Page 1

AMP-210

AMP-210-EUR

600A AC TRMS

Clamp Multimeter

AMP-220

AMP-220-EUR

600A AC / DC TRMS

Clamp Multimeter

AMP-310

AMP-310-EUR

600A AC TRMS

Clamp Multimeter

AMP-320

AMP-320-EUR

600A AC / DC TRMS

Clamp Multimeter

Page 2

Page 3

AMP-210 / AMP-210-EUR

600A AC TRMS Clamp Multimeter

AMP-220 / AMP-220-EUR

600A AC/DC TRMS Clamp Multimeter

AMP-310 / AMP-310-EUR

600A AC TRMS Clamp Multimeter

AMP-320 / AMP-320-EUR

600A AC/DC TRMS Clamp Multimeter

User Manual

English

7/2014, 6003318 A

©2014 Amprobe Test Tools.

All rights reserved. Printed in Taiwan

Page 4

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for one year from

the date of purchase unless local laws require otherwise. This warranty does not cover fuses,

disposable batteries or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other

warranty on the behalf of Amprobe. To obtain service during the warranty period, return the

product with proof of purchase to an authorized Amprobe Service Center or to an Amprobe

dealer or distributor. See Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY.

ALL OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED OR STATUTORY - INCLUDING IMPLIED

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY

DISCLAIMED. MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since

some states or countries do not allow the exclusion or limitation of an implied warranty or of

incidental or consequential damages, this limitation of liability may not apply to you.

Repair

All Amprobe returned for warranty or non-warranty repair or for calibration should be

accompanied by the following: your name, company’s name, address, telephone number, and

proof of purchase. Additionally, please include a brief description of the problem or the service

requested and include the test leads with the meter. Non-warranty repair or replacement

charges should be remitted in the form of a check, a money order, credit card with expiration

date, or a purchase order made payable to Amprobe.

In-warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting repair. During

the warranty period, any defective test tool can be returned to your Amprobe distributor for

an exchange for the same or like product. Please check the “Where to Buy” section on www.

Amprobe.com for a list of distributors near you. Additionally, in the United States and Canada,

in-warranty repair and replacement units can also be sent to an Amprobe Service Center (see

address below).

Non-warranty Repairs and Replacement – United States and Canada

Non-warranty repairs in the United States and Canada should be sent to an Amprobe Service

Center. Call Amprobe or inquire at your point of purchase for current repair and replacement rates.

USA: Canada:

Amprobe Amprobe

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 877-AMPROBE (267-7623) Tel: 905-890-7600

Non-warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe distributor for a nominal

charge. Please check the “Where to Buy” section on www.Amprobe.eu for a list of

distributors near you.

Amprobe Europe*

Beha-Amprobe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

www.Amprobe.eu

*(Correspondence only – no repair or replacement available from this address. European customers please

contact your distributor.)

Page 5

AMP-210 / AMP-210-EUR Series TRMS Clamp Multimeters

CONTENTS

SYMBOL ......................................................................................................... 3

SAFETY INFORMATION ................................................................................. 4

UNPACKING AND INSPECTION ..................................................................... 5

MEASUREMENTS ........................................................................................... 6

Measuring AC and DC Voltage ................................................................ 7

Voltage detection (NCV) .......................................................................... 8

Measuring AC and DC Current ................................................................ 9

Precise Low-Current Measurement ......................................................... 10

Microamps μA Measurement .................................................................. 11

Measuring Resistance, Continuity and Diode ........................................ 12

Measuring Capacitance and Temperature ............................................. 13

Measuring

Auto Power Off ........................................................................................ 15

SPECIFICATIONS .............................................................................................16

ELECTRICAL SPECIFICATIONS ....................................................................... 17

MAINTENANCE AND REPAIR ........................................................................21

BATTERY REPLACEMENT ............................................................................... 21

& 3-Phase Rotation .................................................. 14

Page 6

AMP-210 / AMP-210-EUR Series TRMS Clamp Multimeters

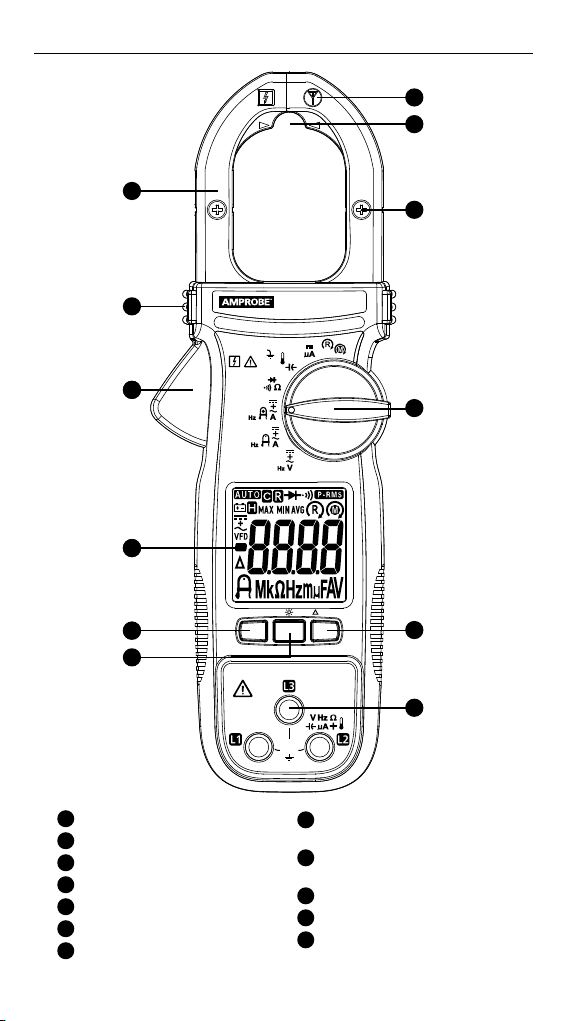

7

8

1

9

2

MAX 600A

600V CAT III

1

3

AMP-320

10

)

NCV(EF

TRMS

1

4

PEAK-RMS

1

5

OFF

ZERO

SELECT HOLDREC

11

6

12

COM

CAT III

600V

1

Jaw

2

Tactile Barrier

3

Jaw Release

4

Display

5

REC/PEAK-RMS Button

6

SELECT/Backlight Button

7

Antenna for Non-Contact

Voltage Detection

8

Precise Low Current

Measuring Location

9

Indicator of the Jaw Center

for Current Measurement

10

Rotary Switch

11

Data Hold/ZERO button

12

Input Terminals

Page 7

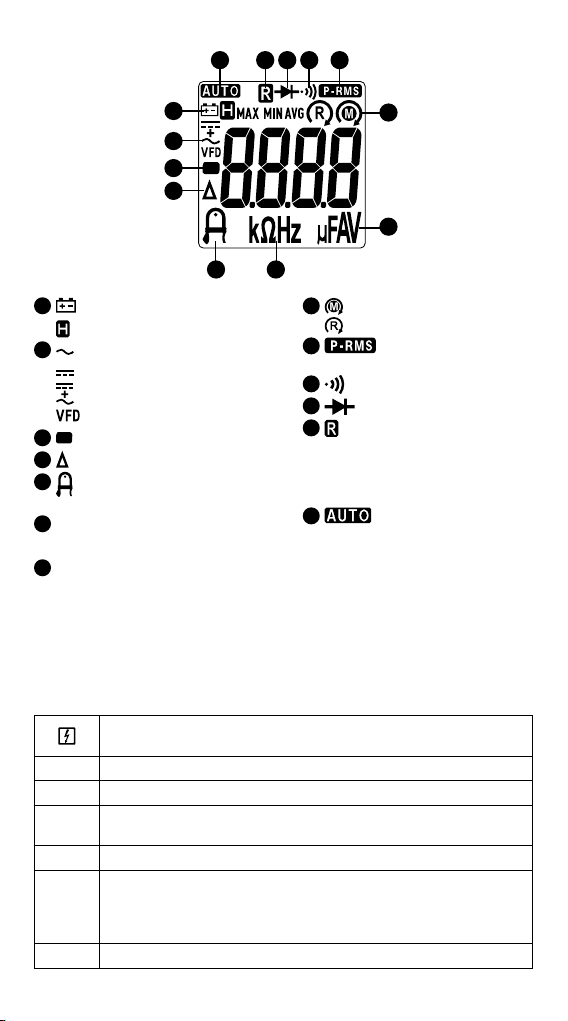

25

24 23 22 21

13

14

15

16

13

Low battery indicator

Data hold

14

Alternative Current (AC)

Direct Current (DC)

AC + DC

Varable Frequency Dive

15

Negative reading

16

Relative zero is active

17

Precise low current

measurement mode

18

kΩ: KiloOhms

Hz: Hertz

19

μF: Microfarads

μA: Microamps

A: Amps

V: Volts

17 18

20

19

20

Motor rotation indicator

Phase rotation indicator

21

PEAK-RMS mode

(in-rush current) is active

22

Continuity buzzer is active

23

Diode test mode is active

24

Recording mode is active

MAX: MAX mode is active

MIN: MIN mode is active

AVG: AVG mode is active

25

Auto-ranging

SYMBOLS

W

T

J

CAT III

B

Application and removal from hazardous live conductors

permitted

Caution! Risk of electric shock.

Caution! Refer to the explanation in this manual.

The equipment is protected by double insulation or reinforced

insulation.

Earth (Ground).

Overvoltage Category lll is for equipment intended to form

part of a building wiring installation. Such equipment includes

socket outlets, fuse panels, and some mains installation control

equipment.

Alternating Current (AC).

3

Page 8

Direct Current (DC).

F

N

Battery.

Underwriters Laboratories. [Note: Canadian and US.]

P

Complies with European Directives.

Conforms to relevant Australian standards.

Do not dispose this product as unsorted municipal waste.

=

Contact aqualified recycler.

SAFETY INFORMATION

The Meter complies with:

• UL/IEC/EN 61010-1, CAN/CSA C22.2 No. 61010-1, Pollution Degree 2,

Measurement category III 600 V

• IEC/EN 61010-2-033

• IEC/EN 61010-2-032

• IEC/EN 61010-031 (test leads)

• EMC IEC/EN 61326-1

Measurement Category III (CAT III) is for equipment intended to form part

of a building wiring installation. Such equipment includes socket outlets,

fuse panels, and some mains installation control equipment.

CENELEC Directives

The instruments conform to CENELEC Low-voltage directive 2006/95/EC and

Electromagnetic compatibility directive 2004/108/EC.

W

Warning: Read Before Using

To avoid possible electric shock or personal injury:

• Use the Meter only as specified in this manual or the protection

provided by the Meter might be impaired.

• Avoid working alone so assistance can be rendered.

• Never measure AC current while the test leads are inserted into the

input jacks.

• Do not use the Meter in wet or dirty environments.

• Do not use the Meter if it appears damaged. Inspect the Meter before

use. Look for cracks or missing plastic. Pay particular attention to the

insulation around the connectors.

• Inspect the test leads before use. Do not use them if insulation is

damaged or metal is exposed.

• Check the test leads for continuity. Replace damaged test leads before

using the Meter.

• Have the Meter serviced only by qualified service personnel.

• Use extreme caution when working around bare conductors or bus

bars. Contact with the conductor could result in electric shock.

• Do not hold the Meter anywhere beyond the tactile barrier.

• When measuring current, center the conductor in the clamp.

4

Page 9

• Do not apply more than the rated voltage, as marked on the Meter,

between the terminals or between any terminal and earth ground.

• Remove test leads from the Meter before opening the Meter case or

battery cover.

• Never operate the Meter with the battery cover removed or the case

open.

• Never remove the battery cover or open the case of the Meter without

first removing the test leads or the jaws from a live conductor.

• Use caution when working with voltages above 30 V ac rms, 42 V ac

peak, or 60 V dc. These voltages pose a shock hazard.

• Do not attempt to measure any voltage that might exceed the

maximum range of the Meter.

• Use the proper terminals, function, and range for your measurements.

• Do not operate the Meter around explosive gas, vapor, or dust.

• When using probes, keep fingers behind the finger guards.

• When making electrical connections, connect the common test lead

before connecting the live test lead; when disconnecting, disconnect

the live test lead before disconnecting the common test lead.

• Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance, continuity, or diodes.

• Use only 1.5V AAA batteries, properly installed in the Meter case, to

power the Meter.

• To avoid false readings that can lead to electrical shock and injury,

replace the battery as soon as the low battery indicator (

Check Meter operation on a known source before and after use.

• When servicing, use only specified replacement parts.

• Adhere to local and national safety codes. Individual protective

equipment must be used to prevent shock and arc blast injury where

hazardous live conductors are exposed.

• Do not use the Meter if the wear indicator in the jaw opening is not

visible.

• Only use the test lead provided with the Meter or UL Listed Probe

Assembly rated CAT III 600V or better.

N) appears.

UNPACKING AND INSPECTION

Your shipping carton should include:

1 Clamp meter

1 Test leads

1 Alligator clip set (AMP-310 and AMP-320 only)

1 Banana plug K-type thermocouple (AMP-310 and AMP-320 only)

1 1.5 V AAA batteries (installed)

1 User manual

1 Carrying case

If any of these items are damaged or missing, return the complete package

to the place of purchase for an exchange.

5

Page 10

MAX 600A

600V CAT III

TRMS

AMP-210

NCV

(EF)

OFF

MAX 600A

600V CAT III

TRMS

AMP-310

)

NCV(EF

OFF

TRMS

MAX 600A

600V CAT III

AMP-220

NCV

(EF)

OFF

MAX 600A

600V CAT III

TRMS

AMP-320

)

NCV(EF

OFF

SELECT HOLDREC

COM

CAT III

600V

AMP-210

AMP-210-EUR

PEAK-RMS

SELECT HOLDREC

COM

CAT III

600V

AMP-310

AMP-310-EUR

ZERO

PEAK-RMS

SELECT HOLDREC

COM

CAT III

600V

AMP-220

AMP-220-EUR

PEAK-RMS

COM

AMP-320

AMP-320-EUR

MEASUREMENTS

W

Warning

To avoid possible electric shock or personal injury:

• When measuring current, center the conductor in the clamp.

• When making current measurements, disconnect the test leads from

the Meter.

• Keep fingers behind Tactile Barrier.

• Use the proper function and range for measurements.

• Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance and diode.

• When using probes, keep fingers behind the finger guards.

• Connecting test leads:

- Connect the common (COM) test lead to the circuit before connecting

the live lead;

- After measurement, remove live lead before removing the common

(COM) test lead from the circuit.

Button Description

SELECT /

Press SELECT button to select the alternative

measurement function on the rotary switch.

Press SELECT button > one second to turn ON or to

turn OFF LCD backlight. LCD backlight automatically

turns off after approximately 32 seconds.

ZERO

SELECT HOLDREC

CAT III

600V

6

Page 11

HOLD / ZERO

REC / PEAK-RMS Press REC button to activate maximum, minimum and

Press HOLD to freeze the display reading (

displayed) and releases the reading when pressed a

second time.

W

Warning

To avoid possible electric shock or personal injury,

when Display HOLD is activated, be aware that the

display will not change when you apply a different

voltage.

ZERO (HOLD) > one second to clear last

Press

reading from the display (

a baseline for applicable selected functions.

DC-Zero mode for dc and ac+dc currents. Press

(HOLD) > one second to activate DC-Zero (display

shows “dc_0” for one second). When nulled value is

larger than ± 5 DC A, an acoustic warning (3 short

beeps) will occur.

average reading memory mode (

is displayed). The meter beeps when MAX and MIN

reading is updated during measurement. Press REC

button again to read the MAX, MIN and AVG reading

in sequence. Press REC button > one second to exit

MAX/MIN/AVG reading memory mode.

Press REC / PEAK-RMS button > one second to enter

PEAK-RMS mode (

inrush current or voltage RMS values (80 ms). Press a

second time > one second to exit.

Note: Auto Power Off is automatically disabled under

MAX/MIN/AVG and PEAKRMS modes.

is displayed) and establish

MAX MIN AVG

is displayed) to capture

is

ZERO

Measuring AC and DC Voltage

To measure ac or dc voltage:

1. Turn the rotary function switch to

2. Press SELECT button to choose measurement function: AC V, DC V,

DC+AC V, Hz or EF(Non contact voltage detection). The display reflects

the chosen function mode. For Model AMP-210 and AMP-220, NCV(EF)

function is designed in an independent rotary switch position. See the

Non-Contact Voltage Detection chapter for details.

3. Connect the black test lead to the COM terminal and the red test lead

to the V terminal. Before connecting the probes to the measurement

points, add any clips to the probes that are necessary.

4. Measure the voltage by touching the probes to the desired test points

of the circuit.

5. View the reading on the display.

6. When measuring AC voltage, press SELECT button to view the

frequency reading on the display.

or

7

Page 12

Note:

• AC V (and hence DC+AC V and Hz) function is equipped with digital

low-pass filter, and is capable of dealing with VFD (Variable Frequency

Drives) signals. It also improves AC V reading stability in noisy electrical

environments.

Voltage Detection (NCV)

Non-Contact Voltage Detection:

1. For AMP-210 and AMP-220 turn the rotary switch to NCV(EF). “EF” is

displayed. For AMP-310 and AMP-320, turn the rotary function switch

to

or . press SELECT button to toggle to NCV(EF) mode (“EF” is

displayed).

2. The voltage detection antenna

end of the stationary clamp jaw for detecting electric field surrounds

energized conductors

3. Detected electric field signal strength is indicated by a series of bargraph segments on the display and beeper. The stronger the electric

field detected, the more bar-graph segments are displayed and more

intense beep sounds.

is located along the top-right

8

Page 13

Measuring AC and DC Current

W

Warning

To avoid electrical shock and injury:

• Remove Test Leads before making current measurements.

• Do not hold the Meter anywhere beyond the tactile barrier.

• Do not use the Meter to measure currents above the maximum rated

frequency (400Hz). Circulating currents may cause the magnetic circuits

of the Jaws reach hazardous excessive temperatures.

To measure AC or DC current:

1. Turn the rotary function switch to

2. Press SELECT button to choose measurement function (AC A, DC A,

DC+AC A, or Hz). The display reflects the chosen function mode.

3. Open the clamp by pressing the jaw release and insert the conductor to

be measured into the clamp. Ensure the jaws are firmly closed.

4. Close the clamp and center the conductor using the jaw alignment

marks.

5. View the current reading on the display.

6. When measuring AC or AC + DC current, press SELECT button to view

the frequency reading on the display.

or .

9

Page 14

W

Caution

During current measurement keep the jaws away from other currentcarrying devices such as transformers, motors or energized wires, as they

may negatively influence accuracy of the measurement.

Precise Low-Current Measurement

W

Warning

To avoid electrical shock and injury:

• Remove Test Leads before making current measurements.

• Do not hold the Meter anywhere beyond the tactile barrier.

• Do not use the Meter to measure currents above the maximum rated

frequency (400Hz). Circulating currents may cause the magnetic circuits

of the Jaws reach hazardous excessive temperatures.

To measure AC or DC low-current for small conductors:

1. Turn the rotary function switch to

2. Press SELECT button to choose measurement function (AC A, DC A,

DC+AC A, or Hz). The display reflects the chosen function mode.

3. Open the clamp by pressing the jaw release and insert the conductor to

be measured into the clamp. Ensure the jaws are firmly closed.

4. Align the conductor at the specified jaw tip area for low-current

measurement

5. View the current reading on the display.

6. When measuring AC or AC + DC current, press SELECT button to view

the frequency reading on the display.

or .

10

Page 15

W

Caution

During current measurement keep the jaws away from other currentcarrying devices such as transformers, motors or energized wires, as they

may negatively influence accuracy of the measurement.

Microamps μA Measurement

The μA DC ( ) function on the Meter is primarily for HVAC flame sensor

testing. To test a heating system flame sensor:

1. Turn the heating unit off and locate the wire

between the gas-burner controller and the flame

sensor.

2. Disconnect one of the flame sensor wires.

3. Turn the rotary switch on the Meter to

4. Connect the black test lead to the COM terminal and

the red test lead to the μA terminal.

5. Using alligator clips, connect a meter in series by

attaching one alligator clip to the disconnected flame

sensor probe and the second one to the disconnected

control-module terminal.

6. Turn heating unit on and check the reading on the

Meter.

7. Refer to the heating unit documentation for what

the correct reading should be.

.

11

Page 16

Measuring Resistance, Continuity and Diode

W

Warning

• To avoid false readings that can lead to electrical shock and injury, deenergize the circuit before taking the measurement.

• To avoid electrical shock when testing resistance/continuity/diode in a

circuit, make sure the power to the circuit is turned off and all capacitors

are discharged. Use DC voltage function to check the capacitors are

discharged.

1. Connect the black test lead to the COM terminal and the red test lead

to the Ω terminal.

2. Turn the rotary switch to

3. Press SELECT button for desired measurement function.

4. Connect the probes across the circuit or component to be tested.

Resistance measurement: The resistance reading appears on the display.

If the circuit is open or resistance exceeds the Meter’s range, the display

reads “OL”.

Continuity measurement: If the circuit is shorted, the Meter beeps and

shows a reading ≤ 10 Ω. (Beeper ON ≤ 10 Ω, OFF > 250 Ω) If the circuit is

open or resistance exceeds the Meter’s range, the display reads OL.

Testing diode: When testing diode, normal forward voltage drop

(forward biased) for a good silicon diode is between 0.400V to 0.900V.

A reading higher than that indicates a leaky diode (defective). A zero

reading indicates a shorted diode (defective). Display reads “OL”

indicates an open diode (defective). Reverse the test leads connections

(reverse biased) across the diode. The display reads “OL” if the diode

is good. Any other readings indicate the diode is resistive or shorted

(defective).

.

12

Page 17

Measuring Capacitance and Temperature

W

Warning

To avoid electrical shock and injury:

• When testing capacitor in a circuit, make sure the power to the circuit is

turned off and all capacitors are discharged.

• When measuring temperature, DO NOT apply the temperature probe to

any live conductive parts.

Capacitance

1. Turn off circuit power, then disconnect and discharge the capacitor

before measuring capacitance.

2. Connect the black test lead to the COM terminal and the red test lead

to the

3. Turn the Meter’s rotary switch to capacitance

4. Connect the probes across the capacitor to be tested. When measuring,

be sure to note the correct polarity of the capacitor.

Temperature

The Meter measures temperature in either Celsius (°C) or Fahrenheit (°F).

1. Connect the banana plug type-K temperature probe to the Meter’s

input terminal noting correct polarity of the probe.

2. Turn the rotary switch to

3. Press SELECT button to select °C or °F. The display reflects the chosen

temperature mode (°C or °F).

4. Position the probe to take the measurement. The reading appears on

the display.

Note: Type-K mini plug temperature probes can also be used with a

plug adaptor with banana pins to type-K socket.

terminal

.

.

13

Page 18

Measuring & 3-Phase Rotation

Measurement is made through the Meter’s terminals L1/L2/L3. Phase

Rotation directions are indicated as symbolic (LCD segments) movements on

the display. Default mode at

. Press SELECT button to toggle between

and modes.

: Hi-sensitivity mode for checking phase rotation of Motors detects

relatively low signal outputs generated spinning a motor shaft,.

: Normal-sensitivity mode for identifying phase sequence of 3-phase

MAINS supply.

W

Caution

Correct rotation detection relies on solid signal connection to all three test

lead terminals simultaneously. Any loose connection will lead to detection

failure and false indication. To verify signal connection and the correct

rotation indication, swap any of two signal connections l to check for

indication of reverse movement.

Hi-sensitivity mode for Motors:

Connect the test lead L1/L2/L3 to the motor connections by using probes

and/or alligator clips. Be sure the power supply is removed from the motor.

From the perspective of looking down the shaft of the motor, speedspin

it clockwise to generate sufficient signal strength for rotary detection. If

the meter indicates a clockwise movement, the motor leads connected to

L1, L2 and L3 of the meter are L1, L2 and L3 (also known as R, S and T),

respectively. If the meter indicates a counter-clockwise movement, swap any

of two motor connections and retest.

14

Page 19

Normal mode

Connect the test lead L1/L2/L3 to the 3-phase mains circuit by using probes

and/or alligator clips. If the meter indicates a clockwise movement, the

phases connected to L1, L2 and L3 of the meter are L1, L2 and L3 (also

known as R, S and T), respectively. If the meter indicates a counter-clockwise

movement, swap any two connects between the meter and phases. Then

retest. Connecting the above mentioned L1, L2 and L3 of a motor and that

of the MAINS respectively should get a clockwise motor movement.

for the MAINS circuit:

Using the Beeper feature on

Press and hold the REC button while turning the rotary switch to

to enable the beeper, the display shows “Enbp”. When making rotary

measurement, if the rotary indication segments indicate a clockwise

movement, the beeper sounds a single long beep per segment cycle. If the

rotary indication segments indicate a counter clockwise movement, the

beeper sounds 3 short beeps per segment cycle.

& mode:

Auto Power Off

The meter turns off if there is no button pushed, rotary function switch

operation for 32 minutes and/or no specified activities below, where

applicable:

1.) Significant measuring readings of above 8.5% of ranges

2.) Non-OL readings for Resistance, Continuity or Diode function

3.) Non-zero readings for Hz function

4.) Significant movement indication as in Phase Rotation functions

The meter will not enter auto power off mode when under normal

measurements. To turn the meter back on, press the SELECT button and

release, or turn the rotary switch off and on to restart the meter.

15

Page 20

SPECIFICATIONS

Display

Sensing

Polarity

Update rate

Operating

temperature

Relative

humidity

Storage

temperature

Pollution

degree

Operating

altitude

Temperature

coefficient

Transient

Protection

Overload

protections

E.M.C.

Agency

approval

Power supply

Power

consumption

Low battery

indication

Auto power

off

Auto power

off power

consumption

3-5/6 digits 6000 counts

True RMS

Automatic

5 per second nominal

32 °F to 104 °F (0 °C to 40 °C)

Maximum relative humidity 80% for temperature up to

31°C, decreasing linearly to 50% relative humidity at 40 °C

-4 °F to 140 °F (-20 °C to 60 °C), < 80% R.H. (with battery

removed)

2

≤ 2000 m

nominal 0.15 x (specified accuracy)/

O

C to 40OC), or otherwise specified

28

6.0 kV (1.2/50 μs surge)

Current & Hz functions via jaws: 600 A ac/dc rms at

< 400Hz

Voltage & 3-Phase Rotation functions via terminals:

660 V dc / 920 V ac rms

Other functions via terminals: 600 V ac/dc rms

Meets EN61326-1:2006

DC A and DC+AC A Functions, in an RF field of 1V/m:

Total Accuracy = Specified Accuracy + 20 digits at around

405MHz

DC μA and Ohm Functions, in an RF field of 1V/m: Total

Accuracy = Specified Accuracy + 25 digits

Other Functions, in an RF field of 3V/m: Total Accuracy =

Specified Accuracy + 20 digits

P

Two 1.5V AAA Size battery

Typical 13mA for Current functions; 4.3mA for others

Approx. 2.85 V for Capacitance & Hz; approx. 2.5 V for

other functions

Idle for 32 minutes

5μA typical

O

C @(0OC to 18OC or

16

Page 21

8.82 x 3.03 x 1.46 in (224 x 77 x 37 mm)

Dimension

(L x W x H)

Weight

Jaw opening

& conductor

diameter

for AMP-220 and AMP-320

8.62 x 3.03 x 1.46 in (219 x 77 x 37 mm)

for AMP-210 and AMP-310

254 g (0.56 lb) for AMP-220 and AMP-320 with batteries

installed

208 g (0.46 lb) for AMP-210 and AMP-310 with batteries

installed

1.37 in (35 mm) max for AMP-220 and AMP-320

1.18 in (30 mm) for AMP-210 and AMP-310

ELECTRICAL SPECIFICATIONS

Accuracy is ± (% reading digits + number of digits) or otherwise specified at

23°C ± 5°C.

Maximum Crest Factor < 2.5:1 at full scale & < 5:1 at half scale or otherwise

specified, and with frequency spectrum not exceeding the specified

frequency bandwidth for non-sinusoidal waveforms.

DC Voltage

Range Accuracy

600.0V ± (1.0 % + 5 LSD)

Input Impedance: 10 MΩ, 100 pF nominal

AC Voltage (with Digital Low-Pass Filter)

Range Accuracy

600.0V ± (1.0 % + 5 LSD)

Frequency: 50 Hz to 60 Hz

Input Impedance: 10 MΩ, 100 pF nominal

DC+AC Voltage (with Digital Low-Pass Filter)

(AMP-220 and AMP-320 only)

Range Accuracy

600.0V ± (1.2 % + 7 LSD)

Frequency: DC, 50 Hz to 60 Hz

Input Impedance: 10 MΩ, 100 pF nominal

PEAK-rms (AC V & AC A for AMP-220, AMP-310 and AMP-320 only)

Response: 80 ms to > 90 %

Continuity

Audible Threshold: ON at ≤ 10 Ω ; OFF at > 250 Ω

Response time: 32ms approx.

17

Page 22

Resistance

Range Accuracy

600.0 Ω, 6.000 kΩ, 60.00 kΩ ± (1.0 % + 5 LSD)

Open Circuit Voltage: 1.0VDC typical

Capacitance

Range Accuracy

200.0 μF, 2500 μF ± (2.0 % + 4 LSD)

1)Accuracy with film capacitor or better

1)

Diode

Range Accuracy

2.000 V ± (1.5 % + 5 LSD)

Test Current: 0.3mA typically

Open Circuit Voltage: < 3.5VDC typically

DC μA (AMP-310 and AMP-320 only)

Range Accuracy Burden Voltage

200.0 μA, 2000 μA ± (1.0 % + 5 LSD) 3.5 mV/μA

Temperature (AMP-310 and AMP-320 only)

Range Accuracy

-40.0 °C to -10.0 °C ±(1% + 1.5 °C)

> -10 °C to 99.9 °C ±(1% + 0.8 °C)

100 °C to 400 °C ±(1% + 1 °C)

-40.0 °F to 14.0 °F ±(1% + 3.0 °F)

> 14.0 °F to 99.9 °F ±(1% + 1.5 °F)

100 °F to 752 °F ±(1% + 2 °F)

K-type thermocouple accuracy tolerances not included

Precise Low Current AC

Range Accuracy

60.00 A ± (1.5 % + 5 LSD)

Frequency: 50 Hz to 60 Hz

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) Specified with relative zero

residual readings, if any.

3) Add 10 LSD to the specified accuracy @ < 4 A

4) AMP-210 and AMP-310, not specified @ < 0.2 A

1) 2) 3) 4)

mode applied to offset the non-zero

18

Page 23

Precise Low Current DC (AMP-220 and AMP-320 only)

Range Accuracy

60.00 A ± (2.0 % + 5 LSD)

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) Specified with DC-zero mode applied to offset the non-zero residual

readings, if any

3) Add 10 LSD to the specified accuracy @ < 4 A

1) 2) 3)

Precise Low Current DC+AC (AMP-220 and AMP-320 only)

Range Accuracy

60.00 A ± (2.0 % + 5 LSD)

Frequency: DC, 50 Hz to 60 Hz

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) Specified with DC-zero mode applied to offset the non-zero residual

readings, if any

3) Add 10 LSD to the specified accuracy @ < 4 A

1) 2) 3)

AC Current

Range Accuracy

4) 5)

60.00 A

60.00 A

, 600.0 A ± (1.8 % + 5 LSD) @ 50 Hz to 100 Hz

4) 5)

, 600.0 A ± (2.0 % + 5 LSD) @ 100 Hz to 400 Hz

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) AMP-220 and AMP-320: maximum crest factor < 2:1 at full scale & < 4:1

at half scale

3) AMP-210 and AMP-310: specified accuracy is for measurements made at

the jaw center. When the conductor is not positioned at the jaw center,

add 2% to specified accuracy for position errors

4) AMP-220 and AMP-320: add 10 LSD to the specified accuracy @ < 9 A

5) AMP-210 and AMP-310: add 10 LSD to specified accuracy @ < 6 A, and not

specified @ < 0.2 A

1) 2) 3)

DC Current (AMP-220 and AMP-320 only)

Range Accuracy

60.00 A 3), 600.0 A ± (2.0 % + 5 LSD)

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) Specified with DC-zero mode applied to offset the non-zero residual

readings, if any

3) Add 10 LSD to the specified accuracy @ < 9 A

1) 2) 3)

19

Page 24

DC+AC Current (AMP-220 and AMP-320 only)

Range Accuracy

3)

60.00 A

60.00 A

, 600.0 A ± (2.2 % + 7 LSD) @ DC, 50 Hz to 100 Hz

3)

, 600.0 A ± (2.7 % + 7 LSD) @ 100 Hz to 400 Hz

1) Induced error from adjacent current-carrying conductor: < 0.01 A/A

2) Specified with DC-zero mode applied to offset the non-zero residual

readings, if any

3) Add 10 LSD to the specified accuracy @ < 9 A

1) 2)

Frequency Hz

Function Sensitivity 1) (Sine rms) Range

600 V 50 V 5.00 Hz to 999.9 Hz

60 A (Precise low current) 40 A 50.00 Hz to 400.0 Hz

60 A, 600 A 40 A 50.00 Hz to 400.0 Hz

Accuracy: ± (1.0 % + 5 LSD)

1)

DC-bias, if any, not more than 50% of Sine rms

& 3-Phase Rotation

measurement:

Voltage Range: 65 V to 600 V (sine wave only)

Frequency Range: 35 Hz to 400 Hz

measurement:

Voltage Range: 0.4 V to 600 V (sine wave only)

Frequency Range: 3 Hz to 400 Hz

Voltage Detection (NCV)

Typical Voltage Bar-graph Indication

20 V (tolerance: 10 V to 36 V) -

55 V (tolerance: 23 V to 83 V) - -

110 V (tolerance: 59 V to 165 V) - - -

220 V (tolerance: 124 V to 330 V) - - - -

440 V (tolerance: 250 V to 600 V) - - - - -

Indication: bar-graph segments and audible beep tones proportional to the

field strength

Detection frequency: 50/60 Hz

Detection antenna: inside the top side of the stationary jaw

20

Page 25

MAINTENANCE AND REPAIR

If the Meter fails to operate, check battery, test leads, etc., and replace as

necessary.

Double check the following:

1. Replace the fuse or battery if the meter does not work.

2. Review the operating instructions for possible mistakes in operating

procedure.

Except for the replacement of the battery, repair of the meter should be

performed only by a Factory Authorized Service Center or by other qualified

instrument service personnel.

The front panel and case can be cleaned with a mild solution of detergent

and water. Apply sparingly with a soft cloth and allow to dry completely

before using. Do not use aromatic hydrocarbons, gasoline or chlorinated

solvents for cleaning.

BATTERY REPLACEMENT

When battery voltage drops below the value required for proper operation,

the battery symbol ( ) appears.

W

Warning

To avoid shock, injury, or damage to the Meter, disconnect test leads before

opening case.

Replacing BATTERY follow below steps:

1. Disconnect the test lead probe from measuring circuit.

2. Turn the Meter to OFF position.

3. Remove the screws from the battery cover and open the battery cover

4. Remove the batteries and replace with 1.5V AAA Size (IEC R03). Observe

correct polarity when installing the batteries.

5. Put the battery cover back and re-fasten the screw. Battery: 2 x 1.5 V

AAA (IEC R03)

21

Page 26

Visit www.Amprobe.com for

• Catalog

• Application notes

• Product specifications

• User manuals

Amprobe

®

www.Amprobe.com

info@amprobe.com

Everett, WA 98203

Tel: 877-AMPROBE (267-7623)

Amprobe® Europe

Beha-Amprobe

In den Engematten 14

79286 Glottertal, Germany

Tel.: +49 (0) 7684 8009 - 0

Please

Recycle

Loading...

Loading...