Page 1

PRM-6

Motor and Phase

Rotation Tester

User Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

PRM-6

Motor and Phase Rotation Tester

Users Manual

4/2015, Rev A

©2015 Amprobe Test Tools.

All rights reserved. Printed in China

English

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

PRM-6 Motor and Phase Rotation Tester

CONTENTS

SYMBOL ............................................................................................................. 3

SAFETY INFORMATION ..................................................................................... 3

UNPACKING AND INSPECTION ......................................................................... 5

USING PHASE SEQUENCE & MOTOR ROTARY TESTER .................................... 5

Determine the Rotary Field Direction ......................................................... 5

Non-Contact Rotary Field Indication ........................................................... 6

Determine the Motor Connection ............................................................... 7

Backlight ....................................................................................................... 8

SPECIFICATIONS ................................................................................................. 8

MAINTENANCE .................................................................................................. 9

Cleaning ........................................................................................................ 9

Replacing and Disposing of the Battery ...................................................... 10

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

PRM-6 Motor and Phase Rotation Tester

9

1

61557-7

61557-7

61557-7

CAT IV 600V

CAT II 1000V

CAT IV 600V

CAT II 1000V

CAT IV 600V

CAT II 1000V

10

11

2

3

4 5

7

8

1

Input terminals for L1 (A), L2 (B), L3 (C)

2

Non-contact motor orientation

symbol and sensor indicator

3

Symbol for L1, L2, L3 indicators

4

Symbol for counter-clockwise

rotation

5

Symbol for clockwise rotation

6

“Warning symbol” for false input

voltage

a

a

a

6

Axm

L1/A

L2/B

6

L3/C

xm

6Axm

6

A

12

7

ON symbol for Non-Contact

Rotary Field Indication

and Determine the Motor

Connection

8

ON button / Backlight

9

Test leads (black, red, yellow)

10

Probe tip cap (black, red, yellow)

11

Test probe (black, red, yellow)

12

Alligator clips (black, red, yellow)

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

SYMBOLS

Caution! Risk of electric shock.

Caution! Refer to the explanation in this manual.

W

The equipment is protected by double insulation or reinforced

T

insulation

Earth (Ground)

J

Measurement category IV (CAT IV) is for measurement

CAT IV

performed at the source of the low-voltage installation.

Examples are electricity meters and measurement on primary

overcurrent protection device and ripple control units.

Orientation symbol for non-contact motor rotary field

indication.

Complies with European Directives.

P

Conforms to relevant Australian standards

Canadian Standards Association (NRTL/C).

)

Do not dispose of this product as unsorted municipal waste.

=

Contact a qualified recycler.

SAFETY INFORMATION

The meter complies with:

IEC/EN 61557-1/-7

IEC/EN 61010-1 3rd Edition, UL61010-1 3rd Ed. and CAN/CSA C22.2 No. 610101-12 to CAT IV 600 V, pollution degree 2

IEC/EN 61010-2-030

IEC/EN 61010-2-31 for test leads

EMC IEC/EN 61326-1

CENELEC Directives

The instruments conform to CENELEC low-voltage directive 2006/95/EC and

electromagnetic compatibility directive 2004/108/EC.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

W

Warning

To prevent possible electrical shock, fire, or personal injury:

• Carefully read all instructions. Read safety information before using or

servicing the tester.

• Comply with local and national safety codes. Use personal protective

equipment (approved rubber gloves, face protection, and flame resistant

clothes) to prevent shock and arc blast injury where hazardous live

conductors are exposed.

• Use the product only as specified, or the protection supplied by the

product can be compromised.

• Do not work alone.

• Consider mechanical risks and risks of rotating mechanical parts. Comply

with local and national safety codes.

• Do not use the tester or test leads if they appear damaged. Examine the

tester and test leads for damaged insulation or exposed metal. Check

test lead continuity. Replace damaged test leads before using the tester.

• Do not touch voltages >30 V AC RMS, 42 V AC peak, or 60 V DC. These

voltages pose electrical shock hazards. Keep fingers behind the finger

guards on the probes and alligator clips.

• To avoid false readings, which could lead to possible electric shock or

personal injury, check the battery and verify operation beforehand on a

known source.

• Do not exceed the Measurement Category (CAT) rating of the lowest

rated individual component of a product, probe, or accessory.

• If the tester is used in a manner not specified in the users manual, the

protection provided by the equipment may be impaired.

• Measurements can be adversely affected by impedances of additional

operating circuits connected in parallel or by transient currents.

• Do not use the PRM-6 with any of the parts removed.

• Disconnect the test leads from energized circuits and from the tester

before opening the battery cover.

• Do not use the product around explosive gas, vapor, or in damp or wet

environments.

• Have the tester serviced only by qualified service personnel.

• Only use the test lead sets provided with the tester. Alternative test

leads may not fulfill the requirements of EN 61557-7.

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

UNPACKING AND INSPECTION

Your shipping carton should include:

1 PRM-6 Motor and Phase Rotation Tester

3 Test leads (black, red, yellow)

3 Test probes (black, red, yellow)

3 Alligator clips (black, red, yellow)

2 1.5V AAA battery (installed)

1 Users manual

1 Carrying case

If any of the items are damaged or missing, return the complete package to

the place of purchase for an exchange.

USING MOTOR AND PHASE ROTATION TESTER

Determine the Rotary Field Direction

To determine the rotary field direction:

1. Connect one end of test leads to the tester’s corresponding terminals L1,

L2, and L3.

2. Connect the alligator clips or the test probes to the other end of the test

leads.

3. Connect the alligator clips/test probes to the three mains phases.

4. L1, L2 and L3 indicators shows voltage is present.

5. The clockwise or counter-clockwise rotary indicator shows the type of

rotary field direction present.

6. If the “Warning Symbol” illuminates, either one or two of the inputs are

connected to the neutral conductor or the voltage difference between

the phases exceed 30% phase to phase or 65% between phase to

neutral.

Note:

• The PRM-6 is powered by the motor or system being tested.

• In environment with poor light condition you can switch on the

Backlight while pressing and hold button “ON” to improve visibility.

W

Warning

The rotary indicator L1, L2 and L3 lights even if the neutral conductor, N, is

connected instead of L1, L2, or L3. Refer to Figure 1 for more information

about what appears on the back of the PRM-6).

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

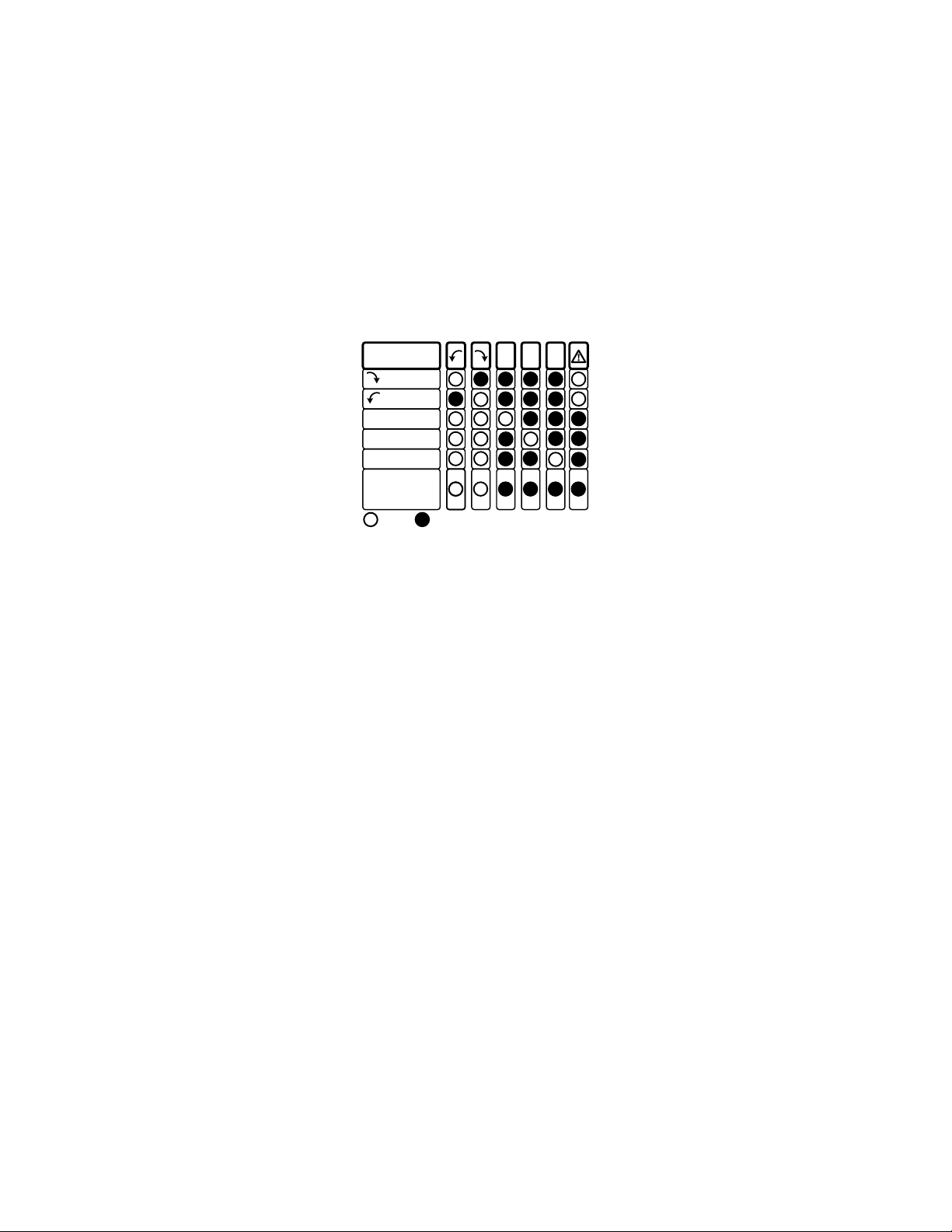

DISPLAY

CORRECT

R

L

FALSE

L R

L1AL2BL3

C

L1 MISSING

L2 MISSING

L3 MISSING

ONE INPUT

CONNECTED

TO N OR PE

OFF ON

Figure 1: Phase indication table

(also printed on the back of the PRM-6)

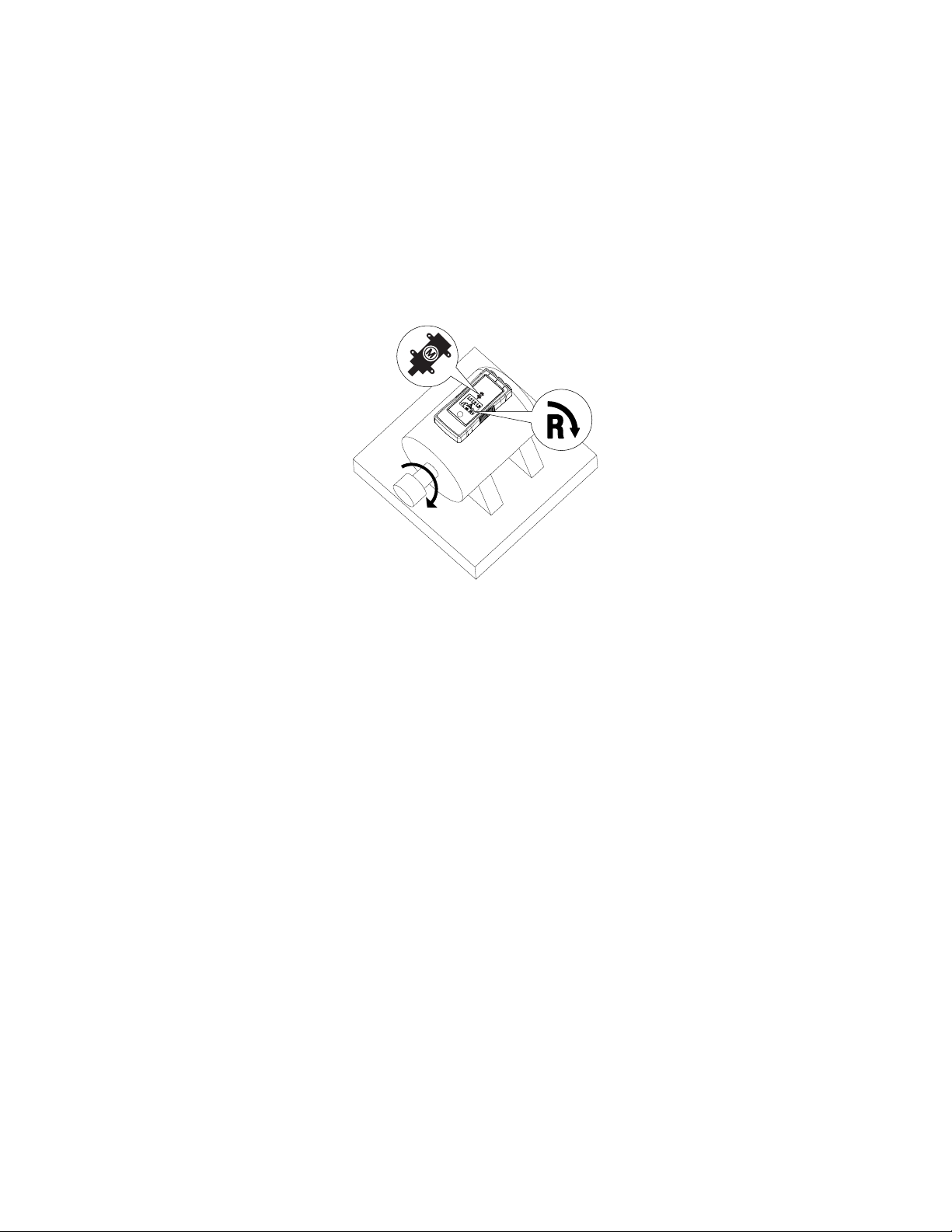

Non-Contact Rotary Field Indication

For non-contact rotary field indication:

1. Disconnect all test leads from the PRM-6 for safety reason.

2. Position the PRM-6 on the motor so it is parallel to the length of the

motor shaft. The sensor of the tester should be in the center of the

motor windings. The tester should be as close as possible to the motor.

See Figure 2.

3. Press and hold the ON button. The LC display shows “ON,” indicating the

PRM-6 is ready for testing.

4. Either the clockwise or counter-clockwise rotary indicator will illuminate,

showing the type of rotary field direction present.

If the LC display don’t show the “ON” symbol, while pressing the ON button,

the battery does not have a charge and needs to be replaced.

WThe Indicator will not operate with motor controlled by frequency

converters. The bottom of the PRM-6 should be oriented towards the drive

shaft. See the Orientation Symbol on the PRM-6.

If the motor was disconnected from electricity for a long time (typically one

year), the residual field / magnetization may be too weak for the tester to

measure the rotation.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Figure 2: Motor Rotation

Determine the Motor Connection

1. Connect one end of test leads to the tester’s corresponding terminals L1,

L2, and L3.

2. Connect the alligator clips or the test probes to the other end of the test

leads.

3. Connect the alligator clips or test probes to the motor connections, L1 to

U, L2 to V, L3 to W.

4. Press the ON button. The LC display shows “ON,” indicating the PRM-6 is

ready for testing.

5. Turn the motor shaft towards the right.

6. Either the clockwise or counter-clockwise rotary indicator will illuminate,

showing the rotary field direction.

If the LC display don’t show the “ON” symbol, while pressing the ON button,

the battery does not have a charge and needs to be replaced.

Note: If you get a another indication of the rotary field direction as expected

then swap two connection from step 3 and repeat testing. Use the new order

of U (L1), V (L2) and W (L3) for further purpose

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Backlight

The backlight is turned on while pressing and hold button “ON” and it is

powered by the battery.

If the backlight don’t illuminate the battery does not have a charge and

needs to be replaced.

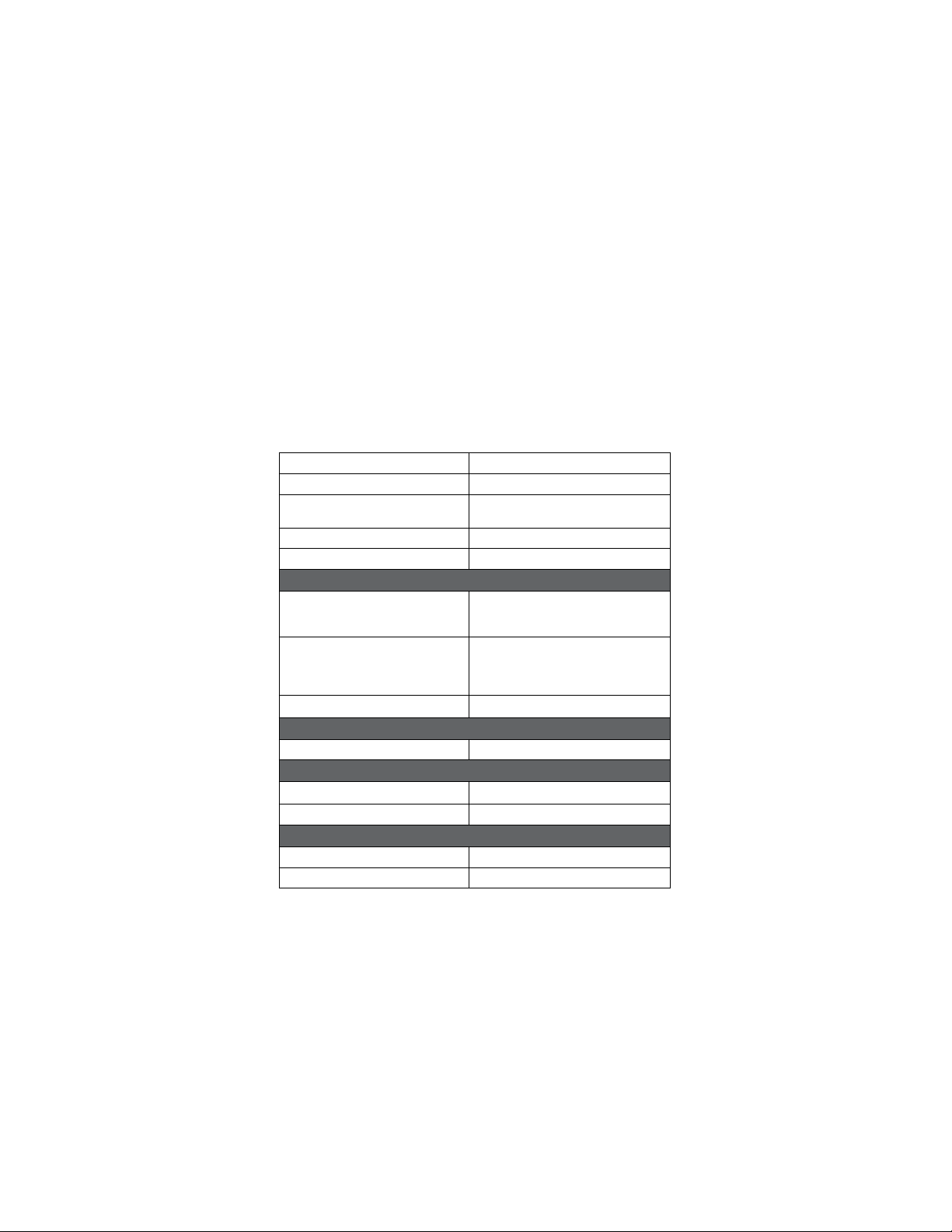

SPECIFICATIONS

3 phase indication

Indication of phase rotation

Indication of motor rotation direction

Non-contact rotary field indication

Determine the motor connection

LC display backlight

Via LCD

Via LCD

Via LCD

Via LCD

Yes

Determine Rotary Field Direction

Frequency range (fn) /

Voltage range (Ume)

Indicaton for false input voltage

Nominal test current (In in per phase)

16...60 Hz / 40...700V AC phase to phase

>60...400 Hz / 50...700V AC phase to

phase

difference of > ±30% between the

phase to phase voltages

(> ± 65% between phase to neutral

voltages)

≤ 3.5 mA

Non-Contact Rotary Field Indication

Frequency range (fn)

16 to 400 Hz

Determine the Motor Connection

Voltage range (Ume)

Frequency range (fn)

≥ 1 V AC phase to phase

2 to 400 Hz

General Specifications

Operating time

Operating temperature

Continuous

O

C to 40OC (32OF to 104OF)

0

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Operating altitude

Humidity (Without condensation)

Storage conditions

Power supply

Battery life

Dust/water resistance

Pollution degree

Dimensions (H x W x D)

Weight

Product Standard

Electrical safety

Overvoltage category

EMC

Agency approvals

Up to 2000 m

≤ 80% RH

O

C to 40OC (32OF to 104OF), ≤ 80% RH

0

2 x 1.5 V AAA alkaline battery

Minimum 2 years for average use

IP 40

2

137 x 65 x 33 mm (5.43 x 2.56 x 1.3 in)

170 g (0.38 lb) (battery installed)

EN 61557 -1/-7

EN 61010-1, EN 61557-7

CAT IV 600 V

Conforms to EN 61326-1

)

P

MAINTENANCE

W

Caution

To prevent damage to the PRM-6:

• Do not attempt to repair or service the PRM-6 unless qualified to do so.

• Make sure that the relevant calibration, performance test, and service

information is being used.

• Do not use abrasives or solvents. Abrasives or solvents will damage the

PRM-6 case.

Cleaning

The only maintenance the PRM-6 requires is inspection and cleaning.

Periodically wipe the case with a mild solution of detergent and water. Apply

sparingly with a soft cloth and allow to dry completely before using. Do not

use aromatic hydrocarbons, gasoline or chlorinated solvents for cleaning.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Replacing and Disposing of the Battery

W

Warning

• To avoid electric shock, disconnect the test leads from the source before

opening the PRM-6 for battery replacement.

• To avoid false readings, which could lead to possible electric shock or

personal injury, replace the battery as soon as the battery is low or

dead.

=

Note: The PRM-6 contains alkaline battery. Do not dispose of the battery

with other solid waste.

Used batteries should be disposed of by a qualified recycler or hazardous

materials handler. Contact your authorized Amprobe Service center for

recycling information.

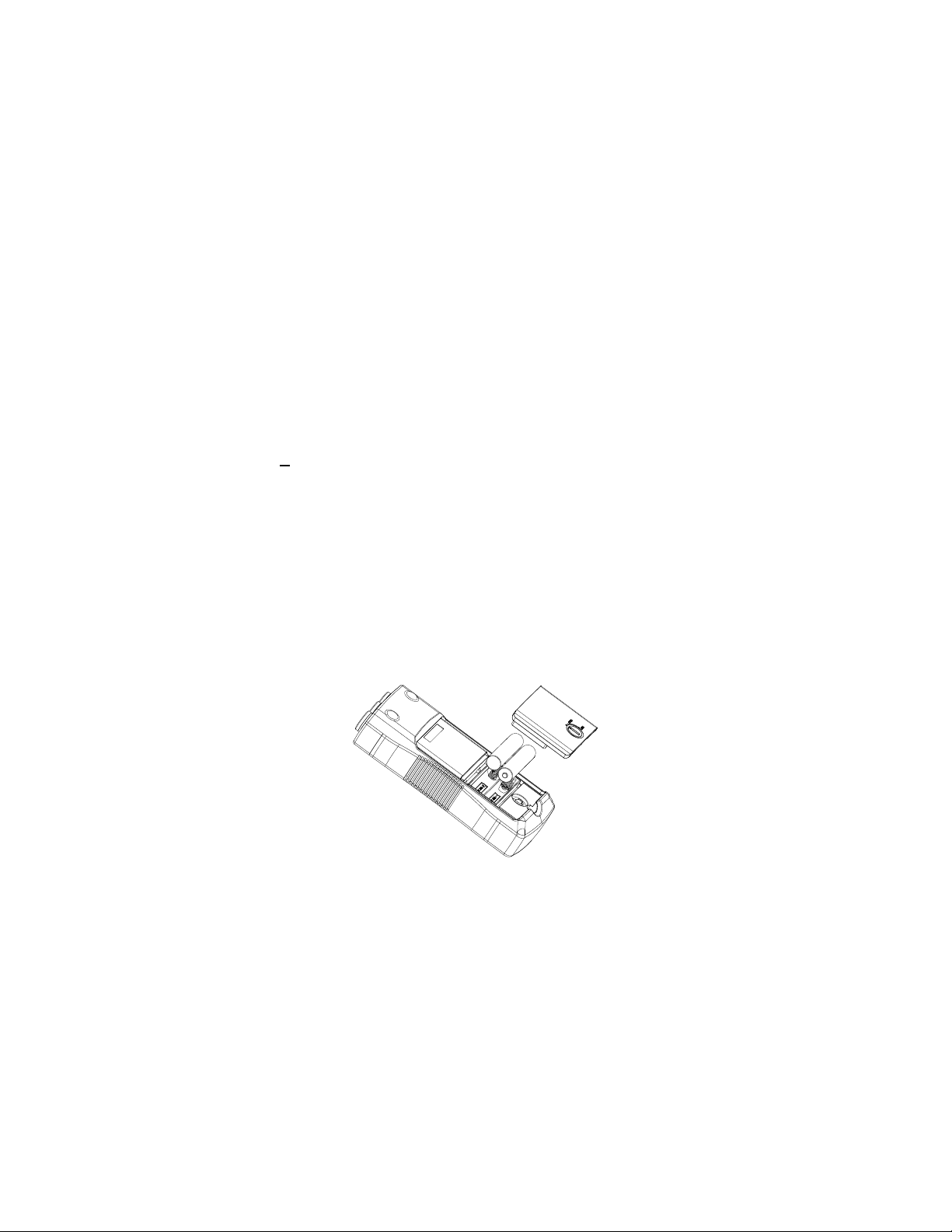

The PRM-6 uses two 1.5 V AAA batteries (supplied). To replace the batteries,

follow these steps and refer to Figure 3:

1. Disconnect test leads from any power source.

2. Place the PRM-6 face down on a nonabrasive surface and loosen the

battery-door lock with a flat screwdriver.

3. Lift the battery cover away from the PRM-6.

4. Replace the batteries as shown in Figure 3. Observe the battery polarity

shown in the battery compartment.

5. Replace the battery cover to the lock position.

AAA

AAA

Figure 3: Replacing batteries

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...