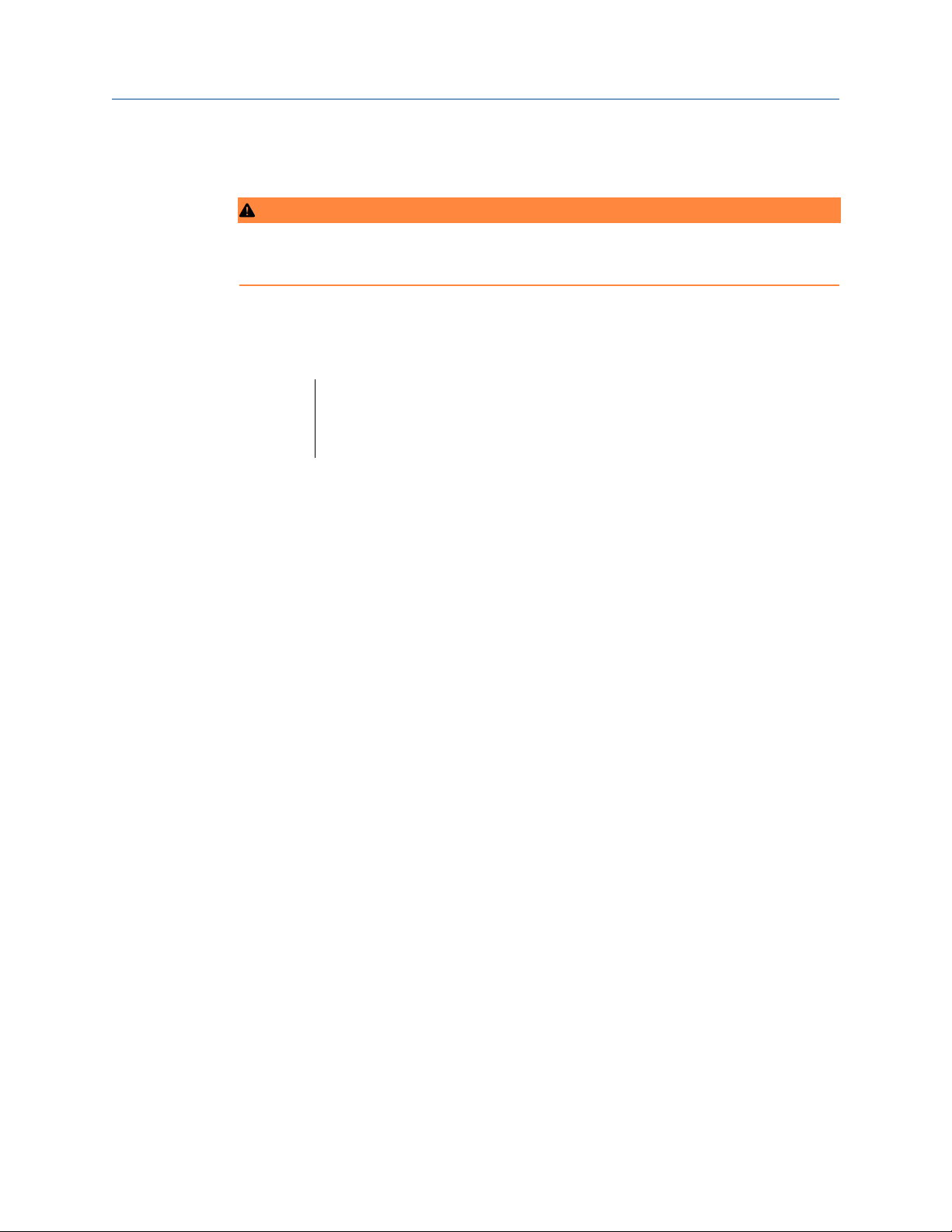

You can view the revision information in a Field Communicator and in AMS Device

Manager.

Figure 1-2: Revision numbers in a 475 Field Communicator

MHM-97408, Rev 22 9

Introduction Reference Manual

September 2020 MHM-97408

Figure 1-3: Revision numbers in AMS Device Manager

10 MHM-97408, Rev 22

Reference Manual Introduction

MHM-97408 September 2020

1.3 Considerations

General

Electrical vibration sensors, such as accelerometers, produce low-level signals proportional

to their sensed vibration. With simple HART configuration, the transmitter converts the

low-level sensor signal to a wireless-enabled signal.

Commissioning

The transmitter can be commissioned before or after installation. You can commission it

on the bench before installation to ensure proper operation and to be familiar with its

functions.

Make sure the instruments are installed in accordance with applicable field wiring

practices.

The AMS 9420 device is powered whenever the power module is installed. To avoid

depleting the power module, remove it when the device is not in use.

Installation

When choosing an installation location and position, provide ample access to the

transmitter. For best performance, the antenna should be vertical, with some space

between objects in a parallel metal plane such as a pipe or metal framework. Pipes or

framework may adversely affect the performance of the antenna.

Power Module

There are two power modules that may be used with the AMS 9420.

Where approved for use, Emerson recommends using the blue power module . The blue

power module is equipped with two "D" size primary lithium/thionyl chloride cells, and

features special power management circuitry for optimum performance with the AMS

9420. Each blue power module contains approximately 10 grams of lithium. The black

power module contains two “C” size primary lithium/thionyl chloride batteries. The black

power module contains approximately 5 grams of lithium; therefore, the blue power

module will operate the AMS 9420 for approximately twice as long as the black power

module.

Note

When upgrading from the black power module to the blue power module, be sure to

order an extended battery cover for each blue power module. To order an extended

battery cover for the blue aluminum housing or the stainless steel housing, contact your

local sales representative.

Under normal conditions, power module materials are self-contained and not reactive as

long as the integrity of the batteries and power module pack are maintained. Take care to

prevent thermal, electrical, or mechanical damage, and protect contacts to prevent

premature discharge.

CAUTION

Use caution when handling power modules. Power modules may be damaged if dropped

from heights in excess of 20 feet.

MHM-97408, Rev 22 11

Introduction Reference Manual

September 2020 MHM-97408

Electrical

Emerson

A9000Px

series

adapters

A power adapter is available to connect the AMS 9420 to an external 11-28

VDC power source. This is used in place of the power module.

When used with a barrier on the power input, the AMS 9420 has the same

ratings for hazardous location requirements.

Power in and external sensors must be wired via separate entries.

An external earth connection, where applicable, should be made to the

earth grounding point on the bottom of the housing.

The full assembly shall maintain a minimum IP rating of IP20.

Field wiring using multiconductor cable shall either have each conductor

enclosed in grounded metal shield or each conductor have a minimum of

0.25 mm (0.01 in) insulation thickness.

Sensor

Make sensor connections through the cable entry at the side of the

connection head. Provide adequate clearance for cover removal.

Environmental

The transmitter operates within specifications for ambient temperatures between –40°F

and 185°F (–40°C and 85°C).

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous location certifications.

1.4 Return of materials

You may need to ship the device to an Emerson Product Service Center for return or

maintenance. Before shipping, contact Emerson Product Support to obtain a Return

Materials Authorization (RMA) number and receive additional instructions.

Emerson Product Support contact information:

Phone

Email

Web

Toll free 800.833.8314 (U.S. and Canada)

+1.512.832.3774 (Latin America)

+63.2 702.1111 (Asia Pacific, Europe, and Middle East)

ap-sms@emerson.com

http://www.emerson.com/en-us/contact-us

Note

If the transmitter has been exposed to hazardous substances, a Material Safety Data Sheet

(MSDS) must be included with the returned materials. An MSDS is required by law to be

available to people exposed to specific hazardous substances.

Shipping considerations for wireless products (Lithium Batteries)

• The unit was shipped to you without the power module installed. Please remove the

power module prior to shipping the unit.

• Each blue power module contains two "D" size primary lithium-thionyl chloride battery

cells; each black power module contains two "C" size primary lithium-thionyl chloride

battery cells. Primary lithium batteries are regulated in transportation by the U.S.

12 MHM-97408, Rev 22

Reference Manual Introduction

MHM-97408 September 2020

Department of Transportation, and are also covered by IATA (International Air

Transport Association), ICAO (International Civil Aviation Organization), and ADR

(European Ground Transportation of Dangerous Goods).

• It is the responsibility of the shipper to ensure compliance with these or any other local

requirements. Please consult current regulations and requirements before shipping.

MHM-97408, Rev 22 13

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

2 Install the AMS 9420

Topics:

• 2.1

• 2.2 Power the AMS 9420 with a power module

• 2.3

• 2.4 Install the end cap

• 2.5 Position the antenna

• 2.6 Liquid Crystal Display (LCD)

• 2.7 Ground the transmitter

Before beginning installation procedures:

Insert the power module only when you are ready to commission the device.

Install the Emerson Wireless Gateway and ensure it functions properly before you activate

the AMS 9420 or any other wireless devices. Power up wireless devices in order of

proximity from the Emerson Wireless Gateway, beginning with the closest. This will result

in a simpler and faster network installation.

Sensors

Power the AMS 9420 with external DC power

WARNING

If the sensor is installed in a high-voltage environment and a fault condition or installation

error occurs, the sensor leads and transmitter terminals could carry lethal voltages. Use

extreme caution when making contact with the leads and terminals.

2.1 Sensors

Each of the AMS 9420 signal inputs uses accelerometers to make vibration measurements.

The term "sensor" applies to both an accelerometer and an accelerometer with embedded

temperature; the word “accelerometer” refers to a sensor that measures only

acceleration. The AMS 9420 uses special low-power sensors (available for purchase from

Emerson) to reduce power consumption and increase power module life. The sensor is

available with or without embedded temperature.

You can use 100 mV/g sensors with the AMS 9420 if you connect the sensors and external

DC power to the Emerson A9000PS-A power adapter.

2.1.1 Sensor operating limits

Low-power sensors with 25 mV/g nominal sensitivity are required when connecting

directly to the AMS 9420 terminals. The Emerson A9000PS-A adapter is required for ICP

accelerometers with a nominal sensitivity of 100 mV/g.

Table 2-1: Standard, low-power sensor operational ranges

Channel DC bias range DC input range AC input range

Accelerometer 1 2–3 VDC 0–5 VDC 0.5–4.5 V (+/-80 g's peak)

14 MHM-97408, Rev 22

®

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Table 2-1: Standard, low-power sensor operational ranges

Channel DC bias range DC input range AC input range

Accelerometer 2 2–3 VDC 0–5 VDC 0.5–4.5 V (+/-80 g's peak)

Temperature 1 N/A -40°C to 125°C N/A

The accelerometers require a DC bias. The AMS 9420 provides the necessary bias and

measures it to verify correct sensor operation. The nominal bias voltage is 2.5 V. If the bias

voltage is outside of the 2–3 V range, the device generates a failed alert for the associated

sensor. The DC input range represents the operational DC range of the signal input. The

AC input range represents the operational AC range of the signal input.

2.1.2 Sensor handling

Note

Each sensor requires a standard 1/4–28-inch mounting location.

CAUTION

Do not drop, hammer, or impact the sensor housing before, during, or after installation.

CAUTION

(continued)

Do not exceed the specified torque when tightening a stud-mounted sensor. Overtightening a sensor will damage the sensing element and void the manufacturer’s

warranty.

CAUTION

Although the integral cable has a built-in strain relief, do not use excessive force when

pulling the cable. Do not exert more than 5-lb of force directly on the sensor connection

during installation. If possible, secure the cable to the machine near the point of sensor

installation.

CAUTION

Do not exert more than 5-lb pull force directly on sensor/cable connection during wire

pulls.

For sensors that have been mounted before pulling the cable through the conduit or

raceway to the AMS 9420, leave the cable bundled and secured to the machine.

Permanent signal degradation takes place when cables are damaged. Do not step on, kink,

twist, or pinch cables. Also take note of the placement of the cable bundle. Do not place

bundles in a manner that may cause strain at the sensor/cable connection.

MHM-97408, Rev 22 15

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

WARNING

If the sensor is installed in a high-voltage environment and a fault condition or installation

error occurs, the sensor leads and transmitter terminals could carry lethal voltages. Use

extreme caution when making contact with the leads and terminals.

For high-voltage environments, attach the sensor leads first before connecting to a power

source.

Tip

Use Spade lugs to improve long-term reliability of sensor wiring.

2.1.3 Sensor mounting/attachment tools and supplies

Mounting tools

• Drill

• Spot face or end mill tool

The spot face tool attaches to a standard electric drill and provides a machined surface

that is at least 1.1 times greater than the diameter of the sensor. The spot face tool also

drills a pilot hole that can then be tapped for a stud mounted sensor.

You can purchase the spot face tool from Emerson (MHM P/N 88101), or you can

substitute a spot face tool with similar characteristics as required. Contact your local sales

representative for assistance.

Figure 2-1: Spot face or end mill tool

Attachment tools and supplies

• 40-200 inch-lb torque wrench with 1/8 in. hex bit

Suggested vendor: Grainger (P/N 4YA74)

Description: 3/8" drive inch-lb torque wrench. You can substitute with any torque

wrench with a range of 40 to 70 inch-lb and less than 5 inch-lb increments.

• 1/4-28" taps and tap handle

• 9/16" open-end wrench

• 1/8" hex Allen key

• Wire brush

16 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

• Plant-approved cleaner/degreaser

• Plant-approved semi-permanent thread locker (e.g. Loctite)

For epoxy mount, you also need the following:

• 2-part epoxy (e.g. Loctite Depend [Emerson P/N A92106] or comparable)

• A212 Mounting Pads

Figure 2-2: A212 mounting pad

• (Optional) Grinder – to create a sufficiently flat mounting surface

2.1.4 Prepare the sensor mount

Stud mount (preferred)

Stud mount provides increased reliability, improved frequency response, and increased

signal sensitivity.

Prerequisites

The mounting location must provide a flat surface of at least 0.5 in. (12.7 mm) in diameter

and a case thickness exceeding 0.4 in. (10.2 mm). If this is not possible, use the epoxy

mount method instead

Procedure

Prepare the spot face or end mill tool by setting the drill bit depth to a minimum of

1.

0.325 in. (8.255 mm).

2.

Using a wire brush and plant-approved cleaner, clean and degrease the surface

area.

Keeping the spot face and end mill tool perpendicular to the machine surface, drill

3.

into the mounting location until the surface is smooth to the touch with no

noticeable irregularities. This may require the spot face tool to remove as much as

0.04 in. (1.016 mm) or more from the surface.

Note

If the spot face is not uniform on all sides, it indicates that the spot face tool is not

perpendicular to the mounting surface, and the resulting surface will not allow the

sensor to be mounted properly. See Sensor mounting diagrams for illustrations of

the correct milling process.

4. Using 1/4-28 in. tap set, tap a pilot hole to a minimum depth of 0.25 in. (6.35 mm).

See Sensor mounting diagrams for an illustration of tapping a pilot hole.

MHM-97408, Rev 22 17

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Epoxy mount (alternative)

If it is not practical to drill into the machine casing, then the epoxy mount method is

acceptable.

Procedure

1. If the equipment surface has a radius of curvature that is less than 4 in. (100 mm),

grind a flat surface approximately 0.5 in. (12.7 mm) in diameter.

2. Using a wire brush and plant-approved cleaner, clean and degrease the surface

area.

3.

Using a 2-part epoxy (such as Emerson P/N A92106), spray the activator onto the

mounting surface. Place a light coat of epoxy on the surface of the mounting pad

and hold firmly against the machine spot face surface for 1 minute.

Note

If the adhesive does not set within 1 minute, it indicates that too much epoxy is

applied or that the mounting surface is not prepared properly. Repeat steps 2–3.

2.1.5 Attach the sensors

Figure 2-3 shows a typical accelerometer, mounting stud, and mounting pad used with

the AMS 9420. The mounting pad is only necessary when doing an epoxy mount.

18 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Figure 2-3: Accelerometer, mounting stud, and optional mounting pad

A. accelerometer

B. mounting stud (included with the accelerometer)

C. mounting pad

Prerequisites

Whenever possible, mount sensors to the machine while pulling cables. If you have to

mount the sensor at another time, secure the bundled cable to the machine and protect it

from damage.

Procedure

1. Using a plant-approved cleaner/degreaser, remove any lubricating fluid used during

the tapping process and if necessary, clean the mounting stud threads.

2. Rub a small amount of semi-permanent thread locker onto the mounting location.

MHM-97408, Rev 22 19

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Figure 2-4: Apply thread locker onto mounting location

3. Using a 1/8 in. Allen key (English mounting stud) or a 4 mm Hex Allen key (metric

mounting stud), loosely screw the mounting stud into the mounting location.

The mounting location is the machine surface when using stud mount and the

mounting pad when using epoxy mount.

4. Using a torque wrench with 1/8 in. hex bit, torque to 7–8 ft-lb (9.5–10.8 N-m) to

tighten the mounting stud.

Figure 2-5: Tighten the mounting stud

20 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

For stud mount: If the mounting stud is still not seated against the spot face after

you apply the correct torque force, it indicates that the tap hole is not deep enough.

Remove the mounting and tap a deeper hole.

5. Apply a thin coat of semi-permanent thread locker to the threads on the sensor

housing.

6. Place the sensor onto the mounting stud and hold it to create the least amount of

cable strain and cable exposure. While holding the sensor, hand-tighten the 9/16 in.

captive nut and use a torque wrench with 9/16 in. open end to finish tightening to

2–5 ft-lb (2.7–6.8 N-m).

Figure 2-6: Hand-tighten the captive nut

If the mounting stud does not disengage from the sensor, use a flathead

screwdriver to hold the stud and turn the hex nut counter-clockwise with a wrench.

MHM-97408, Rev 22 21

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

2.1.6 Secure the sensor cables

WARNING

All wiring should be installed by a trained and qualified electrician. Wiring must conform to

all applicable local codes and regulations. Follow local codes and regulations regarding

wire type, wire size, color codes, insulation voltage ratings, and any other standards.

Using an appropriately sized cable clamp, secure the sensor cable to the machine

approximately 4–5 in. (100–125 mm) from the mounting location. Do not curl into a

bending radius of less than 2.8 in. (71 mm).

Figure 2-7: Securing a cable with temporary cable anchor

If the pulling of cables is not currently scheduled, secure the bundled sensor cables so that

no strain is placed on the integral sensor/cable connectors. Do not let the bundled cable

hang from the sensors. Do not place cables on plant floors, maintenance access areas,

and/or footholds that may cause damage to the cables.

22 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

2.1.7 Conduit installation guidelines

WARNING

All wiring should be installed by a trained and qualified electrician. Wiring must conform to

all applicable local codes and regulations.

• Adhere to IEEE 1100 specifications for grounding.

• Do not exceed a 40 percent fill for conduits.

• Route the conduit away from power trays using these guidelines:

6 in. 110 VAC

12 in. 220 VAC

24 in. 440 VAC

• Attach the conduit to the NPT threaded holes on the side of the AMS 9420.

MHM-97408, Rev 22 23

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

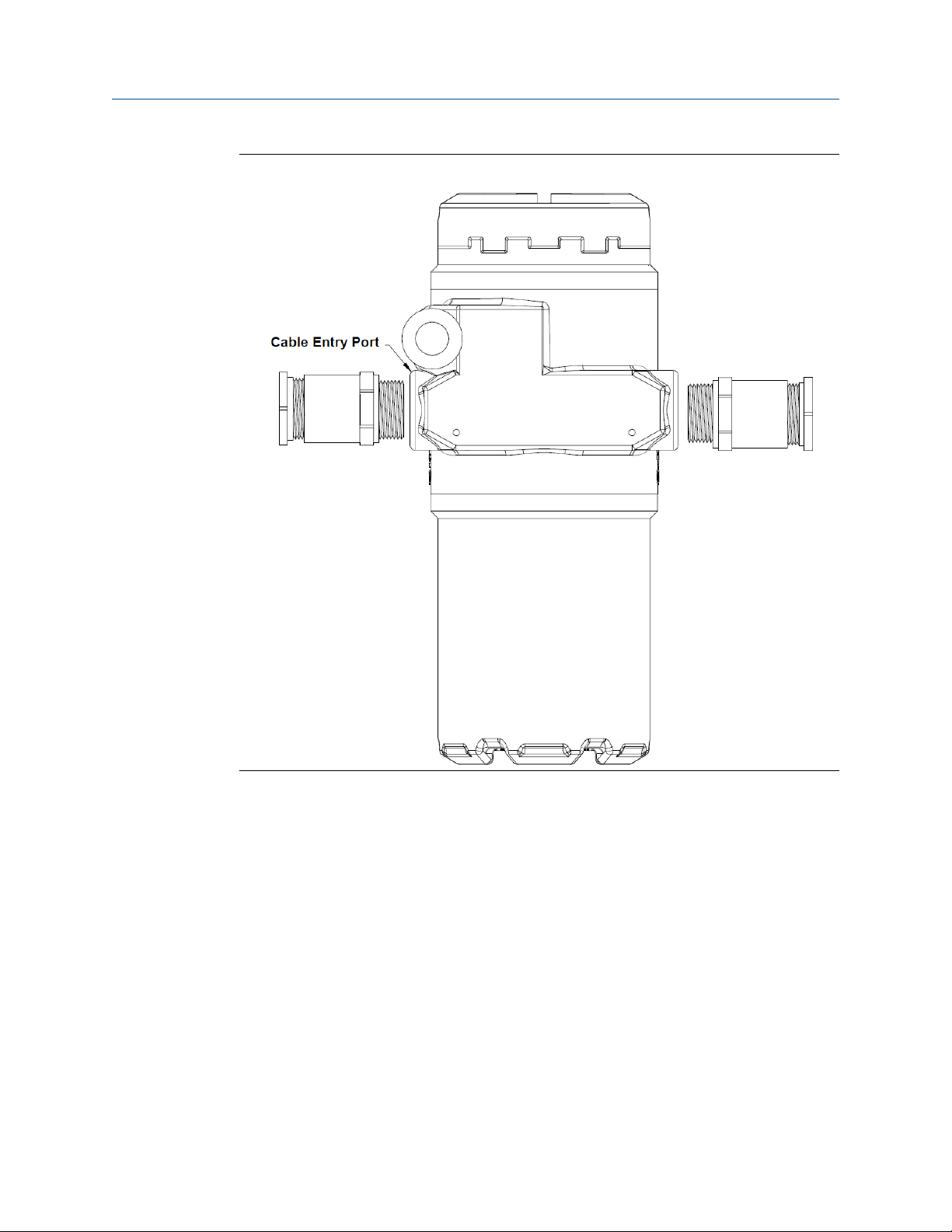

2.1.8 Cable entry port installation guidelines

Power leads and sensor leads enter the rear compartment of the transmitter housing

through conduit openings on the left and right of the housing. Power leads and sensor

leads must enter on opposite sides of the housing. Emerson recommends the sensor leads

enter the same side where the sensor terminal screws are located. Depending on how the

transmitter is powered, you may need to install two sensor cables into one cable entry

port. When the transmitter uses a power module, both cable entry points are available for

use with sensors. You can use the standard cable glands included with the transmitter for

one sensor cable per cable gland. The included cable gland is not approved for use with

two sensor cables. When the transmitter uses external DC power, an extra conduit body is

required, and both sensor leads enter the same conduit opening. Refer to the installation

drawing for details.

Note

Use cable glands to seal the cable entry ports. Ensure that the cable gland grommet fits

the wire properly and does not leak. The wire must snugly fit in the grommet feed-through

in the cable gland to prevent ingress of water and other contaminants. If using one of the

grommets for the standard low-power accelerometers, use a cable with a diameter

between 0.125 to 0.250 in. (3.175 - 6.35 mm) to maintain a good seal. If a good seal is not

possible with the wire selected, use an alternative grommet that provides a good seal.

The following figures show suggested installations.

24 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Figure 2-8: AMS 9420 with extended power module and two sensors

MHM-97408, Rev 22 25

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Figure 2-9: AMS 9420 with external DC power and two sensors

Notes

• When using two sensors with external DC power a dual cable gland adapter is required

(e.g. 'T'-adapter shown in Figure 2-9).

• An external earth connection, where applicable, should be made to the earth

grounding point on the bottom of the housing.

• If using a Stainless Steel housing, stainless steel adapters/glands are also

recommended.

• To ensure long term reliability a minimum of IP56 or NEMA 4 sealing is recommended

for the full assembly.

• All local wiring codes and regulations shall be followed.

When installed in a hazardous location, the following practices are also required:

• Both sensors must enter through the dual cable gland adapter with one sensor per

entry.

• The full assembly shall maintain a minimum IP rating of IP20.

• Field wiring using multiconductor cable shall either have each conductor enclosed in

grounded metal shield or each conductor have a minimum of 0.25 mm (0.01 in)

insulation thickness.

26 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

2.1.9 Attach sensor wiring to the AMS 9420 terminals

Prerequisites

This procedure applies to a typical AMS 9420 installation with low-power sensors. Lowpower accelerometers connect directly to the transmitter terminal block. For information

about using ICP® accelerometers, refer to Power the AMS 9420 with external DC power.

• If you are using armor-jacketed cable longer than 3 meters, you must attach the

ferrites before attaching sensor wiring the AMS 9420 terminals. See Attach 3 ferrites to

an accelerometer with armor-jacketed cable.

• If the sensor signal wires are not equipped with spade lugs, Emerson recommends

installing them before proceeding.

Procedure

1. Tie the sensor's grounding wire (white with black stripe) to the ground screw inside

the AMS 9420.

See callout E in the figures below.

2. Refer to the appropriate figure to connect the sensor signal wires.

Note

You can connect one or two accelerometers to the AMS 9420. You can connect only

one accelerometer with a temperature sensor.

a) Insert a beryllium copper washer on top of each spade lug.

b) Tighten the screw to 15 in-lbs (1.7 N-m).

MHM-97408, Rev 22 27

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

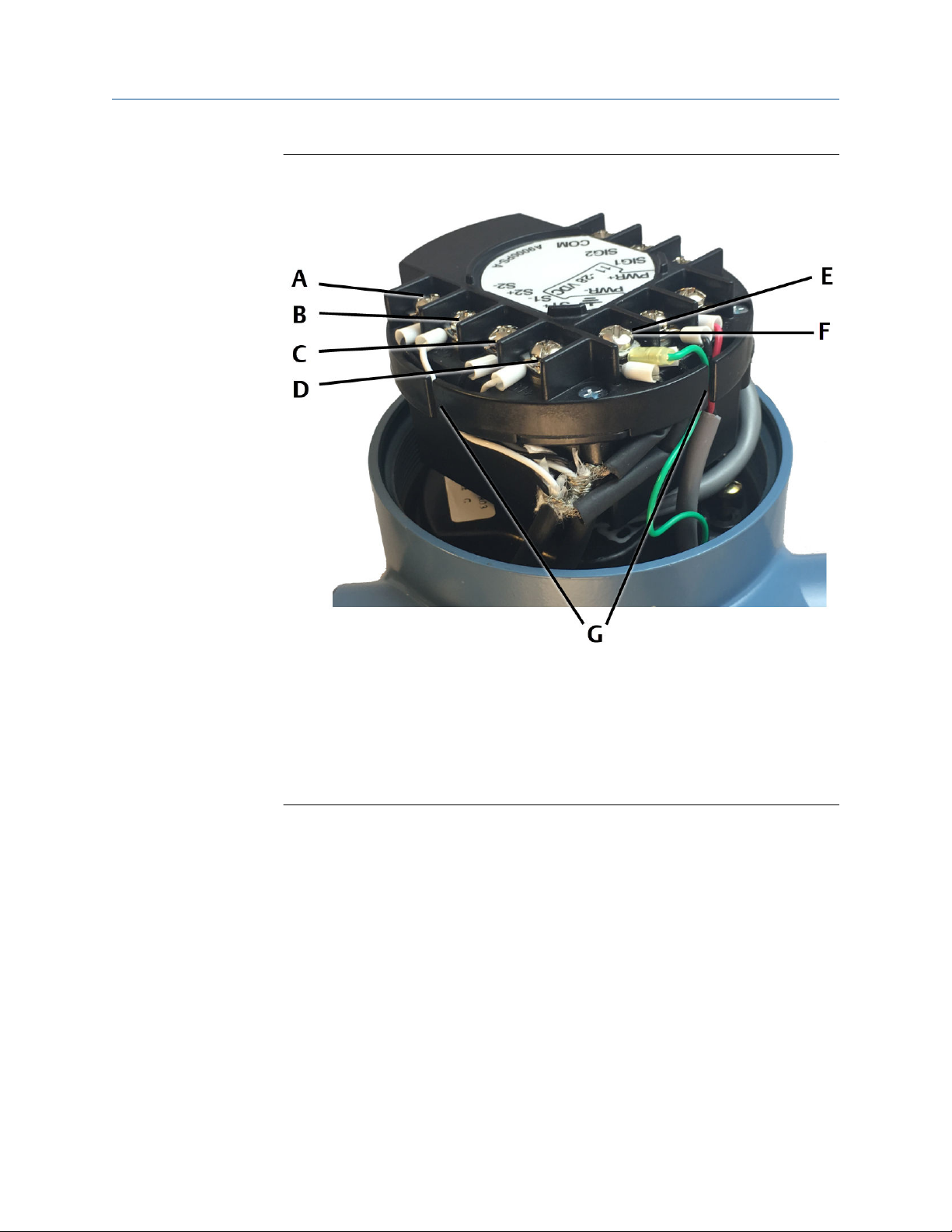

Figure 2-10: AMS 9420 wiring with one accelerometer

A Sensor power Red wire

B Sensor signal White wire

C Unused Unused

D Sensor common Black wire

E Sensor grounding White wire with black stripe

28 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Figure 2-11: AMS 9420 wiring with two accelerometers

A Sensor power 2 red wires

B Sensor 1 signal White wire

C Sensor 2 signal White wire

D Sensor common 2 black wires

E Sensor grounding 2 white wires with black stripe

MHM-97408, Rev 22 29

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Figure 2-12: AMS 9420 wiring with one accelerometer with embedded

temperature

A Sensor power Red wire

B Vibration signal (Signal 1) White wire

C Temperature signal (Signal 2) Green wire

D Sensor common Black wire

E Sensor grounding Bare wire

2.2 Power the AMS 9420 with a power module

Emerson offers power modules to power the AMS 9420 for typical applications. The power

module package includes more documentation. This section includes examples of using

the Blue Power Module with the AMS 9420.

2.2.1 Power module installation and replacement

There are two power modules that may be used with the AMS 9420.

Where approved for use, Emerson recommends using the blue power module . The blue

power module is equipped with two "D" size primary lithium/thionyl chloride cells, and

features special power management circuitry for optimum performance with the AMS

9420. Each blue power module contains approximately 10 grams of lithium.

The black power module contains two “C” size primary lithium/thionyl chloride batteries.

The black power module contains approximately 5 grams of lithium; therefore, the blue

power module will operate the AMS 9420 for approximately twice as long as the black

power module.

30 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Actual power module life can vary dramatically based on the power module being used

and on operating parameters, including whether high-resolution data such as vibration

waveforms and/or spectra are being retrieved from the device.

Under normal conditions, power module materials are self-contained and not reactive as

long as the integrity of the batteries and power module pack are maintained. Take care to

prevent thermal, electrical, or mechanical damage, and protect contacts to prevent

premature discharge.

Upgrading

If you need to upgrade from black power module to a blue power module, Emerson

personnel must apply a new label to your transmitter.

Note

When upgrading from the black power module to the blue power module, be sure to

order an extended battery cover for each blue power module. To order an extended

battery cover for the blue aluminum housing or the stainless steel housing, contact your

local sales representative.

Handling

Under normal conditions, the power module materials are self-contained and are not

reactive as long as the batteries and the power module pack integrity are maintained.

Take care to prevent thermal, electrical, or mechanical damage. Protect the contacts to

prevent premature discharge.

CAUTION

Use caution when handling the power module pack. The power module pack can be

damaged if dropped from heights in excess of 20 feet.

WARNING

Power module hazards remain even when cells are discharged.

Environmental considerations

As with any battery, consult local, national, and international environmental rules and

regulations for proper management of spent batteries. If no specific requirements exist,

you are encouraged to recycle through a qualified recycler. Consult the materials safety

data sheet for power module-specific information.

Shipping

The unit is shipped without the power module installed. Unless you are specifically

instructed to do otherwise, always remove the power module pack from the unit prior to

shipping.

The U.S. Department of Transportation, International Air Transport Association (IATA),

International Civil Aviation Organization (ICAO), and European Ground Transportation of

Dangerous Goods (ADR) regulate the transportation of primary lithium batteries

The shipper is responsible for complying with these or any other local requirements.

Consult current regulations and requirements before shipping.

MHM-97408, Rev 22 31

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

2.2.2 Physical installation

The Blue Power Module (A0701PBU) has been designed with safety in mind. The

connector is keyed so that it cannot be inserted incorrectly, and it uses a patented

mechanism that enables it to be replaced while the transmitter is installed in a hazardous

area. The installation procedure includes replacing the power module and extended

battery cover.

Prerequisites

When replacing a standard Black Power Module with the extended life Blue Power Module,

you also need to replace the smaller end cap (2.5 in / 70 mm) with the extended end cap

(4.5 in / 115 mm).

Procedure

1. Inspect the power module for any obvious signs of damage.

Emerson's SmartPower Power Modules are designed to be rugged. The product

design has been tested in environmental conditions such as extreme temperature,

pressure, vibration and shock. In testing, it also was dropped repeatedly from 3m

height without leading to an unsafe operating condition.

If there are any obvious signs of damage, do not install the power module. Refer to

the Blue Power Module documentation for disposal or recycling of the power

module.

2. Unscrew the power module cover from the AMS 9420.

3.

Connect the power module to the AMS 9420. The power module has a keyed

connection to prevent improper connection.

Figure 2-13: Blue Power Module (A0701PBU) connects using a keyed

connection

32 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Note

Power up wireless devices in order of proximity from the Emerson Wireless

Gateway, beginning with the closest. This will result in a simpler and faster network

installation.

4. Close the extended end cap on the housing and tighten. Always ensure a proper

seal by installing the electronics housing covers so that metal touches metal, but do

not over tighten.

2.3 Power the AMS 9420 with external DC power

Emerson offers Emerson A9000P series adapters to power the AMS 9420 with external DC

power. The adapter package includes documentation, installation drawings, and other

important instructions. You can also find the quick start guide on our website. This section

includes some examples of using the power adapter with the AMS 9420.

2.3.1 Emerson A9000P description of intended use

The Emerson A9000P series adapters are available in two versions: Emerson A9000PA and

Emerson A9000PS-A. They allow an Emerson wireless transmitter to be powered by

external DC power. When installed with an appropriate safety barrier, they can be used in a

hazardous location. Barrier requirements are described in the Emerson A9000Px Quick

Start Guide and installation drawings included with the power adapter.

• Use either version to connect external DC power.

• Use the Emerson A9000PS-A to connect external DC power and up to 2 standard ICP

accelerometers with a nominal sensitivity of 100 mV/g.

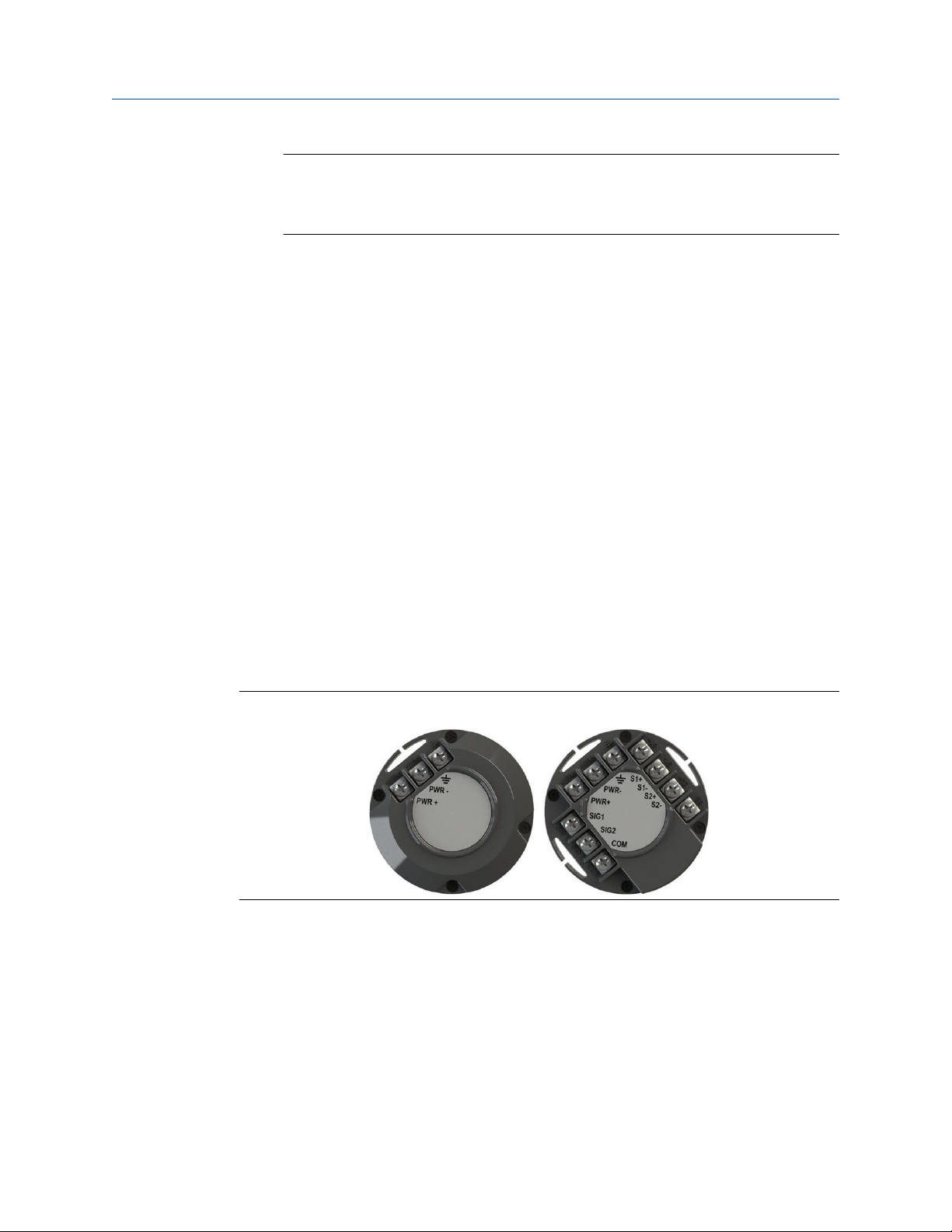

Figure 2-14: Emerson A9000PA (left) and Emerson A9000PS-A (right)

2.3.2 Optional spacer

The spacer is required only when the transmitter has an extended endcap.

MHM-97408, Rev 22 33

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Figure 2-15: Optional spacer

2.3.3 Connect external DC power to Emerson wireless transmitters

You can use all versions of the Emerson A9000P series adapters to connect external DC

power to Emerson wireless transmitters. This example describes connecting the power

adapter.

CAUTION

DC power should only be applied to the power adapter after it is wired and inserted in the

transmitter terminal block.

Procedure

1. Connect the external DC power to the power adapter.

2. Connect the included green chassis ground cable to the power adapter ground and

to the chassis ground point.

The connections are shown in detail in the installation drawing and an example is

shown in

Figure 2-16.

34 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

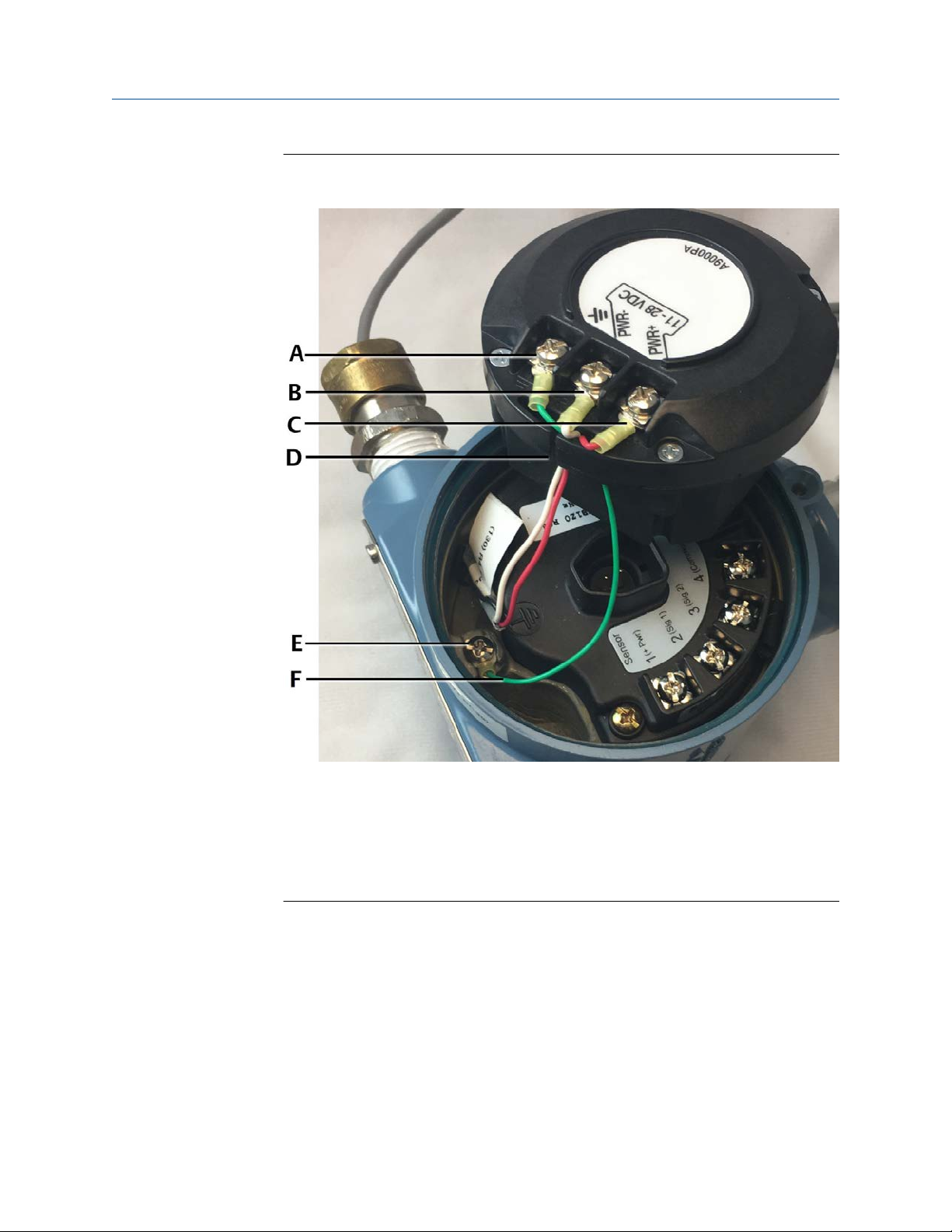

Figure 2-16: External DC power and included cable harness connected to the

power adapter

A. Green chassis ground cable

B. PWR C. PWR +

D.

Slot

E. Chassis ground point

F. Green chassis ground cable

3. Push each wire through the slot.

4. Insert the power adapter into the receptacle on the transmitter terminal block.

5. If the transmitter has an extended end cap, insert the spacer into the end cap.

Otherwise, the spacer is not required.

MHM-97408, Rev 22 35

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

2.3.4 Connect external DC power and ICP® accelerometer inputs to an AMS 9420

With the AMS 9420, use the Emerson A9000PS-A to connect external DC power and up to

2 standard ICP® accelerometers with a nominal sensitivity of 100 mV/g. This example

describes connecting the power adapter.

Note

For a typical AMS 9420 installation, only connect external DC power to the power adapter.

Low-power accelerometers connect directly to the transmitter terminal block.

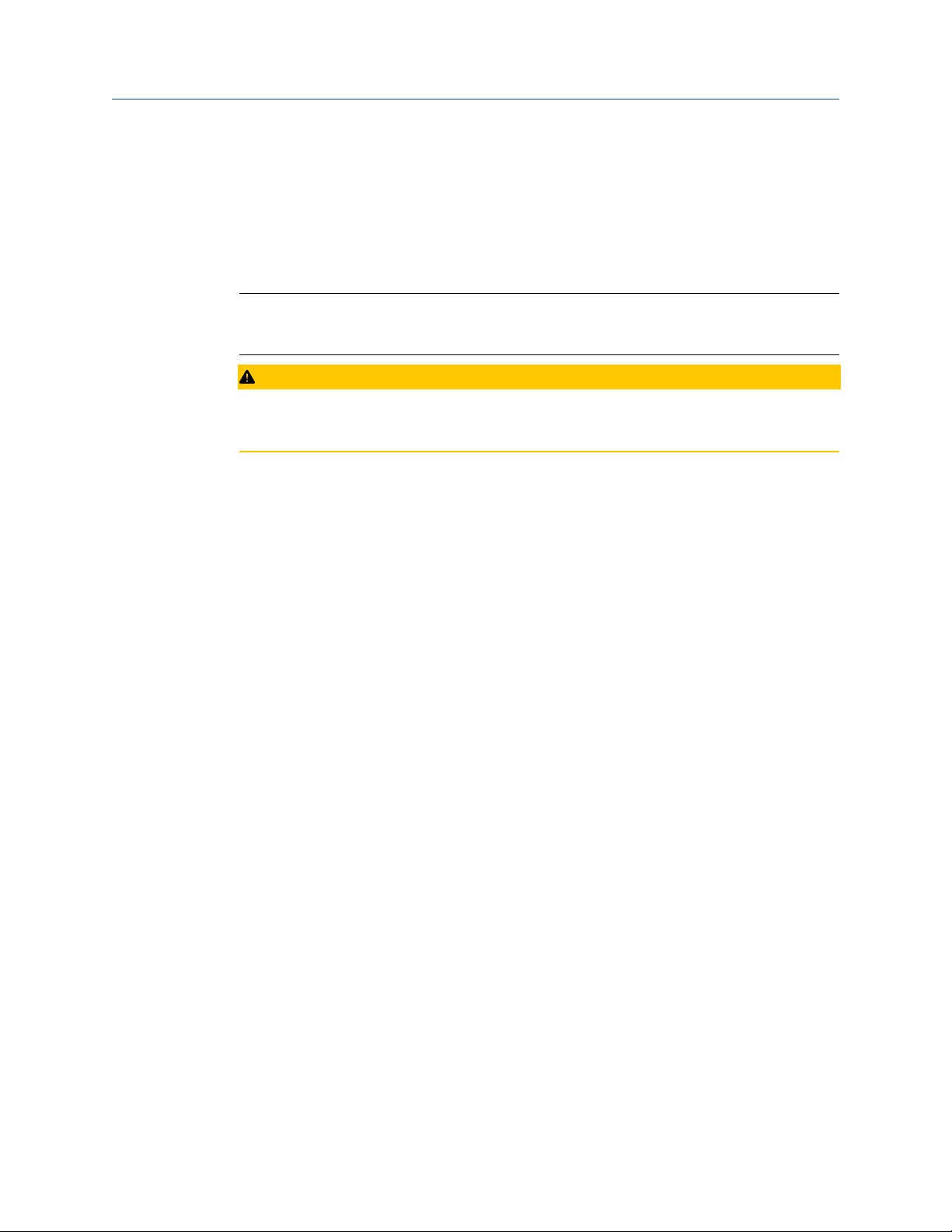

CAUTION

DC power should only be applied to the power adapter after it is wired and inserted in the

transmitter terminal block.

Prerequisites

Connect external DC power and green chassis ground cable to the power adapter. Refer to

the example in Connect external DC power to Emerson wireless transmitters.

Procedure

1. Use the included cable harness to connect the power adapter sensor terminals to

the AMS 9420, as shown in the installation drawing.

The cable harness has three wires: two colored wires and one bare wire. Each wire

has a spade lug on one end and a ferrule on the other end. Connect the spade lugs

to the terminal block. Connect the ferrules to the power adapter. Be careful to

connect each wire to the matching terminal screw. The connections are shown in

detail in the installation drawing and an example is shown in Figure 2-17

.

36 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

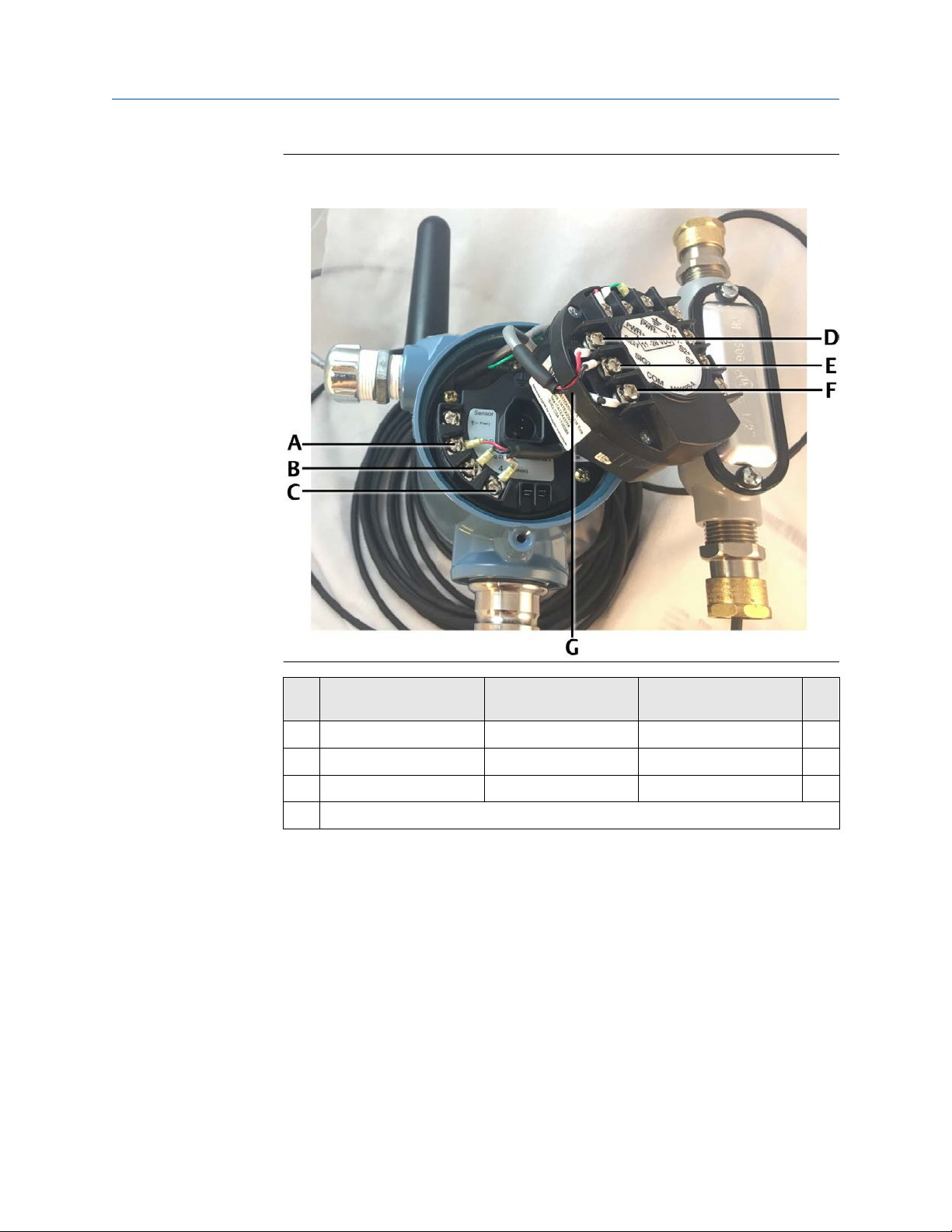

Figure 2-17: Emerson A9000PS-A to AMS 9420 signal connections with

included cable harness

Spade lug to AMS 9420 Cable harness wire Ferrule to Emerson

A9000PS-A

A 2 (Sig 1) color 1 (red shown) SIG1 D

B 3 (Sig 2) color 2 (black shown) SIG2 E

C 4 (Common) unshielded COM F

G Slot

2. Push each wire from the cable harness into the slot. It is easier to push the individual

wires into the slot after connecting the ferrules.

3. Connect the leads from up to two standard ICP® accelerometers with a nominal

sensitivity of 100 mV/g to the terminal screws on the Emerson A9000PS-A.

MHM-97408, Rev 22 37

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

Figure 2-18: Two ICP® accelerometers connected to the power adapter

(rotated view)

A. S2B. S2+

C. S1-

S1+

D.

E. S1 Shield

F. S2 Shield

G. Slots

4. Push each signal cable wire into the slot.

5. Wrap the cable harness counter clockwise around the receptacle on the transmitter

terminal block.

38 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Figure 2-19: Cable harness wrapped around the receptacle

6. Insert the power adapter into the receptacle.

7. If the transmitter has an extended end cap, insert the spacer into the end cap.

Otherwise, the spacer is not required.

2.4 Install the end cap

Note

If you have configured the sensor and network but are not ready to commission the

device, remove the power module to extend operating life.

Prerequisites

Ensure you have the appropriate end cap and spacer as required for your application.

Procedure

1. If required for your application, insert the spacer between the power module or

power adapter and the extended end cap.

2. Attach the end cap.

Always ensure a proper seal by installing the housing cover so that metal touches

metal and the black O-ring is no longer visible, but do not over tighten. A tight seal

ensures that water, water vapor, or other gases do not penetrate into the housing.

MHM-97408, Rev 22 39

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

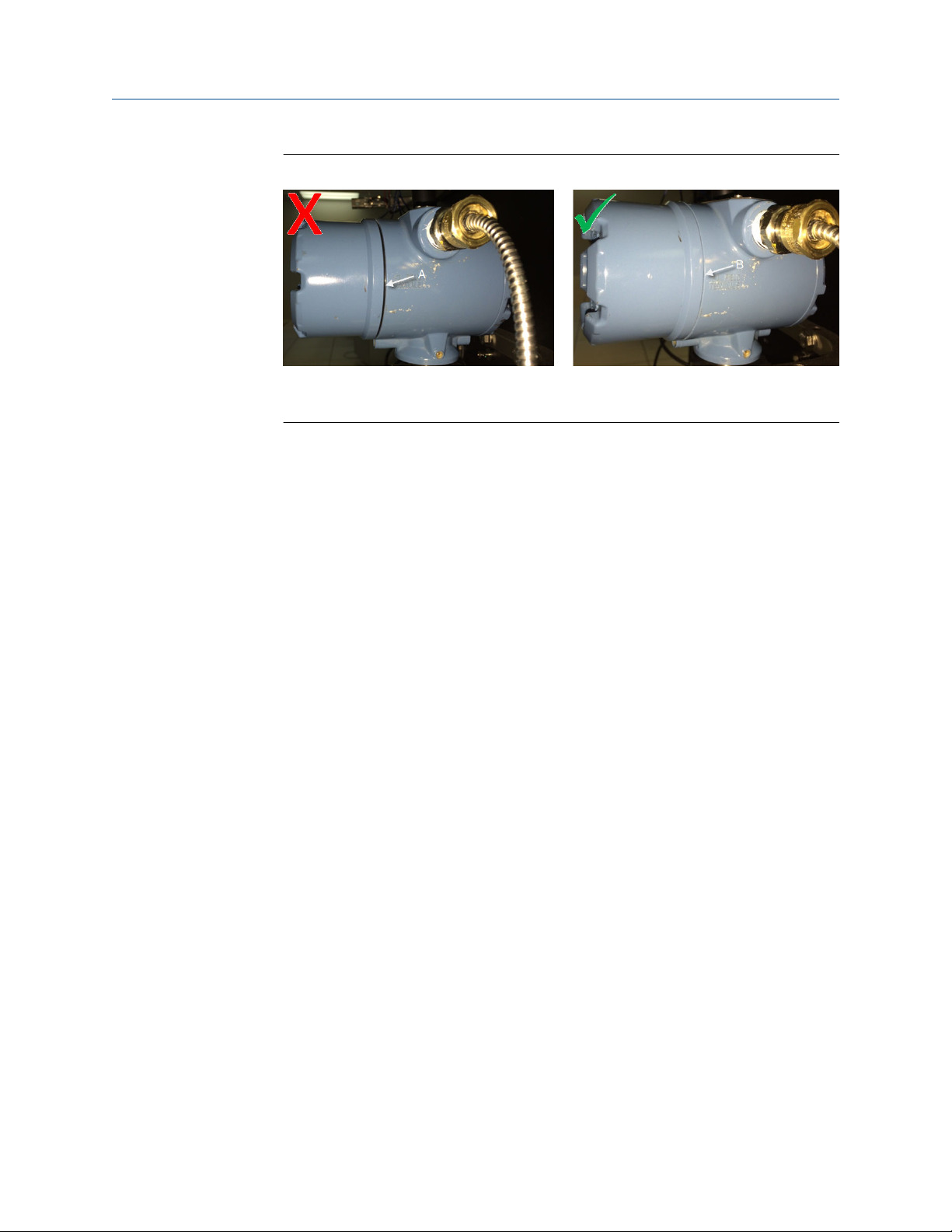

Figure 2-20: Sealing the end cap

A. Improperly sealed end cap. Black O-ring is still visible.

B. Properly sealed end cap. Black O-ring is no longer visible.

3. Use a strapping wrench to tighten the housing cover to safety specification.

Always ensure a proper seal by installing the housing cover so that metal touches

metal and the black O-ring is no longer visible, but do not over tighten. A tight seal

ensures that water, water vapor, or other gases do not penetrate into the housing.

2.5 Position the antenna

Procedure

Position the antenna so it points upward, for optimal performance.

The antenna should be approximately 3 ft. (1 m) from any large structure, building, or

conductive surface to allow for clear communication to other devices.

40 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Figure 2-21: Antenna positions and dimensions

MHM-97408, Rev 22 41

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

2.6 Liquid Crystal Display (LCD)

If you order an LCD, it is shipped attached to the transmitter.

2.6.1 Rotate the LCD

You may need to rotate the LCD depending on the mounting orientation of the device.

WARNING

Do not remove the front electronics end cap or LCD cover while the device is in a

hazardous area.

Removing the cap while the device is in a hazardous area could cause an explosion which

could result in death or serious injury.

CAUTION

The front electronics end cap or LCD cover is certified for hazardous areas in appropriate

gas environments (check the nameplate on the device for details).

Exposing the electronics to a production environment may allow particulates, moisture,

and other airborne chemicals to enter into the device, which could lead to contamination

and potential product performance issues.

Figure 2-22: Installing the LCD

Procedure

1. Remove the LCD cover.

2. Insert the four-pin connector into the interface board, rotate to the correct

position, and snap into place.

The pins can be plugged into any one of four locations depending on which angle of

rotation is desired for the LCD screen.

If the LCD pins are inadvertently removed from the interface board, carefully reinsert the pins before snapping the LCD in place.

42 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

After installation, you can remove the LCD by squeezing the two tabs and pulling

gently. You can then rotate it in 90-degree increments and snap it back in place.

3. Attach the LCD cover.

Always ensure a proper seal by installing the housing cover so that metal touches

metal and the black O-ring is no longer visible, but do not over tighten. A tight seal

ensures that water, water vapor, or other gases do not penetrate into the housing.

Figure 2-23: Sealing the end cap

A. Improperly sealed end cap. Black O-ring is still visible.

B. Properly sealed end cap. Black O-ring is no longer visible.

Important

Moving one LCD around to multiple devices, on an “as need” basis, is NOT

recommended. This can cause reliability problems over time. The connector pins on

the LCD are not designed for repeated connect/disconnect.

2.6.2 Enable the LCD

When you enable the LCD, the AMS 9420 displays information about its network state and

its measurements. This is helpful for configuration, installation, and commissioning. The

LCD provides a visual indication on the status of the device and shows its current

measurements.

Transmitters ordered with the LCD are shipped with the display installed but with the LCD

disabled/turned off. You need to enable the LCD using a 475 Field Communicator or using

AMS Device Manager.

Enable the LCD using a 475 Field Communicator

1. Use the lead set to connect the Field Communicator to the AMS 9420 terminal

block.

2. Turn on the Field Communicator.

3. Select Configure → Manual Setup → General Settings → LCD Mode → Periodic

Display.

Options available for LCD configuration include:

• Not installed – Use this setting if the LCD is not installed.

MHM-97408, Rev 22 43

Install the AMS 9420 Reference Manual

September 2020 MHM-97408

• Periodic Display – Use this setting to show only relevant data. This setting does

not extend the wake cycle.

• Troubleshooting Display – Use this setting when troubleshooting the

transmitter.

• Off – Use this setting to disable the LCD.

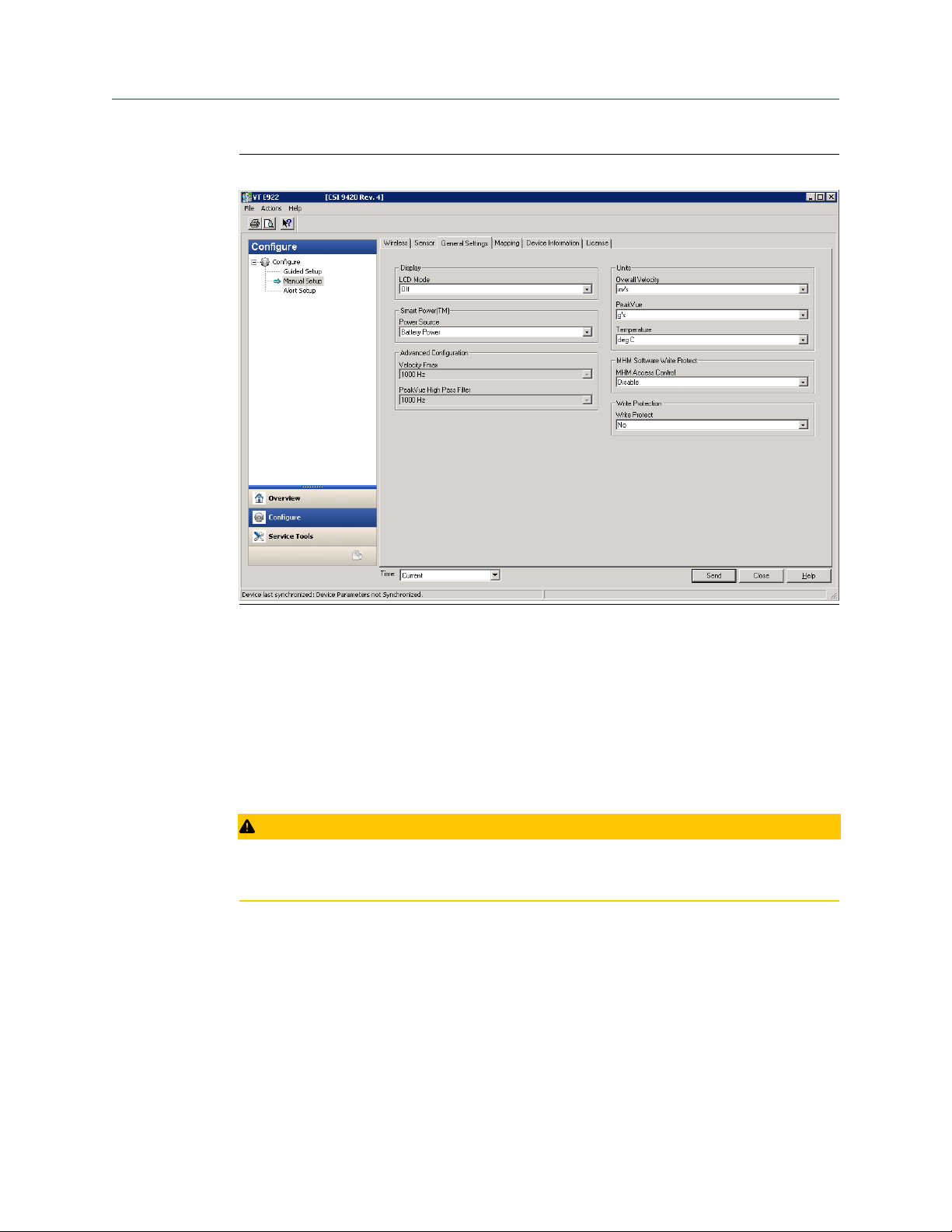

Enable the LCD using AMS Device Manager

Launch AMS Device Manager and locate the network where the AMS 9420 is

1.

connected.

2. Right-click the AMS 9420 device and select

3. Click the General Settings tab and from the LCD Mode drop-down menu, select

Periodic Display.

Options available for LCD configuration include:

• Not installed – Use this setting if the LCD is not installed.

• Periodic Display – Use this setting to show only relevant data. This setting does

not extend the wake cycle.

• Troubleshooting Display – Use this setting when troubleshooting the

transmitter.

• Off – Use this setting to disable the LCD.

Note

When operating the AMS 9420 with the Smart Power Module, disable the LCD in the

transmitter configuration after installation to maximize power module life. While the LCD

module itself consumes very little power, having it activated will alter the operating cycle

of the transmitter in such a way that can impact the power module life by up to 15–20%.

2.6.3 Turn on the LCD

WARNING

Configure → Manual Setup.

Do not remove the front electronics end cap or LCD cover while the device is in a

hazardous area.

Removing the cap while the device is in a hazardous area could cause an explosion which

could result in death or serious injury.

CAUTION

The front electronics end cap or LCD cover is certified for hazardous areas in appropriate

gas environments (check the nameplate on the device for details).

Exposing the electronics to a production environment may allow particulates, moisture,

and other airborne chemicals to enter into the device, which could lead to contamination

and potential product performance issues.

44 MHM-97408, Rev 22

Reference Manual Install the AMS 9420

MHM-97408 September 2020

Procedure

1. Remove the LCD cover.

2. Press the

This displays the Tag name, Device ID, Network ID, Network Join Status, and Device

Status screens.

3. Attach the LCD cover.

Use a strapping wrench to tighten the cover until it will no longer turn and the black

O-ring is no longer visible. Refer to Figure 2-23 for an illustration on how to properly

seal the end cap.

DIAG button to turn the LCD on.

2.7 Ground the transmitter

The transmitter operates with the housing, either floating or grounded. However, the

extra noise in floating systems affects many types of readout devices. If the signal appears

noisy or erratic, grounding the transmitter at a single point may solve the problem.

You can reduce electrostatic current in the leads induced by electromagnetic interference

by shielding. Shielding carries the current to the ground and away from the leads and

electronics. If the transmitter end of the shield is adequately grounded to the transmitter

and the transmitter is properly grounded to the earth ground, very minimal current enters

the transmitter.

If the ends of the shield are left ungrounded, a voltage is created between the shield and

the transmitter housing, and between the shield and earth at the element end. The

transmitter may not be able to compensate for this voltage, causing it to lose

communication and/or generate an alarm. Instead of the shield carrying the current away

from the transmitter, the current flows through the sensor leads and into the transmitter

circuitry where it interferes with circuit operation.

Each accelerometer contains a drain wire that is connected to the sensor shield. This wire

should be connected to the internal grounding screw attached to the housing near the

terminal block.

Ground the transmitter in accordance with local, national, and international installation

codes. You can ground the transmitter through the process connection, the internal case

grounding terminal, or the external grounding terminal.

MHM-97408, Rev 22 45

Configure the AMS 9420 Reference Manual

September 2020 MHM-97408

3 Configure the AMS 9420

Topics:

• 3.1

• 3.2 Configuration with a Field Communicator

• 3.3

• 3.4 Configuration with AMS Machinery Manager

Configuration overview

Configuration with AMS Device Manager

3.1 Configuration overview

You can configure the AMS 9420 either prior to installation or after the device is installed

at the measurement location. You do not need to physically install or connect to the

transmitter to complete the configuration. The transmitter, however, reports an alert until

the sensor is connected; this is the expected behavior.

Note

The specific user interface for performing the configuration varies depending on the host

used.

Procedure

1. Connect to a wired HART interface.

Skip this step if your AMS 9420 is purchased pre-configured from the factory.

2. Set the wireless network credentials (Network ID and Join Key) using wired

connection.

Perform this step for the device to join a wireless network. After the device has

joined, you can complete the rest of the steps over a wireless link.

3.

(Optional)

By default, the tag is VT xxxx, where xxxx is the unique radio ID on the wireless

network. The device joins the network and operates correctly even if no changes are

made, but it is usually preferable to name the device something meaningful for the

specific application.

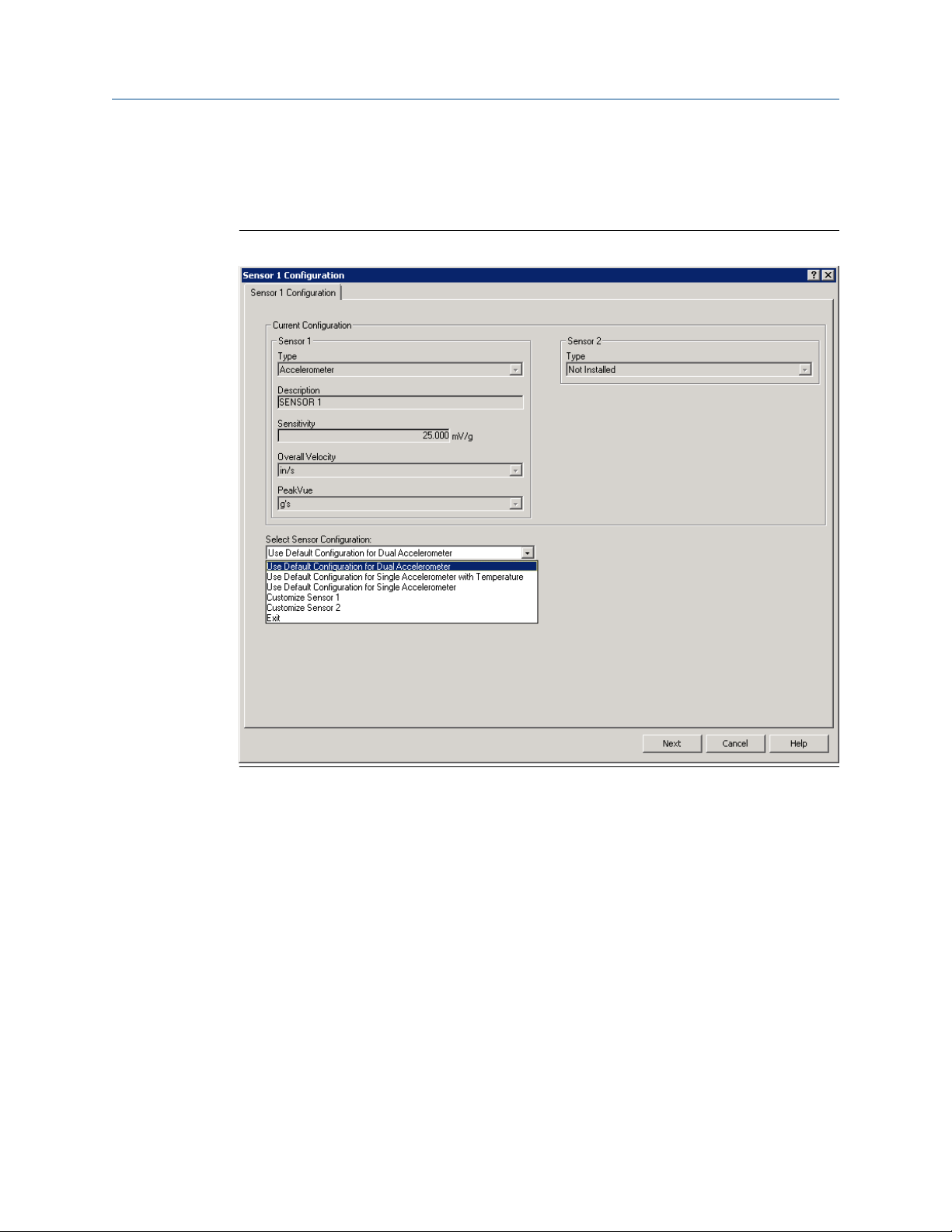

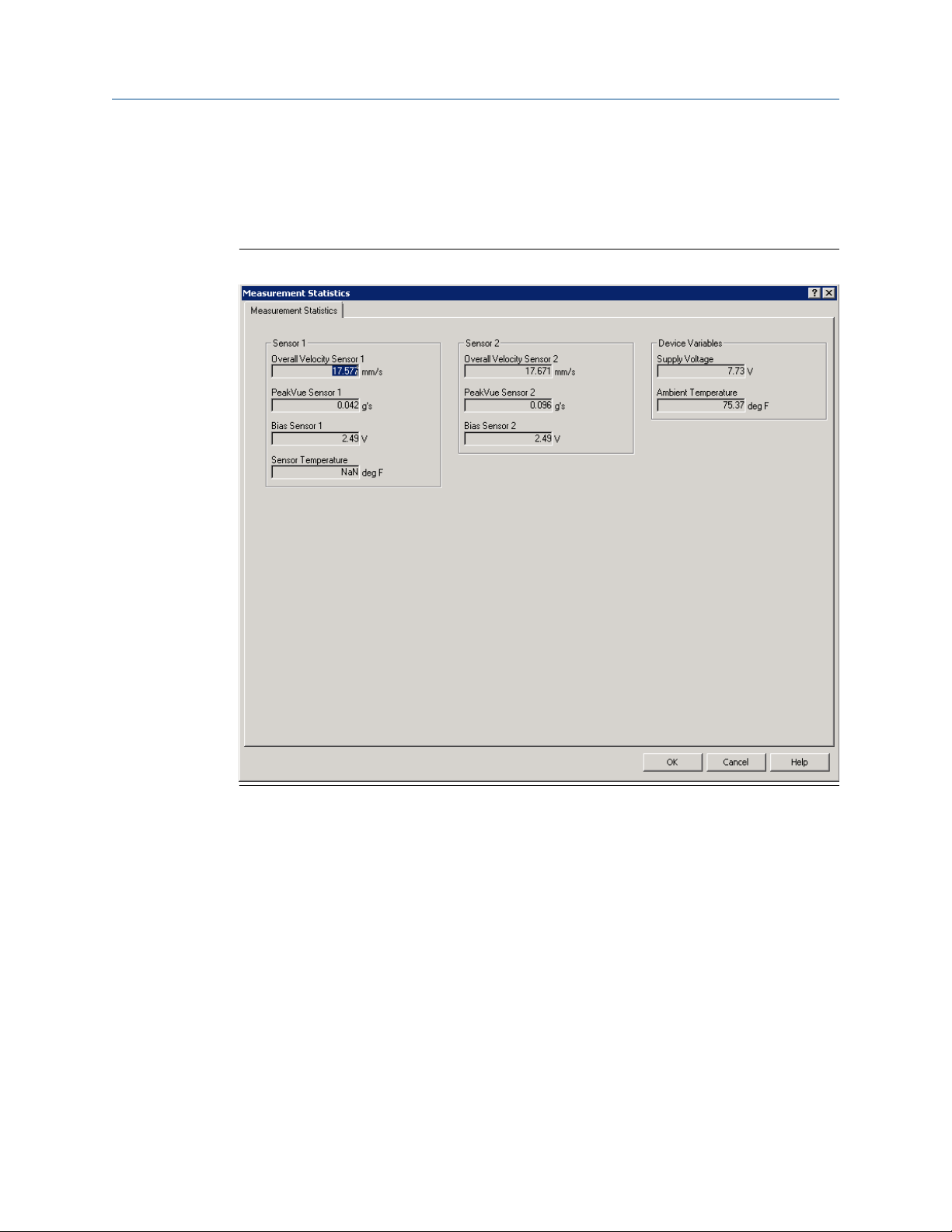

4. Specify the type of sensor installed (for example: 1 accelerometer, 1

accelerometer with temperature, or 2 accelerometers) and name the sensor.

The factory default configuration is one accelerometer named SENSOR 1. Complete

this step for different configurations and name the sensor something meaningful

for the specific application.

46 MHM-97408, Rev 22

Name the device (Tag and Device Description).

Reference Manual Configure the AMS 9420

MHM-97408 September 2020

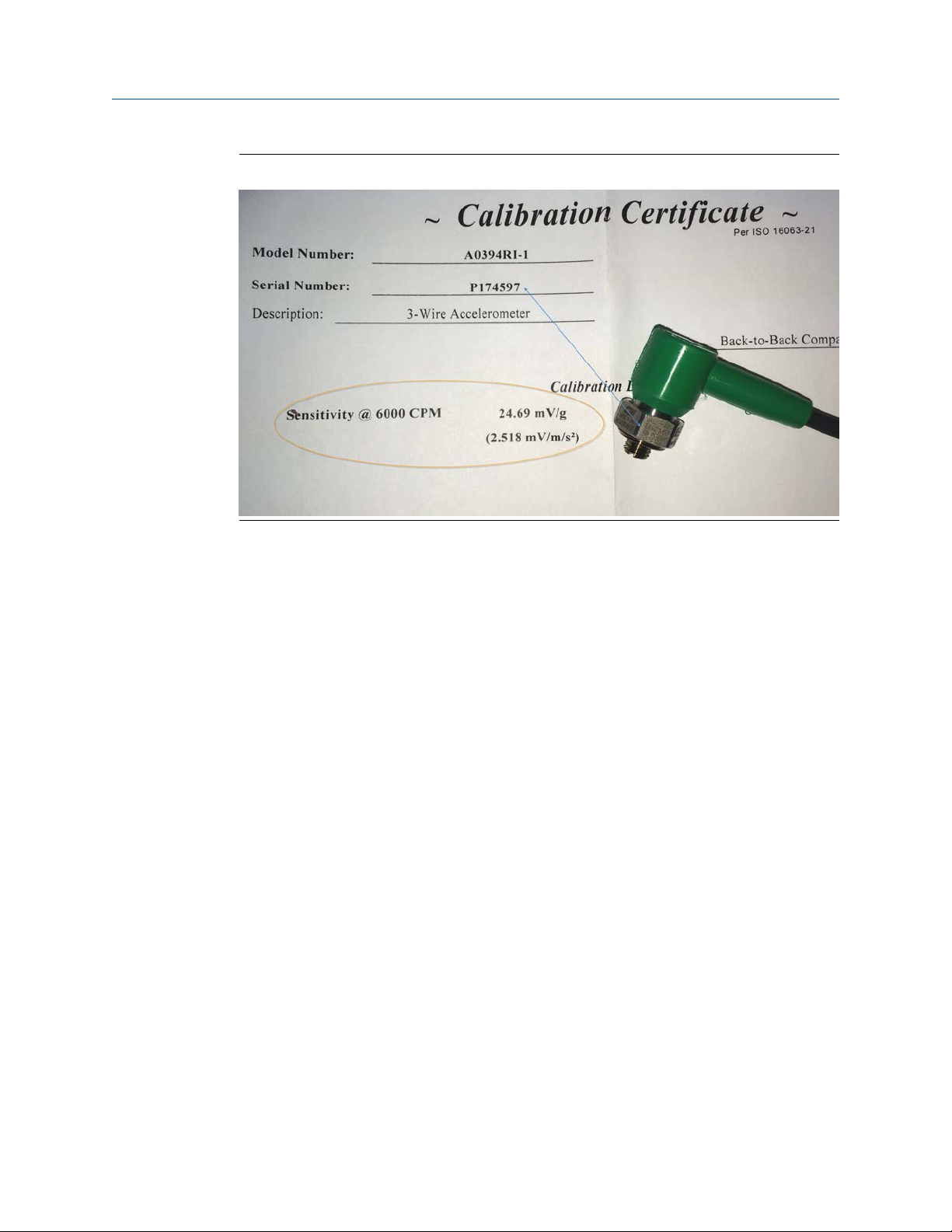

5. Enter the sensor sensitivity setting.

For improved accuracy, replace the nominal sensitivity value of 25 mV/g (2.55 mV

per m/s2) (default) with the value corresponding to your specific sensor. When

using an 100 mV/g sensor with a power adapter, you need to divide the value by

four. See page 53.

6. Specify the units (English, metric, or SI) that will be used for each parameter.

By default, units are set to English, unless the device is shipped to Japan.

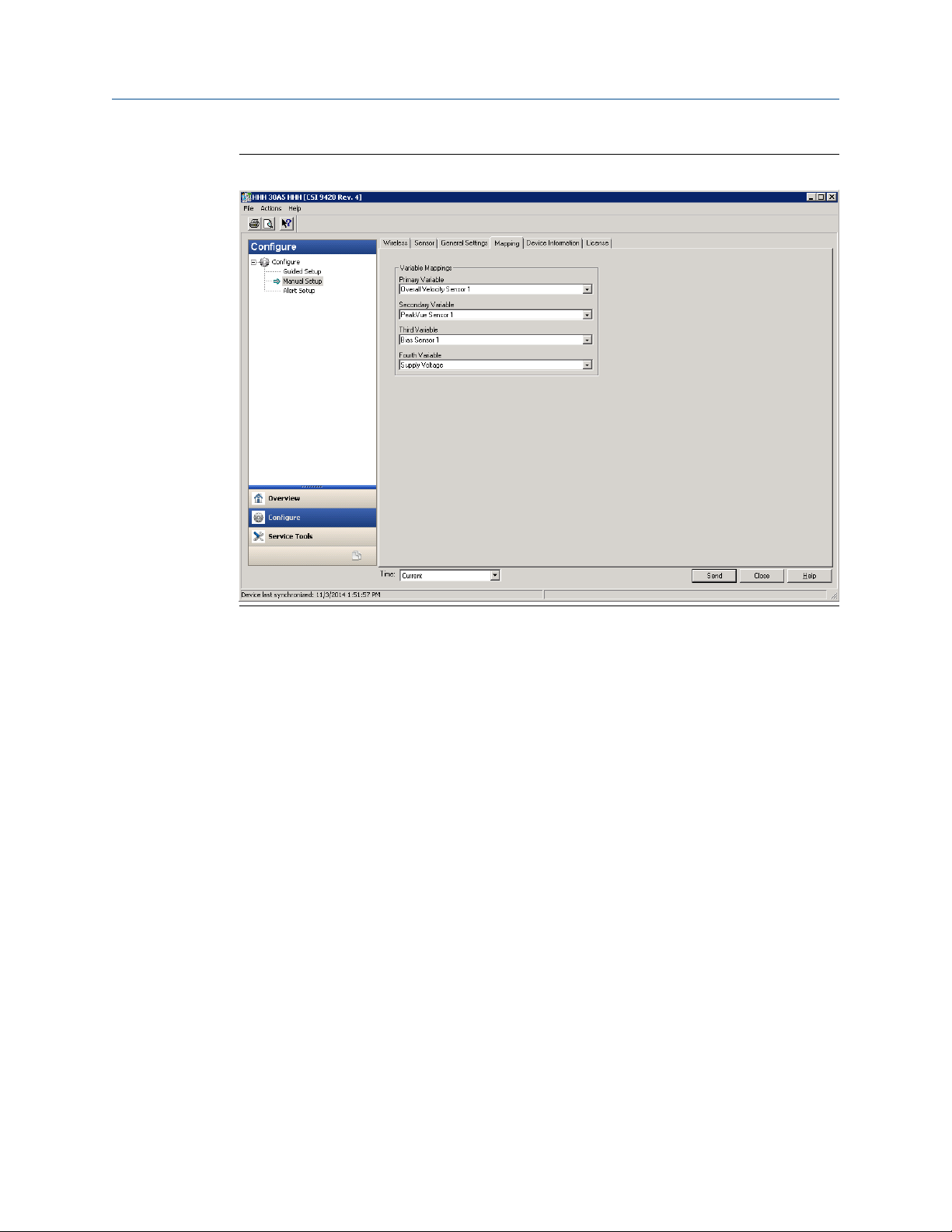

7. Specify which measurements (velocity, temperature, etc.) correspond to the

process variables PV, SV, TV, and QV.

By default, PV is the Overall Velocity on sensor 1, SV is the PeakVue measurement

on sensor 1, TV is the sensor 1 bias voltage, and QV is the supply voltage.

8. Specify alert levels.

Determine the thresholds at which measurement alerts will display and determine

the behavior of device alerts.

9. Specify how the parameters will be published (optimized mode or generic

mode).

By default, the device is configured to use generic mode as it provides the most

consistent overall performance.

10. Specify how often the parameters are published (update rate).

The default update rate is once every 60 minutes. A faster update rate is not

recommended, unless the device is powered by an external power source, as it

significantly reduces the power module life.

11. Optimize for power consumption.

Reduce the publish rate and set the LCD mode to Off to minimize power

consumption. As an additional step, you can configure the PowerSave mode

settings to extend the power module life.

12. Configure trending of parameters.

You can trend parameters in multiple locations such as in a plant historian, in AMS

Machinery Manager, and in a DCS control system.

13. If the device configuration will not be managed by a HART DCS (such as

DeltaV), specify whether AMS Machinery Manager can make configuration

changes.

By default, the device is set for a DCS to manage the configuration, and changes

from AMS Machinery Manager are not permitted. You can, however, allow AMS

Machinery Manager to make configuration changes by enabling MHM Access

Control from AMS Device Manager or from a Field Communicator.

14. If the device is licensed for the Advanced Diagnostics application (spectral data

retrieval), configure storage of energy bands, spectra, and waveforms in the

AMS Machinery Manager database.

With the Advanced Diagnostics application, you can collect data on-demand,

automatically at periodic intervals, or on alert. Store on Alert is the recommended

operating mode.

MHM-97408, Rev 22 47

Configure the AMS 9420 Reference Manual

September 2020 MHM-97408

3.1.1 Connect to a wired HART interface

Unless the AMS 9420 is purchased pre-configured from the factory, you must connect it to

a wired HART interface. This is to define device credentials that allow the device to

communicate on your wireless network. You can also define other device configurations

such as sensor type and alert thresholds at this time.

Notes

• Use the wired HART interface only for configuration. Dynamic variables (such as

measured vibration parameters) are not updated when communicating on the wired

interface.

• The AMS 9420 does not communicate simultaneously on both the wired and wireless

HART interfaces. You will lose wireless connectivity when you connect to the wired

HART interface. Configuration changes are not reflected in a wireless host until

connection has been re-established. To avoid loss of synchronization, disconnect hosts

relying on the wireless link when communicating with the device on the wired

interface.

For example, if you are viewing a configuration screen in AMS Device Manager through

a wireless link, and you leave this screen open while making changes with a Field

Communicator, you will have to exit AMS Device Manager and then re-open it (or rescan the device) after the wireless connection has been restored in order to see the

changes.

Procedure

1. Remove the transmitter back cover.

This exposes the terminal block and HART communication terminals.

48 MHM-97408, Rev 22

Reference Manual Configure the AMS 9420

MHM-97408 September 2020

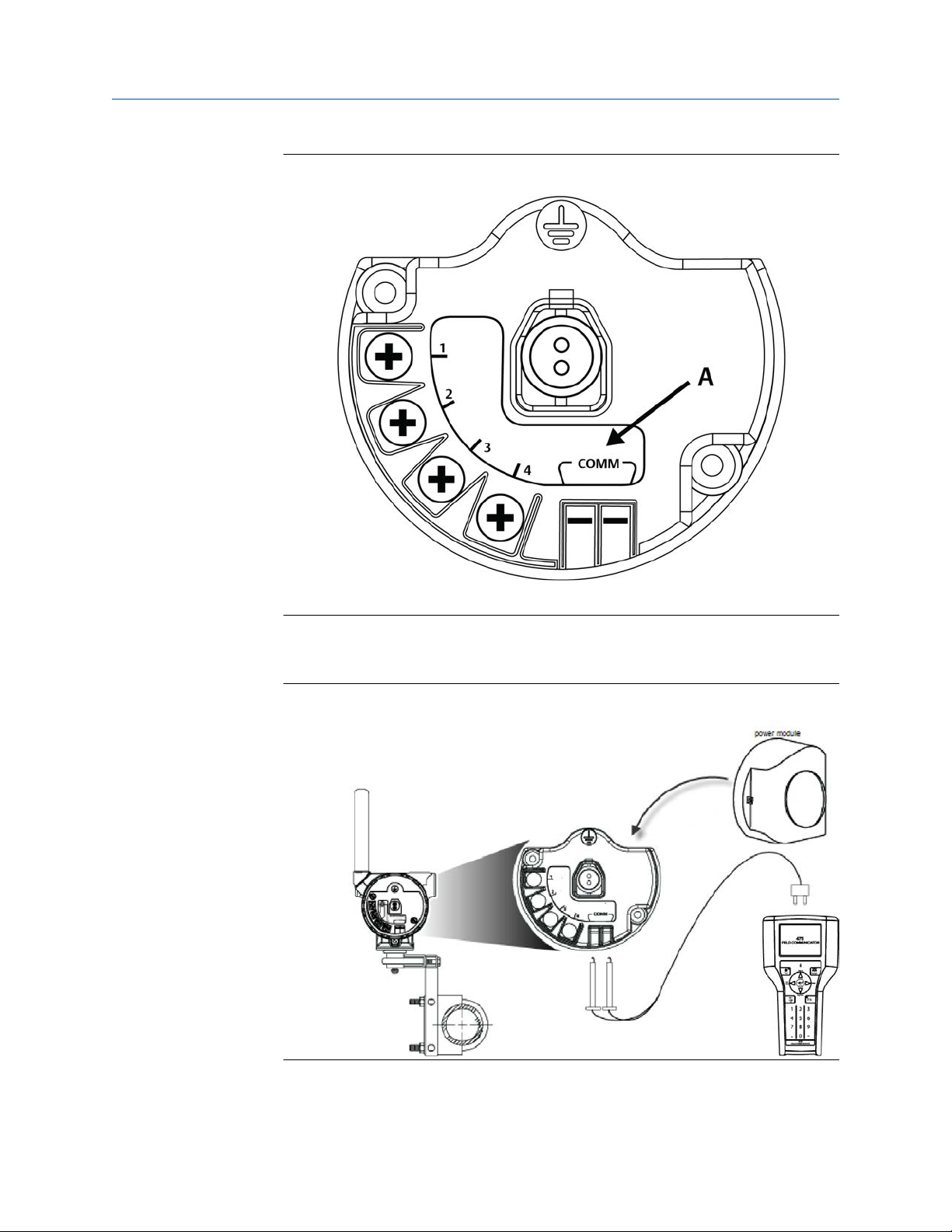

Figure 3-1: AMS 9420 terminal block

A. AMS 9420 COMM terminals (power module version)

2. Connect a power module, if there is not a power source already such as the power

adapter.

Figure 3-2: Field Communicator and power module connection

3. Configure using a Field Communicator, AMS Device Manager, or any HART-enabled

host.

MHM-97408, Rev 22 49

Configure the AMS 9420 Reference Manual

September 2020 MHM-97408

Press Send to send configuration changes to the transmitter.

The AMS 9420 enters “HART Listen” mode for communication on the wired

interface. HART Listen is displayed on the optional LCD, if it is installed.

If the device is unable to enter the HART Listen mode during its boot sequence or

while performing its real-time vibration measurement, retry the initial wired HART

handshaking sequence.

If repeated attempts to establish wired communication fail, you can force the

device into a HART Listen mode. When in a safe location, remove the transmitter

front cover and press the CONFIG button once. The device enters HART Listen

mode, and it remains in this mode until you press the CONFIG button, the power

cycles, or no activity is seen on the wired interface for three minutes. Pressing the

CONFIG button a second time causes the device to exit HART Listen mode.

WARNING

Do not remove the front electronics end cap or LCD cover while the device is in a

hazardous area.

Removing the cap while the device is in a hazardous area could cause an explosion

which could result in death or serious injury.

CAUTION

The front electronics end cap or LCD cover is certified for hazardous areas in

appropriate gas environments (check the nameplate on the device for details).

Exposing the electronics to a production environment may allow particulates,

moisture, and other airborne chemicals to enter into the device, which could lead to

contamination and potential product performance issues. In all cases, whenever

opening the front end cap, be sure to seal it completely afterwards by tightening

until the black O-ring is no longer visible. For an illustration on how to properly seal

the end cap, see Figure 2-23.

4. When configuration is complete over the wired HART interface, disconnect the

transmitter from the communication wires to re-establish wireless communication.

This may take several minutes.

3.1.2 Set the wireless network configuration

This enables the transmitter to communicate with the Emerson Wireless Gateway and

with other systems. This is the wireless equivalent of connecting wires from a transmitter

to a control system input.

Procedure

1. From the Emerson Wireless Gateway, click System Settings

Network Settings to obtain the Network ID and Join Key.

2. Using a Field Communicator or AMS Device Manager with a wired modem, enter

the Network ID and Join Key so that they match the Network ID and Join Key from

the Emerson Wireless Gateway.

→ Network →

50 MHM-97408, Rev 22

Reference Manual Configure the AMS 9420

MHM-97408 September 2020

Note

If the Network ID and Join Key are not identical to the gateway settings, the AMS

9420 will not communicate with the network.

MHM-97408, Rev 22 51

Configure the AMS 9420 Reference Manual

September 2020 MHM-97408

3.1.3 Configuration options

The AMS 9420 configuration options control the following operations:

• How measurement results are reported and how often are they reported

• The number and type of sensors installed

• How and when alerts are generated

Table 3-1 shows the default device configuration. You can change these configurations

from AMS Device Manager or from a Field Communicator.

Table 3-1: Default device configuration

Configuration option Default value

Publishing mode

Update rate

PowerSave mode

LCD mode

Power source

MHM Access Control

Write Protect

Sensor Configuration

Sensor type 1 Accelerometer (sensor 2 not installed)

Sensor sensitivity setting 25 m V/g

Velocity Fmax 1000 Hz

PeakVue true Fmax 1000 Hz

Velocity spectrum lines of resolution 400 lines

PeakVue spectrum lines of resolution 1600 lines

Units

Generic

60 minutes

PowerSave Skip Multiplier of 1X

Off

Power module/battery

Disabled

No

English

Overall velocity: in/s RMS

PeakVue: g's peak

Temperature: °C

Variable mappings

PV Overall velocity, sensor 1

SV PeakVue, sensor 1

TV Bias, sensor 1

QV Supply voltage

52 MHM-97408, Rev 22

Reference Manual Configure the AMS 9420

MHM-97408 September 2020

3.1.4 Sensor configuration

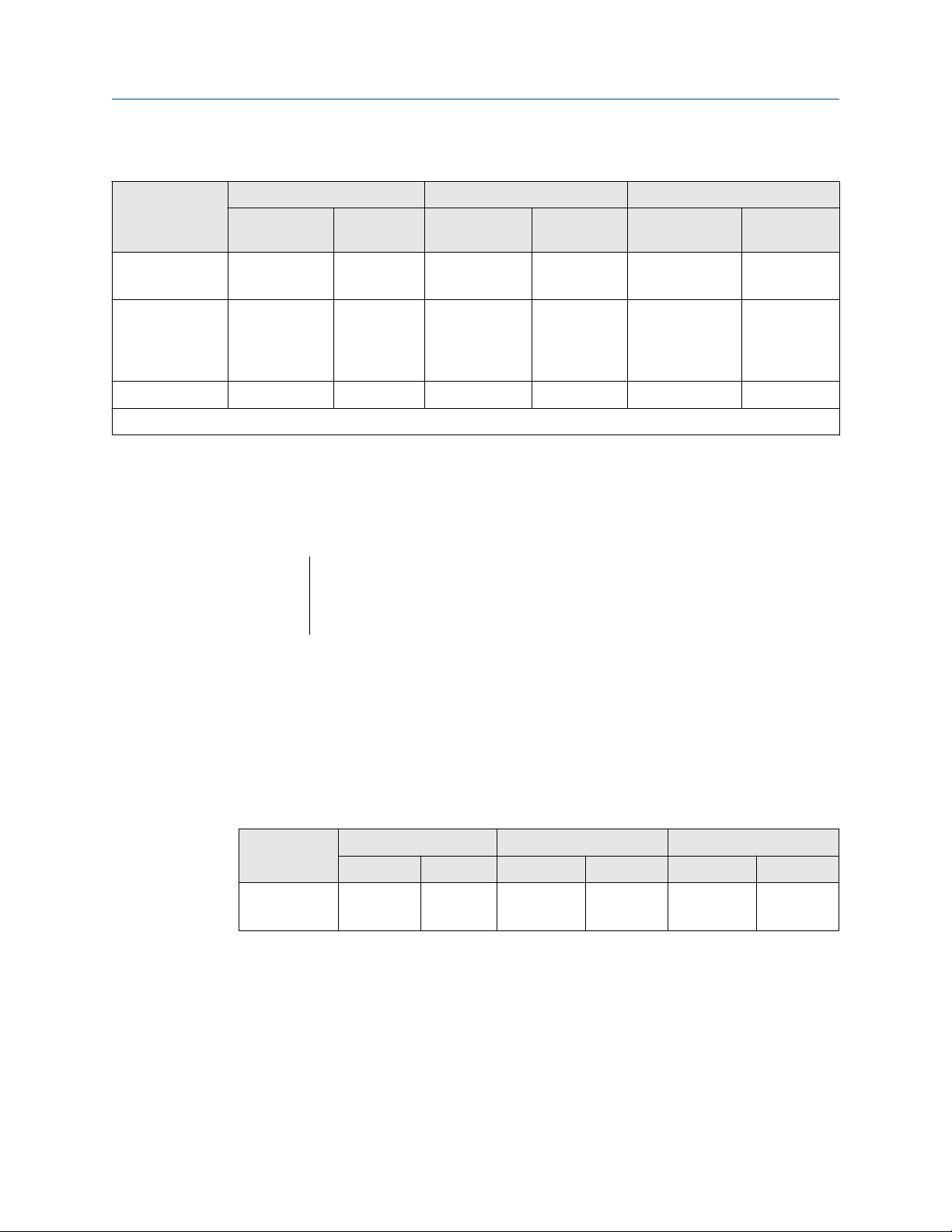

Possible sensor configurations and variable mappings

The AMS 9420 can be installed with two accelerometers, or with one accelerometer with

an embedded temperature sensor. Table 3-2 shows the possible sensor configurations and

variable mappings.

Table 3-2: Possible sensor configurations and variable mappings

Available process variables based on sensor configuration

Dynamic process

variables

Sensor 1: Accelerometer

Sensor 2: Not Installed

Sensor 1 and 2: Accelerometer

with Temperature

Sensor 1: Accelerometer

Sensor 2: Accelerometer

PV

SV

TV

QV

Unmapped device

variables

Overall Velocity Sensor 1 Overall Velocity Sensor 1 Overall Velocity Sensor 1

PeakVue Sensor 1 PeakVue Sensor 1 PeakVue Sensor 1

Bias Sensor 1 Sensor Temperature Overall Velocity Sensor 2

Supply Voltage Supply Voltage PeakVue Sensor 2

Bias Sensor 1

Ambient Temperature

Ambient Temperature

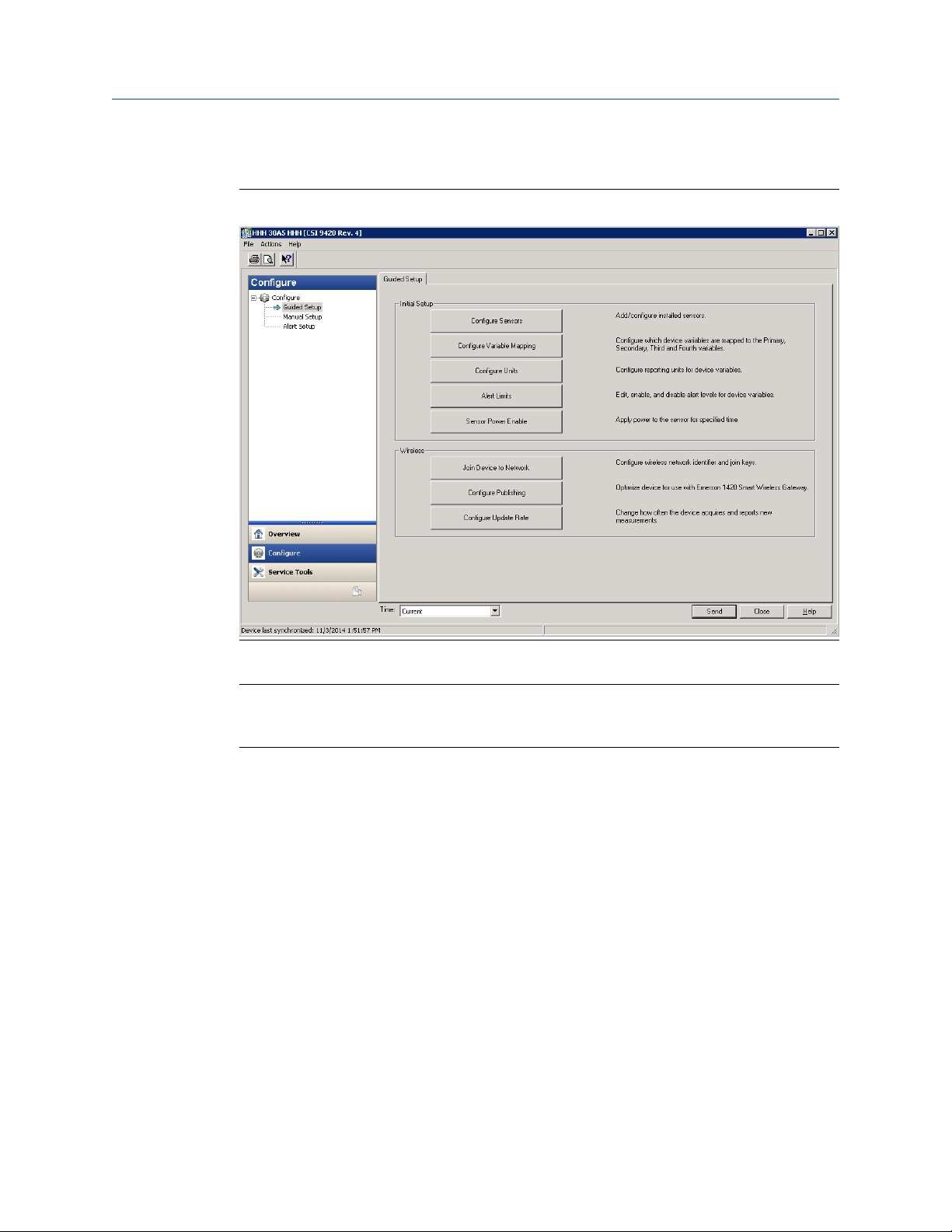

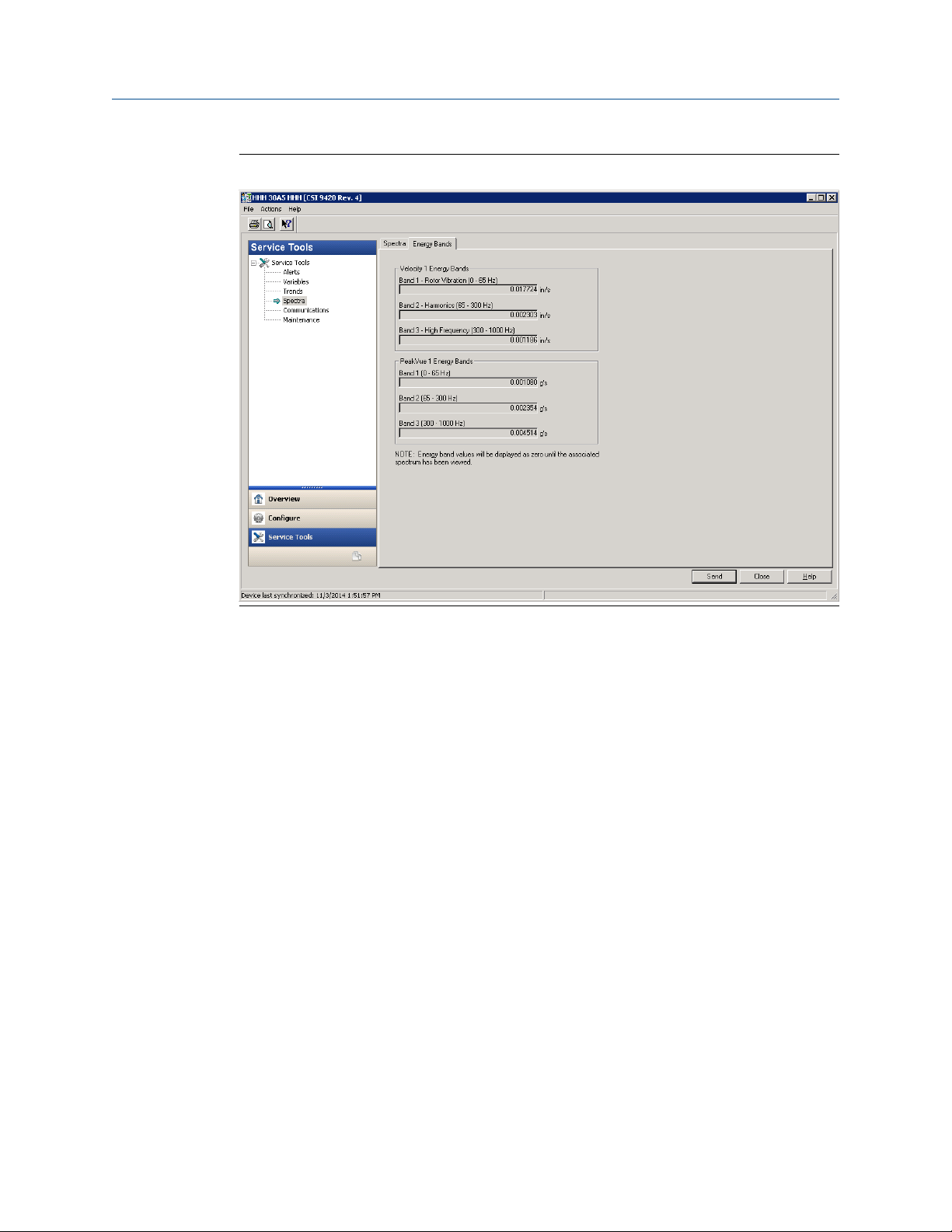

Bias Sensor 1