Amprobe CR50A User Manual [en, de, es, fr]

CR50A

Capacitance,

Resistance Meter

User Manual

• Bedienungshandbuch

• Manualdeuso

• Moded’emploi

Cx

200

n

20m

200p

200

ZERO

ADJUST

(20 )

OFF

20

2k

2M

20M

CR50

F

20

k

200

k

2m

200

20

2

20n

2n

CAP.

ZERO

ADJUST

Rx

DISCHARGE CAPACITOR

BEFORE CONNECTING

nF

pF

F

MF

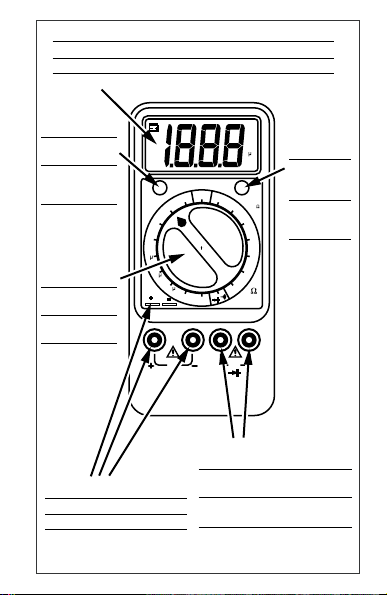

Function/Range/

Off Selector

Funktion-/Bereich-

/Aus Schalter

Selector de

Función/Escala/Off

Sélecteur fon-

ctions/calibres/

marche-arrêt

Resistance

Zero

Adjustment

Nullabgleich

für Widerstandsmessung

Ajuste de cero

para medidas

de resistencia

Mise à zero

pour mesure de

résistance

Capacitance Zero

Adjustment

Nullabgleich für

Kapazitätsmessung

Ajuste de cero para

medidas de

capacidad

Mise à zéro pour

mesure de

capacité

3-1/2 digit LCD; decimal point, function and unit indicators

3-1/2 Digit LCD ; Dezimalpunkt, Funktions- und Einheitsanzeigen

LCD de 3-1/2 dígitos, punto decimal, indicadores de función y unidades

LCD 3-1/2 digits ; point décimal, indicateurs de fonctions et d'unités

Input Terminals for resistance, diode

test and continuity

Eingänge für Widerstand, Durchgangsund Diodentest

Entradas para medidas de resistencia,

continuidad y prueba de diodos

Entrées pour mesure de résistance,

test de diodes et continuité

Capacitance Input Terminals

Eingänge für Kapazitätsmessung

Entradas para medidas de capacidad

Entrées pour mesure de capacité

CR50A

Capacitance,

Resistance Meter

User Manual

• Bedienungshandbuch

• Manual de uso

• Mode d’emploi

PN 1566212

©2007 Amprobe Test Tools.

All rights reserved. Printed in Taiwan

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material

and workmanship for 1 year from the date of purchase.

This warranty does not cover fuses, disposable batteries

or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other

warranty on Amprobe’s behalf. To obtain service during the

warranty period, return the product with proof of purchase

to an authorized Amprobe Test Tools Service Center or

to an Amprobe dealer or distributor. See Repair Section

for details. THIS WARRANTY IS YOUR ONLY REMEDY. ALL

OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED OR

STAUTORY - INCLUDING IMPLIED WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE OR MERCHANTABILITY,

ARE HEREBY DISCLAIMED. MANUFACTURER SHALL NOT

BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY

CAUSE OR THEORY. Since some states or countries do not

allow the exclusion or limitation of an implied warranty or

of incidental or consequential damages, this limitation of

liability may not apply to you.

Capacitance, Resistance Meter

Contents

Symbols .................................................................................... 1

Warnings and Precautions ......................................................2

Overload Indication ................................................................ 2

Preparation For Use - Unpacking ...........................................2

Measuring Procedures ............................................................ 2

Safety Test Leads ..................................................................... 4

Specifications ...........................................................................4

Troubleshooting/Maintenance ...............................................6

Repair .......................................................................................7

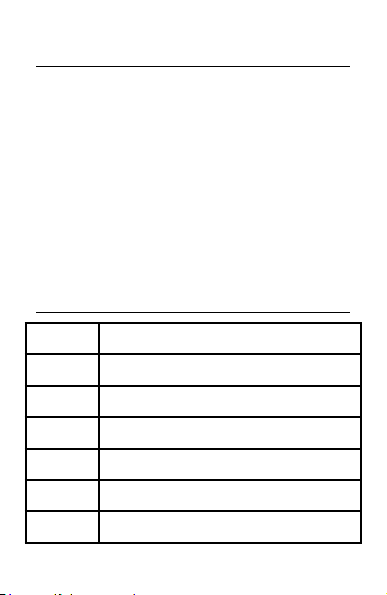

Symbols

Battery

Refer to the manual

Double insulated

Audible tone

Fuse

Complies with EU directives

Conforms to relevant Australian standards

1

WarningsandPrecautions

• Do not exceed the maximum overload limits per function (see

specifications) nor the limits marked on the instrument itself.

• Inspect instrument, test leads and accessories before every

use. Do not use any damaged part.

• Never ground yourself when taking measurements.

• Do not touch exposed circuit elements or probe tips.

• Never replace a fuse with one of a different rating. Do not

operate instrument in an explosive atmosphere.

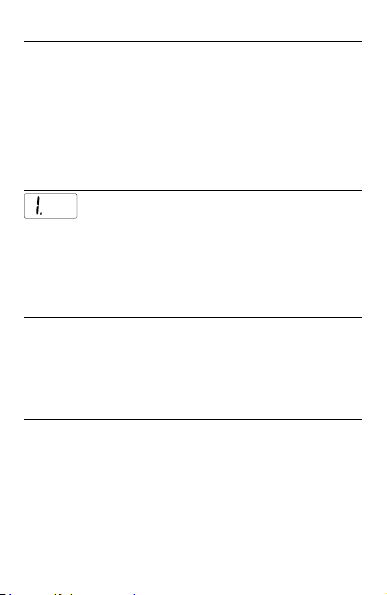

OverloadIndication

Range overload is indicated by “1” in the display with

all other digits blanked. Select the next higher range

until a value is displayed. If overload condition still exists in the

highest range, the measured value is beyond the range of the

meter. Overload indication is normal in the OHMS range when

the leads are not connected to anything or when the measured

value is higher than the selected resistance range.

PreparationForUse-Unpacking

Your shipping carton should include the CR50A, one test lead set

(one black, one red), one pair of alligator clips, one 9V battery

(installed), one spare 0.1A/250V fuse (inside the case), a holster, a

warranty card and this manual. If any item is damaged or missing,

return to the place of purchase for an exchange.

MeasuringProcedures

General: When connecting or disconnecting test leads to/from

a circuit, always first turn off power to device or circuit being

tested and discharge all capacitors.

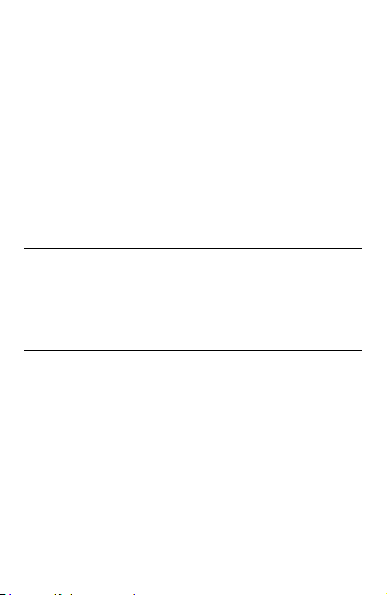

Resistance Measurement (Fig -1-)

1. Turn off power to the resistance to be measured

and discharge any capacitors. Any voltage present

during a resistance measurement will cause inaccurate

readings.·Connect red test lead to +Rx Input (red) and black

test lead to -Rx Input.

2. Set Function/Range Switch to the desired Ω position.

2

3. Connect test leads to resistance or circuit to be measured.

4. Read resistance value on Digital Display. Open circuits will be

displayed as an overload condition.

Note: On the 20Ω range, an adjustment potentiometer (ZERO

ADJ.) allows you to zero out the test lead resistance. Short the

test leads and adjust the knob until the display reads zero.

Diode and Transistor Test (Fig -2-)

The diode test measures the voltage drop across the diode junction.

1. Connect the red test lead to the +Rx Input (red) and the black

test lead to the –Rx Input.

2. Set the Function/range switch to position.

3. Apply probe tip of red lead to the anode and black lead to

the cathode of the diode. The meter’s display indicates the

forward voltage drop (approximately 0.7V for silicon diode

or 0.4V for germanium diode). Meter will display overload

condition for an open diode.

4. Reverse test lead connections to the diode to perform a

reverse bias test. Overload indicates a good diode.

Note: Overload condition for both reverse and forward bias tests

indicate an open diode. A low voltage reading for both bias tests

indicates a shorted diode. If the diode is shunted by a resistor of

1000 ohms or less, it must be removed from the circuit before

taking the measurement. Bipolar transistor junctions may be

tested in the same manner described above.

Continuity Test

The Continuity test checks electrical continuity between two

contact points.

1. Set the Function/Range switch to .

2. Plug the black test lead into the –Rx jack (black) and connect

the test lead tip to one of the contact points.

3. Plug the red test lead into the +Rx jack (red) and connect its

test lead point to the other contact point. (See Figure 1 for

connections).

4. The internal beeper emits a tone when resistance is less than

approx. 75Ω

Capacitance Measurement (Fig -3-)

Discharge all voltage from the capacitor (via a 100kΩ resistor)

before measuring its value.

3

1. Connect the red test lead to the Cx+ input and the black test

lead to the Cx– input.

2. Set the function/range switch to the capacitance range that

gives the best resolution.

3. Apply probe tips to the capacitor leads. When measuring

electrolytic capacitors, observe correct polarity.

4. Read the capacitance value on the display (you may have

to wait a few seconds until the capacitor is fully charged). If

“OL” appears in the highest range, the capacitor is too large

to be measured.

Note: For small value measurements utilize CAP Zero Adjust to

eliminate test lead capacitance (±20pF).

Note: Small value capacitors can also be measured by inserting

their leads directly into the slots in the meter.

SafetyTestLeads

The test leads included with your meter have shrouded

banana plugs to eliminate the possibility of shock if the plugs

accidentally pull out of the meter while making a measurement.

Always inspect the test leads for damage before making any

measurements.

Specications

General Specifications

Display: 3 1/2 digit LCD, 1999 counts

Zero Adjustment: Adjustment potentiometer

Overrange Indication: “1” is displayed

Low Battery Indication: is displayed when the battery voltage

drops below accurate operating level. Change battery when

low battery is indicated.

Display Update Rate: 2/sec, nominal

Operating Temperature: 0°C to 50°C, 0 to 70% Relative Humidity

Storage Temperature: -20°C to 60°C, 0 to 80% RH, battery

removed

Power: Standard 9V transistor battery, NEDA 1604, JIS 006P, IEC

6F22

Battery Life (Typical): 200 hours alkaline, 150 hours carbon-zinc

4

Dimensions (H x W x D): 6.1 x 2.8 x 1.3 inches, (15.1 x 7.0 x 3.8 cm)

Weight (including battery): 8 ounces (200 grams)

Accessories: One pair of test leads, two alligator clips, one spare

fuse (FP125) installed in battery compartment, battery, holster

and Operator’s Manual

Agency Approvals:

This product complies with requirements of the following

European Community Directives: 89/336/EEC (Electromagnetic

Compatibility) and 73/23/EEC (Low Voltage) as amended by

93/68/EEC (CE Marking).

However, electrical noise or intense electromagnetic fields in the

vicinity of the equipment may disturb the measurement circuit.

Measuring instruments will also respond to unwanted signals that may

be present within the measurement circuit. Users should exercise care

and take appropriate precautions to avoid misleading results when

making measurements in the presence of electronic interference.

Electrical Specifications

Accuracies at 23°C ± 5°C, <75% RH.

Resistance

Range Accuracy:

20Ω ±1.2% rdg.

200Ω ±(0.5% rdg +3 dgt)

2k-2MΩ ±(0.5%rdg + 1dgt)

20MΩ ±(3.0% rdg + 1dgt)

Resolution: 0.01 in 20Ω rg.

OL Protection, all Ranges: 500VDC or AC RMS

Open Circuit Voltage: 0.3VDC;

3.0VDC on 20Ω and 200Ω ranges

Capacitance

Range Accuracy Test Frequency:

200pF ±(0.5% rdg +1 dgt +0.5pF) 820Hz

2000pF to 2µF ±(0.5% rdg +1 dgt) 820Hz

20µF ±(0.5% rdg +1 dgt) 82Hz

200µF ±(0.5% rdg +1 dgt) 8.2Hz

2mF ±(1% rdg +1 dgt) 8.2Hz

20mF ±(1.5% rdg +1 dgt) 8.2Hz

EMC

5

Test Voltage: < 3.5V

Input Protection: 0.1A/250V Fast Acting Fuse

Diode Test

Test Current/Voltage: 1mA (approx.) / 3.2VDC

Display: Forward Junction Voltage

Continuity Indicator

Audible Indication: Less than 75Ω

OL Protection: 500VDC or AC

Optional Accessories

VC30A: Vinyl Carrying Case (for meter and holster)

DL243D: Deluxe Test Lead Set

TL36A: Replacement Safety Test Leads w/alligator clips.

Troubleshooting/Maintenance

If there appears to be a malfunction during the operation of

the meter, the following steps should be performed in order to

isolate the cause of the problem:

1. Check the battery.

2. Review the operating instructions for possible mistakes

3. in operating procedure.

4. Inspect and test the Test Probes for a broken or intermittent

connection.

5. Inspect and test the fuse. See Fuse Replacement.

Except for the replacement of the battery or fuse, repair of the

multimeter should be performed only by a Factory Authorized

Service Center or by other qualified instrument service personnel.

The front panel and case can be cleaned with a mild solution

of detergent and water. Apply sparingly with a soft cloth and

allow to dry completely before using. Do not use aromatic

hydrocarbons or chlorinated solvents for cleaning.

Battery/Fuse Replacement

To prevent electrical shock hazard, turn off the

multimeter and any device or circuit under test and

disconnect the test leads before removing the rear

cover.

Warning

6

1. Remove the screws and lift off the rear case.

2. Fuse Replacement: Remove the blown fuse (5 x 20mm) from

the fuse holder. Replace with a 0.1A/250V quick acting glass

fuse (one spare fuse is located on the right side of the battery

compartment). Amprobe replacement fuse part number is FP

125.

3. Battery replacement: Remove battery and replace with NEDA

type 1604 or equivalent 9-volt alkaline battery.

4. Reassemble the instrument.

Use of an incorrect fuse could result in serious injury

or even death. Failure to turn off the multimeter

before installing the battery could result in damage to

instrument and battery.

Warning

Repair

All test tools returned for warranty or non-warranty repair or

for calibration should be accompanied by the following: your

name, company’s name, address, telephone number, and proof of

purchase. Additionally, please include a brief description of the

problem or the service requested and include the test leads with

the meter. Non-warranty repair or replacement charges should be

remitted in the form of a check, a money order, credit card with

expiration date, or a purchase order made payable to Amprobe®

Test Tools.

In-Warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery

before requesting repair. During the warranty period any

defective test tool can be returned to your Amprobe® Test Tools

distributor for an exchange for the same or like product. Please

check the “Where to Buy” section on www.amprobe.com for a

list of distributors near you. Additionally, in the United States

and Canada In-Warranty repair and replacement units can also

be sent to a Amprobe® Test Tools Service Center (see address

below).

7

Non-Warranty Repairs and Replacement – US and Canada

Non-warranty repairs in the United States and Canada should be

sent to a Amprobe® Test Tools Service Center. Call Amprobe®

Test Tools or inquire at your point of purchase for current repair

and replacement rates.

In USA In Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-Warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe®

Test Tools distributor for a nominal charge. Please check the

“Where to Buy” section on www.amprobe.com for a list of

distributors near you.

European Correspondence Address*

Amprobe® Test Tools Europe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

*(Correspondence only – no repair or replacement available from

this address. European customers please contact your distributor.)

8

Cx

200

n

20m

200p

200

ZERO

ADJUST

(20 )

OFF

20

2k

2M

20M

CR50

F

20

k

200

k

2m

200

20

2

20n

2n

CAP.

ZERO

ADJUST

Rx

DISCHARGE CAPACITOR

BEFORE CONNECTING

Cx

200

n

20m

200p

200

ZERO

ADJUST

(20 )

OFF

20

2k

2M

20M

CR50

F

20

k

200

k

2m

200

20

2

20n

2n

CAP.

ZERO

ADJUST

Rx

DISCHARGE CAPACITOR

BEFORE CONNECTING

1

2

1.520 k

4

3

2

1

Cathode Anode

Cathode

600 - 900 mV

<1 V

Anode

4

3

2

1

OK

OK

OK

OK

9

Cx

200

n

20m

200p

200

ZERO

ADJUST

(20 )

OFF

20

2k

2M

20M

CR50

F

20

k

200

k

2m

200

20

2

20n

2n

CAP.

ZERO

ADJUST

Rx

DISCHARGE CAPACITOR

BEFORE CONNECTING

F

3

1

3

2

4

10

Loading...

Loading...