Page 1

AT-7000

Advanced Wire Tracers

AT-7020

AT-7030

User Manual

Page 2

Page 3

AT-7000

Advanced Wire Tracer

AT-7020

AT-7030

User Manual

English

9/2014, Rev A

©2014 Amprobe Test Tools.

All rights reserved.

Page 4

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for 1 year from

the date of purchase. This warranty does not cover fuses, disposable batteries or damage from

accident, neglect, misuse, alteration, contamination, or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other warranty on Amprobe’s behalf.

To obtain service during the warranty period, return the product with proof of purchase to

an authorized Amprobe Test Tools Service Center or to an Amprobe dealer or distributor. See

Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY. ALL OTHER WARRANTIES

- WHETHER EXPRESS, IMPLIED OR STAUTORY - INCLUDING IMPLIED WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY DISCLAIMED.

MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some

states or countries do not allow the exclusion or limitation of an implied warranty or of

incidental or consequential damages, this limitation of liability may not apply to you.

Repair

All Amprobe tools returned for warranty or non-warranty repair or for calibration should

be accompanied by the following: your name, company’s name, address, telephone number,

and proof of purchase. Additionally, please include a brief description of the problem or

the service requested and include the test leads with the meter. Non-warranty repair or

replacement charges should be remitted in the form of a check, a money order, credit card

with expiration date, or a purchase order made payable to Amprobe.

In-warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During

the warranty period, any defective test tool can be returned to your Amprobe distributor for

an exchange for the same or like product. Please check the “Where to Buy” section on

www.Amprobe.com for a list of distributors near you. Additionally, in the United States and

Canada, in-warranty repair and replacement units can also be sent to an Amprobe Service

Center (see address below).

Non-warranty Repairs and Replacement – United States and Canada

Non-warranty repairs in the United States and Canada should be sent to an Amprobe Service

Center. Call Amprobe or inquire at your point of purchase for current repair and replacement

rates.

USA: Canada:

Amprobe Amprobe

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 888-993-5853 Tel: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Non-warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe distributor for a nominal

charge. Please check the “Where to Buy” section on www.Amprobe.eu for a list of

distributors near you.

Amprobe Europe*

Beha-Amprobe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

www.Amprobe.eu

*(Correspondence only – no repair or replacement available from this address. European

customers please contact your distributor.)

Page 5

AT-7000 Series

CONTENTS

1. PRECAUTIONS AND SAFETY MEASURES ............................................................. 2

2. KIT COMPONENTS ................................................................................................. 5

2.1 AT-7000-R Receiver ........................................................................................................6

2.2 AT-7000-T Transmitter ...................................................................................................8

2.3 TL-7000 Test Lead & Accessory Kit ................................................................................9

2.4 SC-7000 Signal Clamp (AT-7030 Kit) ............................................................................10

2.5 BR-7000-T Signal Booster Rechargeable Battery Pack (AT-7030 Kit) ......................... 10

3. MAIN APPLICATIONS ............................................................................................ 11

3.1 Tracing Energized Wires

• SMART SENSOR ..........................................................................................................12

• TIP SENSOR Energized ................................................................................................14

3.2 Tracing De-Energized Wires

• TIP SENSOR De-Energized ..........................................................................................16

3.3 Identifying Breakers and Fuses

• BREAKER Energized (Energized Circuits) ..................................................................18

• BREAKER De-Energized (De-Energized Circuits) ......................................................20

3.4 Non-Contact Voltage Mode (NCV) ...............................................................................21

4. SPECIAL APPLICATIONS ........................................................................................ 22

4.1 GFCI-Protected Circuit Wire Tracing .............................................................................22

4.2 Finding Breaks/Opens ...................................................................................................22

4.3 Finding Shorts ...............................................................................................................23

4.4 Tracing Wires in Metal Conduit ...................................................................................24

4.5 Tracing Non-Metallic Pipes and Conduits ....................................................................24

4.6 Tracing Shielded Wires ..................................................................................................24

4.7 Tracing Underground Wires ..........................................................................................25

4.8 Tracing Low Voltage Wires and Data Cables ............................................................... 25

4.9 Sorting Bundled Wires ..................................................................................................25

4.10 No Access to Bare Conductors (Signal Clamp) ...........................................................26

4.11 Locating Loads (Signal Clamp) ....................................................................................27

5. MAINTENANCE - BATTERY AND FUSE REPLACEMENT ........................................ 28

6. SPECIFICATIONS ..................................................................................................... 31

1

Page 6

1. PRECAUTIONS AND SAFETY MEASURES

General

For your own safety and to avoid damage to the instrument we suggest you to follow the

procedures listed below:

NOTE: Before and during measurements be diligent to follow the instructions.

• Make sure that the electrical instrument is operating properly before use.

• Before attaching any of the conductors, make sure that the voltage present in the

conductor is in the range of the instrument.

• Keep the instruments in their carrying case when not in use.

• If the transmitter or receiver will not be used for a long time, remove the batteries to

prevent leakage in the instruments.

• Use Amprobe approved cables and accessories only.

Safety precautions

• In many instances, you will be working with dangerous level of voltage and/or current,

therefore, it is important that you avoid direct contact with any uninsulated, current

carrying surfaces. Wear appropriate insulated gloves and protective clothing in

hazardous voltage areas

• Do not measure voltage or current in wet or dusty places

• Do not measure in presence of gas, explosive materials or combustibles

• Do not touch the circuit under test if no measurement is being taken

• Do not touch exposed metal parts, unused terminals, circuits and so on

• Do not use the instrument if it seems to be malfunctioning (i.e. if you notice

deformations, breaks, leakage of substances, and absence of messages on the display

and so on.)

Safety information

The product complies with:

• UL/IEC/EN 61010-1, CAN/CSA C22.2 No. 61010-1, Pollution Degree 2, Measurement

category IV 600 V

• IEC/EN 61010-2-033

• IEC/EN 61010-2-032

• IEC/EN 61010-031 (test leads)

• EMC IEC/EN 61326-1

Measurement Category IV (CAT IV) is for circuits that are directly connected to the primary

utility power source for a given building or between the building power supply and the

main distribution board. Such equipment may include electricity tariff meters and primary

over current protection devices.

CENELEC Directives

The instruments conform to CENELEC Low-voltage directive 2006/95/EC and Electromagnetic

compatibility directive 2004/108/EC.

2

Page 7

1. PRECAUTIONS AND SAFETY MEASURES

�Warnings: Read Before Using

To avoid possible electric shock or personal injury:

• Use the Meter only as specified in this manual or the protection provided by the

instrument might be impaired.

• Avoid working alone so assistance can be rendered.

• Never measure ac current while the test leads are inserted into the input jacks.

• Do not use the Meter in wet or dirty environments.

• Do not use the Meter if it appears damaged. Inspect the Meter before use. Look

for cracks or missing plastic. Pay particular attention to the insulation around the

connectors.

• Inspect the test leads before use. Do not use them if insulation is damaged or metal is

exposed.

• Check the test leads for continuity. Replace damaged test leads before using the Meter.

• Have the Meter serviced only by qualified service personnel.

• Use extreme caution when working around bare conductors or bus bars. Contact with

the conductor could result in electric shock.

• Do not hold the Meter anywhere beyond the tactile barrier.

• Do not apply more than the rated voltage, as marked on the Meter, between the

terminals or between any terminal and earth ground.

• Remove test leads from the Meter before opening the Meter case or battery cover.

• Never operate the Meter with the battery cover removed or the case open.

• Never remove the battery cover or open the case of the Meter without first removing

the test leads from a live conductor.

• Use caution when working with voltages above 30 V ac rms, 42 V ac peak, or 60 V dc.

These voltages pose a shock hazard.

• Do not attempt to measure any voltage that might exceed the maximum range of the

Meter.

• Use the proper terminals, function, and range for your measurements.

• Do not operate the Meter around explosive gas, vapor, or dust.

• When using probes, keep fingers behind the finger guards.

• When making electrical connections, connect the common test lead before

connecting the live test lead; when disconnecting, disconnect the live test lead before

disconnecting the common test lead.

• To avoid false readings that can lead to electrical shock and injury, replace the battery

as soon as the low battery indicator appears. Check Meter operation on a known

source before and after use.

• When servicing, use only specified replacement parts.

• Adhere to local and national safety codes. Individual protective equipment must

be used to prevent shock and arc blast injury where hazardous live conductors are

exposed.

• Only use the test lead provided with the Meter or UL Listed Probe Assembly rated CAT

IV 600V or better.

3

Page 8

1. PRECAUTIONS AND SAFETY MEASURES

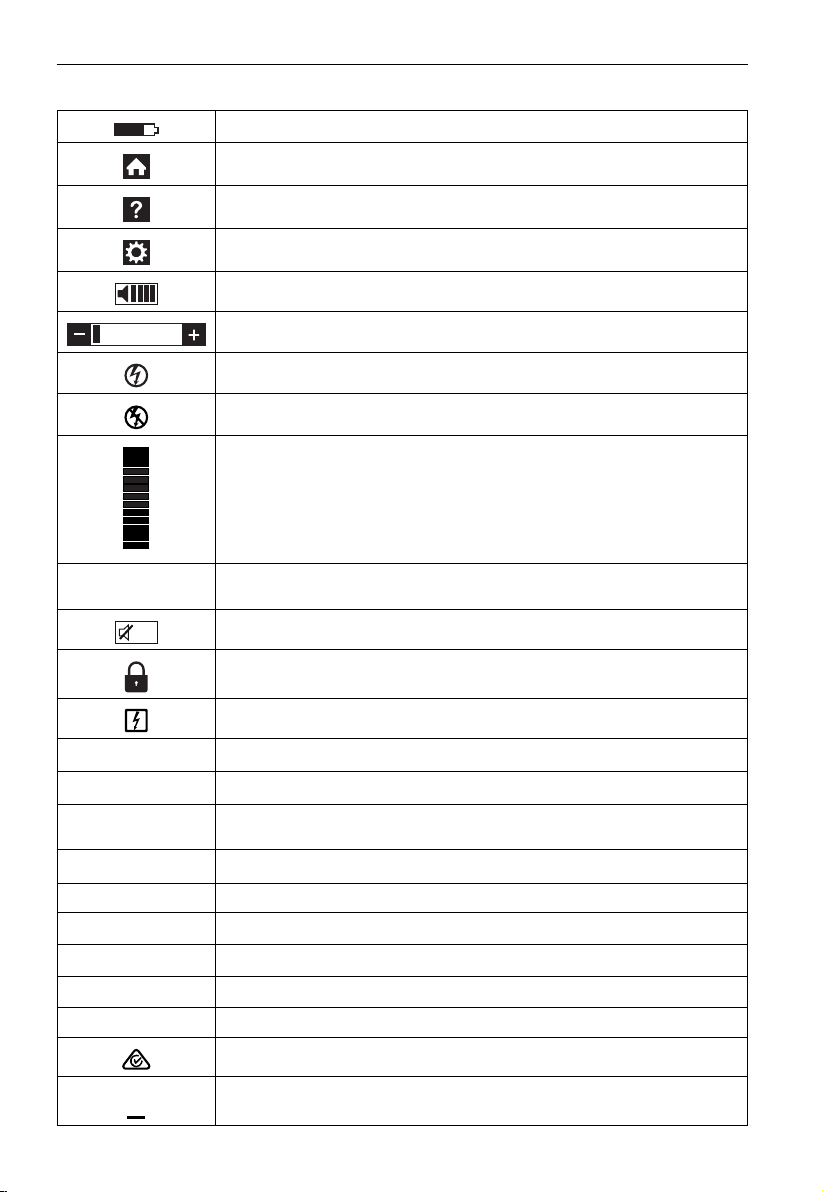

Symbols used in this product

Battery status – Displays the remaining battery charge

Home – Return to home screen when selected

Help – Enters to the help mode when selected

Settings – Enters to the settings menu when selected

Volume– Displays the volume in four levels

Sensitivity indicator – Displays the sensitivity level from 1 to 10.

Icon indicating energized system

Icon indicating de-energized system

99

Signal strength indicator – Shows the strength of the signal

from 0 to 99

SIGNAL

MAN/AUTO

Shows whether the sensitivity adjustment is in Manual or

Automatic mode

Indicates the volume is muted.

Lock indicates if the Auto sensitivity lock is active

(Only in Auto sensitivity mode)

Application and removal from hazardous live conductors permitted

�

T

J

CAT IV

B

F

)

P

=

Caution! Risk of electric shock.

Caution! Refer to the explanation in this Manual.

The equipment is protected by double insulation or

reinforced insulation.

Earth (Ground).

Overvoltage up to Category IV 600V (transient protection up to 8kV)

Alternating Current (AC).

Direct Current (DC).

Conforms to relevant North American Safety Standards.

Complies with European Directives.

Conforms to relevant Australian standards.

Do not dispose of this product as unsorted municipal waste. Contact

a qualified recycler.

4

Page 9

1. PRECAUTIONS AND SAFETY MEASURES

This manual contains information and warnings that must be followed for operating the

tester safely and maintaining the tester in a safe operating condition. If the tester is used in

a manner not specified by the manufacturer, the protection provided by the tester may be

impaired. This tester meets water and dust protection IP40 per IEC60529 Ed 2.1 (2001). Do

not use in rainfall! The tester is double insulated for protection per EN61010-1:2010 3rd Ed

to CAT IV 600V.

CAUTION: Do not connect the Transmitter to a separate ground in Electrically Susceptible

Patient areas of a health care facility. Make the ground connection first and disconnect it

last.

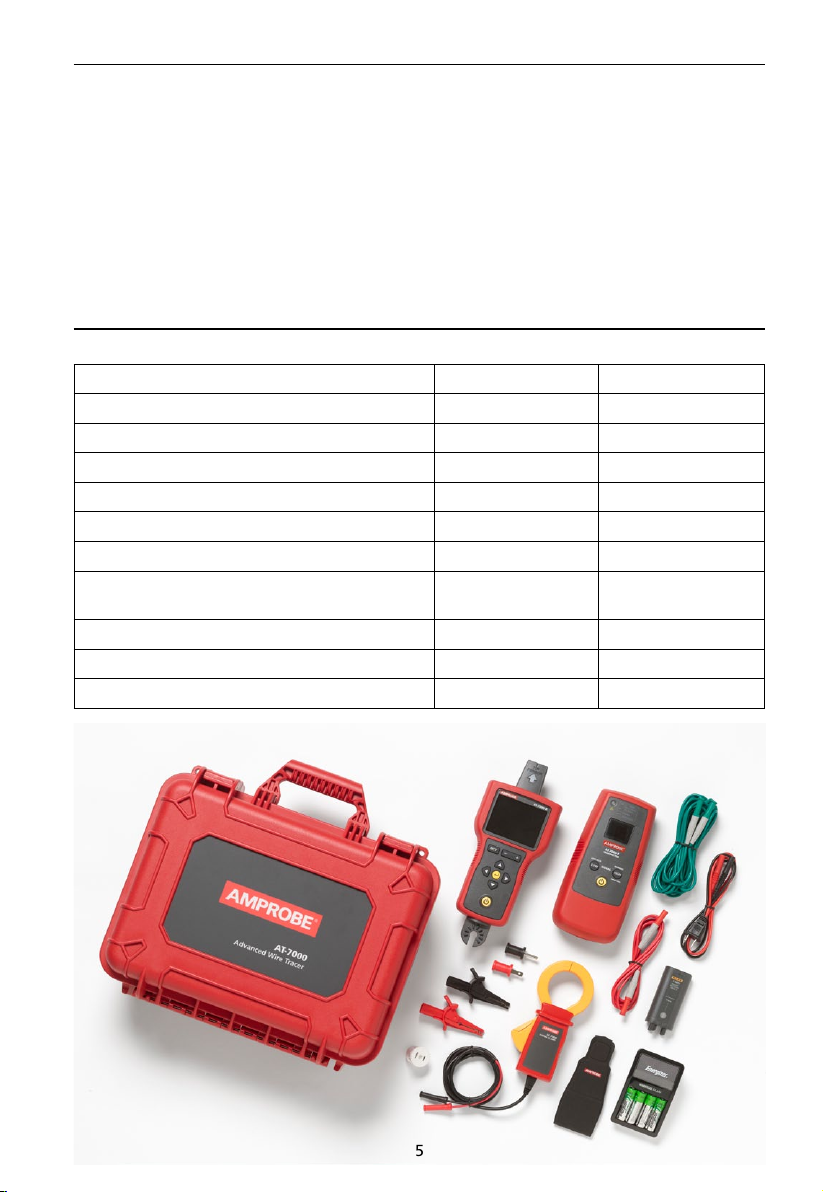

2. KIT COMPONENTS

Your shipping box should include:

AT-7020 KIT AT-7030 KIT

AT-7000-R RECEIVER 1 1

AT-7000-T TRANSMITTER 1 1

TL-7000 TEST LEAD AND ACCESSORY KIT 1 1

CC-7000 HARD CARRYING CASE 1 1

USER MANUAL 1 1

BR-7000-T LI-ION RECHARGEABLE BATTERY - 1

BR-7000-R WITH 4AA RECHARGEABLE

BATTERIES

SC-7000 SIGNAL CLAMP - 1

HS-1 MAGNETIC HANGER - 1

1.5 V AA (IEC R6) BATTERY 10 -

- 1

5

Page 10

2. KIT COMPONENTS

2.1 AT-7000-R Receiver

The AT-7000-R Receiver detects the signal generated by the AT-7000-T transmitter along wires

using either the TIP SENSOR or SMART SENSOR and displays this information on the full color TFT

LCD display.

Active tracing using a signal generated by the AT-7000-T Transmitter

The SMART SENSOR works with a 6 kHz signal generated along energized wires (above 30V

AC/DC) and provides an indication of the wire position and direction relative to the receiver.

The SMART SENSOR is not designed to work on de-energized systems; for that application

the TIP SENSOR should be used in de-energized mode.

The TIP SENSOR may be used on either energized or de-energized wires and can be used for

general tracing, tracing in tight spaces, locating breakers, pinpointing wires in bundles or in

junction boxes. The TIP SENSOR mode will pinpoint the wire location with both an audible

and visual indication of detected signal strength, but unlike SMART SENSOR mode it will not

provide wire direction or orientation.

Note: The receiver will NOT detect signals from the wire through metal conduit or shielded

cable. Refer to Special Applications, section 4.4 “Tracing Wires In Metal Conduit” for

alternative tracing methods.

TIP SENSOR

SMART SENSOR

(Back side)

LCD DISPLAY

Full color TFT display

NCV BUTTON

Non-Contact

Voltage mode

4-WAY

NAVIGATION KEYS

RUBBER OVER

MOLDED ENCLOSURE

SENSITIVITY ADJUSTMENT

BUTTON (-/+)

ENTER BUTTON

Selects the functions

POWER BUTTON

Turns unit On / Off

BATTERY COMPARTMENT

(Back side)

HOT STICK ATTACHMENT POINT

Figure 1: Overview of AT-7000-R Receiver

6

Page 11

2. KIT COMPONENTS

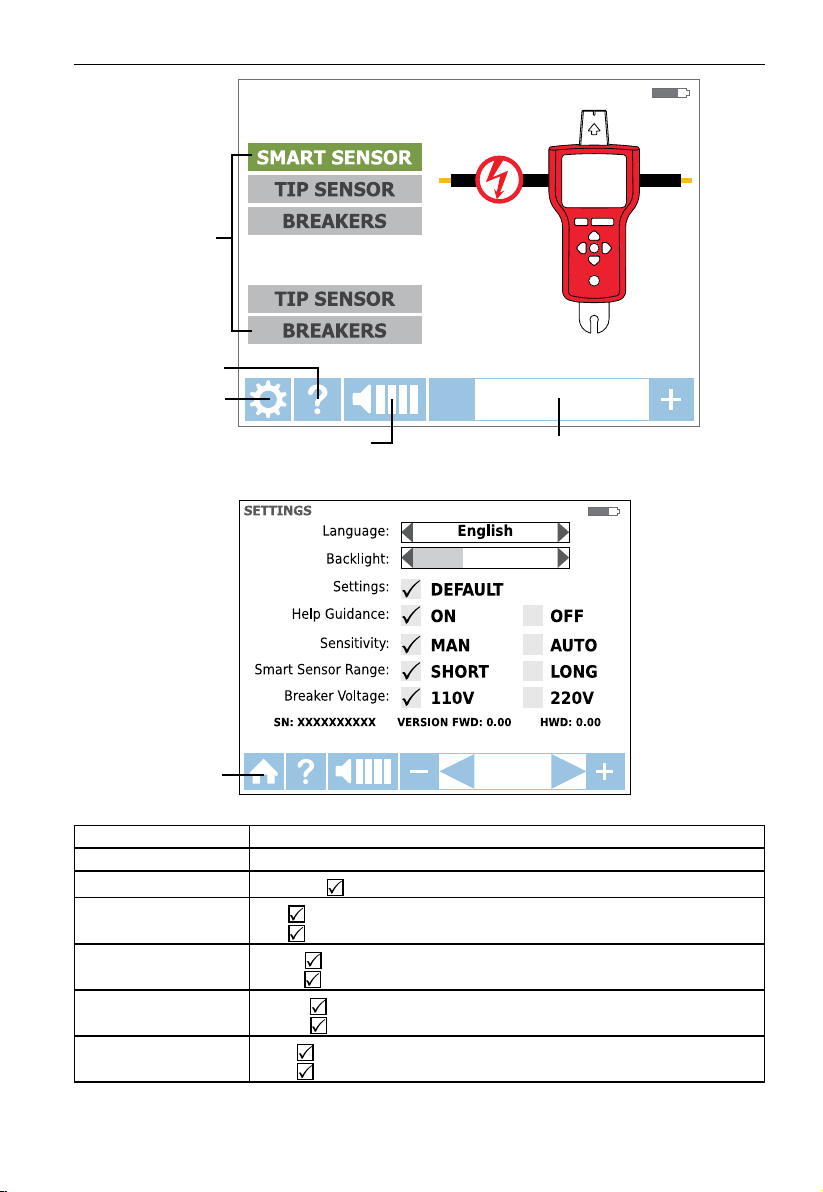

Main applications

ENERGIZED:

DE-ENERGIZED:

Help guide

Setting menu

Buzzer volume adjustment

Home menu

Language English, French, German, Spanish, Italian

Backlight 25%, 50%, 75%, 100%

Setting

Help Guidance

Sensitivity*

Smart Sensor Range

Breaker Voltage

*Note: The Auto and Manual sensitivity mode can be easily changed by pressing the + and

– key at the same time when the receiver is in a tracing mode. When sensitivity mode is set

to “Auto” manual adjustment is disabled.

Figure 1a: Overview of all elements on home screen

Figure 1b: Overview of all elements on the setting menu

DEFAULT

ON

OFF : Device will start without guidance

MAN

AUTO : Auto sensitivity adjustment

SHORT

LONG : For wire detection between 3 and 20 feet

110V

220V

: Restore default settings

: Device will guide you through each mode

: Manual sensitivity adjustment (+) and (-) keys

: For wire detection up to 3 feet

: For 110V to 120V systems

: For 220V to 240V systems

--

Sensitivity adjustment

7

Page 12

2. KIT COMPONENTS

2.2 AT-7000-T Transmitter

The AT-7000-T Transmitter works on energized and de-energized circuits up to 600V AC/DC

in Category I-IV electrical environments.

The transmitter will measure the line voltage and display it on the transmitter’s color

TFT LCD display screen. Based on detected voltage it will automatically switch to either

energized mode (30 to 600V AC/DC) or de-energized mode (0 to 30V AC/DC). The energized

mode uses a lower transmission frequency (6kHz) than de-energized mode (33 kHz) to

reduce signal coupling with nearby metallic objects and improve results. If the circuit is

energized the red LED in the upper left corner of the AT-7000-T transmitter will light.

IMPORTANT! Note that the red LED light will turn on when connected to an energized

circuit. Select the correct energized or de-energized mode on the AT-7000-R receiver when

choosing your tracing mode.

Energized mode: In energized mode the transmitter draws very low current from the

energized circuit and generates a 6.25 kHz signal. This is very important feature of the

AT-7000-T, since drawing current does not inject any signal that would harm sensitive

equipment connected to the circuit. The signal is also generated in a direct path between

the transmitter and the power source, thus NOT placing a signal onto any branches enabling

wiring tracing directly back to the breaker panel. Please note that due to this feature, the

transmitter has to be connected on the load side of the circuit.

De-energized mode: In de-energized mode the transmitter injects a 32.8 kHz signal onto the

circuit. In this mode, since the signal is injected, it will travel through all the circuit branches.

It is a high frequency, very low energy signal that will not harm any sensitive equipment

TEST LEADS CONNECTION JACKS

RED LED VOLTAGE INDICATOR

Indicates the transmitter mode

1. Red: Energized circuit mode

2. Amber: Overload

3. OFF: De-energized circuit

mode

COLOR TFT LCD DISPLAY

LOW/PRECISION MODE

For precision applications

ON / OFF BUTTON

RUBBER OVERMOLDED

ENCLOSURE

Figure 2: Overview of AT-7000-T Transmitter

HIGH/NORMAL MODE

Used for most applications

BATTERY COMPARTMENT

(Back side)

8

Page 13

2. KIT COMPONENTS

Power Mode

Transmission

Frequency &

Amplitude

Detected Voltage

Figure 2a: Overview of AT-7000-T Transmitter LCD Screen

Transmission

Frequency

2.3 TL-7000 Test Lead & Accessory Kit

All AT-7000 kits come with our complete test leads & accessory kit. The kit supports a

wide range of standard and specialty applications and contains test leads and adaptors as

outlined below:

TL-7000

US power cord with banana plugs 1

Test lead (red). 6.4 ft. (1.9m) 1

Test lead (green), 25 ft. (7.7 m) 1

Alligator clip set (red, black) 1

Plug adaptor – flat pin (red) 1

Plug adaptor – round pin (black) 1

Light socket adaptor 1

9

Page 14

2. KIT COMPONENTS

2.4 SC-7000 Signal Clamp

(included with AT-7030, option for AT-7020)

The clamp accessory is used for applications

when there is no access to the bare

conductors. The clamp attachment enables

the AT-7000-T Transmitter to induce a

signal through the insulation into either

energized or de-energized wires. The

signal will travel through the wire in both

directions and into all the branches. This

transmission method will not damage any

sensitive electronic equipment connected to

the circuit.

JAW

HAND GUARD

JAW TRIGGER

INPUT LEADS WITH

BANANA PLUG

2.5 BR-7000-T Signal Booster Rechargeable Battery Pack

(included with AT-7030, option for AT-7020)

The BR-7000-T Signal Booster Rechargeable Battery Pack

provides increased power to the AT-7000-T Transmitter,

enabling improved wire tracing results in energized, deenergized and clamp modes. This 7.2V, 2.2 Ah Lithium-Ion

(Li-Ion) battery pack automatically begins recharging when

the transmitter is connected to circuits between 90V - 270V.

The outside of the battery features a LED status indicator that

shows the remaining battery charge with the push of a button.

10

Page 15

3. MAIN APPLICATIONS

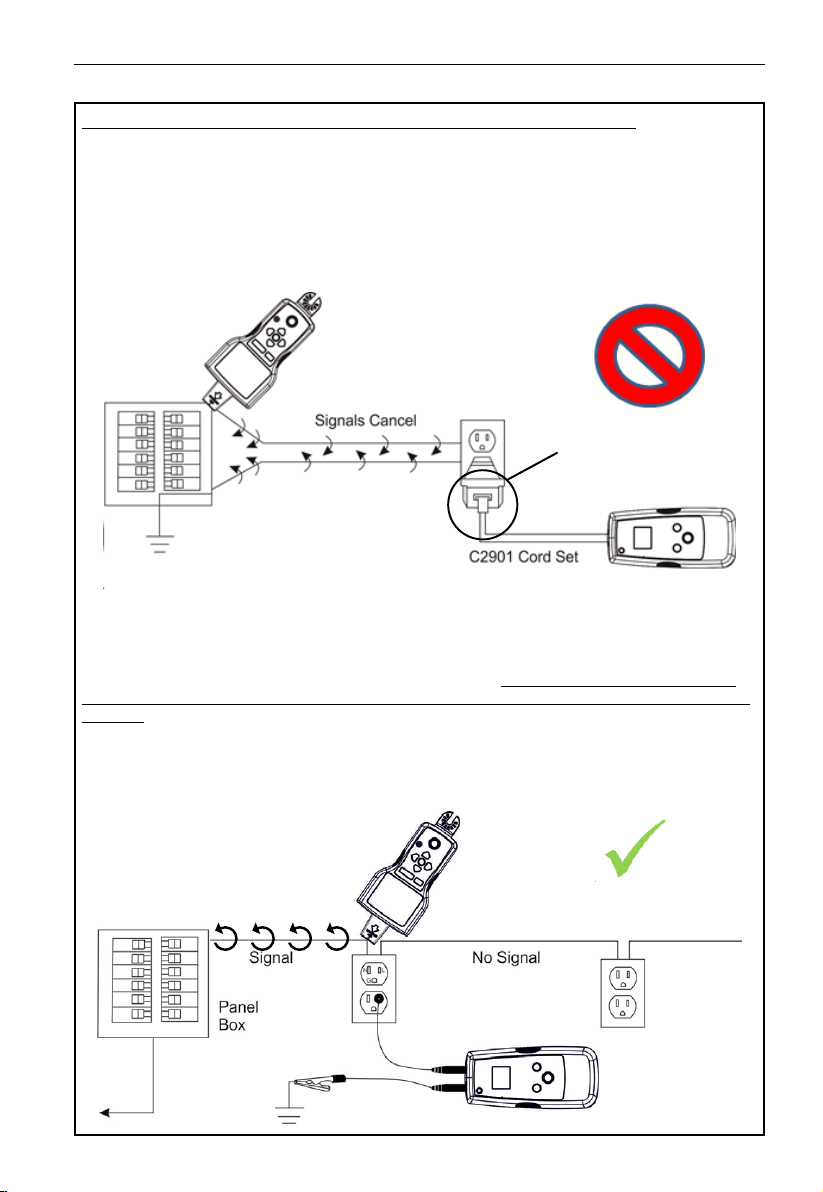

• �IMPORTANT NOTICE, PLEASE READ BEFORE YOU START TRACING

Avoiding signal cancellation problems with a separate ground connection

The signal generated by the transmitter creates an electromagnetic field around the wire.

This field is what is detectable by the receiver. The clearer this signal, the easier it is to trace

the wire.

If transmitter is connected to two adjacent wires on the same circuit (for example, hot and

neutral wires on a Romax cable), the signal travels in one directions through the first wire and

then returns (with opposite direction) through the second one. This causes creation of two

electromagnetic fields around each wire with opposite direction. These opposing fields will

partially or completely cancel each other out, making wire tracing difficult if not impossible.

AT-7000-R

Not recommended. This

wire connection causes

signal cancellation

AT-7000-TFigure 3a

To avoid the cancellation effect, a separate ground connection method should be used.

The red test lead of the transmitter should be connected to the hot wire of the circuit

you wish to trace, and the green lead to a separate ground, such as water pipe, ground

stake, metal grounded structure of the building, or outlet ground connection of an outlet

on a different circuit. It is important to understand that an acceptable separate ground

is NOT the grounding terminal of any receptacle on the same circuit as the wire you wish

to trace. If hot wire is energized and the transmitter is properly connected to a separate

ground, the red LED on a transmitter will light up. The separate ground connection create

the maximum signal strength, because the electromagnetic field created around the hot

wire is not being cancelled by a signal on the return path flowing along an adjacent wire

(hot or neutral) in the opposite direction, but rather through the separate ground circuit.

To Transformer

Figure 3b

11

AT-7000-R

Avoiding signal

cancellation effect

AT-7000-T

Page 16

3. MAIN APPLICATIONS - SMART SENSOR (Energized)

3.1 Tracing Energized Wires

SMART SENSOR

The SMART SENSOR enables easier wire tracing by

showing the direction and position of the wire and

is the recommended method for tracing energized

wires (does not work on de-energized circuits, use

de-energized

TIP SENSOR for that application).

SMART SENSOR

Connecting transmitter test leads

1. Connect green and red test leads to the

transmitter (polarity does not matter)

2. . Connect red lead to energized hot wire (on

the load side of the system). The signal will

ONLY be transmitted between the outlet to

which the transmitter is connected and the

source of power

(see Figure 3a).

3. Connect green wire to a separate ground

(metal building structure, metal water pipe,

or ground wire on a separate circuit).

*Note: Please note that if working with GFCI protected circuits, this method will trip the

GFCI protection. Refer to Special Applications, section 4.1 “GFCI-Protected Circuit Wire

Tracing” for alternative tracing methods.

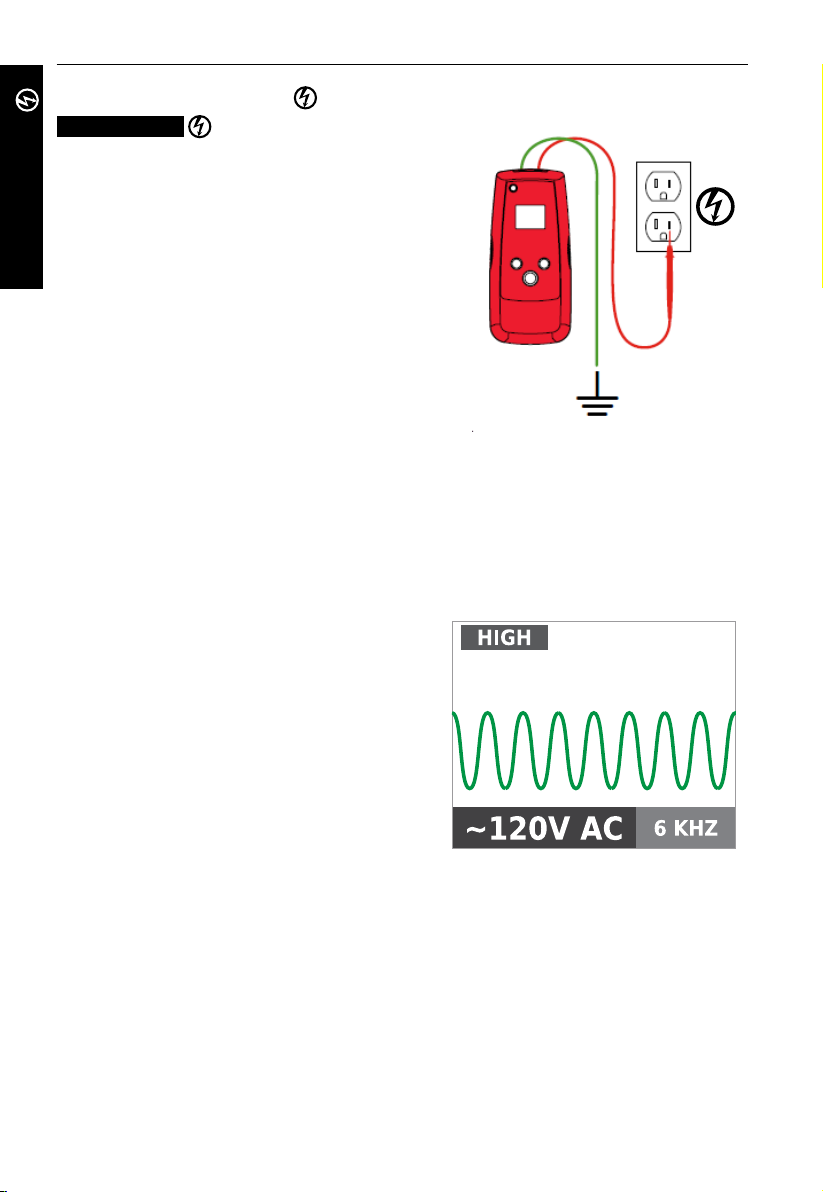

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the

transmitter.

2. Verify that the test leads are properly

connected - the red LED voltage status

should indicator should be on, indicating

that the circuit is energized. If not, make

sure that

• the circuit is energized

• the separate ground green wire is

properly grounded. If the ground wire is

not properly grounded the red LED will

not light, even when connected to an

energized circuit.

3. Select HIGH signal mode for most

applications. Screen will appear as shown

in Figure 3.1b.

Note: The LOW signal precision mode can be used to limit the signal level generated by the

transmitter in order to more precisely pinpoint wire location. A lower signal level reduces

coupling to neighboring wires and metal objects and helps to avoid misreading due to

ghost signals. A lower signal also helps to prevent oversaturating the receiver with a

strong signal that covers a large area. The LOW mode function is rarely used, only for most

demanding precise wire tracing applications.

Figure 3.1a

Proper connection with separate ground

Figure 3.1b

Transmitter screen showing signal in

HIGH mode with 6kHz frequency for

energized circuit

12

Page 17

3. MAIN APPLICATIONS - SMART SENSOR (Energized)

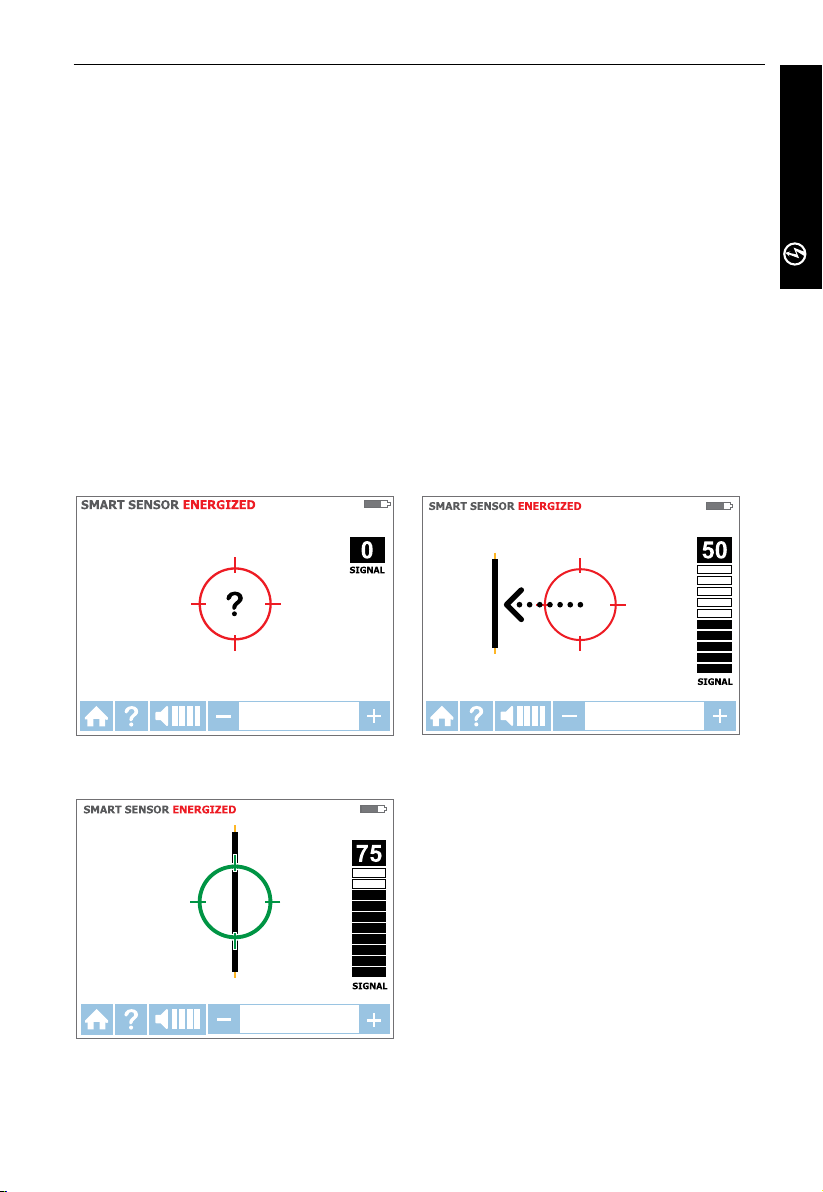

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select SMART SENSOR mode by using the directional arrows to highlight this operating

mode and pressing the yellow ENTER button.

3. Hold the receiver with the Smart Sensor on the rear of the unit facing the target area.

If the screen flashes a “?” in a red target then no signal is detected. Move the Smart

Sensor closer to the target area until the signal is detected and you see a directional

arrow. If no signal is detected increase the sensitivity using the “+” button on the

receiver. (see Figure 3.1c)*

4. Move the Receiver in direction indicated by the arrow on the screen (see Figure 3.1d)

5. Green target symbol indicates that the Receiver is directly over the wire. If Receiver

will not lock on the wire, decrease sensitivity using the “-“ on the keypad or set the

transmitter to transmit at LOW level (Precision). (see Figure 3.1e)

6. Press ENTER when complete to return to Home screen.

*Note: For best results, keep the receiver at least 3 feet from the transmitter and its test

leads to minimize signal interference and improve wire tracing results. Select the “Long”

Smart Sensor Range in the Settings Menu if working with wires that are greater than 3 feet

deep.

SMART SENSOR

Figure 3.1c

No signal detected

Figure 3.1e

Receiver locked on wire

Figure 3.1d

Wire on the left

13

Page 18

3. MAIN APPLICATIONS - TIP SENSOR (Energized)

3.1 Tracing Energized Wires

TIP SENSOR

TIP SENSOR mode is used for the following

applications: pinpointing a wire in a bundle,

tracing in corners and confined spaces such as

junction boxes or inside enclosures.

Connecting transmitter test leads

1. Connect green and red test leads to the

transmitter (polarity does not matter)

2. Connect red lead to energized hot wire (on

the load side of the system).

The signal will ONLY be transmitted between

the outlet to which the transmitter is

connected and the source of power (see

Figure 3b).

TIP SENSOR

3. Connect green wire to a separate ground

(metal building structure, metal water pipe,

or ground wire on a separate circuit).

*Note: Please note that if working with GFCI protected circuits, this method will trip the

GFCI protection. Refer to Special Applications, section 4.1 “GFCI-Protected Circuit Wire

Tracing” for alternative tracing methods.

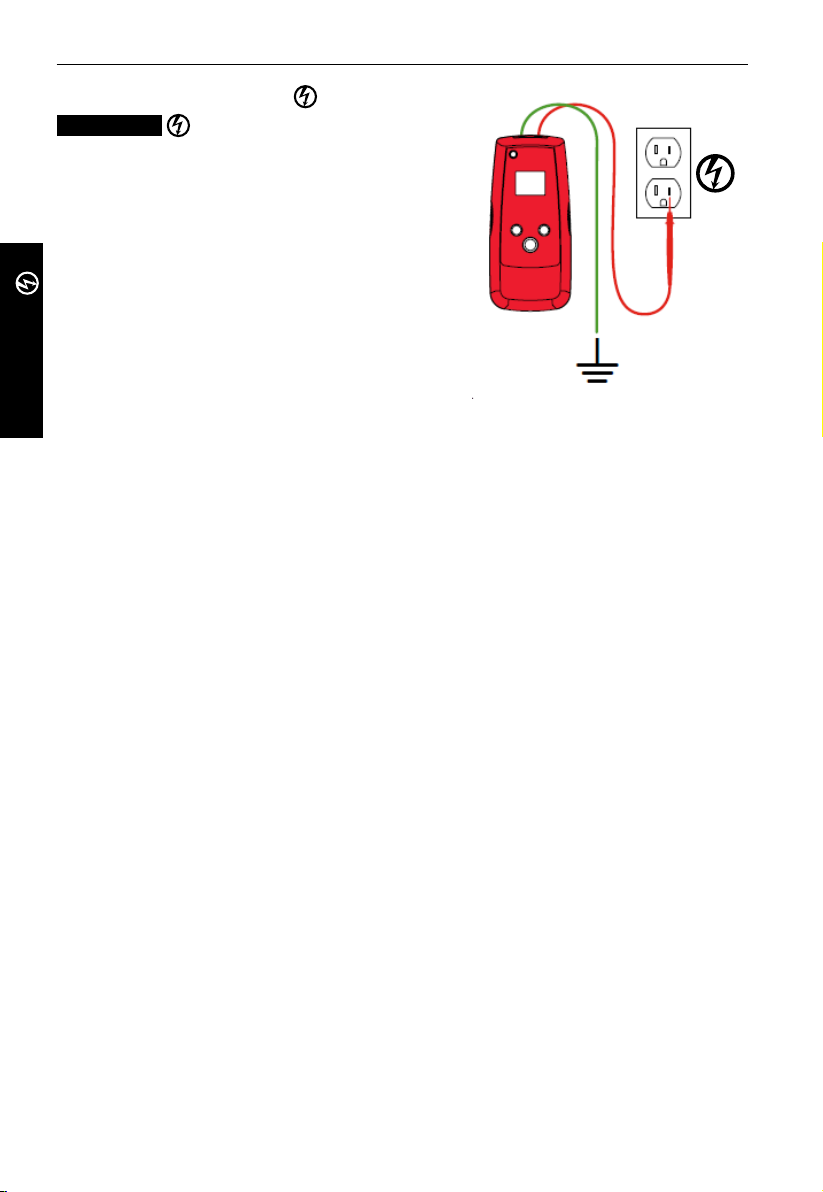

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the transmitter.

2. Verify that the test leads are properly connected - the red LED voltage status should

indicator should be on, indicating that the circuit is energized. If not, make sure that

•the circuit is energized

•the separate ground green wire is properly grounded. If the ground wire is not

properly grounded the red LED will not light, even when connected to an energized

circuit.

3. Select HIGH signal mode for most applications. Screen will appear as shown in Figure

3.1b.

Note: The LOW signal precision mode can be used to limit the signal level generated by the

transmitter in order to more precisely pinpoint wire location. A lower signal level reduces

coupling to neighboring wires and metal objects and helps to avoid misreading due to

ghost signals. A lower signal also helps to prevent oversaturating the receiver with a

strong signal that covers a large area. The LOW mode function is rarely used, only for most

demanding precise wire tracing applications.

Figure 3.1f

Proper connection with separate ground

14

Page 19

3. MAIN APPLICATIONS - TIP SENSOR (Energized)

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select Energized TIP SENSOR mode by using the directional arrows to highlight this

operating mode and pressing the yellow “ENTER” button. Screen as shown in 3.1i will

appear.

3. Hold the receiver with the Tip Sensor facing the target area.

4. Scan target area with Tip Sensor to find highest signal level. While tracing, periodically

adjust sensitivity to keep signal strength near 75. Increase or decrease sensitivity

by pressing + or – on the keypad. If signal is too strong for precise locating, change

transmitter to LOW mode.

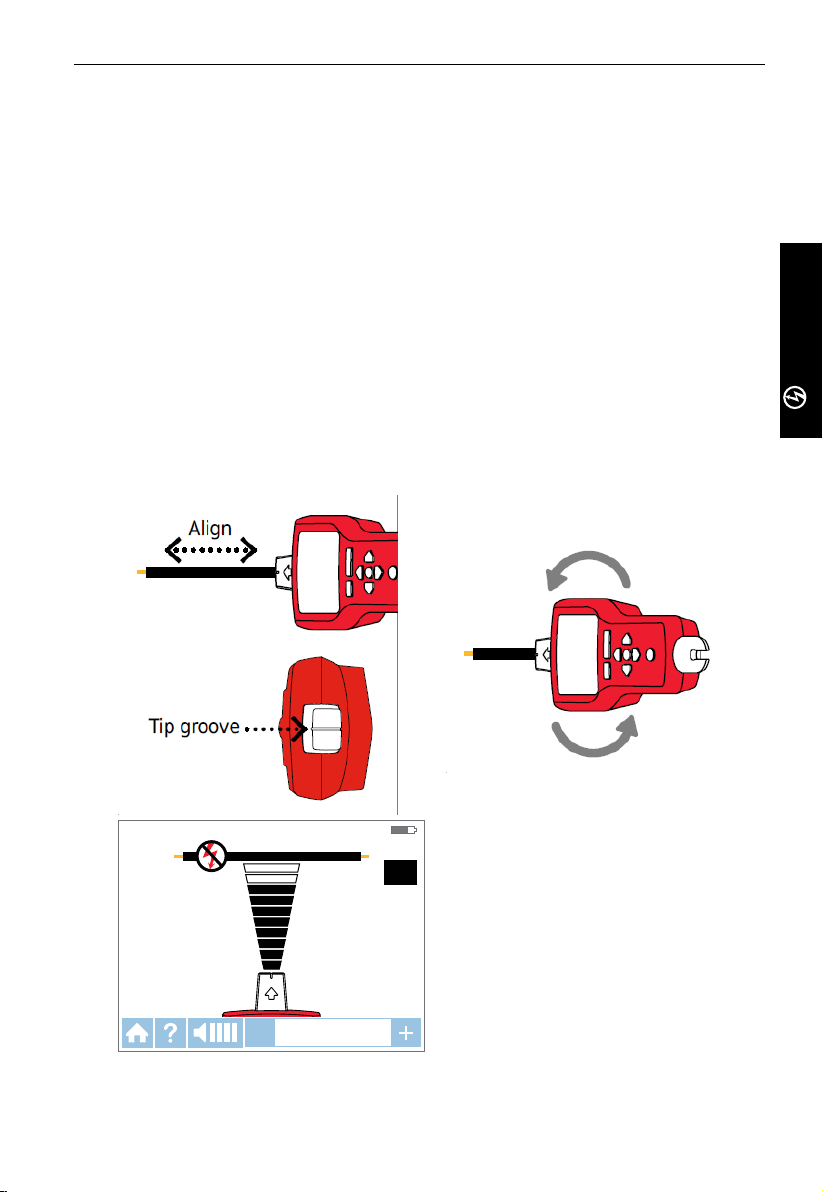

5. Receiver Positioning: For best results, align groove on tip sensor with wire direction as

shown. Signal may be lost if not properly aligned. (see Figure 3.1g)

6. To verify wire direction, periodically rotate receiver 90 degrees. Signal strength will be

highest when wire is aligned with Tip Sensor groove. (see Figure 3.1h)

7. Press ENTER when complete to return to Home screen.

Note: For best results, keep the receiver at least 3 feet from the transmitter and its test

leads to minimize signal interference and improve wire tracing results.

TIP SENSOR

Figure 3.1g

TIP SENSOR DE-ENERGIZED

0-30V AC/DC

-

-

Figure 3.1h

75

SIGNAL

Figure 3.1i

Receiver showing signal detected in

Energized TIP SENSOR mode

15

Page 20

3. MAIN APPLICATIONS - TIP SENSOR (De-Energized)

3.2 Tracing De-energized Wires

TIP SENSOR

De-energized TIP SENSOR mode is used for general

wire tracing, pinpointing wires in bundles, tracing

in tight corners and confined spaces such as

junction boxes or inside enclosures.

Connecting transmitter test leads

1. Connect green and red test leads to the

transmitter (polarity does not matter)

2. Connect red lead to de-energized hot wire

(on the load side of the system).

In de-energized mode the signal will be

injected to ALL branches of the circuit, not

just between the outlet and the breaker as in

energized modes.

3. Connect green wire to a separate ground

(metal building structure, metal water pipe,

or ground wire on a separate circuit).

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the transmitter.

TIP SENSOR

2. The red LED voltage status should indicator should be off, indicating that the circuit is

de-energized. If LED is on, disconnect power to the circuit.

3. Select HIGH signal mode for most applications. Screen will appear as shown in Figure

3.2b

Note: The LOW signal precision mode can be used to limit the signal level generated by the

transmitter in order to more precisely pinpoint wire location. A lower signal level reduces

coupling to neighboring wires and metal objects and helps to avoid misreading due to

ghost signals. A lower signal also helps to prevent oversaturating the receiver with a

strong signal that covers a large area. The LOW mode function is rarely used, only for most

demanding precise wire tracing applications.

Figure 3.2a

Proper connection with separate ground

HIGH

0V DC

33 KHZ

Figure 3.2b

16

Page 21

-

-

3. MAIN APPLICATIONS - TIP SENSOR (De-Energized)

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select De-Energized TIP SENSOR mode by using the directional arrows to highlight this

operating mode and pressing the yellow “ENTER” button. Screen will appear as shown

in Figure 3.2c

3. Hold the receiver with the Tip Sensor facing the target area.*

4. Scan target area with Tip Sensor to find highest signal level. While tracing, periodically

adjust sensitivity to keep signal strength near 75. Increase or decrease sensitivity

by pressing + or – on the keypad. If signal is too strong for precise locating, change

transmitter to LOW mode.

TIP SENSOR DE-ENERGIZED

75

SIGNAL

0-30V AC/DC

Figure 3.2c

5. Press ENTER when complete to return to Home screen.

TIP SENSOR

*Note: For best results, keep the receiver at least 3 feet from the transmitter and its test

leads to minimize signal interference and improve wire tracing results.

De-energized mode uses a different antenna in the Tip Sensor than in energized mode.

Specific alignment of the Tip Sensor groove to the wire is not required. De-energized wire

tracing results are based only on how close the Tip Sensor is to the wire.

17

Page 22

3. MAIN APPLICATIONS - BREAKERS (Energized)

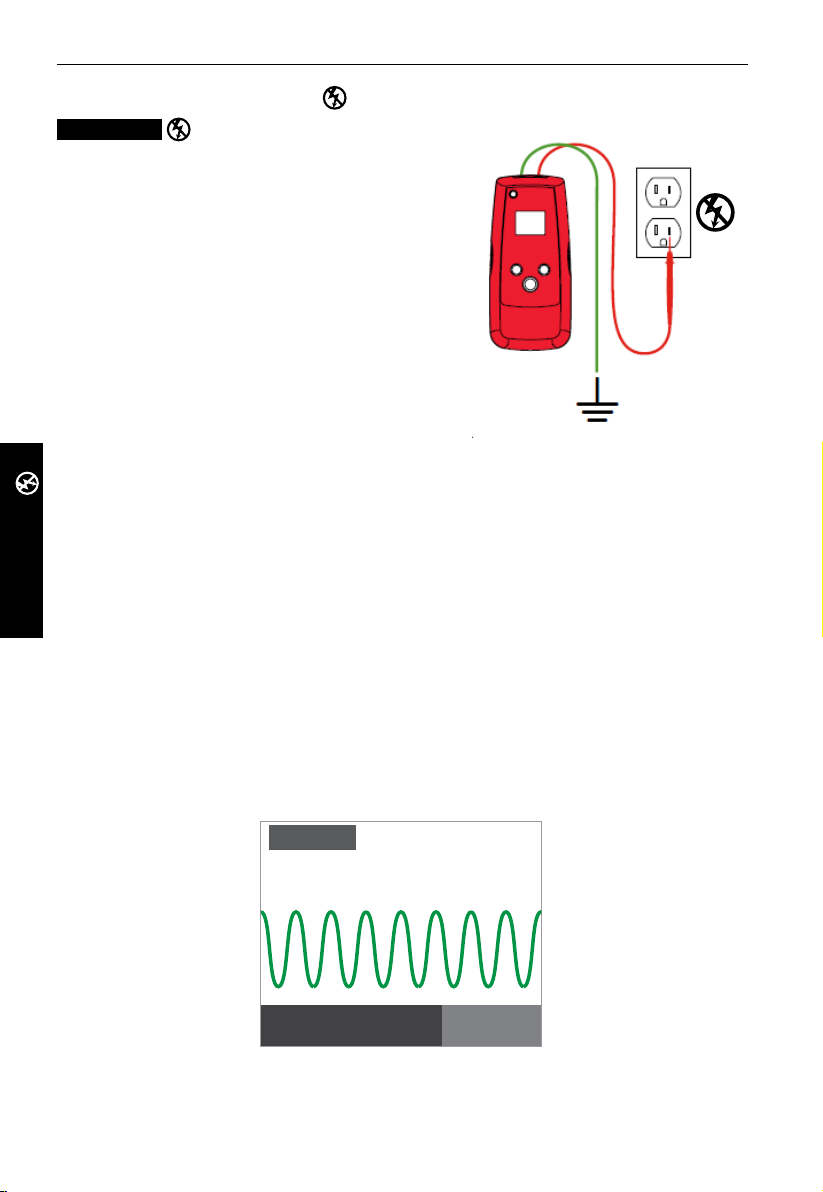

3.3 Identifying Breakers and Fuses

Energized breaker locating

BREAKERS

Connecting transmitter test leads

1. Use test leads with standard plug

connection for receptacles and black and

red test leads with alligator clips when

connecting to wires.

2. Plug test leads into Transmitter. Polarity

is not important.

3. Connect plug to outlet, or if using test

leads connect them to hot and neutral

wires.

Note: For breaker locating, a simplified

direct connection to hot and neutral wires

can be used because these wires are

separated at the breaker panel. There is no

risk of signal cancellation effect if wires are at least a few inches (centimeters) away from

each other. However the separate ground connection as shown in Energized TIP SENSOR

should be used for superior results specifically if wires need to be traced in addition to

breaker identification.

The simplified direct connection to hot and neutral wire will NOT trip the GFCI circuit.

Figure 3.3a

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the transmitter.

2. Verify that the test leads are properly connected - the red LED voltage status indicator

should be on, indicating that the circuit is energized. If not, make sure that

•the circuit is energized

•the test leads are fully plugged into the transmitter

•ground green wire is properly grounded (if using separate ground connection

method). If the ground wire is not properly grounded the red LED will not light, even

when connected to an energized circuit.

3. Select HIGH signal mode for breaker tracing.

BREAKERS

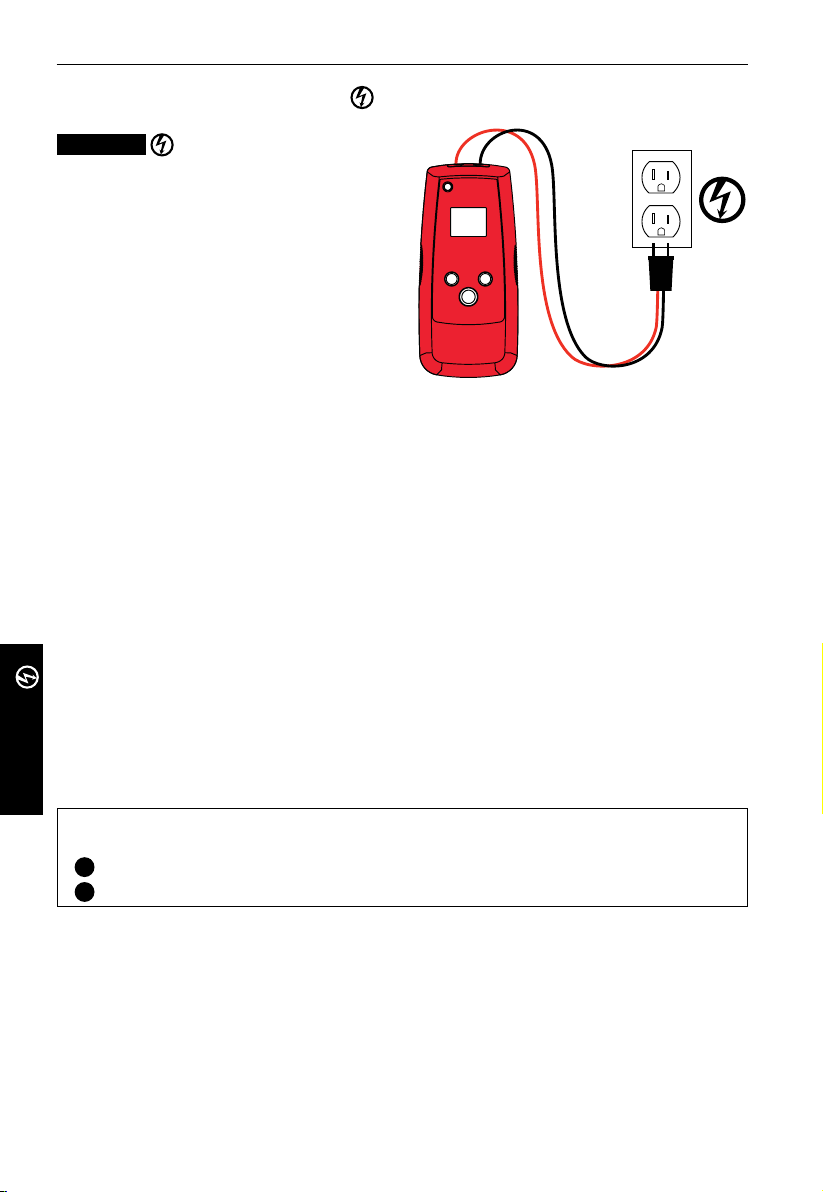

Receiver Process Overview

Tracing breakers is a two-step process:

1

SCAN - Scan each breaker for one second. The receiver will record tracing signal levels.

2

LOCATE - The receiver will indicate the single breaker with the strongest recorded signal.

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select Energized BREAKERS mode by using the directional arrows to highlight this

operating mode and pressing the yellow “ENTER” button.

18

Page 23

3. MAIN APPLICATIONS - BREAKERS (Energized)

1

Step 1 -

1. The unit will automatically start in

2. Scan each breaker for a half second by touching it with the Tip Sensor. Make sure the

groove on the Tip Sensor is parallel to the breaker lengthwise (See Figure 3.3d)

3. To assure sufficient time between the scans, wait for active green arrow and audible

alert (2-beeps) before moving to the next breaker.

4. Scan all breakers – the order of scanning does not matter. You can scan breakers

multiple times. The receiver is recording the highest detected signal.

SCAN:

1

SCAN mode as shown in Figure 3.3b.

2

LOCATE

Figure 3.3b

LOCATE mode – receiver checking breakers

LOCATE mode – receiver identified breaker

SCAN mode – receiver scanning breakers

Step 2 -

1. Select LOCATE mode by using the directional arrows to

highlight this operating mode and pressing the yellow

“ENTER” button. (See figure 3.3c)

2. Rescan each breaker by touching each with the Tip Sensor

for a half second. Active red arrow indicates scanning process

(see Figure 3.3c). Make sure the groove on the Tip Sensor is

parallel to the breaker lengthwise.(See Figure 3.3d)

3. Rescan all breakers until solid green arrow and audible alert

(continuous beep) indicates that the correct breaker was

found. (See figure 3.3e)

4. Press ENTER when complete to return to Home screen.

Usage Tip: The accuracy of breaker identification results can be verified by switching the

receiver to Energized TIP SENSOR mode and checking that that the signal level of the

breaker identified by the receiver is the highest among all breakers.

Figure 3.3c

Figure 3.3d

Figure 3.3e

BREAKERS

19

Page 24

3. MAIN APPLICATIONS - BREAKERS (De-Energized)

3.3 Identifying De-Energized Breakers and Fuses

De-Energized breaker locating

BREAKERS

Connecting transmitter test leads

1. Use test leads with standard plug

connection for receptacles and black and

red test leads with alligator clips when

connecting to wires.

2. Plug test leads into Transmitter. Polarity

is not important.

3. Connect plug to outlet, or if using test

leads connect them to hot and neutral

wires.*

* The separate ground connection as shown

in De-Energized TIP SENSOR should be used

for superior results specifically if wires

need to be traced in addition to breaker

identification.

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the transmitter.

2. The red LED voltage status should indicator should be off, indicating that the circuit is

de-energized. If LED is on, disconnect power to the circuit.

3. Select HIGH signal mode for breaker tracing.

Figure 3.3f

Receiver Process Overview

Tracing breakers is a two-step process:

1

SCAN - Scan each breaker for one second. The receiver will record tracing signal levels.

2

LOCATE - The receiver will indicate the single breaker with the strongest recorded signal.

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select De-Energized BREAKERS mode by using the directional arrows to highlight this

operating mode and pressing the yellow “ENTER” button.

3. Step 1 a) Select SCAN mode by using the directional arrows to highlight this operating mode

BREAKERS

b) Scan each breaker for a half second by touching it with the Tip Sensor. Make sure the

c) To assure sufficient time between the scans, wait for active green arrow and audible

d) Scan all breakers – the order of scanning does not matter. You can scan breakers

1

SCAN

and pressing the yellow “ENTER” button.

groove on the Tip Sensor is parallel to the breaker lengthwise

alert (2-beeps) before moving to the next breaker.

multiple times. The receiver is recording the highest detected signal.

20

Page 25

3. MAIN APPLICATIONS - BREAKERS (De-Energized)

2

4. Step 2 -

a) Select LOCATE mode by using the directional arrows to highlight this operating mode

and pressing the yellow “ENTER” button.

b) Scan each breaker again for a half second each by touching it with the Tip Sensor.

Active red arrow indicates scanning process. Make sure the groove on the Tip Sensor is

parallel to the breaker lengthwise.

c) Rescan all breakers until solid green arrow and audible alert (continuous beep)

indicates that the correct breaker was found.

d) Press ENTER when complete to return to Home screen.

Usage Tip: The accuracy of breaker location can be verified by switching the receiver to

De-Energized TIP SENSOR mode, and checking that that the signal level of the breaker

identified by the receiver is the highest among all breakers.

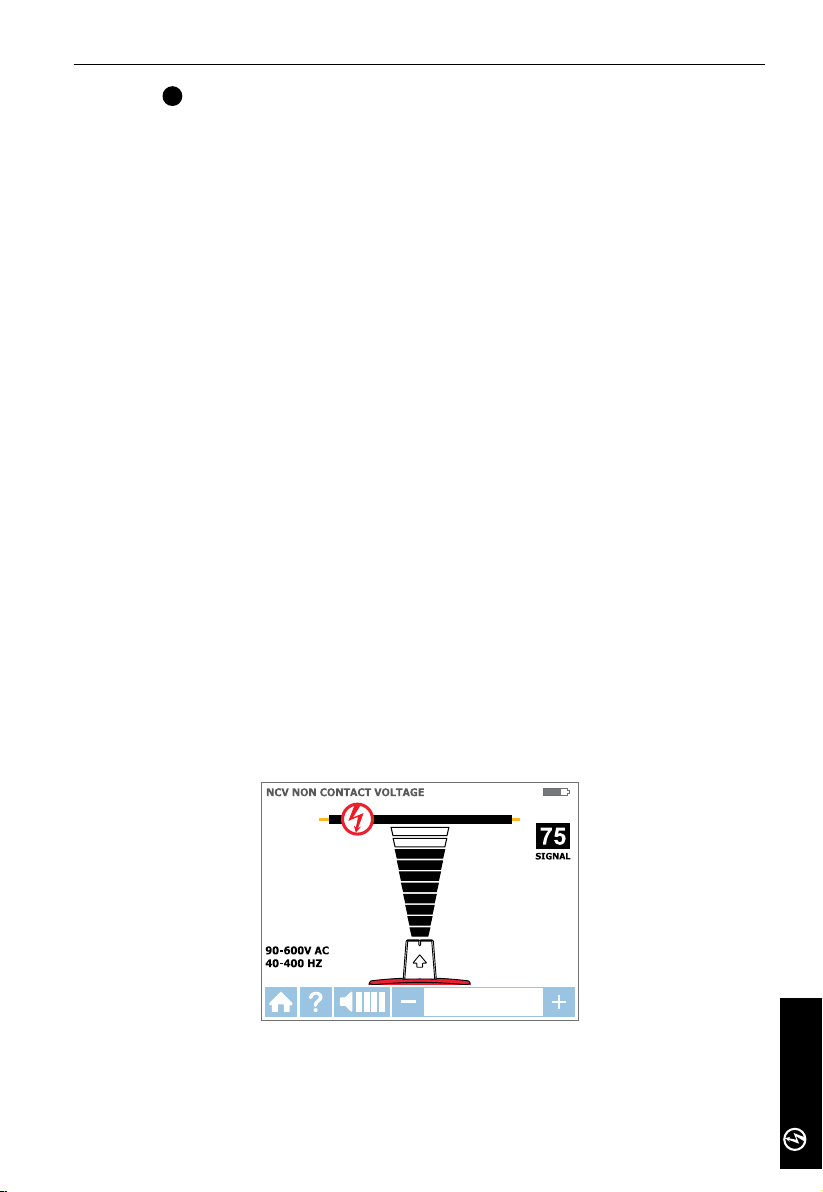

3.4 NCV Mode

The NCV (Non-Contact Voltage) mode is used to verify that the wire is energized. This

method does not require the use of the transmitter. The receiver will detect an energized

cable if the voltage is between 90V and 600V AC and between 40 and 400Hz. No current

flow is necessary.

Note: For safety, before working with wires, always verify that they are de-energized with

an additional tester.

NCV mode operation:

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Press ‘NCV’ push button to select the Non-Contact Voltage mode.

3. Hold the receiver with the Tip Sensor against the wire.

4. For precise pinpointing of hot wire versus neutral wire, increase or decrease sensitivity

by pressing + or – on the keypad.

5. Press ENTER when complete to return to Home screen.

LOCATE

Voltage detection in NCV mode using Tip Sensor

21

NCV MODE

Page 26

4. SPECIAL APPLICATIONS

4.1 GFCI-Protected Circuit Wire Tracing

Connecting AT-7000-T transmitter to GFCI protected circuits.

Connecting a transmitter to an energized GFCI protected circuit using separate ground

method will trip the GFCI protection. Use following methods to work with GFCI protected

circuits (for de-energized GFCI-protected outlet that is not tripped, you can connect test

leads directly to the outlet contacts using de-energized TIP SENSOR mode)

Method 1 – Bypass the GFCI circuitry to avoid tripping GFCI:

(for energized GFCI-protected outlets only)

• Remove the protective receptacle wall plate

• Using the alligator clip attach a red test lead to the screw connecting the energized hot

wire to the receptacle

• Connect green test lead using separate ground method as described in Energized TIP

SENSOR mode

• Perform tracing as described in one of the Energized modes: SMART SENSOR, TIP

SENSOR or BREAKER.

Method 2 – Do NOT use separate ground to avoid tripping GFCI:

(for GFCI-protected outlets and breakers)

• Connect transmitter test leads to Neutral and Hot wires.

• Perform tracing as described in one of the Energized modes: SMART SENSOR, TIP

SENSOR or BREAKER.

Note: This type of connection causes signal coupling and reduces signal strength. If the

signal is too weak or untraceable, use Method 3.

Method 3 - De-energize the circuit:

(for GFCI-protected breakers)

• De-energize the circuit

• Connect a transmitter directly to the wire as described in De-Energized TIP SENSOR

mode

• Perform tracing as described in the desired De-Energized mode (TIP SENSOR for wire

tracing or BREAKER for breaker identification).

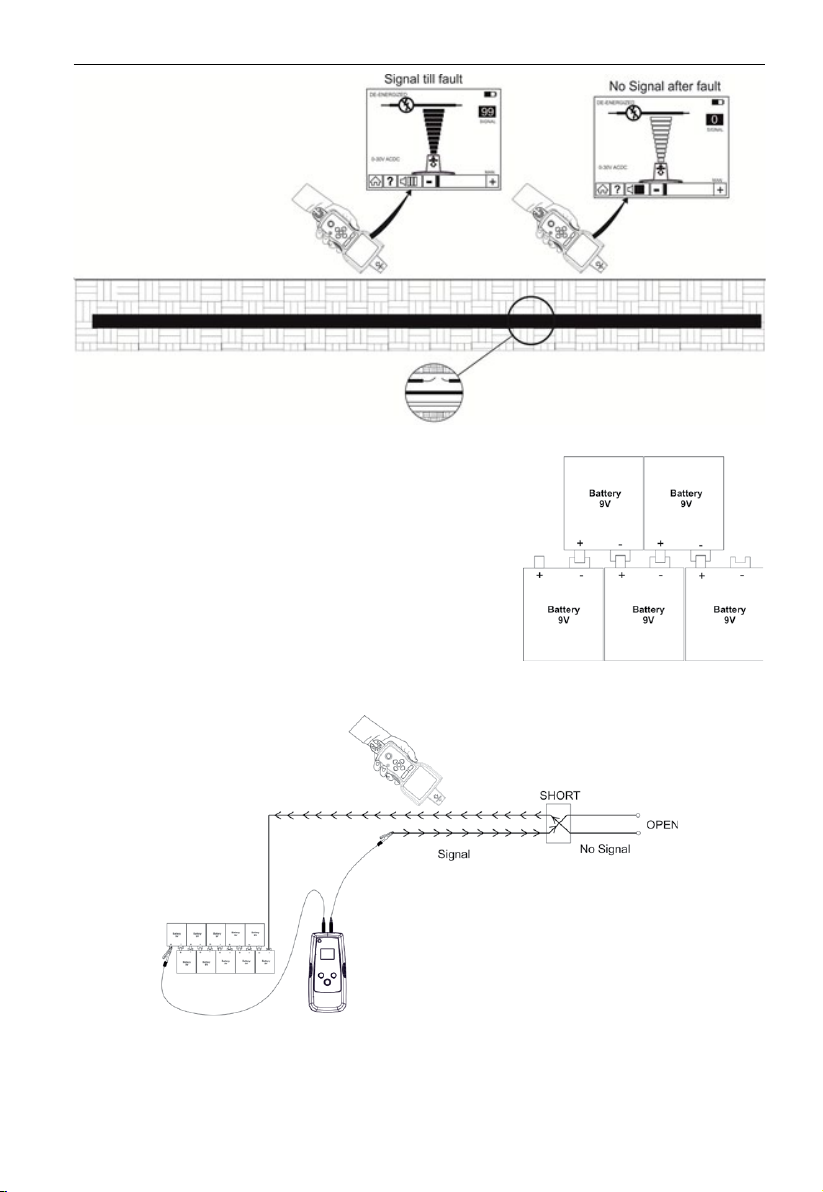

4.2 Finding Breaks/Opens

It is possible to pinpoint the exact location where the wire is broken using the de-energized

TIP SENSOR mode, even if wire is located behind walls, floors or ceilings:

1. Make sure that wire is de-energized.

2. Use steps described in the De-Energized TIP SENSOR mode to connect the transmitter

and perform tracing. (see section 3.2)

The tracing signal generated by the AT-7000-T transmitter will be conducted along the wire

as long as there is continuity in the metal conductor. To find the place of fault, trace the

wire until the signal stops. To verify the place of the fault, move transmitter to the other

end of the wire and repeat tracing from the opposite end. If signal stops at the exact same

location you have found the place of the break.

Note: If the place of fault is not found, the open may be a high resistance break (partially

open circuit). Such a break would stop higher currents from flowing but will conduct

the tracing signal through the break. Such faults will not be detected until the wire is

completely open.

22

Page 27

4. SPECIAL APPLICATIONS

Trace the wire by moving

receiver back and forth at

1ft/sec

4.3 Finding Shorts

Shorted wires will cause a breaker to trip. Disconnect the

wires, and make sure the ends of the wires on both sides

of the cable are isolated from each other and other wires

or loads.

Interconnect ten (10) 9V batteries in series, by connecting

negative “-“contact of one battery to the positive “+” on

the other one. The 10 batteries will create safe 90V DC

power source.

Connect the circuit as shown in the illustration below.

AT-7000-T

Setup the receiver to Energized TIP SENSOR mode. Start tracing the cable until you find the

location where the signal stops. To verify the place of the fault, move the transmitter to the

other end of the wire and repeat tracing from the opposite end. If the signal stops at the

exact same location you have found the place of break.

Note: This method will be affected by signal cancellation effect. Expect a very weak signal.

23

Page 28

4. SPECIAL APPLICATIONS

4.4 Tracing Wires in Metal Conduit

The AT-7000-R receiver will not be able to pick up the signal from the wire through the

metal conduit. The metal conduit will completely shield the tracing signal.

Note: The receiver will be able to detect wires in non-metallic conduit. For these

applications follow general tracing guidelines.

In order to trace wires in conduit:

1. Use either energized or de-energized TIP SENSOR mode (refer to section 3.1 or 3.2 as

appropriate)

2. Open junction boxes and use the receiver TIP SENSOR to detect which wire in the

junction box is carrying the signal.

3. Move from junction box to junction box to follow the path of the wire.

Note: Applying signal directly to the conduit will send signal through all the conduit

branches making tracing of one particular conduit path not possible.

4.5 Tracing Non-Metallic Pipes and Conduits

The AT-7000 can indirectly trace plastic conduits and pipes using the following steps:

1. Insert fish tape or wire inside the conduit.

2. Connect the AT-7000-T transmitter red test lead to the fish tape and the green ground

wire to a separate ground (see section 3.2 for further set-up instructions).

3. Set the Receiver to De-energized TIP SENSOR mode to trace the conduit

(refer to section 3.2).

4. The receiver will pick up the signal conducted by fish tape or wire through the conduit.

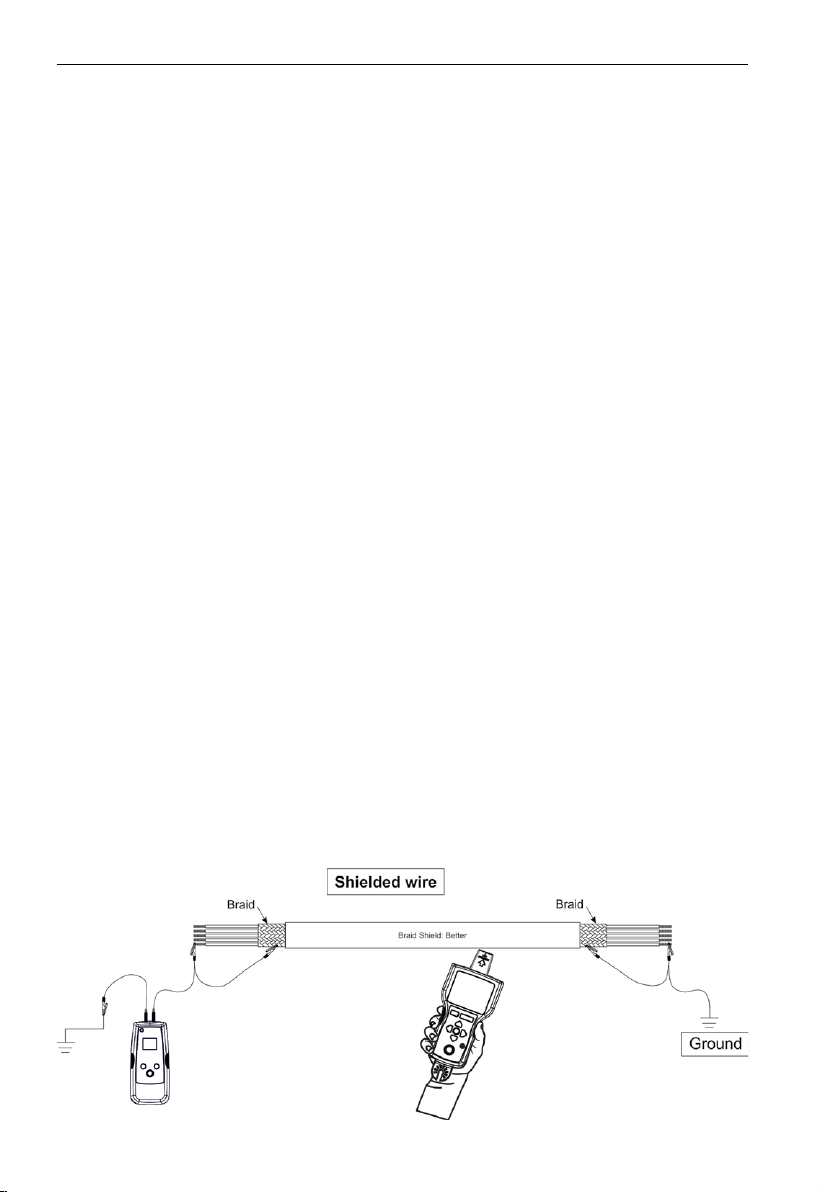

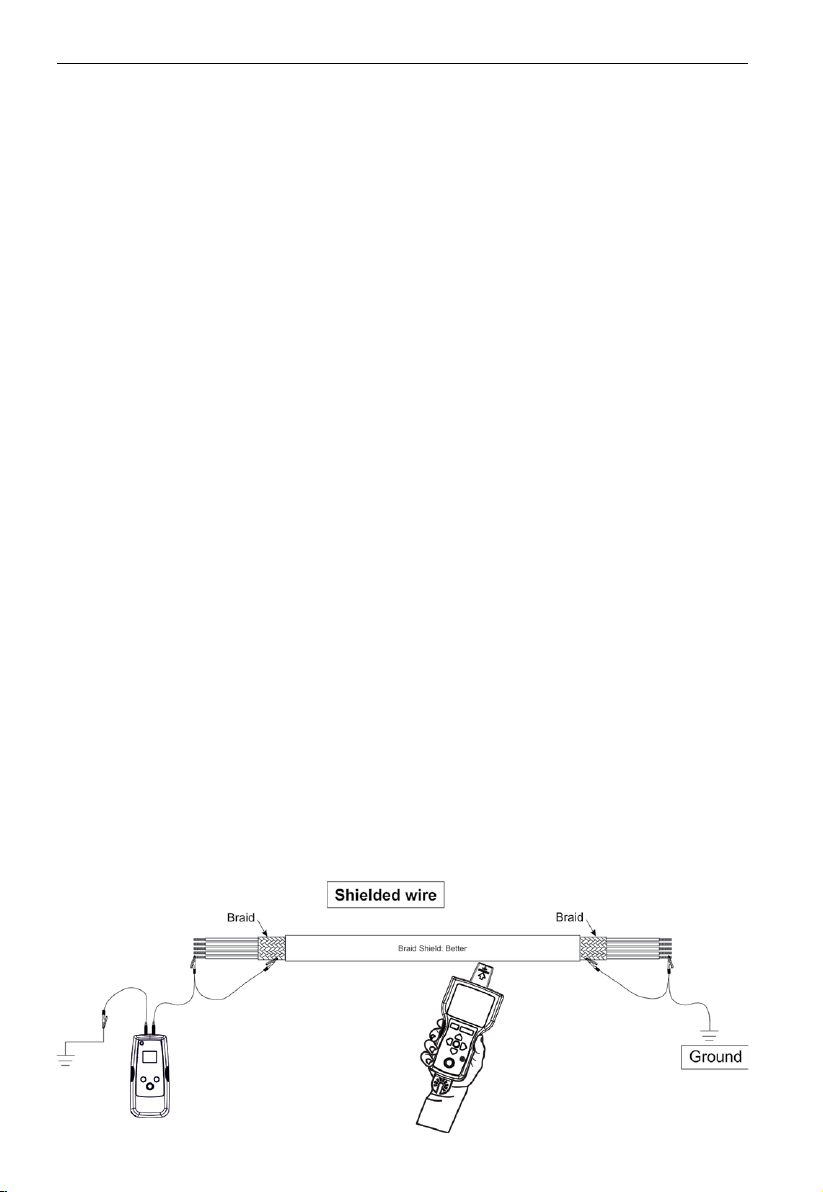

4.6 Tracing Shielded Wires

The AT-7000-R receiver will not be able to pick up the signal from the shielded wire. The

shield will completely stop the tracing signal.

In order to trace these types of wires:

1. Connect the AT-7000-T transmitter directly to the shield (connect red test lead to the

shield and the green test lead to the separate ground).

2. Set the receiver to the De-Energized TIP SENSOR mode to trace the wire.

3. For best results disconnect the shield from the ground at the point where transmitter is

connected, and leave the other end grounded.

AT-7000-T

24

Page 29

4. SPECIAL APPLICATIONS

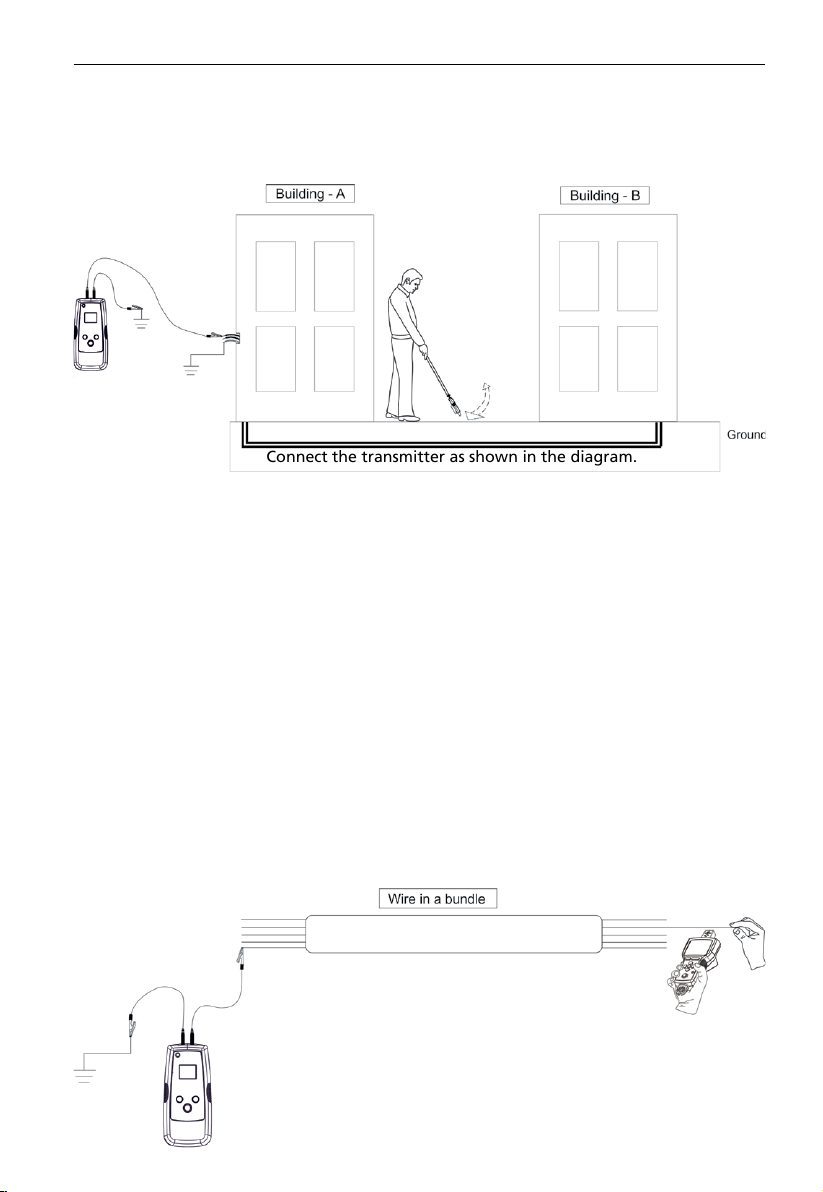

4.7 Tracing Underground Wires

The AT-7000 can trace wires underground, the same way it can locate wires behind walls or floors.

Perform tracing as described in Energized SMART SENSOR mode or Energized / De-Energized

TIP SENSOR modes.

You can use a hot sick attachment to make tracing more ergonomic and convenient.

AT-7000-T

Connect the transmitter as shown in the diagram.

4.8 Tracing Low Voltage Wires and Data Cables

The AT-7000 can trace data, audio, and thermostat cables (to trace shielded data cables,

refer to section 4.6 “Tracing Shielded Wires”).

Trace data, audio, and thermostat cables as follows:

1. Connect the AT-7000-T transmitter using the separate ground method described in

section 3.2 “Tracing De-Energized Wires”.

2. Set the AT-7000-R receiver to De-energized TIP SENSOR mode and trace the wire (see

section 3.2 for further detailed set-up instructions).

4.9 Sorting Bundled Wires

Identifying a specific wire in a bundle

Connect the AT-7000-T transmitter using Energized or De-Energized TIP SENSOR mode. If

connecting to energized wire, make sure the transmitter is connected on the load side.

Select respectively Energized or De-energized TIP sensor mode on AT-7000-R receiver. As far

as it is possible pull one wire at the time way from other wires in the bundle and touch it

with the TIP sensor. The strongest signal indicates the proper wire in the bundle.

AT-7000-T

25

Page 30

4. SPECIAL APPLICATIONS

4.10 No Access to Bare Conductors (Signal Clamp)

The clamp accessory is used for applications where there is no access to the bare conductor

to connect transmitter test leads. When clamp is connected to the transmitter, it enables the

AT-7000-T to induce signal to energized or de-energized wire through the insulation. The

signal will travel through the wire both directions and it will affect all the branches. This

method is safe to use for any sensitive electronic equipment.

Connect the clamp

1. Connect the SC-7000 test leads to the

terminals of the transmitter

(polarity does not matter).

2. Clamp the SC-7000 Signal Clamp around the

conductor. To increase the signal strength

wind a few turns of conductor wire around

the clamp if possible.

Figure 4.10a

Transmitter in CLAMP mode

Set up the AT-7000-T Transmitter:

1. Press ON/OFF key to turn on the transmitter. The red LED voltage status indicator should

be OFF when clamp is connected and when working with either energized or deenergized systems.

2. Press HIGH signal mode for 2 seconds to select the clamp mode on the transmitter. The

clamp mode generates a boosted 6kHz signal in order to provide superior tracing results.

The screen on the Transmitter should appear as in Figure 4.10a.

Using AT-7000-R Receiver

1. Press ‘ON/OFF’ push button to turn on the receiver and wait for the home screen (boot

up time is around 30 seconds).

2. Select Energized TIP SENSOR mode by using the directional arrows to highlight this

operating mode and pressing the yellow “ENTER” button.

3. Hold the receiver with the Tip Sensor facing the target area.

4. Scan target area with Tip Sensor to find highest signal level. While tracing, periodically

adjust sensitivity to keep signal strength near 75. Increase or decrease sensitivity by

pressing +or – on the keypad.

5. Receiver Positioning: For best results, align groove on tip sensor with wire direction as

shown. Signal may be lost if not properly aligned.

6. To verify wire direction, periodically rotate receiver 90 degrees. Signal strength will be

highest when wire is aligned with Tip Sensor groove.

26

Page 31

4. SPECIAL APPLICATIONS

Figure 4.10b

7. PRESS ENTER when complete to return to home screen.

*Note: For best results, keep the receiver at least 3 feet from the transmitter and its test

leads to minimize signal interference and improve wire tracing results.

Figure 4.10c

4.11 Locating Loads (Signal Clamp)

The clamp accessory can be used to map loads to

specific breakers on both energized and

de-energized systems. There is no need to

disconnect power.

1. Clamp the SC-7000 around the wire at the

breaker panel.

2. Set up the transmitter and receiver as described

in the previous section 4.10 “No Access to Bare

Conductors (Inductive Clamp)’.

3. Scan face plates of receptacles and wires

connecting loads with the TIP Sensor of the

AT-7000-R. If using on a de-energized system

you must set the receiver to de-energized TIP

SENSOR mode.

4. All the wires, receptacles and loads that have a

strong signal as indicated by the AT-70000-R are

connected to the breaker.

27

Page 32

5. MAINTENANCE

Changing battery for transmitter:

The battery compartment on the back of the AT-7000-T is designed to make it easy for

the user to change the battery. A screw is added to secure the battery in case the unit is

dropped. The 7.2V BR-7000-T Signal Booster Rechargeable Battery Pack or 6 AA alkaline

batteries may be used. The BR-7000-T does not need to be removed to charge. It will begin

recharging whenever the AT-7000-T is plugged into an energized outlet (90V-270V).

OR

Figure 5.1: Changing transmitter battery

28

BR-7000-T

Page 33

5. MAINTENANCE

1. Make sure that the Transmitter is turned off.

2. Use the star screw driver to unscrew the holding screws.

3. Remove the battery cover.

4. Install Batteries using the battery clip.

5. Replace the battery cover and secure it with the provided screw.

Changing receiver battery:

The battery compartment on the back of the AT-7000-R is designed to make changing

batteries easy. Four (4) AA 1.5V alkaline or 1.2V rechargeable batteries may be used.

Figure 5.2: Changing receiver battery

1. Make sure that the Receiver is turned off.

2. Use screw driver to unscrew the captive screw.

3. Remove the battery cover.

4. Install batteries using the battery clip.

5. Replace the battery cover and secure it with the

provided screw.

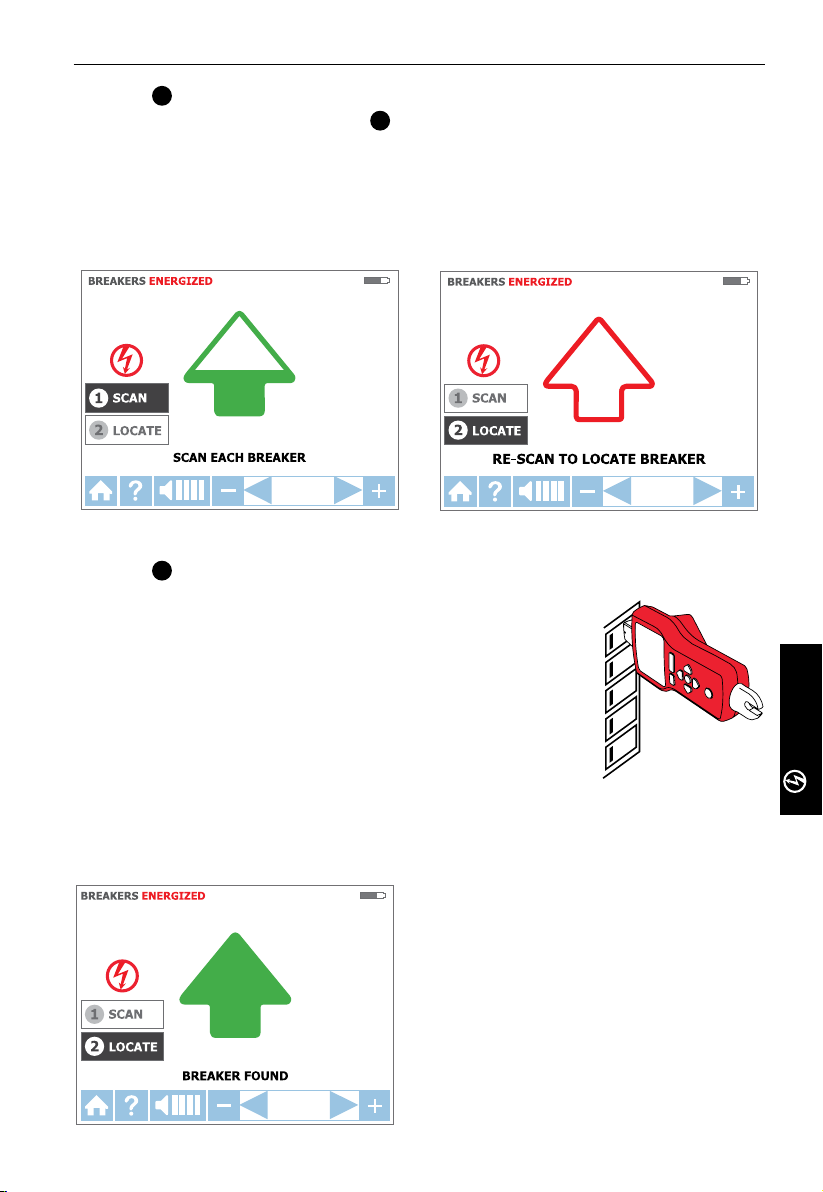

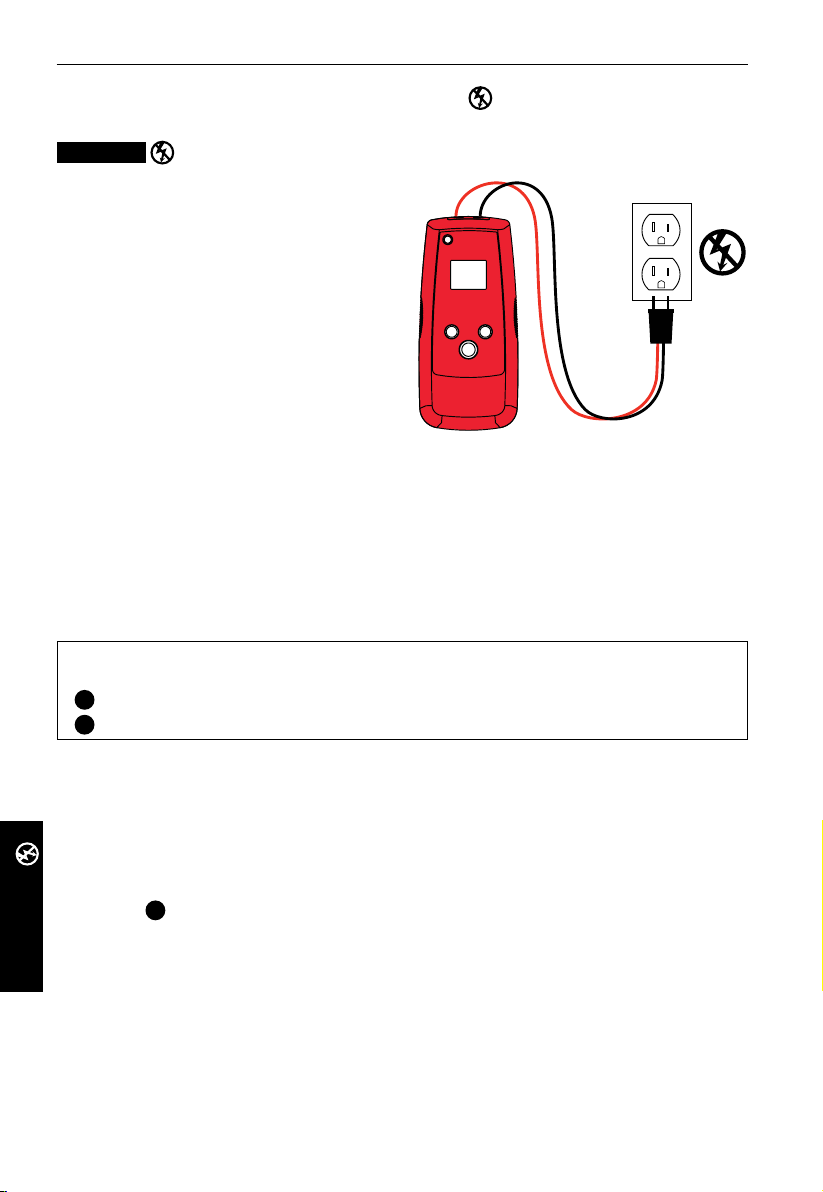

Transmitter battery charging:

The BR-7000 Signal Booster Rechargeable Battery Pack will

automatically begin recharging whenever the Transmitter

is connected to an energized circuit with voltage between

90-270 Volts AC. When connected to an energized circuit the

Transmitter does not need a battery as the Transmitter uses

power from the line.

29

Transmitter battery charging

Figure 5.3

Page 34

5. MAINTENANCE

Transmitter fuse replacement:

Figure 5.4: Transmitter fuse replacement

� Warning: To avoid shock, injury, or damage to the Transmitter, disconnect test

leads before opening case.

1. Disconnect all test leads from the Transmitter.

2. Make sure that the transmitter is turned off.

3. Use the star screw driver to unscrew the holding screws.

4. Remove the fuse cover by pulling it upwards as shown in figure 5.4.

5. Remove the fuse from the fuse holder.

6. Insert the new fuse in the fuse holder. 3.15A , 600V MAX, SLOW 5X20MM

7. Insert the fuse cover and secure it with the holding screws and tighten with the Star

screw driver.

30

Page 35

6. SPECIFICATIONS

AT-7000-R AT-7000-T SC-7000

LCD size 3.5" 1.77" NA

LCD Dimensions 2.76 x 2.07 1.1 x 1.38 in NA

LCD Resolution

(pixels)

LCD type TFT RGB x TFT NA

Color LCD Yes Ye s NA

Backlight Yes Ye s NA

mDDR 64 MB 64 MB NA

FLASH memory 128 MB 128 MB NA

Audio 95 dB No NA

Operating

Temperature

range

Storage

Temperature

Operating

Humidity

Operating

altitude

Measurement

Category

Transient

protection

Pollution degree 2 2 2

Drop test 1 meter 1 meter 1 meter

Power Supply 4x AA Alkaline battery 90-270V AC/DC,

Power

consumption

Charging voltage

(BR-7000-T)

Charging duration

(BR-7000-T)

Booting time 30-sec 20-sec NA

Non-Rechargeable

Battery lifetime

320 x 240 128 x 160 NA

0 to 120F (-17.77C to

49C)

(-40 to 150F) (-40 to

65.5C)

95% R.H max 95% R.H max 95% R.H max

2000m 2000m 2000m

CAT IV 600V

NA 8.00kV

4xAA battery: 2W BR-7000-T battery: 2W

No 85-270V (±5%) NA

No 16Hrs NA

9 Hrs 9 Hrs NA

0°F to 120°F

(-17.77°C to 49°C)

-40°F to 150°F

(-40°C to 65.5°C)

CAT IV 600V CAT IV 600V

(1.2/50uS surge)

40-400 Hz

BR-7000-T: 7.2V;

LI-ION Battery

6x AA Alkaline Battery

6xAA battery:2W

AC line voltage

(Charging state): 10W

AC line voltage: 3W

0°F to 120°F

(-17.77°C to 49°C)

-40°F to 150°F

(-40°C to 65.5°C)

NA

NA

NA

31

Page 36

6. SPECIFICATIONS

Rechargeable

Battery lifetime

(BR-7000-T)

Leakage current

(non-rechargeable)

Leakage current

(rechargeable)

IP Rating IP52 IP40 IP52

Sampling rate 6.25kHz Signal:

Signal Response Audible beep,

Response time Smart mode: 750 mSec

Voltage

Measurement

NCV NA 90-600V AC

LED Indicator Green Flashing:

Operating

Frequency

Acoustic

Indication

Current output

(Low ) Energized

Current output

(High) Energized

Current output

(Low ) with BR7000-T Energized

No 10 Hrs NA

1.1 to 2.6uA 6 to 14uA NA

NA 1.2 to 4uA NA

62.5KSPS

32.768kHz: 256KSPS

NCV: 62.5 kSPS

bargraph display,

numeric display

Tip Sensor Energized:

300 mSec

Tip Sensor De-Energized:

750 mSec

NCV: 500 mSec

Battery monitoring:

5 Sec

NA 9-600V, DC to 400Hz

Signal Detection

Enrgized: 6.25kHz

De-Energized:

32.768kHz

1 kZ Piezo Buzzer NA NA

NA 53 mA rms NA

NA 92 mA rms NA

NA 53 mA rms NA

62.5 kSPS NA

Numeric display NA

Voltage measurement:

1.5 Sec

Battery monitoring:

5 Sec

Accuraccy:

(±10%) 9-109V AC/DC

(±5%) 110-600V AC/DC

Accuraccy: (±5%)

Red: Energized

OFF: De_Energized

Orange: Over voltage

Voltage measurement:

40-400 Hz

Energized: 6.25 kHz

De-Energized:

32.768 kHz

instantaneous

NA

NA

NA

Enrgized: 6.25kHz

De-Energized:

32.768kHz

32

Page 37

6. SPECIFICATIONS

Current output

(High) with BR7000-T Energized

Voltage output

(Low)

De-Energized

Voltage output

(High)

De-Energized

Voltage output

(Clamp mode)

De-Energized

Range Detection

(Open air)

Jaw Opening NA NA 2-in (5.08cm)

Fuse NA 3.15A , 600V MAX,

Dimensions 10.92x4.43x2.55-in

Weight 1.20 lb (0.544 kg) 1.30 lb (0.593 kg) 0.648 lb (0.294 kg)

NA 120 mA rms NA

NA 60 Vp-p NA

NA 120 Vp-p NA

NA 180 Vp-p 1.5 Vp-p

Smart mode

Pinpointing: Around

1.97-in (5 cm) radius

(±2%)

Direction indication:

Up to 5FT (152.4cm)

(±2%)

TIP Sensor: Energized

Pinpointing: Around

1.97-in (5 cm) (±1%)

Detection: Up to 22-FT

(670.56cm) (±1%)

TIP Sensor: De-Energized

Detection: Up to 14-FT

(426.72cm) (±5%)

NCV (40-400 Hz)

Pinpointing: Around

1.97-in (5cm) radius

(±5%)

Detection: Up to 4-FT

(121.92cm) (±5%)

(27.75x11.25x64.83cm)

NA NA

SLOW 5X20MM

8.5x4x2.2-in

(21.59x10.16x5.59cm)

NA

8.2x3.2x 1.68-in

(208.28 x 81.28x 42.67

mm)

33

Page 38

Page 39

AT-7000

Traceur de câble avancé

AT-7020

AT-7030

Manuel de l’utilisateur

Français

9/2014, Rev A

©2014 Amprobe Test Tools.

Tous droits réservés.

Page 40

Garantie limitée et limitation de responsabilité

Votre produit Amprobe sera exempt de défauts de matériaux et de fabrication pendant

1 an à compter de la date d'achat. Cette garantie ne s'applique pas aux fusibles, aux

piles jetables ou endommagées par accident, à la négligence, à la mauvaise utilisation,

à l'altération, à la contamination ou aux conditions anormales d'utilisation ou de

manipulation. Les revendeurs ne sont pas autorisés à prolonger toute autre garantie au nom

de Amprobe. Pour une réparation au cours de la période de garantie, retournez le produit

avec la preuve d'achat à un centre de service d'outils d'essai autorisé par Amprobe ou à

un revendeur ou un distributeur Amprobe. Voir la section Réparation pour plus de détails.

CETTE GARANTIE EST VOTRE SEUL RECOURS. TOUTES LES AUTRES GARANTIES – QU'ELLES

SOIENT EXPLICITES, IMPLICITES OU JURIDIQUES – Y COMPRIS LES GARANTIES IMPLICITES

D'ADÉQUATION À UN USAGE PARTICULIER OU MARCHAND, SONT EXCLUES. LE FABRICANT

NE SERA PAS RESPONSABLE DES DOMMAGES SPECIAUX, INDIRECTS, ACCESSOIRES OU

CONSECUTIFS PROVENANT DE TOUTE CAUSE OU THEORIE. Etant donné que certains pays ou

états n'autorisent pas l'exclusion ou la limitation des garanties implicites ou des dommages

directs ou indirects, cette limitation de responsabilité peut ne pas s'appliquer à vous.

Réparation

Tout outil Amprobe retourné pour réparation sous garantie ou hors garantie ou pour

l'étalonnage doit être accompagné des documents suivants :votre nom, le nom de votre

société, votre adresse, votre numéro de téléphone et la preuve d'achat. De plus, veuillez

inclure une brève description du problème ou du service demandé et incluez les cordons de

mesure avec le compteur. Les frais de réparation ou de remplacement non garantis doivent

être réglés sous forme de chèque, mandat, carte de crédit avec date d'expiration ou bon de

commande payable à Amprobe.

Réparation et remplacement couverts par la garantie – Tous les pays

Veuillez lire la déclaration de garantie et vérifier la pile avant de demander une réparation.

Pendant la période de garantie, tout outil de vérification défectueux peut être retourné

à votre distributeur Amprobe pour un échange de produit identique ou similaire. Veuillez

consulter la section « Où acheter » sur www.amprobe.eu pour obtenir une liste des

distributeurs près de chez vous. En outre, aux États-Unis et au Canada, les réparations sous

garantie et les unités de remplacement peuvent également être envoyés à un centre de

service Amprobe (voir adresse ci-dessous).

Réparation et remplacement non couverts par la garantie – États-Unis et Canada

Pour les réparations non couvertes par la garantie aux États-Unis et au Canada, l'appareil

doit être envoyé à un centre de service Amprobe. Appelez Amprobe ou renseignez-vous

auprès de votre point de vente pour les tarifs de réparation et de remplacement actuels.

États-Unis : Canada :

Amprobe Amprobe

Everett, WA 98203 Mississauga (Ontario) L4Z 1X9

Tél. : 888-993-5853 Tél. : 905-890-7600

Télécopie : 425-446-6390 Télécopie : 905-890-6866

Réparation et remplacement non couverts par la garantie – Europe

Les unités hors garantie européenne peuvent être remplacées par votre distributeur

Amprobe pour une somme modique. Veuillez consulter la section « Où acheter » sur le site

www.Amprobe.eu pour obtenir une liste des distributeurs près de chez vous.

Amprobe Europe*

Beha-Amprobe

In den Engematten 14

79286 Glottertal, Allemagne

Tél. : +49 (0) 7684 8009 - 0

www.Amprobe.eu

*(Correspondance uniquement : aucune réparation ou remplacement à cette adresse.

Clients européens, veuillez contacter votre distributeur.)

Page 41

Série AT-7000

TABLE DES MATIÈRES

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ ........................................................... 2

2. COMPOSANTS DU KIT ........................................................................................... 5

2.1 Récepteur AT-7000-R .....................................................................................................6

2.2 Transmetteur AT-7000-T ................................................................................................8

2.3 Kit câble d’essai et accessoires TL-7000 ........................................................................9

2.4 Pince de signal SC-7000 (AT-7030 Kit) ..........................................................................10

2.5 Ensemble de batteries rechargeables amplificatrices

de signal BR-7000-T (AT-7030 Kit) ................................................................................. 10

3. PRINCIPALES APPLICATIONS ................................................................................ 11

3.1 Tracer des fils sous tension

• CAPTEUR INTELLIGENT ..............................................................................................12

• CAPTEUR DE POINTE ..................................................................................................14

3.2 Tracer des fils hors tension

• CAPTEUR DE POINTE hors tension .............................................................................16

3.3 Identifier les disjoncteurs et les fusibles

• DISJONCTEUR Sous tension (Circuits sous tension) ..................................................18

• DISJONCTEUR Hors tension (Circuits hors tension) ..................................................20

3.4 Mode NCV ......................................................................................................................21

4. SPECIAL APPLICATIONS ........................................................................................ 22

4.1 Traçage de fils dans les circuits à protection DDFT ......................................................22

4.2 Trouver les sectionnements/ouvertures .......................................................................22

4.3 Trouver des courts-circuits ............................................................................................23

4.4 Tracer des fils dans un conduit métallique .................................................................24

4.5 Tracer des tuyaux et des conduits non métalliques .....................................................24

4.6 Tracer des fils blindés ....................................................................................................24

4.7 Tracer des fils souterrains ..............................................................................................25

4.8 Tracer des fils à basse tension et des câbles de données ............................................25

4.9 Trier des fils en faisceau ................................................................................................25

4.10 Aucun accès aux conducteurs dénudés (Pince de signal) ..........................................26

4.11 Localiser des charges (Pince de signal) .......................................................................27

5. MAINTENANCE - REMPLACEMENT DE LA PILE .................................................... 28

6. SPÉCIFICATIONS ..................................................................................................... 31

1

Page 42

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

Généralités

Pour votre propre sécurité et pour éviter d'endommager l'instrument, nous vous

recommandons de suivre les procédures indiquées ci-dessous :

NOTA : Avant et pendant les mesures, efforcez-vous de suivre les instructions.

• Assurez-vous que l'instrument électrique fonctionne correctement avant de l'utiliser.

• Avant de raccorder les conducteurs, assurez-vous que la tension présente dans le

conducteur est dans la plage de l'instrument.

• Conservez les instruments dans leur mallette de transport quand vous ne les utilisez

pas.

• Si le transmetteur ou le récepteur ne vont pas être utilisés pendant une longue

période, retirez les piles pour éviter toute fuite dans les instruments.

• Utilisez uniquement des câbles et des accessoires approuvés par Amprobe.

Précautions de sécurité

• Dans de nombreux cas, vous travaillerez avec des niveaux dangereux de tension et/

ou de courant. Il est par conséquent important d'éviter tout contact direct avec des

surfaces non isolées conduisant du courant. Portez des gants isolants et des vêtements

de protection appropriés dans les zones de tension dangereuse

• Ne mesurez pas la tension ou le courant dans des endroits humides ou poussiéreux

• Ne mesurez pas en présence de gaz, de matériaux explosifs ou de combustibles

• Ne touchez pas le circuit en essai si aucune mesure n'est en cours

• Ne touchez pas les pièces métalliques apparentes, les bornes non utilisées, les circuits,

etc.

• N'utilisez pas l'instrument s'il semble présenter un dysfonctionnement (à savoir si vous

remarquez des déformations, des cassures, une fuite de substances, une absence de

messages à l'écran, etc.)

Informations de sécurité

Ce produit est conforme à :

• UL/IEC/EN 61010-1, CAN/CSA C22.2 No. 61010-1, degré de pollution 2, catégorie de

mesure IV 600 V

• IEC/EN 61010-2-033

• IEC/EN 61010-2-032

• IEC/EN 61010-031 (câbles d'essai)

• EMC IEC/EN 61326-1

La catégorie de mesure IV (CAT IV) concerne les circuits directement connectés à la source

d'alimentation du service principal pour un bâtiment donné ou entre l'alimentation

électrique du bâtiment et le tableau de distribution principal. Un tel équipement peut

comprendre des compteurs électriques et des dispositifs de protection principaux contre les

surintensités.

Directives CENELEC

Les instruments sont conformes à la directive basse tension CENELEC 2006/95/CE et la

directive de compatibilité électromagnétique 2004/108/CE.

2

Page 43

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

� Avertissements : Lire avant utilisation

Pour éviter tout risque d'électrocution ou de blessure :

• Utilisez l'appareil de mesure comme indiqué dans ce manuel, dans le cas contraire la

protection fournie par l'instrument pourrait être compromise.

• Évitez de travailler seul pour pouvoir bénéficier d'une assistance.

• Ne mesurez jamais de courant CA lorsque les câbles d'essai sont insérés dans les prises

d'entrée.

• N'utilisez pas l'appareil de mesure dans des environnements humides ou sales.

• N'utilisez pas l'appareil s'il semble endommagé. Inspectez l'appareil avant utilisation.

Recherchez d'éventuelles fissures ou du plastique manquant. Faites particulièrement

attention à l'isolation autour des connecteurs.

• Inspectez les câbles d'essai avant utilisation. Ne les utilisez pas si l'isolation est

endommagée ou si le métal est exposé.

• Vérifiez la continuité des câbles d'essai. Remplacez les câbles d'essai endommagés

avant d'utiliser le multimètre.

• Seul du personnel qualifié peut se charger de l'entretien.

• Utilisez avec une grande prudence lorsque vous travaillez avec des conducteurs

ou barres omnibus exposés. Le contact avec le conducteur pourrait causer une

électrocution.

• Ne tenez pas le multimètre au-delà de la barrière tactile.

• N'appliquez jamais une tension plus élevée que la tension nominale, indiquée sur

l'appareil, entre les bornes ou entre une borne et la terre.

• Retirez les câbles d'essai de l'appareil avant d'ouvrir le boîtier ou le couvercle des piles

du multimètre.

• N'utilisez jamais le multimètre lorsque le couvercle des piles ou le boîtier est ouvert.

• Ne retirez jamais le couvercle des piles et n'ouvrez jamais le boîtier du multimètre sans

d'abord retirer les câbles d'essai d'un conducteur sous tension.

• Faites preuve de prudence en travaillant sur des tensions supérieures à 30 V ca. eff, 42

V ca crête ou à 60 V cc. Ces tensions posent des risques d'électrocution.

• N'essayez pas de mesurer des tensions qui peuvent dépasser la plage maximale du

multimètre.

• Utilisez les bornes, la fonction et la plage qui conviennent pour les mesures envisagées.

• Ne pas utiliser le multimètre à proximité de gaz explosifs, de poussière ou de vapeur.

• Lors de l'utilisation de sondes, placez vos doigts derrière les protège-doigts.

• Si vous effectuez des connexions électriques, raccordez le cordon commun avant de

raccorder le câble de test sous tension. Lors de la déconnexion, débranchez le cordon

de mesure sous tension avant de débrancher le cordon commun.

• Pour éviter les mauvaises lectures, ce qui peut poser des risques d'électrocution ou de

blessure corporelle, remplacez la pile dès que le voyant de pile faible s'affiche. Vérifiez

le fonctionnement du multimètre sur une source connue avant et après utilisation.

• Lors des réparations, n'utilisez que les pièces de rechange préconisées.

• Conformez-vous aux normes locales et nationales de sécurité. De l'équipement de

protection individuelle doit être utilisé pour éviter les chocs et les blessures lorsque des

conducteurs en fonctionnement sont exposés.

• Utilisez uniquement les câbles d'essai fournis avec le multimètre ou une sonde certifiée

UL de classe CAT IV 600 V ou de mesure plus élevée.

3

Page 44

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

Symboles utilisés dans ce produit

Statut de la batterie : affiche la charge de batterie restante

Accueil : retourne à l'écran d'accueil si sélectionné

Aide : accède au mode aide si sélectionné

Paramètres : accède au menu paramètres si sélectionné

Volume : affiche le volume selon quatre niveaux

Indicateur de sensibilité : affiche le niveau de sensibilité de 1 à 10.

Icône indiquant un système sous tension

Icône indiquant un système hors tension

99

Indicateur d'intensité du signal : indique l'intensité du signal de 0 à 99

SIGNAL

MAN/AUTO

�

T

J

CAT IV

B

V

)

P

=

Indique si le réglage de la sensibilité est en mode Manuel ou

Automatique

Indique si le volume est coupé.

Le verrou indique si le verrouillage automatique de la sensibilité est

actif (uniquement en mode sensibilité automatique)

Application et retrait des conducteurs sous tension dangereux

autorisés

Attention! Risque de choc électrique.

Attention! Reportez-vous aux explications de ce guide.

Cet équipement est protégé par une isolation double ou renforcée.

Prise de terre.