Page 1

User’ Manual

MultiTest 1000

Release EN 1.00 of the 17/09/2002

Copyright Amprobe 2002

Page 2

AMPROBE

MULTITEST1000

Index:

1. SAFETY PRECAUTIONS AND PROCEDURES ........................................................3

1.1. PRELIMINARY INSTRUCTIONS ......................................................................................3

1.2. DURING USE ....................................................................................................................4

1.3. AFTER USE.......................................................................................................................4

2. GENERAL DESCRIPTION ......................................................................................... 5

2.1. FUNCTIONS......................................................................................................................5

2.2. INSTRUMENT DESCRIPTION..........................................................................................6

3. PREPARATION FOR USE .........................................................................................8

3.1. INITIAL CONTROL............................................................................................................8

3.2. POWER SUPPLY..............................................................................................................8

3.3. CALIBRATION...................................................................................................................8

3.4. STORAGE .........................................................................................................................8

3.5. HOW TO SET LANGUAGE AND MEASUREMENT UNIT ................................................9

4. DESCRIPTION OF THE ROTARY SWITCH FUNCTIONS....................................... 11

4.1. LOWΩ: CONTINUITY TEST OF EARTH, PROTECTIVE AND EQUALIZING

POTENTIAL CONDUCTORS ..........................................................................................11

4.1.1. MODE "CAL" ...............................................................................................................................12

4.1.2. PROCEDURE FOR MEASURING CONTINUITY OF EQUALIZING POTENTIAL CONDUCTORS MODE "AUTO",

"R+TIMER", "R-TIMER".............................................................................................................14

4.1.3. ANOMALOUS CASES DURING "AUTO", "R+TIMER", "R-TIMER" TESTS..........................................16

4.2. MΩ: INSULATION RESISTANCE MEASUREMENT WITH TEST VOLTAGE OF 50V,

100V, 250V, 500V OR 1000V ....................................................................................18

4.2.1. PROCEDURE FOR MEASURING INSULATION RESISTANCE IN ANY MODE .............................................19

4.2.2. SPECIAL CASES WHICH MAY OCCUR DURING THE TESTS "MAN" & "TIMER" ....................................24

: PHASE SEQUENCE INDICATOR ...........................................................................25

4.3

.

4.3.1. MODE " " ................................................................................................................................26

4.3.2. ANOMALOUS CASES WHICH MAY OCCUR DURING PHASE SEQUENCE TESTS ......................................28

4.4. EARTH ρ: EARTH RESISTANCE AND RESISTIVITY MEASUREMENT.......................30

4.4.1. MEASUREMENT PROCEDURE FOR "2P" TEST MODE ........................................................................31

4.4.2. MEASUREMENT PROCEDURE FOR "3P" TEST MODE ........................................................................35

4.4.3. MEASUREMENT PROCEDURE FOR "ρ" TEST MODE ..........................................................................38

4.4.4. ANOMALOUS CASES WHICH MAY OCCUR DURING EARTH ρ TESTS ..................................................40

5. HOW TO SAVE, RECALL AND CLEAR DATA STORED IN MEMORY..................42

5.1. SAVE: "SAVE" KEY.........................................................................................................42

5.2. RECALL: "RCL" KEY.......................................................................................................43

5.3. CLEAR: "CLR" KEY.........................................................................................................44

6. RESET OF THE INSTRUMENT AND DEFAULT PARAMETERS ...........................46

6.1. RESET PROCEDURE.....................................................................................................46

6.2. DEFAULT PARAMETERS...............................................................................................46

7. INSTRUMENT CONNECTION TO A PC .................................................................. 47

8. MAINTENANCE........................................................................................................48

8.1. GENERAL........................................................................................................................48

8.2. BATTERY REPLACEMENT ............................................................................................48

8.3. INSTRUMENT CLEANING..............................................................................................48

9. TECHNICAL SPECIFICATIONS............................................................................... 49

9.1. TECHNICAL FEATURES ................................................................................................49

9.1.1. SAFETY STANDARDS ....................................................................................................................51

9.1.2. GENERAL SPECIFICATIONS ...........................................................................................................51

9.2. ENVIRONMENT ..............................................................................................................52

9.2.1. ENVIRONMENTAL WORKING CONDITIONS .......................................................................................52

9.2.2. EMC...........................................................................................................................................52

9.3. ACCESSORIES...............................................................................................................52

10. SERVICE...................................................................................................................53

10.1. WARRANTY CONDITIONS.............................................................................................53

11. PRACTICAL REPORTS FOR ELECTRICAL TESTS............................................... 54

11.1. LOWΩ: CONTINUITY MEASUREMENT ON PROTECTIVE CONDUCTORS................54

EN - 1

Page 3

AMPROBE

MULTITEST1000

11.2. INSULATION RESISTANCE MEASUREMENT OF THE ELECTRICAL INSTALLATIONS

(250VDC, 500VDC, 1000VDC)........................................................................................55

11.3. MEASUREMENT OF FLOOR INSULATION RESISTANCE IN MEDICAL ROOMS.......57

11.4. CHECK OF THE CIRCUIT SEPARATION ......................................................................58

11.5 EARTH RESISTANCE MEASUREMENT, VOLTAMPEROMETRIC METHOD ..............61

11.6 EARTH RESISTIVITY MEASUREMENT.........................................................................63

Release EN 1.00 of the 17/09/2002

EN - 2

Page 4

1. SAFETY PRECAUTIONS AND PROCEDURES

This instrument conforms to safety standards EN61557 and EN 61010-1 relating to

electronic measuring instruments.

For your own safety as well as that of the instrument you are recommended

to follow the procedures described in this instruction manual and carefully

read all the notes preceded by the symbol

Strictly adhere to the following instructions before and during measurements:

) Do not take measurements in wet environments.

) Do not take measurements in environments with explosive gas, fuels or dust.

) Keep yourself insulated from the object under test.

) Avoid any contact with exposed metal parts, ends of test leads not in use, circuits, etc.

) Do not take any measurements in the case of unusual conditions of the instrument

such as deformation, breakage, leakage of substances, absence of displayed readings

etc.

) Pay careful attention when measuring voltages exceeding 25V in particular places

(building yards, swimming pools...) and 50V in ordinary places because of the risk of

electric shock.

The following symbols are used in this manual:

Caution: refer to the instructions reported in this manual; improper use may

damage the apparatus or its components.

AC Voltage or Current.

Unidirectional pulsating Voltage or Current.

Rotary switch of the instrument.

WARNING

.

1.1. PRELIMINARY INSTRUCTIONS

) This instrument has been designed for use in environments with a pollution degree 2.

) It can be used for tests on electrical installations with over voltage category III up to

265V (to Earth).

) You are recommended to comply with the standard safety regulations aimed at:

9 Protecting you against dangerous currents.

9 Protecting the instrument against improper use.

) Only the leads supplied with the instrument guarantee compliance with the safety

standards. They must be in good condition and must be replaced, if necessary, with

identical models.

) Do not take measurements on circuits exceeding the specified voltage limits.

Page 5

) Do not take any measurement under environmental conditions beyond the limits

specified in this manual.

) Check that batteries have been installed correctly.

) Before connecting test leads to the circuit under test, check that the rotary switch

position is correct.

) Check that the display and rotary switch indicate the same function.

1.2. DURING USE

Carefully read the following recommendations and instructions:

WARNING

Non-compliance with the Warnings and/or Instructions may damage the

apparatus and/or its components or injure the operator

.

) Before selecting any function disconnect the test leads from the circuit under test.

) When the instrument is connected to the tested circuit never touch any test lead that is

not being used.

) Avoid taking resistance measurements in the presence of external voltages; even

though the instrument is protected, a high voltage may cause malfunctions.

WARNING

If the symbol is displayed during use interrupt testing and replace

batteries following the procedure described under paragraph 8.2. The

instrument is capable of keeping the data stored even though batteries are

not installed.

1.3. AFTER USE

) When the measurements are completed disconnect the test leads from the circuit

under test and after that switch OFF the instrument.

) Remove batteries when the apparatus remains unused for long periods of time.

Page 6

2. GENERAL DESCRIPTION

Dear Customer, we thank you for your patronage. The instrument you have just purchased

will grant you accurate and reliable measurements provided that it is used according to the

present manual’s instructions.

The instrument was designed to grant the user the utmost safety conditions thanks to a

new concept assuring double insulation and over voltage category III.

2.1. FUNCTIONS

) LOWΩ: Continuity test of earth, protective and equalizing potential conductors with

test current greater than 200mA and open circuit voltage ranging from 4V

to 24V.

) R

: Measurement of insulation resistance with DC test voltage 50V, 100V,

ISO

250V, 500V or 1000V.

)

: Indication of phase sequence.

) EARTH ρ: Measurement of earth resistance and earth resistivity.

) RS232: Rotary switch position for RS232 communications.

Page 7

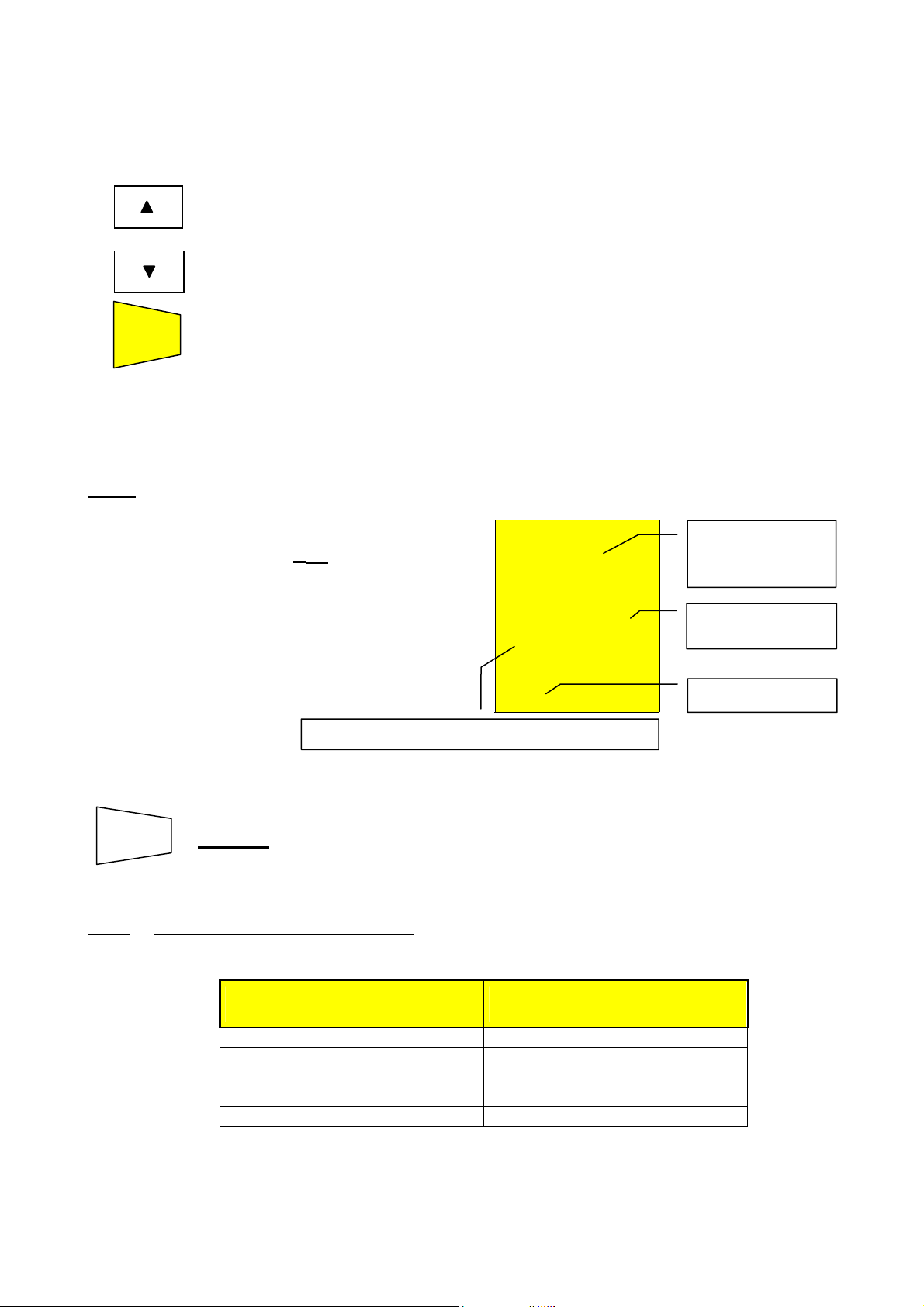

2.2. INSTRUMENT DESCRIPTION

1

2

∆

Un/I

n

FUNC

S UL

DIST

LEGEND:

1. Display

Function keys

2.

Rotary switch

3.

FUNC

START

3

Un

DIST

STOP

DISP

CLR

RCL

ESC

START

STOP

DISP

CLR

RCL

SAVE

ESC

) FUNCTION key to select measuring mode.

) U

/ DIST key for selection of rated voltage or distance depending on

n

which measurement is selected.

) key for increasing the test duration interval or to scroll the results of

the stored tests.

) key for decreasing the test duration interval or to scroll the results of

the stored tests.

) ON/OFF key. Keep it pressed a few seconds switch off the instrument.

Release when beep sounds.

) START/STOP key for start or to stop tests.

) DISPLAY key to display the stored results.

) CLEAR key to cancel the stored results.

) RECALL/ESCAPE key to recall the stored tests (RCL) and leave the

selected function or mode (ESC).

Page 8

SAVE

) SAVE key to save tests.

Page 9

3. PREPARATION FOR USE

3.1. INITIAL CONTROL

This instrument has been checked mechanically and electrically prior to shipment.

Care has been taken to ensure that the instrument reaches you under safe conditions.

However, you are recommended to perform a rapid check to detect any possible damage

that may have been caused during transport. Should this be the case, immediately contact

Amprobe.

Assure the packaging contains all the parts listed under paragraph 9.3. In case of

discrepancies contact the dealer.

In case you have to send the instrument back please follow the instructions reported in

paragraph 10.

3.2. POWER SUPPLY

Six AA batteries not included in the package supply the instrument. To replace batteries

follow the instructions in paragraph 8.2.

When batteries are low the symbol

instructions indicated in paragraph 8.2.

3.3. CALIBRATION

The instrument fulfils the technical specifications listed in this manual. The performance of

the specifications is guaranteed for one year.

3.4. STORAGE

In order to assure the accuracy of the measurements, after a period of storage in extreme

environmental conditions, wait for the instrument to return to normal operating conditions

(see environmental specifications listed in paragraph 9.2.1).

is displayed. To replace batteries follow the

Page 10

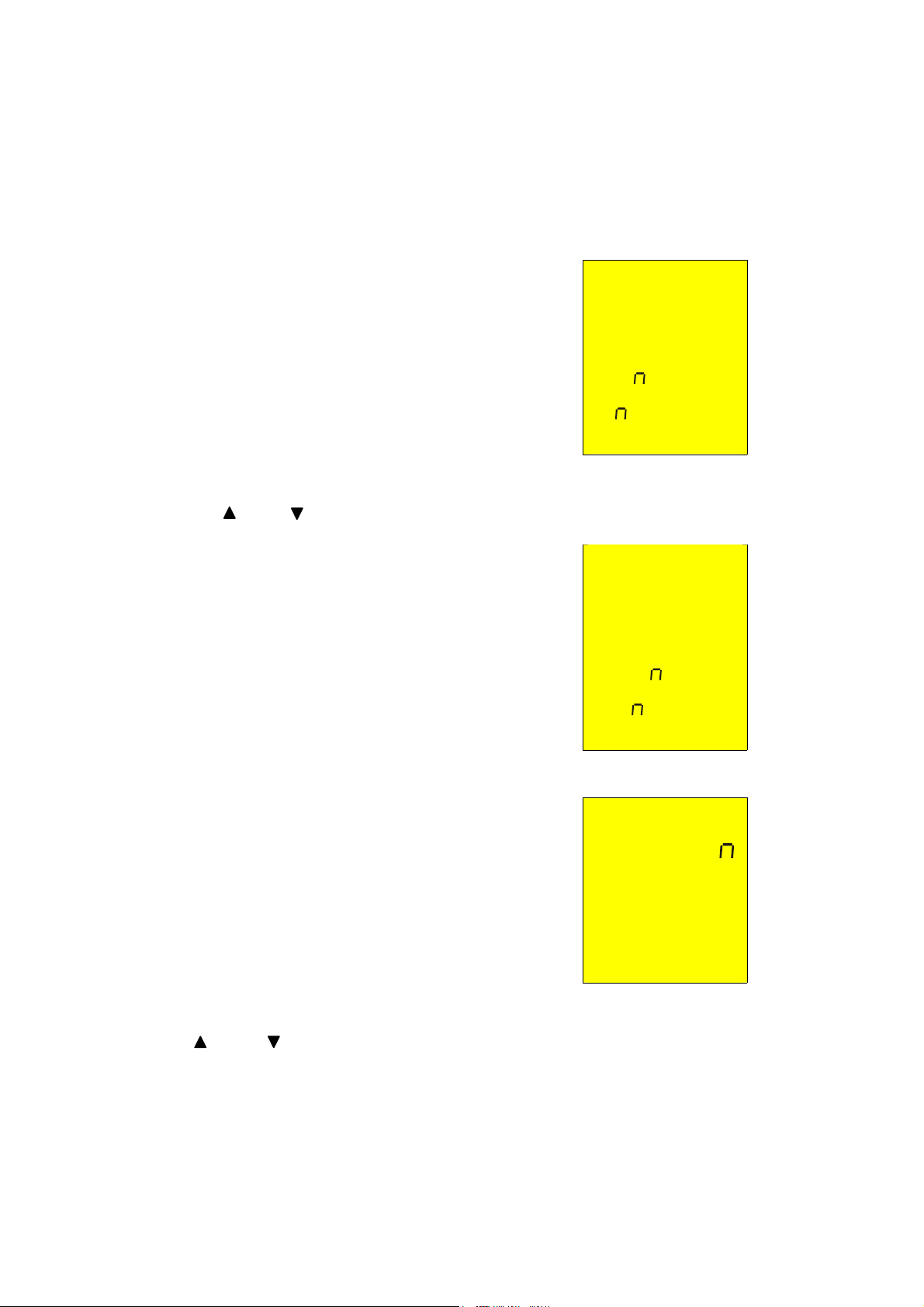

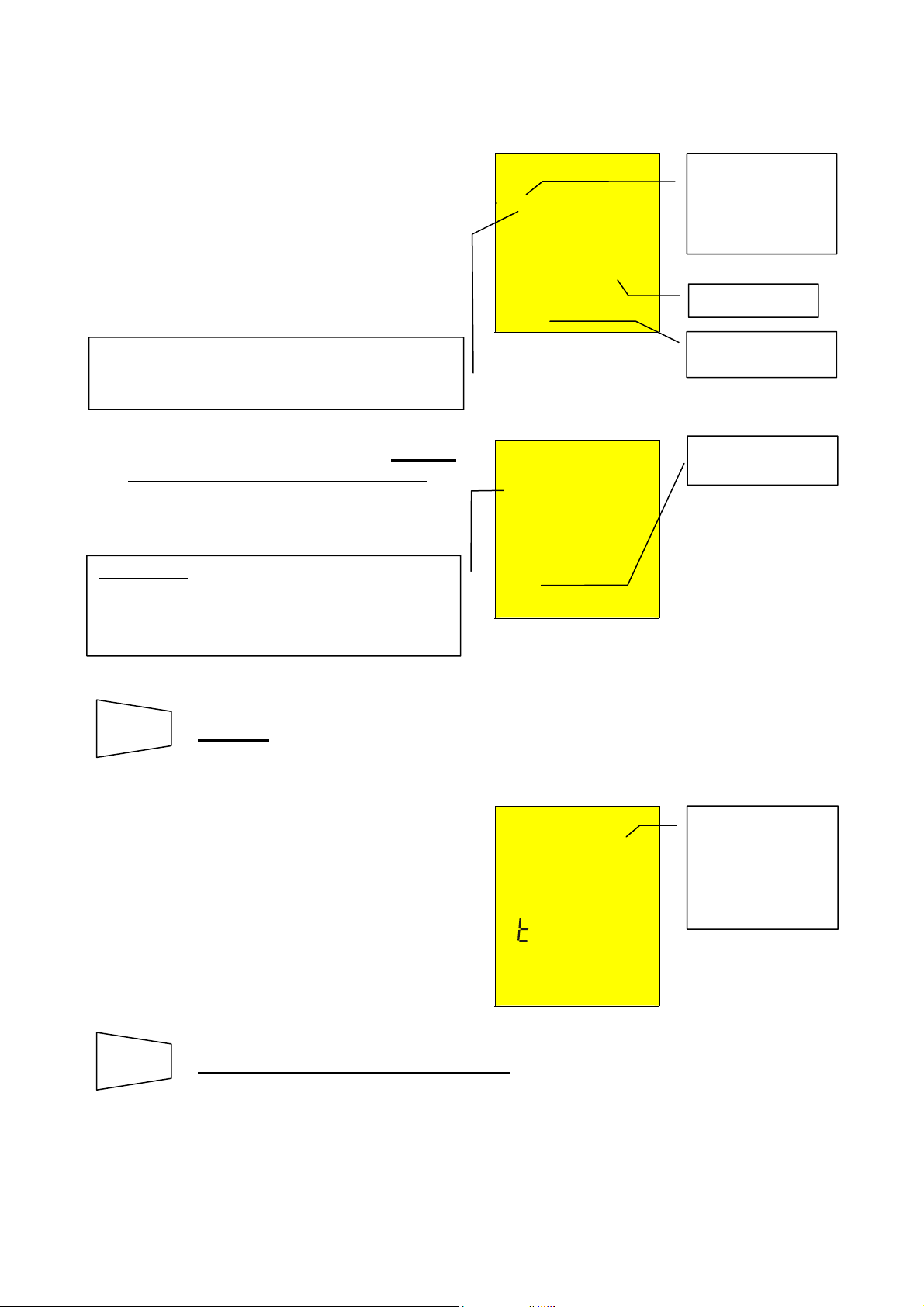

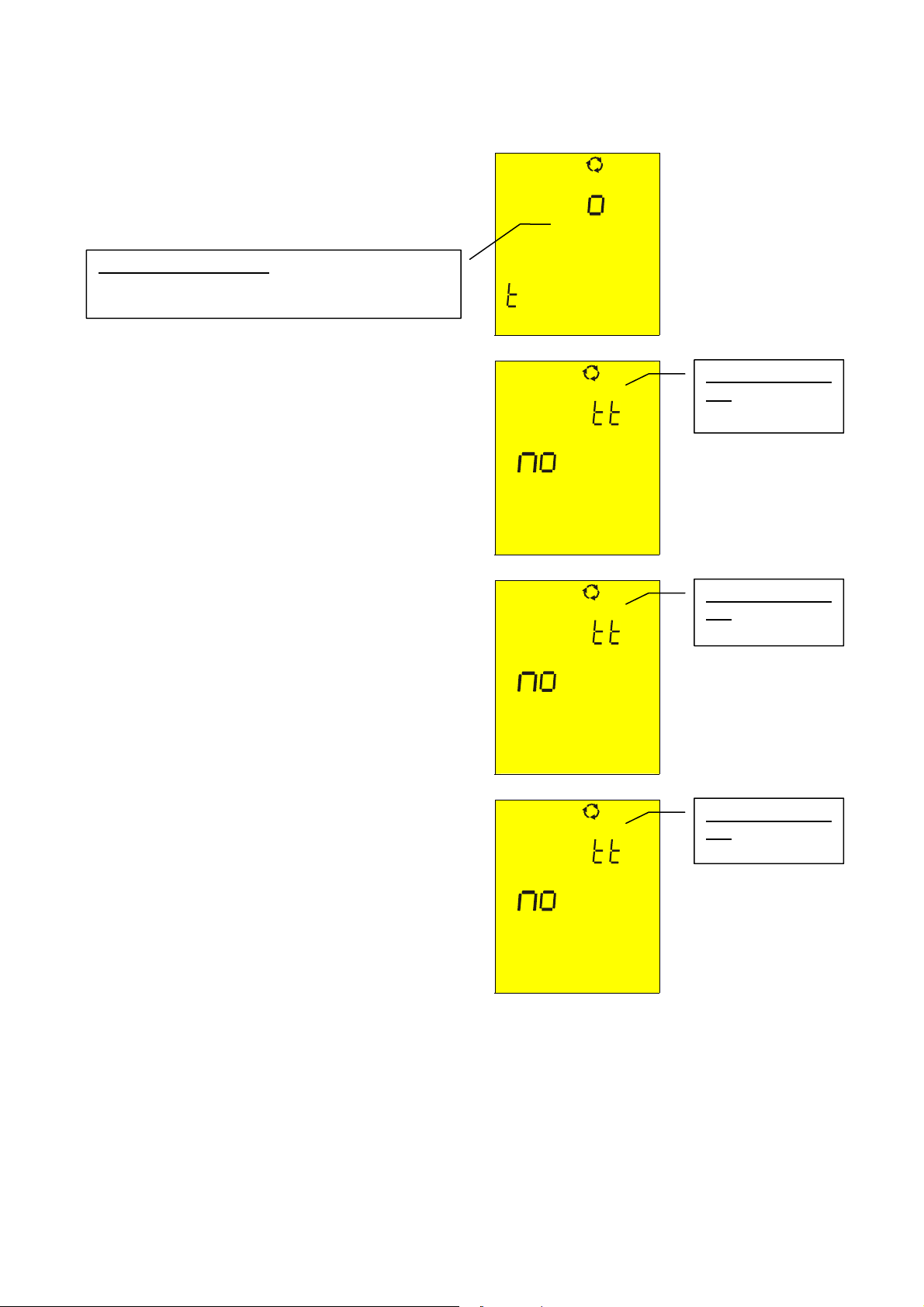

3.5. HOW TO SET LANGUAGE AND MEASUREMENT UNIT

It is possible to set the language and the distance measurement unit (in earth resistivity)

by following this procedure:

1. While pressing the FUNC button switch ON the instrument (the rotary switch position

isn't relevant).

2.

)

The following screen will appear.

LA

E

3. Choose the desired language between English, Spanish, German and Italian by

pressing the and keys (appear En, ES, dE, IT).

4.

)

Push the SAVE key confirming the

choice. The instrument will display the

following screen.

)

Push ESC key leaving language

selection menu without confirming any

change.

OK

LA

E

5.

)

The instrument will display the following

screen.

le

m

6. Choose the desired distance measurement unit between meter and feet that change by

pushing and keys (appear m and ft).

7.

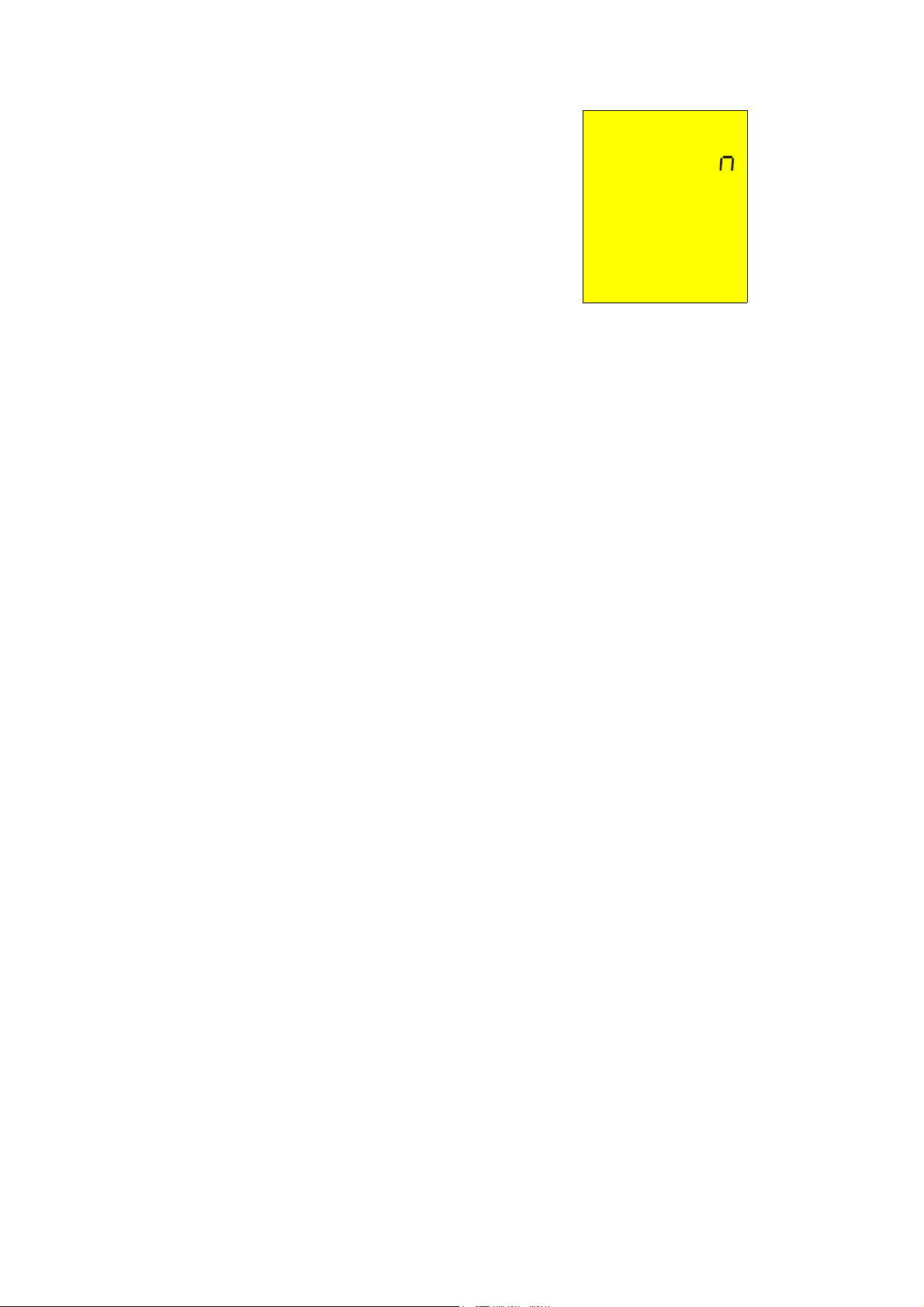

Page 11

)

Push SAVE key confirming the choice.

The instrument will display the following

screen.

le

)

Push ESC key leaving this menu without

confirming any change.

m

OK

Page 12

4. DESCRIPTION OF THE ROTARY SWITCH FUNCTIONS

4.1. LOWΩ: CONTINUITY TEST OF EARTH RESISTIVITY, PROTECTIVE AND

EQUALIZING POTENTIAL CONDUCTORS

The measurement is performed with a test current greater than 200 mA and open circuit

voltage ranging from 4 to 24V DC according to EN 61557-2 and VDE 0413 part 4.

FUNC

Note:

If the resistance is lower than 5Ω (including the resistance of the calibration) the

Before carrying out the continuity test make sure that there is no voltage at the

ends of the conductor under test.

Turn the rotary knob to the LOWΩ position.

Switch on the instrument.

The FUNC key permits you to select one of the following measuring modes:

) AUTO mode (the instrument carries out two measurements with reversed

polarity R+ and R-, and displays their average value R

recommended for the continuity test.

) R + TIMER mode (measurement with positive polarity and the ability to

set the duration time of the test). In this case the operator can set a

measuring time long enough to permit him to move the protective

conductors while the instrument is carrying out the test to detect any bad

connection.

) R – TIMER mode (measurement with negative polarity and the ability to

set the duration time of the test). In this case the operator can set a

measuring time long enough to permit him to move the protective

conductors while the instrument is carrying out the test to detect any bad

connection.

) Mode CAL (compensation of the resistance of the cables used for the

measurement).

continuity test is performed by the instrument with a current greater than 200mA. If

the resistance is greater than 5Ω, the continuity test is performed by the

instrument using a decreasing current.

WARNING

). This mode is

avg

Page 13

A

p

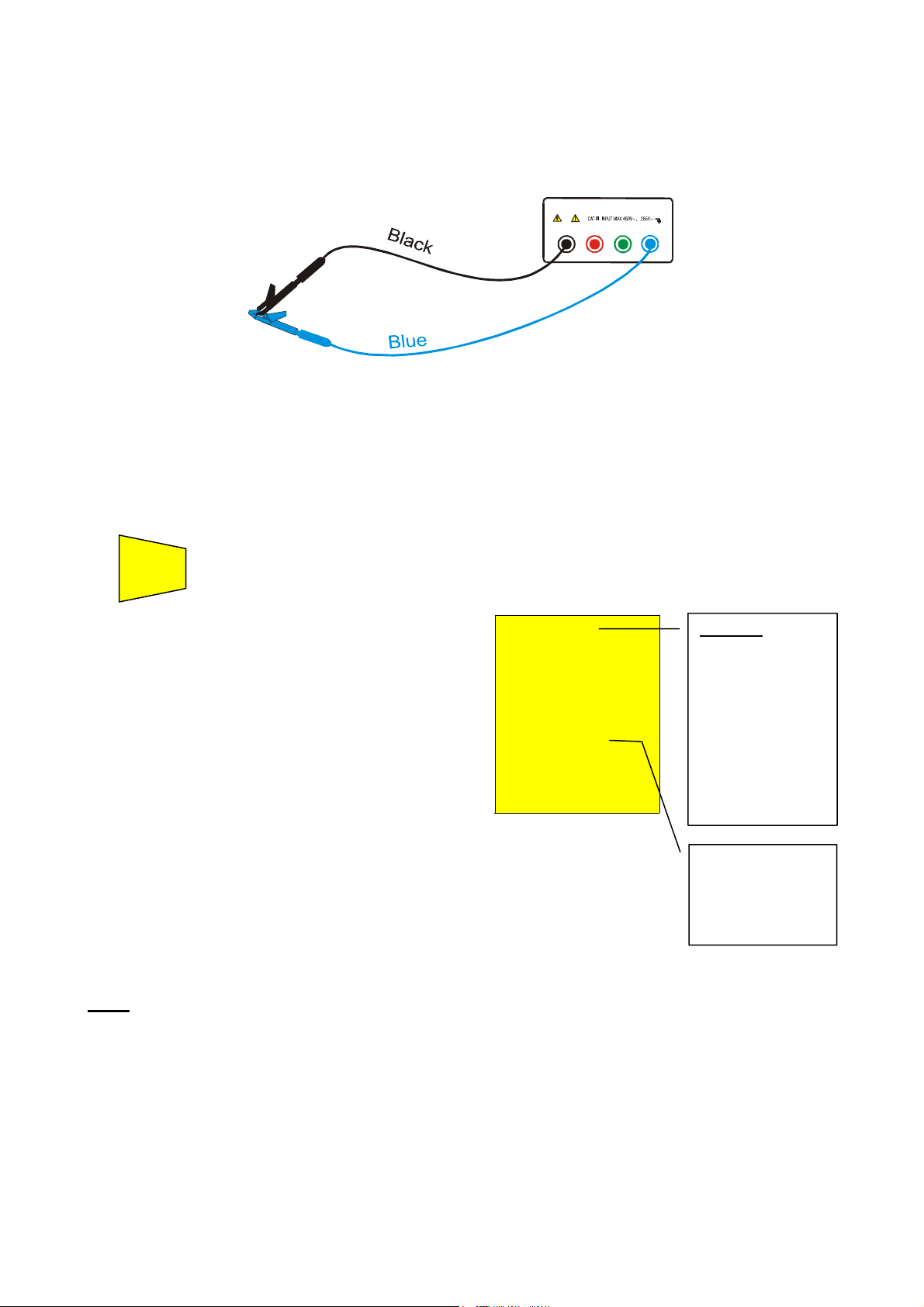

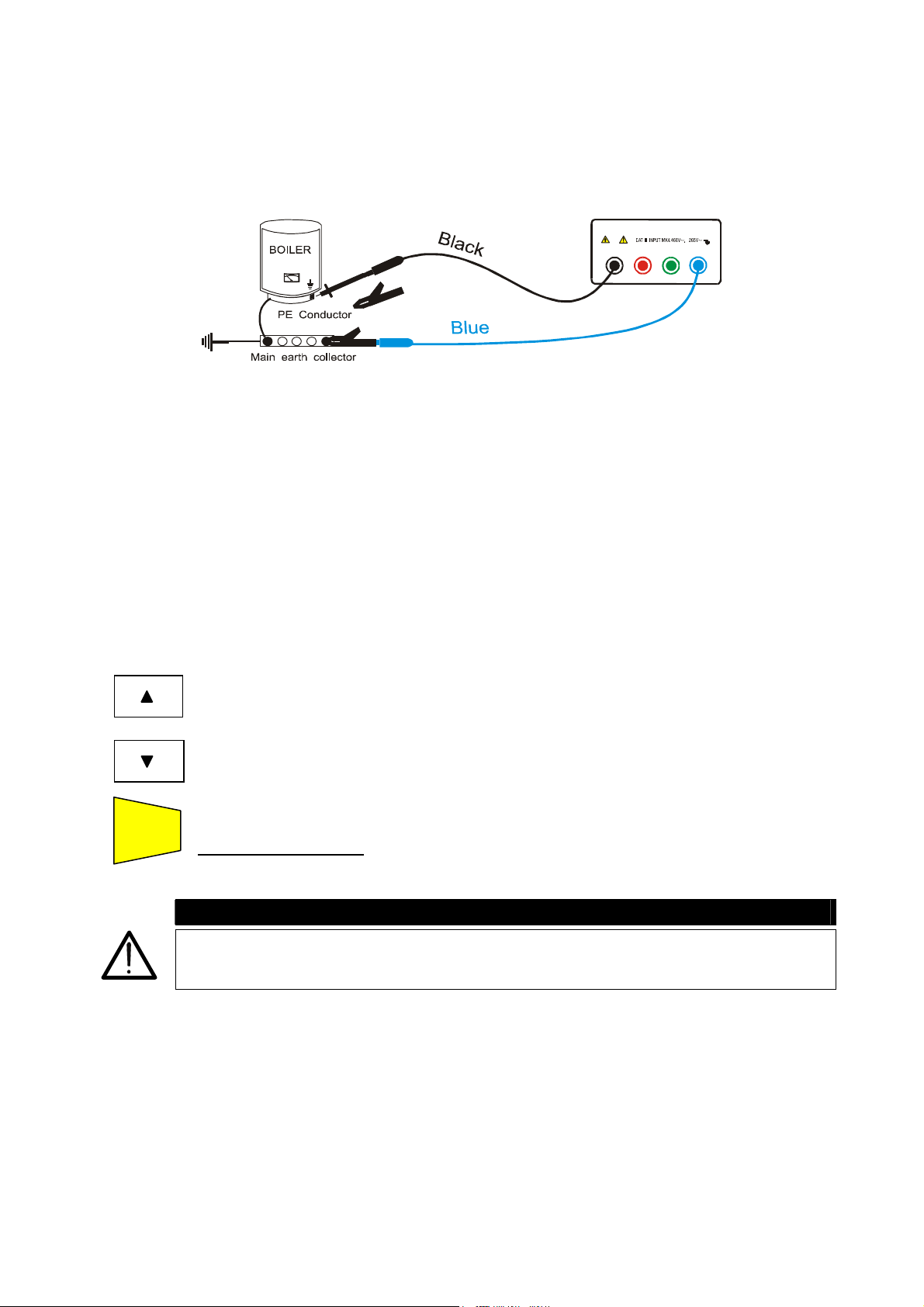

4.1.1. "CAL" Mode

1. Select the CAL mode using the FUNC key.

2. Connect the black and blue cables to the instrument input terminals T1 and T4

respectively:

B2 B3

B1

B4

Connection of instrument terminals during calibration procedure.

3. If the cables supplied with the instrument are not long enough for the measurement you can

extend the blue cable.

4. Connect the alligator clips to the cable terminals.

5. Short-circuit the measuring cable ends making sure that the conductive parts of the alligator

clips make a good contact with each other (see previous picture).

START

6. Press the START/STOP key. The instrument carries out the calibration.

STOP

)

t the end of the test

CAL LOWΩ

the result is stored and

used as the OFFSET

0.00

(i.e. it is subtracted

from any continuity

test performed) for all

the subsequent

measurements until a

203 mA

Ω

new calibration is

performed.

This screen is displayed for only 2 seconds

then the instrument emits a double beep

(indicating that the calibration is completed) and

displays the default screen relative to the

LOWΩ test under AUTO mode.

Message CAL:

means that the

instrument was

calibrated; this

symbol remains

on the display

for any further

measurement

even though the

unit is switched

off and on again.

Current supplied

by the instrument

during the

calibration

rocedure.

Note: The instrument effects the calibration of cables with resistance lower of 5Ω.

Page 14

Ω

CABLES USED FOR THE TEST If the cables are changed or extended be sure and

recalibrate the instrument. During a continuity

test, if the resistance value free of calibration (that

is the resistance value less the calibration offset

value) is negative, the symbols

blinking CAL are displayed (refer to 5

paragraph 4.1.3).

Never disconnect the test leads while the word “Measuring” is being

displayed.

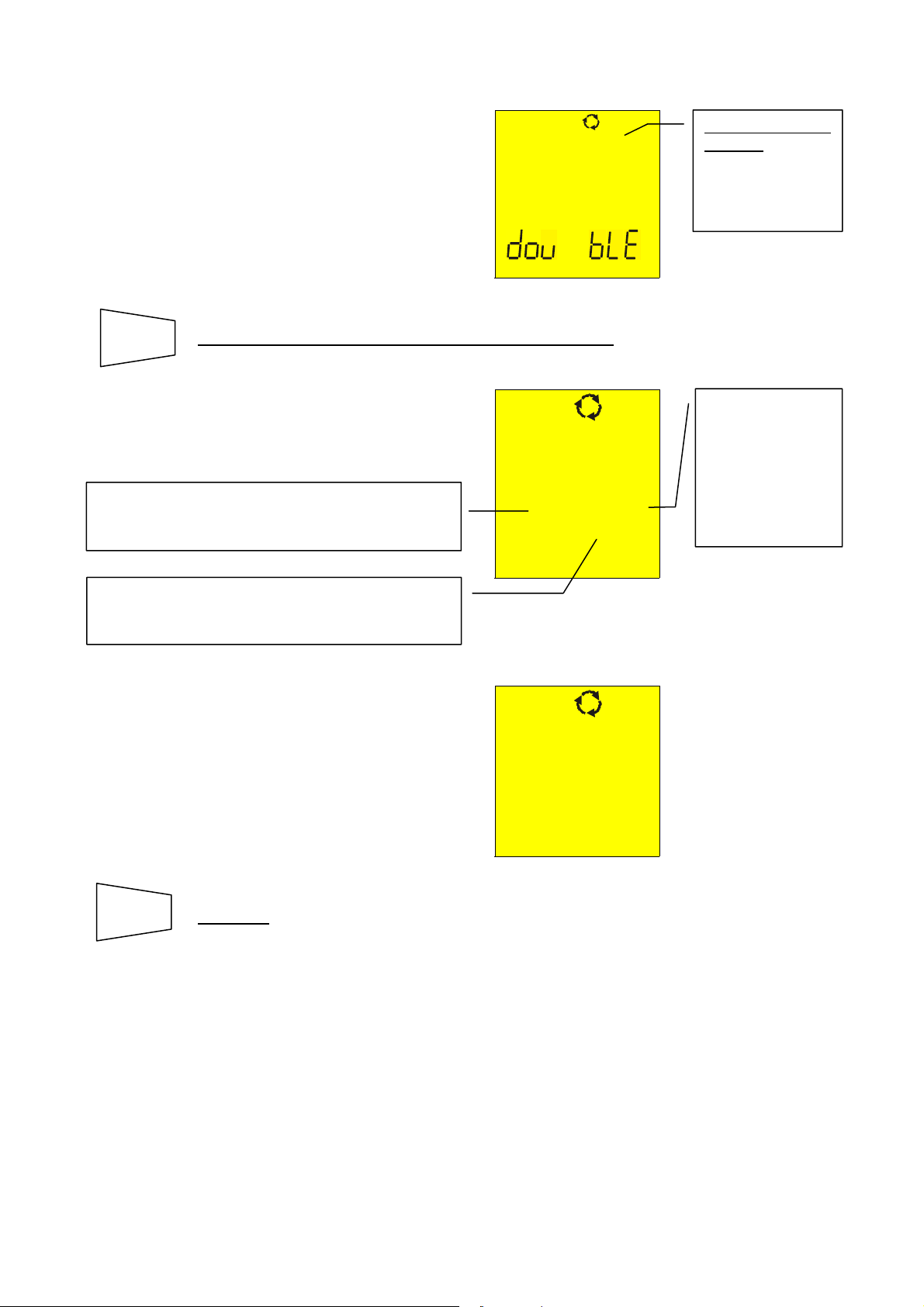

4.1.1.1. Procedure to cancel calibration parameters and cal symbol

To cancel the calibration parameters (and

the symbol CAL) it is necessary to perform a

calibration procedure with a resistance

greater than 5Ω (for example with the test

leads disconnected). When a cancellation is

completed this screen is displayed first,

followed by the screen below:

The screen alongside is displayed for 2

seconds, after which the instrument emits a

long beep and then displays the default

screen relative to the LOWΩ test under

AUTO mode without the symbol CAL.

WARNING

LOWΩ

ν> 5

cal

Measuring

LOWΩ

es

cal

ν as well as

th

screen

Message >5Ω:

means that the

instrument

detected a

resistance greater

than 5Ω therefore

it will proceed

with Reset

procedure.

Message rES:

means that the

instrument

cancelled

(RESET) the

calibration

parameter

Page 15

4.1.2. Procedure for measuring continuity of equalizing potential conductors mode

"AUTO", "R+TIMER", "R-TIMER"

1. Select the desired mode using the FUNC key.

2. Connect the black and blue cables to the instrument input terminals T1 and T4

respectively.

B2 B3

B1

B4

Connection of the instrument terminals during LOWΩ test.

3. If the cables supplied with the instrument are not long enough for the measurement you can

extend the black cable.

4. Connect two alligator clips to the cable terminals.

5. Short-circuit the measuring cable ends making sure that the conductive parts of the alligator

clips make a good contact to each other. Press the START/STOP key. If the instrument

displays a resistance value other than 0.00 repeat the instrument calibration (see

paragraph 4.1.1).

6. Connect the instrument terminals to the ends of the conductor on which the continuity test is

to be performed (see previous picture).

7. If the mode "R+TIMER" or "R-TIMER" was selected use the following keys to select

the duration time of the test:

Press this key to increase the duration time of the test (Tmax=15 seconds).

Press this key to decrease the duration time of the test (Tmin=1 second).

START

8. Press the START/STOP key. The instrument takes the measurement.

STOP

In R+/R- Timer mode

press START/STOP key again if the test is to be stopped.

WARNING

Never disconnect the test leads while the word “Measuring” is being

displayed.

Page 16

A

T

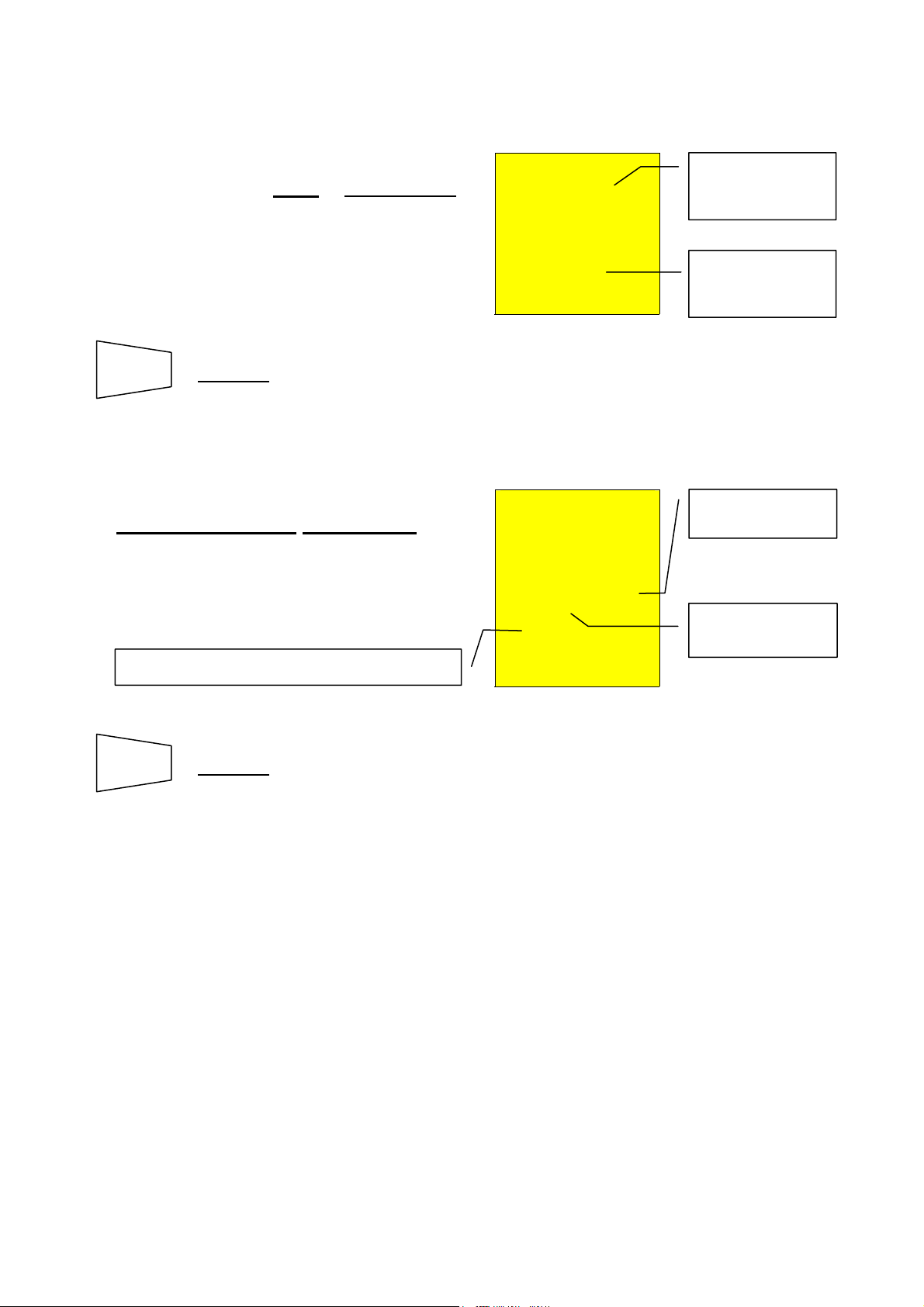

4.1.2.1. Mode "AUTO"

)

At the end of the test, if the average

resistance value Ravg

is less than 5Ω

the instrument emits a double beep

indicating the positive outcome of the

test and displays a screen similar to the

screen alongside.

SAVE

SAVING

: The test results can be stored pressing the SAVE key twice

(refer to paragraph 5.1).

4.1.2.2. Mode "R+TIMER" or “R-TIMER"

)

If during the test a resistance value

R+Timer or R–Timer less than 5Ω was

detected, the instrument (after the set

time has elapsed) emits a double beep

indicating a positive outcome of the

test & displays a screen similar to the

screen alongside.

The symbols R+ or R- are displayed.

SAVE

SAVING

: The test can be stored pressing the SAVE key twice (refer to

paragraph 5.1).

CAL LOWΩ

.07 Ω

219 mA

AUTO

CAL LOWΩ

.08 Ω

219 mA

5 s

R+

R-

IMER

Average

resistance value

Ravg.

verage test

current value

Iavg.

Duration time of

the test.

Value of the test

current I+ or I-.

Page 17

Ω

A

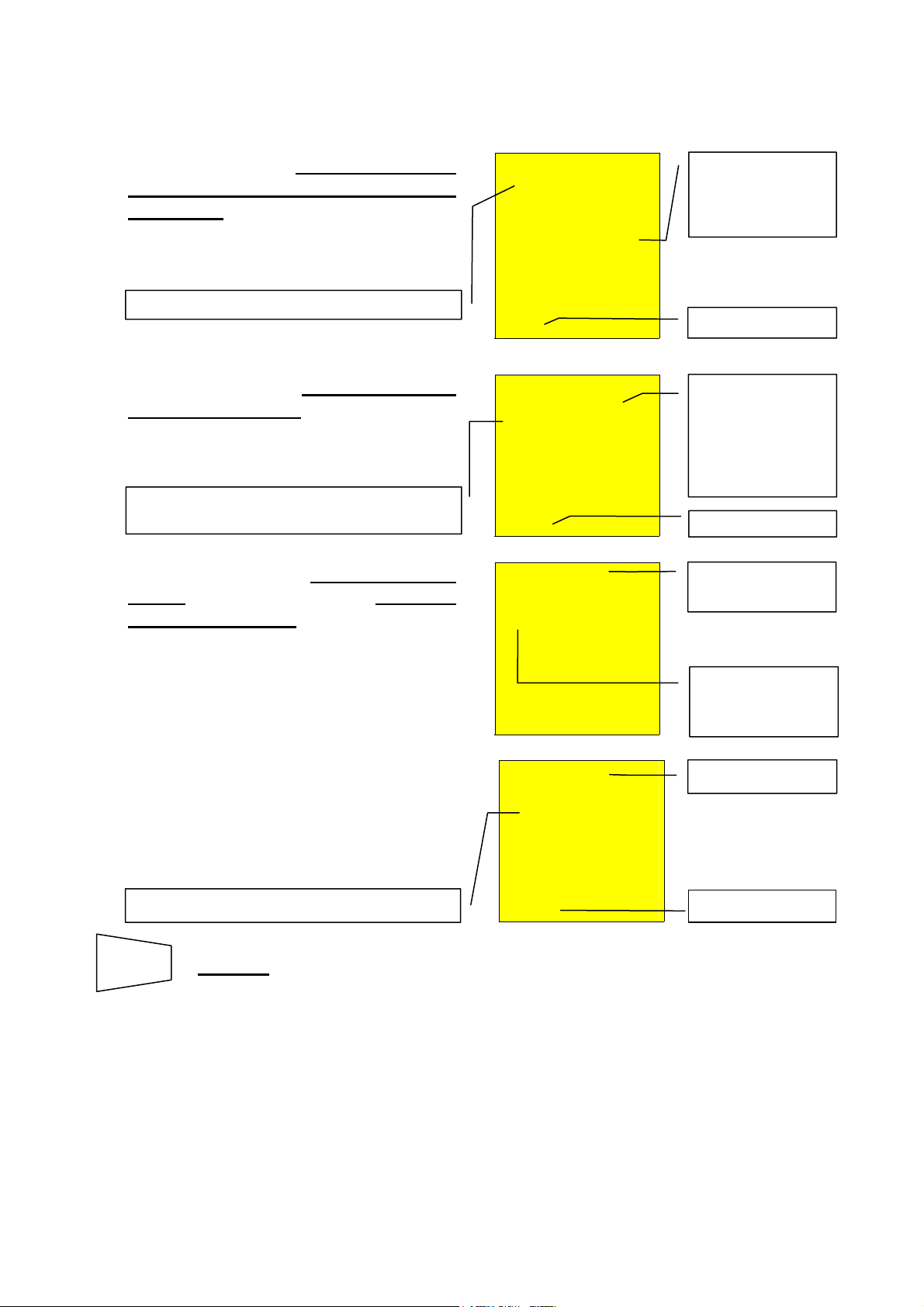

4.1.3. Anomalous cases during "AUTO", "R+TIMER", "R-TIMER" tests

)

In case a value of Ravg or R+ or R-

greater than or equal to 5Ω but less

than 99.9Ω was detected, at the end of

the test the instrument emits a long

beep and displays a screen similar to

the screen alongside.

ATTENTION: value of R

greater than 5

CAL LOWΩ

5.75 Ω

216 mA

5 s

AUTO

Only in the case

R+TIMER or RTIMER was

selected.

AUTO mode.

)

In AUTO mode, if a Ravg or R+ or R-

greater than 99.9Ω was detected, at

the end of the test the instrument emits

a long beep and displays the screen

alongside.

ATTENTION: value of R

high.

or R+ or R- is too

avg

CAL LOWΩ

99.9 Ω

- - - mA

AUTO

99.9Ω is the

maximum value

that can be

measured in the

LOWΩ AUTO or

R+ or R-mode.

)

In the case mode R+TIMER or RTIMER was selected and a R+ or R-

greater than 99.9Ω was detected, the

instrument emits an intermittent beep

during the test, a long beep at the

end of the test and displays the screen

alongside.

CAL LOWΩ

99.9 Ω

- - - mA 4 s

R+

TIMER

99.9Ω is the

maximum value.

ATTENTION:

value of R+ or Ris too high.

)

In case that:

R

MEASURED-RCALIBRATION

< 0Ω the

instrument displays the screen

alongside.

CAL LOWΩ

0.00 Ω

Blinking CAL.

219 mA

ATTENTION: R

MEASURED-RCALIBRATION

< 0

UTO

AUTO mode.

SAVE

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

Page 18

A

)

If the terminal voltage is greater than

10V, the instrument does not perform

the test and displays a screen similar to

the screen alongside for 5 seconds.

fter which, the instrument displays the

screen relative to the selected test

mode LOWΩ under AUTO mode.

SAVE

THIS RESULT CANNOT BE SAVED

CAL LOWΩ

13V

VOL

AG

.

ATTENTION: the

test was not

completed

because of

voltage at the

terminal ends.

Page 19

4.2. MΩ: INSULATION RESISTANCE MEASUREMENT WITH TEST VOLTAGE

OF 50V, 100V, 250V, 500V OR 1000V

Refer to EN 61557-2 and VDE 0413 part 1.

WARNING

Before performing the insulation test make sure that the circuit under test is

not energized and all the relative loads are disconnected.

Turn the rotary knob to the MΩ position.

Switch on the instrument.

FUNC

The FUNC key permits the operator to select one of the following measuring

modes (which can be shown cyclically by pressing the FUNC key):

) MAN mode (minimum test time of 4 seconds or the key press duration of

the START/STOP key). Recommended test

.

) TIMER mode (test duration is set to the selected interval (from 10 to 999

seconds). This test can be performed in case a minimum measuring time

is required.

Page 20

4.2.1. Procedure for measuring insulation resistance in any mode

1. Select the desired mode by means of the FUNC key.

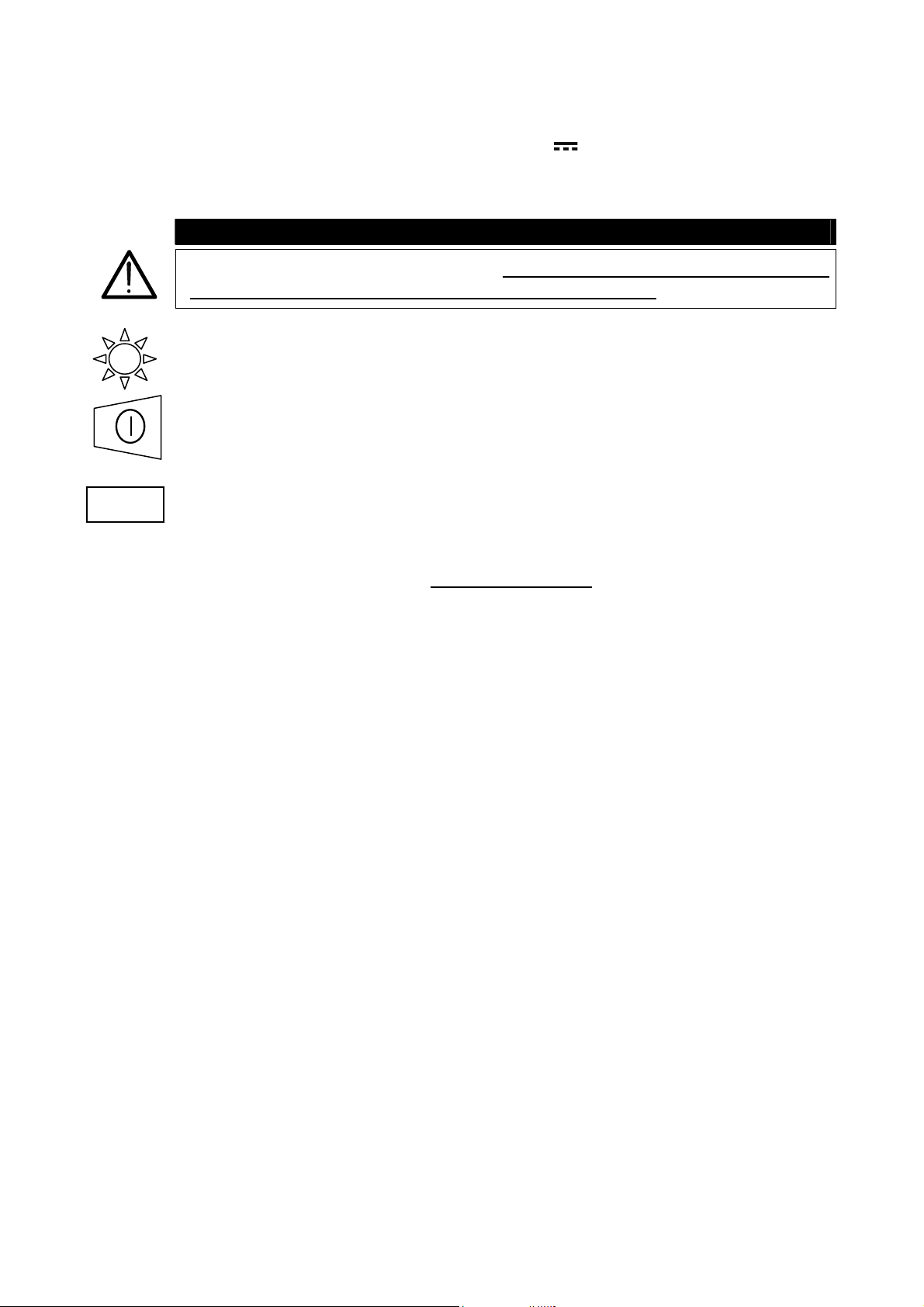

2. Connect the black and blue cables to the instrument input terminals T1 and T4

respectively.

M

B2 B 3 B4B1

Insulation between phase and earth in an electrical

installation using untied cables.

3. If the cables supplied with the instrument are not long enough for the measurement you can

extend the blue cable.

4. Connect the instrument terminals to the object that is to be submitted to the insulation

test after disconnecting the circuit under test and all the relative loads (see

previous picture).

5. By pressing the U

Un

DIST

key select the test voltage suitable for the type of

test to be carried out (see table). The values to be selected are:

n

• 50V (test on telecommunication system)

• 100V • 500V

• 250V • 1000V

Standard Brief description Test voltage Maximum limit value

> 0.250MΩ

> 0.500MΩ

> 1.0MΩ

> 50kΩ (if V<500V)

> 100kΩ (if V>500V)

> 230kΩ

> 1MΩ

CEI 64-8/6

CEI 64-8/4

Systems SELV or PELV

Systems up to 500V (Civil installations)

Systems over 500V

Floor and wall insulation in civil installations

Floor and wall insulation in systems over 500V

250VDC

500VDC

1000VDC

500VDC

1000VDC

EN60439 Electrical panel boards 230/400V 500VDC

EN60204 Electrical equipment of machines 500VDC

CEI 64-4 Floor insulation in medical rooms 500VDC

<1MΩ (if the floor is at least 1 year old)

<100MΩ (if the floor is at least 1year old)

Test voltage values and the relative maximum limit values for the most common kinds of test.

WARNING

If “Measuring” is displayed the instrument is performing the measurement.

During this phase do not disconnect the test leads, as the circuit under test

may remain charged at a dangerous voltage due to the parasite capacitance

Page 21

of the installation. Independently of the working mode selected the instrument

throws a resistance in the output terminals at the end of each test to

discharge the parasite capacitance of the circuit.

Page 22

4.2.1.1. Mode "MAN"

START

6. Press the START/STOP key.

STOP

The instrument performs the test lasting:

9 Minimum 4 seconds in case the key is pressed and released.

9 Until the key is released for all the other cases.

)

At the end of the test, in case the

resistance value R

to be lower than R

detected results

ISO

(depending on

MAX

the selected voltage see following table)

and the test is performed at the

selected rated voltage value, the

instrument emits a double beep

indicating the positive outcome of the

test displays a screen similar to the

screen alongside.

R

ISO

00 MΩ

500 V 20

s

MAN

Rated voltage value

selected for the test.

R

insulation

ISO

resistance value

Test duration.

In this case the

START/STOP

key has been

pressed for 20

seconds.

Manual mode.

.

The values of measured resistance of isolation always must be confronted with the

normative limits (see table) for being able to assert if the system is to norm.

SAVE

SAVING

: The test can be stored pressing the SAVE key twice (refer to

paragraph 5.1).

Page 23

4.2.1.2. Mode "TIMER"

6. Use the following keys to set the duration time of the test:

Press this key to increase the duration time of the test (Tmax=999 seconds).

Press this key to decrease the duration time of the test (Tmin=10 seconds).

START

7. Press the START/STOP key.

STOP

The instrument completes the measurement when the set time has elapsed.

999 seconds → Maximum value of the test duration.

10 seconds → Minimum value of the test duration.

Note:

Pressing the START/STOP key again the test gets immediately interrupted.

)

At the end of the test, in case the

resistance value R

lower than R

(depending on the

MAX

detected is

ISO

selected voltage see following table) and

the test is performed at the selected

rated voltage value, the instrument

emits a double beep indicating the

positive outcome of the test displays

one screen similar to the screen

alongside.

Rated voltage value selected for the Timer test.

R

ISO

07 MΩ

500 V 20

s

TIMER

Insulation

resistance value

R

ISO.

Duration of the

test.

Timer mode.

SAVE

SAVING

: The test can be stored pressing the SAVE key twice (refer to

paragraph 5.1).

Note

: The maximum resistance value R

on the rated voltage selected for the test. In particular:

Rated voltage selected

for the test

50VDC

100VDC

250VDC

500VDC

1000VDC

that can be measured in mode MΩ depends

MAX

R

= Maximum resistance

MAX

value

99.9MΩ

199.9MΩ

499MΩ

999MΩ

1999MΩ

Page 24

Maximum resistance values measurable under MΩ mode depend on the rated voltage selected.

Page 25

p

4.2.2. Special cases which may occur during the tests "MAN" & "TIMER"

)

In case a value of R

R

was detected (depending on the

MAX

selected voltage see following Note

table, the instrument emits a double

beep at the end of the test indicating

the positive outcome of the test and

displays a screen similar to the screen

alongside.

Maximum resistance value that can be measured

(999Ω is displayed if a rated voltage of 500V was

selected see table).

greater than

ISO

R

ISO

999 MΩ

500 V 20

s

MAN

The symbol ">"

means that the

resistance value

R

is greater

ISO

than R

Test duration

Selected mode

MAN

)

In case a test is performed at a voltage

lower than the set rated voltage, at

the end of the test the instrument emits

R

ISO

0.01 MΩ

Selected mode

MAN

a long beep and displays a screen

similar to the screen alongside.

ATTENTION: the test of resistance R

performed at a voltage value lower than the set

rated voltage. Low insulation case. This case

occurs under low insulation conditions or in the

resence of capacitance on the installation.

ISO

was

500 V 20

s

MAN

MAX

SAVE

SAVING

: The test can be stored pressing the SAVE key twice (refer to

paragraph 5.1).

)

If the terminal voltage is greater than

30V, the instrument does not perform

the test, displays the screen alongside

for 5 seconds after which, it shows the

default screen relative to the R

under selected mode.

SAVE

THIS RESULT CANNOT BE SAVED.

ISO

test

R

ISO

ν 33V

VOL

AG

ATTENTION: the

test was not

carried out.

Check that the

circuit is not

energized.

Page 26

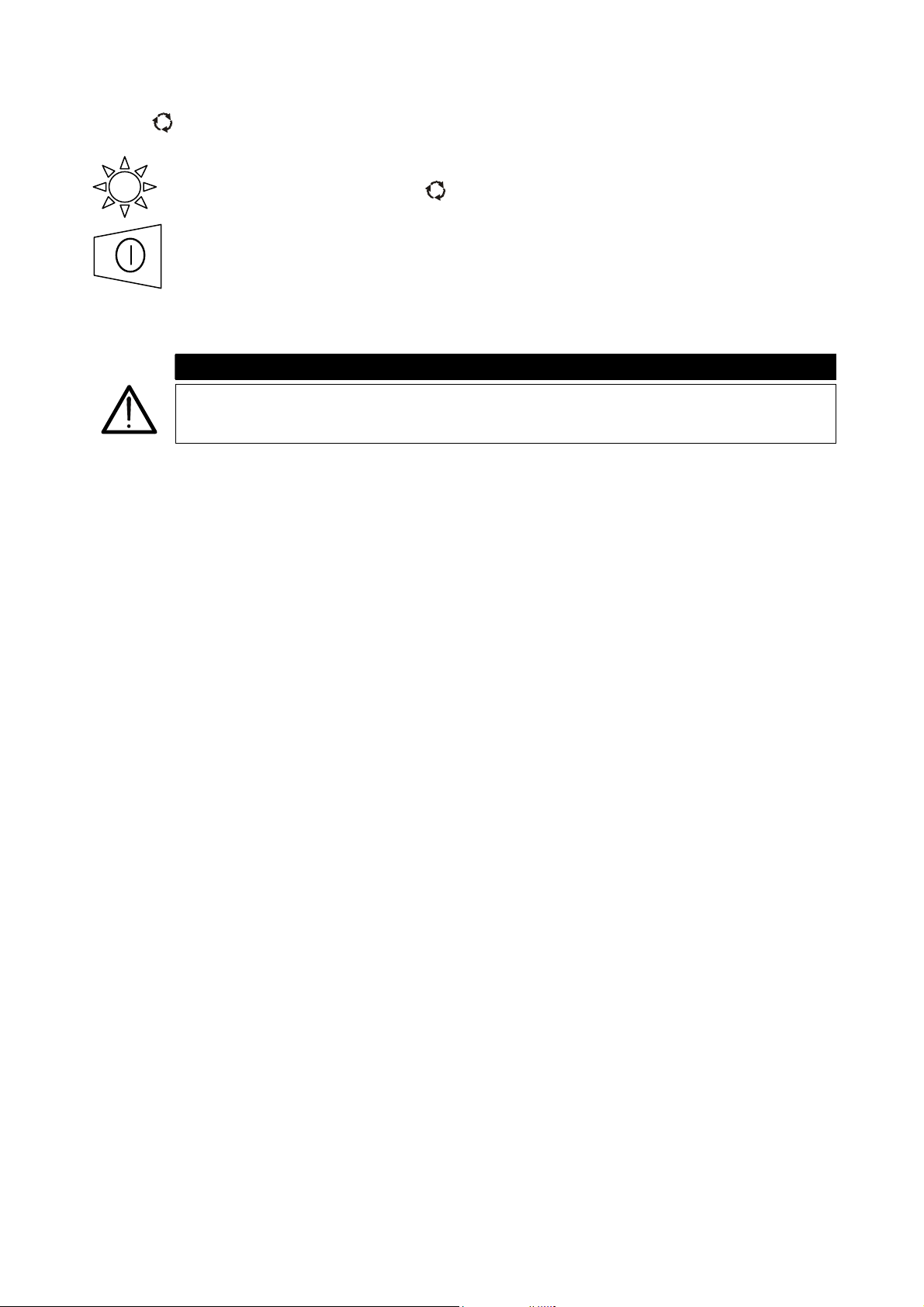

4.3. : PHASE SEQUENCE INDICATOR

Turn the rotary knob to the

position.

Switch on the instrument.

WARNING

Never disconnect the test leads while the word “Measuring” is being

displayed.

Page 27

A

A

4.3.1. Mode " "

1. Connect the three black, red and green connectors of the untied cables in the corresponding

input terminals of the instrument T1, T2, T3 and the alligator clips to the free ends of the

cables.

L1

L2

L3

N

B2 B3

B1

B4

Instrument connection for phase sequence indication L1=black cable, L2=blue cable, L3=green cable

2. Connect the alligator clips to the three phases of the system under test. The instrument

displays the following screen (before pushing START/STOP key):

Voltage value between Phase1 and Phase2.

386 V

Voltage value between Phase3 and Phase1.

388V 388V

Voltage value between Phase2 and Phase3.

START

4. Press the START/STOP key to start the measurement of phase

STOP

sequence, one of the following screen will be displayed:

)

t the end of the test the instrument

displays the values alongside in case of

correct phase sequence

, which means

the black cable is connected to the

phase1=L1, the blue cable to the

phase2=L2 and green cable to the

phase3=L3.

)

t the end of the test the instrument

displays the values alongside in case of

wrong phase sequence.

123

ν

Message "123":

indicates that the

phase sequence

is correct.

Message "213":

indicates that the

phase sequence

is wrong.

213

WARNING

Page 28

SAVE

Never disconnect the test leads while the word “Measuring” is being

displayed.

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

Page 29

p

4.3.2. Anomalous cases which may occur during phase sequence tests

)

In the case that every delta voltage is

lower than 100V, the instrument does

not perform the test and displays the

screen alongside.

L

Message “Lo VOL tAG”: the instrument has at

least one low voltage. The instrument does not

perform the test.

)

If the voltage present at the T1 input is

too low, when START/STOP is pressed

the instrument displays the message

alongside.

)

If the voltage present at the T2 input is

too low, when START/STOP is pressed

the instrument displays the message

alongside.

VOL

AG

ν A

l1

ν A

Message “Att no

L1”: voltage of

phase 1 is too low

Message “Att no

L2”: voltage of

phase 2 is too low

)

If the voltage present at the T3 input is

too low, when START/STOP is pressed

the instrument displays the message

alongside.

l2

ν A

l3

Message “Att no

L3”: voltage of

hase 3 is too low

Page 30

)

If two measurement cables were

connected to the same phase

conductor, when START/STOP is

pressed the instrument displays the

message alongside.

SAVE

THE PREVIOUS RESULTS CANNOT BE SAVED

)

If one cable is not connected to the

network or one phase is absent, the

instrument displays the screen

alongside

Black cable=L1 is not connected to one phase of

the installation. Voltage between phase L3 and

phase L1 is null (L3 - L1).

ν ph

.

0 V

0 V 388

V

Message “PH

double”: two

cables are

connected to the

same phase

conductor.

Black cable= L1

is not connected

to one phase of

the installation.

Voltage between

phase L2 and

phase L3 is not

null (L2- L3).

Black cable=L1 is not connected to one phase of

the installation. Voltage between phase L1 and

phase L2 is null (L1-L2).

)

If two or more cables of the instrument

are not connected, it displays the screen

alongside.

SAVE

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

0 V

0 V 0 V

Page 31

4.4. EARTH ρ: EARTH RESISTANCE AND RESISTIVITY MEASUREMENT

Turn the rotary knob to the EARTH ρ position.

FUNC

The resistance is measured with a 4-cable voltamperometric method, so the value

measured is not dependant on the utilized cables. For this reason this method doesn’t

need any cable calibration.

If the cables aren’t long enough, lengthen them or utilize cables longer than the standard

ones.

Switch on the instrument.

The FUNC key permits to select one of the following measuring modes

(which can be shown cyclically when pressing the key):

) Mode “2P” (the instrument measures earth resistance between 2 points).

) Mode “3P” (the instrument measures earth resistance using two auxiliary

earth rods).

) Mode “ρ“ (the instrument measures earth resistivity).

Page 32

A

play

4.4.1. Measurement procedure for "2P" test mode

1. Select "2P" earth measurement mode using the F1 key.

2. Connect the Black, Red, Green and Blue cables to the corresponding input terminals of the

instrument T1, T2, T3, T4 (see possible connections in the following picture).

3. Connect the black, and green cables to the earth plant and red and blue cables to the

auxiliary rod.

B2 B3

B4B1

2 points earth resistance measurement

START

4. Press the START/STOP key. The instrument starts the test.

STOP

)

t the end of the test the instrument

displays the values alongside.

EARTH

Resistance value

measured

0.96

Average value of earth resistance calculated over

the number of test dis

ed.

2P

0.93 Ω

WARNING

Ω

Mode “2P”.

Never disconnect the test leads while the word “Measuring” is being

displayed.

SAVE

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

Note

: If START/STOP key was pressed and held, the instrument takes more

consecutive tests.

5. When a new value is acquired the instrument emits a short sound and calculates the

new average value.

Page 33

6. Press the DISP key to show how many measurements are in average

DISP

value calculation and the measuring mode.

7. Press CLR key if you want to cancel the medium value of the resistance

CLR

and the number of measurements that are included in the calculation.

Page 34

When the environmental conditions preclude the “3P” measurement mode, as for example

in a city center. In TT plants it is possible to measure the earth resistance with the

simplified “2P” method that gives a higher value than the “3P” mode does.

An auxiliary rod is necessary; it must have an insignificant earth resistance and must be

independent of the earth plant under test.

In the picture above, a water tube is used as the auxiliary rod. But, any metallic object

fixed to the ground could replace it.

Example: if the operator takes three consecutive measurements, the instrument displays

st

1

measurement:

main display = measured resistance value (Ex: 0.90Ω)

secondary display on the left-hand side = 001 (no. of measurements = 1

means that 1 earth measurement has been taken)

secondary display = average of the measurements taken (in case just one

measurement has been taken the medium value is equal to the measured

value, in this case 0.90Ω)

nd

2

measurement:

main display = measured resistance value (Ex: 0.96Ω)

secondary display = average of the measurements taken ((Val1+Val2)/no.

of measurements = (0.90+0.96)/2 = 0.93Ω)

3rd measurement:

main display = measured resistance value (Ex: 0.93Ω)

secondary display = average of the measurements taken ((Val1+Val2)/no.

of measurements = (0.90+0.96+0.93)/3 = 0.93Ω)

Note

: Any test with a result over 1999Ω is not inserted in the calculation of medium

value.

Example: 1

st

measurement:

main display: 1.07Ω

secondary display: 1.07Ω

2nd measurement

main display: 4.15Ω

secondary display: 2.61Ω

rd

measurement (not inserted in the medium value)

3

main display: >1999Ω

secondary display: 2.61Ω

Page 35

4.4.1.1. Earth resistance measurement from a socket

On TT installations it’s possible to take an earth measurement with a simplified method

that gives an excess value (therefore safer), using the NEUTRAL of the national Energy

Board taken directly from a socket as an auxiliary rod; if also the earth connection is

available, naturally the measurement can be taken on the socket directly, between

NEUTRAL and EARTH.

Although this test is not provided for by CEI 64.8 at present, it gives a value which many 3wires comparison tests proved to be revealing for earth resistance.

B2 B3

B4B1

Earth measurement with simplified method on panel board

WARNING

If you want to take the measurement using the neutral and the earth of a

standard wall socket, you may accidentally connect to the hot leg. In this

case the display will show the voltage, the symbol

(wrong insertion) and

won’t take any measurement even if START/STOP is pressed.

WARNING

Never disconnect the test leads while the word “Measuring” is being

displayed.

Page 36

A

A

the number of test displayed

4.4.2. Measurement procedure for "3P" test mode

The measurement is taken according to what is prescribed for CEI 64.8, IEC 781, VDE

0413, EN61557-5.

1. Select "3P" earth measurement mode using the F1 key.

2. Connect the Black, Red, Green and Blue cables to the corresponding input terminals of the

instrument T1, T2, T3, T4 (see possible connections in the following picture).

3. Connect the black, and green cables to the earth plant and red and blue cables to the

auxiliary rods.

B2

B4B1

B3

3 points earth resistance measurement

Measuring small earth plants, current probe must be positioned a distance from the earth

equipment outline corresponding to five times the diagonal of the area of the earth

equipment under test, measuring big earth plants this distance could be reduced up to one

times the diagonal.

START

4. Press the START/STOP key. The instrument starts the test.

STOP

)

t the end of the test the instrument

displays the values alongside.

EARTH

Resistance value

measured

0.96

verage value of earth resistance calculated over

.

2P

0.93 Ω

WARNING

Ω

Mode “2P”.

The display of “Measuring” means that the instrument is measuring. During

this phase never disconnect test leads.

Page 37

SAVE

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

Page 38

Note: If the START/STOP key was pressed and held, the instrument takes more

consecutive tests.

5. When a new value is acquired the instrument emits a short sound and calculates the

new average value.

6. Press DISP key to show how many measurements are in average value

DISP

calculation and the measuring mode.

CLR

7. Press CLR key if you want to cancel the medium value of the resistance

and the number of measurements which are included in the calculation.

Example: if the operator takes three consecutive measurements, the instrument displays

st

1

measurement:

main display = measured resistance value (Ex: 0.90Ω)

secondary display on the left-hand side = 001 (no. of measurements = 1

means that 1 earth measurement has been taken)

secondary display = average of the measurements taken (in case just one

measurement has been taken the medium value is equal to the measured

value, in this case 0.90Ω)

nd

2

measurement:

main display = measured resistance value (Ex: 0.96Ω)

secondary display = average of the measurements taken ((Val1+Val2)/no.

of measurements = (0.90+0.96)/2 = 0.93Ω)

3rd measurement:

main display = measured resistance value (Ex: 0.93Ω)

secondary display = average of the measurements taken ((Val1+Val2)/no.

of measurements = (0.90+0.96+0.93)/3 = 0.93Ω)

: Any test with result over 1999Ω is not inserted in the calculation of medium value.

Note

Example: 1

st

measurement:

main display: 1,07Ω

secondary display: 1,07Ω

nd

measurement

2

main display: 4,15Ω

secondary display: 2,61Ω

rd

measurement (not inserted in the medium value)

3

main display: >1999Ω

secondary display: 2,61Ω

Page 39

4.4.3. Measurement procedure for "ρ" test mode

The earth resistivity is a very useful measurement. Its’ value can help a designer correctly

size the earth rods in an earth plant.

The measurement is taken according to what is prescribed for CEI 64.8, IEC 781, VDE

0413, EN61557-5

1. Select "ρ" earth measurement mode using the F1 key.

2. Connect the Black, Red, Green and Blue cables to the corresponding input terminals of the

instrument T1, T2, T3, T4 (see possible connections in the following picture).

3. Connect the cables to the auxiliary rods (see connections in the following picture).

B2 B3 B4B1

a

a

a

a

Earth resistivity measurement

4. To select the distance DIST between the rods. This parameter can be set

Un

DIST

from 1 to 10 meters or 3 to 30 feet.

)

At the end of the test the instrument

-ρ

displays the values alongside.

5

m

SE LE

Distance between the rods set value.

5. Press and keys to select the distance value.

6. Press ESC key to leave this menu confirming the settings.

RCL

ESC

START

STOP

Page 40

A

7. Press the START/STOP key. The instrument starts the test.

)

t the end of the test the instrument

ρ

displays the values alongside.

36.5

Earth resistivity value

Ωm

2

0.93 Ω

WARNING

Never disconnect the test leads while the word “Measuring” is being

displayed.

SAVE

SAVING

: The tests can be stored by pressing the SAVE key twice

(refer to paragraph 5.1).

Note

: If START/STOP key is pressed & held, the instrument takes more consecutive

tests.

8. When a new value is acquired the instrument emits a short sound and calculates the

new average value.

9. Press DISP key to show how many measurements are in average value

DISP

calculation and the measuring mode.

10. Press CLR key if you want to cancel the medium value of the resistance

CLR

and the no. of measurements which are included in the calculation.

Note

: Any test with result over 1999Ω is not inserted in the calculation of medium value.

Example: 1

st

measurement (D=1):

main display: 6,6Ωm

secondary display: 6,6Ωm

nd

measurement (D=1):

2

Page 41

main display: 4,15Ω

secondary display: 2,61Ω

rd

measurement (not inserted in the medium value)

3

main display: >1999Ω

secondary display: 2,61Ω

4.5. ANOMALOUS CASES WHICH MAY OCCUR DURING EARTH ρ TESTS

)

If the amperometric circuit is

interrupted, when pressing

START/STOP the instrument can’t read

- - -

the minimum current, therefore a

rC indicates a

high resistance

value.

screen similar to the one beside

appears. Make sure that the terminals

are connected correctly and that the

amperometric rod (blue conductor) has

not been driven into non-conductive

- - - c

ground. If necessary, pour water

around the rod.

SAVE

THE PREVIOUS RESULTS CANNOT BE SAVED

.

)

If the instrument measures an

interfering voltage greater than 30V

on the amperometric circuit, it

doesn’t perform the test and a screen

similar to the one beside appears.

31 V

Voltage value on the amperometric circuit

SAVE

THE PREVIOUS RESULT CANNOT BE SAVED

VOL

AG

.

Page 42

)

If the resistance measured is greater

than the full scale of the instrument,

after pressing START/STOP the

instrument performs the test and a

screen similar to the one beside

appears.

)

If the resistivity measurement is greater

than the following value

1999x6.28x(distance between the rods

selected), after pressing START/STOP

the instrument performs the test and a

screen similar to the one beside

appears.

SAVE

SAVING

: The tests can be stored pressing the SAVE key twice (refer

to paragraph 5.1).

>1999 Ω

- - -

- - -

1999 Ω

- - -

- - -

1999Ω is the full

scale of the

instrument.

1999Ω is the full

scale of the

instrument.

Page 43

5. HOW TO SAVE, RECALL AND CLEAR DATA STORED IN MEMORY

5.1. SAVE: "SAVE" KEY

If the results relative to the tests performed are to be stored you can proceed as follows:

SAVE

1. Press the SAVE key once.

)

If the memory of the instrument is not

MEM

empty it displays the screen alongside.

Number of the memory location in which the

measurement results will be stored.

3

PLA

Value of the parameter PLA related to the

measurement to be saved.

02

2. Use the & keys to increase or decrease the value of the PLA

(Place) parameter

to be related to the measurement that is to be

saved. This parameter helps the operator to classify the tests

performed.

Example: If the tests are to be carried out in a building, the operator

can associate the measurements performed in a room

with a given value of the parameter PLA. In this way

different values of the parameter PLA will correspond to

different rooms.

SAVE

3. Press the SAVE key again, the instrument emits two beeps,

confirming that the test results have been stored.

RCL

ESC

Press RCL/ESC key at any time

back to the measurement selected.

to leave the memory menu and go

Page 44

5.2. RECALL: "RCL" KEY

If you want to recall

the stored test results proceed as follows:

RCL

1. Press the RCL/ESC key.

ESC

)

If the memory of the instrument is not

empty it displays the screen alongside.

Number of the memory location in which the

measurement result was stored.

MEM

3

Pla

Value of the parameter PLA related to the

saved measurement

02

2. Use the & keys to select the memory location number to be

displayed.

3. Press the DISP key to display the test result related to the selected

DISP

memory location.

4. Use the & keys again if you want to display again the numbers of

memory locations.

RCL

ESC

Press RCL/ESC key at any time

to the measurement selected.

to leave the memory menu and go back

Page 45

5.3. CLEAR: "CLR" KEY

If you want to cancel

the stored tests results proceed as follows:

RCL

1. Press the RCL/ESC key. The instrument displays a screen like the

ESC

following:

Number of the memory location in which the

measurement result was stored.

MEM

3

Value of the parameter PLA related to the

saved measurement.

Pla

02

2. Use the & keys to select the number of the memory location.

ATTENTION: The instrument will cancel all the results stored from the memory location

selected to the last.

3. Press the DISP key to display the test result related to the memory

DISP

location selected.

CLR

4. Press CLR once. The blinking

symbol "clr" is displayed. Now you face

two possibilities:

Last location with data stored.

MEM

C i

The instrument cancels the memory cells from

n.2 to n.8, where n.2 is the one selected by

the operator while n.8 is the last test saved in

the instrument.

02

08

CLR

Press CLR again if the tests selected are to be cancelled

starting from the one selected down to the last one saved.

RCL

ESC

Page 46

Press RCL/ESC to nullify the clearing phase. The blinking

symbol "clr" disappears.

RCL

ESC

Press RCL/ESC key at any time

to the measurement selected.

to leave the memory menu and go back

Page 47

6. RESET OF THE INSTRUMENT AND DEFAULT PARAMETERS

BEFORE OF A RESET PROCEDURE DOWNLOAD THE STORED TESTS ON A PC

6.1. RESET PROCEDURE

1. Press the DISP, CLR, RCL keys and then ON/OFF key.

2.

The screen alongside is

displayed for 5 seconds, after

which the instrument emits a beep

and then displays the screen

relative to the function selected

with the rotary switch.

ATTENTION: the reset procedure will cancel all the stored tests and it will set the

default parameters in the instrument.

6.2. DEFAULT PARAMETERS

After a RESET the default parameters set on the instrument are:

es

Function Parameter RESET default parameter

Mode AUTO

LOWΩ

Calibration Offset

Mode R+/R- TIMER

TIMER is set at 1s

0

Mode MAN

R

ISO

EARTH ρ

Memory

Test voltage 500V

Mode TIMER TIMER is set at 60s

Parameter DIST DIST = 1

Parameter PLA P = 1

Memory state 0

Page 48

7. INSTRUMENT CONNECTION TO A PC

The connection between PC and instrument is created using the serial port and optical

serial cable, provided with the software package.

Before making the connection it is necessary to select the COM port used for the

transmission. To set this parameter start the software and look up the help on line.

ATTENTION

To transfer the stored data from the instrument to the PC keep to the following procedure:

FUNC

: The selected port shall NOT be shared by other devices or applications

(example mouse, modem, etc.)..

1. Turn the switch on position RS232.

2. By means of the FUNC key select the mode "SEr":

Then proceed according to the software instruction manual to transfer the

measurements performed.

)

The communication between

instrument and PC occurs.

SE

Note

: The download speed is: 9600 baud (see software instruction manual).

Page 49

8. MAINTENANCE

8.1. GENERAL

1. The instrument you have purchased is a precision instrument. Strictly follow the

instructions for use and storage reported in this manual to avoid any possible damage

or danger during use.

2. Do not use this tester under unfavorable conditions of high temperature or humidity. Do

not expose to direct sunlight.

3. Be sure to turn off the tester after use. If the instrument is not to be used for a long

period you are recommended to remove the batteries to avoid acid leakage that may

damage the internal circuits of the instrument.

8.2. BATTERY REPLACEMENT

When the symbol

Only skilled technicians can perform this operation. Before replacing batteries

make sure that all test leads have been disconnected from input terminals. The

instrument will retain the data stored even though the batteries are not

installed.

1. Switch OFF the instrument.

2. Remove all the test leads from the input terminals.

3. Unscrew the fixing screw from the battery compartment cover and remove it.

4. Remove all batteries replacing them with 6 new ones.

5. Fix the screw on the battery compartment cover.

8.3. INSTRUMENT CLEANING

Use a soft dry cloth to clean the instrument. Never use wet cloths, solvents, water, etc.

is displayed batteries are to be replaced.

WARNING

Page 50

9. TECHNICAL SPECIFICATIONS

9.1. TECHNICAL FEATURES

Accuracy is indicated as [% of reading + number of digits]. It refers to the atmospheric

conditions listed in paragraph 9.2.1.

- Continuity (LOWΩ)

Test mode

AUTO, R+TIMER, R-TIMER

Test current >200mA DC up to 5Ω (include the resistance of the calibration)

Test current resolution 1mA

Open circuit Test Voltage 6V < V0 < 12V

Measuring range (Ω) Resolution (Ω)

0,01 – 19,99 0,01

20,0 – 99,9 0,1

- Insulation resistance (R

Test voltage (V)

50

100

250

500

1000

ISO

)

Measuring range (Ω) Resolution (Ω)

0,01 - 19,99 0,01

20,0 - 49,9 0,1

50,0 - 99,9 0,1

0,01 - 19,99 0,01

20,0 - 99,9 0,1

100,0 - 199,9 0,1

0,01 - 19,99 0,01

20,0 - 199,9 0,1

200 - 249 1

250 - 499 1

0,01 - 19,99 0,01

20,0 - 199,9 0,1

200 - 499 1

500 - 999 1

0,01 - 19,99 0,01

20,0 - 199,9 0,1

200 - 999 1

1000 - 1999 1

Accuracy

±(2% rdg + 2 dgt)

Accuracy

±(2% rdg + 2 dgt)

±(5% rdg + 2 dgt)

±(2% rdg + 2 dgt)

±(5% rdg + 2 dgt)

±(2% rdg + 2 dgt)

±(5% rdg + 2 dgt)

±(2% rdg + 2 dgt)

±(5% rdg + 2 dgt)

±(2% rdg + 2 dgt)

±(5% rdg + 2 dgt)

Automatic selection of the measuring range

Open circuit voltage Rated voltage test –0% +10%

Short circuit current <6,0mA with 500V set

Rated measuring current >2,2mA with 500V on 230kΩ

1mA a 1KΩ x V

(≠ 500 V)

NOM

- AC voltage

Measuring range (V) Resolution (V) Accuracy

0 ÷ 460

1

- Earth resistance measurement with voltamperometric method

Measuring range (Ω) Resolution (Ω)

0,01 ÷ 19,99

20,0 ÷ 199,9

200 ÷ 1999

Test current <10mA 77,5Hz

Open load test voltage <20V RMS

0,01

0,1

1

±(3% rdg + 2 dgt)

Accuracy

±(5% rdg + 3 dgt)

Page 51

Page 52

- Earth resistivity ρ measurement

Measuring range (Ω) Resolution (Ωm)

0.06 ÷ 19,99 Ωm 0,01 Ωm

20.0 ÷ 199.9 Ωm 0.1 Ωm

200 ÷ 1999 Ωm 1 Ωm

2,00 ÷ 19,99 kΩm 0.01 kΩm

20.0 ÷ 125,5 kΩm (*) 0.1 kΩm

(*) with D = 10m

Test current <10mA 77,5Hz

Open load test voltage <20V RMS

Accuracy

±(5% rdg + 3 dgt)

9.1.1. Safety standards

The instrument complies with: EN 61010-1 + A2(1997)

Product norms: IEC61557-1, -2, -3, -4, -5, -6

Insulation: Class 2, double insulation

Pollution level: 2

Inside use; max height: 2000m

Overvoltage category: CAT III 460V∼ T1-T2-T3-T4 / 265V∼ to earth

9.1.2. General specifications

Mechanical features

Dimensions: 222(L) x 165(La) x 105(H)mm

Weight (batteries included): approx. 1200g

Power supply

Battery type: 6 batteries 1.5 V – LR6 – AA – AM3 – MN 1500

Low battery indication: The symbol is displayed when the battery

voltage is too low.

Battery life: About 40 hours in stand-by or

500 LowΩ tests or

250 R

tests 500V/500kΩ or

ISO

1000 Loop, phase sequence tests

300 Earth or ρ tests.

Display: LCD custom 65mmx65mm

Memory: 350 tests

Serial interface: opto-isolated RS232 to download stored data to a

PC.

Page 53

9.2. ENVIRONMENT

9.2.1. Environmental working conditions

Reference temperature: 23° ± 5°C

Working temperature: 0°C ÷ 40 °C

Relative humidity allowed: <80%

Storage temperature: -10 ÷ 60 °C

Storage humidity: <80%

9.2.2. EMC

This instrument was designed in compliance with the EMC standards in force and its

compatibility has been tested for EN61326-1 (1998) + A1 (1999).

This instrument conforms to European directive for CE standards.

This instrument complies with the requirements of the European Low Voltage

Directives 73/23/CEE and EMC 89/336/CEE, amended with 93/68/CEE.

9.3. ACCESSORIES

The accessories provided with the instrument depend on the model purchased according

to the following table. The accessory is named standard when it is sold together with the

instrument in a single package.

Standard accessories

Description Code Description Code

Set with 4 cables, 4 alligator

clips and 2 test leads

alligator clip) and 4 rods

MTL-MT1 Software and Manual

GP2-CON

Serial cable C2001 Bag with 4 cables (bananaCarrying case CC-MT1

Optional accessories

Set for carrying belt CN0050

www.amprobe.com

Page 54

10. SERVICE

10.1. WARRANTY CONDITIONS

Congratulations! Your new instrument has been quality crafted according to quality standards and

contains quality components and workmanship. It has been inspected for proper operation of all of

its functions and tested by qualified factory technicians according to the long-established standards

of our company.

Your instrument has a limited warranty against defective materials and/or workmanship for 1 year

from the date of purchase provided that, in the opinion of the factory, the instrument has not been

tampered with or taken apart.

Should your instrument fail due to defective materials, and/or workmanship during this 1

year period, a no charge repair or replacement will be made to the original purchaser. Please

have your dated bill of sale, which must identify the instrument model number and serial

number and call the number listed below:

Repair Department

ATP – Amprobe, TIF, Promax

Miramar, FL

Phone: 954-499-5400

800-327-5060

Fax: 954-499-5454

Website: www.amprobe.com

Please obtain an RMA number before returning product for repair.

Outside the U.S.A. the local representative will assist you. Above limited warranty covers repair

and replacement of instrument only and no other obligation is stated or implied.

Page 55

11. PRACTICAL REPORTS FOR ELECTRICAL TESTS

11.1. LOWΩ: CONTINUITY MEASUREMENT ON PROTECTIVE CONDUCTORS

PURPOSE OF THE TEST

Check the continuity of:

a) Protective conductors (PE), main equalizing potential conductors (EQP), secondary

equalizing potential conductors (EQS) in TT and TN-S systems.

b) Neutral conductors having functions of protective conductors (PEN) in TN-C system.

NOTE: This test is to be preceded by a visual check verifying the existence of yellow-

green protective and equalizing potential conductors as well as compliance of the

sections used with the standards’ requirements.

INSTALLATION PARTS TO BE CHECKED

Connect one of the

test leads to the

protective

conductor of the

FM socket and the

other to the

equalizing potential

node of the earth

installation.

Connect one of the

test leads to the

external mass (in

this case the water

pipe) and the other

to the earth

installation using

for example the

protective

conductor of the

closest FM socket.

Examples for continuity measurement on conductors

Page 56

Check the continuity among:

a) Earth poles of all the plugs and earth collector or node.

b) Earth terminals of class I instruments (Boiler etc.) and earth collector or node.

c) Main external masses (water, gas pipes etc.) and earth collector or node.

d) Auxiliary external masses to the earth terminal.

ALLOWABLE VALUES

The standards CEI 64-8/6 do not give any indication of the maximum resistance values in

order to be able to declare a positive outcome of a continuity test.

The standard CEI 64-8/6 simply requires that the instrument in use warns the operator if

the test was not carried out with a current of at least 0.2 A and an open circuit voltage

ranging from 4 V to 24 V.

The resistance values can be calculated according to the sections and lengths of the

conductors under test. If the instrument detects values of some resistance the test can be

considered as passed.

11.2. INSULATION RESISTANCE MEASUREMENT OF THE ELECTRICAL

INSTALLATIONS (250VDC, 500VDC, 1000VDC)

PURPOSE OF THE TEST

Check that the insulation resistance of the installation complies with the requirements of

standards CEI 64-8/6.

NOTE: This test is to be performed on an open circuit with all loads disconnected

.

INSTALLATION PARTS TO BE CHECKED

a) Between each active conductor and the earth (the neutral conductor is considered an

active conductor except in the case of TN-C systems where it is considered part of the

earth (PEN). During this measurement all active conductors can

be connected to each

other, in case the measurement result does not fall within the standard limits the test is

to be repeated for each single conductor.

b) Among active conductors

insulation among the active conductors when this is possible (ATTENTION)

. The standard CEI 64-8/6 recommends checking the

.

ALLOWABLE VALUES

The values of test voltage and minimum insulation resistance are reported in the following

table (CEI64-8/6 Tab. 61A):

Rated circuit voltage (V) Test voltage (V)

SELV and PELV* 250

Up to 500 V included, except for the

above circuits.

500

Over 500 V 1000

Insulation resistance (MΩ)

≥0.250

≥0.500

≥1.000

* In the new standards the terms SELV and PELV replace the old definitions "safety low

voltage" or "functional".

Page 57

Test voltage values and relative limit values for the most common kinds of test.

Page 58

11.3. MEASUREMENT OF FLOOR INSULATION RESISTANCE IN MEDICAL ROOMS

PURPOSE OF THE TEST

Check that the floor is made of material whose insulation resistance complies with the

requirements of the standards CEI 64-4 (3.05.03).

INSTALLATION PARTS TO BE CHECKED

The test shall be performed between:

a) Two electrodes whose distance to each other shall be one meter.

b) One electrode on the floor and the equalizing potential node.

EQUALIZING POTENTIAL NODE

T

Test a):

Connect one test lead of the instrument

to the equalising potential node and the

other to one of the electrodes placed

on the floor at a distance higher than

one meter away from earthed objects

.

TEST LEADS

T

Test b ):

Connect the instrument test leads to

the electrodes placed on the floor at

a reciprocal distance of one meter

.

Measurements of floor insulation resistance in medical rooms

The electrodes shall consist of a plate having a surface of 20 cm2, weight equal to approx.

1 Kg (2.2 lb), and a moisture absorbent paper (or thin cotton cloth) with the same surface

placed between the metal plate and the floor.

The insulation resistance is represented, both for the measurements indicated in "a" and

for the measurements indicated in "b", by the average of 5 or more tests performed in

different positions at a distance greater than 1 m away from earthed objects.

ALLOWABLE VALUES

The maximum values of the calculated resistance are the following:

- 1 MΩ for measurements performed on a new floor.

- 100 MΩ for the periodic tests performed after the first year from the floor construction

and for the periodic checks every 4 years.

All the values shall be registered on a protocol of the initial tests (64-4 5.1.02).

Page 59

11.4. CHECK OF THE CIRCUIT SEPARATION

PURPOSE OF THE TEST

The test, to be performed in case the protection is realized through separation (64-8/6

612.4, SELV or PELV or electrical separation), shall check that the insulation resistance

measured according to the indications below (depending on the separation type) complies

with the limits reported in the table relative to the insulation measurements.

INSTALLATION PARTS TO BE CHECKED

• SELV system (Safety Extra Low Voltage):

9 Measure the resistance between the active parts of the circuit under test (separate)

and the active parts of the other circuits.

9 Measure the resistance between the active parts of the circuit under test (separate)

and the earth.

The resistance shall not be lower than 0.25MΩ with a test voltage of 250VDC.

• PELV system (Protective Extra Low Voltage):

9 Measure the resistance between the active parts of the circuit under test (separate)

and the active parts of the other circuits.

The resistance shall not be lower than 0.25MΩ with a test voltage of 250VDC.

• Electrical separation:

9 Measure the resistance between the active parts of the circuit under test (separate)

and the active parts of the other circuits.

9 Measure the resistance between the active parts of the circuit under test (separate)

and the earth.

The resistance shall not be lower than 0.5MΩ with a test voltage of 500VDC and 1MΩ with

a test voltage of 1000VDC.

ALLOWABLE VALUES

The test result is positive when the insulation resistance indicates values greater or equal

to those indicated in the table reported in the section relative to insulation tests.

Please note that:

A SELV system is a system of category zero or very low safety voltage featured by:

independent source (ex. batteries, small generator) or safety (ex. safety transformer)

power supply, protection separation to other electrical systems (double or reinforced

insulation or a metal screen connected to the earth) and no earthed points (insulated from

the earth).

A PELV system is a system of category zero or very low safety voltage featured by:

independent source (ex. batteries, small generator) or safety (ex. safety transformer)

power supply, protection separation to other electrical systems (double or reinforced

insulation or a metal screen connected to the earth) and there are earthed points (not

insulated from the earth).

Page 60

A system with Electrical separation is featured by: insulation transformer or autonomous

source with equivalent features (ex. generator) power supply, protection separation to

other electrical systems (insulation not lower than that of the insulation transformer) and

protection separation to the earth (insulation not lower than that of the insulation.

Page 61

EXAMPLE OF CHECKING THE SEPARATION AMONG ELECTRICAL CIRCUITS

Insulation or safety transformer making

the separation among the circuits.

TEST AMONG THE ACTIVE PARTS

Connect a test lead of the instrument

to one of the two conductors of the

separate circuit and the other to one of

the conductors of a no separate circuit.

Between active parts of

the separated circuit...

...and among those

others circuits

EQUALIZING POTENTIA L NODE

TEST BETWEEN ACTIVE

PARTS AND THE EARTH

Connect a test lead of the

instrument to one of the two

conductors of the separate

circuit and the other to the

equalising potential node.

This test is to be effected

only for SELV circuits or

with electrical separation.

…and Earth installation

Measurement of separation among the installation circuits

Page 62

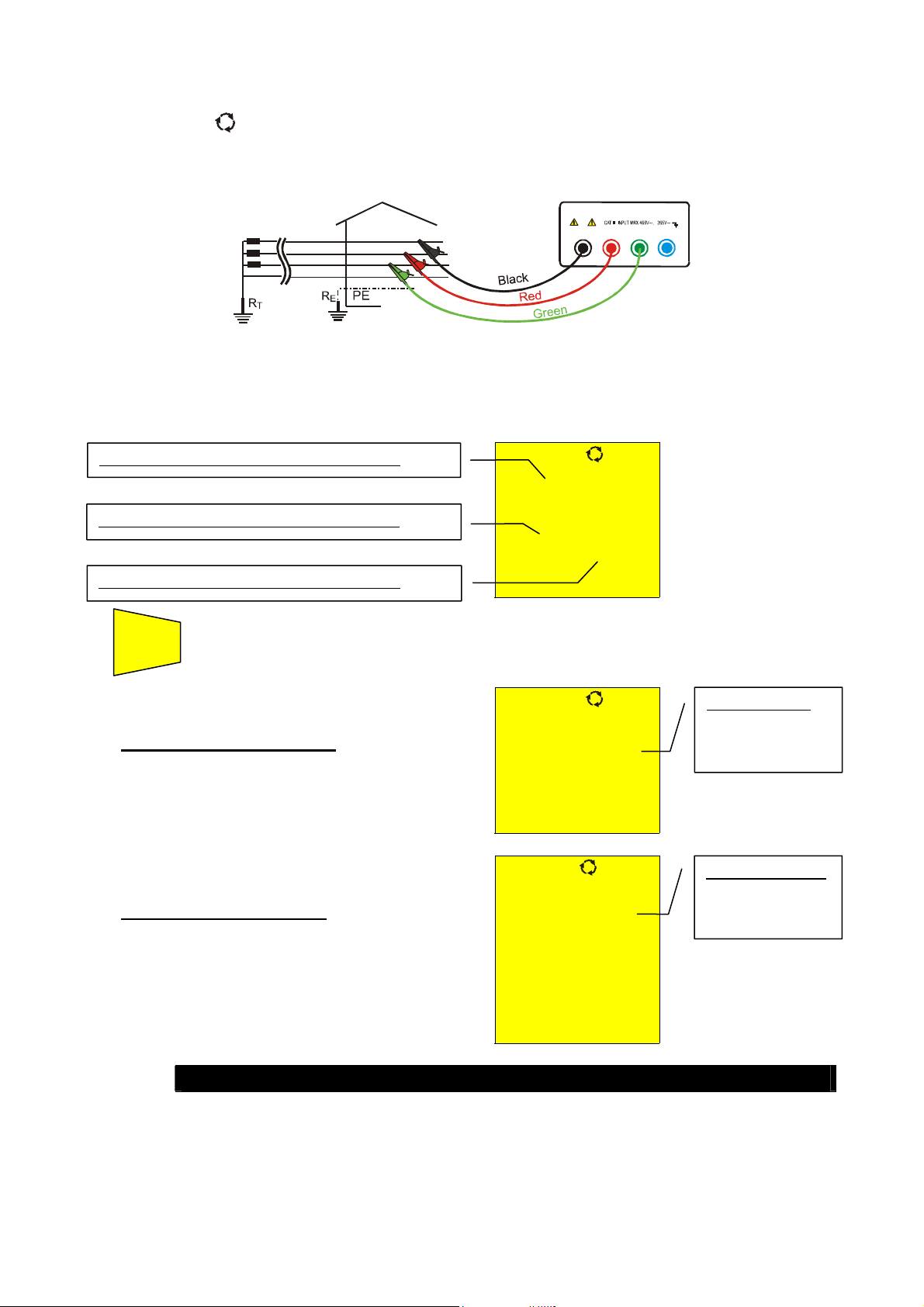

11.5. EARTH RESISTANCE MEASUREMENT, VOLTAMPEROMETRIC METHOD

Method for small earth plant

Let a current circulate between the earth rod and a current probe positioned at a distance

from the earth equipment outline corresponding to five times the diagonal of the area

delimiting the earth equipment. Positions the voltage probe halfway between the earth rod

and the current probe, then measure the voltage between the two.

Use several rods in parallel and moisten

the surrounding ground if the instrument

does not manage to supply the current

necessary to perform the test because

of an high earth resistance.

Re d

Green

Bl u e

Bl a c k

Earth resistance measurement for small earth plant

Method for big earth plant

Also this procedure is based on the voltamperometric method, but it’s mainly used when

it’s difficult to position the auxiliary current rod at a distance corresponding to fivefold the

diagonal of the area of the earth equipment. Position the current probe at a distance equal

to the diagonal of the area of the earth equipment. To make sure that the voltage probe is

positioned outside the area affected by the rod under test, take more measurements, first

positioning the voltage probe halfway between the rod and the current probe, and then

moving the probe both towards the earth rod and towards the current probe.

Page 63

Use several rods in parallel and moisten

the surrounding ground if the instrument

does not manage to supply the current

necessary to perform the test because

of an high earth resistance.

Re d

Green

Bl a c k

Earth resistance measurement for big earth plant

Bl u e

Page 64

11.6. EARTH RESISTIVITY MEASUREMENT

PURPOSE OF THE TEST

This test measures the resistivity value of the ground in order to define the type of rods to

be used.

EQUIPMENT PARTS TO BE TESTED

For the resistivity test admissible values do not exist. The various values measured by

positioning the rods at increasing distances “a” must be specified in a graph. According to

the resulting curve, suitable rods will be chosen. Metal parts buried in the ground, such as

pipes, cables or other rods, can affect the test results. In case of doubt take a second

measurement positioning the rods at an equal distance "a", but rotating their axis by 90°.

Black

R

Green

d

e

2

2° Measurement:

compared to the previous measurement

the rods are rotated by

90°.

90°

a

a

e