Page 1

INSULATION TESTER

AMB-25

INSTRUCTION MANUAL

sACm:

MEM

READ

HOLD

K

M

VG

1. SAFETY INFORMATION

The circuit under test must be de-energized and isolated before

connections are made except for voltage measurement.

Verify operation prior to measuring hazardous voltages (voltage

above 30V AC rms, 42V AC peak and 60V DC).

Do not touch the Circuit connections during a test.

Disconnect the live test lead before disconnecting the neutral

test lead.

After insulation tests, to protect electric shock, capacitive circuits

must to be discharged.

Do not use the meter if the low battery indicator (

showed.

Test leads (including crocodile clips) must be in good order,

clean and no broken or cracked.

Do not use the meter if it looks damaged.

Do not use the meter around explosive gas, vapor or dust.

Do not push test button before all connection and preparation is

done. The instrument must only be used by suitably trained and

competent persons.

Do not use the meter with any parts or cover removed.

Do not use the meter in a wet environment.

U.S. PAT. NO. 478,017

JAPAN PAT. NO. 1180870

CHINA PAT. NO. ZL02367250.1

Warnings and Safety symbols:

Caution refer to this manual before using the meter.

Dangerous voltages.

Meter is protected throughout by double insulation or

reinforced insulation.

Comply with IEC1010-1

When servicing, use only specified replacement parts.

1

BT

) is

Page 2

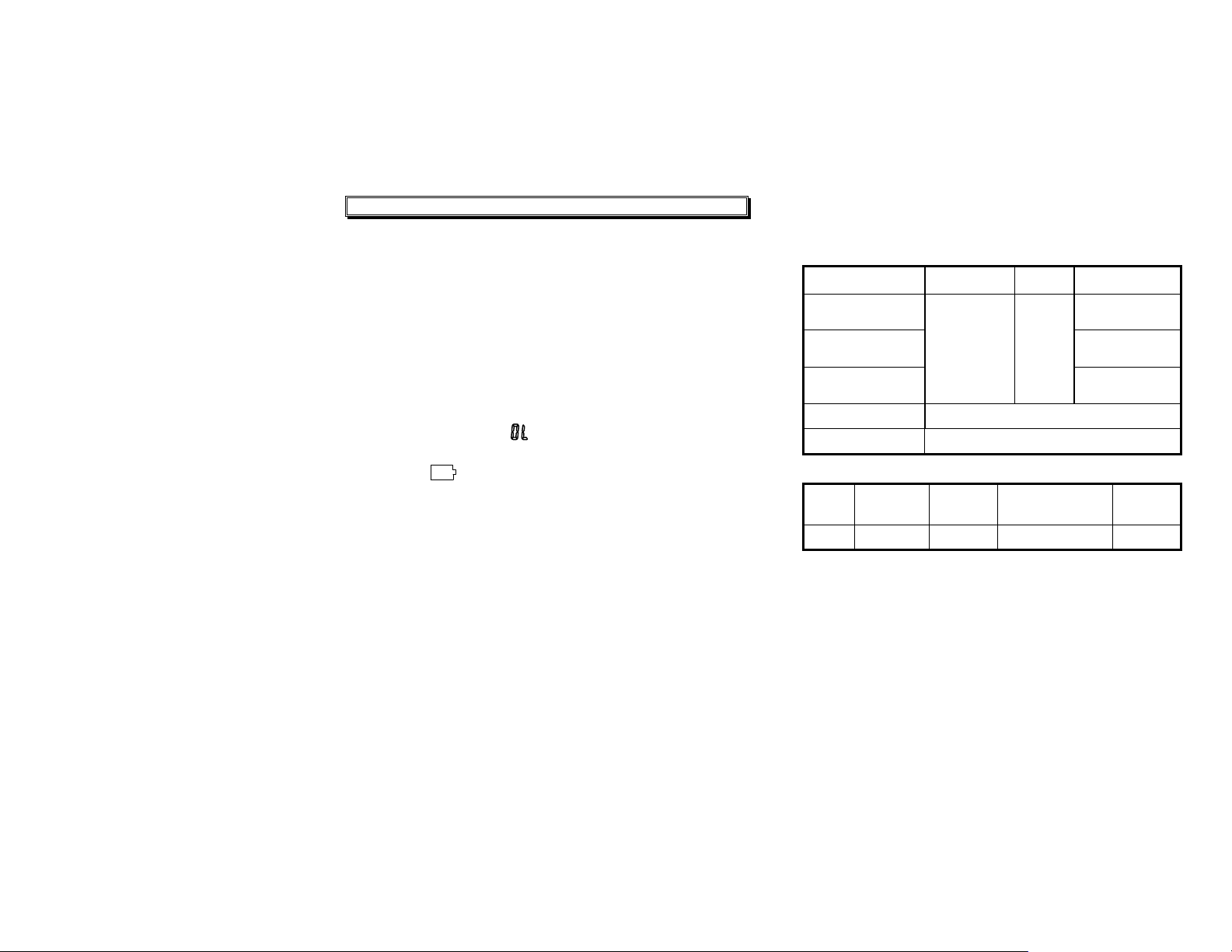

2. SPECIFICATIONS

Ω

2-1 General Information

Environment conditions :

c Installation CategoriesⅢ 1000V

d

Pollution Degree 2

e Altitude up to 2000 meters

f Indoor use only

Safety Meets of IEC61010-1 and IEC61557

Display : Dual display, 3-3/4 Digital readout with analog bar

Sampling Rate : 2.5 sample/sec.

Manual data Memory and Read : Memory capacity 9 set.

Over Range Indicator : “

Low Battery Indication :

Operating Temperature and Humidity:

Temperature Coefficient : 0.10 x (specified accuracy)/ ℃

Storage Temperature and Humidity :

Battery : 6 x 1.5V Size “AA” battery.

Fuse : 6mm x 32mm (0.25 x 1.25 inch), 0.5A 1000V, Fast Acting.

Dimensions : 235 (L) x 116 (W) x 54(H) mm ,

Weight : Approx. 520g (1.15 LB), include battery

Accessories : Test leads, 6pcs battery, Holster, operation manual.

indication.

” will be displayed.

BT

The (

below the operating voltage.

0℃ to 50℃ (32℉ to 122℉) below 80% RH (noncondensing).

-10℃ to 60℃ (14℉ to 140℉) below 70% RH (noncondensing)

) will be displayed when the battery voltage drop

(9.3”L x 4.6”W x 2.1”H)

2

2-2 Electrical Specifications

Accuracies are specified as:

±(...% of reading + ...digits) at 23℃ ±5℃,below 80% RH.

Insulation Resistance

Range Resolution Accuracy Test Voltages

40MΩ/400MΩ

400MΩ/1000M

/500V

400MΩ/ 2000M

/1000V

Analog Bar Graph

Nominal Current

Resistance & Continuity (<40Ω)

Range Resolution Accuracy

Ω

999.9

0.1Ω

40MΩ: 10 K

Ω

400MΩ:100 K

4000MΩ: 10M

Ω

3%+5

Ω

(<1000M)

Ω

5%+5

(>1000M)

0 to 4000MΩ

Max. open Circuit

1%+2 3V 1000Vrms

3

250V+20% ~ -0%

500V+20% ~ -0%

1000V+20% ~ -0%

≧

1mA

Voltage

Overload

Protection

Page 3

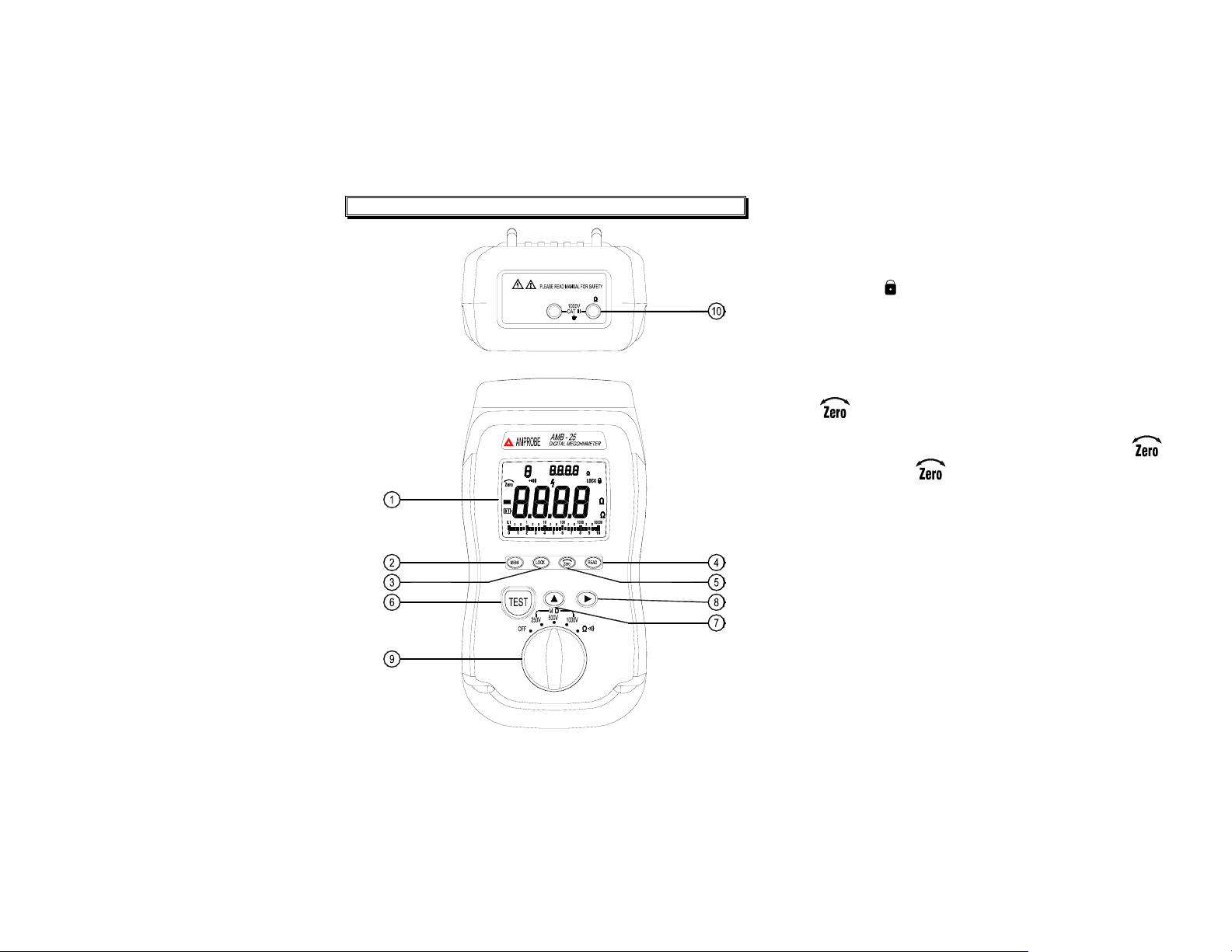

3. PARTS & CONTROLS

MEM

READ

COM V

4

c

LCD display.

d

MEM key : Manual data memory control key.

e

LOCK key : Locks the test Insulation Resistance (MΩ).

a). Press and hold down TEST key, then press LOCK key, the

“ LOCK ” icon appears on the display.

b). In MΩ mode continuously applies the test voltage to the circuit to

be tested. The beeper sounds every 2 seconds to remind you

that you are in the LOCK mode.

c). Press Lock or TEST key again to exit the mode.

f

READ key: Manual memory data reading control key.

g

key: In Ω function, turns the test lead resistance

compensation ON.

VM

M

V

h

TEST key :

the

display indicates 0.0Ω.

icon appears on the display and the main

Touch the probe tips together, then press

key,

a). Used for MΩ test functions.

b). Press and hold TEST key until the main display reading is stable.

▼▲

i j

keys : In READ mode, select the memory data location for

direct reading the data from the display.

k

Rotary switch : To select a measurement function.

l

Input terminals.

5

Page 4

Display :

MEM

READ

DC

V

M

M

c

Manual data memory and read location indicator.

d

Beeper symbol shows if beeper turned on in

e

High voltage warning symbol flashes, if voltage ≧ 30V is present on the

probes.

f

Resistance reading held from the last measurement in MΩ and

function.

g

Zero symbol is on if test leads are zeroed out.

h

Lock symbol is on if the TEST mode is locked in MΩ functions.

i

Low battery symbol.

j

Main display reading for all functions.

k

Analog bar graph displays resistance on a logarithmic scale and

voltage on a linear scale. The value always tracks the main display.

Ω

function.

6

4. BEFORE OPERATION

Warning

To avoid electrical shock remove test leads before opening case or

battery cover. Do not operate with battery cover open.

To avoid electrical shock when performing resistance tests, remove

all power from the circuit to be measured.

To avoid electrical shock, first connect the test leads to the meter

inputs before you make connection to the circuit under test.

To avoid electrical shock, do not touch test lead tips, test points or

terminals when pressing TEST.

4-1 How to connect test leads.

Ω

Connect the red test lead into the “ VΩ ” terminal and the black

lead into the “ COM ” terminal.

4-2 Battery Check & Replacement

1). If battery power is not sufficient, LCD will display “

Replacement of 6 pcs new batteries, type 1.5V size “AA” is required.

2). Use a screw drive to unscrew the screw secured on battery cover.

Take out the used batteries and replace 6 pcs new batteries.

3). Place back the battery cover and secure the screw.

4-3 Auto-Power-Off

1). The meter automatically turns off after 15 minutes of non-use.

2). To turn the meter back on, turn the rotary switch to OFF, then to

the desired function.

4-4 Test Leads Check

Set the range select switch to the “

crocodile clips with the test lead tips, Clip alligator clips with lead

other. The indicator should read <0.5Ω. When the leads are not

connected the display will read infinity indicated by “

will ensure that test leads are under working condition.

Ω

” range. Connect the

BT

-

-

”. This

”.

Page 5

4-5 Manual Data Memory and Read Mode :

1). Clear the manual memorized data

c Set the function switch to OFF position to turn off the meter.

d Press and hold down "MEM" key, and turn on the meter.

When LCD shows "dEL" which means the manual memorized

data is erased.

2). Manual data memory

c Press "MEM" key each time, one set of reading to will be

stored to the memory. At this moment, LCD will show the

"MEM" mark and the memory address number. Total memory

size is 9 sets.

d When the memory is full, LCD will show " 9 " memory address

number.

3). Read Manual memory data

c Press "READ" key to enter READ mode, the LCD will show

"READ" mark and the memory address number.

d Press " " or " " key to select the desired memory address

number data for display.

e Press " READ " key again to exit this mode.

7

8

5. Ω RESISTANCE AND CONTINUITY MEASUREMENTS

1). Set the function switch to

2). Connect red test lead to “ VΩ ” terminal and black test lead to

“ COM ” terminal.

3). Connect the probe to the circuit to be measured. Measure

voltage first to ensure that no haszardous voltage is present, then

switch to ohms.

4). Read the resistance value from the display. If the resistance is

approximately 40Ω or less, the meter will beep.

Ω

position.

6. MΩ INSULATION RESISTANCE MEASUREMENTS

6-1 Measuring Insulation Resistance

Measuring insulation resistance requires the application of

potentially dangerous voltage to the circuit. This may include

exposed bonded metal work.

Before proceeding, ensure that the installation is correctly wired

and no personnel are endangered by any test.

1). Set the function switch to the desired MΩ test voltage position.

2). Connect red test lead to “ VΩ ” terminal and black test lead to

“ COM ” terminal.

3). The display will show “-----“ until the TEST button is pushed.

Press and hold the TEST key. The upper right display shows

the test voltage applied to the circuit under test. The main

display shows the resistance until a stable resistance reading is

displayed on the main display.

Page 6

4). Keeping the probes on the test points when release the TEST key.

9

The upper right display shows the measured resistance reading

and the circuit now discharges through the meter, while the

main display reading shows the decreasing voltage, keep the

probe touched to test points until the circuit is completely

discharged and the main display shows “-----“.

The upper right display holds the resistance reading until a new

test is started or a different function is selected.

6-2 Using the LOCK Function to Measure Insulation Resistance

The LOCK function holds the test voltage on the probes. Use

LOCK function to make long duration measurements, don’t need to

push and hold the TEST key.

1). Press and hold the TEST key, then press the LOCK key to enter

LOCK mode. In this mode, a potentially dangerous voltage is

continuously applied to the probes.

In this mode, if the probes are disconnected from the circuit, the

meter cannot discharge any potentially dangerous capacitive

voltages left on the circuit.

Ensure that the circuit is de-energized before connecting the test

probes.

2). Press LOCK or TEST key to disable the Lock function.

10

7. POWER TOOLS AND SMALL APPLIANCES

This test would also apply to other similar equipment that has a line cord.

For double insulated power tools, one leads of megohmmeter to be

connected to the housing. The other leads would be connected to some

metal part of the tool (e.g. chuck, blade).

Note: The switch of the device must be in the “ON” position and the main

power should be disconnected.

MOTORS

AC-Disconnect the motor from the line by disconnecting the wires at the

motor terminals or by opening the main switch. If the main switch is

used and the motor also has a starter then the starter must be held, by

some means, in the “ON” position. In the latter case, the measured

resistance will include the resistance of the motor, wire and all other

components between the motor and the main switch. If a weakness is

indicated, the motor and other components should be checked

individually.

If the motor is disconnected at the motor terminals, connect one

megohmmeter lead to the grounded motor housing and the other lead to

one of the motor leads.

Disconnect the motor from the line. To test the brush rigging, field coils

and armature connect one megohmmeter lead to the grounded motor

housing and the other lead to the brush on the commutator.

If the resistance measurement indicates a weakness, raise the brushes

off the commutator and separately test the armature, field coils and

brush rigging by connecting one megohmmeter lead to each of them

Page 7

individually, leaving the other connected to the grounded motor housing.

The above also applies to DC Generators.

11

CABLES

Disconnect the cable from power. Also disconnect opposite end to avoid

errors of any leakage from other equipment. Check each conductor to

ground and /or lead source by connecting one megohmmeter lead to a

ground and /or lead source and the other megohmmeter lead to each of the

conductors in turn. Check insulation resistance between conductors by

connecting megohmmeter leads to conductors in pairs.

8. FUSE CHECK & REPLACEMENT

8-1 Testing the Fuse

1). Set the function switch to LoΩ position.

2). Connect the test leads to the input terminals and short then together.

3). Press TEST key, the display should indicate approximately 0.5Ω, if the

display reads OL, replace the fuse as described next and test again.

12

8-2 Replace the Fuse

Warning

To avoid electric shock, personal injury or damage to the meter, use

only the specified fuse.

1). Set the function switch to OFF position.

2). Disconnect test leads from any power source.

3). Place the meter face down on a nonabrasive surface and loosen the

four screws.

4). Take off the bottom cover.

5). Remove the fuse, replace with a new fuse.

6). Place the bottom cover on and secure the four screws.

7). Test the fuse (refer 8-1 Testing the Fuse).

9. BATTERY REPLACEMENT

1). Set the function switch to OFF position.

2). Disconnect test leads from any power source.

3). Place the meter face down on a nonabrasive surface and loosen the

two screws.

4). Take off the battery cover.

5). Remove the battery, replace with six new batteries.

6). Place the battery cover on and secure the two screws.

10. MAINTENANCE & CLEANING

Maintenance & Clearing :

1). Repairs or servicing not covered in this manual should only be

performed by qualified personnel.

2). Periodically wipe the case with a dry cloth.

Do not use abrasives or solvents on this instrument.

Page 8

13

WARRANTY

Congratulations! Your new instrument has been quality

crafted according to quality standards and contains quality

components and workmanship. It has been inspected for

proper operation of all of its functions and tested by qualified

factory technicians according to the long-established

standards of our company.

Your instrument has a limited warranty against defective

materials and/or workmanship for one year from the date of

purchase provided that, in the opinion of the factory, the

instrument has not been tampered with or taken apart.

Should your instrument fail due to defective materials,

and/or workmanship during this one-year period, a no

charge repair or replacement will be made to the

original purchaser. Please have your dated bill of sale,

which must identify the instrument model number and

serial number and call the number listed below:

Repair Department

ATP – Amprobe, TIF, Promax

Miramar, FL

Phone: 954-499-5400

800-327-5060

Fax: 954-499-5454

Website: www.Amprobe.com

Please obtain an RMA number before returning product

for repair.

Outside the U.S.A. the local representative will assist you.

Above limited warranty covers repair and replacement of

instrument only and no other obligation is stated or implied.

Miramar, FL

Phone: 954-499-5400

Fax: 954-499-5454

www.Amprobe.com

Page 9

Sep-2003

Loading...

Loading...