Page 1

AT-6000

Advanced Wire Tracers

AT-6020

AT-6030

User Manual

EN FR ES

NCV

Page 2

Page 3

AT-6000

Advanced Wire Tracer

AT-6020

AT-6030

User Manual

English

8/2017, 6009478 Rev B

©2017 Amprobe Test Tools.

All rights reserved. Printed in China.

Page 4

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for one

year from the date of purchase unless local laws require otherwise. This warranty does

not cover fuses, disposable batteries or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers are not

authorized to extend any other warranty on the behalf of Amprobe. To obtain service

during the warranty period, return the product with proof of purchase to an authorized

Amprobe Service Center or to an Amprobe dealer or distributor. See Repair Section for

details. THIS WARRANTY IS YOUR ONLY REMEDY. ALL OTHER WARRANTIES - WHETHER

EXPRESS, IMPLIED OR STATUTORY - INCLUDING IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY DISCLAIMED. MANUFACTURER

SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or

countries do not allow the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to you.

Repair

All Amprobe returned for warranty or non-warranty repair or for calibration should be

accompanied by the following: your name, company’s name, address, telephone number,

and proof of purchase. Additionally, please include a brief description of the problem or

the service requested and include the test leads with the meter. Non-warranty repair or

replacement charges should be remitted in the form of a check, a money order, credit card

with expiration date, or a purchase order made payable to Amprobe.

In-warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During

the warranty period, any defective test tool can be returned to your Amprobe distributor

for an exchange for the same or like product. Please check the “Where to Buy” section

on amprobe.com for a list of distributors near you. Additionally, in the United States and

Canada, in-warranty repair and replacement units can also be sent to an Amprobe Service

Center (see address below).

Non-warranty Repairs and Replacement – United States and Canada

Non-warranty repairs in the United States and Canada should be sent to an Amprobe

Service Center. Call Amprobe or inquire at your point of purchase for current repair and

replacement rates.

USA: Canada:

Amprobe Amprobe

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe distributor for a nominal

charge. Please check the “Where to Buy” section on beha-amprobe.com for a list of

distributors near you.

Beha-Amprobe*

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

beha-amprobe.com

*(Correspondence only – no repair or replacement available from this address. European

customers please contact your distributor.)

Page 5

AT-6000 Series

CONTENTS

1. PRECAUTIONS AND SAFETY MEASURES ............................................................. 2

2. KIT COMPONENTS ................................................................................................. 4

2.1 AT-6000-R Receiver ........................................................................................................5

2.2 AT-6000-T Transmitter ...................................................................................................7

2.3 CT-400 Signal Clamp (AT-6030 Kit) ...............................................................................10

3. MAIN APPLICATIONS ............................................................................................ 11

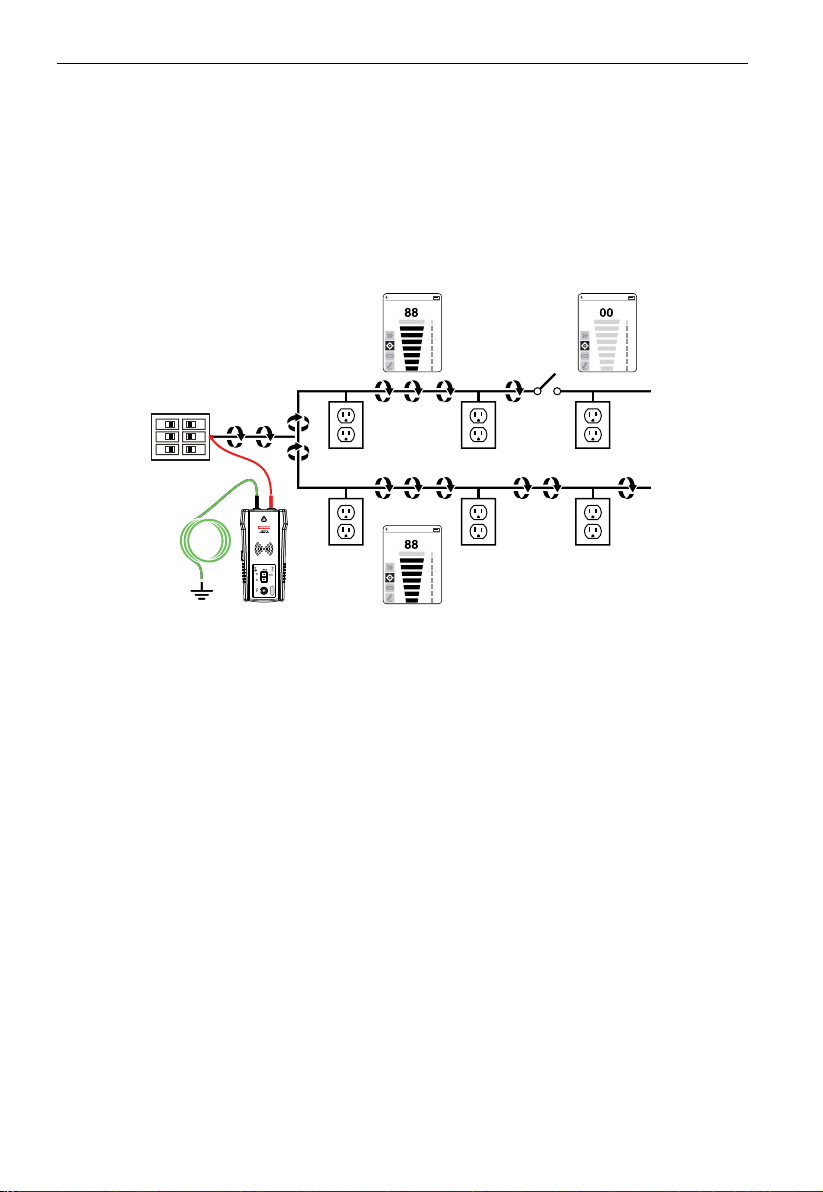

3.1 Tracing Energized and De-energized Wires .................................................................12

3.2 Identifying Breakers and Fuses (Energized and De-energized) ...................................15

3.3 Non-contact Voltage Mode (NCV) and Passive Tracing ................................................ 17

4. SPECIAL APPLICATIONS ........................................................................................ 18

4.1 GFCI-Protected Circuit Wire Tracing .............................................................................18

4.2 Finding Breaks/Opens ...................................................................................................18

4.3 Finding Shorts ...............................................................................................................19

4.4 Tracing Wires in Metal Conduit ...................................................................................19

4.5 Tracing Non-Metallic Pipes and Conduits ....................................................................20

4.6 Tracing Shielded Wires ..................................................................................................20

4.7 Tracing Underground Wires ..........................................................................................21

4.8 Tracing Low Voltage Wires and Data Cables ............................................................... 21

4.9 Sorting Bundled Wires ..................................................................................................21

4.10 Mapping a Circuit Using Test Leads Connection ........................................................22

4.11 Tracing Breakers on Systems with Light Dimmers ......................................................22

4.12 Signal Clamp - Closed Loop Circuits ............................................................................22

4.13 Signal Clamp - Mapping Circuits ..................................................................................24

5. MAINTENANCE ...................................................................................................... 25

5.1 Battery Replacement ......................................................................................................25

5.2 Fuse Replacement ...........................................................................................................28

6. SPECIFICATIONS ..................................................................................................... 29

1

Page 6

1. PRECAUTIONS AND SAFETY MEASURES

General

For your own safety and to avoid damage to the instrument it is suggested to follow the

procedures listed below:

NOTE: Before and during measurements be diligent to follow the instructions.

• Make sure that the electrical instrument is operating properly before use.

• Before attaching any of the conductors, make sure the voltage present in the

conductor is within the range of the instrument.

• Keep the instruments in their carrying case when not in use.

• If the Transmitter or Receiver will not be used for a long time, remove the batteries to

prevent leakage in the instruments.

• Use Amprobe approved cables and accessories only.

Safety precautions

• In many instances, dangerous levels of voltage and/or current may be present. Therefore,

it is important to avoid direct contact with any uninsulated current carrying surfaces.

Insulated gloves and protective clothing should be worn in hazardous voltage areas.

• Do not measure voltage or current in wet, damp or dusty places.

• Do not measure voltage in the presence of gas, explosive materials or combustibles.

• Do not touch the circuit under test if no measurement is being taken.

• Do not touch exposed metal parts, such as unused terminals and circuits.

• Do not use the instrument if it appears to be malfunctioning (i.e. if you notice

deformations, breaks, leakage of substances, absence of messages on the display, etc).

SYMBOLS

�

Caution! Refer to the explanation in this manual.

X

WARNING HAZARDOUS VOLTAGE. Risk of electric shock.

Consult user documentation.

The equipment is protected by double insulation or reinforced insulation.

T

Earth (Ground).

Fuse.

Battery.

®

Certified by CSA Group to North American safety standards.

Conforms to relevant South Korean EMC Standards.

Electromagnetic Compatibility:

Korea (KCC): Class A Equipment (Industrial Broadcasting & Communication Equipment)

[1]

This product meets requirements for industrial (Class A) electromagnetic wave

equipment and the seller or user should take notice of it. This equipment is intended for

use in business environments and is not to be used in homes.

Conforms to relevant Australian standards.

Complies with European Directives.

This product complies with the WEEE Directive marking requirements. The affixed

label indicates that you must not discard this electrical/electronic product in domestic

household waste. Product Category: With reference to the equipment types in the

WEEE Directive Annex I, this product is classed as category 9 “Monitoring and Control

Instrumentation” product. Do not dispose of this product as unsorted municipal waste.

[1]

2

Page 7

1. PRECAUTIONS AND SAFETY MEASURES

Safety information

The product complies with:

• UL/IEC/EN 61010-1, CAN/CSA C22.2 No. 61010-1, Pollution Degree 2, Measurement

CAT III 600 V MAX

• IEC/EN 61010-2-033

• IEC/EN 61010-2-032

• IEC/EN 61010-031 (test leads)

• EMC IEC/EN 61326-1

Measurement Category III (CAT III) is applicable to test and measure circuits connected

to the distribution part of the building’s low-voltage MAINS installation. This part of the

installation is expected to have a minimum of two levels of over-current protective devices

between the transformer and possible connecting points.

CENELEC Directives

The instrument conforms to CENELEC Low-voltage directive 2014/35/EU and Electromagnetic

compatibility directive 2014/30/EU.

X�Warnings: Read Before Using

To avoid the possibility of electric shock or personal injury:

• Use the Product only as specified in this manual or the protection provided by the

instrument may be compromised.

• Avoid working alone so assistance can be rendered.

• Test on a known signal source within the rated voltage range of the Product both

before and after use to ensure the Product is in good working conditions.

• Do not use the Product around explosive gas, vapor, or in damp or wet environments.

• Inspect the Product before use and do not use if it appears damaged. Check for cracks

or missing plastic. Pay particular attention to the insulation around the connectors.

• Inspect the test leads before use. Do not use if insulation is damaged or metal is exposed.

• Do not use the Product if it operates incorrectly. Protection may be impaired. When in

doubt, have the Product serviced.

• Check the test leads for continuity. Replace damaged test leads before using the Product.

• Have the Product serviced only by qualified service personnel.

• Use extreme caution when working around bare conductors or bus bars. Contact with

the conductor could result in electric shock.

• Do not hold the Product beyond the tactile barrier.

• Do not apply more than the rated voltage and CAT rating, as marked on the Product,

between the terminals or between any terminal and earth ground.

• Remove test leads from the Product before opening the Product case or battery cover.

• Never operate the Product with the battery cover removed or the case open.

• Use caution when working with voltages above 30 V AC RMS, 42 V AC peak, or 60 V

DC. These voltages pose a shock hazard.

• Do not attempt to connect to any circuit carrying voltage that may exceed the maximum

range of the Product.

3

Page 8

1. PRECAUTIONS AND SAFETY MEASURES

• Use the proper terminals, functions and ranges for your measurements.

• When using alligator clips, keep fingers behind the finger guards.

• Use only exact fuse replacement and specified replacement parts.

• When making electrical connections, connect the common test lead before

connecting the live test lead; when disconnecting, disconnect the live test lead before

disconnecting the common test lead.

• To avoid false readings that can lead to electrical shock and/or injury, replace or

recharge the batteries as soon as the low battery indicator appears. Check Meter

operation on a known source before and after use.

• Use only AA batteries, properly installed in the Meter case, to power the Product (see

Section 5.1: Battery Replacement).

• When servicing, use only specified user serviceable replacement parts.

• Adhere to local and national safety codes. Individual protective equipment must be used

to prevent shock and arc blast injury where hazardous live conductors are exposed.

• Only use the test lead provided with the Product or UL Listed Probe Assembly rated

CAT III 600 V or better.

• Do not use the HOT STICK (TIC 410A) to operate the AT-6000-R Receiver at voltages above 600 V.

• Remove the batteries if the Meter is not used for an extended period of time, or if

stored in temperatures above 122 °F (50 °C). If the batteries are not removed, battery

leakage can damage the Meter.

• Follow all battery care and charging instructions from the battery manufacturer.

This manual contains information and warnings that must be followed for safe operation

and maintenance of the instrument. If the Product is used in a manner not specified by the

manufacturer, the protection provided by the Product may be impaired. This Product meets water

and dust protection IP52 (Receiver) and IP40 (transmitter and signal clamp) per IEC 60529. Do NOT

operate outside during periods of rainfall. The Product is double insulated for protection per EN

61010-1 to CAT III 600 V.

CAUTION: Do not connect the Transmitter to a separate ground in Electrically Susceptible

Patient areas of a health care facility. Make the ground connection before disconnecting.

4

Page 9

2. KIT COMPONENTS

Your shipping box should include:

AT-6020 KIT AT-6030 KIT

AT-6000-R RECEIVER 1 1

AT-6000-T TRANSMITTER 1 1

TL-6000 TEST LEAD AND ACCESSORY KIT* 1 1

CC-6000 HARD CARRYING CASE 1 1

USER MANUAL 1 1

RECHARGEABLE BATTERIES - 12

BATTERY CHARGERS - 3

CT-400 SIGNAL CLAMP - 1

1.5 V AA (IEC LR6) BATTERY 12 -

*TL-6000 test lead and accessory kit includes:

• 2 x 1 m test leads (red, black)

• 1 x 7 m test lead (green)

Optional accessories:

HS-1 MAGNETIC HANGER

TL-7000-25M TEST LEAD (25 m long)

HOT STICK (TIC 410A)

• 2 x alligator clips (red, black)

• 1 x US Socket adapter

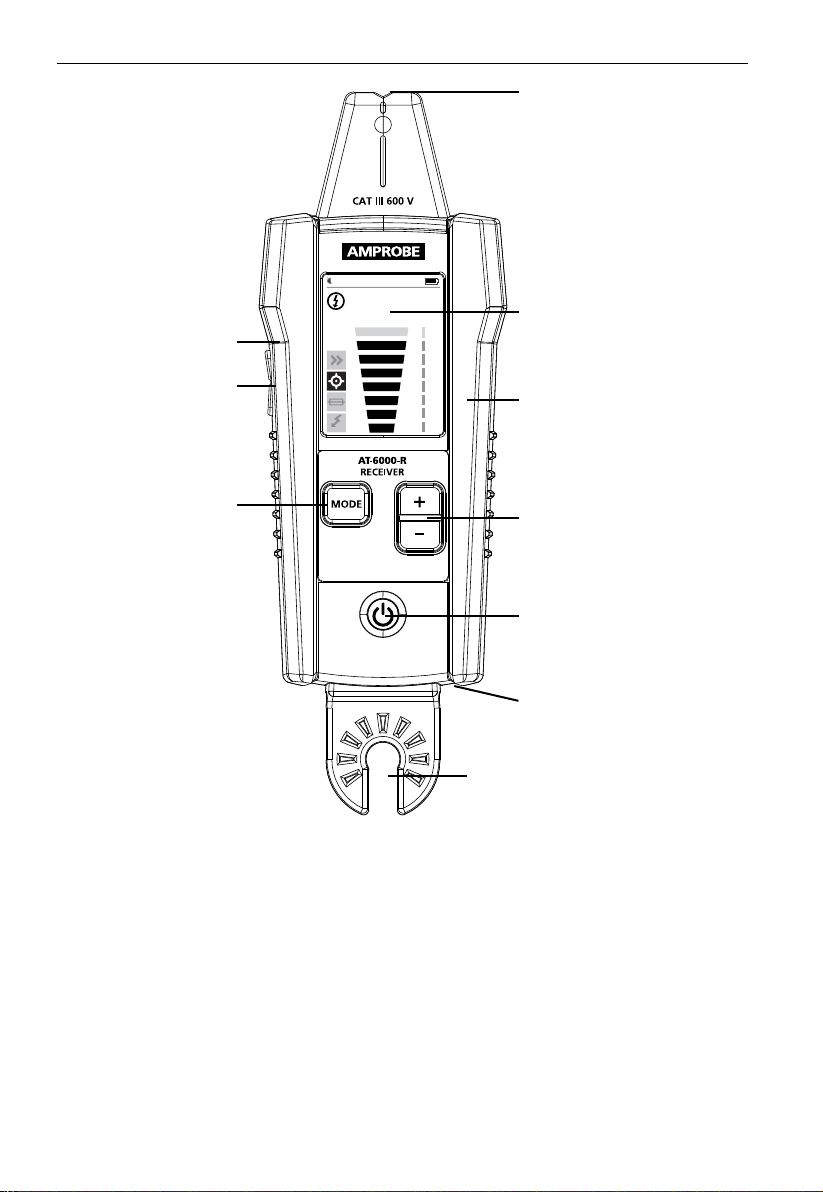

2.1 AT-6000-R Receiver

The AT-6000-R Receiver detects the signal in wires and cables using the following methods:

Active (using Transmitter)

The AT-6000-T Transmitter generates a signal capable of tracing either Energized or De-energized wires.

The main advantage this method is the ability to trace the path of the particular wire using

the Receiver. Since the signal is not present in any neighboring wires, the Receiver will

detect only the wire that is connected to the Transmitter.

The active tracing method is used when the Receiver is set to Quick Scan, Precision Tracing

or Breaker Locating.

Passive (without Transmitter)

The passive method utilizes the Receiver by tracing Energized wires between 90-600 V AC

through electromagnetic fields.

This method is both easy and convenient because it does not require the Transmitter.

However, the Receiver is not selective to a particular wire and will indicate any Energized

wire between 90-600 V AC.

This method is best for simple tracing applications where the wire is Energized and no other

wires are located nearby.

Passive tracing method is used when the Receiver is set to Non-contact voltage (NCV) detection mode.

Note: The Receiver will NOT detect signals from a wire through metal conduit or shielded

cable. Refer to Special Applications, section 4.4 “Tracing Wires In Metal Conduit” for

alternative tracing methods.

5

Page 10

2. KIT COMPONENTS

TIP SENSOR

TACTILE BARRIER

VOLUME

ADJUSTMENT

BUTTON (+/-)

FUNCTION BUTTON

Toggles between

modes:

- Quick Scan

- Precision Tracing

- Breaker Locating

- NCV-contact detecion

(Non-contact voltage)

Figure 2.1: Overview of AT-6000-R Receiver

88

NCV

LCD DISPLAY

Full color TFT display

RUBBER OVER

MOLDED ENCLOSURE

SENSITIVITY ADJUSTMENT

BUTTON (+/-)

POWER BUTTON

Turns unit On / Off

BATTERY COMPARTMENT

(Back side)

HOT STICK ATTACHMENT POINT

(Do not use for voltage higher

than 600 V)

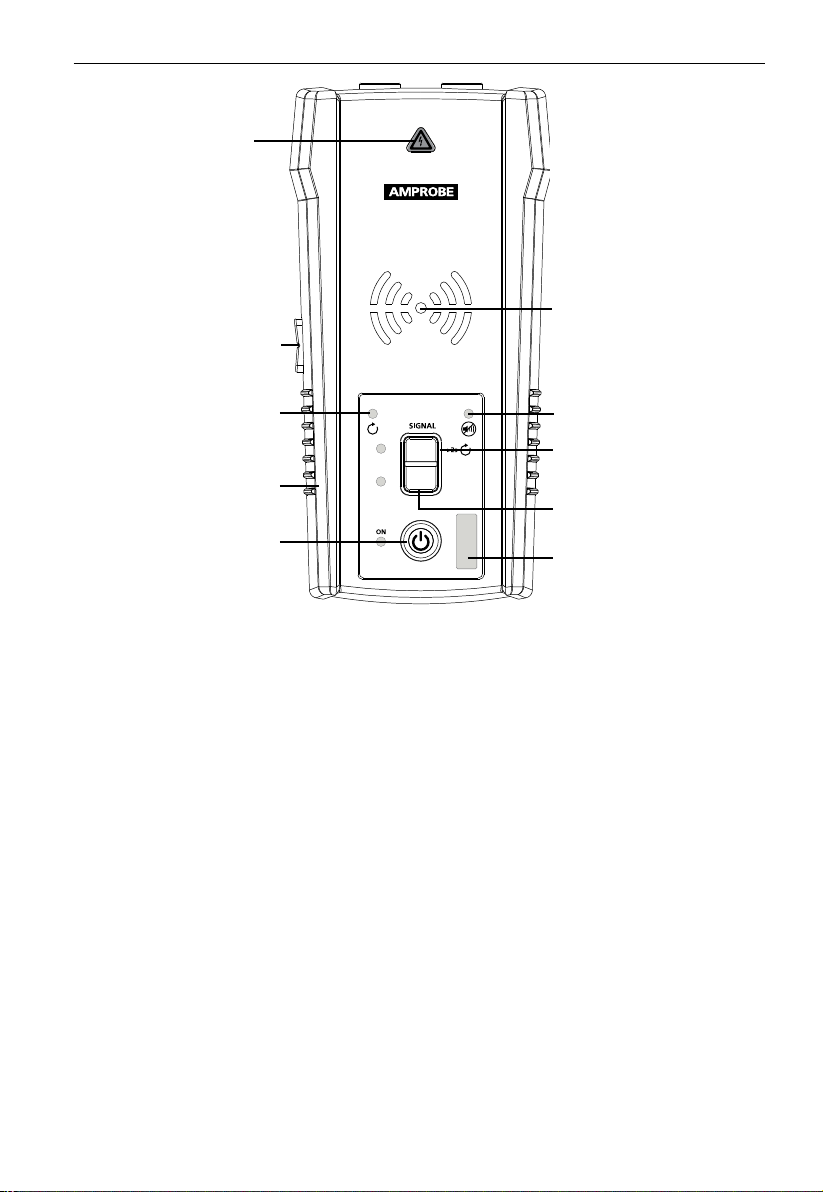

2.2 AT-6000-T Transmitter

6

Page 11

2. KIT COMPONENTS

The AT-6000-T Transmitter works on Energized and De-energized circuits up to 600 V AC/DC

in Category I through Category III electrical environments.

Transmitter signal modes:

High Signal (Hi) – The HIGH mode function is recommended for most wire tracing

applications on Energized and De-energized circuits including breaker location. This

function will be used the majority of the time.

Low Signal (Lo) – The LOW mode function is only appropriate for the most demanding and

precise wire tracing applications, as it limits the signal level generated by the Transmitter

in order to pinpoint the wire location more precisely. A lower signal level reduces coupling

to neighboring wires and metal objects, which avoids misreadings due to ghost signals. A

lower signal also prevents oversaturating the Receiver with a strong signal that covers too

large of an area.

Loop mode – This mode is initiated by pressing and holding this Hi button for two seconds.

It should be used when working with closed loop De-energized circuits, such as shorted

wires, shielded cables or De-energized wires that are grounded on the far-end.

How is the Loop function different from the Hi or Lo settings when using test leads?

Both HIGH and LOW modes generate a signal in all open branches of the De-energized

circuit. This is useful when tracing open wires. Hi/Lo modes will NOT work on wires that are

grounded on the far-end because the signal cannot be generated.

Loop mode generates a signal (current flow) in closed loop De-energized circuits only. Loop

mode is used to pinpoint the location of a short (because the current will not be able to

flow in open branches) and to trace wires that are grounded on the far end (because the

loop is closed via grand connection).

Note: Loop mode only works on De-energized circuits. It is automatically disabled when the

Transmitter is connected to an Energized line with test leads.

Figure 2.2a: Generating a signal with HIGH and LOW modes

Figure 2.2b: Generating a signal in Loop mode

7

Page 12

2. KIT COMPONENTS

Working with the Transmitter:

When the Transmitter is on and connected to the circuit with test leads, it checks for

voltage. A red Voltage Warning Indicator will light up if the Transmitter detects dangerous

voltage levels above 30 V AC/DC.

IMPORTANT!

The Voltage Warning Indicator light will blink when overvoltage (> 650 V AC/DC) is

detected. In case of overvoltage immediately disconnect the Transmitter from the circuit.

If the High (Hi) or Low (Lo) Signal button is pressed momentarily, the Transmitter starts

generating a tracing signal. Based on the detected voltage, the Transmitter automatically

switches to either:

• Energized mode (30 to 600 V AC/DC) generating 6 kHZ frequency

• De-energized mode (0 to 30 V AC/DC) generating 33 kHz frequency

Energized mode uses a lower transmission frequency (6 kHz) than De-energized mode

(33 kHz) to reduce signal coupling between wires. De-energized mode requires a higher

frequency in order to generate a reliable signal.

Energized mode: In Energized mode, the Transmitter draws a very low current from the

Energized circuit and generates a 6 kHz signal. This is a very important feature of the

Transmitter, since drawing current does not inject any signal that would harm sensitive

equipment connected to the circuit. The signal is also generated in a direct path between

the Transmitter and the power source, thus NOT placing a signal onto any branches enabling

wiring tracing directly back to the breaker panel. Please note that due to this feature, the

Transmitter has to be connected on the load side of the circuit.

De-energized mode: In De-energized mode, the Transmitter injects a 33 kHz signal onto the

circuit. In this mode, the signal will travel though all the circuit branches because it is

injected. The high frequency/low energy signal will not harm any sensitive equipment.

8

Page 13

2. KIT COMPONENTS

VOLTAGE WARNING

INDICATOR

1. Red: Energized

2. Off: De-energized

3. Blinking: Overvoltage

VOLUME

ADJUSTMENT

BUTTON (+/-)

AT-6000-T

TRANSMITTER

TRANSMISSION MODE

INDICATOR

LOOP MODE INDICATOR

RUBBER OVERMOLDED

ENCLOSURE

ON / OFF BUTTON

HI

LO

MUTE INDICATOR

HIGH SIGNAL MODE

Press >2s for Loop mode

LOW (PRECISION) MODE

BATTERY STATUS

Figure 2.3: Overview of AT-6000-T Transmitter

ON/OFF: Short press to turn the Transmitter on. Long press >2s to turn the Transmitter off.

Volume adjustment: The volume can be changed by short presses on VOLUME UP/DOWN

buttons. In addition to mute, four volume levels are available. The chosen volume level will

be shown on LED display for a short time. If sound is muted, the MUTE LED light will be on.

The sound pattern is different depending on chosen operating mode.

Voltage Warning light: The warning light will be ON for Energized circuits (30 to 600 V

AC/DC), OFF for De-energized circuits (0 > 30 V AC/DC), and BLINKING if an overvoltage is

detected (> 650 V AC/DC).

LED display:

The LED diodes will blink with different rhythm depending on the chosen operating mode.

Transmitting in HIGH mode – Fast blinking,

Transmitting in LOW mode – Slow blinking,

Transmitting in LOOP mode – Alternating blinking.

High mode: Short press on HI pushbutton to turn on HIGH transmitting mode. Second short

press on HI button to turn off transmitting.

Low mode: Short press on LO pushbutton to turn on LOW transmitting mode. Second short

press on LO button to turn off transmitting.

Loop mode: Long press (>2s) on HI pushbutton to turn on Loop mode. Short or long press on

HI button to turn off Loop mode.

9

Page 14

2. KIT COMPONENTS

2.3 CT-400 Signal Clamp

(included with AT-6030 option for AT-6020)

The Signal Clamp accessory is used for applications when where is no access to the bare

conductors. The clamp attachment enables the Transmitter to induce a signal through the

insulation into either wires. The clamp works on low impedance closed circuits.

CONNECTORS TO

TRANSMITTER

JAW

TACTILE

BARRIER

JAW

RELEASE

TEST LEAD

Figure 2.4: Overview of CT-400 Signal Clamp

10

Page 15

3. MAIN APPLICATIONS

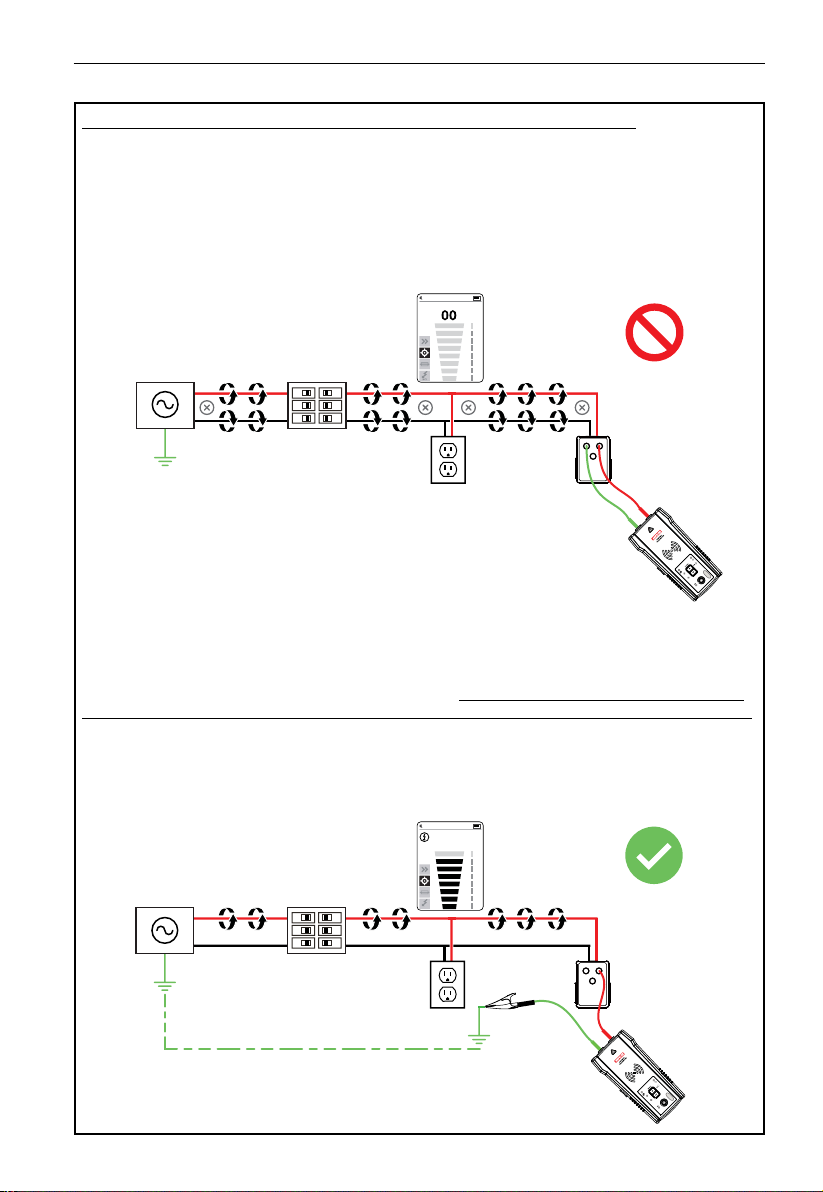

X� IMPORTANT NOTICE, PLEASE READ BEFORE STARTING TRACING

Avoiding signal cancellation problems with a separate ground connection

The signal generated by the Transmitter creates an electromagnetic field around the wire.

This field is what is detectable by the Receiver. The clearer this signal, the easier it is to trace

the wire.

If Transmitter is connected to two adjacent wires on the same circuit (for example, hot and

neutral wires on a Romax cable), the signal travels in one direction through the first wire

and then returns (in opposite direction) through the second. This causes the creation of two

electromagnetic fields around each wire with opposite direction. These opposing fields will

partially or completely cancel each other out, making wire tracing difficult if not impossible.

To avoid the cancellation effect, a separate ground connection method should be used.

The red test lead of the Transmitter should be connected to the hot wire of the circuit you

wish to trace, and the green lead to a separate ground, such as water pipe, ground stake,

metal grounded structure of the building, or outlet ground connection of an outlet on a

different circuit. It is important to understand that an acceptable separate ground is NOT

the grounding terminal of any receptacle on the same circuit as the wire you wish to trace.

If hot wire is Energized and the Transmitter is properly connected to a separate ground,

the red LED on the Transmitter will light up. The separate ground connection creates

maximum signal strength because the electromagnetic field created around the hot wire is

not being cancelled by a signal on the return path flowing along an adjacent wire (hot or

neutral) in the opposite direction, but rather through the separate ground circuit.

11

88

NCV

Page 16

AT-6000-T

TRANSMITTER

3. MAIN APPLICATIONS - TRACING ENERGIZED AND DE-ENERGIZED WIRES

3.1 Tracing – Energized and De-energized Wires

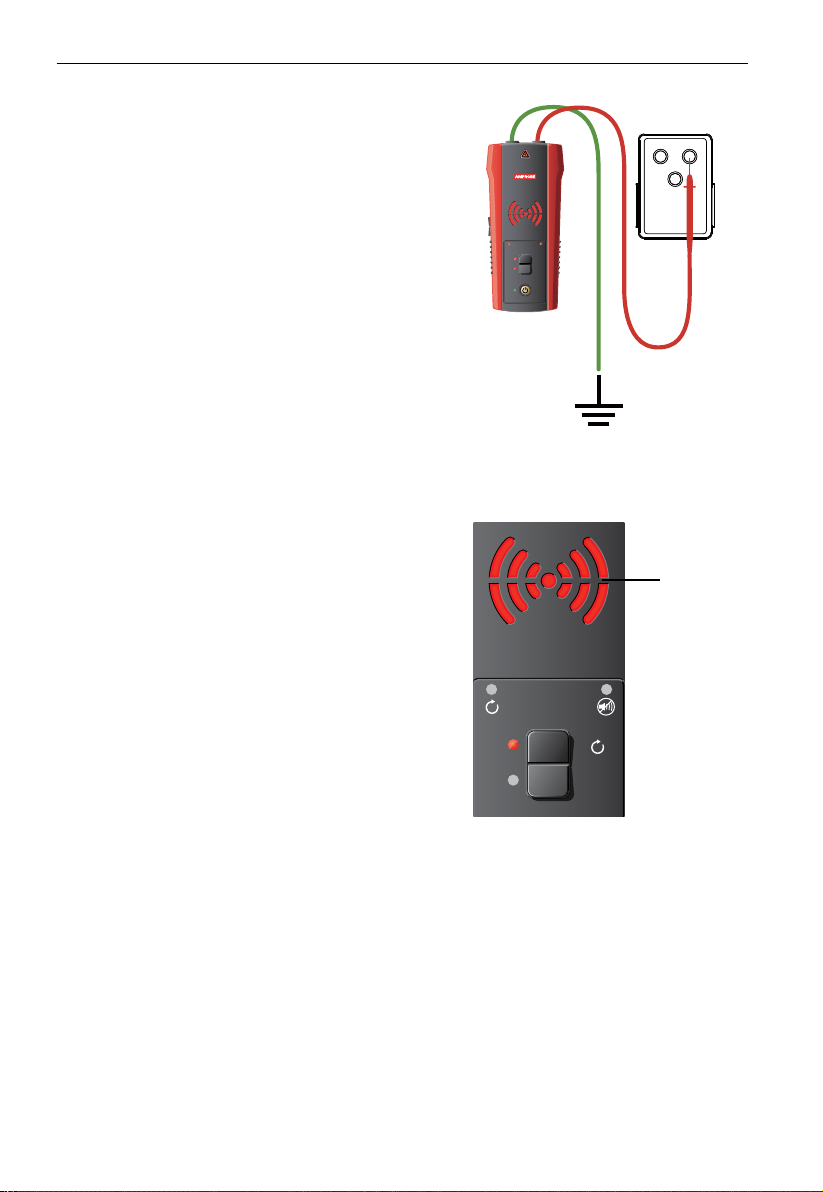

Connecting test leads to the Transmitter

1. Connect the green and red test leads to the

Transmitter (polarity does not matter).

2. Plug the socket adapter onto the receptacle and

connect the red lead to the Energized hot wire

(on the load side of the system). The signal will

ONLY be transmitted between the load-side

to which the Transmitter is connected and the

source of power (see Figure 3.1a).

3. Connect the green wire to a separate ground

(metal building structure, metal water pipe, or

ground wire on a separate circuit).

*Note: Please note that if working with GFCI

protected circuits, this method will trip the GFCI

protection. Refer to Special Applications, section 4.1

“GFCI-Protected Circuit Wire Tracing” for alternative

tracing methods.

Setting up the AT-6000-T Transmitter

1. Press ON/OFF key to turn on the Transmitter.

2. Verify that the test leads are properly

connected; the red LED voltage status

light should be on for circuits with voltage

above 30 V AC/DC, and it should be off for

De-energized circuits below 30 V AC/DC.

Note: Make sure to use the separate ground

connection as described above.

3. Select HIGH signal mode by pressing HI for

most applications. Screen will appear as

shown in Figure 3.1b. The LED display will

quickly begin to blink.

Note: The LOW signal precision mode can be

used to limit the signal level generated by the

Transmitter in order to more precisely pinpoint

wire location. A lower signal level reduces coupling

to neighboring wires and metal objects and helps

to avoid misreading due to ghost signals. A lower

signal also helps to prevent oversaturating the

Receiver with a strong signal that covers too large

an area. The LOW mode function is only used

for the most demanding and precise wire tracing

applications.

AT-6000-T

TRANSMITTER

SIGNAL

>2s

HI

LO

ON

Figure 3.1a: Proper connection with

separate ground

BLINKING

SIGNAL

>2s

HI

LO

Figure 3.1b: Transmitter indicator

showing signal in HIGH mode

12

Page 17

3. MAIN APPLICATIONS - TRACING ENERGIZED AND DE-ENERGIZED WIRES

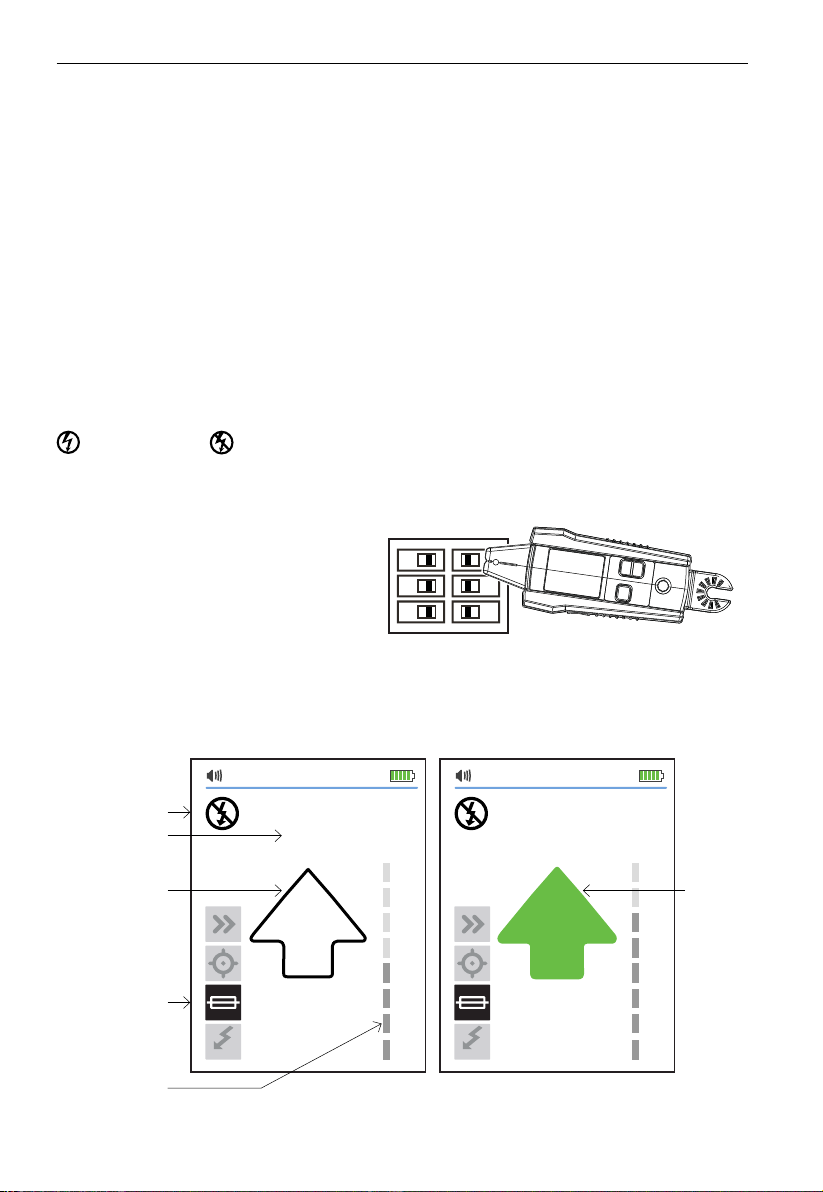

Using the AT-6000-R Receiver in Quick Scan Mode

Quick Scan mode detects wires at a longer distance (between a wire and the Receiver) but

with less precision than Precision Tracing or Breaker modes. This feature is used to verify that

the tracing signal is present and to quickly follow the path of the wire. Switch to Precision

Tracing mode to precisely pinpoint the wire, or to Breaker mode to locate a breaker.

1. Press ON/OFF push button to turn on the Receiver. It will automatically start in Quick

Scan mode, which is the default.

2. Scan a target area with the Tip Sensor to find a signal, then begin tracing the detected

wire. Increase or decrease sensitivity of the Receiver by pressing + or - on the keypad as

necessary.

3. For best results while tracing Energized wires, align groove on the Tip Sensor with wire

direction as shown in Figure 3.1c and Figure 3.1d. Signal may be not detected if not

properly aligned. To verify wire direction, periodically rotate the Receiver 90 degrees.

Signal strength will be the highest when wire is aligned with the Tip Sensor groove.

Depending on the detected signal, the Receiver automatically switches to either

Energized

manual setup is necessary.

Note: For best results, keep the Receiver at least 3 feet away from the Transmitter and test

leads to minimize signal interference.

or De-energized mode, and displays this information on the LCD. No

NC V

NC V

Figure 3.1c: Signal not detected Figure 3.1d: Signal detected

13

Page 18

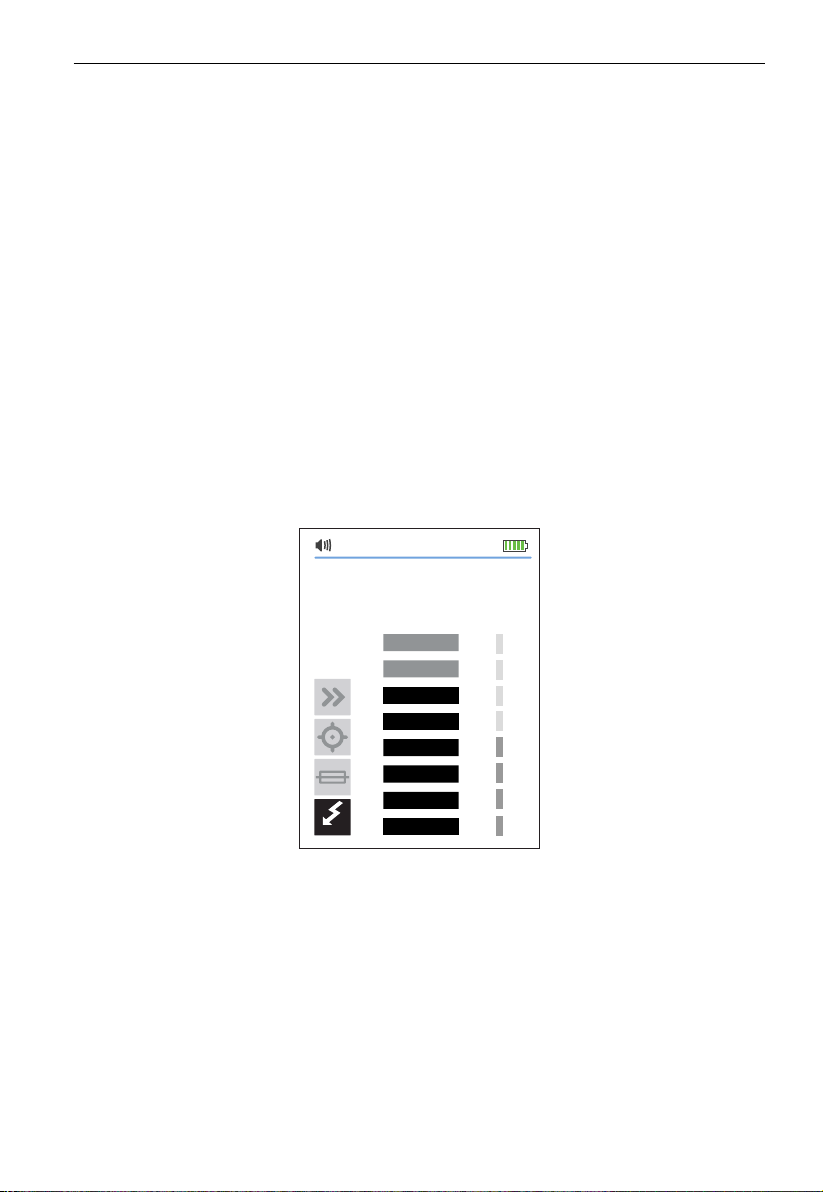

3. MAIN APPLICATIONS - TRACING ENERGIZED AND DE-ENERGIZED WIRES

Using the AT-6000-R Receiver in Precision Tracing Mode

Use Precision Tracing mode to precisely pinpoint the wire location or the place of the fault.

The Receiver will indicate detected signal strength using a two digit readout, bar graph and

sound.

1. Press the MODE button until the Precision Tracing function is selected.

2. Scan target area with the Tip Sensor to find the highest signal level. While tracing,

periodically adjust sensitivity to keep the signal strength near 50. Increase or decrease

sensitivity by pressing + or - on the keypad. If the signal is too strong for precise

locating, change the Transmitter to LOW mode.

3. For best results while tracing Energized wires, align groove on the Tip Sensor with wire

direction as shown in Figure 3.1e. Signal may be not detected if not properly aligned.

To verify wire direction, periodically rotate the Receiver 90 degrees. Signal strength will

be the highest when wire is aligned with the Tip Sensor groove.

Depending on the detected signal, the Receiver automatically switches to either

Energized

manual setup is necessary.

or De-energized mode, and displays this information on the LCD. No

Align

Figure 3.1e: Aligning the tip sensor groove

Note: For best results, keep the Receiver at least 3 feet from the Transmitter and test leads

to minimize signal interference.

Sound volume

Energized

88

Quick Scan

Precision Tracing

Breaker Locating

Non-contact voltage

detection, passive tracing

NC V

Figure 3.1f: Screen display

Tip

groove

Battery status

Signal strength (0-99)

Sensitivity level (1-8)

Bargraph - proportional

to signal strength

14

Page 19

3. MAIN APPLICATIONS - TRACING ENERGIZED AND DE-ENERGIZED WIRES

AT-6000-T

TRANSMITTER

ON

HI

LO

SIGNAL

>2s

3.2 Identifying Breakers and Fuses (Energized and De-energized)

Breaker mode automatically adjusts the sensitivity of the Receiver. As a result, the Receiver

will pinpoint and indicate just one correct breaker. This enhancement helps to remove signal

strength analysis from the breaker identification process that is typical for less advanced

wire tracers.

Note: For breaker locating, a simplified direct connection to hot and neutral wires can be

used because these wires are separated at the breaker panel. There is no risk of signal

cancellation effect if wires are at least a few inches away from each other. However, the

separate ground connection (see pg. 11) should be used for superior results specifically if

wires need to be traced in addition to breaker identification.

The simplified direct connection to hot and neutral wire will NOT trip the GFCI circuit.

AT-6000-T

TRANSMITTER

SIGNAL

>2s

HI

LO

ON

Figure 3.2a: Simplified direct connection

Connecting the test leads

1. Connect the Transmitter using either simplified direct connection or separate ground

connection.

2. If the simplified direct connection method is used, connect the test leads directly to

the hot and neutral wires. While locating a breaker, wires will not be traceable as the

signals will cancel each other out.

3. For separate ground connection, first connect the red lead to the Energized hot wire

on the load side of the system. The signal will ONLY be transmitted between the outlet

to which the Transmitter is connected and the source of power.

4. Connect the green lead to a separate ground, such as a metal building structure, metal

water pipe, or ground wire on a separate circuit.

Setting up the AT-6000-T Transmitter

1. Press the ON/OFF key to turn on the Transmitter.

2. Verify that the test leads are properly connected. The red LED voltage status light will

illuminate for Energized circuits with a voltage above 30 V AC/DC. If the voltage is

De-energized, the light will be off.

3. Select the HIGH signal mode for Breaker Locating.

Figure 3.2b: Separate ground connection

(Preferred)

15

Page 20

3. MAIN APPLICATIONS – LOCATING BREAKERS

Using the AT-6000-R Receiver

1. Press the ON/OFF push button to turn on the Receiver and continue pressing the MODE

button until Breaker Locating mode is selected.

2. Align the groove on the Tip Sensor with the breaker lengthwise (See Figure 3.2c).

3. Scan all breakers in any order. Breakers can be scanned multiple times. The Receiver

records the highest signal level and will automatically adjust sensitivity. The Receiver

may beep and the green arrow may light up several times during this step.

4. Locate the breaker by scanning all breakers again; the Receiver should indicate only

one breaker.

Important note: Differentiation in breaker designs, height and internal contact structure

may affect the precision of breaker identification. For most reliable results, remove the

breaker panel cover and perform a scan on the wires instead of the breakers.

If more than one breaker is indicated during the last step, continue scanning the indicated

breakers until only one is positively identified.

Depending on the detected signal, the Receiver automatically switches to either Energized

or De-energized mode, and displays this information on the LCD. No manual setup

necessary. The automatic sensitivity adjustment can be reset or adjusted using the +/- buttons.

Usage Tip: The accuracy of breaker

identification results can be verified by

switching the Receiver to Precision Tracing

mode and checking that the signal level of

the breaker identified by the Receiver is

the highest among all the breakers.

Before starting the next locating process

for new circuit or a branch, connect the

Transmitter and reset the Receiver by

either pressing + button to select high

sensitivity or switching the Receiver off

and then on.

Energized/

De-energized

signal

detected

Signal

Strength

55

Figure 3.2c: Aligning the Tip

Sensor groove with the breaker

75

is

Breaker

searching

Breaker

locating

Sensitivity

level

NC V

Breaker

found

NC V

Figure 3.2d: Reading the Receiver screen

16

Page 21

3. MAIN APPLICATIONS – LOCATING BREAKERS

3.3 Non-contact Voltage Mode (NCV) and Passive Tracing

The NCV (Non-Contact Voltage) mode is used to verify if the wire is Energized and to

perform tracing without the use of the Transmitter. The Receiver will detect and trace an

Energized cable if the voltage is between 90 V and 600 V AC and between 40 and 400 Hz.

No current flow is necessary.

Note: For safety, always verify that wires are De-energized with an additional tester before

working with them.

NCV mode operation

1. Press ON/OFF push button to turn on the Receiver.

2. Continue pressing MODE button until the Non-Contact Voltage function is selected.

Passive tracing

Scan the target area with the Tip Sensor to find the highest signal level. While tracing,

periodically adjust the sensitivity to keep the signal strength near 50. Increase or decrease

sensitivity by pressing.

Verifying if wire is Energized

Hold the Receiver with the Tip Sensor against the wire. For precise pinpointing of hot wire

versus neutral wire, increase or decrease sensitivity by pressing + or - on the keypad.

75

NC V

Figure 3.3: Voltage detection in NCV mode using Tip Sensor

17

Page 22

4. SPECIAL APPLICATIONS

4.1 GFCI-Protected Circuit Wire Tracing: Connecting the AT-6000-T Transmitter to

GFCI Protected Circuits

Connecting the Transmitter to an Energized GFCI protected circuit using a separate ground

method will trip the GFCI protection. Use the following methods to work with GFCI

protected circuits. For a De-energized GFCI-protected outlet that is not tripped, you can

connect test leads directly to the outlet contacts using the De-energized Tip Sensor mode.

Method 1 – Bypass the GFCI circuitry to avoid tripping GFCI:

(for Energized GFCI-protected outlets only)

• Remove the protective receptacle wall plate.

• Using the alligator clip, attach the red test lead to the screw to connect the Energized

hot wire to the receptacle.

• Connect the green test lead using a separate ground method.

• Perform tracing as described in the Quick Scan or Precision Tracing sections.

Method 2 – Do NOT use separate ground to avoid tripping GFCI:

(for GFCI-protected outlets and breakers)

• Connect the Transmitter with the test leads to the Neutral and Hot wires.

• Perform tracing as described in one of the following modes: Quick Scan, Precision

Tracing or Breaker Locating.

Note: This type of connection causes signal coupling and reduces signal strength. If the

signal is too weak or untraceable, use Method 3.

Method 3 - De-energize the circuit:

(for GFCI-protected breakers)

• Connect the Transmitter directly to the wire as described in wire tracing modes (Quick

Scan and Precision).

• Perform tracing as described in one of the following modes: Quick Scan, Precision

Tracing or Breaker Locating.

4.2 Finding Breaks/Opens

It is possible to pinpoint the exact location where a wire is broken using the Precision

Tracing mode, even if the wire is located behind walls, floors or ceilings.

1. Make sure that wire is De-energized.

2. Use the steps described in the Precision Tracing mode to connect the Transmitter and

perform tracing.

3. For best results, ground all De-energized wires that run in parallel with the black test lead.

Figure 4.2: Locating a break or open

18

Page 23

4. SPECIAL APPLICATIONS

The tracing signal generated by the Transmitter is conducted along the wire as long as there is

continuity in the metal conductor. To find a fault, trace the wire until the signal stops. To verify

the fault’s location, move the Transmitter to the other end of the wire and repeat, tracing from

the opposite end. If signal stops at the exact same location, the fault has been located.

Note: If the place of the fault is not found, the result may be a high resistance break

(partially open circuit). Such a break would stop higher currents from flowing but will

conduct the tracing signal through the break. Such faults will not be detected until the wire

is completely open.

4.3 Finding Shorts

Shorted wires will cause a breaker to trip. To correct this, disconnect the wires and make

sure the ends of the wires on both sides of the cable are isolated from each other and other

wires or loads.

1. Connect the Transmitter with the test leads to the circuit as shown in Figure 4.3.

2. Turn the Transmitter to Loop mode by pressing HIGH button for two seconds. Verify that

the Loop LED is ON.

3. Setup the Receiver to a wire tracing mode (either Quick Scan or Precision Tracing).

Start tracing the cable until the signal stops. To verify the place of the fault, move the

Transmitter to the other end of the wire and repeat tracing from the opposite end. If the

signal stops at the exact same location the fault has been located.

Figure 4.3: Tracing a cable to find shorts

Note: This method will be affected by signal cancellation effect. Expect a relatively weak signal.

4.4 Tracing Wires in Metal Conduit

The Receiver is unable to pick up the signal from a wire through a metal conduit. The metal

conduit will completely shield the tracing signal.

Note: The Receiver will be able to detect wires in a non-metallic conduit. For these

applications follow general tracing guidelines.

To trace wires in a metal conduit:

1. Use the Quick Scan or Precision Tracing modes.

2. Open junction boxes and use the Receiver Tip Sensor to detect which wire in the

junction box is carrying the signal.

3. Move from junction box to junction box to follow the path of the wire.

Note: Applying a signal directly to the conduit will send the signal through all the conduit

branches, making tracing a particular conduit path impossible.

19

Page 24

4. SPECIAL APPLICATIONS

4.5 Tracing Non-Metallic Pipes and Conduits

The Transmitter can indirectly trace plastic conduits and pipes using the following steps:

1. Insert fish tape or wire inside the conduit.

2. Connect the Transmitter with the red test lead to the fish tape and the green ground

wire to a separate ground (see wire tracing section 3.1 for further set-up instructions).

3. Set the Receiver to Quick Scan or Precision Tracing modes to trace the conduit.

4. The Receiver will pick up the signal conducted by the fish tape or wire through the conduit.

4.6 Tracing Shielded Wires

Shielded wire prevents the Receiver from detecting a tracing signal when following the

standard user instructions. To effectively trace shielded wire, follow these procedures.

If shielded wire is grounded at the far-end:

1. Setup Transmitter in Loop mode by pressing HIGH button for two seconds. Verify that

the Loop LED is ON.

2. Disconnect the ground on the near-end of the shielded wire and connect the shield to

one of the terminals of the Transmitter (polarity does not matter) with a test lead.

3. Connect the second output of the Transmitter to a separate ground.

4. Set the Receiver to a wire tracing mode to trace the shield (refer to section 3.1).

Figure 4.6a: Tracing a shielded wire grounded at the far-end

If shielded wire is disconnected from ground at the far-end:

1. Set the Transmitter to a wire tracing mode (see section 3.1).

2. Disconnect the ground on the near-end of the shielded wire and connect the shield to

one of the terminals of the Transmitter (polarity does not matter) with a test lead.

3. Connect the second output of the Transmitter to a separate ground.

4. Set the Receiver to a wire tracing mode to trace the shield.

Figure 4.6b: Tracing a shielded wire disconnected from the ground at far-end

20

Page 25

4. SPECIAL APPLICATIONS

4.7 Tracing Underground Wires

The AT-6000 can trace Energized and De-energized wires underground the same way it can

locate wires behind walls or floors.

Perform tracing using a separate ground connection. The HOT STICK (TIC 410A) attachment can

be used to make tracing more ergonomic and convenient.

Figure 4.7: Tracing Underground Wires

4.8 Tracing Low Voltage Wires and Data Cables

The AT-6000 can trace data, audio and thermostat cables (to trace shielded data cables, refer

to section 4.6 “Tracing Shielded Wires”).

Trace data, audio, and thermostat cables

1. Connect the Transmitter using the separate ground method (see section 3.1).

2. Set the Receiver to a wire tracing mode and trace the wire.

4.9 Sorting Bundled Wires

Identify a specific wire in a bundle

1. Connect the Transmitter and set to a wire tracing mode. If connecting to an Energized

wire, make sure the Transmitter is connected on the load side.

2. Select a wire tracing mode on the Receiver.

3. One at a time, pull each wire away from the others and touch it with the Tip Sensor. The

strongest signal indicates the proper wire in the bundle.

4. Adjust the Receiver sensitivity as required with +/- buttons.

Figure 4.9: Identifying a specific wire in a bundle

21

Page 26

4. SPECIAL APPLICATIONS

4.10 Mapping a Circuit using Test Leads Connection

Mapping a circuit can be only performed on a De-energized circuit when using test leads

connection.

1. Switch the breaker to the OFF position.

2. Set up the Transmitter and Receiver as described in the Precision Tracing section 3.1.

3. Scan face plates of receptacles and wires connecting loads with the Tip Sensor of the

Receiver

4. All the wires, receptacles and loads that have a strong signal as indicated by the Receiver

are connected to the breaker.

Figure 4.10: Mapping a circuit using test leads connection

4.11 Tracing Breakers on Systems with Light Dimmers

Light dimmers can produce a significant amount of electrical “noise” that consists of

multi-frequency signals. In some rare situations, the Receiver can misread this noise, often

called a “ghost” signal, as a Transmitter - generated signal. Therefore, the Receiver may

provide wrong readings.

When locating breakers or fuses on systems with light dimmers, the dimmer should be off

(the light switch is off). This prevents the Receiver from indicating a wrong breaker/fuse.

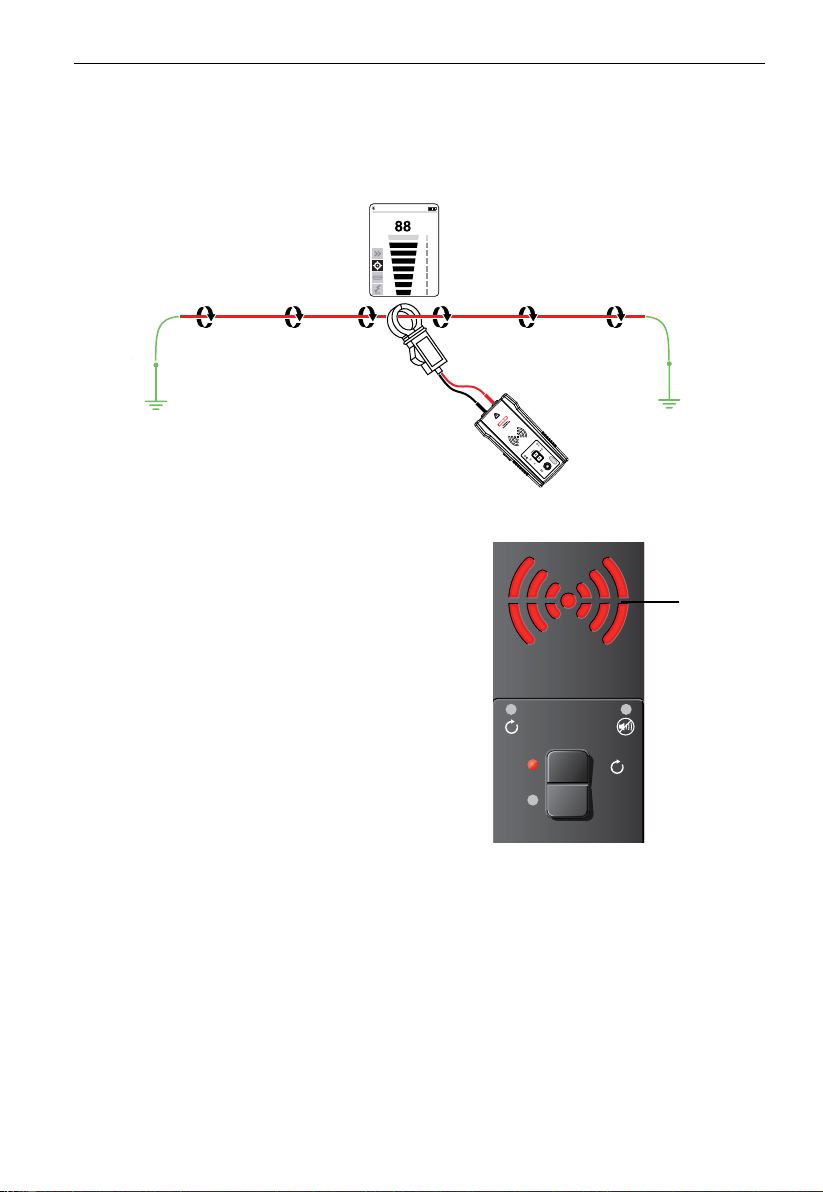

4.12 Signal Clamp - Closed Loop Circuits

Closed loop, De-energized and low impedance circuits

The clamp accessory is used for applications where there is no access to a bare conductor

to connect the test leads. When the clamp is connected to the Transmitter, it enables the

Transmitter to induce a signal to the Energized or De-energized wire through the insulation.

Typical applications of the Signal Clamp include tracing conduits or shields grounded on

both ends. For signal cables and De-energized wires or loads, temporarily ground the circuit

on both ends to perform tracing.

22

Page 27

4. SPECIAL APPLICATIONS

AT-6000-T

TRANSMITTER

Connecting the Signal Clamp

1. Connect the CT-400 test leads to the terminals of the Transmitter (polarity does not

matter).

2. Clamp the CT-400 Signal Clamp around the conductor. To increase the signal strength,

wind a few turns of the conductor wire around the clamp if possible.

Figure 4.12a: Connecting the clamp

Setting up the AT-6000-T Transmitter

1. Press the ON/OFF key to turn on the Transmitter.

The red LED voltage status indicator should be OFF

when the clamp is connected and when working

with either Energized or De-energized systems.

2. Press HIGH signal mode and hold

pushbutton for >2 seconds to select the

Loop mode on the Transmitter. The clamp

mode generates a boosted 6 kHz signal in order to

provide superior tracing results. The screen on the

Transmitter should appear as in Figure 4.12b.

Using the AT-6000-R Receiver

1. Press the ON/OFF push button to turn on the Receiver.

2. Select either Quick Scan or Precision Tracing mode.

3. Hold the Receiver with the Tip Sensor facing the

target area.

4. Scan the target area with the Tip Sensor to find the highest signal level. While tracing,

periodically adjust the sensitivity to keep the signal strength near 50. Increase or

decrease the sensitivity by pressing + / - on the keypad.

5. Receiver Positioning: For best results while tracing Energized wires, align the groove on

the Tip Sensor with the wire direction as shown. The signal may be lost if not properly

aligned.

6. To verify the wire direction, periodically rotate the Receiver 90 degrees. Signal strength

will be highest when wire is aligned with the Tip Sensor groove.

SIGNAL

>2s

HI

LO

Figure 4.12b: Transmitter indicator

showing signal in Loop mode

BLINKING

23

Page 28

4. SPECIAL APPLICATIONS

4.13 Signal Clamp - Mapping Circuits

The clamp accessory can be used to map loads to the specific breakers on both Energized

and De-energized circuits. There is no need to disconnect the power.

1. Connect the CT-400 test leads to the terminals of the Transmitter (polarity does not

matter) and select HIGH mode.

2. Clamp the CT-400 around the hot (line) wire at the breaker panel.

3. Select Quick Scan mode on the Receiver with the highest sensitivity level.

Scan the face plates of receptacles and wires by touching them with the Tip Sensor of the

Receiver. All the wires, receptacles and loads that the Receiver indicates in the Quick Scan

mode are connected to the breaker.

Note: Expect a relatively weak signal. For best performance, install fully charged high

capacity rechargeable batteries to the Transmitter. Use the “Mapping a circuit using test

leads connection” method if a much stronger signal is required.

Figure 4.13a: Using the Signal Clamp to map loads to specific breakers

Align

Tip

groove

Figure 4.13b: Aligning the Tip Sensor groove

*Note: For best results, keep the Receiver at least 3 feet from the Transmitter and its test

leads to minimize signal interference and improve wire tracing results.

24

Page 29

5. MAINTENANCE

5.1 Battery Replacement

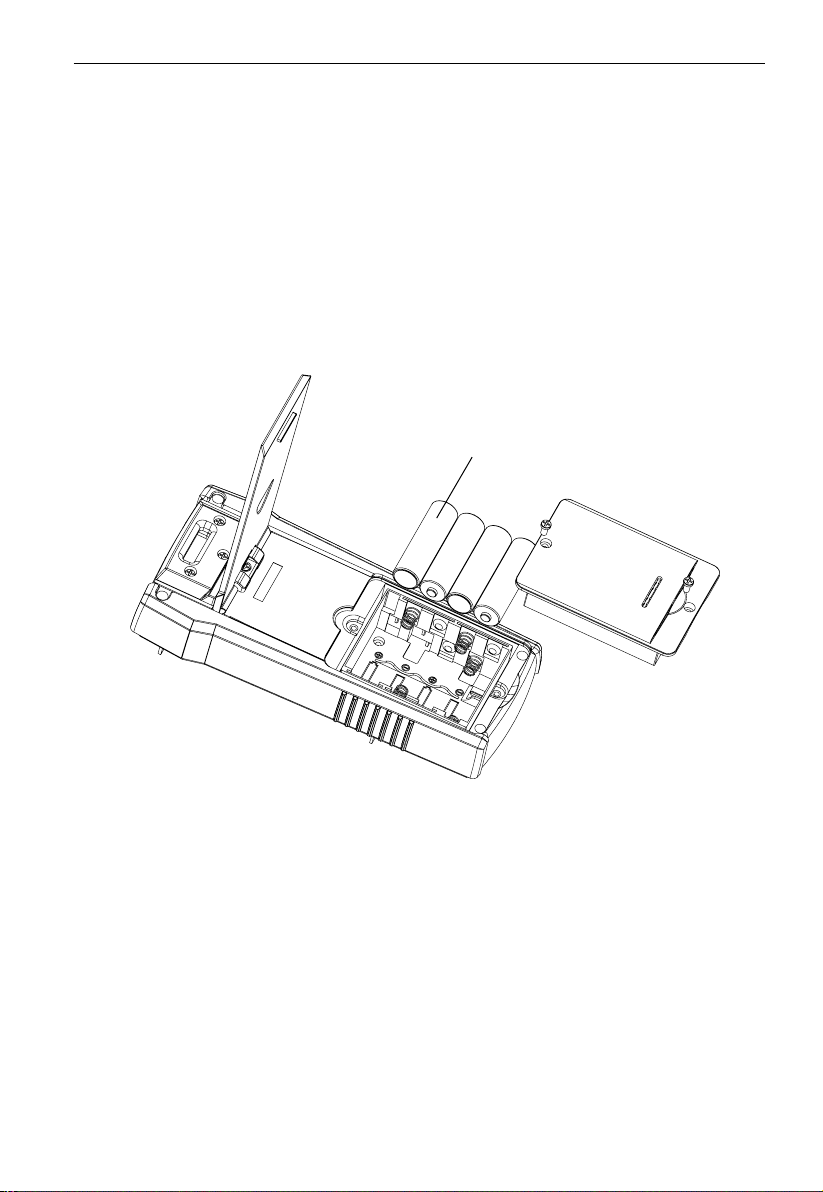

Changing the Transmitter Batteries

The battery compartment on the back of the Transmitter is designed to make it easy for

the user to change the batteries. A screw is added to secure the battery in case the unit is

dropped. Eight (8) AA alkaline or rechargeable NiMH batteries may be used. NiMH batteries

need to be removed to be charged.

Note: Batteries do not come pre-installed in the Transmitter.

1. Make sure that the Transmitter is turned off and disconnected from the circuit.

2. Use a star screw driver to unscrew the battery compartment screws.

3. Remove the battery cover.

4. Install batteries.

5. Replace the battery cover and secure it with the screws.

8 x AA batteries

Figure 5.1: Changing the Transmitter batteries

25

Page 30

5. MAINTENANCE

Manual Selecting of Transmitter Battery Type

The type of batteries being used-Alkaline or rechargeable NiMH-are recognized

automatically during power up of the device or may be defined manually by the user.

Set battery type as alkaline:

1. Make sure that the Transmitter is turned off.

2. Press and hold the VOLUME UP (+) button.

3. While volume up button is pressed, press the POWER ON button. The chosen battery

type will be alkaline.

Set battery type as rechargeable NiMH:

1. Make sure that the Transmitter is turned off.

2. Press and hold the VOLUME DOWN (-) button.

3. While volume down button is pressed, press the POWER ON button. The chosen battery

type will be rechargeable NiMH.

If the battery type is not defined manually, it will be recognized automatically. Automatic

battery type recognition draws more current and can be unreliable if inadequate or

old batteries are used. The automatic battery recognition can also be unreliable if the

rechargeable batteries have not been charged in over one month.

Transmitter Battery Status

Related to 8 AA batteries same type and connected in series.

BATTERY TRESHOLD ALKALINE

Device will power off if voltage is below 6.9 V

Battery empty – RED LED blinking if voltage is > 7.3 V and < 9.4 V

0-10% - RED LED is ON for voltages > 9.6 V and < 9.9 V

10-40% - Two yellow LEDs are ON for voltages > 10 V and < 10.8 V

40-75% - Three green LEDs are ON or voltages > 10.9 V and < 12 V

> 75% - Four green LEDs are ON for voltages > 12 V

BATTERY TRESHOLD NiMH

Device will power off if voltage is below 6.9 V

Battery empty – RED LED blinking if voltage is > 7.1 V and < 7.3 V

0-10% - RED LED is ON for voltages > 7.4 V and < 7.6 V

10-40% - Two yellow LEDs are ON for voltages > 7.7 V and < 8.5 V

40-75% - Three green LEDs are ON or voltages > 8.6 V and < 9.7 V

> 75% - Four green LEDs are ON for voltages > 9.8 V

26

Page 31

5. MAINTENANCE

Changing the Receiver Batteries

The battery compartment on the back of the Receiver is designed to make it easy for the user to

change the batteries. Four (4) AA 1.5 V alkaline or 1.2 V rechargeable batteries may be used.

Note: Batteries do not come pre-installed in the Receiver.

1. Make sure that the Receiver is turned off.

2. Use a screw driver to unscrew the captive screw.

3. Remove the battery cover.

4. Install batteries.

5. Replace the battery cover and secure it with the provided screw.

4 x AA batteries

Figure 5.2: Changing the Receiver batteries

Note: The Receiver automatically recognizes if batteries are alkaline or rechargeable and

adapts the battery indication to provide the right information.

Old rechargeable batteries and certain alkaline batteries may not provide accurate battery

level indication. Turn on the device while holding the volume + button to automatically

adjust battery indication for rechargeable or alkaline batteries.

27

Page 32

5. MAINTENANCE

5.2 Fuse Replacement

Transmitter Fuse Replacement:

X�

Warning: To avoid shock, injury, or damage to the Transmitter, disconnect test leads

before opening case.

1. Disconnect all test leads from the Transmitter.

2. Make sure the Transmitter is turned off.

3. Use a star screw driver to unscrew the tilt-stand screws.

4. Remove the battery door and remove all batteries.

5. Use a star screw driver to unscrew holding screws.

6. Remove the back cover by pulling it upwards as shown in figure 5.3.

7. Remove the fuse from the fuse holder.

8. Insert the new fuse (1.6 A, 700 V MAX, FAST Ø 6X32 mm) in the fuse holder.

9. Insert the back cover, secure it with the holding screws and tighten with a star screw driver.

Fuse

Figure 5.3: Transmitter fuse replacement

28

Page 33

6. SPECIFICATIONS

Features AT-6000-R AT-6000-T CT-400

Measurement

Category

Operating

Voltage

Operating

Frequency

Hazardous

Voltage Detection

Signal Indications Numeric bar graph display

Response Time Tip Sensor (Energized /

Current Output of

Signal (typical)

Signal Voltage

Output (nominal)

Range Detection

(open air)

CAT III 600 V CAT III 600 V CAT IV 600 V,

0 to 600 V AC/DC 0 to 600 V AC/DC 0 to 1000 V AC

Energized: 6.25 kHz

De-Energized: 32.768 kHz

See NCV detection > 30 V AC/DC N/A

and audible beep

De-energized): 500 ms

NCV: 500 ms

Battery voltage

monitoring: 5 sec

N/A Energized circuit:

N/A De-energized circuit:

Tip Sensor (Energized):

Max distance via air: up to

20 ft (6.1 m)

Pinpointing: approx. 1.97

in (5 cm)

Tip Sensor (De-energized):

Max distance via air: up to

14.7 ft (4.5 m)

Pinpointing: approx. 1.97

in (5 cm)

NCV detection (40 to 400 Hz):

Max. sensitivity: 90 V, up

to 6.56 ft (2 m)

Min. sensitivity: 600 V, up

to 0.39 in (1 cm)

Energized: 6.25 kHz

De-Energized: 32.768 kHz

LEDs and audible beep N/A

Line voltage monitoring:

1 sec

Battery voltage

monitoring: 5 sec

HI mode: 60 mA RMS

LO mode: 30 mA RMS

De-energized circuit:

HI mode: 130 mA RMS

LO mode: 40 mA RMS

Loop mode: 160 mA RMS

LOW: 29 V RMS, 120 Vp-p

HIGH: 33 V RMS, 140 Vp-p

With CT-400:

Loop model: 31 V RMS,

120 Vp-p

N/A N/A

CAT III 1000 V

Wire tracing: 32.768 kHz

AC current measurement:

45 Hz to 400 Hz

Instantaneous

1 mA/A for AC current

measurement with

multimeter

De-energized circuit:

2.4 V RMS, 24 Vp-p

29

Page 34

6. SPECIFICATIONS

General specifications

Features AT-6000-R AT-6000-T CT-400

Display Size LCD 2.5 in (6.35 cm) LEDs N/A

Display Dimensions

(W x H)

Display Resolution 240(RGB) x 320 pixels N/A N/A

Display Type TFT-LCD (262 K) LEDs N/A

Display Color True, 16bit/color Operating mode LEDs: red

Booting Time < 3 sec < 2 sec N/A

Backlight Yes N/A N/A

Operating

Temperature

Operating Humidity 45%: -4 °F to <50 °F

Storage Temperature

and Humidity

Operating Altitude 0 to 6561 ft (2000 m) 0 to 6561 ft (2000 m) 0 to 6561 ft (2000 m)

Transient Protection N/A 6.00 kV (1.2/50µS surge) N/A

Pollution Degree 2 2 2

IP Rating IP 52 IP 40 IP 40

Drop Test 3.28 ft (1 m) 3.28 ft (1 m) 3.28 ft (1 m)

Power Supply 4 x AA (alkaline or NiMH

Power Consumption

(typical)

Battery Life (typical) Approx. 16 h Hi/Lo mode: approx. 25 h

Low Battery

Indication

Fuse N/A 1.6 A, 700 V, fast-acting,

Maximum

Conductor Size

Dimensions

(L x W x H)

Weight

(batteries installed)

Certifications

1.45 x 1.93 in

(36.72 x 48.96 mm)

-4 °F to 122 °F

(-20 °C to 50 °C)

(-20 °C to <10 °C)

95%: 50 °F to <86 °F

(10 °C to <30 °C)

75%: 86 °F to <104 °F

(30 °C to <40 °C)

45%: 104 °F to 122 °F

(40 °C to 50 °C)

-4 °F to 158 °F

(-20 °C to 70 °C), <95% RH

rechargeable)

110 mA Hi/Lo mode: 70 mA

Yes Yes N/A

N/A N/A 1.26 in (32 mm)

Approx. 7.2 x 2.95 x 1.69 in

(183 x 75 x 43 mm)

Approx. 0.6 lb (0.27 kg) Approx. 1.25 lb (0.57 kg) Approx. 0.25 lb (0.114 kg)

P

N/A N/A

N/A

Battery status LEDs:

green, yellow, red

-4 °F to 122 °F

(-20 °C to 50 °C)

45%: -4 °F to <50 °F

(-20 °C to <10 °C)

95%: 50 °F to <86 °F

(10 °C to <30 °C)

75%: 86 °F to <104 °F

(30 °C to <40 °C)

45%: 104 °F to 122 °F

(40 °C to 50 °C)

-4 °F to 158 °F

(-20 °C to 70 °C), <95% RH

8 x AA (alkaline or NiMH

rechargeable)

Loop mode with Clamp:

90 mA

Consumption without

signal transmission: 10 mA

Loop mode: approx. 18 h

Ø 6x32mm

Approx. 7.2 x 3.66 x 1.97 in

(183 x 93 x 50 mm)

P

32 °F to 122 °F

(0 °C to 50 °C)

95%: 50 °F to <86 °F

(10 °C to <30 °C)

75%: 86 °F to <104 °F

(30 °C to <40 °C)

45%: 104 °F to <122 °F

(40 °C to <50 °C)

-4 °F to 140 °F

(-20 °C to 60 °C), <95% RH

N/A

N/A

N/A

N/A

Approx. 5.9 x 2.75 x 1.18 in

(150 x 70 x 30 mm)

P

30

Page 35

6. SPECIFICATIONS

Accessory specifications

Features ADPTR-SCT TL-6000

Measurement Category CAT II CAT III (test leads)

Operating Voltage and Current 0 to 120 V AC, 4 A, max. 1000 V, 16 A max. (red/green leads)

Operating Frequency 50 Hz to 60 Hz N/A

Operating Temperature 32 °F to 122 °F

(0 °C to 50 °C)

Operating Humidity 95%: 50 °F to <86 °F

Storage Temperature and

Humidity

Operating Altitude 0 to 6561 ft (2000 m) 0 to 6561 ft (2000 m)

Pollution Degree 2 2

IP Rating IP 40 IP 20

Drop Test 3.28 ft (1 m) 3.28 ft (1 m)

Dimensions Approx. 2.95 x 1.97 x 2.56 in

Weight Approx. 0.125 lb (0.057 kg) Approx. 0.75 lb (0.34 kg)

Certifications

(10 °C to <30 °C)

75%: 86 °F to <104 °F

(30 °C to <40 °C)

45%: 104 °F to <122 °F

(40 °C to <50 °C)

-4 °F to 140 °F

(-20 °C to 60 °C), <95% RH

(75 x 50 x 65 mm)

CAT IV (alligator clips)

600 V, 16 A max. (black lead)

600 V, 10 A max. (alligator clips)

32 °F to 122 °F

(0 °C to 50 °C)

95%: 50 °F to <86 °F

(10 °C to <30 °C)

75%: 86 °F to <104 °F

(30 °C to <40 °C)

45%: 104 °F to <122 °F

(40 °C to <50 °C)

-4 °F to 140 °F

(-20 °C to 60 °C), <95% RH

Red/black leads: 3.28 ft (1 m)

Green lead: 22.97 ft (7 m)

Alligator clips:

approx. 3.74 x 1.77 x 0.94 in

(95 x 45 x 24 mm)

31

Page 36

Page 37

AT-6000

Détecteur de câbles avancé

AT-6020

AT-6030

Manuel de l’utilisateur

Français

8/2017, 6009478 Rév. B

©2017 Amprobe Test Tools.

Tous droits réservés. Imprimé en Chine.

Page 38

Limites de garantie et de responsabilité

Ce produit Amprobe sera exempt de vices au niveau des matériaux et de la fabrication pendant

un an à partir de la date d’achat sauf législation locale contraire. Cette garantie ne s'applique pas

aux fusibles, aux piles jetables ni à tout endommagement accidentel du produit par suite d'une

mauvaise utilisation, d'une modication, contamination, négligence ou d'un fonctionnement ou

manipulation dans des conditions anormales. Les revendeurs ne sont pas autorisés à proposer une

quelconque autre garantie pour le compte d’Amprobe. Pour bénécier de la garantie, renvoyez

le produit accompagné d'un justicatif d'achat auprès d'un centre de services agréé par Amprobe

ou à un distributeur ou revendeur Amprobe. Voir la section Réparation pour tous les détails.

CETTE GARANTIE EST VOTRE SEUL RECOURS. TOUTES AUTRES GARANTIES, EXPLICITES, IMPLICITES

OU STATUTAIRES, NOTAMMENT LES GARANTIES DE QUALITE MARCHANDE OU D'ADAPTATION

A UN OBJECTIF PARTICULIER SONT EXCLUES PAR LES PRESENTES. LE FABRICANT NE SERA EN

AUCUN CAS TENU RESPONSABLE DE DOMMAGES PARTICULIERS, INDIRECTS, ACCIDENTELS OU

CONSECUTIFS, NI D'AUCUNS DEGATS OU PERTES DE DONNEES, SUR UNE BASE CONTRACTUELLE,

EXTRA-CONTRACTUELLE OU JURIDIQUE. Étant donné que certains pays ou états n'admettent pas

les exclusions ou limitations d'une condition de garantie implicite ou de dégâts accidentels ou

indirects, cette limitation de la responsabilité pourrait ne pas s'appliquer à vous.

Réparation

Tous les produits Amprobe renvoyés pour toute réparation couverte ou non par une garantie ou

pour tout étalonnage doit être accompagné de : votre nom, le nom de la société, une adresse,

un numéro de téléphone et un justicatif d'achat. Ajoutez également une brève description

du problème ou du service demandé et incluez les cordons de test avec l’appareil. Les frais de

remplacement ou de réparation hors garantie doivent être acquittés par chèque, mandat, carte de

crédit avec date d'expiration, ou par bon de commande payable à l'ordre d'Amprobe.

Remplacements et réparations sous garantie – Tous pays

Veuillez lire la déclaration de garantie et vériez la pile avant de demander une réparation.

Pendant la période de garantie, tout outil de test défectueux peut être renvoyé auprès de votre

distributeur Amprobe pour être échangé contre un produit identique ou similaire. Consultez

la section « Where to Buy » (points de vente) sur le site amprobe.com pour obtenir la liste des

distributeurs dans votre région. Au Canada et aux États-Unis, les appareils devant être remplacés

ou réparés sous garantie peuvent également être envoyés dans un centre de services Amprobe

(voir les adresses ci-dessous).

Remplacements et réparations hors garantie – Canada et États-Unis

Les appareils à réparer hors garantie au Canada et aux États-Unis doivent être envoyés dans un

centre de service Amprobe. Appelez Amprobe ou renseignez-vous auprès de votre lieu d’achat

pour connaître les tarifs de remplacement ou de réparation en vigueur .

États-Unis : Canada :

Amprobe Amprobe

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tél. : 877-AMPROBE (267-7623) Tél : 905-890-7600

Remplacements et réparations hors garantie – Europe

Les appareils européens non couverts par la garantie peuvent être remplacés par votre distributeur

Amprobe pour une somme symbolique. Consultez la section « Where to Buy » (points de vente) sur

le site beha-amprobe.com pour obtenir la liste des distributeurs dans votre région.

Beha-Amprobe*

In den Engematten 14

79286 Glottertal, Allemagne

Tél. : +49 (0) 7684 8009 - 0

beha-amprobe.com

*(Réservée à la correspondance – Aucune réparation ou remplacement n’est possible à cette

adresse. Nos clients européens doivent contacter leur distributeur.)

Page 39

Série AT-6000

SOMMAIRE

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ ........................................................... 2

2. COMPOSANTS DU KIT ........................................................................................... 4

2.1 Récepteur AT-6000-R .....................................................................................................5

2.2 Transmetteur AT-6000-T ................................................................................................7

2.3 Pince de signal CT-400 (kit AT-6030) ............................................................................10

3. APPLICATIONS PRINCIPALES ................................................................................. 11

3.1 Détecter des câbles sous tension et hors tension .......................................................12

3.2 Identifier des disjoncteurs et des fusibles (sous tension et hors tension) ..................15

3.3 Mode de tension sans contact (NCV) et détection passive .........................................17

4. APPLICATIONS SPÉCIFIQUES ................................................................................. 18

4.1 Détecter des câbles sur circuit protégé par GFCI .........................................................18

4.2 Identifier des ruptures/ouvertures ................................................................................18

4.3 Identifier des courts-circuits .........................................................................................19

4.4 Détecter des câbles dans un conduit métallique ........................................................19

4.5 Détecter des câbles et tuyaux non métalliques ...........................................................20

4.6 Détecter des câbles blindés ...........................................................................................20

4.7 Détecter des câbles souterrains ....................................................................................21

4.8 Détecter des câbles basse tension et de données ........................................................21

4.9 Trier des câbles emmêlés ...............................................................................................21

4.10 Cartographier un circuit en connectant des cordons de mesure ...............................22

4.11 Détecter des disjoncteurs sur des systèmes avec variateurs de lumière ....................22

4.12 Pince de signal - Circuits fermés ..................................................................................22

4.13 Pince de signal - Cartographier des circuits ................................................................24

5. ENTRETIEN ............................................................................................................. 25

5.1 Remplacement des piles ................................................................................................25

5.2 Remplacement des fusibles ...........................................................................................28

6. SPÉCIFICATIONS ..................................................................................................... 29

1

Page 40

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

Généralités

Pour votre propre sécurité et afin de ne pas endommager l’instrument, nous vous conseillons de suivre les

procédures indiquées ci-dessous:

REMARQUE: Avant et pendant la prise des mesures, suivez rigoureusement les instructions.

• Assurez-vous que l’instrument électrique fonctionne correctement avant de l’utiliser.

• Avant de raccorder tout conducteur, assurez-vous que la tension présente dans le conducteur est

comprise dans la plage de l’instrument.

• Rangez les instruments dans leur mallette de transport lorsque vous ne les utilisez pas.

• Si vous n’envisagez pas d’utiliser le transmetteur ou le récepteur pendant une longue période,

retirez les piles afin de prévenir toute fuite dans les instruments.

• Utilisez uniquement des câbles et accessoires homologués par Amprobe.

Précautions de sécurité

• Dans de nombreux cas, les niveaux de tension et/ou de courant peuvent être dangereux. De ce fait,

il est essentiel d’éviter tout contact direct avec les surfaces porteuses de courant non isolées. Portez

des gants isolants ainsi que des vêtements de protection dans les zones de tension dangereuse.

• Ne mesurez pas la tension ou le courant dans des environnements humides, mouillés ou

poussiéreux.

• Ne mesurez pas la tension en présence de gaz, de matériaux explosifs ou de combustibles.

• Ne touchez pas le circuit soumis au test si aucune mesure n’est prise.

• Ne touchez pas les parties métalliques exposées telles que les bornes et les circuits non utilisés.

• N’utilisez pas l’instrument s’il semble défectueux (ex. si vous remarquez des déformations, ruptures,

fuites ou substances, une absence de messages sur l’écran, etc.).

SYMBOLES

�

Attention! Reportez-vous à l'explication dans ce manuel.

X

AVERTISSEMENT DE TENSION DANGEREUSE Risque d´électrocution.

Consulter la documentation utilisateur.

L’équipement est protégé par une double isolation ou une isolation renforcée.

T

Mise à la terre.

Fusible.

Batterie.

®

Certifié conforme aux normes de sécurité en vigueur en Amérique du Nord par CSA Group.

Conforme aux normes CEM sud-coréennes.

Compatibilité électromagnétique:

Corée (KCC): Equipement de classe A (Équipement de communication et diffusion industriel)

[1]

Cet appareil est conforme aux exigences des équipements générateurs d'ondes électromagnétiques

industriels (classeA), et le fournisseur ou l'utilisateur doit en tenir compte. Cet équipement est destiné

à l'utilisation dans des environnements professionnels et non à domicile.

Conforme aux normes australiennes en vigueur.

Conforme aux directives européennes.

Ce produit est conforme aux normes de marquage de la directive DEEE. La présence de cette

étiquette indique que cet appareil électrique/électronique ne doit pas être mis au rebut avec

les déchets ménagers. Catégorie de produit: Cet appareil est classé parmi les «instruments de

surveillance et de contrôle» de catégorie9 en référence aux types d'équipements mentionnés

dans l'Annexe I de la directive DEEE. Ne jetez pas ce produit avec les déchets ménagers non triés.

[1]

2

Page 41

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

Consignes de sécurité

L'appareil est conforme aux normes suivantes:

• UL/IEC/EN 61010-1, CAN/CSA C22.2 N° 61010-1, Degré de pollution2, Mesure

CAT III 600 V MAX

• CEI/EN61010-2-033

• CEI/EN61010-2-032

• IEC/EN 61010-031 (cordons de mesure)

• EMC IEC/EN 61326-1

La catégorie de mesure III (CATIII) s´applique aux circuits de test et de mesure connectés à la section

de distribution de l´installation SECTEUR basse tension de l´immeuble. Cette section de l’installation

doit contenir au minimum deux niveaux de dispositifs de protection contre les surtensions entre le

transformateur et les éventuels points de connexion.

Directives CENELEC

L'instrument est conforme à la directive basse tension 2014/35/EU et à la directive de compatibilité

électromagnétique 2014/30/EU de CENELEC.

X�Avertissements: Précautions à lire avant utilisation

Pour éviter tout risque d’électrocution ou de blessure corporelle:

• Utilisez le produit en respectant les consignes de ce manuel afin de ne pas compromettre la

protection de l’instrument.

• Ne travaillez pas seul afin de pouvoir bénéficier d’une assistance éventuelle.

• Essayez sur une source de signal connue dans la gamme de tension nominale du produit avant et

après utilisation pour vous assurer que le produit est en bon état de fonctionnement.

• N’utilisez pas le produit à proximité d´un gaz explosif, de vapeurs, dans un environnement humide

ou mouillé.

• Inspectez le produit avant utilisation et ne l’utilisez pas s'il semble endommagé. Recherchez

d´éventuels défauts ou fissures dans le plastique. Inspectez particulièrement l'isolant autour des

connecteurs.

• Inspectez les cordons de mesure avant l’utilisation. N’utilisez pas l’équipement si l'isolant est

endommagé ou si des parties métalliques sont mises à nu.

• N’utilisez pas le produit s´il ne fonctionne pas correctement. Sa protection est peut-être

défectueuse. En cas de doute, faites vérifier l'appareil.

• Effectuez un essai de continuité sur les cordons. Remplacez les cordons de mesure endommagés

avant d'utiliser le produit.

• Faites réparer ou entetenir le produit uniquement par des techniciens qualifiés.

• Procédez avec extrême prudence en travaillant aux abords de conducteurs nus ou de barres

omnibus. Un contact avec le conducteur pourrait entraîner un choc électrique.

• Ne tenez pas le produit au-dessus de la barrière tactile.

• N’appliquez jamais de tension supérieure à la tension nominale et à la valeurCAT, indiquée sur le

produit, entre les bornes ou entre une borne quelconque et la terre.

• Retirez les cordons de mesure du produit avant d’ouvrir son boîtier ou le compartiment de la pile.

• N’utilisez jamais le produit si le compartiment de la pile a été retiré ou si le boîtier est ouvert.

• Procédez avec prudence en travaillant avec des tensions supérieures à 30VAC efficaces, à 42 VAC

crête ou à 60VDC Ces tensions présentent un risque d'électrocution.

• Ne tentez pas de raccorder de circuit porteur de tension susceptible de dépasser la plage maximale du

produit.

• Utilisez les bornes, les fonctions et les plages qui conviennent pour les mesures envisagées.

3

Page 42

1. PRÉCAUTIONS ET MESURES DE SÉCURITÉ

• Lorsque vous utilisez les pinces crocodile, placez les doigts derrière la collerette de protection.

• Utilisez uniquement les fusibles exacts de rechange ainsi que les pièces de rechange agréées.

• En établissant les raccordements électriques, branchez le cordon de mesure commun avant la

polarité au potentiel ; pour déconnecter les cordons de mesure, commencez par celui au potentiel.

• Pour éviter les mesures erronées pouvant présenter des risques d’électrocution et/ou de

blessure, remplacez ou rechargez les piles dès l'apparition du témoin de piles faibles. Vérifiez le

fonctionnement de la pince sur une source connue avant et après l’emploi.

• Utilisez uniquement des piles AA correctement installées dans le boîtier du multimètre pour

alimenter le produit (voir Section5.1: Remplacement des piles).

• En cas de réparation, n'utilisez que des pièces de rechange agréées en bon état de fonctionnement.

• Respectez les codes locaux et nationaux de sécurité en vigueur. Utilisez un équipement de