Page 1

User’ Manual

MultiTest 2000

Release EN 1.00 of the 05/09/2002

© Copyright Amprobe 2002

Page 2

AMPROBE

MULTITEST2000

INDEX

1. SAFETY PRECAUTIONS AND PROCEDURES.......................................................................................... 1

1.1. Forwards................................................ ......................................................................................................................1

1.2. Preliminary Instruction.................... .. ... .. .. ..... .. ... .. .. ... .... ... .. ... .. .. ... .... ... .. .. ... .. .. ..... .. ... .. .. ... .............................................2

1.3. During Use............................................................................................................................. ......................................3

1.4. After Use......................................................................................................................................................................4

2. GENERAL DESCRIPTION........................................................................................................................... 5

2.1. Introduction............................................................................. .....................................................................................5

2.2. Functions.....................................................................................................................................................................5

3. PREPARATION FOR USE.................................................... ....................................................................... 7

3.1. Initial Control................................................................................................................................................................7

3.2. Power Supply..............................................................................................................................................................7

3.3. Calibration...................................................................................................................................................................9

3.4. Storage.................................................................................................................................... ....................................9

4. INSTRUMENT DESCRIPTION... ... .... ... .... ....... .... ... .... ... .... ....... .... ... .... .... ... ....... .... .... ... .... ... ........ ... .... .........11

4.1. Display Description...................................................................... ............................ ................................. .................13

4.2. Initial Screen................................................................................................................................. .............................13

4.3. Backlight function......................................................................................................................................................14

5. INITIAL SETTINGS............................... ..................................................................................................... ..15

5.1. How To Adjust The Contrast........................................................................................................................... ..........15

5.2. How To Set Date And Time ................................ ......................................................................................................15

5.3. How To Set The Language........................................ ...............................................................................................16

5.4. How To Adjust The Country......................................................................................................................................16

5.5. RESET........................................................................... ............................................................................................17

6. SAFETY TEST FUNCTIONS.......................................................................................................................19

6.1. LOWΩ: Continuity Test with 200mA Test Current...................................................................................................19

6.1.1. Calibrating the test leads ("CAL" Mode).........................................................................................................................21

6.1.2. Measurement Procedure................................................................................. .... .... .......................................................24

6.1.3. Results of "AUTO" mode................................................................................................................................................25

6.1.4. Results of "RT+" and "RT-" modes.................................................................................................................................26

6.1.5. "AUTO", RT+", "RT-" faulty cases...................................................................................................................................27

6.2. MΩ: Insula t io n r e s is t a n c e Me a s u re m e n t w i th 5 0 V , 10 0 V , 2 50 V , 5 00 V , 1 0 00 V T e st V o l t a g e...................................... .30

6.2.1. Measurement Procedure................................................................................. .... .... .......................................................30

6.2.2. Results of "MAN" mode..................................................................................................................................................34

6.2.3. Results of "TMR" mode............................................... ..... .................................................... ...........................................36

6.2.4. "MAN" and "TIMER" mode faulty cases................................................... .... .... ...............................................................38

6.3.

6.4. EARTH: Soil Resistance and Resistivity Measurements.........................................................................................44

: Phase Sequence Indicator................................................................................................................................39

6.3.1. Measurement procedure and results of " " mode............................................... .... .... ...............................................39

6.3.2. LOOP Faulty Cases.................................................................................................................................................42

6.4.1. Measurement procedure and results of "2-W"and "3-W" mode....................................................... .... ...........................45

6.4.2. Measurement procedure and results of "ρ" mode......................................................................................... .... .... ....... 48

6.4.3. "2-W", "3-W" and "ρ" faulty cases.................................................................................................................................50

7. AUX: MEASUREMENT WITH EXTERNAL PROBES.................................... .... ... .... ....... .... ... .... ... .... ... .... ..54

7.1. ENVIRONMENTAL PARAMETER AND LEAKAGE CURRENT: REAL TIME MEASUREMENT...........................55

7.2. ENVIRONMENTAL PARAMETER AND LEAKAGE CURRENT: RECORDING.....................................................59

7.2.1. AUX Basic setting: RECORDER CONFIG....................................................................................... ...............................59

7.3. SOUND LEVEL MEASUREMENT PROCEDURE ............. ....................................................... ...............................63

8. ANALYZER .................................................................................................................................................67

8.1. Basic Setting: ANALYZER CONFIG.........................................................................................................................69

8.1.1. Type of electrical system under test...............................................................................................................................69

8.1.2. How to set the fundamental frequency........................................................................................................................... 69

8.1.3. How to set the current range..........................................................................................................................................70

EN-1

Page 3

AMPROBE

MULTITEST2000

8.1.4. How to set the Clamp Type.............................................................................................................................................71

8.1.5. How to set the value of the transformer voltage ratio (TV RATIO).................................................................................71

8.1.6. How to enable/disable the password..............................................................................................................................71

8.2. Basic Setting: RECORDER CONFIG ................................................................ ............................ ...........................73

8.3.

ANALYZER FUNCTIONS.........................................................................................................................................86

8.4. "VOLTAGE" Function................................................................................................................................................88

8.4.1. Symbols.......................................................................................................................................................................... 88

8.4.2. "METER" mode...............................................................................................................................................................89

8.4.3. "HARM" mode.............................................................................. .... ...............................................................................91

8.4.4. "WAVE" mode.................................................................................................................................................................93

8.5. "CURRENT" Function...............................................................................................................................................95

8.5.1. Symbols.......................................................................................................................................................................... 95

8.5.2. “METER" mode...............................................................................................................................................................96

8.5.3. “HARM" mode.................................................................................................................................................................98

8.5.4. "WAVE" mode...............................................................................................................................................................100

8.6. "POWER" Function .................................................................................................................................................102

8.6.1. Symbols........................................................................................................................................................................ 102

8.6.2. "METER" mode.............................................................................................................................................................103

8.6.3. "WAVE" mode...............................................................................................................................................................105

8.7. "ENERGY" Function................................................................................................................................................107

8.7.1. Symbols........................................................................................................................................................................ 107

8.7.2. "METER" mode.............................................................................................................................................................108

8.8. Measuring Procedures............................................... .. ... .... ... .. ... .. .. ... .... ... .. .. ... .. .. ... .... ... .. .. ... ..................................110

8.8.1. Using the Instrument in a Single Phase System........................................................................................................... 110

8.8.2. Using the Instrument in a Three Phase System........................................................................................................... 111

9. SAVING RESULTS.................................................................................. ..................................................113

9.1. Saving Safety Test Results......................................................... ............................................................................113

9.2. Saving DisplAyed Values of ANALYZER Function ............... .................................................................................114

10. RECORDINGS...........................................................................................................................................115

10.1. Start A Recording....................................................................................................................................................115

10.2. During A Recording............................................................................................ .....................................................118

10.2.1. MENU key.....................................................................................................................................................................119

10.2.2. Rotary Switch during a recording.................................................................................................................................. 120

10.3. Stopping A Recording Or An Energy Measurement............................................ .......................... .........................120

11. INSTRUMENT'S MEMORY............................................................................... ........................................122

11.1. SAFETY TEST MEMORY..................................... ... .. .. ..... ... .. .. ... .. ..... .. .. ... .. .. ..... .. ... .. .. ... .... ... .. ... .. ...........................122

11.2. ANALYZER MEMORY............................................................................................................................................124

12. CONNECTING THE INSTRUMENT TO A PC............ ...............................................................................126

13. MAINTENANCE ........................................................................................................................................128

13.1. General Instruction................................................ ... .. .. ... .. ..... .. ... .. .. ... .... ... .. .. ... .. ..... .. .. ... .. .......................................128

13.2. Battery Replacement .................................................................................................................................... ...........128

13.3. Instrument Cleaning................................................................................................................................................129

14. TECHNICAL SPECIFICATIONS ........................................................................ ... .... ... ........ ... .... ... ...........130

14.1. Technical Features..................................................................................................................................................130

14.1.1. Safety Test functions....................................................................................................................................................130

14.1.2. ANALYZER and AUX functions....................................................................................................................................132

14.2. Standards............................................................ ............................ ............................. ...........................................134

14.2.1. General.........................................................................................................................................................................134

14.2.2. Safety Test.................................................................................................................................................................... 134

14.2.3. ANALYZER...................................................................................................................................................................134

14.2.4. AUX ..............................................................................................................................................................................134

14.3. General Specifications................................................. ... .. .. ... ..... .. .. ... .. .. ..... .. ... .. .. ... .... ... .. .. ................................. ....135

14.3.1. Mechanical Data...........................................................................................................................................................135

14.3.2. Power supply................................................................................................................................................................135

14.3.3. Display.......................................................................................................................................................................... 135

14.3.4. Memory.........................................................................................................................................................................135

14.4. ENVIRONMENT.................................................................................................................... ..................................135

14.5. ACCESSORIES ...................................... ............................. ............................ .......................................................137

EN-2

Page 4

AMPROBE

MULTITEST2000

15. SERVICE..................................................................................................................................... ..............138

15.1. WARRANTY CONDITIONS............................................ .................................................................................. ......138

15.2. SERVICE............................................................................................................ .....................................................139

16. PRACTICAL REPORTS FOR ELECTRICAL TESTS ............................................... ... .... .... ... .... ... .... ... ....140

16.1. Continuity Test On Protective Conductors .............................................................................................. ...............140

16.2. Check Of The Circuit Separation...................................................................................................................... ......143

16.3. Measurement Of Floor Insulation Resistance In Medical Rooms Cei 64-4...........................................................149

16.5. Earth Resistivity Measurement................................................................... ............................................................153

16.6. Voltage Anomalies (Voltage Sag and Surge)........................ .......................... .......................... .............................156

16.7. Voltage and current Harmonics ................... .. ... .. .. ... .. ... .... ... .. .. ... .. .. ... .. ..... .. .. ... .. .. ... .. ..... .. ... .. .. ... .............................157

16.7.1. Theory........................................................................................................................................................................... 157

16.7.2. Limit values for harmonics............................................................... .... .........................................................................160

16.7.3. Presence of harmonics: causes............................................................................... .... .... .............................................160

16.7.4. Presence of harmonics: consequences............................................... .... .... ................................................................. 161

16.8. Power and Power Factor definition.................................................................. .......................................................162

16.8.1. Conventions on powers and power factors.............................................................. .....................................................166

16.8.2. 3 Phase 3 Wire System.................................................. ..............................................................................................168

16.9. Measuring Method: outlines....................................................................................................................................170

16.9.1. Integration periods.................................................. ...................................................................................................... 170

16.9.2. Power factor calculations..............................................................................................................................................170

17. APPENDIX 1 – MESSAGES DISPLAYED................................................................................................172

18. APPENDIX 2 – RECORDABLE PARAMETERS: SYMBOLS...................................................................174

Z:\bkp\manuali\Sirius - MultiTest\Manuali\M_MultiTest2000_EN1_00.doc

EN-3

Page 5

AMPROBE

MULTITEST2000

1. SAFETY PRECAUTIONS AND PROCEDURES

1.1. FORWARDS

This instrument conforms to the safety standards EN61557 and EN 61010-1 relating to

electronic measuring instruments.

ν

WARNING:

Strictly adhere to the following instructions before and during measurements:

Do not measure voltage or current in wet or dusty places;

Do not measure in presence of gas, explosive materials or combustibles;

Do not touch the circuit under test if no measurement is being taken;

Do not touch exposed metal parts, unused terminals, circuits and so on;

Do not effect any measurement in case of unusual conditions of the instrument such as

deformation, breakage, leakage of substances, absence of display readi ng etc;

Do not use the External power supply adapter (optional code A0050) if you notice

deformation, or breakage in the case, in the wire or in the plugs;

Pay careful attention when measuring voltages exceeding 25V in particular places

(building yards, swimming pools, etc.) and 50V in ordinary places because of the risk of

electric shock;

Use only cables and accessories approved by Amprobe;

The following symbols are used in this manual:

Caution: refer to the instructions in this manual; improper use may damage the

apparatus or its components.

For your own safety as well as that of the instrument you are

recommended to follow the procedures described in this

instruction manual and carefully read all the notes preceded by

the symbol

.

Page 6

AMPROBE

Ο

1.2. PRELIMINARY INSTRUCTION

This instrument has been designed for use in environments with a pollution level 2 and

up to (and no more than) 2000 meters altitude.

It can be used for Safety Test on Installation with Over voltage Category III 300V~

(phase to earth) and for voltage and current measurements on installations with over

voltage category III 600 V~ phase-to-phase / 300 V~ phase to earth or CATII 350 V

phase to earth.

AC Voltage or Current.

Unidirectional pulsating Voltage or Current.

Rotary switch of the instrument.

MULTITEST2000

Page 7

AMPROBE

Please keep to the usual safety standards aimed at:

♦ Protecting against dangerous currents;

♦ Protecting the instrument against incorrect operations.

Only the accessories supplied with the instrument guarantee compliance with the

safety standards. Accordingly, they must be in good conditions and, if necessary, they

must be replaced with identical models.

Do not take measurements on circuits exceeding the specified current and voltage

limits.

Before connecting cables, alligator clips and clamps to the circuit under test, make sure

that the right function has been selected.

Do not take any measurements under environmental conditions beyond the limits

specified in paragraph 14.4.

Check that batteries are not weak and are installed correctly.

Before connecting test leads to the circuit under test, check that rotary switch position

is correct.

1.3. DURING USE

Please read the following recommendations carefully and instructions:

MULTITEST2000

ν

WARNING:

Before selecting any function disconnect the test leads from the circuit under test.

When the instrument is connected to the circuit under test do not touch any unused

terminal.

Avoid taking resistance measurements in the presence of external voltages; even

though the instrument is protected, a high voltage may cause malfunctions.

When measuring current, other currents located near the leads may affect the

measuring accuracy.

Non-compliance with the Warnings and/or Instructions may

damage the apparatus and/or its components or injure the

operator.

Page 8

AMPROBE

When measuring current, always position the wire in the middle of the jaws in order to

obtain the highest accuracy.

A measured value remains constant if the "HOLD" function is active. Should you notice

that the measured value remains unchanged, disable the “HOLD” function.

ν

WARNING:

1.4. AFTER USE

• After use, turn off the instrument by pressing & holding ON/OFF for a few seconds.

• Remove batteries wh en the apparatus remain s unused for long periods. Plea se follow

the storage instructions described at paragraph 14.4.

MULTITEST2000

The symbol " " shows the battery charge: When it is

completely black the batteries are full charged, while the "

symbol indicates weak batteries. When the batteries are too low

to execute a test, the instrument will show a warning message.

In this case, interrupt testing and replace batteries, following the

procedure described in paragraph 13.2. The instrument is

capable of keeping the data stored even though batteries are

not installed. The Instrument Date and Time settings aren't lost

if you change the batteries within 24hours.

"

Page 9

AMPROBE

MULTITEST2000

2. GENERAL DESCRIPTION

2.1. INTRODUCTION

Dear Customer, we thank yo u for you r patrona ge . The instrume nt you ha ve ju st purch ased

will grant you accurate and reliable measurements provided that it is used according to the

present manual’s instructions.

The instrument was designed to grant the user the utmost safety conditions thanks to a

new concept assuring double insulation and over voltage category III.

2.2. FUNCTIONS

The instrument is able to perform the following tests:

LOWΩ: Continuity Test of Protection and Equalising conductors with a test current

higher than 200mA and open circuit volt age ranging from 4V to 24V.

MΩ: Measurement of insulation resistance with DC test voltage 50V, 100V,

250V, 500V or 1000V.

: Indication of phase rotation sequence

EARTH Measurement of Earth Resistance and Resisivity using Earth rods.

AUX: Measurement and Recording of leakage current or environmental values

(temperature, humidit y, Air Speed, Luminance a nd Sound lev el).

ANALYZER: The Instrument allows the followin g operations:

Display in real time the electrical parameters of a single-phase

systems and the harmonic analysis of voltage and current.

Conduct a direct Energy measurement (without memorizing).

Memorize (by pressing the SAVE key) the sampled values of the

Parameters present at instrument input generating a "Smp" record

inside instrument memory. It will be possible to analyze the

memorized data ONLY by transferring it to a PC.

Record simultaneously (pressing the START key after a proper set

up): RMS values of voltage, current, corresponding harmonics, active,

reactive and apparent powers, power factors and cosϕ, active,

reactive and apparent energies, voltage anomalies (voltage sag and

surge) with 10ms resolution. It will be possible to analyze the

recorded data ONLY by transferring them to a PC.

Page 10

AMPROBE

MULTITEST2000

CAUTION

Please note the difference between memorize and record. These terms

will be used repeatedly in this manual. Please focus on their de finitions and

distinctions.

Page 11

AMPROBE

MULTITEST2000

3. PREPARATION FOR USE

3.1. INITIAL CONTROL

This instrument has been checked mechanically and electrically prior to shipment.

Care has been taken to ensure that the instrument reaches you under safe conditions.

You are recommended, however, to carry out a rapid check to detect any possible

damage, which might have been caused during transport. Should this be the case,

immediately contact Amprobe.

Also, check that the packagi ng contains all the parts listed und er paragraph 14.5. In case

of discrepancies contact the dealer.

In case you have to send the instrument back please follow the instructions reported in

paragraph 15.

3.2. POWER SUPPLY

The instru ment can be pow e red by:

6 batteries 1.5V AA series located in the compartment on the back of the instrument

(not included in the package). For battery life see paragraph 14. 3.1.

An external power supply adapter (optional code A0050) to be used only for

ANALYSIS and AUX functions. We recommend that you use only A0050 HT Power

Supply adapter.

For your own safety you’re not able to use the external power supply adapter during

Safety Test (LOWΩ, MΩ,

button the Instrument will show the message "ν REMOVE POWER".

The symbol

shows the battery charge: If it is completely "black" the batteries are

fully charged, while the

low to execute the test the instrument will show a warning message. In this case interrupt

,EARTH rotary Switch positions). If you press the START

symbol indicates weak batteries. When the batteries are too

Page 12

AMPROBE

MULTITEST2000

testing and replace the batteries following the procedure described in paragraph 13.2. The

instrument is capable of keeping the data sto red eve n though batte ries are not insta lle d.

The Instrument Date and Time settings aren't lost if you change the batteries within

24hours.

Page 13

AMPROBE

MULTITEST2000

CAUTION

For recordings (ANALYSIS and AUX function) ALWAYS use the external

power supply adapter (optional code A0050) even the instrument allows the

operator to perform a recording using internal batteries. If during a recording

the external power supply adapter is de-energized, the instrument will

continue the recording using the internal battery power until the batteries

are exhausted (the data stored up to the point the instrument shuts down

won’t get lost). Because of this we recommend you ALWAYS insert a new

set of batteries before a long recording.

The instru ment uses soph i sticated al gorithms to prolong the battery life. Specifically:

The instrument switches OFF the backlight Automatically after 5 seconds.

If the instrument is displaying in real time (and the external power supply adapter is not

connected), after about 5 minutes from the last key press or switch rotation the

instrument turns off automatically ("AUTOPOWER OFF" procedure).

If the instrument is recording or is measuring energy (and the external power supply is

not connected), after about 5 minutes from the last key press or switch rotation the

instrument starts a special procedure to save the batteries ("ECONOMY MODE"): the

instrument keeps recording but the display is turned off.

3.3. CALIBRATION

The instrument fulfils the technical specifications listed in this manual. The performance of

the specifications is guaranteed for one year.

3.4. STORAGE

In order to maintain the accuracy of the measurements, after a period of storage in

extreme environmental conditions, wait the necessary time for the apparatus to return to

normal operating conditions (see environmental specifi cations listed in parag rap h 14.4).

Page 14

AMPROBE

MULTITEST2000

Page 15

AMPROBE

MULTITEST2000

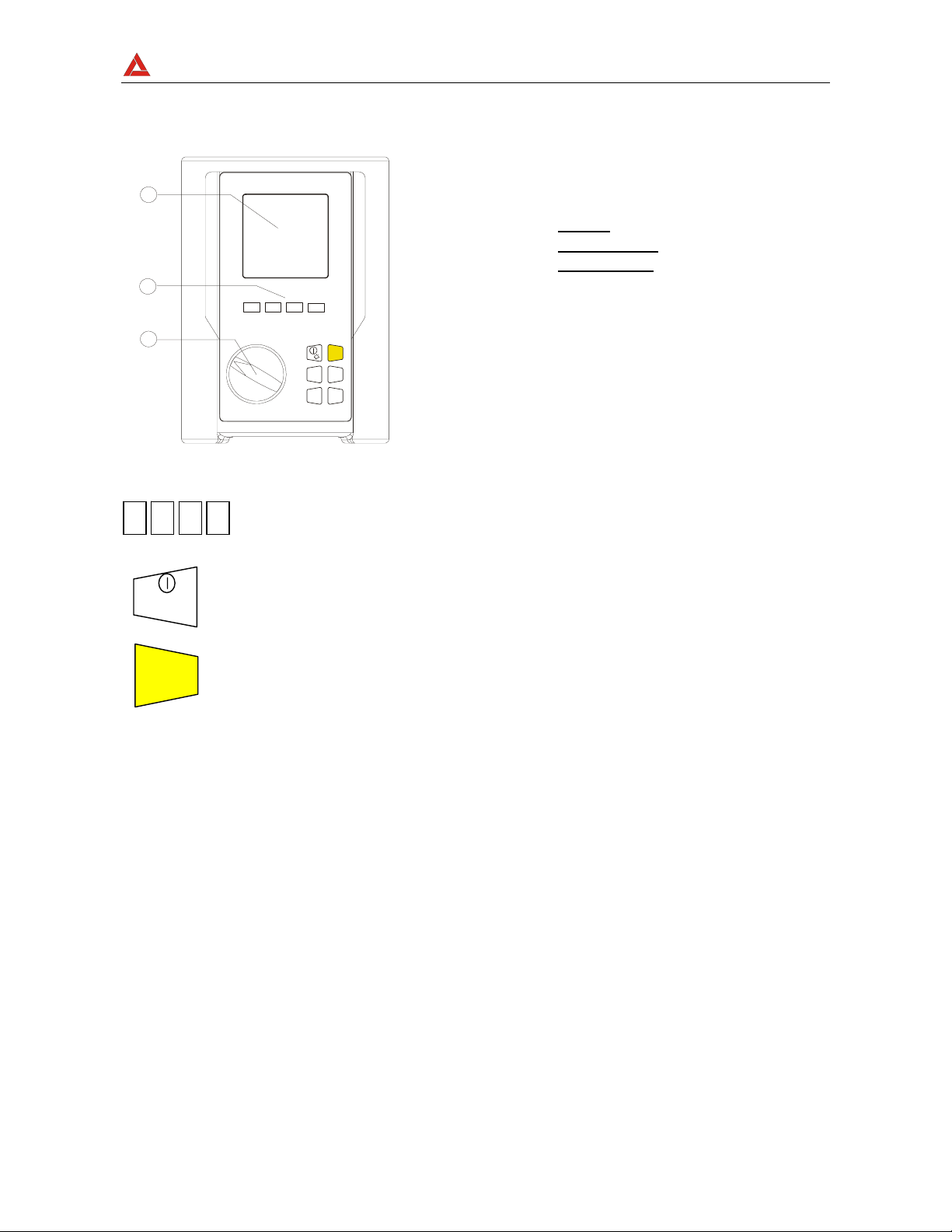

4. INSTRUMENT DESCRIPTION

LEGEND:

1

2

F1 F3F4F2

1.

Display

Function Keys

2.

3.

Rotary swit ch

F1

ON

START

3

F2 F4 F3

/

OFF

STOP

START

STOP

HOLD

SAVE

ENT ER

MENU ESC

Front panel of the Instrument

Multifunction Keys.

ON/OFF and backlight key. Press it for few seconds to switch OFF the

instrument, press it briefly to activate the backlight function.

This key starts (and stops) the measurements.

Page 16

AMPROBE

MULTITEST2000

This key saves the result displayed.

SAVE

HOLD

ENTER

This key has 2 functions: it is the confirmation key inside the

configuration menu and it freezes the displayed results using the

ANALYZER function.

MENU

This key opens the General Configuration Menu.

ESC

This key cancels modification in the configuration menus or the selected

working modes.

Page 17

AMPROBE

MULTITEST2000

4.1. DISPLAY DESCRIPTION

The display is a graphic module with a resolution of128 x 128 pixels

The first line of the display shows date and time. If not correct, you can set the exact ones

according to the procedure described at paragraph 5.2.

On the top right corner of the display you can always see the battery indicator and, if the

external power supply adapter (optional code A0050) is connected, the corresponding

symbol.

LOWΩ 05.06.01

----Ω

R+ R-

----Ω ----Ω

---mA ---mA

AUTO 0.11Ω

FUNC CAL

27.09.00 17:35:12

SINGLE PHASE

V1 = 230.2 V

Vpk1 = 325.5 V

ThdV = 0.0 %

freq = 50.0 Hz

HARM WAVE

VOLTAGE

These symbols will be omitted in the following illustrations.

4.2. INITIAL SCREEN

When turning on the instrument by pressing ON/OFF, this screen will appear for a few

seconds:

MT 2000

AMPROBE

SN:00000000 V: X.XX

Page 18

AMPROBE

MULTITEST2000

BAUD RATE 57600

Here you can see:

• Serial number of the instrument (SN.:)

• Firmware software release (V.X.XX:)

• Transmission speed through serial RS232 (Baud Rate)

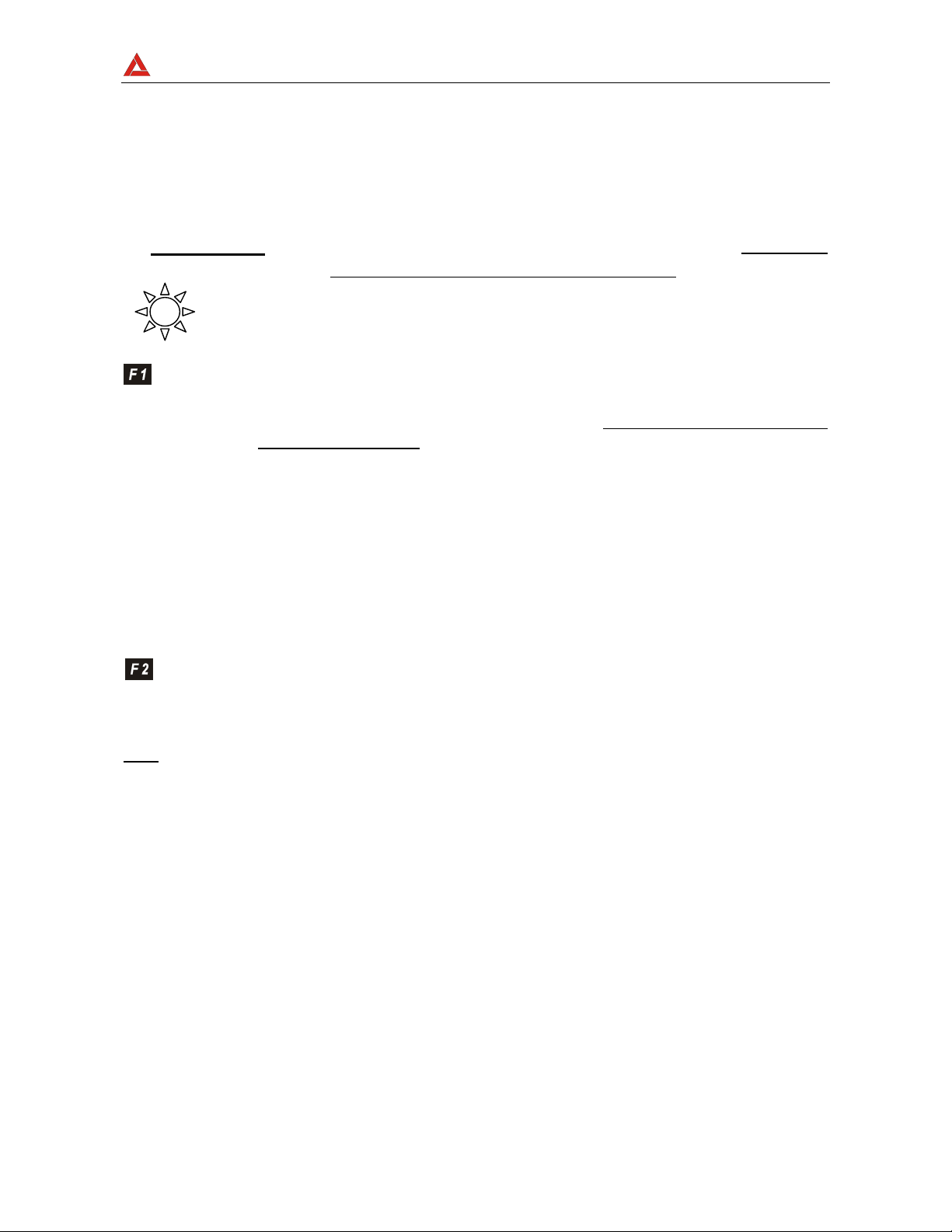

4.3. BACKLIGHT FUNCTION

When the instrument is turned on, pressing, briefly, the ON/OFF button, the backlight will

be enabled. The light will be automatically turned off after 5 seconds.

If the batteries are too low the instrument will automatically disable the backlight function.

Page 19

AMPROBE

MULTITEST2000

5. INITIAL SETTINGS

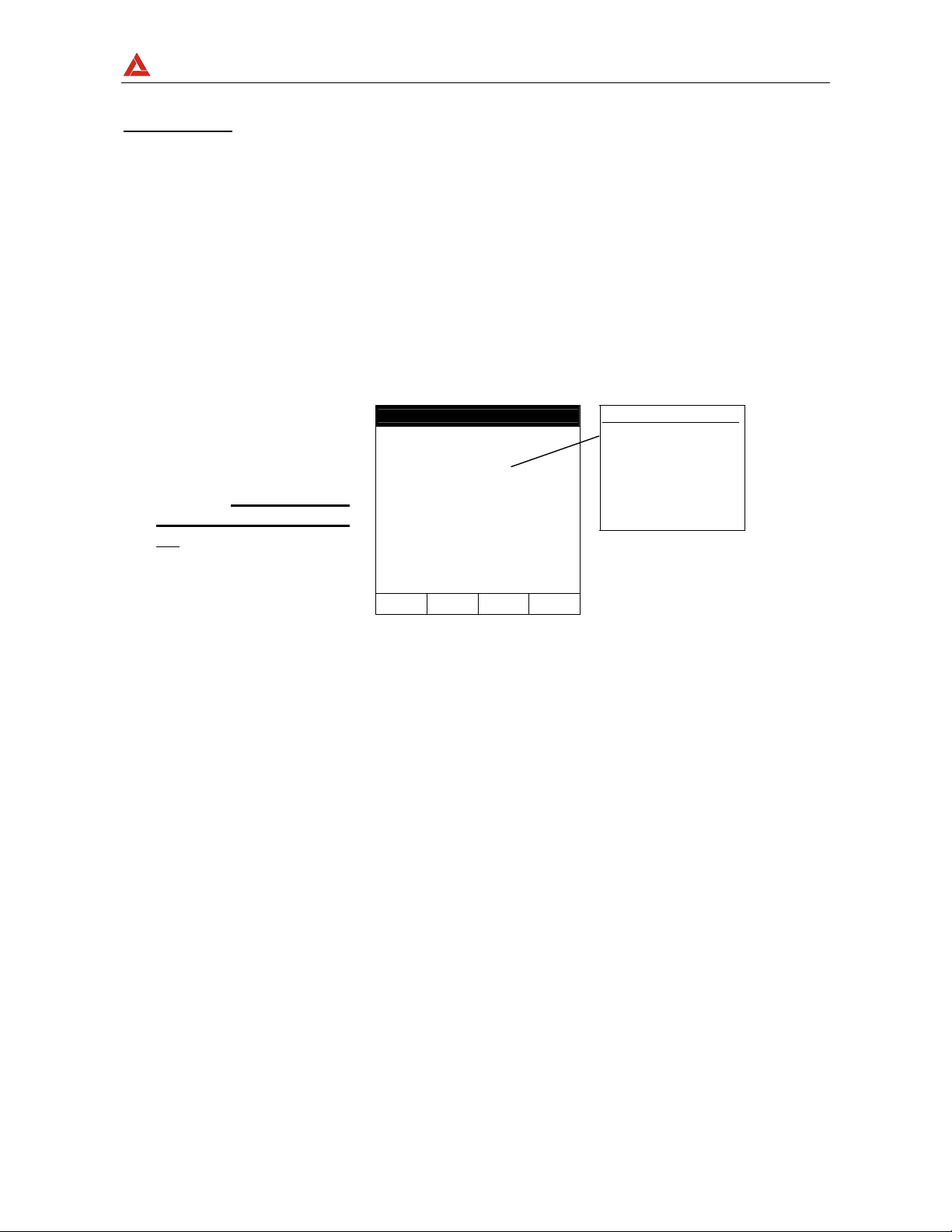

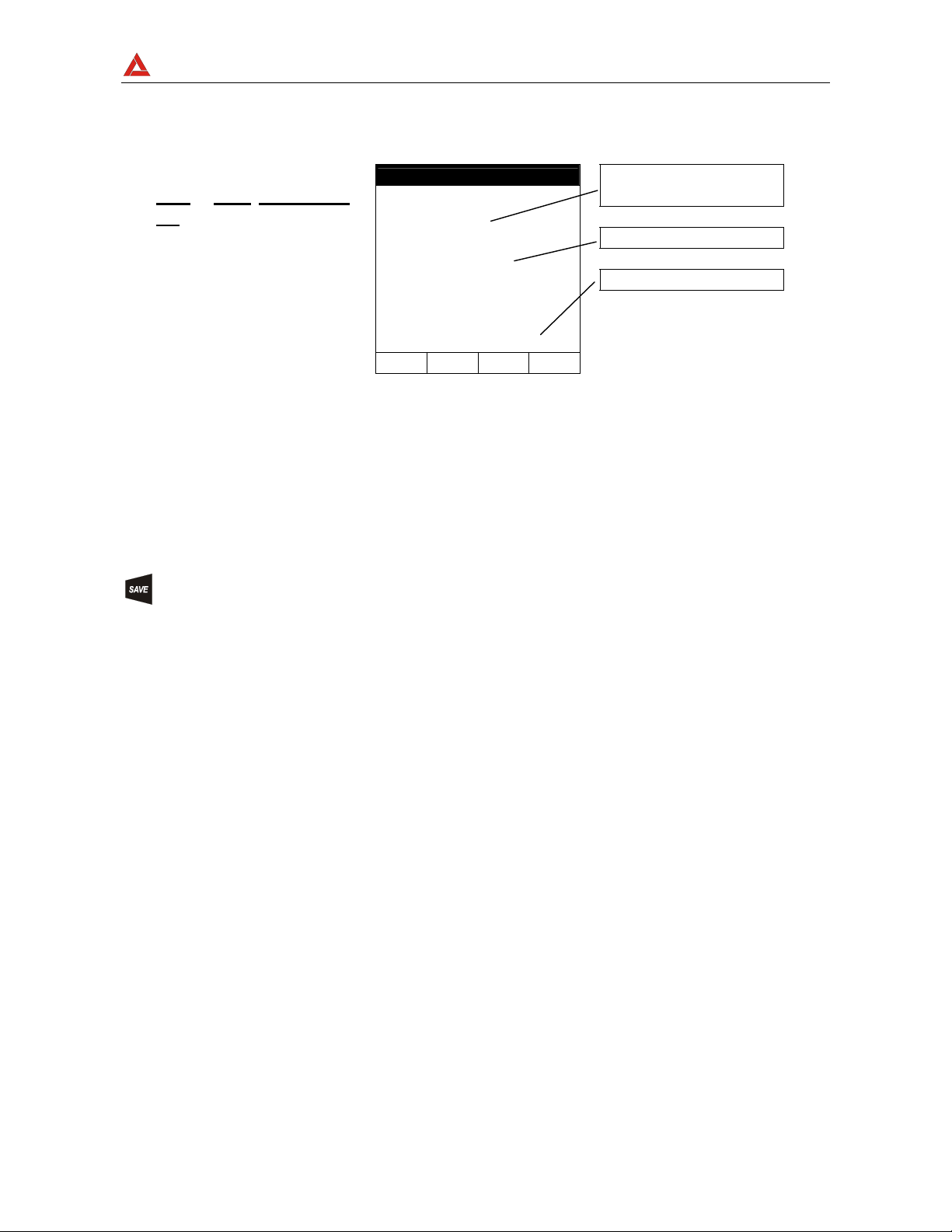

By pressing the MENU key the following screen will be displayed:

It’s not possible to enter the MENU during a recording or a Real Time Energy

measurement. Pressing this button during a recording will display the main recording

parameters (see paragraph 10.2).

5.1. HOW TO ADJUST THE CONTRAST

By pressing the multifunction keys F1 and F2, position the cursor on the CONTRAST item

and then press the ENTER key.

By pressing the multifunction keys F3 and F4, adjust the contrast (higher values

correspond to a higher contrast while lower values correspond to a lower contrast) and

press the ENTER key to SAVE the change or press ESC to quit the modification.

This setting will remain unchanged after turning off the instrument.

5.2. HOW TO SET DATE AND TIME

By pressing the multifuncti on keys F1 and F2, position the cursor on the DATE&TIME item

and then press the ENTER key.

The time is expressed as hh:mm (2 digit for hours, 2 digit for minutes) military time.

Press the ENTER key to SAVE the change or press ESC to quit the modification.

This setting will remain unchanged after turning off the instrument.

MENU GENERAL

SAFETY TEST MEMORY

ANALYZER MEMORY

RESET

ANALYZER CONFIG

RECORDER CONFIG

CONTRAST

DATE&TIME

LANGUAGE

COUNTRY

↓ ↑

Page 20

AMPROBE

MULTITEST2000

5.3. HOW TO SET THE LANGUAGE

By pressing the multifunction keys F1 and F2, position the cursor on the LANGUAGE (EN)

or LINGUA (IT) item and confirm it by pressing the ENTER key.

By pressing the multifunction keys F1 and F2, position the cursor on the desired language

and press the ENTER key to SAVE the change or press ESC to cancel the modification.

This setting will remain unchanged after turning off the instrument.

5.4. HOW TO ADJUST THE COUNTRY

By pressing the multifunction keys F1 and F2, position the cursor on the COUNTRY item

and confirm it by pressing the ENTER key. By pressing the multifunction keys F1 and F1,

select the Country among the following possibilities:

UE_m: European Countries: Distance setting in "meter" for Resistivity measurement

US_m: United States: Distance setting in "meter" for Resistivity measurement

US_ft: United States: Distance setting in "feet" for Resistivity measurement

Press the ENTER key to SAVE the change or press ESC to quit the modification.

This setting will remain unchanged after turning off the instrument.

Page 21

AMPROBE

MULTITEST2000

5.5. RESET

This option re-establishes the default settings of the instrument.

The default settings of the instrument consist of:

ANALYZER CONFIG:

Full scale of the clamps: 1000A

Transformer ratio: 1

Type of electrical equipment: 4 wires

Password: enabled

RECORDER CONFIG:

Start: Manual (the recording is started

at 00 sec mark on clock after pressing

the START/STOP key)

Stop: Manual

Integration period: 15min

Recording o f harmonics: ON

Recording of Voltage anomalies (Sag and Surge: ON

Voltage Reference for Sag and Surge detection: 230V

Upper Limit for Sag and Surge detection: 6%

Lower Limit for Sag and Surge detection: 10%

Selected vo ltages: V1

Selected voltage harmonics: THD, 01, 03, 05, 07

Selected currents: I1

Selected current harmonics: THD, 01 , 03, 05, 07

CO-GENERATION: OFF

Powers, Pf and c osϕ selected: P1

Q1i

Q1c

S1

Pf1

dpf1

Energies: Ea1

Eri1

Erc1

Page 22

AMPROBE

MULTITEST2000

The RESET command will not erase the instrument’s memory.

Page 23

AMPROBE

MULTITEST2000

6. SAFETY TEST FUNCTION S

6.1. LOWΩ: CONTINUITY TEST WITH 200mA TEST CURRENT

The measurement is taken according to EN 61557-2 and VDE 0413 part 4.

ν

WARNING:

Turn the rotary knob to the LOWΩ position.

This key allows the operator to select one of the following measuring modes:

AUTO mode (the instrument carries out two measurements with reversed

polarity and displays their average value). This mode is recommended

for the continuity test.

RT+ mode (measurement with positive polarity and the ability to set the

duration time of the test). In this case the operator can set a measuring

time long enough to permit them to move the protective conductors while

the instrument is carrying out the test so as to detect any bad

connections.

RT- mode (measurement with negative polarity and the ability to set th e

duration time of the test). In this case the operator can set a measuring

time long enough to permit him to move the protective conductors while

the instrument is carrying out the test so as to detect any bad connection.

This key permits the operator to perform a calibration (compensation for the

resistance of the cables used for the measurement).

Before carrying out the continuity test be sure that there is no

voltage at the ends of the conductor under test.

N.B.

If the resistance is lower than 5Ω (including the resistance of the calibration) the

continuity test is executed by the instrument with a test current higher than 200mA.

Page 24

AMPROBE

MULTITEST2000

If the resistance is higher than 5Ω the continuity test is executed by the instrument

with a current lower than 200mA.

We recommend that you check the calibration of the test leads before executing a

measurement according to next paragraph.

Page 25

AMPROBE

MULTITEST2000

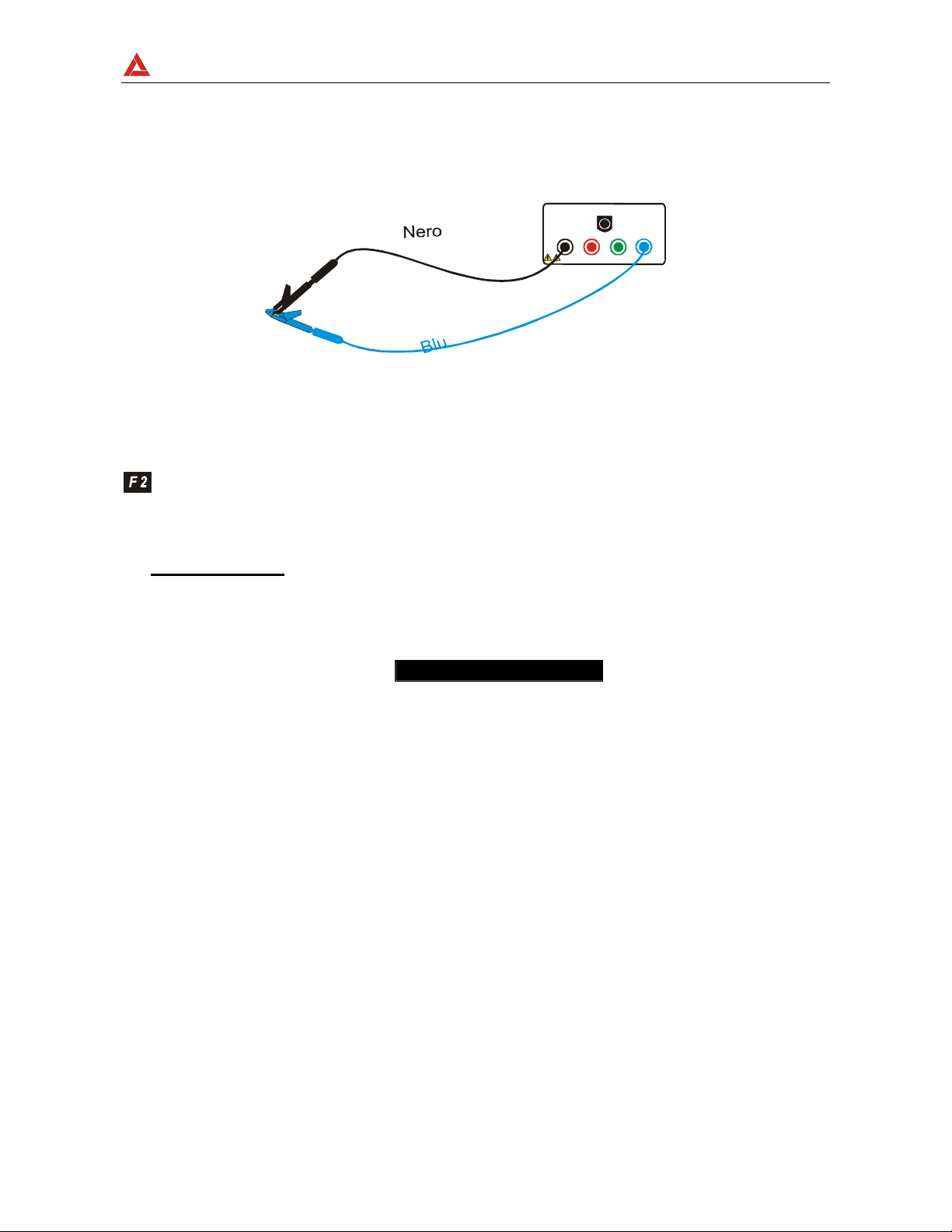

6.1.1. Calibrating the test leads ("CAL" Mode)

1. Connect the black and blue test leads to B1 and B4 input terminals

respectively.

B2 B3

B4B1

Connection of instrument terminals during calibration procedure.

2. If the test leads supplied with the instrument are not long enough for the

measurement yo u can ex tend t he blue ca ble.

3. Short-ci r c u i t the measuring cable ends making sure that the condu ctive parts of the

alligator clips make good contact with each other (see previous picture).

4. Press th e F2 key. The instrument performs the calibration.

ν

ATTENTION:

Never disconnect the test leads when the message

"MEASURING" is displayed.

LOWΩ 05.06.01

Page 26

AMPROBE

MULTITEST2000

----Ω

R+ R-

----Ω ----Ω

---mA ---mA

AUTO 0.11Ω

FUNC CAL

A numerical value

in this field means

that the instrument

has been

calibrated; this

value remains on

the display for

any further

measurement

even though the

unit is switched off

and on again.

5. At the end of the test the result is stored and used as OFFSET (that is to say

that it is subtracted from any continuity test carried out) for all the

subsequent measurements.

Note

: The instrument performs the calibration only if the resistance of the test leads is

lower than 5Ω.

Page 27

AMPROBE

MULTITEST2000

TEST LEADS Before each measurement always assure that the

calibration is for the cables in use. During a

continuity test, if the resistance value free of

calibration (that is the resistance value less the

calibration offset value) is negative, the symbolν

is displayed. Probably the calibration resistance

value stored in the instrument memory is not for

the cables in use, therefore a new calibration must

be performed.

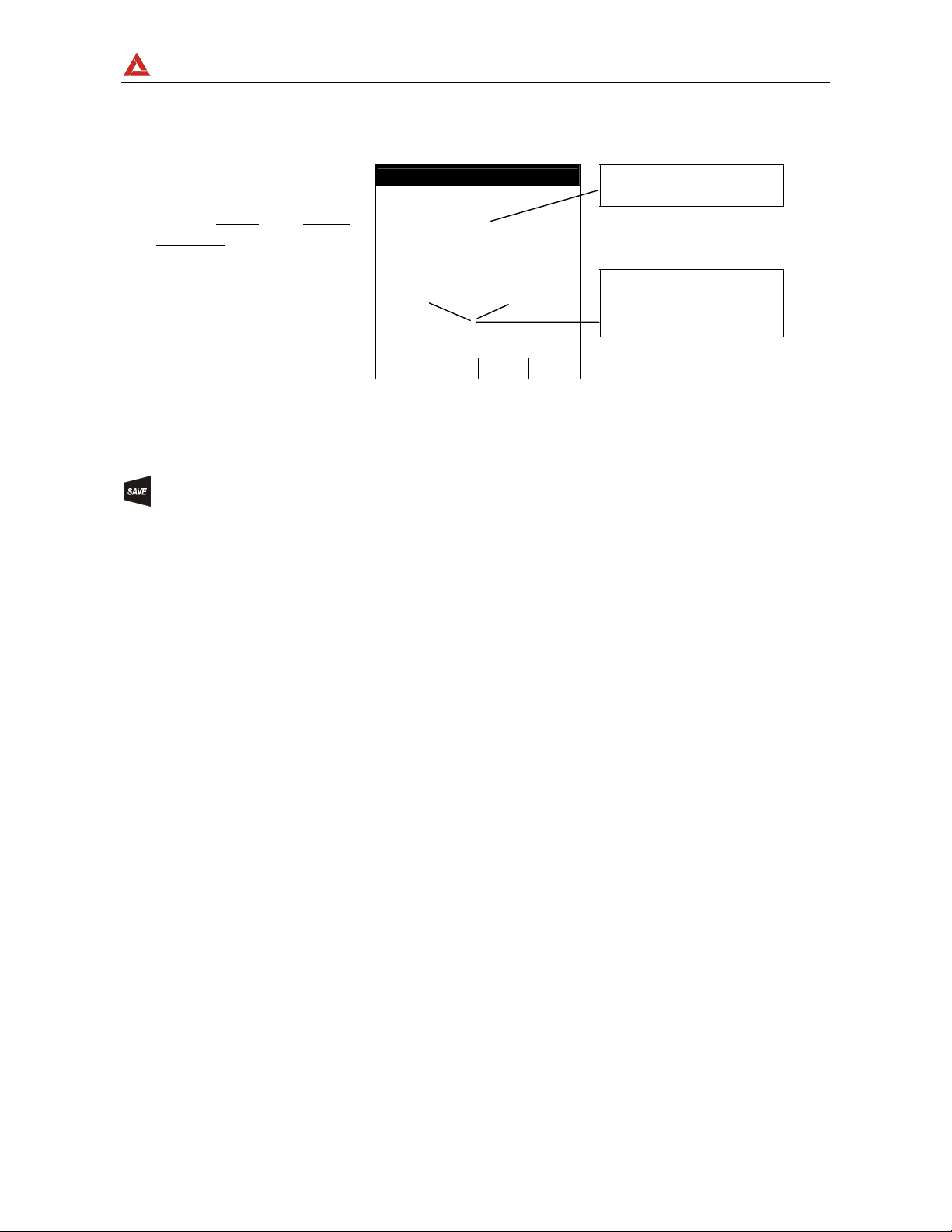

6.1.1.1. Procedure to reset test leads calibration parameters

To cancel calibration

parameters it is

necessary to perform a

calibration procedure

with a resistance of

test leads higher than

5Ω (for example with

open test leads). When

a cancellation is effected

the screen to the right

is displayed temporarily.

LOWΩ 05.06.01

ν

>

99.9

R+ R-

----Ω ----Ω

---mA ---mA

AUTO 0.11Ω

FUNC CAL

Ω

Message >99.9Ω:

means that the

instrument detected a

resistance higher

than 5Ω therefore it

will proceed with

Reset proced ure.

Page 28

AMPROBE

MULTITEST2000

6.1.2. Measurement Procedure

1. Select the desired mode using the F1 key.

2. Connect the black and blue test leads to B1 and B4 input terminals respectively

START

STOP

B2 B3

B4B1

Connection of the test leads during LOWΩ test.

3. If the cables su ppli e d with the instrument are not long enough for the measurement

you can extend the blue cable.

4. Short-circuit the test leads making sure that the conductive parts of the alligator clips

make a good contact to each other. Press the START key. If the display doesn't

show 0.00Ω repeat the test leads calibration (see paragraph 6.1.1).

5. Connect the instrument terminals to the ends of the conductor under test (see

previous picture).

6. If the mode "RT+" or "RT-" was selected use the F3, F4 keys to set the

duration of the test.

7. Press the START key. The instrument will execute the measurement. In RT+/RT-

(Timer mode) you can press START key again if you want to stop the test before the

duration set is expir ed.

ν

WARNING:

Never disconnect the test leads when the message

"Measuring" is displayed.

Page 29

AMPROBE

A

MULTITEST2000

6.1.3. Results of "AUTO" mode

t the end of the test, if

the average resistance

value Ravg

than 5Ω the instrument

emits a double sound

signal indicating the

positive outcome of

the test and displays a

screen similar to the

screen to the right.

is lower

LOWΩ 05.06.01

1.05Ω

R+ R-

1.07Ω 1.03Ω

219mA 219mA

AUTO 0.11Ω

FUNC CAL

Average resistance value

(Ravg)

Resistance values and

corresponding test currents

obtained after exchanging

the polarities of test leads

The displayed result can be stored by pressing the SAVE key twice (refer to

paragraph 9.1).

Page 30

AMPROBE

MULTITEST2000

6.1.4. Results of "RT+" and "RT-" modes

If a resistance value

or RT- lower than

RT+

5Ω is detected, the

instrument emits a

double sound signal

indicating the positive

outcome of the test

displays a screen similar

to the screen to the

right.

LOWΩ 05.06.01

1.07Ω

219mA

RT+ 0.11Ω TIME: 10s

FUNC CAL

↑ ↓

Max Resistance value of

R+ or R-.

Test current

Duration of the Test

Note: We recommend the use of alligator clips and to assure the alligator clips make good

contact with the conductor under test. Indeed , in this test the instrument gives as a

final result the maximum measured value of R+ or R- and using test leads instead of

alligator clips could give you faulty results due to faulty contact between the test leads

and conductor under test

The displayed result can be stored by pressing the SAVE key twice (refer to

paragraph 9.1).

Page 31

AMPROBE

MULTITEST2000

6.1.5. "AUTO", RT+", "RT-" faulty cases

If the instrument detect

the External Power

supply adapter

connected to instrument

will show the message

displayed to the right.

LOWΩ 05.06.01

-.- -Ω

R+ R-

---Ω ---Ω

---mA ---mA

ν REMOVE POWER

AUTO 0.11Ω

FUNC CAL

Disconnect the External

Power Supply Adapter

If the terminal voltage is

higher than 15V, the

instrument does not

perform the test and

displays the screen to

the right for 5 seconds.

LOWΩ 05.06.01

R+ R-

-.--Ω -.--Ω

---mA ---mA

AUTO 0.11Ω

FUNC CAL

-.- -Ω

ν VOLT IN INPUT

ATTENTION: the test was

not performed because of

voltage at the terminal

ends.

Page 32

AMPROBE

MULTITEST2000

In the case that:

R

CALIBRATION>RMEASURED

the instrument displays

the screen to the right.

LOWΩ 05.06.01

ν 0.00Ω

R+ R-

0.00Ω 0.00Ω

219mA 219mA

CAL > RES

AUTO 0.11Ω

FUNC CAL

ATTENTION:

R

CALIBRATION >RMEASURED

THE PREVIOUS RESULTS CAN'T BE SAVED

.

If the value of

Resistance is higher

than 5Ω (but lower than

99.9Ω) the instrument

emits a long beep and

displays a screen similar

to the screen to the right

LOWΩ 05.06.01

ν 5.17Ω

R+ R-

5.17Ω 5.17Ω

209mA 209mA

AUTO 0.11Ω

FUNC CAL

Resistance value higher

than 5Ω

Test current

The displayed result can be stored pressing the SAVE key twice (refer to

paragraph 9.1).

Page 33

AMPROBE

MULTITEST2000

If the value of

Resistance is higher

than 99.9Ω the

instrument emits a long

beep and displays the

screen to the right.

LOWΩ 05.06.01

ν> 99.9Ω

R+ R-

-.--Ω -.--Ω

---mA ---mA

AUTO 0.11Ω

FUNC CAL

Resistance value higher

than 99.9Ω

ATTENTION: Value of

Resistance Out of Range

The displayed result can be stored pressing the SAVE key twice (refer to

paragraph 9.1).

Page 34

AMPROBE

6.2. MΩ: INSULATION RESISTANCE MEASUREMENT WITH 50V, 100V, 250V,

The measurements comply with IEC 61557-2 and VDE 0413 part 1.

ν

ATTENTION:

Turn the rotary knob to the MΩ position.

The F1 key allows the operator to select one of the following measuring

modes:

MAN mode (Manual mode) Recommended test.

TMR mode (Timer mode: test duration depends on the selected interval

6.2.1. Measurement Procedure

1. Select the desired mode using the F1 key.

2. Connect the test leads to the instrument input terminals B1 and B4 respectively,

MULTITEST2000

500V, 1000V TEST VOLTAGE

Before performing an insulation test make sure that the circuit

under test is not energised and all the loads are disconnected.

from 10 to 999 seconds). This test can be executed when the test

required a defined duration.

Page 35

AMPROBE

MULTITEST2000

M

I1

B2

B4B1

B3

Example: insulation measurement between phase and

earth in an electrical installation using untied cables.

3. If the cables supplied with the instrument are not long enough for the measurement

you can extend the blue cable.

4. Connect the instrument terminals to the object that is to be submitted to the

insulation test after de-energizing the circuit under test and all the relative

loads (see previous picture).

5. B y means o f F2 select the test voltage suitable for the type of test to be

performed (see Table1). The values to be selected are:

• 50V (test on telecommunication system)

• 100V

• 250V

• 500V

• 1000V

Page 36

AMPROBE

MULTITEST2000

Standard Br ief descr iption Test voltage Maximum limit value

> 0.250MΩ

> 0.500MΩ

> 1.0MΩ

> 50kΩ (se V<500V)

> 100kΩ (se V>500V)

> 230kΩ

> 1MΩ

CEI 64-8/6

CEI 64-8/4

Floor and wall insulation in civil installations

Floor and wall insulation in systems over 500V

Systems SELV or PELV

Systems up to 500V (Civil installations)

Systems over 500V

250VDC

500VDC

1000VDC

500VDC

1000VDC

EN60439 Electrical panel boards 230/400V 500VDC

EN60204 Electrical equipment of machines 500VDC

CEI 64-4 Floor insulation in medical rooms 500VDC

<1MΩ (if the floor is at least 1 year old)

<100MΩ (if the floor is at least 1year o ld)

Table1: Table reporting the test voltage and the corresponding limit values for

few Guidelines.

Rated voltage selected

for the test

50VDC

100VDC

250VDC

500VDC

1000VDC

R

= Maximum resistance

MAX

value

99.9MΩ

199.9MΩ

499MΩ

999MΩ

1999MΩ

Table2: Table of maximum resistance values which can be measured under MΩ

mode depending on the rated voltage selected.

6. If the "TMR" mode was selected use the F3, F4 keys to set the duration time of

the test:

Page 37

AMPROBE

MULTITEST2000

ν

ATTENTION:

Never disconnect the test leads from the circuit under test when

the message "MEASURING" is being displayed, as the circuit

under test may remain charged at a dangerous voltage. The

instrument has an internal "safety resistor" which is connect to

output terminal before the end of the test in order to discharge

the parasite capacities of the installation.

START

STOP

7. Press the START key.

The instrument will start the test.

MAN Mode: The test will take 4 seconds (maximum). If you keep

the START key pressed longer than 4 seconds the test

continues until the key is released.

TMR mode: The test will take the time set. If you want to stop

the test when it's running, press the START/STOP key again.

Page 38

AMPROBE

A

MULTITEST2000

6.2.2. Results of "MAN" mode

t the end of the test if

the insulation

resistance is lower

than R

and the instrument

generates the

Nominal test Voltage,

the instrument emits a

double beep,

indicating the positive

outcome of the test

(see Table2)

MAX

MΩ 05.06.01

1.07

514V 15s

MAN 500V

FUNC VNOM

MΩ

Insulation Resistance

Voltage during the Test

Duration of the Test

Test mode

Test voltage set

and displays a screen

similar to the screen to

the right.

In order to evaluate the test you must compare the result with the limits indicated in the

Guidelines (see Table1).

The displayed result can be stored pressing the SAVE key twice (according to

paragraph 9.1).

If the Insulation

resistance is higher

than R

the instrument emits a

double beep at the end

(see Table2),

MAX

MΩ 05.06.01

> 999

M

Ω

Maximum resistance value

which can be measured

(999Ω is displayed if a

rated voltage of 500V was

selected, see Table2).

Page 39

AMPROBE

of the test indicating

the positive outcome

of the test and displays

one screen similar to the

screen to the right.

MULTITEST2000

523V 15s

MAN 500V

The symbol ">" means that

the resistance value is

higher than R

MAX

.

FUNC VNOM

Test duration

The displayed result can be stored by pressing the SAVE key twice (refer to

paragraph 9.1).

Page 40

AMPROBE

MULTITEST2000

6.2.3. Results of "TMR" mode

At the end of the test if

the Insulation

resistance is lower

than R

and the instrument

generated the

Nominal test Voltage,

the instrument emits a

(see Table2)

MAX

double beep

indicating the positive

outcome of the test

MΩ 05.06.01

1.07

514V 15s

TMR 500V TIME:60s

FUNC VNOM

M

Ω

↓

Insulation Resistance

Voltage during the Test

Duration of the Test

Test mode

and displays a screen

similar to the screen to

the right.

The displayed result can be stored by pressing the SAVE key twice (according to

paragraph 9.1).

If the Insulation

resistance is higher

than R

the instrument emits a

double beep at the end

of the test indicating

(see Table2),

MAX

MΩ 05.06.01

> 999

M

Ω

Maximum resistance value

that can be measured

(999Ω is displayed if a

rated voltage of 500V was

selected, see Table2).

The symbol ">" means that

Page 41

AMPROBE

MULTITEST2000

the positive outcome

of the test and displays

a screen similar to the

screen to the right.

523V 15s

TMR 500V TIME:60s

the resistance value is

.

higher than R

MAX

FUNC VNOM

↑ ↓

Test duration

The displayed result can be stored pressing the SAVE key twice (according to

paragraph 9.1).

Page 42

AMPROBE

MULTITEST2000

6.2.4. "MAN" and "TIM ER" mode faulty cases

If the instrument

detects the External

Power supply adapter

the instrument will

show the message

displayed to the right.

MΩ 05.06.01

-.- -

---V 15s

ν REMOVE POWER

MAN 500V

FUNC VNOM

M

Ω

Disconnect the External

Power Supply Adapter

If the instrument

detects a Voltage

between the input

terminals higher than

15V, the instrument

does not perform the

test and displays the

screen to the right for

5 seconds.

MΩ 05.06.01

-.- -

---V 15s

ν VOLT IN INPUT

MAN 500V

FUNC VNOM

M

Ω

ATTENTION: the test can't be

executed. Check that the circuit is

not energized.

This result can't be saved

Page 43

AMPROBE

MULTITEST2000

If the instrument can't

generate the Nominal

Test Voltage it will

emit a long beep and

displays a screen

similar to the screen

to the right.

MΩ 05.06.01

ν 1.17 MΩ

107V 15s

MAN 500V

FUNC VNOM

Insulation Resistance

ATTENTION: the test of

resistance R

voltage value lower than the

set rated voltage. Low

insulation case. This case

occurs under low insulation

conditions or in the presence of

capacitance on the installation.

ISO

Test Duration

was taken at a

The displayed result can be stored by pressing the SAVE key twice (refer to

paragraph 9.1).

6.3.

: PHASE SEQUENCE INDICATOR

Turn the rotary knob to the

position.

6.3.1. Measurement procedure and results of "

" mode

1. Connect the Black, Red and Green connectors of the split cables to their

corresponding input terminals of the instrument B1, B2, B3.

Page 44

AMPROBE

A

MULTITEST2000

1

3

I1

B2 B3

B1

B4

Instrument connection for Phase Sequence Detection in a 400V three-phase system

2. Press the START key to execute a test.

t the end of the test

the instrument emits a

double beep

indicating that the test

has correctly

terminated and

displays the values to

the right.

LOOP 05.06.01

123

FRQ=60.0HZ V1-2=115V

V2-3=113V V3-1=114V

OK

Phase Sequence OK

Value of the Phase to Phase

Voltage

Page 45

AMPROBE

MULTITEST2000

Working mode

This result ca n be stored pressing the SAVE key twice (refer to paragraph 9.1).

Page 46

AMPROBE

MULTITEST2000

6.3.2. LOOP Faulty Cases

In the "

Phase-to-Phase voltage

is lower than 100V, the

instrument displays the

screen to the right.

" mode, if a

LOOP 05.06.01

- - -

FRQ =60.0HZ V1-2=111V

V2-3= 0 V V3-1= 0V

ν LOW VOLTAGE T

PHASE ROTATION

Phase "T2 Voltage is lower

than 100V

In the "

instrument detects two

phases connected

together it displays the

screen to the right.

" mode, if the

LOOP 05.06.01

- - -

FRQ =60.0HZ V1-2=107V

V2-3= 0 V V3-1=107V

ν PHASE DOUBLED

PHASE ROTATION

Two phases are connected

together.

THE PREVIOUS RESULTS CANNOT BE SAVED

.

Page 47

AMPROBE

MULTITEST2000

In the

voltage of one or more

phase is too low, one or

more phases has a low

voltage the instrument

will show a screen

similar to the along side

displayed.

mode, if the

LOOP 05.06.01

123

FRQ =60.0HZ V1-2=391V

V2-3= 0V V3-1= 0V

NOT CORRECT

Phase Sequence not

correct

Message “LOW Voltage

Phase T”: means that

Phase T has a low voltage

value. Similar message for

Phase R and S.

This result can be stored pressing the SAVE key twice (refer to paragraph 9.1).

Page 48

AMPROBE

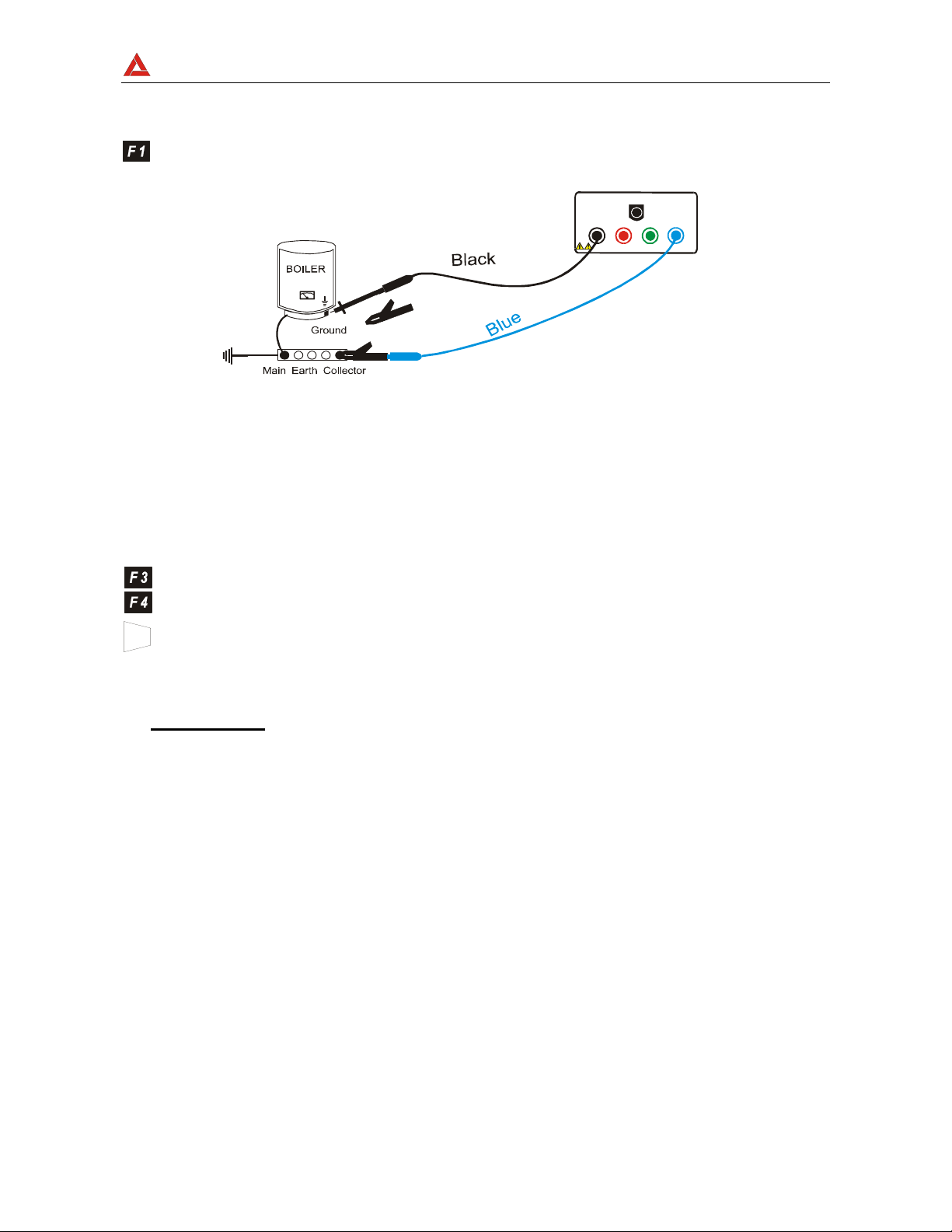

6.4. EARTH: SOIL RESISTANCE AND RESISTIVITY MEASUREMENTS

Turn the rotary knob to the EARTH

The F1 key permits to select one of the following measuring modes (which

can be shown cyclically when pressing the key):

Mode "2-W" (the instrument measures the resistance between 2 points).

Mode "3-W" (the instrument measures the resistance using two auxiliary

Mode "ρ" (the instrument measures the ground resistivity).

ν

ATTENTION:

MULTITEST2000

position.

earth rods).

Never disconnect the test leads from the circuit under test when

the message "MEASURING" is displayed

Page 49

AMPROBE

MULTITEST2000

6.4.1. Measurement procedure and results of "2-W"and "3-W" mode

1. Select "2-W" or "3-W" Earth measurement mode by means of the F1 key.

2. Connect the Black, Red, Green and Blue cables to the corresponding input terminals

of the instrume nt B1, B2, B3, B4 (see possible connections in the following pictures).

1

3

N

I1

B4

B2 B3

B1

Connection for 3 point Earth resistance

measurement

I1

B2 B3

B1

1

3

N

I1

B2

B4B1

B3

1

3

N

Transf

Connection for 2 point Earth Resistance

measurement

1

3

N

B4

Connection for measuring the resistance between an extraneous conductive part and the earth system

Page 50

AMPROBE

MULTITEST2000

START

STOP

3. Press the START key. The instrument starts the test.

Page 51

AMPROBE

A

MULTITEST2000

t the end of the test

the instrument emits a

double beep indicating

that the test is

correctly terminated

and displays the values

to the right.

"3 Point" Working mode

EARTH 05.06.01

0.77

Test:04

RAVG=0.74Ω

3-W

FUNC CLR

Vd= 1V

Ω

Earth Resistance value

expressed in Ω.

Voltage value of electrical

noise

Number of Test

Average Value of Earth

Resistance calculated over

the Number of Test

displayed.

4. The instrument will show automatically the average value of the Earth resistance

calculate over the tests performed. Press F2 to RESET this value and the number of

Test.

This result can be stored by pressing the SAVE key twice (refer to paragraph 9.1).

Page 52

AMPROBE

A

MULTITEST2000

6.4.2. Measurement procedure and results of "ρ" mode

1. Select

ρ

measurement mode by means of the F1 key.

2. Select the distance d between the earth rods by means the F3 and F4 keys.

The Distance meas uri ng unit c omply with Cou ntry s ettin g (see par . 5.4).

3. Connect the 4 Bl ack, Red, Green and Blue connectors of the single cables in the

corresponding input terminals of the instrument B1, B2, B3, B4.

I1

B2 B3

B1

B4

ddd

d

Instrument connection for Earth resistivity measurement

START

STOP

4. Press the START key. The instrument starts the test.

t the end of the test

the instrument emits a

double beep

indicating that the

test is correctly

terminated and

EARTH 05.06.01

1.77

Vd= 1V

Ωm

Earth Resistivity value

expressed in Ωm.

Voltage value of electrical

noise

Page 53

AMPROBE

displays the values to

the right.

"ρ" Working mode

MULTITEST2000

Test:04

ρAVG=0.74Ω

ρ DIST= 2m

FUNC CLR ↑ ↓

Number of Test

Average Value of Earth

Resistivity calculated over the

Number of Test di splayed.

5. The instrument will show automatically the Average value of the Earth Resistivity

calculate over the tests performed. Press F2 to RESET this value and the number of

Test.

This result can be stored by pressing the SAVE key twice (refer to paragraph 9.1).

Page 54

AMPROBE

MULTITEST2000

6.4.3. "2-W", "3-W" and "ρ" faulty cases

If the instrumen t detects

the External Power

supply adapter

connected to instrument

will show the message

displayed to the right.

EARTH 05.06.01

- - -

Test:04

RAVG=0.74Ω

3-W

FUNC CLR

Vd= ---V

ν REMOVE POWER

Ω

Disconnect the External

Power Supply Adapter

If the Instrument detect

a voltage values higher

than 5V the instrument

will shows the screen

displayed to the right.

EARTH 05.06.01

ν - - -

Test:04

RAVG=0.74Ω

3-W

FUNC CLR

Vd= 230V

ν VOLT IN INPUT

Ω

Warning symbol: Voltage

noise in input.

Page 55

AMPROBE

The message "Rc

high" indicates that the

instrument can't

produce the minimum

current necessary for

measurement. Check

that the terminals are

correctly connected

and the Auxiliary earth

rod connected to B4

(blue conductor) has

not been inserted in a

pebbly or poorly

conductive ground. If

necessary pour some

water around the rod.

MULTITEST2000

EARTH 05.06.01

- - -

Test:04

RAVG=0.74Ω

3-W

FUNC CLR

Vd= 1V

ν Rc HIGH

Ω

Message "Rc": Check

Auxiliary Earth rods.

THE PREVIOUS RESULTS CANNOT BE SAVED

.

Page 56

AMPROBE

MULTITEST2000

If the Instrument

detects a Resistance

value higher than

1999Ω, the instrument

will show the screen to

the right.

EARTH 05.06.01

> 1999

Test:04

RAVG=0.74Ω

3-W

FUNC CLR

Vd= 1V

Ω

Message ">1999" means that

the resistance value is higher

than the maximum

measurable.

This result ca n be stored pressing the SAVE key twice (refer to paragraph 9.1).

If the Instrument

detects a Resistivity

value higher than

1999kΩm, the

instrument will show

the screen to the right.

EARTH 05.06.01

> 1999

Test:04

Vd= 1V

kΩm

Message ">1999" means that

the resistivity value is higher

than the maximum

measurable.

Page 57

AMPROBE

MULTITEST2000

ρAVG=0.74kΩm

ρ DIST=5m

FUNC CLR ↑ ↓

This result ca n be stored pressing the SAVE key twice (refer to paragraph 9.1).

Page 58

AMPROBE

MULTITEST2000

7. AUX: MEASUREMENT WITH EXTERNAL PROBES

Turn the rotary knob to the AUX position.

The F4 function key selects between the following functions:

Environmental Parameter & Leakage Current (mA, °C, °F, RH%, m/s, mV, Lux)

Sound Level Measurement

The "Environmental Parameter & Leakage Current" mode allows the following operations:

Display in real time the values coming from external probes or clamps.

Memorize the values displayed (pressing SAVE key).

Record (pressing the START key after a proper setting) an Input signal

coming from an External Probe or clamp among the possibilities

illustrated above. It will be possible to analyze the recorded data

ONLY by downloading it to a PC.

Please observe the difference between memorize and record: the former means that the

instrument stores in its’ memory only the actual values displayed while the latter means

that you want to store the course of the input signals during a recording time.

The "Sound Level Measurement" mode allows the following operations :

Display, in real time, the values coming from the external probe of sound

pressure level (Type 1).

Calculates, at the end of measurement, the Equivalent Level of noise

LeqT

Page 59

AMPROBE

MULTITEST2000

7.1. ENVIRONMENTAL PARAMETER AND LEAKAGE CURRENT: REAL TIME

MEASUREMENT

This working mode allows real time measurement and recording of Environmental

Parameters and Leakage current

1. Press this key to choose "AUX" mode input.

2. Pressing this function key will change the measuring unit of the instrument's

input. The following possibilities will be displayed circularly:

- - - (Instrument's input disabled)

mA (Leakage current)

°C (Celsius Temperature)

°F (Fahrenheit Temperature)

HR% (Relative humidity)

m/s (Air Speed)

mV (Voltage)

LUX (20) (Luminance: Full Scale 20Lux)

LUX (2k) (Luminance: Full Scale 2kLux)

LUX (20k) (Luminance: Full Scale 20kLux)

3. Connect the External probe or clamp to the I1 input.

Page 60

AMPROBE

MULTITEST2000

I3

B1

B2 B3 B4

Example of External probes connections

ν

ATTENTION:

While in the OFF position, some probe's output the Battery

voltage (approx 9V which is over the expected full scale). This

could influence the measurement of the instrument's inputs. So

NEVER connect the probes with the Selector placed in the OFF

position.

Page 61

AMPROBE

MULTITEST2000

PE (Protection Cunductor)

PHASE

NEUTRAL

SINGLE PHASE

LOAD OR

ELECTRICAL PLANT

PE (Protection Cunductor)

R

S

T

N

THREE PHASE

LOAD OR

ELECTRICAL PLANT

I1

B1

B2 B3 B4

Indirect Leakage Current measurement

in a single phase system

Indirect Leakage Current measurement

I1

B1

B2 B3 B4

in a three phase system

PHASE

NEUTRAL

PE (Protection C u nductor)

B1

I1

B2 B3 B4

SINGLE PHASE

LOAD OR

ELECTRICAL PLANT

DISCONNECT

ADDITIONAL

X

GROUNDING

Direct Leakage Current measurement in

a single phase system

R

S

T

N

PE (Protection Cunductor)

I1

B1

B2 B3 B4

THREE PHASE

LOAD OR

ELECTRICAL PLANT

DISCONNECT

ADDITIONAL

X

GROUNDING

Direct Leakage Current measurement in

a three phase system

4. The Instrument shows in real time the values present at the input.

Example of screen.

05.06.01 11:43:04

AUX

Example of Input Signal 1

Page 62

AMPROBE

MULTITEST2000

In1= 23°C

In1 PG+

5. Press this key to enable/disable the HOLD function (updating interruption of the

displayed data). When the HOLD function is enabled, the word HOLD is

displayed. This key is disabled during a recording. It's not possible to run a

recording if this function is enabled.

6. The displayed result can be stored by pressing the SAVE key twice (refer to

paragraph 9.1).

Page 63

AMPROBE

MULTITEST2000

7.2. ENVIRONMENTAL PARAMETER AND LEAKAGE CURRENT: RECORDING

Before starting a recording we recommend that you confirm that the real time values are

correct. Follow the measurement procedure described in paragraph 7.1.

In addition it's essential that the Instrument settings correspond to the accessories is use.

For this we recommend that you check the instrument's setting before executing an AUX

recording.

To this purpose please check the RECORDER CONFIG settings.

MENU: to enter in the MENU mode and change the instrument settings. It’s

not possible to enter the configuration MENU during a recording or an

energy measurement.

START/STOP: to record the selected parameters according to the instrument’s

settings (refer to chapter 10).

7.2.1. AUX Basic setting: RECORDER CONFIG

Place the rotary switch in the AUX position, press the MENU key, using the F1/F2 keys

select the RECORDER CONFIG item and press the ENTER Key.

MENU GENERAL

SAFETY TEST MEMORY

ANALYZER MEMORY

RESET

ANALYZER CONFIG

RECORDER CONFIG

CONTRAST

DATE&TIME

LANGUAGE

COUNTRY

↓ ↑

Page 64

AMPROBE

MULTITEST2000

It’s not possible to enter the MENU during a recording or a Real Time Energy

measurement.

This option allows you to check and eventually modify the recording parameters and the

selected parameters (up to a maximum of 3). The RECORDER CONFIG mode is divided

into 2 separate sub-pages:

st

1

page: This page allows you to set the START/ STOP mode (AUTO or

MANUAL), the START and STOP time (if AUTO mode is selected) and

the Integration Period value. Press ENTER to confirm the settings and

pass to the following page.

Press ESC to leave the Menu without modifying the existing parameters.

The page of the "RECORDER CONFIG" menu is as foll ows:

Page 65

AMPROBE

↑

MULTITEST2000

To Select MANUAL or AUTOMATIC

start/stop mode, place the cursor on

MANU or AUTO using the

multifunction key F1 or F2 and select

the desir e d mode using F3 or F4.

Use the multifunction keys F1, F2

to position the cursor on the

desired word and use the

multifunction keys F3 / F4 to modify

the value.

Press ENTER to confirm and

proceed inside the Menu the Menu

keeping the settings made.

Press ESC to leave the Menu

without modifying the existing

parameters.

MENU

RECORDER CONFIG

START

MANU

STOP

MANU

INT. PERIOD: 15min

↓

st

1

Page of the RECORDER

CONFIG MENU

+ -

Symbols Description Advised settings

START:MAN

The recording of all the selected parameters will start at 00

seconds after pressing START/STOP (see chapter 7).

☺

Page 66

AMPROBE

MULTITEST2000

STOP:MAN

START:AUTO

STOP:AUTO

INT. PERIOD

For eventual messages displayed see appendix 1 – MESSAGES DISPLAYED.

The recording of all the selected parameters will be interrupted

manually by pressing START/STOP (see chapter 9).

The recording of all the sel ected va lues wil l be start ed / int errupte d

at the set dates and times. In order to start the r ecording the user

will have to press START/STOP to set the instrument in Stand-by

mode until the start date and time previously set (see chapter 7).

The value of this parameter determines every how m any sec onds

the values of the select ed parameters will be memorised (se e

chapter 16.4.1). Available choices:

5sec,10sec,30sec,1min, 2min 5min, 10min, 15min, 30min, 60min.

☺

15min

☺

Page 67

AMPROBE

MULTITEST2000

7.3. SOUND LEVEL MEASUREMENT PROCEDURE

This working mode allows real time measurement of the Sound Pressure Level.

1. Press this key to access to "SOUND" mode.

2. Connect the Sound Level probe (class 1) to instrument using the original Serial

Optical cable (C2001) and the adapter.

F1 F3F4F2

START

STOP

HOLD

SAVE

ENTER

MEN U ESC

Connection between HT55 and the instrument

3. Set the switch on the Sound Level probe to ON position.

The noise probe HT55 is not equipped with the auto-power-off device, in

order to allow also long measurements. To maximize the battery duration

put the instrument ON only during the measurements.

START

STOP

4. Press START/STOP to run the measurement. The message "HT55 no RS232"

means that the instrument is not correctly connected with the noise probe HT55.

Please check:

ATTENTION

Page 68

AMPROBE

MULTITEST2000

- the Sound Level Probe batteries.

- if the Switch on the Sound Level Probe in the ON position.