Page 1

DM-4 Power Quality Recorder

Page 2

DM-4 Power Quality Recorder

TABLE OF CONTENTS

1. PRECAUTIONS AND SAFETY MEASURES.............................................................................. 3

1.1 GENERAL................................................................................................................... 3

1.2 PRELIMINARY INSTRUCTIONS ............................................................................... 3

1.3 DURING USE.............................................................................................................. 4

1.4 AFTER USE................................................................................................................ 4

2.GENERAL DESCRIPTION ........................................................................................................... 5

2.1 INTRODUCTION ........................................................................................................ 5

2.2 FUNCTIONS............................................................................................................... 5

3. PREPARING THE INSTRUMENT................................................................................................ 6

3.1 INITIAL CHECK.......................................................................................................... 6

3.2 INSTRUMENT POWER SUPPLY............................................................................... 6

3.3 CALIBRATION............................................................................................................ 6

3.4 STORAGE.................................................................................................................. 7

4. HOW TO OPERATE..................................................................................................................... 7

4.1 INSTRUMENT: DESCRIPTION................................................................................. 7

4.2 KEYBOARD: DESCRIPTION.................................................................................... 7

4.3 USING THE DM-4 WITH THE REMOTE USER INTERFACE (PDA)........................ 8

4.4 DISPLAY DESCRIPTION OF THE REMOTE USER INTERFACE (PDA................... 9

4.4.1 VIEW REAL TIME DATA........................................................................................ 9

4.4.2 SETUP ANEW RECORDING SESSION................................................................13

5. MAIN MENU................................................................................................................................15

6. RECORDING CONFIGURATION.............................................................................................

7. STARTING A RECORDING

4.4.3 SET DATE AND TIME FOR AUTOMATIC RECORDING SESSION.....................14

5.1 INITIAL SETTINGS....................................................................................................15

5.1.1 HOW TO SET THE DATE AND TIME?...................................................................16

5.2 DEFAULT SETTINGS: ANALYZER CONFIG.............................................................16

5.2.1 HOW TO SET THE TYPE OF ELECTRICAL SYSTEM UNDER TEST.................17

5.3 BASIC SETTING: RECORDER CONFIG..................................................................18

5.3.1 MDL PARAMETER SETUP.....................................................................................18

5.3.2 MDL VOLTAGE ANOMALIES.................................................................................18

5.4 ADVANCED SETTING: RECORDER CONFIGURATION..........................................19

5.4.1 SETTING THE PARAMETERS INDIVIDUALLY......................................................20

5.4.2 ADVANCED MDL PARAMETER SETUP.................................................................20

5.4.3 SET UP THE PARAMETERS FOR VOLTAGE........................................................20

5.4.4 SETUP THE PARAMETERS FOR CURRENT........................................................21

5.4.5 SETUP THE PARAMETERS FOR POWER............................................................21

5.4.6 SETUP THE PARAMETERS FOR VOLTAGE HARMONICS..................................22

5.4.7 SETUP THE PARAMETERS FOR CURRENT HARMONICS.................................23

5.5 DOWNLOAD DATA....................................................................................................24

5.5.1 DOWNLOAD DATA WITH THE REMOTE USER INTERFACE (PDA)...................24

5.5.2 VIEW DOWNLOADED DATA..................................................................................25

5.5.3 RECORDING INFORMATION................................................................................25

5.5.4 DELETE SESSION.................................................................................................26

5.5.5 RESET....................................................................................................................29

........................................................................................................30

.

.

30

Page 3

DM-4 Power Quality Recorder

8. RECORDING IN PROCESS........................................................................................................32

9. STOPPING A RECORDING........................................................................................................33

10. CONNECTING THE INSTRUMENT TO A PC...........................................................................34

11. MEASURING PROCEDURES..................................................................................................35

12. MAINTENANCE........................................................................................................................40

13. TECHNICAL SPECIFICATIONS..............................................................................................41

14. APPENDIX 1 – RECORDABLE PARAMETERS: SYMBOLS.................................................46

15. APPENDIX 2 – THEORETICAL OUTLINES............................................................................47

16. AFTER-SALE SERVICE..........................................................................................................56

9.1 STOP A RECORDING WITH THE REMOTE USER INTERFACE (PDA).................33

9.2 STOPA RECORDING WITH THE DOWNLOAD SUITE............................................33

11.1 USING THE INSTRUMENT IN A SINGLE PHASE SYSTEM..................................35

11.2 USING THE INSTRUMENT IN A THREE PHASE

4- WIRE SYSTEM (WYE)........................................................................................36

11.3 USING THE INSTRUMENT IN A THREE PHASE 3- WIRE

SYSTEM (DELTA).......................................................................................................38

12.1 GENERAL................................................................................................................40

12.2 BATTERY REPLACEMENT.....................................................................................40

13.1 FEATURES............................................................................................................. 41

13.1.1 VOLTAGE MEASUREMENT................................................................................41

13.1.2 VOLTAGE ANOMALIES DETECTION (MANUAL SELECTION OF

RANGE) VOLTAGE.................................................................................................41

13.1.3 CURRENT MEASUREMENT (USING EXTERNALTRANSDUCER)................. ..41

13.1.4 POWER MEASUREMENT (COS

13.1.5 COSΘ MEASUREMENT.....................................................................................42

13.1.6 MEASUREMENT OF HARMONICS....................................................................43

13.1.7 TEMPERATURE DRIFT....................................................................................... 43

13.1.8 SAFETY............................................................................................................... 43

13.1.9 GENERAL CHARACTERISTICS......................................................................... 44

13.2 ENVIRONMENT...................................................................................................... 44

13.2.1 OPERATING CONDITIONS................................................................................ 44

13.3 ACCESSORIES...................................................................................................... 45

13.3.1 STANDARD ACCESSORIES...............................................................................45

15.1 VOLTAGE ANOMALIES (VOLTAGE SAG AND SURGE; SPIKE).......................... .47

15.2 VOLTAGE AND CURRENT HARMONICS..............................................................48

15.2.1 THEORY............................................................................................................. . 48

15.2.2 LIMIT VALUES FOR HARMONICS.....................................................................49

15.2.3 PRESENCE OF HARMONICS: CAUSES........................................................... 50

15.2.4 PRESENCE OF HARMONICS: CONSEQUENCES............................................50

15.3 POWER AND POWER FACTOR: DEFINITIONS...................................................51

15.3.1 CONVENTIONS ON POWERS AND POWER FACTORS..................................53

15.3.2 3 PHASE 3 WIRE SYSTEM..............................................................................54

15.4 MEASURING METHOD: OUTLINES......................................................................55

15.4.1 INTEGRATION PERIODS................................................................................... .55

15.4.2 POWER FACTOR CALCULATIONS.................................................................. ..55

ARRANTY............................................................................................................56

16.1 W

16.2 SERVICE................................................................................................................56

Θ: 0.5C – 0.5I).................................................42

Page 4

DM-4 Power Quality Recorder

1. PRECAUTIONS AND SAFETY MEASURES

1.1 GENERAL

For your own safety and to avoid damaging the instrument we suggest you follow

the procedures hereby prescribed and to carefully read all the notes preceded by

the symbol m.

Before and during measurements please be very diligent in following instructions below:

• Do not measure voltage or current in wet or dusty places

• Do not measure in presence of gas, explosive materials or combustibles

• Do not touch the circuit under test if no measurement is being taken

• Do not touch exposed metal parts, unused terminals, circuits and so on

• Do not use the instrument if it seems to be malfunctioning

• Use only cables and accessories approved by Amprobe

The following symbols are used in this manual:

m Caution: keep to what is prescribed by the manual. An incorrect use could

damage the instrument or its components

c High voltage: risk of electric shock

1.2 PRELIMINARY INSTRUCTIONS

• This instrument has been designed for use in places with pollution class 2.

• It can be used for

voltage category III 600 V~ phase to phase / 346 V~ phase to earth and of excess

voltage category II 1000 V~ phase to phase / 577 V~ phase to earth.

voltage and current measurements in installations of excess

3

Page 5

DM-4 Power Quality Recorder

• Please keep to the usual safety standards aimed at:

Protecting against dangerous currents;

Protecting the instrument against incorrect operations.

• Only the accessories supplied with the instrument guarantee compliance with the

safety standards. Accordingly, they must be in good condition and, if necessary,

they must be replaced with identical models.

• Do not take measurements on circuits exceeding the specified current and

voltage limits.

• Before connecting voltage leads and clamps to the circuit under test, make sure

that the circuit configuration has been selected.

1.3 DURING USE

Please read carefully:

CAUTION

Should you fail to keep to the prescribed instructions you could damage

m

the instrument and/or its components or endanger your safety.

• When the instrument is connected to the circuit under test, do not touch any

unused terminal.

• When measuring current, other currents located near the leads may affect the

measuring accuracy.

• When measuring current, always position the wire in the very middle of the jaws

in order to obtain the highest accuracy.

1.4 AFTER USE

• After use, turn off the instrument by pressing the ON/OFF push button.

• If you won’t be using the instrument for long periods of time, use the storage

instructions described in paragraph 3.4.

4

Page 6

DM-4 Power Quality Recorder

2.GENERAL DESCRIPTION

2.1 INTRODUCTION

The DM-4 also referred to as the Modular Data Logger (MDL), addresses the needs

of the most demanding Power Quality professionals. The device incorporates full set

of measuring features crucial for complete Power Quality analysis. An innovative

Remote User Interface (PDA) allows safe, easy and convenient operation of the

device remotely. Remote User Interface (PDA) is also used for data viewing, analysis and transfer. Independently, the DM-4 can be used directly with a PC using

Download Suite software. Since the DM-4 does not have any control buttons on its

enclosure, it is protected against setup changes by unauthorized persons while the

device is recording, eliminating the need for password protection.

2.2 FUNCTIONS

The DM-4 is able to:

• Display in real time the electrical parameters of a single phase, two phase or

three-phase system (wye or delta) and the harmonic analysis of voltages and currents.

• Conduct a direct Energy measurement.

• Record simultaneously (pressing the RECORD key after a proper connection &

device configuration): RMS values of voltages, currents, corresponding harmonics;

active, reactive and apparent powers, power factor and cos

Θ; active, reactive and

apparent energies; voltage sag and surge with 14ms resolution; and voltage spike

with 100ns resolution.

It will be possible to analyze the recorded data by down-

loading the file using the Remote User Interface (PDA) or Download Suite.

• Record Data (pressing RECORD key) the sampled values of the Parameters

present at the instrument’s input.

It will be possible to analyze the recorded

data by downloading the file with the Remote User Interface (PDA) device

or a PC using the Download Suite.

5

Page 7

DM-4 Power Quality Recorder

3. PREPARING THE INSTRUMENT

3.1 INITIAL CHECK

This instrument has been checked before shipment from an electrical and mechanical point of view. All possible precautions have been taken in order to deliver it in

perfect condition. Notwithstanding, on receipt of the instrument we suggest that

you check it summarily to make sure that no damage has occurred in transit.

Should you find irregularities, please contact the carrier immediately. Furthermore,

make sure that the parcel contains all the accessories and parts listed on Table

13.3.1. In case of discrepancies, please contact your dealer. Should it be necessary to return the instrument to the supplier, please keep to the instructions given

at paragraph 16.1.

3.2 INSTRUMENT POWER SUPPLY

The instrument can be powered by:

• 8 batteries 1.5V AA located in the compartment on the back of the instrument

• An external power supply code DM-4EXTPS supplied with the instrument

(standard accessory).

CAUTION

m

3.3 CALIBRATION

The instrument complies with the standards mentioned in this manual. Its performance is guaranteed for one year from the purchase date.

For recordings ALWAYS use the external power supply (even though the

instrument allows the operator to perform a recording using internal batteries).

6

Page 8

DM-4 Power Quality Recorder

3.4 STORAGE

For long time storage, please remove batteries to prevent leakage into the unit. Store

unit in a safe location with room temperature conditions. To guarantee accurate

measurements after a long storage period in severe environmental conditions, wait

until the instrument resumes its normal conditions (see environmental conditions

listed in paragraph 13.2).

4. HOW TO OPERATE

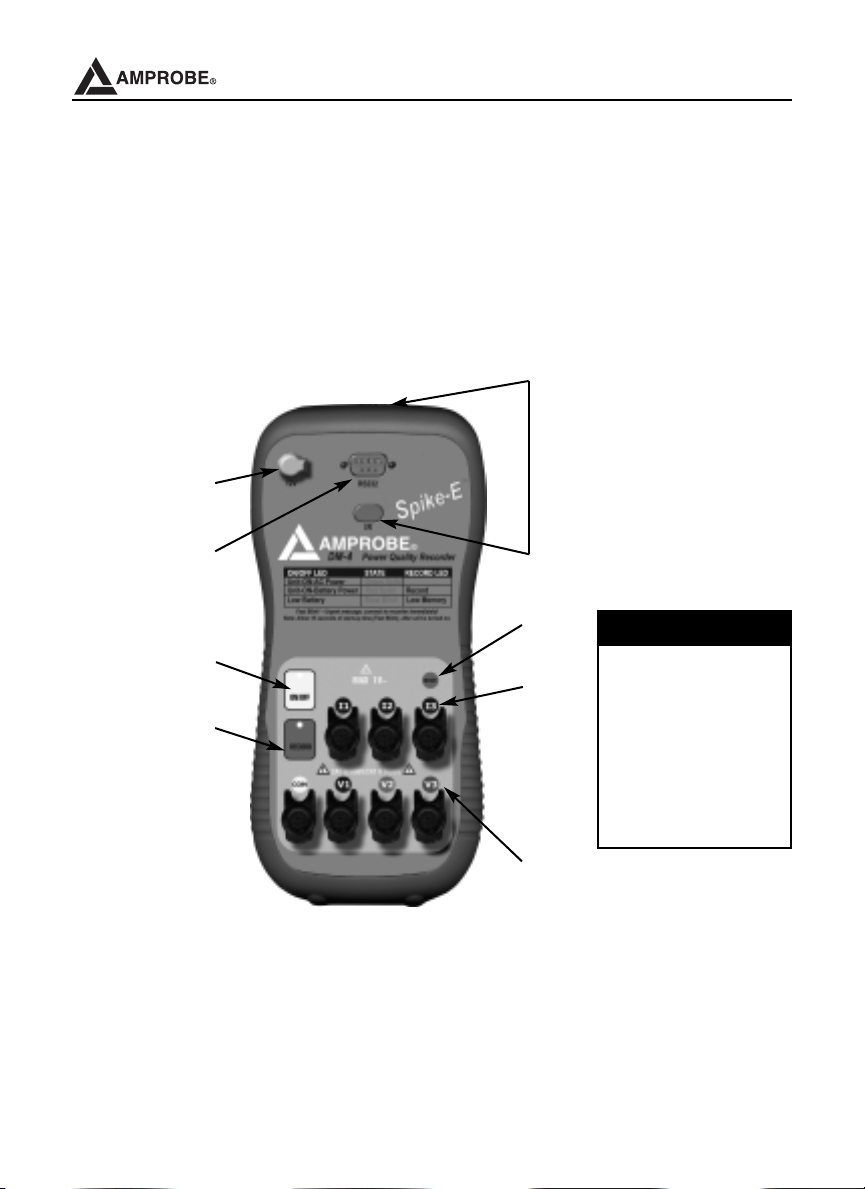

4.1 INSTRUMENT: DESCRIPTION

4

5

6

7

3

8

2

LEGEND

1. Voltage Inputs

2. Current Inputs

3. Infrared Ports

4. External Power

Supply Plug

5. RS232 Serial Connector

6. ON/OFF Push Button

7. Record Push Button

8. Reset Push Button

1

4.2 KEYBOARD: DESCRIPTION

The following keys are available:

ON/OFF: turning on – turning off / (Green LED for AC and Red LED for Battery)

RECORD: to start/stop manually a recording

RESET: to reset the unit

7

Page 9

DM-4 Power Quality Recorder

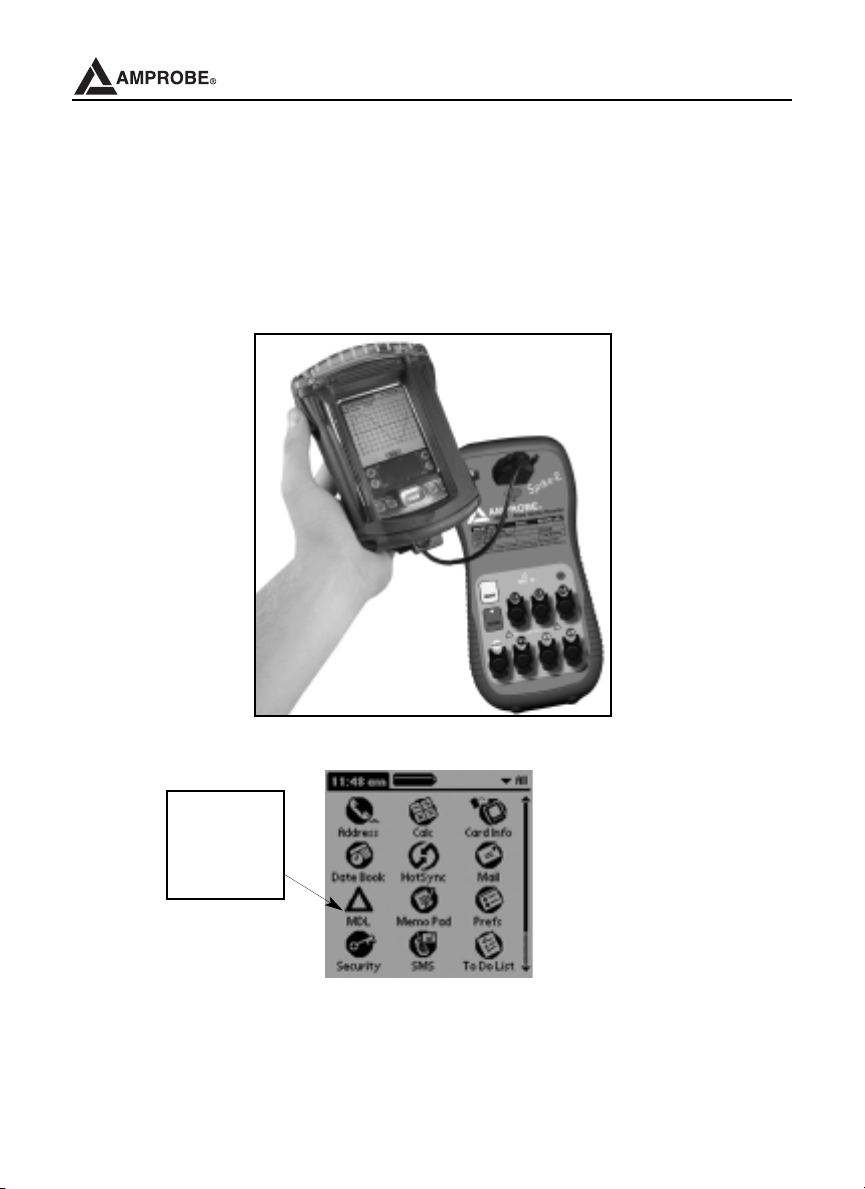

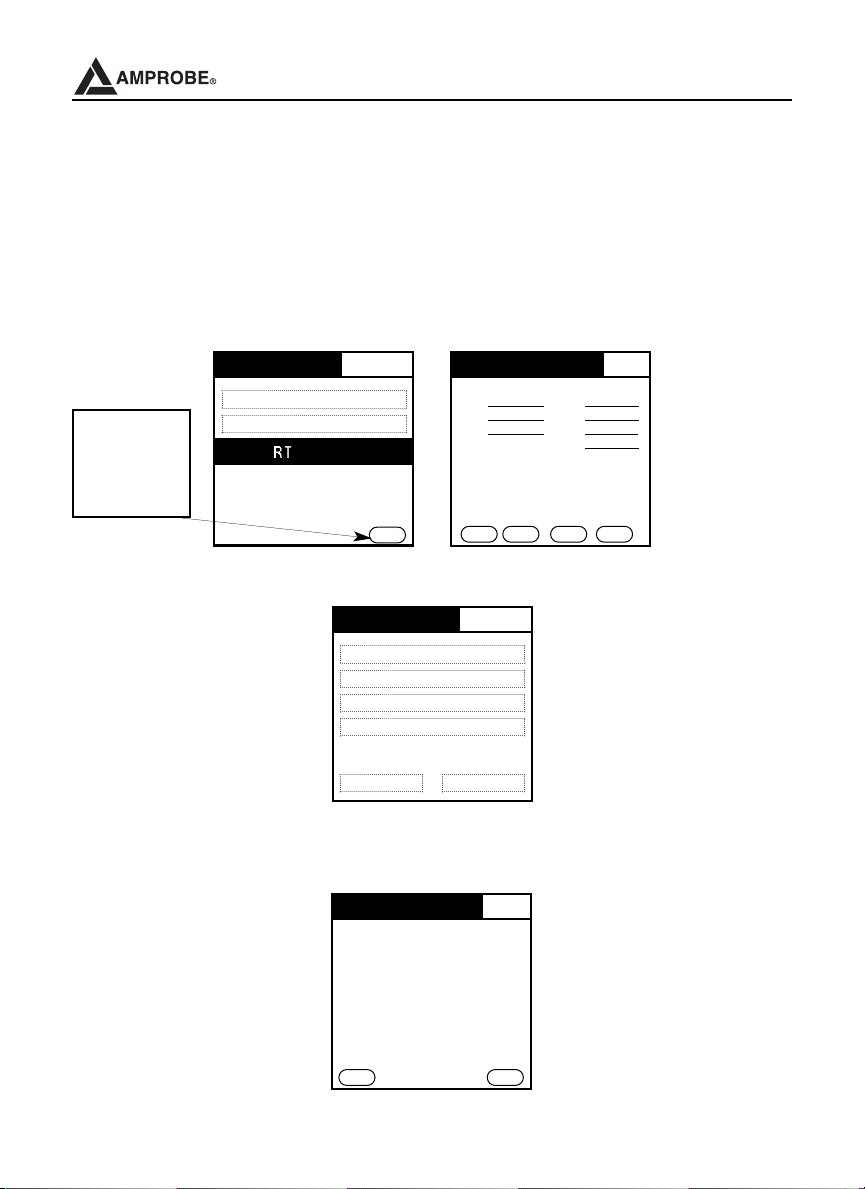

4.3 USING THE DM-4 WITH THE REMOTE USER INTERFACE (PDA)

• Connect the Remote User Interface (PDA) to the DM-4 using the provided cable

• Turn ON the DM-4 by pressing on the ON/OFF push button

• Turn ON the Remote User Interface (PDA) by pressing the power button

• Click on the MDL (Modular Data Logger) icon

Click MDL

icon to

enter the

program.

8

Page 10

DM-4 Power Quality Recorder

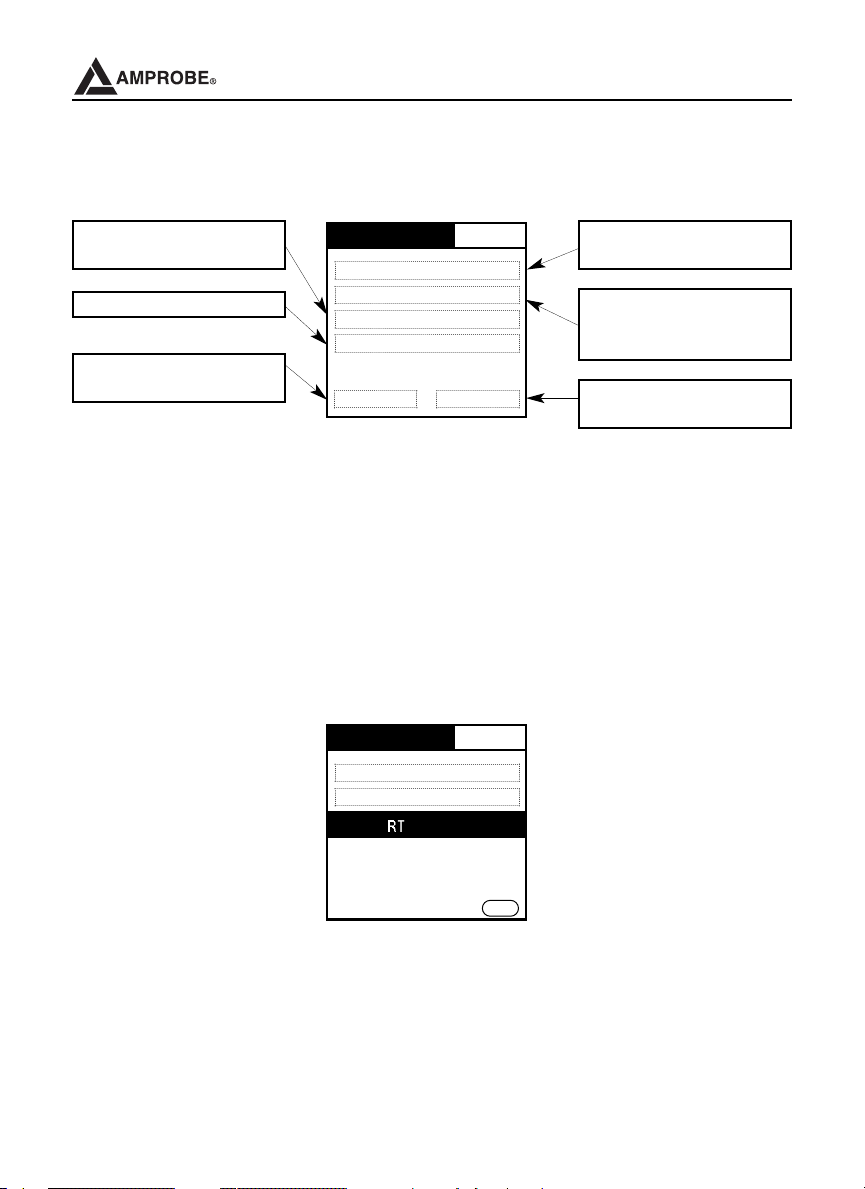

4.4 DISPLAY DESCRIPTION OF THE REMOTE USER INTERFACE (PDA)

Download the

recorded files.

View the downloaded files.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Display real time information

of the monitored system.

Allow the user to setup

recording sessions with the

desired configuration.

Delete recording or

downloaded files.

Delete Session Device Status

Display the status of the

device.

4.4.1 View Real Time Data

When monitoring an electrical system in real time, the user needs to know the

type of system configuration the device is hooked up to in order to have the

correct readings. Refer to section 11 for more information on the different types of

electrical system configurations.

• From the MDL Main Menu screen, click on View Real Time Data. The following

screen will appear.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

R

TM Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

P 60 Hz

P 1000 Amps

OK

• Select the desired electrical system configuration you want to monitor.

• Select the fundamental frequency of the system

• Select the type of clamp you are using with the DM-4 to monitor the

electrical system.

• Click OK to accept the system setup.

9

Page 11

DM-4 Power Quality Recorder

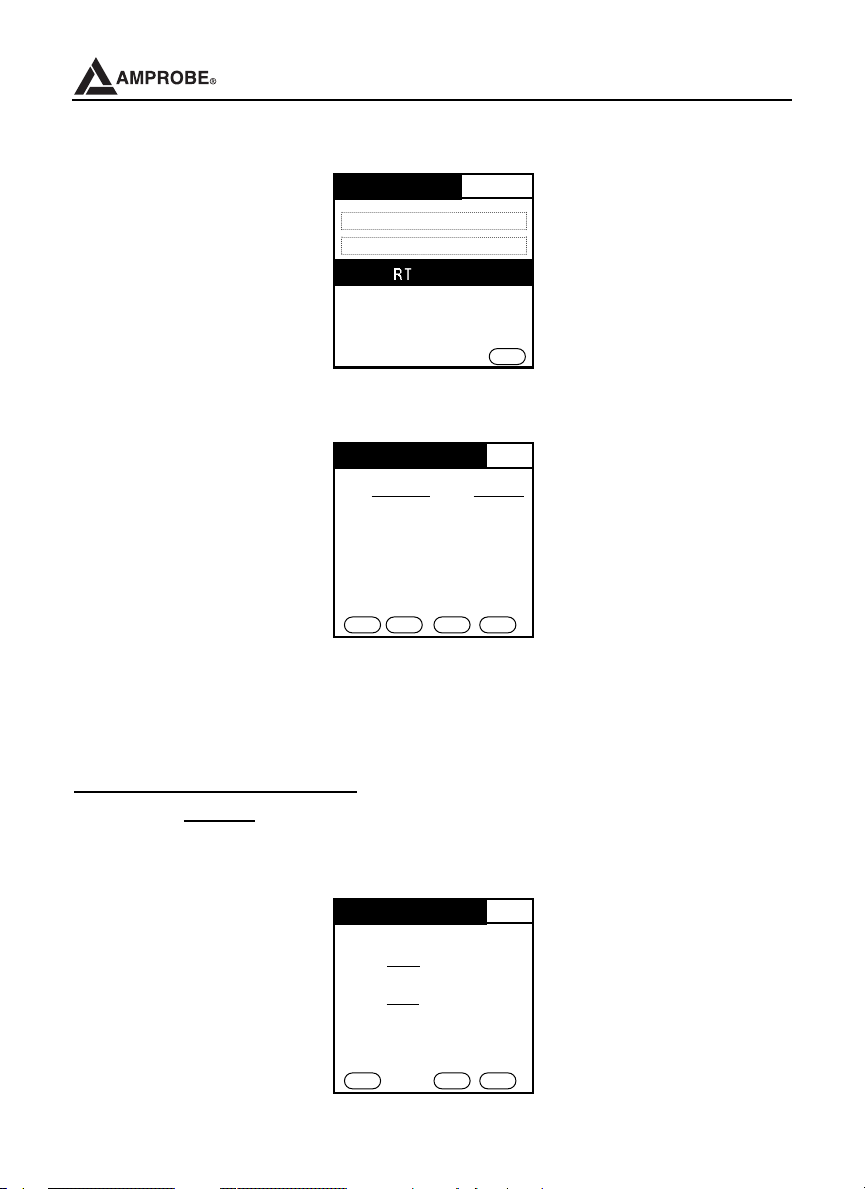

• 1-Phase 2-wire, 60Hz System using 1000A clamp

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

R

TM Setup

Phase Selection: P 1 Ø 2 W (Y)

Fund. Frequency:

Clamp Type:

P 60 Hz

P 1000 Amps

OK

• Select 1Ø2W, 60Hz, 1000A and then click OK. The following screen will appear:

Voltage & Current

V1: 116.13V __ l1: 3.96A

Back Voltage Current Power

• Once you get into this screen, you can get real time readings for voltage and

current and their associated waveforms and harmonics. You can also get

readings for power.

How to Monitor Voltage Only?

Click on the Voltage button located at the bottom of the screen. The voltage

reading for the monitoring phase will be displayed with its respective frequency.

Real Time Voltage

V1

Volt

(V) 0.00

Freq

(Hz) 0.00

Back Harm Scope

10

Page 12

DM-4 Power Quality Recorder

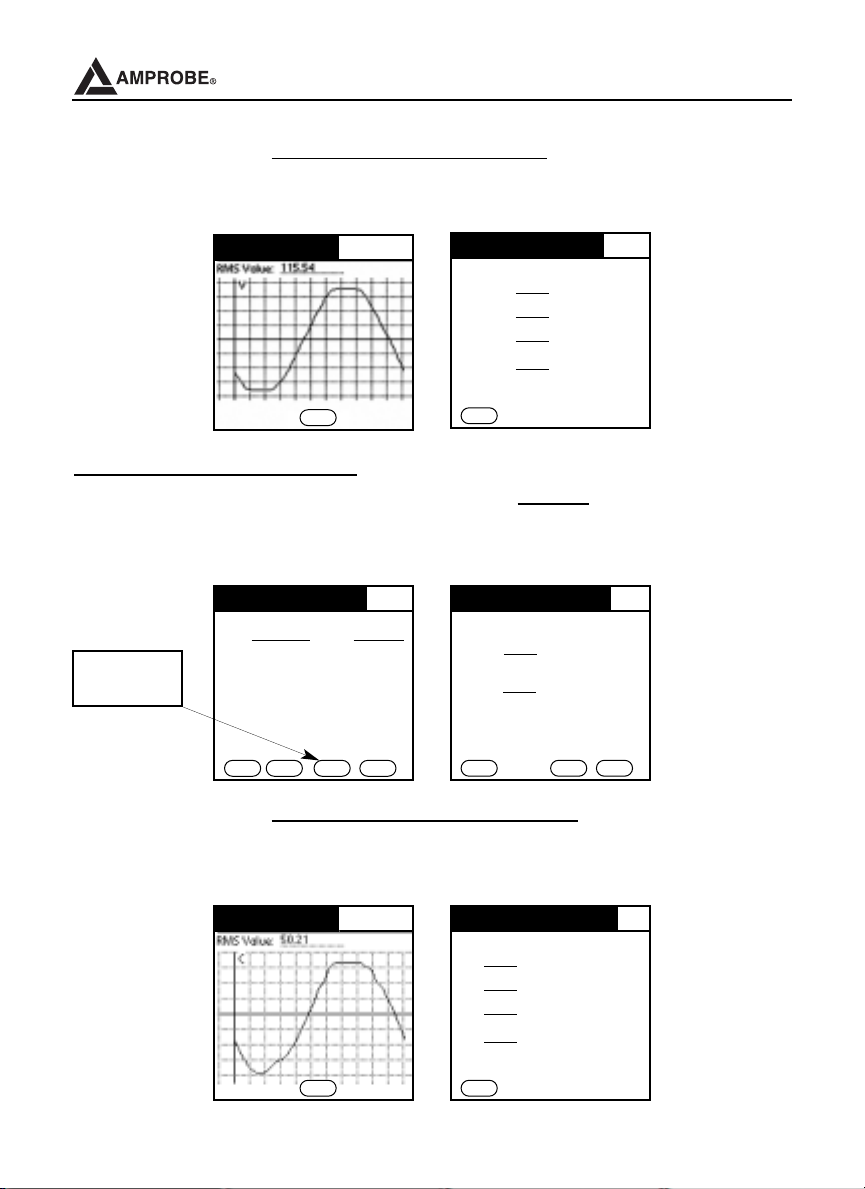

In order to display the voltage waveform or harmonics for the monitored phase,

click on Scope or Harm buttons. The waveform or the harmonics table for the

monitored voltage phase will be displayed.

oltage 1

Real Time Mode

P V

Real Time Voltage

V1

Harm 1 0.00

Harm 3 0.00

Harm 5 0.00

Harm 7 0.00

Close

Back

How to Monitor Current Only?

From the Voltage and Current screen, click on the Current button. You will be

prompted to the current only real time display. The RMS value for the monitored

phase will be reported with its respective frequency.

Voltage & Current

V1: 116.13V __ l1: 3.96A

Click

Current

Back Voltage Current Power

In order to display the current waveform or the harmonics

Real Time (Current)

Ø1

Cur

(A) 0.00

Freq

(Hz) 0.00

Back Harm Scope

for the monitored

phase, click on Scope or Harm buttons. The waveform graph or the harmonics

table for the monitored Current phase will be displayed.

Real Time Mode

P Current 1

Real Time Harmonics

Ø1

1 0.00

3 0.00

0.00

5

7 0.00

Close

Back

11

Page 13

DM-4 Power Quality Recorder

How to Monitor Power Only?

From the Voltage and Current screen menu, click on the Power button located at

the bottom of the screen.The Real Time Power screen will appear as shown

below with the following information: Real Power: P (kW); Reactive Power: Q

(kVAR); Apparent Power: S (kVA); True Power Factor: pF; and the displacement

power factor: dPf. To return to the previous screen, click on the Back button.

Real Time (Power)

Ø1 Ø2 Ø3 Total

P(kW) 0.00 0.00 0.00 0.00

Q(kVAR) 0.00 0.00 0.00 0.00

Click

Back

S(kVA) 0.00 0.00 0.00 0.00

PF 0.00 0.00 0.00 0.00

dPF 0.00 0.00 0.00 0.00

Back

3- Phase 4-wire, 60Hz System Using 1000A Clamp

• Once you have the DM-4 connected with your electrical system, you can follow

the same steps from paragraph 4.3 to paragraph 4.4.1.

• Select 3Ø4W, 60Hz, 1000A and then click OK.

Voltage & Current

V1: 0.000V _ _ l1: 0.00A

V2: 0.000V _ _ l2: 0.00A

V3: 0.000V __

Back Voltage Current Power

l3: 0.00A

ln: 0.00A

_

Click OK

to accept

the System

Setup

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

R

TM Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

P 60 Hz

P 1000 Amps

OK

• The Voltage and Current screen should display the readings for all three phases

as shown above.

• You can access the readings for voltage, current and power with their respective

waveforms and harmonics tables as described on “How to monitor voltage only?”,

“How to monitor current only?”, and “How to monitor power only?” in paragraph

4.4.1 for the 1Ø2W system.

12

Page 14

DM-4 Power Quality Recorder

3-Phase 3-wire, 60HZ system with 1000A Clamp

Because the 3Ø3W system doesn’t have a neutral wire, you need to follow the

proper direction given in this manual to connect the DM-4 with the 3Ø3W

electrical system you want to monitor. Refer to paragraph 11.3

• Follow the same procedures as for 1Ø2W and 3Ø4W systems. The following

screen should appear when accepting the system configuration setup for 3Ø3W.

Voltage & Current

V1: 0.000V _ _ l1: 0.00A

V2: 0.000V _ _ l2: 0.00A

V3: 0.000V __ l3: 0.00A _

Back Voltage Current Power

ln: 0.00A

Click OK

to accept

the System

Setup

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

R

TM Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

P 60 Hz

P 1000 Amps

OK

4.4.2 Setup A New Recording Session

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

From the main menu, click on “Setup A New Recording Session”. The MDL

system Setup menu will be displayed.

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

START:

P 60 Hz

P 1000 Amps

P Manual

ST

Back

OP:

P Manual

Next

13

Page 15

DM-4 Power Quality Recorder

The MDL System setup allows you to configure the data logger device for the type

of power system you want to perform the recording.

• Phase Selection: 1Ø2W; 1Ø3W; 3Ø3W (Delta configuration); 3Ø4W (Wye configuration).

• Fund. Frequency: 50-Hz; 60-Hz

• Clamp Type: 100 Amps; 1000 Amps; 3000 Amps

• Integration Period: 5s, 15s, 30s, 1min, 5min, 15min, 30min, 1 hr

• Start: Manual or Automatic

- Manual: Recording session starts when you click on the “Record Now”

button in later screen

- Automatic: Recording session will start at the preset time.

• Stop: Manual or Automatic

- Manual: Recording session stops when you click on “stop recording”

- Automatic: Recording session stops at the preset time.

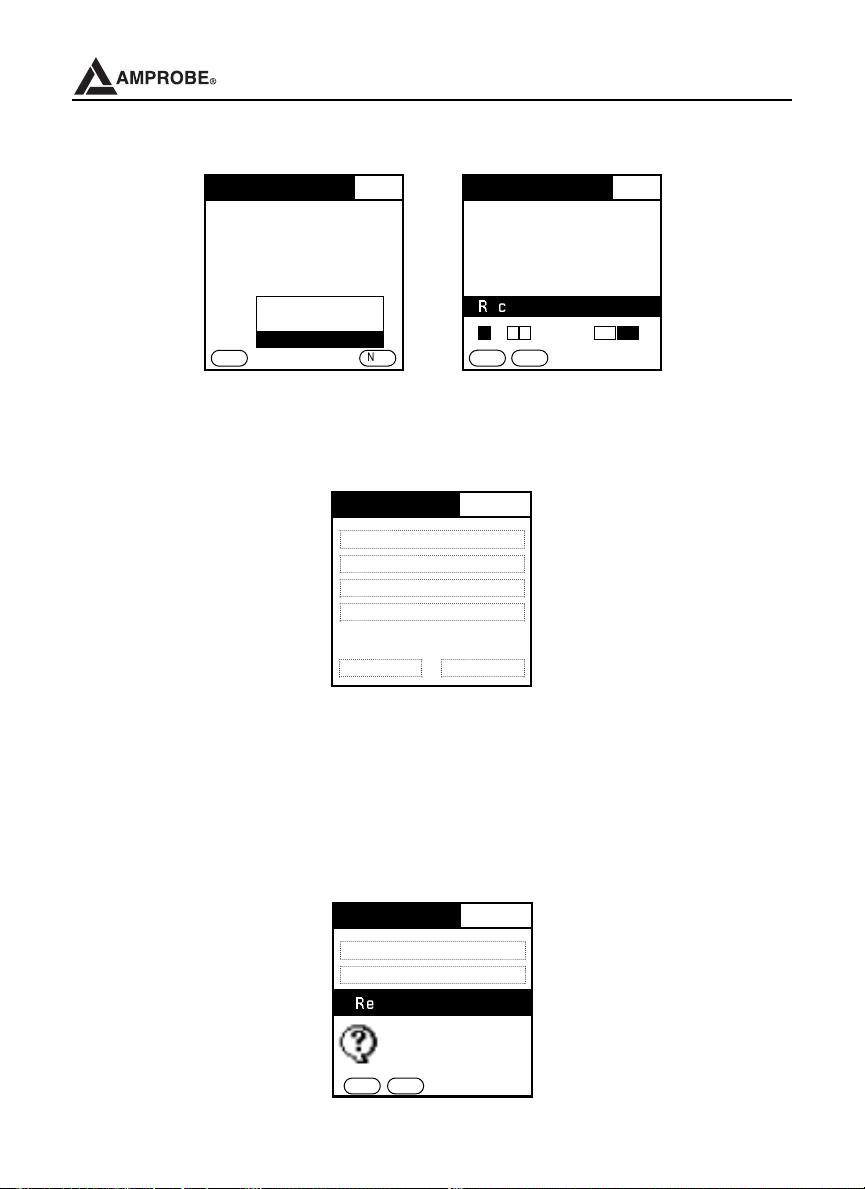

4.4.3 Set Date and Time For Automatic Recording Session

To set the date and time for an Automatic Recording session, follow the

steps below as shown on the screens on the previous page:

• Click on the drop down box of “START” and select “Set Time”

• Click on the drop down box of “Set Time” and select “Choose date”

• Select a date between the actual date of the year and 2031. (

NOTE: You cannot

choose a date in the past, for example 2001 is not a valid date).

• Repeat Step.2 to choose the time and click OK after a selection is made.

• Once you click on the RECORD button, the preset recording is stored in

memory. You can disconnect the Remote User Interface (PDA) at this point.

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

T

Clamp

Integration Period:

:

T

AR

ST

OP:

ST

Back

P 60 Hz

ype:

P 1000

P 5 sec

ime

T

P Set

ue 3/15/05 3:08 pm

P T

ime

T

P Set

ue 3/15/05 3:08 pm

P T

Amps

Next

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

T

Clamp

Integration Period:

START:

STOP:

Back

P 60 Hz

ype:

P Set Time

Now

P Tue 3/15/05 3:08 pm

Choose Date

Choose Date

P Set Time

Choose Time

P Tue 3/15/05 3:08m

P 1000

P 5 sec

Amps

14

Next

Recording Start Date

Q 2005 R

Jan Feb Mar Apr May Jun

Jul Aug Sep Oct Nov Dec

S M T W T F S

1 2 3 4 5

6 7 8 9 10 11 12

13 14

20 21 22 23 24 25 26

27 28 29 30 31

Cancel

(15)

Today

16 17 18 19

Page 16

DM-4 Power Quality Recorder

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Type:

Clamp

Integration Period:

START:

STOP:

Back

P 60 Hz

Amps

P 1000

P 5 sec

P Set Time

Now

P Tue 3/15/05 3:08 pm

Choose Date

P Set Time

Choose Time

Choose Time

P Tue 3/15/05 3:08m

Next

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

Integration Period:

START:

R

ecording Start Time

3 : 0 8 AM PM

OK

P Set Time

H

P

Cancel

P 60 Hz

P 1000 Amps

P 5 sec

5. MAIN MENU

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

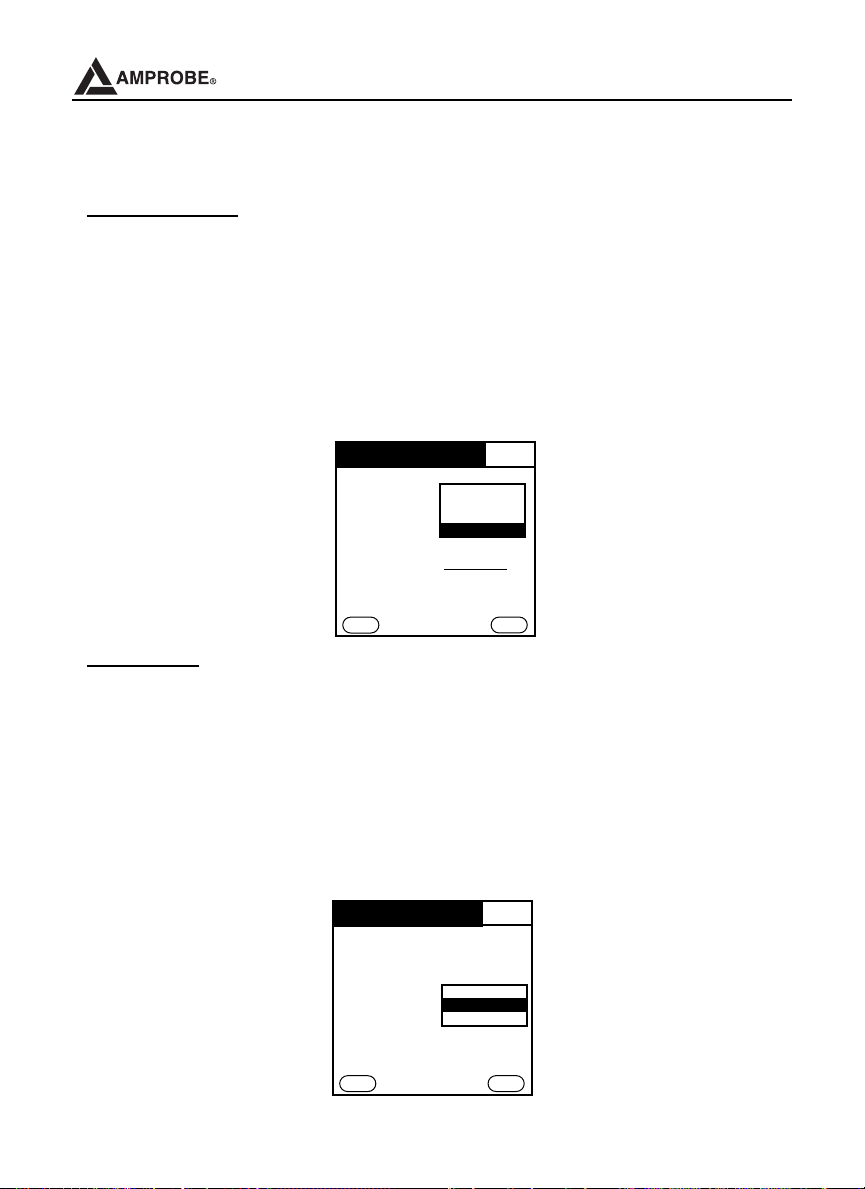

5.1 INITIAL SETTINGS

Initial settings are the last settings the user configured the unit at the time of the

last use. Each time you access the device with the Remote User Interface (PDA) ,

you will be asked if you would like to retrieve the device existing settings. Click YES

to retrieve the existing settings and NO to reset the device with the Remote User

Interface (PDA) settings.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

R

etrieve Settings?

Do you want to retreive

current settings from the

device?

No

Yes

15

Page 17

DM-4 Power Quality Recorder

5.1.1 How to Set the Date and Time?

When connecting to the data logger, if the date and time of the device are different

from the Remote User Interface (PDA), the program will ask you if you would like

to synchronize the data logger with the Remote User Interface (PDA). Click on YES

to set the date and time manually or automatically. Click on NO to continue to use

the device. Important!!! (If you do not set the device time correctly, the auto-

matic recording will not take place.)

Connecting

If you are using serial port, make sure

that the device is connecting using

appropriate cable.

Wrong Settings

The data logger’s date and

v

time are not in sync with the

Palm. Do you want to

change the settings

No

Yes

Click Yes

to change

the settings

Set Time

Synchronize time with Palm’s clock

Y

Palm Time: 10/3/05 2:27pm

Set time manually

Set Date: 10/3/05

Set Time: 2:27pm

Click Done

to accept

the change

Done

Device Status

Record @ undefined

Device time 10/3/05 2:29 pm

Battery 100%

Memory 0%

F/W ver 1.0b3

Back

Set

NOTE. You can also use the Download Suite program to set the date and time in

the device.

5.2 DEFAULT SETTINGS: ANALYZER CONFIG

The basic setting allows you to quickly set the device for a recording session with

all the 456 parameters selected.

16

Page 18

DM-4 Power Quality Recorder

5.2.1 How to Set the Type of Electrical System Under Test

• Phase Selection

This parameter permits you to select the type of electrical system under test among

the following configurations:

1Ø2W: Single phase system

1Ø3W: Single phase system

3Ø3W: 3 wires system (three-phase system without neutral)

3Ø4W: 4 wires system (three-phase system with neutral)

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

Integration Period:

Comment: Recording 1

START: P Manual

STOP:

Back

P Manual

1Ø2W

1Ø3W

P 60 Hz

3Ø3W (Delta)

3Ø4W (Y)

Next

• Clamp Type

The value of this parameter must always be equal to the clamp type you are

using. Three types of clamps are available:

1000A: For Standard clamps of 1000 Amps

3000A: For Flexible clamps of 3000 Amps.

100A: For miniature clamps of 100 Amps.

Set the desired value by selecting the clamp type using the drop-down box.

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

Integration Period:

START:

STOP:

Back

Comment:

P Manual

P Manual

17

P 60 Hz

100

1000 AMPS

3000 AMPS

AMPS

Next

Page 19

DM-4 Power Quality Recorder

5.3 BASIC SETTING: RECORDER CONFIG

This option allows you to check and eventually modify the recording parameters

and the selected parameters (up to a maximum of 456).

5.3.1 MDL Parameter Setup

This option allows you to setup the parameters for a recording session. When using

the Remote User Interface (PDA) in basic setting, selecting any block will enable

all the parameters under this block.

MDL Parameter Setup

Y

RMS Voltage (all phases)

Y

RMS Current (all phases)

Y

Voltage Harmonics

Y

Current Harmonics

Voltage Frequency & Phase Shift

Y

Y

Current Frequency & Phase Shift

Power/Energy/PF(all phases)

Y

Demand

Y

Waveform

Y

Back

Next

To select/deselect a function block, just click on the checked box. The check mark

(√) indicates that the function block has been selected.

5.3.2 MDL Voltage Anomalies

This option allows you to setup the parameters for all the anomalies (Sag, Surge,

and Spike).

MDL Voltage Anomolies

Voltage Anomalies

Back

Next

To select the voltage anomalies function block, just click on the checked box.

A check mark (√) indicates that the function block is enabled.

18

Page 20

DM-4 Power Quality Recorder

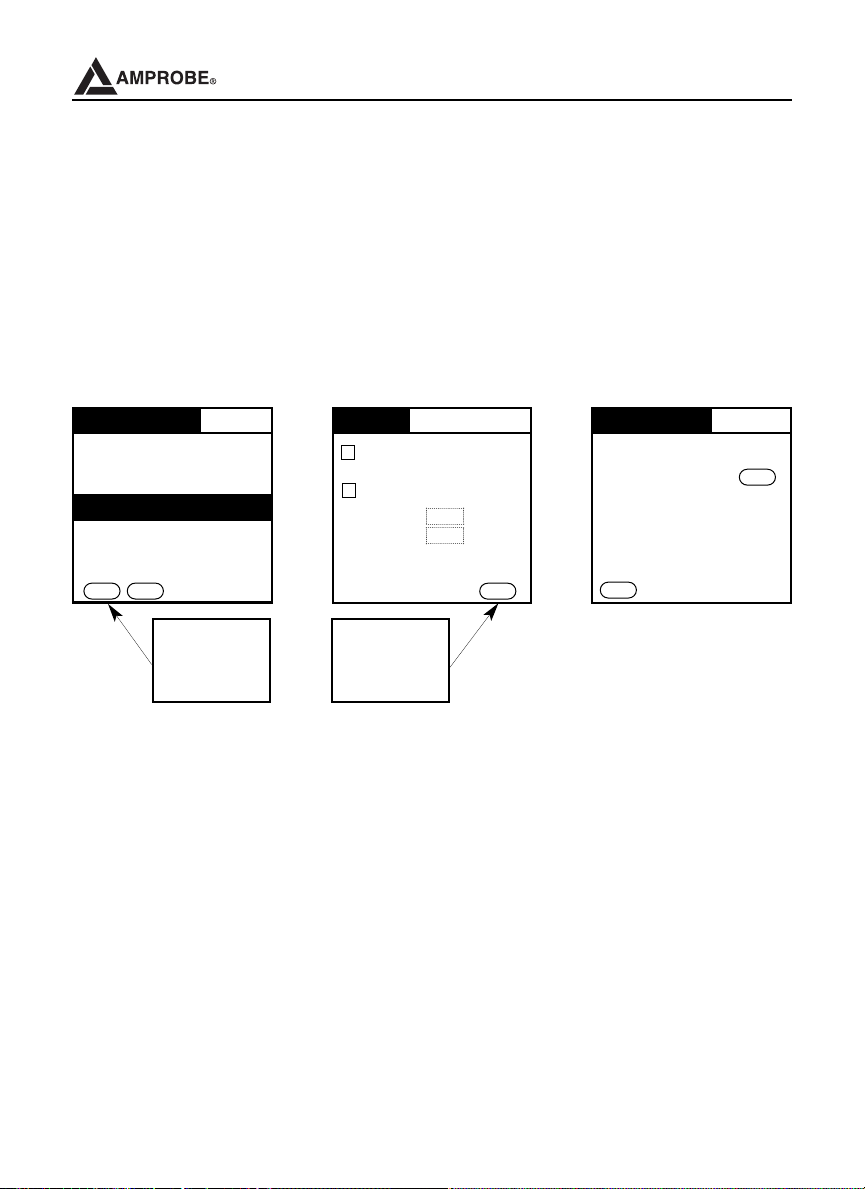

5.4 Advanced Setting: Recorder Configuration

The advanced setting option allows you to setup the desired parameters you want

for a recording session.

To enter the advanced setting mode:

1) From the MDL main menu screen, click on

MDL Main Menu and select Options

MDL-Main Menu

Click

MDL-Main

Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

2) From Options down drop list, choose MDL Preferences

Control Optons

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

Preferences

MDL

Beam MDL

About MDL

3) From MDL Preferences menu, select Advanced Mode by clicking on the

checked box. A check mark (√) indicates a selection. Press Ok to complete the

selection. You should return to the main menu.

MDL-Main Menu

View Real Time Data

MDL-Main Menu

MDL Preferencesu

Advance Mode:

Setup a New Recording Session

Comm Port:

Download Data

iew Downloaded Data

V

P Serial

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

19

Page 21

DM-4 Power Quality Recorder

5.4.1 Setting the Parameters Individually

To set-up the parameters individually for a recording session, select “Setup a New

recording Session

” from the MDL Main Menu. The MDL System Setup will

appear. Click on Next to enter the MDL Parameter Setup screen.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

Integration Period:

START: P Manual

STOP:

Back

P 60 Hz

P 1000 Amps

P 5 sec

Comment: Recording 1

P Manual

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage NA

Harmonics NA

Frequency NA

Phase Shift NA

Waveform

Back

Y

Y Y

A

A

A

Y

Y Y

Y

Y Y

Next

5.4.2 Advanced MDL Parameter Setup

The advanced MDL parameter setup option allows you to select one or all the

parameters for one or all the phases for Voltage, Current, and Power.

5.4.3 Set up the Parameters for Voltage

1Ø2W Single Phase 1Ø3W Single Phase

MDL Parameter Setup

Voltage Current Power

Variable Ø1

Voltage

Harmonics

Frequency

Phase Shift

Waveform

Back

A

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø12

Voltage

Harmonics

Frequency

Phase Shift

Waveform

Back

Y

Y Y

A

A

Y

Y

Y

Y

Next

3Ø3W Delta Configuration 3-phase 3Ø4W Wye Configuration 3-phase

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage NA

Harmonics NA

Frequency

Phase Shift NA

Y

Back

W

aveform

Y

Y Y

A

A

A

NA

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage NA

Harmonics NA

Frequency

Phase Shift NA

Y

Back

aveform

W

Y

A

20

Y Y

A

A

NA

Next

Page 22

5.4.4 Setup the Parameters for Current

1Ø2W Single Phase 1Ø3W Single Phase

DM-4 Power Quality Recorder

MDL Parameter Setup

oltage Current Power

V

Variable Ø1

Current

Harmonics

Frequency

Phase Shift

Waveform

Back

A

Next

MDL Parameter Setup

oltage Current Power

V

Variable Ø1 Ø2

Current

Harmonics

Frequency

Phase Shift

W

Back

aveform

Y

Y

A

A

Y

Y

Y

Y

Next

3Ø3W Delta Configuration 3-phase 3Ø4W Wye Configuration 3-phase

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage

Harmonics

Frequency NA

Phase Shift NA

Y

Back

Waveform

Y

Y Y

A

A

A

Y

Y

A

Y Y

Y Y

Y

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage

Harmonics

Frequency NA

Phase Shift NA

Y

Waveform

Back

Y

Y Y

A

A

A

Y

Y Y

Y

Y Y

Y

A

Next

5.4.5 Setup the Parameters for Power

1Ø2W Single Phase 1Ø3W Single Phase

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 TOT

P (KWh)

Q (kVARh)

S(kVAh)

PF

dPF

PF true/displ

Back

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 TOT

P (KWh)

Q (kVARh)

S(kVAh)

PF

dPF

PF true/displ

Back

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Next

21

Page 23

DM-4 Power Quality Recorder

3Ø3W Delta Configuration 3-phase 3Ø4W Wye Configuration 3-phase

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2

P (KWh)

Q (kVARh)

S(kVAh)

PF

dPF

PF true/displ

Back

Ø3 TOT

Y

Y Y

Y

Y

Y

Y

Y Y

Y

Y Y

Y

Y Y

Y

Y Y

Y

Y

Y

Y

Y

Y

Next

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2

P (KWh)

Q (kVARh)

S(kVAh)

PF

dPF

PF true/displ

Back

Ø3 TOT

Y

Y Y

Y

Y

Y

Y

Y Y

Y

Y Y

Y

Y Y

Y

Y Y

Y

Y

Y

Y

Y

Y

Next

5.4.6 Setup the Parameters for Voltage Harmonics

To setup the parameters for voltage harmonics, you must be in the advanced

mode

when programming with the Remote User Interface (PDA).

1) From the main menu, select

start a new recording session. The MDL System

Setup screen appears. If you have already setup the device for the system you

want to monitor, click on NEXT and the MDL parameter setup screen should

appear. If you haven’t done so, refer to section 5.2.1

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

MDL System Setup

Phase Selection: P 3 Ø 4 W (Y)

Fund. Frequency:

Clamp Type:

Integration Period:

START: P Manual

STOP:

Back

P 60 Hz

P 1000 Amps

P 5 sec

Comment: Recording 1

P Manual

Next

22

Page 24

DM-4 Power Quality Recorder

2) From the MDL parameter setup screen, select voltage and choose “A”

(harmonic) under the phase you want to monitor. You need to setup each phase

separately when monitoring more than one phase.

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage NA

Harmonics NA

Frequency NA

Phase Shift NA

Waveform

Back

Y

Y Y

A

A

A

Y

Y Y

Y

Y Y

Y

Y Y

Next

Harmonics Phase-1

Harmonics Phase-2

Harmonics Phase-3

3) From the Harmonics setup screen, you can select the harmonics you want to

enable by clicking on the numbers. To unselect a number, just click on it another

time. Click on

done to confirm the selections.

Recording Start Date

Harmonics

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48 49 50

51

Select All

Clear All

Done

Recording Start Date

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48 49 50

51

Select All

Harmonics

Clear All

Harmonics #’s

1, 3, 7, 15 and

49 are selected

Done

5.4.7 Setup the Parameters for Current Harmonics

To setup the parameters for current harmonics, repeat step 5.4.5 and select

Current in step.2

MDL Parameter Setup

Voltage Current Power

Variable Ø1 Ø2 Ø3 N

Voltage

Harmonics

Frequency NA

Phase Shift

Back

Waveform

Y

A

Y

Y

Y Y

A

Y Y

Y Y

Y

A

A

NA

Next

23

Page 25

DM-4 Power Quality Recorder

5.5 Download Data

After a recording session, you can retrieve your data by downloading the file from

the device to your PC, using the Download Suite, or from the device to your

Remote User Interface (PDA).

5.5.1 Download Data with the Remote User Interface (PDA)

To retrieve a file from the device with your Remote User Interface (PDA), click on

Download Data from the MDL main menu. On the

Remote Recordings screen,

select the file you want to download and click on Download. Once Downloading

recording is complete, you will be redirected back to the Remote Recordings

screen. If you don’t have any more recording files to download, click on the back

button to return to the main menu.

Click

Download

Data

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

Remote Recordings

1/1/70 12:46 am

Downloading Recording...

Remote Recordings

1/1/70 12:46 am

Back

Mobile Datalogger

45%

Cancel

24

Delete

Download

Click

Download

Page 26

DM-4 Power Quality Recorder

5.5.2 View Downloaded Data

This option allows you to view all downloaded files in the Remote User Interface

(PDA). Once a file is downloaded, you can select it to be viewed. To view a downloaded file, click on

View Downloaded Data from the MDL main menu. The pro-

gram will prompt you to the Saved Recordings screen. Select the file you want to

view by clicking on it once.

Saved Recordings

Recordings Date Time

2760 1/1/70 12:46am

1111069687 3/17/05 2:28pm

Click

Click View

Downloaded

Data

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Recorded

Delete Session Device Status

From This screen,

you can select the

recorded information

you want to view by

clicking on any item

on the list.

Back

Recording Parameters

Recording Information

- V Voltage RMS

- V Harmonics

- V Frequency

- V Phase Shift

- Voltage Anomalities (Spikes)

- Power (P,Q,S,PF,dPF)

- Energy (Ep, Eq, Es)

- Demand

Back

- I Current RMS

- I Harmonics

- I Frequency

- I Phase Shift

Next

Data

5.5.3 Recording Information

The recording information dialog box allows you to view the settings that have been

used in this recording session. Click on “OK” to return to the recording

parameters

screen.

Recording Information

Fund Freq: 60

System: 3

Int. Period: 5

Clamp: 1000

Start: 3/17/05 2:28pm

Stop: 3/17/05 3:12pm

Comment:

Monday031405

Click OK

25

OK

Page 27

DM-4 Power Quality Recorder

5.5.4 Delete Session

To delete a recording session from the device, choose Delete Session from the

main menu. The device will prompt you to the remote recording files. From the

remote recording files screen, select a file or the files you want to delete and then

click on Delete.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Remote Recordings

4/20/05 2:00pm

4/25/05 10:55 am

4/25/05 1:45 pm

4/25/05 1:45 pm

Select the

recording

session you

want to delete

and click on

Delete Session Device Status

Back

Delete

Download

Delete

Symbols Description Advised Settings

START:MAN The recording of all the selected parameters will start at

00 seconds after pressing RECORD

STOP:MAN The recording of all the selected parameters will be

interrupted manually by pressing RECORD.

START:AUTO

STOP:AUTO

The recording of all the selected values will be started /

interrupted at the set dates and times. In order to start

☺☺

☺☺

the recording the user will have to select RECORD to

set the instrument in Stand-by mode until the start date

and time previously set.

INT. PERIOD The value of this parameter determines how many sec-

onds the values of all the selected parameters will be

15min

stored. Available choices:

5sec, 15sec, 30sec, 1min, 5min, 15min, 30min, 1hr.

☺☺

HARM REC. Enable = the instrument will record the values of the

selected voltage and current harmonics

corresponding to the voltages and currents selected in

the corresponding pages “Voltage” and “Current”.

Example: If the following Parameters are selected:

a) Phase Voltage 1 and 2, Thd, Harmonics 1, 3, 5.

b) Phase Current 2 and 3, Thd, Harmonics 3, 5, 7.

The instrument will record:

a) The Phase Voltage 1 and 2, Thd and Harmonics 1,3,5 of the Phase

Voltage 1 and 2 while it will not record anything about Phase Voltage 3

b) The Phase Current 2 and 3, Thd and Harmonics 3,5,7 of the Phase

Current 2 and 3 while it will not record nothing about Phase Current 1

☺☺

Disable = the instrument will not record any voltage or

current harmonic selected

26

Page 28

DM-4 Power Quality Recorder

Symbols Description Advised Settings

ANOM REC. Enable = the Instrument will record Voltage Sag, Surge,

and voltage spike

Disable = the instrument will not record any voltage

Sag, Surge, and voltage spike.

V1, V2, V3

V12, V23 or

V32, V31

Thd, DC, 01...51 Voltage Total Harmonic Distortion, DC Component,

Vref (Only if

ANOM. REC flag

has been enable)

LIM+, LIM(Only if ANOM.

REC flag has

been set ON)

I1, I2, I3, IN RMS value of the current of phase 1, phase 2, phase 3

Thd, DC, 01..51 Current Total Harmonic Distortion, DC Component,

Pt, P1, P2, P3,

P12, P32, P31

RMS value of the voltage of phase 1, phase 2, phase 3

respectively, values of the phase-to-phase voltages 1-2,

2-3 or 3-2 and 3-1.

01..51 Harmonics respectively

RMS reference value for Voltage used in Voltage

Anomalies detection (Voltage Sag and Surge).

The Reference is:

a) Voltage Phase to Neutral for Single Phase and 4

wires three phase system

b) Voltage Phase to Phase for 3 wires three phase system

High and Low Voltage Percent threshold used in

Voltage Anomalies detection (Voltage Sag and Surge).

Example: Three Phase System 4 wires.

Vref = 120, LIM+= 10%, LIM-=10% =>

High Lim = 132V, Low Lim = 108.0V

The Instrument will detect a voltage Anomalies if the

RMS Voltage Values (calculated every 14ms) beyond

the above calculated thresholds

and of the neutral respectively.

01..51 Harmonics respectively

Values of the active power (total, of phase 1, phase 2

and phase 3) (only for 3 wires measurement)

value of the power measured by the W

3-2 respectively.

attmeter 1-2 and

3 wires V12V32V

4 wires V1, V2, V

Thd,01,03,05,07

4 wires Pt, P1, P2, P3

☺☺

☺☺

Single phase: V1

3

☺☺

Thd,01,03,05,07

☺☺

Single phase: 230V

3 wires: 400V

4 wires: 230V

☺☺

Single phase: 120V

3 wires: 480V

4 wires 277V

☺☺

Single phase: I1

3 wires: I1, I2, I3

4 wires I1, I2, I3, IN

☺☺

Single phase: P1

3 wires: Pt

31

27

Page 29

DM-4 Power Quality Recorder

Symbols Description Advised Settings

Qt, Q1, Q2, Q3,

Q12, Q32, Q31

-Qt, -Q1, -Q2, -Q3,

-Q12, -Q32, -Q31

St, S1, S2, S3,

S12, S32, S31

Values of the inductive reactive power (total, of phase 1,

phase 2, phase 3) (only for 3 wires measurement) value

of the reactive inductive power measured by the VAR

meters 1-2 and 3-2 respectively

Values of the capacitive reactive power (total, of phase

1, phase 2, phase 3) (only for 3 wires measurement)

value of the reactive capacitive power measured by the

VA meters 1-2 and 3-2 respectively

Values of the apparent power (total, of phase 1, phase 2,

phase 3) (only for 3 wires measurement) value of the power

measured by the VAmeters 1-2 and 3-2 respectively

☺☺

Single phase: Q1

3 wires: Qt

4 wires Qt, Q1, Q2, Q3

☺☺

Single phase: S1

3 wires: St

4 wires St, S1, S2, S3

Pft, Pf1, Pf2, Pf3 Values of the power factors (total, of phase 1, phase 2

and phase 3 respectively)

dpft, dpf1, dpf2,

dpf3

Eat, Ea1, Ea2,

Ea3

Ert, Er1, Er2, Er3 Values of the inductive reactive energy (total, of phase

-Ert, -Er1, -Er2, Er3

Est, Es1, Es2, Es3 Values of the Apparent Energy (total, of phase 1,

Selecting a power factor (Pf) or a cosΘ (dPf) for the recording automatically their inductive value

and their capacitive value will be recorded separately.

Values of the cosΘ (total, of phase 1, phase 2 and

phase 3 respectively)

Values of the active energy (total, of phase 1, phase 2,

phase 3)

1, phase 2 and phase 3)

Values of the capacitive reactive energy (total, of phase

1, phase 2, phase 3)

phase 2, phase 3)

Single phase: Pf1 dPf1

☺☺

3 wires: Pft dPft

4 wires Pft Pf1 Pf2

Pf3dPft dPf1 dPf2

dPf3

☺☺

Single phase: Ea1

3 wires: Eat

4 wires Eat Ea1 Ea2

Ea3

☺☺

Single phase: Er1

3 wires: Ert

4 wires Ert Er1 Er2

Er3

☺☺

Single phase: Es1

3 wires: Est

4 wires Est

Es3

Es1

Es2

28

Page 30

DM-4 Power Quality Recorder

5.5.5 RESET (PRESS AND HOLD RESET KEY WHILE PRESSING ON RECORD)

This option re-establishes the default settings of the instrument.

The default settings of the instrument consist of:

ANALYZER CONFIG:

Frequency: 60Hz

Full scale of the clamps: 1000A

Type of electrical system: 4 wires

RECORDER CONFIG:

Start: Manual (the recording is started at 00 sec mark on clock after pressing the RECORD key)

Stop: Manual

Integration period: 5S

Recording of harmonics: ON

Recording of Sag and Surge: OFF

Voltage Reference for Sag and Surge detection: 480V

Upper Limit for Sag and Surge detection: 10%

Lower Limit for Sag and Surge detection: 10%

Selected voltages: V1, V2, V3

Selected voltage harmonics:

Selected currents: I1, I2, I3, IN

Selected current harmonics:

Powers, Pf and cosΘΘselected:

Pt, P1, P2, P3

Qt, Q1, Q2, Q3

Qt, Q1, Q2, Q3

St, S1, S2, S3

Pft, Pf1, Pf2, Pf3

dpft, dpf1, dpf2, dpf3

Energies:

Eat, Ea1, Ea2, Ea3

Erit, Eri1, Eri2, Eri3

Erct, Erc1, Erc2, Erc3

Est, Es1, Es2, Es3

Note: The RESET command will not erase the instrument’s memory.

29

Page 31

DM-4 Power Quality Recorder

6. RECORDING CONFIGURATION

More practically, we may schematize the right procedure of use as follows:

1) Connect the External Power Supply

2) Check and eventually modify the basic settings of the instrument.

3) Select the parameters to be recorded.

4) Connect the DM-4 to the electrical system to be tested and push the

ON/OFF button

5) Evaluate the values of the parameters under test

6) If you want to record:

A) Decide what to record

B) Select MDL Setup Parameter and check if the existing parameters meet

your requirements

7) Start the recording by pressing RECORD.

7. STARTING A RECORDING

You can start a recording manually or automatically. Therefore, after setting all the

parameters and click on RECORD, the instrument will start recording:

MANUALLY: The recording will start when Instrument’s time reaches the “00” seconds value after pressing RECORD.

AUTOMATICALLY: If the operator has clicked on RECORD the instrument will

remain in stand-by until the date and time previously set, then the recording will start.

If the operator has not clicked on RECORD, the recording will never start.

m

For recordings ALWAYS use the external power supply even though the

instrument allows the operator to perform a recording using internal batteries.

CAUTION

30

Page 32

DM-4 Power Quality Recorder

If during a recording the external power supply is de-energized, the instrument will

continue the recording using the internal battery power until the batteries are

exhausted (the data stored until the definitive turning off won’t get lost). For this

reason we recommend that you

ALWAYS insert a new set of batteries before a

long recording.

• If the instrument is recording or is measuring energy (and the external

power supply is not connected), the recording will continue until the batteries

are exhausted.

Before starting a recording the operator should first evaluate the state of the

equipment, decide what to record and set the instrument accordingly.

In order to facilitate this task the instrument has been factory pre-set with a

general configuration which should fit most cases. Using the RESET option

(See paragraph 5.6).

By pressing

RECORD the recording of the selected parameters is started

according to the settings made in the MENU (see paragraphs 5.2 and 5.3).

As the default value of the integration periods is set at 5 seconds the instrument will

store data in the temporary memory every 5 seconds. Afterwards the instrument will

explain the results saved in the temporary memory and will save the first series of

values in the permanent memory. Therefore, if an integration period of 5 seconds has

been set, the recording will continue for about 5 seconds before producing a set of

recorded values. If the recording is interrupted before the selected integration period

has completely elapsed, the data stored in the temporary memory (SRAM) will not be

elaborated and the corresponding series of values won’t be transferred to the

permanent memory (FLASH).

31

Page 33

DM-4 Power Quality Recorder

8. RECORDING IN PROCESS

If during a recording the external power supply is de-energized, the instrument will

continue the recording using the internal battery power until the batteries are

exhausted (the data stored up to the point the instrument shuts down won’t get

lost). For this we recommend you

a long recording. You may not be able to download this file with the Remote User

Interface (PDA) device. We recommend that you use the Download Suite to open

this file.

During a recording the following commands are disabled:

• AUTOPOWER OFF function

• ON/OFF key

• RESET key

Click “DEVICE STATUS” on the main menu and the following screen will appear:

ALWAYS insert a new set of batteries before

This page includes:

1) Recording information

2) Device Date and Time

3) Battery condition

4) Memory size available

5) Firmware version

Device Status

Recording @ 0 (undefined)

Device Time 1/1/70 12:06 am

Battery 100%

Memory 99%

F/W ver 1.2

Back

32

Set

Page 34

DM-4 Power Quality Recorder

9. STOPPING A RECORDING

The instrument uses a protective routine to avoid the risk of being disturbed or

interrupted during a recording or an energy measurement. Once a recording has

been started using automatic record mode, it won’t be sufficient to press the

RECORD key on the device to stop the recording. You need to use the Remote

User Interface (PDA) or the download suite to stop the recording.

9.1 Stop a Recording with the REMOTE USER INTERFACE (PDA)

To stop a recording with the Remote User Interface (PDA) , click on the MDL Main

Menu screen and then select STOP RECORDING.

MDL-Main Menu

View Real Time Data

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

Control Optons

Start Recording

View Real Time Data

Stop Recording

Setup a New Recording Session

Download Data

View Downloaded Data

Delete Session Device Status

9.2 Stop a Recording with the Download Suite

To stop a recording with the download suite, go to control panel screen window and

then click on stop recording.

33

Page 35

DM-4 Power Quality Recorder

10. CONNECTING THE INSTRUMENT TO A PC

In order to connect the instrument to a PC you must connect the serial cable

shipped with the instrument to the serial output of the PC.

The DM-IV serial cable has the following inner connections:

2

Male connector 9 pins 3

on the instrument side 5

2

3 Female connector 9 pins

5 on the PC side

The available transmission speeds are the following:

4800, 9600, 19200, 57600(default value)

The value of the transmission speed (Baud Rate) must be selected on the Remote User

Interface (PDA) or the Download Suite in order to have proper communication. The download suite will always look for COM1 first if the setting is set to

AUTOMATICALLY.

For download suite instructions please refer to software help file.

In order to transfer the recorded data from the instrument to the PC the following

procedure must be followed:

1) Switch ON the instrument

2) Connect the serial output of the instrument to the serial output of the

PC through the serial cable

34

Page 36

DM-4 Power Quality Recorder

3) Install the software and start it – Close the introduction window

4) Press F2 and follow the commands.

5) Refer to software help file for further instructions.

11. MEASURING PROCEDURES

11.1 USING THE INSTRUMENT IN A SINGLE PHASE SYSTEM

CAUTION

The maximum voltage between L1 and COM inputs is CATIII 635V~

m

phase-phase and 370V~ phase – earth. Do not measure voltages

exceeding the limits prescribed by this manual. Should you exceed the

voltage limits you could damage the instrument and/or its components

or endanger your safety.

Phase 1

Phase 2

Neutral

Phase 3

Black

Yellow

Instrument connection in a single-phase system

CAUTION

m

1) Check the cables connection.

2) Connect the phase and neutral voltage wires according to the connections

shown in the above picture.

If possible, before connecting the instrument to the electrical system,

remove the power off the electrical system.

35

Page 37

DM-4 Power Quality Recorder

3) Turn ON the unit by pressing the ON/OFF push button

4) If you want to measure current and power, connect the clamp meter to the phase

conductor respecting the specifications shown on the clamp and the connections

shown in the picture.

5) Apply voltage to the electrical equipment under test (if previously shut off for the

instrument connection).

6)The values of the available electrical parameters will be displayed on the Remote

User Interface (PDA) display or the PC screen. For further details see the Remote

User Interface (PDA) settings.

7) If you want to record, simply press the RECORD push button on the device.

11.2 USING THE INSTRUMENT IN A THREE PHASE 4- WIRE SYSTEM (WYE)

CAUTION

The maximum voltage between L1, L2, L3 & COM inputs is CAT III 635

m

V~ phase – phase 370 V~ phase to earth. Do not measure voltages

exceeding the limits prescribed by this manual. Should you exceed the

voltage limits you could damage the instrument and/or its components

or endanger your safety.

Phase 1

Phase 2

Neautral

Phase 3

Black

Red

Yellow

Blue

Instrument connection in a three-phase 4 wire system

36

Page 38

DM-4 Power Quality Recorder

CAUTION

m

1) Check the cables connection.

2) Connect the phase and neutral voltage wires respecting the connections shown

in the picture.

3) If you want to measure current and power, connect the clamp meter to the phase

conductor respecting the specifications shown on the clamp and the connections

shown in the picture. In case of doubts select the position

connecting one clamp at a time, check if:

a) The phase sequence is correct

b) The active power P of each phase is positive.

c) The value of the Pf of each phase is not excessively low (typically it’s not lower

4) Apply voltage to the electrical equipment under test (if previously shut off for the

instrument connection).

5) The values of the available electrical parameters will be displayed.

6) If you want to record:

a) Check and, if needed, modify the values of the basic parameters (see

b) Check and, if needed, modify the recording parameters.

c) To start the recording press

If possible, before connecting the instrument to the electrical equipment

to be tested take the power supply off the electrical equipment.

POWER and,

than 0.4). In case the Pf is lower than 0.4, check if the phase voltage is

associated to the right clamp meter (for example the voltage of phase 1 must

be associated to the clamp meter no. 1).

paragraphs 5.2 and 5.3).

RECORD.

37

Page 39

DM-4 Power Quality Recorder

11.3 USING THE INSTRUMENT IN A THREE PHASE 3- WIRE SYSTEM (DELTA)

CAUTION

m

The maximum voltage between V1, V2, V3 and COM (L2) inputs is

CATIII 600V~ phase-phase. Do not measure voltages exceeding the

limits prescribed by this manual. Should you exceed the voltage limits

you could damage the instrument and/or its components or endanger

your safety.

m

m

Phase 1

Phase 2

Phase 3

Instrument connection in a 3 wires three-phase system (DELTA)

Black

Red

Blue

CAUTION

Please note that in this case the yellow cable (neutral) is connected with

the red cable on phase 2. You can use any phase you want as reference.

CAUTION

If possible, before connecting the instrument to the electrical equipment

to be tested take the power supply off the electrical equipment.

38

Page 40

DM-4 Power Quality Recorder

1) Check, and if needed modify, the basic settings of the instrument (see

paragraphs 5.2 and 5.3). Particularly, the 3 wires mode must be set.

2) Connect the phase and neutral voltage wires respecting the connections shown

in the picture.

3) If you want to measure current and power, connect the clamp meter to the phase

conductor respecting the specifications shown on the clamp and the connections

shown in the picture. Check if:

a) The phase sequence is correct

b) The active power P of each phase is positive.

c) The value of the Pf of each phase is not excessively low (typically it’s not lower

than 0.4). In case the Pf is lower than 0.4, check if the phase voltage is

associated to the right clamp meter (for example the voltage of phase 1 must

be associated to the clamp meter no. 1).

d) After checking, and if needed modifying, the connection of the instrument to

the equipment re-set the

3 wires mode and the connections shown in the

picture (yellow and red wire together).

4) Apply voltage to the electrical equipment under test (if previously shut off for the

instrument connection).

5) The values of the available electrical parameters will be displayed of the instrument.

6) If you want to record:

a) Check and eventually modify the values of the basic parameters (see

paragraphs 5.2-5.3).

b) Check and eventually modify the recording parameters (see How to set the

parameters using Remote User Interface (PDA).

c) To start the recording press

RECORD

39

Page 41

DM-4 Power Quality Recorder

12. MAINTENANCE

12.1 GENERAL

The DM-4 is a precision instrument. For its’ use and storage, follow the recommendations

and instructions contained in this manual in order to avoid possible damages. Never use

the instrument in environments with a high humidity or temperature. Always turn off the

instrument if it is not in use.

12.2 BATTERY REPLACEMENT

When the battery indicator indicates less than 50% ( q ), the batteries must

be replaced.

CAUTION

Only qualified technicians should operate the instrument. Before

m

1) Disconnect cables and clamps from the circuit under test.

2) Turn the instrument off by pressing ON/OFF push button.

3) Remove the cables from the input terminals.

4) Unscrew the screw of the battery cover and remove the cover.

5) Replace the batteries with 8 new 1.5 V - AA.

6) Reposition the cover and fasten it with the proper screw.

replacing the batteries, disconnect the test leads from circuit under

voltage in order to avoid electrical shocks.

(Alkaline LR6 is strongly recommended.)

12.3 CLEANING

Use a soft dry cloth to clean the instrument. Do not use wet clothes, solvents,

water and so on.

40

Page 42

DM-4 Power Quality Recorder

13. TECHNICAL SPECIFICATIONS

13.1 FEATURES

The accuracy is stated as [1% of the reading ± number of 2 digits]. It refers to the

following atmospheric conditions: temperature 73°F± 2°F (23°C ± 1°C) with relative humidity < 75%.

13.1.1 Voltage Measurement

Range Accuracy Resolution Input Impedance

20-370V ±(3%+2digit) 0.1V 300kΩ (phase-neutral)

310-635V 0.1V 600kΩ (phase-phase)

13.1.2 Voltage Anomalies Detection (Manual Selection of Range) Voltage

Range Accuracy Resolution Input Impedance

20-370V ±(3%+2digit) 0.1V 300kΩ (phase-neutral)

310-635V 0.1V 600kΩ (phase-phase)

Time

Accuracy (ref. to 60Hz) Resolution

±8.33ms (1/2 period of fundamental) 8.33ms (1/2 period of fundamental)

13.1.3 Current Measurement (Using external transducer)

Range Accuracy Resolution Input

Impedance

Protection against

overloads

0.005-0.26V ±(2%+2digit) 100kΩ 5V

0.26-1V

Minimal Current measurable is equal to 0.5% of Clamp Full Scale

41

Page 43

13.1.4 Power Measurement (cosΘΘ: 0.5c – 0.5i)

Value Ranges Accuracy Resolution

0 – 999.9W

Active Power

1KW – 999.9KW

1MW – 999.9MW

0 – 999.9VAR

Reactive Power

1KVAR – 999.9KVAR

1MVAR – 999.9MVAR

0 – 999.9VA

Apparent Power

1KVA – 999.9KVA

±(3%+2digit)

1MVA – 999.9MVA

0 – 999.9Wh

Active Energy

1KWh – 999.9KWh

1MWh – 999.9MWh

0 – 999.9VARh

Reactive Energy

1KVARh – 999.9KVARh

1MVARh–999.9MVARh

DM-4 Power Quality Recorder

13.1.5 CosΘΘMeasurement

CosΘ Resolution Accuracy (expressed

0.20

0.50 4˚

0.80 5˚

in degrees)

3˚

0.01

42

Page 44

13.1.6 Measurement of Harmonics

Voltage

Range Accuracy Resolution

DC – 25h

26h – 33h

34h – 51h

The voltage harmonics will be null under the following threshold:

- DC: if <1V or <2% of 1stharmonic

- 1stharmonic: if <2V

- 2nd- 51st: if <1V or <2% 1stharmonic

±(5.0%+2digit)

±(10.0%+2digit)

±(15.0%+2digit)

Current

Range Accuracy Resolution

DC – 25h

26h – 33h

34h – 51h

The voltage harmonics will be null under the following threshold:

- DC: if <2% of 1stharmonic or < 0,2% of clamp full scale

- 1stharmonic: if < 0,2% of clamp full scale

- 2nd- 51st: if<2% 1stharmonic or < 0,2% of clamp full scale

Setting the FLEX option 3000A CT the DC component will be ignored.

±(5.0%+2digit)

±(10.0%+2digit)

±(15.0%+2digit)

DM-4 Power Quality Recorder

0.1V

0.1A

13.1.7 Temperature Drift

Temperature drift: 0.1 x accuracy/K

13.1.8 Safety

Insulation: Class 2

Pollution: 2

Over-voltage category: CAT III 600V~ (Phase-phase)

CAT II 1000V~ (Phase-Phase)

43

Page 45

DM-4 Power Quality Recorder

13.1.9 General Characteristics

Mechanical Features

Dimensions: 8.9” (L) x 4.1” (La) x 2.1” (H)

225(L) x 104(La) x 54(H) mm

Weight: 3.3 Lb (1.5kg)

Internal Power Supply: 8 batteries 1.5V series AA

Battery Life: 3-hours

External Power Supply: Use only Amprobe power supply Adapter code DM4EXTPS

Display: LED

Sampling Speed: 83.33 usec at 60Hz.

No. of Samples Per Period: 128

Clamp

Opening: 2.15” (53 mm)

Maximum Diameter of The Cable: 2.00” (50 mm)

13.2 ENVIRONMENT

13.2.1 Operating conditions

Reference Temperature:

73°F ± 2°F (23°C ± 1°C)

Operating Temperature: 32°F to 122°F (0°C to 50 °C)

Relative Humidity: <70%

Storage Temperature: 14°F to 140°F (-10°C to 60 °C)

Storage Humidity: <80%

44

Page 46

13.3 ACCESSORIES

13.3.1 Standard Accessories

The package contains:

Replacement Parts Part Number

DM-4 Power Quality Recorder

Remote user interface (PDA) with

connection cable

Instrument

Carrying case

External power supply 12VDC

1000A Clamp

Test Leads & Alligator Clips

(Set of 4)

PDA/DM-4 Interface Cable

RS-232 Computer Cable

Remote User Interface

Protective Case

RS-232 To USB Converter Cable

1 User Manual

Download Suite

Palm OS software

Recommended Tungsten E2 Ordered

through PALM retailers, visit www.palm.com

DM-4

HW1254A

DM-4EXTPS

DM-CT-BKCE

DVL-2

RS-PDA

C232NG1

DM-4CASE

RS-USB

www.amprobe.com

www.amprobe.com

www.amprobe.com

45

Page 47

DM-4 Power Quality Recorder

14. APPENDIX 1 – RECORDABLE PARAMETERS: SYMBOLS

Symbol Description

V1, V2, V3 RMS value of the voltage of phase 1, phase 2, phase 3 respectively

V12, V23 V31 Value of phase to phase voltages

I1, I2, I3 RMS value of the current of phase 1, phase 2, phase 3 respectively

IN RMS value of the current of the neutral

DC Continuous component of voltage or current

h01 ∏ h51 Harmonic 01 ∏ Harmonic 51 of voltage or current

ThdV Factor of total harmonic distortion of the voltage (see paragraph 14.2)

ThdI Factor of total harmonic distortion of the current (see paragraph 14.2)

Pt, P1, P2, P3 Values of the total active power, of phase 1, phase 2, phase 3 respectively

P12, P32, P13 (only for 3 wires measurement) Value of the power measured by the

Wattmeter. 1-2 and 3-2 respectively (see paragraph 14.3.2)

Qt, Q1, Q2, Q3 Values of the total reactive power, of phase 1, phase 2, phase 3 respectively

Q12, Q32, Q13 (only for 3 wires measurement) Value of the power measured by the

VARmeter 1-2 and 3-2 respectively (see paragraph 14.3.2)

St, S1, S2, S3 Values of the total apparent power, of phase 1, phase 2, phase 3 respectively

S12, S32, S13 (only for 3 wires measurement) Value of the power measured by the

VAmeter 1-2 and 3-2 respectively (see paragraph 14.3.2)

Pft, pf1, pf2, pf3 Value of the total power factors, power factors of phase 1, phase 2, phase 3

respectively

dPft, dpf1, dpf2, dpf3 Values of the total cosΘ, of phase 1, phase 2, phase 3 respectively

Eat, Ea1, Ea2, Ea3 Values of the total active energy, of phase 1, phase 2, phase 3 respectively

Ert, Er1, Er2, Er3 Values of the total inductive reactive Energy, of phase 1, phase 2, phase 3

respectively

-Ert, -Er1, -Er2, -Er3 Values of the total capacitive reactive Energy, of phase 1, phase 2, phase

3 respectively

Est, Es1, Es2, Es3 Values of the total

Apparent Energy, of phase 1, phase 2, phase 3 respectively

Negative Q (reactive power) indicates capacitive phase shift. Negative P

cates generation not load and the CTs should be reversed, rotated 180º.

46

(real or active power) indi

-

Page 48

DM-4 Power Quality Recorder

15. APPENDIX 2 – THEORETICAL OUTLINES

15.1 VOLTAGE ANOMALIES (VOLTAGE SAG AND SURGE; SPIKE)

The instrument records as voltage anomalies all those rms values, calculated every

11ms, beyond the percent thresholds of Voltage Reference (Vref) set during the programming. The maximum upper limit percent is reduced as Vref approaches 1000V.

THE REFERENCE MUST BE SET TO

Nominal Voltage Phase to Neutral: for Single Phase and 4 wires three phase system

Nominal Voltage Phase to Phase: for 3 wires three phase system

Example1: Three Phase System 3 wires

Vref = 400V, LIM+= 10%, LIM-=10% =>

High Lim = 480 x (1+10/100) = 528V

Low Lim = 480 x (1-10/100) = 452V

Example2: Three Phase System 4 wires

Vref = 277V, LIM+= 5%, LIM-=5% =>

High Lim = 277 x (1+5/100) = 290.85V

Low Lim = 277 x (1-5/100) = 263.15V

The Instrument will detect Voltage Anomalies if the RMS Voltage Values (calculated every 11ms) beyond the above calculated thresholds. These limits remain

unchanged throughout the recording period.

When a Voltage Anomaly Occurs the Instrument Records:

• The number corresponding to the phase where the anomaly occurred.

• The “direction” of the anomaly: “UP” and “DN” identify respectively voltage drops

(sag) and peaks (Surge).

• The date and time of the beginning of the event in the form day, month, year, hour,

minutes, seconds, hundredths of second.

• The duration of the event, in seconds with a resolution of 11ms.

• The minimum (or maximum) value of voltage during the event.

47

Page 49

DM-4 Power Quality Recorder

15.2 VOLTAGE AND CURRENT HARMONICS

15.2.1 THEORY