Page 1

Supplement

Title: 30XR-A Users Supplement Issue: 1

Part Number: 2728971 Issue Date: 9/06

Print Date: July 2006 Page Count: 1

Revision/Date:

This supplement contains information

necessary to ensure the accuracy of the

above manual.

© 2006 Amprobe© Test Tools. All rights reserved.

Page 2

30XR-A Users Supplement

Change #1

On page 7, under General Specification, change

Operating environment:

From: 0 ºC to 50 ºC at <70% R.H.

To: 0 ºC to 50 ºC at <70% R.H. for all functions

except ranges 10A ranges: 0 ºC to 40 ºC at

<70% R.H.

9/06 1

Page 3

Professional

Digital

Multimeter

with Non-Contact

Voltage Tester

Users Manual

·

Mode d'emploi

·

Bedienungshandbuch

·

Manuale d'Uso

·

Manual de uso

30XR-A30XR-A

Page 4

MIN MAX

20M

2M

200k

30XR-A

NON

CONTACT

HOLD

VOLTAGE

OFF

600

600

V

2

20k

2k

BATT 1.5V

mA

10A

V

200

200

20

20

2

200m200m

10 A

10 A

200

200m

1.5V

20m

9V

2m

BATT

200

CAT 600V

A

CAT 300V

BATT 9V

V

COM

200mA

MAX

FUSED

MAX

10A MAX

600V

FUSED

600V

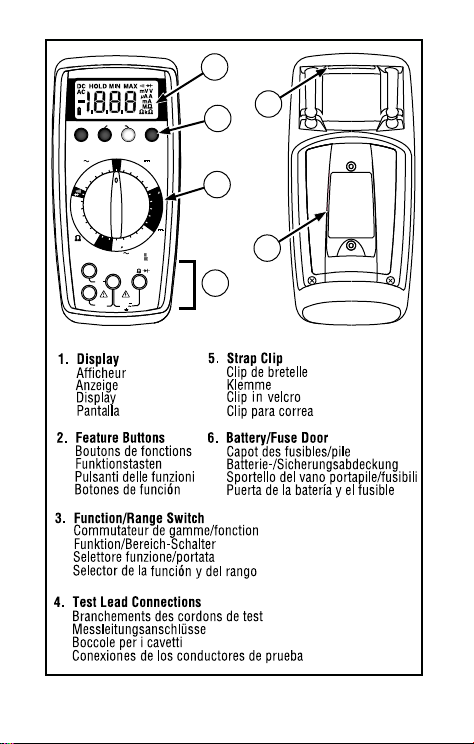

1

5

2

MADE IN TAIWAN

PATENTS PENDING

www.amprobe.com

200

200m

3

2m

20m

A

6

4

30XR-A

Page 5

30XR-A

Professional Digital Multimeter

Users Manual

• Mode d’emploi

• Bedienungshandbuch

• Manuale d’Uso

• Manual de uso

PN 2728917

July 2006

©Amprobe® Test Tools.

All rights reserved. Printed in Taiwan.

Page 6

Page 7

30XR-A Digital Multimeter

Contents

Making Measurements...............................................................................2

Verify Instrument Operation...................................................................2

Correcting an Overload (o) Indication W ............................................2

Measuring DC Voltage .................................See Figure -1- ...................2

Measuring AC Voltage .................................See Figure -2- ...................2

Preparing for Current Measurements ....................................................2

Measuring DC Current .................................See Figure -3- ...................3

Measuring AC Current .................................See Figure -4- ...................3

Measuring Resistance .................................See Figure -5- ...................3

Measuring Continuity (<50 Ohms)...............See Figure -6- ...................3

Checking Diodes..........................................See Figure -7- ...................3

Measuring NCV (Non-Contact Voltage)........See Figure -8-...................4

Testing Battery Voltage (1.5 and 9 volt).......See Figure -9- ...................4

Additional Features ....................................................................................4

Product Maintenance..................................................................................5

Battery and Fuse Replacement.....................See Figure -10- .................5

Repair .........................................................................................................5

WARRANTY........................................................................................... 6

Electrical Specifications.............................................................................7

To Avoid possible electric shock, personal injury, damage to the meter or the

equipment under test, adhere to the following practices:

• Do not exceed the maximum overload limits per function (see specifications)

nor the limits marked on the instrument itself. Never apply more than 600 VDC

between the test lead and earth ground.

• Inspect DMM, test leads and accessories before every use. Do not use any

damaged part.

• Never ground yourself when taking measurements. Do not touch exposed

circuit elements or probe tips.

• Do not operate the instrument in an explosive atmosphere.

• Exercise extreme caution when measuring voltage >20 V // current >10 mA //

AC power line with inductive loads // AC power line during electrical storms //

current, when the fuse blows in a circuit with open circuit voltage >600 V //

servicing CRT equipment.

• Always measure current in series with the load – NEVER ACROSS a voltage

source. Check fuse first. Never replace a fuse with one of a different rating.

• Do not change the position of the Function/Range Switch while the MIN MAX or

the HOLD feature is enabled. Erroneous readings will result.

• Remove test leads before opening battery or case to change battery or fuses.

XWSafety Information

Users Manual

1

Page 8

2

Symbols Used in this Manual

B Battery W Refer to the manual

T Double insulated X Dangerous Voltage

F Direct Current J Earth Ground

B Alternating Current R Audible tone

P Complies with EU directives

I Fuse

@ Underwriters

Laboratories, Inc

Making Measurements

Verify Instrument Operation

Before attempting to make a measurement, verify that the instrument is operational

and the battery is good. If the instrument is not operational, have it repaired before

you attempting to make a measurement.

Correcting an Overload (0o) Indication W

An oor indication may appear on the display to indicate that an overload condition

exists. For voltage and current measurements, an overload should be immediately

corrected by selecting a higher range. If the highest range setting does not

eliminate the overload, interrupt the measurement until the problem is identified

and eliminated. The o indication is normal for some functions; for example,

resistance, continuity, and diode test.

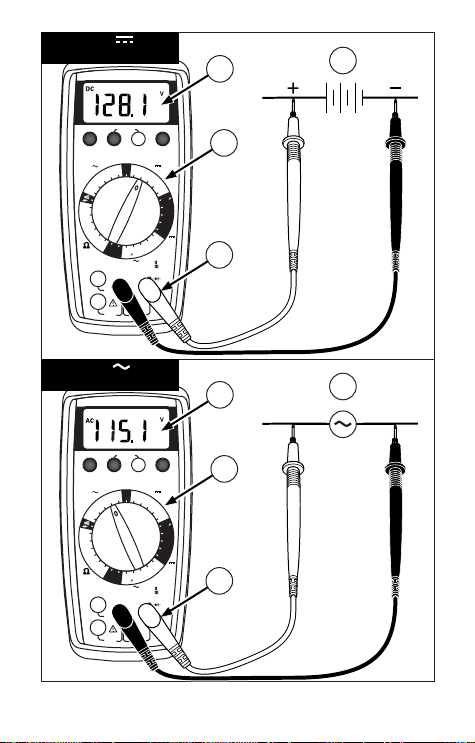

Measuring DC Voltage See Figure -1-

1. Set the Range Switch to an appropriate L range.

Select the highest range and work down if the voltage level is unknown.

2. Connect the Test Leads: Red to VΩG, Black to COM.

3. Connect the Test Probes to the circuit test points.

4. Read the display, and, if necessary, fix any overload (o) conditions.

Measuring AC Voltage See Figure -2-

1. Set the Range Switch to an appropriate K range.

Select the highest range and work down if the voltage level is unknown.

2. Connect the Test Leads: Red to VΩG, Black to COM.

3. Connect the Test Probes to the circuit test points.

4. Read the display, and, if necessary, fix any overload (o) conditions.

Preparing for Current Measurements

• Turn off circuit power before connecting the test probes.

• Allow the meter to cool between measurements if current measurements

approach or exceeds 10 amps.

• A warning tone sounds if you connect a test lead to a current input before you

select a current range.

• Open circuit voltage at the measurement point must not exceed 600 V.

• Always measure current in series with the load. Never measure current across

a voltage source.

Page 9

3

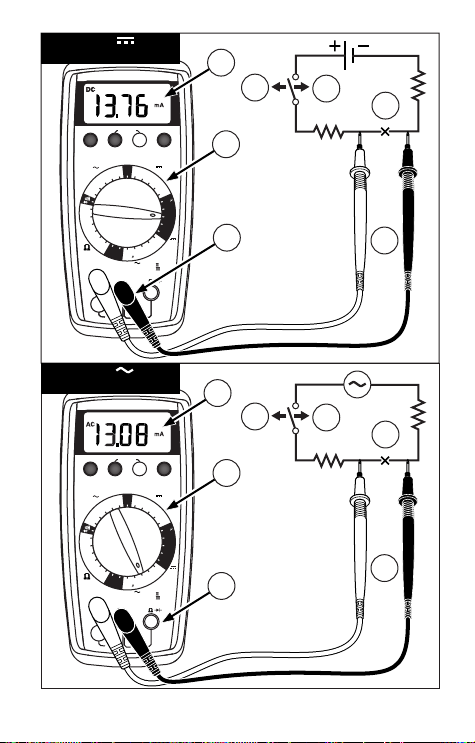

Measuring DC Current See Figure -3-

1. Set the Range Switch to an appropriate A range.

Select the highest range and work down if the current level is unknown.

2. Connect the Test Leads: Red to mA or 10 A, Black to COM.

3. Turn off power to the circuit being measured.

4. Open the test circuit (X) to establish measurements points.

5. Connect the Test Probes in series with the load.

6. Turn on power to the circuit being measured.

7. Read the display, and, if necessary, fix any overload (o) conditions.

Measuring AC Current See Figure -4-

1. Set the Range Switch to an appropriate ? range.

Select the highest range and work down if the current level is unknown.

2. Connect the Test Leads: Red to mA or 10 A, Black to COM

3. Turn off power to the circuit being measured.

4. Open the test circuit (X) to establish measurements points.

5. Connect the Test Probes in series with the load.

6. Turn on power to the circuit being measured.

7. Read the display, and, if necessary, fix any overload (o) conditions.

Measuring Resistance See Figure -5-

1. Set the Range Switch to an appropriate Ω range.

Select the highest range and work down if the resistance level is unknown.

2. Connect the Test Leads: Red to VΩG, Black to COM.

3. Turn off power to the circuit being measured. Never measure resistance across

a voltage source or on a powered circuit.

4. Discharge any capacitors that may influence the reading.

5. Connect the Test Probes across the resistance.

6. Read the display. If o appears on the highest range, the resistance is too large

to be measured.

Measuring Continuity (<50 Ohms) See Figure -6-

1. Set the Range Switch to R.

2. Connect the Test Leads: Red to VΩG, Black to COM.

3. Turn off power to the circuit being measured.

4. Discharge any capacitors that may influence the reading.

5. Connect the Test Probes across the resistance.

6. Listen for the tone that indicates continuity (< 50 Ohms).

Checking Diodes See Figure -7-

1. Set the Range Switch to G.

2. Connect the Test Leads: Red to VΩG, Black to COM.

3. Turn off power to the circuit being measured.

4. Free at least one end of the diode from the circuit.

5. Connect the Test Probes across the diode.

6. Read the display. A good diode has a forward voltage drop of about 0.6 V. An

open or reverse biased diode will read o.

Page 10

4

Measuring NCV (Non-Contact Voltage) See Figure -8-

1. Range switch may be set to OFF or any function/range.

2. Test leads are not used for the NCV test.

3. Press the NCV button. The display goes blank, a tone sounds and the red LED

next to the NCV button on the front panel lights up to verify that the instrument

is operational. While pressing the button hold the top-center of the meter

(sensor location) close to the conductor/circuit in question.

4. If a voltage of in the range of 70 to 600 V ac is present, a tone sounds and the

red LED next to the NCV button on the front panel lights up.

Testing Battery Voltage (1.5 and 9 volt) See Figure -9-

1. Set the Range Switch to the appropriate BATT setting, 1.5 V or 9 V.

2. Connect the Test Leads: Red to BATT 1.5 V or BATT 9 V, Black to COM.

3. Connect the Test Probes across the battery. The meter applies an appropriate

load to the battery.

4. Read the display. A good 1.5 volt battery should measure >1.2 V, and a good

9 volt battery should measure > 7.2 V.

Additional Features

Input Lead Warning

The 30XR-A emits a continuous tone to indicate that the user has placed the unit in

a potentially dangerous configuration. Specifically, a test lead is in a current

connector and the Range Switch is set to measure some other function. If, in this

configuration, the DMM is connected to a voltage source, very high and potentially

dangerous current could result. The meter includes fast acting fuses as additional

protection for all current ranges.

MIN MAX Measurements

XWWARNING

To avoid erronoeus readings, do not change the position of the

Function/Range Switch while the MIN MAX function is enabled.

The MIN MAX function works within the active measurement mode to capture and

display the minimum or maximum reading associated with that measurement.

Pressing the MIN MAX button for less than 1 second enables the function and

shows MIN or MAX along with the appropriate minimum or maximum reading on

the display. Each subsequent press toggles between the two modes. To exit the

function, press the MIN MAX button for more than 1 second.

HOLD Measurements

XWWARNING

To avoid erronoeus readings, do not change the position of the

Function/Range Switch while the HOLD function is enabled.

The HOLD function is used to make a measurement and hold the reading after

removing the leads from the test circuit. Pressing the HOLD button during a

measurement will capture and hold the reading. Pressing the HOLD button again

will release the display for subsequent measurements.

Page 11

5

Product Maintenance

Cleaning

To clean the meter, use a soft cloth moistened with water. Using benzene, alcohol,

acetone, ether, paint thinner, lacquer thinner, ketone or other solvents may deform

or discolor the meter and its display.

Troubleshooting

If the meter appears to operate improperly, check the following items first.

1. Review the operating instructions to ensure the meter is being used properly.

2. Inspect and test the continuity of the test leads.

3. Make sure the battery is in good condition. The low battery symbol B appears

when the battery falls below the level where accuracy is guaranteed. Replace a

low-battery immediately.

4. Check the condition of the fuses if the current ranges operate incorrectly.

XWWARNING

To avoid electrical shock remove the test leads from both the

meter and the test circuit before accessing the battery or the

fuses.

Battery and Fuse Replacement See Figure -10-

To access these parts, you must first remove the cover from the battery

compartment. The battery cover is on the rear of the meter and is held in place with

two screws. After removing these screws, you can easily remove and replace the

battery. To replace the mA fuse, pry it from its clips using a small screwdriver. A

spare mA fuse is located between the battery and the mA fuse.

Battery: 9 V NEDA mA Fuse: Fast Blow 250 mA/600 V (Amprobe® FP375)

To replace the 10 A fuse, remove the battery, remove the four rear-case screws,

separate the case, remove the 10 A fuse cover, and remove and replace the 10 A

fuse. Re-install the fuse cover.

10 A Fuse: Fast Blow 10 A/600 V, minimum interrupt rating 30 kA (10 x 38 mm)

fuse (Amprobe® FP160) or equivalent.

Repair

All test tools returned for warranty or non-warranty repair or for calibration should

be accompanied by the following: your name, company’s name, address, telephone

number, and proof of purchase. Additionally, please include a brief description of

the problem or the service requested and include the test leads with the meter.

Non-warranty repair or replacement charges should be remitted in the form of a

check, a money order, credit card with expiration date, or a purchase order made

payable to Amprobe® Test Tools.

In-Warranty Repairs and Replacement – All Countries

Please read the warranty statement and check your battery before requesting

repair. During the warranty period any defective test tool can be returned to your

Amprobe® Test Tools distributor for an exchange for the same or like product.

Please check the “Where to Buy” section on www.amprobe.com for a list of

distributors near you. Additionally, in the United States and Canada In-Warranty

repair and replacement units can also be sent to a Amprobe® Test Tools Service

Center (see below for address).

Page 12

6

Non-Warranty Repairs and Replacement – US and Canada

Non-warranty repairs in the United States and Canada should be sent to a

Amprobe® Test Tools Service Center. Call Amprobe® Test Tools or inquire at your

point of purchase for current repair and replacement rates.

In USA In Canada

Amprobe® Test Tools Amprobe® Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel: 888-993-5853 Tel: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Non-Warranty Repairs and Replacement – Europe

European non-warranty units can be replaced by your Amprobe® Test Tools

distributor for a nominal charge. Please check the “Where to Buy” section on

www.amprobe.com for a list of distributors near you.

European Correspondence Address*

Amprobe® Test Tools Europe

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

*(Correspondence only – no repair or replacement available from this address.

European customers please contact your distributor).

WARRANTY

The 30XR-A Digital Multimeter is warranted against any defects of material or

workmanship within a period of one (1) year following the date of purchase of the

multimeter by the original purchaser or original user. Any multimeter claimed to be

defective during the warranty period should be returned with proof of purchase to

an authorized Amprobe® Test Tools Service Center or to the local Amprobe® Test

Tools dealer or distributor where your multimeter was purchased. See maintenance

section for details. Any implied warranties arising out of the sale of a Amprobe®

Test Tools multimeter, including but not limited to implied warranties of

merchantability and fitness for a particular purpose, are limited in duration to the

above stated one (1) year period. Amprobe® Test Tools shall not be liable for loss

of use of the multimeter or other incidental or consequential damages, expenses,

or economical loss or for any claim or claims for such damage, expenses or

economical loss. Some states do not allow limitations on how long implied

warranties last or the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Page 13

7

Specifications

General Specifications

Display: 3½ digit liquid crystal display

(LCD) with a maximum reading of

1999.

Polarity: Automatic, positive implied,

negative polarity indication.

Overrange: (OL) or (-OL) is displayed.

Zero: Automatic.

Low battery indication: The B is

displayed when the battery voltage

drops below the operating level.

Measurement rate: 2.5 per second,

nominal.

Operating environment: 0 °C to 50 °C

at < 70 % R.H.

Storage temperature: -20 °C to 60 °C,

0 to 80 % R.H. with battery removed

from meter.

Temperature Coefficient: 0.1 ×

(specified accuracy) per °C. (0 °C to

18 °C, 28 °C to 50 °C).

Environment: Indoor use, Altitude up to

2000 m

Power: Single standard 9-volt battery,

NEDA 1604, JIS 006P, IEC 6F22.

Battery life: 200 hours typical with

carbon-zinc.

Dimensions: 196 x 92 x 60 mm ( 7.7” x

3.5” x 2.4”).

Weight: Approx. 426 .( 0.94 lb.) without

holster, including battery.

Accessories: One pair test leads

(TL36), 9 V battery (installed), Magna

Grip™ Holster, and Operating

Instructions.

Warranty: One (1) Year

Approvals:

>

LISTED

950Z

P

Safety: Conforms to UL1244;

EN61010-1: Cat II - 600V / Cat III 300V; Class 2, Pollution degree II.

The 30XR-A is recommended for use

with local level power distribution,

appliances, portable equipment, etc,

where only smaller transient

overvoltages may occur, and not for

primary supply lines, overhead lines

and cable systems.

EMC: Conforms to EN61326-1.

This product complies with

requirements of the following European

Community Directives: 89/ 336/ EEC

(Electromagnetic Compatibility) and 73/

23/ EEC (Low Voltage) as amended by

93/ 68/ EEC (CE Marking). However,

electrical noise or intense

electromagnetic fields in the vicinity of

the equipment may disturb the

measurement circuit. Measuring

instruments will also respond to

unwanted signals that may be present

within the measurement circuit. Users

should exercise care and take

appropriate precautions to avoid

misleading results when making

measurements in the presence of

electronic interference.

Electrical Specifications

(at 23 °C ± 5 °C, <75 % R.H. noncondensing)

DC VOLTS

Ranges: 200 mV, 2 V, 20 , 200 V, 600 V

Accuracy: All ranges, ± (1.0 % rdg +

1 dgt)

Resolution: 100 μV in 200 mV range

Input impedance: 10 MΩ

Overload protection: 200 mV range:

600 V dc or 600 V ac rms 15 seconds.

Other ranges: 600 V dc or 600 V ac rms

Page 14

8

AC VOLTS (45 Hz – 500 Hz)

Ranges: 200 m, 2 V, 20 V, 200 V, 600 V

Accuracy: All ranges, ± (1.5 % rdg +

4 dgts)

Resolution: 100 μV in 200 mV range

Input impedance: 10 MΩ

Overload protection: 200 mV range:

600 V dc or 600 ac rms 15 seconds.

Other ranges: 600 V dc or 600 V ac rms

DC CURRENT

Ranges: 200 µA, 2 mA, 20 mA, 200 mA,

10 A

Accuracy:

200 μA to 200 mA ranges: ± (1.5 % rdg

+ 1 dgt)

10 A range: ± (2.0 % rdg + 3 dgts)

Resolution: 0.1 µA in 200 μA range

Burden voltage:

200 μA Range: 1 mV/ 1 μA

2 mA Range: 100 mV/ 1 mA

20 mA Range: 13 mV/ 1 mA

200 mA: 4.6 mV / 1 mA

10 A: 40 mV / 1 A

Overload Protection:

μA / mA input: F 0.25 A /600 V, Min.

I.R. 30 kA, (6.3x32 mm)

10 A input: F 10 A / 600 V, Min. I.R.

100 kA, (10x38 mm) (

10 A for 4 minutes

maximum followed by a 12 minute cooling

period

)

AC CURRENT (45 Hz – 500 Hz)

Ranges: 200 μA, 2 mA, 20 mA,

200 mA,10 A

Accuracy:

200 μA to 200 mA ranges: ± (2.0 % rdg

+ 4 dgts)

10 A range: ± (2.5 % rdg + 4 dgts)

Resolution: 0.1 μA in 200 μA range

Burden voltage: See DC Current

Overload Protection:

μA / mA input: F 0.25 A /600 V, Min.

I.R. 30 kA, (6.3x32 mm)

10 A input: F 10 A / 600 V, Min. I.R.

100 kA, (10x38 mm) (

10 A for 4 minutes

maximum followed by a 12 minute cooling

period

)

RESISTANCE

Ranges: 200 Ω, 2 kΩ, 20 kΩ, 200 kΩ,

2 MΩ, 20 MΩ

Accuracy:

200 Ω to 200 kΩ ranges: ± (1.0 % rdg

+ 4 dgts)

2 MΩ ranges: ± (1.5 % rdg + 4 dgts)

20 MΩ range: ± (2.0 % rdg + 5 dgts)

Resolution: 100 mΩ in 200 Ω range

Open circuit volts:

200 Ω range: 3.0 V dc

Other ranges: 0.3 V dc typical

Overload protection: 600 V dc or

600 V ac rms

CONTINUITY

Audible indication: 75 Ω ± 25 Ω

Response time: 100 ms

Overload protection: 600 V dc or

600 V ac rms

DIODE TEST

Test current: 1.0 mA (approximate)

Accuracy: ± (1.5 % rdg + 3 dgts)

Resolution: 0.001 V

Open circuit volts: 3.0 V dc typical

Overload protection: 600 V dc or

600 V ac rms

BATTERY TEST

Ranges: 1.5 V, 9 V

Accuracy: ± (3.5 % rdg + 2 dgts)

Resolution: 1 mV, 10 mV

Load Test current:

1.5 V range: 150 mA typical

9 V range: 5 mA typical

Overload protection: 600 V dc or

600 V ac rms

NON-CONTACT VOLTAGE (NCV)

AC Volts: 70 V to 600 V ac

Red LED and Audible Indicator

REPLACEMENT PARTS

TL36 – Test Lead Set w/ Alligator clips

FP375 - Fuse Pack 250 mA/600 V

(4 each)

FP160 - Fuse Pack 10 A/600 V (2 each)

Page 15

9

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

3

4

2

1

V

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

3

4

2

V

2

1

1

30XR-A

30XR-A

Page 16

10

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

MAX

600V

600V

2

3

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

7

4

2

1

1

5

5

3

6

4

3

6

4

A

A

7

30XR-A

30XR-A

Page 17

11

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

2

3

5

4

1

6

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

2

1

5

3

4

6

5

6

30XR-A

30XR-A

Page 18

12

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

MAX

600V

600V

6

2

7

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

8

NCV

1

1

3

5

4

2

M

A

X

6

0

0

V

6

0

0

V

2

0

0

m

A

M

A

X

F

U

S

E

D

1

0

A

M

A

X

F

U

S

E

D

CAT 600V

CAT 300V

HO

LD

30

X

R

-A

M

IN M

A

X

V

B

A

T

T

9

V

B

A

T

T

1

.

5

V

COM

10A

mA

V

6

0

0

6

0

0

2

0

02

0

0

2

0

0

m

2

0

0

m

2

0

M

2

M

2

0

k

2

0

0

k

2

k

2

0

0

2

0

0

m

2

0

m

2

0

2

0

2

2

V

A

1

0

A

2

0

0

2

m

B

A

TT

O

FF

2m

200

m

200

2

0m

A

1

0 A

1.5V

9

V

3

4

30XR-A

30XR-A

Page 19

13

(2)

(4)

MAX

600V

600V

200mA

MAX

FUSED

10A MAX

FUSED

CAT 600V

CAT 300V

HOLD

MIN MAX

NON

CONTACT

VOLTAGE

V

BATT 9V

BATT 1.5V

COM

10A

mA

V

600

600

200

200

200m200m

20M

2M

20k

200k

2k

200

200m

20m

20

20

2

2

V

A

10 A

200

2m

BATT

OFF

2m

200m

200

20m

A

10 A

1.5V

9V

4

9

2

1

BATT

3

(2)

10

30XR-A

Page 20

14

Page 21

30XR-A Digital Multimeter

Table des matières

Opérations de mesure...............................................................................2

Vérifier le fonctionnement de l’appareil...............................................2

Correction d’une indication de surcharge (o).................................... 2

Mesures de tension c.c...................................Voir Figure -1- ............2

Mesures de tension c.a...................................Voir Figure -2- ............2

Préparation des mesures de courant ..................................................2

Mesures de courant c.c. .................................Voir Figure -3- ............3

Mesures de courant c.a. .................................Voir Figure -4- ............3

Mesures de résistance ...................................Voir Figure -5- ............3

Mesures de continuité (< 50 ohms)................Voir Figure -6- ............3

Contrôle de diodes..........................................Voir Figure -7- 3

Mesures NCV (Tension sans contact).............Voir Figure -8- ............4

Test de tension de pile (1,5 et 9 volts)............Voir Figure -9- ............4

Autres fonctions .......................................................................................4

Entretien du produit..................................................................................5

Remplacement des fusibles et des piles .........Voir Figure -10- ..........5

Réparation ................................................................................................5

GARANTIE ..........................................................................................6

Caractéristiques générales........................................................................7

Caractéristiques électriques......................................................................7

Pour éviter les chocs électriques, les risques de blessures ou d’endommagement

du multimètre ou de l’équipement testé, respecter les pratiques suivantes :

• Ne pas dépasser les limites de surcharge maximum par fonction (voir les

caractéristiques techniques) ou les limites indiquées sur l’appareil lui-même.

Ne jamais appliquer plus de 600 V c.c. entre le cordon de test et la terre.

• Inspecter le multimètre numérique, les cordons de test et les accessoires avant

toute utilisation. Ne pas utiliser de pièce endommagée.

• Ne jamais se mettre à la terre en prenant des mesures. Ne toucher ni aux

éléments de circuit exposés ni aux pointes des sondes.

• Ne pas utiliser l’appareil dans une atmosphère explosive.

• Faire preuve d’extrême prudence en mesurant une tension > 20 V // un

courant > 10 mA // les lignes d’alimentation secteur avec charges inductives //

les lignes d’alimentation secteur pendant les orages électriques // un courant

alors que le fusible a sauté dans un circuit avec une tension en circuit

ouvert > 600 V // lors d’une intervention sur un appareil à écran cathodique.

• Toujours mesurer le courant en série avec la charge – JAMAIS AUX BORNES

d’une source de tension. Vérifier d’abord le fusible. Ne jamais installer un

fusible de calibre différent.

• Ne changez pas la position du commutateur Function/Range alors que la

fonction MIN MAX ou HOLD est active.

• Retirer les cordons de test avant d’ouvrir le compartiment ou le boîtier pour

remplacer la pile ou les fusibles.

XWConsignes de sécurité

Mode d'emploi

1

Page 22

2

Symboles utilisés dans ce mode d’emploi

B Pile W Se reporter au mode

d’emploi

T Double isolation X Tension dangereuse

F Courant continu J Prise de terre

B Courant alternatif R Signal sonore

P Conforme aux directives de

l’UE

I Fusible

@ Underwriters

Laboratories, Inc.

Opérations de mesure

Vérifier le fonctionnement de l’appareil

Avant d’essayer de prendre une mesure, vérifiez que l’appareil est opérationnel et

que la pile est en bon état. Si l’appareil n’est pas opérationnel, faites-le réparer

avant de procéder à une mesure.

Correction d’une indication de surcharge (o)

Une indication 0o apparaît parfois sur l’affichage pour indiquer la présence d’une

surcharge. Pour les mesures de courant et de tension, cette situation de surcharge doit

être immédiatement corrigée en sélectionnant une gamme plus élevée. Si le choix de la

gamme la plus élevée n’est pas suffisant, interrompez la mesure tant que le problème n’a

pas été identifié et éliminé. L’indication 0o est normale pour certaines fonctions ;

notamment pour la résistance, la continuité et le contrôle de diodes.

Mesures de tension c.c. Voir Figure -1-

1. Réglez le commutateur de gamme sur la gamme L appropriée.

Si le niveau de tension est inconnu, sélectionnez la gamme la plus élevée puis

revenez vers les gammes plus basses.

2. Branchez les cordons de test : rouge à VΩG, noir à COM.

3. Branchez les sondes de test aux points de test du circuit.

4. Lisez l’affichage et corrigez le cas échéant toute surcharge (o).

Mesures de tension c.a. Voir Figure -2-

1. Réglez le commutateur de gamme sur la gamme K appropriée.

Si le niveau de tension est inconnu, sélectionnez la gamme la plus élevée puis

revenez vers les gammes plus basses.

2. Branchez les cordons de test : rouge à VΩG, noir à COM.

3. Branchez les sondes de test aux points de test du circuit.

4. Lisez l’affichage et corrigez le cas échéant toute surcharge (o).

Préparation des mesures de courant

• Mettez le circuit hors tension avant de brancher les sondes de test.

• Laissez le multimètre refroidir entre les mesures si les mesures de courant

approchent ou dépassent 10 ampères.

• Un signal sonore retentit quand on branche un cordon de test dans une entrée

de courant avant d’avoir sélectionné une gamme de courant.

• La tension en circuit ouvert au point de mesure ne doit pas dépasser 600 V.

• Toujours mesurer le courant en série avec la charge. Ne jamais mesurer le

courant aux bornes d’une source de tension.

Page 23

3

Mesures de courant c.c. Voir Figure -3-

1. Réglez le commutateur de gamme sur la gamme A appropriée.

Si le niveau de courant est inconnu, sélectionnez la gamme la plus élevée puis

revenez vers les gammes plus basses.

2. Branchez les cordons de test : rouge à mA or 10 A, noir à COM.

3. Mettez hors tension le circuit à mesurer.

4. Ouvrez le circuit de test (X) pour établir les points de mesure.

5. Branchez les sondes de test en série avec la charge.

6. Mettez sous tension le circuit à mesurer.

7. Lisez l’affichage et corrigez le cas échéant toute surcharge (o).

Mesures de courant c.a. Voir Figure -4-

1. Réglez le commutateur de gamme sur la gamme ? appropriée.

Si le niveau de courant est inconnu, sélectionnez la gamme la plus élevée puis

revenez vers les gammes plus basses.

2. Branchez les cordons de test : rouge à mA or 10 A, noir à COM.

3. Mettez hors tension le circuit à mesurer.

4. Ouvrez le circuit de test (X) pour établir les points de mesure.

5. Branchez les sondes de test en série avec la charge.

6. Mettez sous tension le circuit à mesurer.

7. Lisez l’affichage et corrigez le cas échéant toute surcharge (o).

Mesures de résistance Voir Figure -5-

1. Réglez le commutateur de gamme sur la gamme Ω appropriée.

Si le niveau de résistance est inconnu, sélectionnez la gamme la plus élevée

puis revenez vers les gammes plus basses.

2. Branchez les cordons de test : rouge à VΩG, noir à COM.

3. Mettez hors tension le circuit à mesurer. Ne mesurez jamais la résistance aux

bornes d’une source de tension sur un circuit alimenté.

4. Déchargez les condensateurs susceptibles d’influencer la lecture.

5. Branchez les sondes de test aux bornes de la résistance.

6. Lisez l’affichage. Si o apparaît sur la gamme la plus élevée, la résistance est

trop grande pour être mesurée.

Mesures de continuité (< 50 ohms) Voir Figure -6-

1. Réglez le commutateur de gamme sur R.

2. Branchez les cordons de test : Rouge à VΩG, noir à COM.

3. Mettez hors tension le circuit à mesurer.

4. Déchargez les condensateurs susceptibles d’influencer la lecture.

5. Branchez les sondes de test aux bornes de la résistance.

6. Notez la tonalité qui indique la continuité (< 50 ohms).

Contrôle de diodes Voir Figure -7-

1. Réglez le commutateur de gamme sur G.

2. Branchez les cordons de test : rouge à VΩG, noir à COM.

3. Mettez hors tension le circuit à mesurer.

4. Libérez du circuit au moins une extrémité de la diode.

5. Branchez les sondes de test aux bornes de la diode.

6. Lisez l’affichage. Une diode en bon état présente une chute de tension dans le

sens direct d’environ 0.6 V. Une diode ouverte ou polarisée dans le sens

inverse indique o.

Page 24

4

Mesures NCV (Tension sans contact) Voir Figure -8-

1. Réglez le commutateur de gamme sur OFF ou sur n’importe quelle

fonction/gamme.

2. Les cordons de test ne sont pas utilisés pour le test NCV.

3. Appuyez sur le bouton NCV. L’affichage se vide, une tonalité retentit et le

voyant rouge près du bouton NCV sur le panneau avant s’allume pour vérifier le

bon fonctionnement de l’appareil. Tenez le point central supérieur du

multimètre (emplacement du capteur) près du conducteur/circuit en question,

tout en appuyant sur le bouton NCV.

4. Si une tension dans la gamme 70 à 600 V c.a. est détectée, une tonalité retentit

et le voyant ROUGE près du bouton NCV s’allume sur le panneau avant.

Test de tension de pile (1.5 et 9 volts) Voir Figure -9-

1. Réglez le commutateur de gamme sur le paramètre BATT approprié, 1.5 V

ou 9 V.

2. Branchez les cordons de test : rouge à BATT 1.5 V ou BATT 9 V, noir à COM.

3. Reliez les sondes de test aux bornes de la pile. Le multimètre applique une

charge appropriée à la pile.

4. Lisez l’affichage. Une pile de 1.5 volts en bon état doit mesurer > 1.2 V, et une

pile de 9 volts en bon état doit mesurer > 7.2 V.

Autres fonctions

Avertissement de cordon d’entrée

Le 30XR-A émet une tonalité continue pour signaler que l’unité a été placée dans

une configuration potentiellement dangereuse. En particulier, si un cordon de test

est dans un connecteur de courant et si le commutateur de gamme est réglé pour

mesurer une autre fonction. Dans une telle configuration, si le multimètre

numérique est connecté à une source de tension, cela risque d’entraîner un courant

potentiellement dangereux et très élevé. Le multimètre utilise des fusibles

instantanés comme protection supplémentaire pour toutes les gammes de courant.

Mesures MIN MAX

XWAVERTISSEMENT

Pour éviter les lectures erronées, ne pas modifier la position du

commutateur Function/Range alors que la fonction MIN MAX est

active.

La fonction MIN MAX permet dans le mode de mesure actif de saisir et d’afficher la

valeur minimum ou maximum associée à cette mesure. Une pression du bouton

MIN MAX pendant moins d’une seconde active la fonction et affiche MIN ou MAX

avec la valeur minimum ou maximum sur l’affichage. Chaque pression consécutive

permet de basculer entre les deux modes. Pour quitter cette fonction, appuyez sur

le bouton MIN MAX pendant plus d’une seconde.

Mesures en maintien HOLD

XWAVERTISSEMENT

Pour éviter les lectures erronées, ne pas modifier la position du

commutateur Function/Range alors que la fonction HOLD est active.

La fonction HOLD permet d’effectuer une mesure et de maintenir la valeur relevée

après avoir retiré les cordons du circuit de test. Une pression du bouton HOLD

pendant une mesure saisit et maintient la valeur relevée. Une nouvelle pression du

bouton HOLD libère l’affichage pour les mesures suivantes.

Page 25

5

Entretien du produit

Nettoyage

Nettoyez le multimètre à l’aide d’un chiffon doux imbibé d’eau. L’utilisation de

benzène, d’alcool, d’acétone, d’éther, de diluant pour peinture, de diluant à

peinture-laque, de cétone ou d’autres solvants risque de déformer ou de décolorer

le multimètre et son afficheur.

Dépannage

Si le multimètre ne semble pas fonctionner normalement, vérifiez d’abord les

éléments suivants.

1. Relisez les consignes d’utilisation pour confirmer que le multimètre est utilisé

correctement.

2. Inspectez et testez la continuité des cordons de test.

3. Assurez-vous que la pile est en bon état. Le symbole de pile faible B apparaît

lorsque la tension de la pile tombe en dessous du niveau garantissant la

précision. Remplacez une pile faible immédiatement.

4. Vérifiez l’état des fusibles si les gammes de courant ne fonctionnent pas

correctement.

XWAVERTISSEMENT

Pour éviter les chocs électriques, retirer les cordons de test du multimètre

et du circuit de test avant d’accéder à la pile ou aux fusibles.

Remplacement des fusibles et des piles Voir Figure -10-

Pour accéder à ces éléments, retirez d’abord le couvercle de la pile. Le couvercle de

pile est derrière le multimètre ; il est maintenu en place par deux vis. Une fois ces

vis retirées, vous pouvez facilement extraire et remplacer la pile. Pour remplacer le

fusible mA, séparez-le de ses attaches à l’aide d’un petit tournevis. Un fusible mA

de rechange se trouve entre la pile et le fusible mA.

Pile : 9 V NEDA Fusible mA : Instantané 250 mA/600 V (Amprobe FP375)

Pour remplacer le fusible 10 A, enlevez la pile, retirez les quatre vis du boîtier

arrière, séparez les parties du boîtier, retirez le capot du fusible 10 A, et retirez et

remplacez le fusible 10 A. Remettez le capot du fusible.

Fusible 10 A : Inst antané 10 A/600 V, fusible (Amprobe FP160) à pouvoir de

coupure nominal minimum de 30 kA (10 x 38 mm), ou équivalent.

Réparation

Tous les outils de test renvoyés pour un étalonnage ou une réparation couverte ou

non par la garantie doivent être accompagnés des éléments suivants : nom, raison

sociale, adresse, numéro de téléphone et justificatif d'achat. Ajoutez également une

brève description du problème ou du service demandé et incluez les cordons de

test avec le multimètre. Les frais de remplacement ou de réparation hors garantie

doivent être acquittés par chèque, mandat, carte de crédit avec date d'expiration ou

par bon de commande payable à l'ordre de Amprobe Test Tools.

Remplacements et réparations sous garantie – Tous pays

Veuillez lire la déclaration de garantie, et vérifier la pile avant de demander une

réparation. Pendant la période de garantie, tout outil de test défectueux peut être

renvoyé auprès de votre distributeur Amprobe Test Tools pour être échangé

contre un produit identique ou similaire. Consultez la section « Where to Buy » sur

le site www.amprobe.com

pour obtenir la liste des distributeurs dans votre région.

Au Canada et aux Etats-Unis, les appareils devant être remplacé ou réparé sous

garantie peuvent également être envoyés dans un centre de services Amprobe

Test Tools (voir les adresses ci-dessous).

Page 26

6

Remplacements et réparations hors garantie – Canada et

Etats-Unis

Les appareils à réparer hors garantie au Canada et aux Etats-Unis doivent être

envoyés dans un centre de services Amprobe Test Tools. Appelez Amprobe

Test Tools ou renseignez-vous auprès de votre lieu d’achat pour connaître les tarifs

en vigueur pour le remplacement ou les réparations.

Aux Etats-Unis Au Canada

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, Ontario L4Z 1X9

Tél. : 888-993-5853 Tél. : 905-890-7600

Fax : 425-446-6390 Fax : 905-890-6866

Remplacements et réparations hors garantie – Europe

Les appareils européens non couverts par la garantie peuvent être remplacés par

votre distributeur Amprobe Test Tools pour une somme nominale. Consultez la

section « Where to Buy » sur le site www.amprobe.com pour obtenir la liste des

distributeurs dans votre région.

Adresse postale européenne*

Amprobe Test Tools Europe

P.O. Box 1186

5602 B.D. Eindhoven

Pays-Bas

*(Réservée à la correspondance – Aucun remplacement ou réparation n’est

possible à cette adresse. Nos clients européens doivent contacter leur distributeur).

GARANTIE

Le multimètre numérique 30XR-A est garanti contre tout défaut de fabrication ou

de main d’œuvre pendant une période d’un (1) an à compter de la date d’achat du

multimètre par l’acheteur initial ou l’utilisateur initial. Tout multimètre faisant l’objet

d’un défaut pendant la période de garantie doit être renvoyé accompagné d’un

justificatif d’achat auprès d’un centre de services agréé par Amprobe Test ou du

distributeur ou du revendeur local de Amprobe Test Tools où l’achat du

multimètre a été effectué. Voir la section Entretien pour tous les détails. Toutes les

garanties implicites résultant de la vente d’un multimètre Amprobe Test Tools, y

compris mais sans s’y limiter les garanties de commercialisation ou d’adaptation à

un usage particulier, sont limitées à la durée d’un (1) an déjà citée. Amprobe Test

Tools ne sera pas tenu responsable de la privation de jouissance du multimètre ou

d’autres dommages directs ou indirects, frais ou pertes économiques ni des

poursuites engagées pour de tels dommages, frais ou pertes économiques.

Certains pays n’admettent pas les limitations sur la durée des garanties implicites,

ni sur l’exclusion ou la limitation des dommages directs ou indirects ; il est donc

possible que les limitations ou exclusions de cette garantie ne s’appliquent pas

dans votre cas. La présente garantie confère certains droits juridiques : la

législation du pays ou de l’état peut vous en accorder d’autres.

Page 27

7

Caractéristiques

Caractéristiques générales

Affichage : Afficheur à cristaux liquides

(LCD) à 3½ chiffres de résolution avec une

lecture maximum de 1999.

Polarité : Indication de la polarité négative,

à implication positive, automatique.

Dépassement de gamme : (OL) ou

(-OL) s’affiche.

Zéro : Automatique.

Témoin de pile faible : Le symbole

B est affiché lorsque la tension de pile

chute en dessous du niveau d’exploitation.

Vitesse de mesure : 2.5 fois par seconde,

nominal.

Environnement de fonctionnement :

0 °C à 50 °C à < 70 % H.R.

Température d’entreposage : -20 °C à 60

°C, 0 à 80 % H.R. avec la pile extraite du

multimètre.

Coefficient thermique : 0.1 × (précision

spécifiée) par °C. (0 °C à 18 °C, 28 °C à 50

°C).

Environnement : Utilisation à l’intérieur de

locaux, altitude jusqu’à 2000 m.

Alimentation : Pile standard unique

de 9 volts, NEDA 1604, JIS 006P,

CEI 6F22.

Durée de vie de pile : 200 heures en

moyenne pour pile au carbone-zinc.

Dimensions : 196 x 92 x 60 mm (7.7 x 3.5

x 2.4 pouces).

Poids : Environ 426 g ( 0.94 lb) sans l’étui,

pile incluse.

Accessoires : Une paire de cordons de test

(TL36), pile 9 V (installée), étui Magna

Grip et Mode d’emploi.

Garantie : Un (1) an

Homologations :

>

LISTED

950Z

P

Sécurité :

Conforme à EN61010- 1: Cat II –

600 V/Cat III – 300 V ; Classe 2, degré

de pollution II ; UL1244.

Il est recommandé pour les appareils, les

équipements portables et la distribution

d’énergie au niveau local, etc., où seules de

petites surtensions transitoires sont

possibles ; il n’est pas destiné aux lignes du

réseau d’alimentation électrique primaire,

aux lignes aériennes ou aux systèmes

câblés.

CEM :

Conforme à EN61326-1.

Ce produit est conforme aux exigences des

directives suivantes de la Communauté

européenne : 89/336/CEE (Compatibilité

électromagnétique) et

73/23/CEE (Basse tension) modifiée par

93/68/CEE (marquage CE). Toutefois, le

bruit électrique ou les champs

électromagnétiques intenses à proximité de

l’équipement sont susceptibles de perturber

le circuit de mesure. Les appareils de

mesure réagissent également aux signaux

indésirables parfois présents dans le circuit

de mesure. Les utilisateurs doivent faire

preuve de prudence et prendre les mesures

nécessaires pour éviter les erreurs de

mesure en présence de parasites

électromagnétiques.

Caractéristiques électriques

(à 23 °C ± 5 °C, < 75 % H.R. sans

condensation)

VOLTS C.C.

Gammes : 200 mV, 2 V, 20 V, 200 V, 600 V

Précision : Toutes gammes, ± (1.0 %

lecture + 1 chiffre)

Résolution : 100 µV dans la gamme

200 mV

Impédance d’entrée : 10 MΩ

Protection contre les surcharges:

Gamme

200 mV: 600 V c.c. ou

600V c.a. eff

15 secondes. Autres gammes: 600 V c.c.

ou 600 V c.a. eff

Page 28

8

VOLTS C.A. (45 Hz – 500 Hz)

Gammes : 200 mV, 2 V, 20 V, 200 V, 600 V

Précision : Toutes gammes, ± (1,5 %

lecture + 4 chiffres)

Résolution : 100 µV dans la gamme

200 mV

Impédance d’entrée : 10 MΩ

Protection contre les surcharges:

Gamme

200 mV: 600 V c.c. ou 600 V c.a. eff

15 secondes. Autres gammes: 600 V c.c.

ou 600 V c.a. eff

COURANT C.C.

Gammes : 200 µA, 2 mA, 20 mA,

200 mA, 10 A

Précision :

Gammes 200 µA à 200 mA : ± (1.5 %

lecture + 1 chiffre)

Gamme 10 A : ± (2.0 % lecture + 3 chiffres)

Résolution : 0.1 µA dans la gamme 200 µA

Tension de charge :

Gamme 200 µA : 1 mV/1 µA

Gamme 2 mA : 100 mV/ 1 mA

Gamme 20 mA : 13 mV/ 1 mA

200 mA : 4.6 mV/ 1 mA

10 A : 40 mV/ 1 A

Protection contre les surcharges :

Entrée µA/mA : F 0.25 A/600 V, Min.

I.R. 30 kA, (6.3 x 32 mm)

Entrée 10 A : F 10 A/600 V, Min. I.R.

100 kA, (10 x 38 mm) (10 A pendant

4 minutes maximum suivis d’une 12 minute

période de refroidissement

)

COURANT C.A. (45 Hz – 500 Hz)

Gammes : 200 µA, 2 mA, 20 mA,

200 mA,10 A

Précision :

Gammes 200 µA à 200 mA : ± (2.0 %

lecture + 4 chiffres)

Gamme 10 A : ± (2.5 % lecture + 4 chiffres)

Résolution : 0.1 µA dans la gamme

200 µA

Tension de charge : Voir Courant c.c.

Protection contre les surcharges :

Entrée µA/mA : F 0.25 A/600 V, Min.

I.R. 30 kA, (6.3 x 32 mm)

Entrée 10 A : F 10 A/600 V, Min. I.R.

100 kA, (10 x 38 mm) (

10 A pendant

4 minutes maximum suivis d’une 12 minute

période de refroidissement

)

RESISTANCE

Gammes : 200 Ω, 2 kΩ, 20 kΩ,

200 kΩ, 2 MΩ, 20 MΩ

Précision :

Gammes 200 Ω à 200 kΩ : ± (1.0 %

lecture + 4 chiffres)

Gamme 2 MΩ : ± (1.5 % lecture +

4 chiffres)

Gamme 20 MΩ : ± (2.0 % lecture +

5 chiffres)

Résolution : 100 mΩ dans la gamme

200 Ω

Volts en circuit ouvert :

Gamme 200 Ω : 3.0 V c.c.

Autres gammes : 0.3 V c.c. normal

Protection contre les surcharges :

600 V c.c. ou 600 V c.a. eff.

CONTINUITE

Indication sonore : 75 Ω ± 25 Ω

Temps de réponse : 100 ms

Protection contre les surcharges :

600 V c.c. ou 600 V c.a. eff.

TEST DE DIODE

Courant de test : 1.0 mA (approximatif)

Précision : ± (1.5 % lecture + 3 chiffres)

Résolution : 0.001 V

Volts en circuit ouvert : 3.0 V c.c. normal

Protection contre les surcharges :

600 V c.c. ou 600 V c.a. eff.

TEST DE PILE

Gammes : 1.5 V, 9 V

Précision : ± (3.5 % lecture + 2 chiffres)

Résolution : 1 mV, 10 mV

Courant de test de charge :

Gamme 1.5 V : 150 mA normal

Gamme 9 V : 5 mA normal

Protection contre les surcharges :

600 V c.c. ou 600 V c.a. eff.

TENSION SANS CONTACT (NCV)

Volts c.a. : 70 V A 600 V c.a.

Voyant rouge et indicateur sonore

PIECES DE RECHANGE

Ensemble de cordons de test TL36 avec

pinces crocodiles

Ensemble de fusibles FP375

250 mA/600 V (4 par unité)

Ensemble de fusibles FP160 10 A/600 V

(2 par unité)

Page 29

30XR-A Digital Multimeter

Inhalt

Messungen durchführen..............................................................................2

Nachweisen der Funktionsfähigkeit des Instruments .............................2

Beheben einer Überlastanzeige (o) ......................................................2

Messen von Gleichspannung..........................Siehe Abbildung -1- .......2

Messen von Wechselspannung ......................Siehe Abbildung -2- .......2

Vorbereitung für Strommessungen .......................................................2

Messen von Gleichstrom ................................Siehe Abbildung -3-.......3

Messen von Wechselstrom.............................Siehe Abbildung -4-....... 3

Messen von Widerstand ................................Siehe Abbildung -5- .......3

Messen von Kontinuität (< 50 Ohm)...............Siehe Abbildung -6- .......3

Prüfen von Dioden..........................................Siehe Abbildung -7- .......3

Messen von NCV (Non-Contact

Voltage/Kontaktlose Spannung)......................Siehe Abbildung -8- .......4

Prüfen von Batteriespannung (1,5 und 9 Volt) Siehe Abbildung -9-....... 4

Zusätzliche Eigenschaften............................................................................ 4

Produktwartung........................................................................................... 5

Ersetzen der Batterie und Sicherung...............Siehe Abbildung -10- .....5

Reparatur.....................................................................................................5

GARANTIE .............................................................................................6

Allgemeine technische Daten.......................................................................7

Elektrische Spezifikationen ..........................................................................7

Zur Vermeidung von Stromschlag, Verletzungen und Beschädigung des

Meßgeräts oder des zu prüfenden Geräts folgende Sicherheitsvorkehrungen

einhalten:

• Die maximalen Überlastungsgrenzen der einzelnen Funktionen (siehe

Technische Daten) und die auf dem Instrument markierten Grenzwerte nicht

überschreiten. Zwischen Messleitung und Masse niemals mehr als 600 VDC

anlegen.

• Vor jedem Gebrauch des DMM, die Messleitungen und das Zubehör prüfen.

Keine beschädigten Teile verwenden.

• Niemals selbst geerdet sein, wenn Messungen durchgeführt werden. Keine

freiliegenden Schaltungselemente oder Prüfspitzen berühren.

• Das Messgerät nicht in Umgebungen mit explosiven Gasen betreiben.

• In den folgenden Situationen besondere Vorsicht walten lassen: Messung von

Spannung > 20 V // Stromstärke >10 mA // Wechselspannungsleitungen mit

Induktivlasten // Wechselspannungsleitungen während Gewittern // Strom mit

einer durchgebrannten Sicherung in einem Schaltkreis mit Leerlaufspannung

> 600 V // bei der Wartung von Kathodenröhrengeräten.

• Strommessung immer in Serie mit der Last - NIEMALS über eine

Spannungsquelle. Zuerst die Sicherung prüfen. Niemals eine Sicherung durch

eine Sicherung anderer Nennlast ersetzen.

• Um fehlerhafte Messergebnisse zu vermeiden, die Stellung des

Funktion/Bereichschalters nicht verändern, während die Funktionen MIN MAX

oder HOLD aktiviert sind.

• Vor dem Ersetzen der Batterie oder von Sicherungen die Prüfleiter entfernen

und dann das Batteriefach bzw. das Gehäuse öffnen.

XWSicherheitsinformationen

Bedienungshandbuch

1

Page 30

2

Symbole in diesem Handbuch

B

Batterie W Im Handbuch

nachlesen

T

Schutzisoliert X Gefährliche Spannung

F

Gleichstrom J Erde, Masse

B

Wechselstrom R Akustischer Alarm

P

Übereinstimmung mit

EU-Richtlinien

@ Underwriters

Laboratories, Inc.

I

Sicherung

Messungen durchführen

Nachweisen der Funktionsfähigkeit des Instruments

Bevor Messungen durchgeführt werden, sicherstellen, dass das Instrument

funktionsfähig ist und die Batterie in gutem Zustand ist. Wenn das Instrument nicht

funktionsfähig ist, muss es repariert werden, bevor versucht wird, eine Messung

durchzuführen.

Beheben einer Überlastanzeige (o)

Wenn eine Überlastbedingung vorliegt, erscheint unter Umständen o in der

Anzeige. Bei Spannungs- und Strommessungen sollten Überlastbedingungen sofort

durch Wählen eines höheren Bereichs behoben werden. Wenn die höchste

Bereichseinstellung die Überlast nicht behebt, die Messung unterbrechen, bis das

Problem identifiziert und behoben wurde. Die Anzeige o ist für einige Funktionen

normal, z.B. für Widerstand, Kontinuität und Diodenprüfung.

Messen von Gleichspannung Siehe Abbildung -1-

1. Den Bereichsschalter in einen geeigneten L Bereich schalten.

Den höchsten Bereich auswählen und dann verringern, falls der

Spannungspegel unbekannt ist.

2. Die Messleitungen anschließen. Rot an VΩG, Schwarz an COM.

3. Die Messleitungenan die Prüfpunkte des Stromkreises anschließen.

4. Die Anzeige ablesen und bei Bedarf vorkommende Überlastbedingungen (o)

beheben.

Messen von Wechselspannung Siehe Abbildung -2-

1. Den Bereichschalter in einen geeigneten K Bereich schalten.

Den höchsten Bereich auswählen und dann verringern, falls der

Spannungspegel unbekannt ist.

2. Die Messleitungen anschließen. Rot an VΩG, Schwarz an COM.

3. Die Prüfleiter an die Prüfpunkte des Stromkreises anschließen.

4. Die Anzeige ablesen und bei Bedarf vorkommende Überlastbedingungen (o)

beheben.

Vorbereitung für Strommessungen

• Vor dem Anschließen der Messleitungen den Strom des Stromkreises abschalten.

• Das Messgerät zwischen den Messungen abkühlen lassen, wenn die

Strommessungen 10 A erreichen oder überschreiten.

• Ein Warnsignal ertönt, wenn eine Messleitung an einen Stromeingang

angeschlossen wird, bevor ein Strombereich ausgewählt wurde.

• Die Leerlaufspannung am Messpunkt darf 600 V nicht überschreiten.

Page 31

3

• Strom immer in Serie mit der Last messen. Strom niemals über eine

Spannungsquelle messen.

Messen von Gleichstrom Siehe Abbildung -3-

1. Den Bereichschalter in einen geeigneten A Bereich schalten.

Den höchsten Bereich auswählen und dann verringern, falls der Strompegel

unbekannt ist.

2. Die Messleitungen anschließen. Rot an mA oder 10 A, Schwarz an COM.

3. Die Stromversorgung des zu messenden Schaltkreises ausschalten.

4. Den zu prüfenden Stromkreis (X) öffnen, um Messpunkte bereitzustellen.

5. Die Messleitungen in Serie mit der Last anschließen.

6. Die Stromversorgung des zu messenden Schaltkreises einschalten.

7. Die Anzeige ablesen und bei Bedarf vorkommende Überlastbedingungen (o)

beheben.

Messen von Wechselstrom Siehe Abbildung -4-

1. Den Bereichschalter in einen geeigneten ? Bereich schalten.

Den höchsten Bereich auswählen und dann verringern, falls der Strompegel

unbekannt ist.

2. Die Messleitungen anschließen. Rot an mA oder 10 A, Schwarz an COM.

3. Die Stromversorgung des zu messenden Schaltkreises ausschalten.

4. Den zu prüfenden Stromkreis (X) öffnen, um Messpunkte bereitzustellen.

5. Die Messleitungen in Serie mit der Last anschließen.

6. Die Stromversorgung des zu messenden Schaltkreises einschalten.

7. Die Anzeige ablesen und bei Bedarf vorkommende Überlastbedingungen (o)

beheben.

Messen von Widerstand Siehe Abbildung -5-

1. Den Bereichschalter in einen geeigneten Ω Bereich schalten.

Den höchsten Bereich auswählen und dann verringern, falls der

Widerstandspegel unbekannt ist.

2. Die Messleitungen anschließen. Rot an VΩG, Schwarz an COM.

3. Die Stromversorgung des zu messenden Schaltkreises ausschalten. Strom

niemals über eine Spannungsquelle oder in einem stromführenden Stromkreis

messen.

4. Alle Kondensatoren, die die Messung beeinflussen könnten, entladen.

5. Die Testsonden über dem Widerstand anlegen.

6. Die Anzeige ablesen. Wenn im höchsten Bereich o erscheint, ist der

Widerstand zu hoch, um gemessen zu werden.

Messen von Kontinuität (< 50 Ohm) Siehe Abbildung -6-

1. Den Bereichschalter auf R schalten.

2. Die Messleitungen anschließen. Rot an VΩG, Schwarz an COM.

3. Die Stromversorgung des zu messenden Schaltkreises ausschalten.

4. Alle Kondensatoren, die die Messung beeinflussen könnten, entladen.

5. Die Testsonden über dem Widerstand anlegen.

6. Auf den Ton achten, der Kontinuität (< 50 Ohm) anzeigt.

Prüfen von Dioden Siehe Abbildung -7-

1. Den Bereichschalter auf G schalten.

2. Die Messleitungen anschließen. Rot an VΩG, Schwarz an COM.

3. Die Stromversorgung des zu messenden Schaltkreises ausschalten.

4. Mindestens ein Ende der Diode vom Schaltkreis lösen.

5. Die Testsonden über der Diode anlegen.

Page 32

4

6. Die Anzeige ablesen. Eine gute Diode hat Vorwärtsspannungsabfall ungefähr

0,6 V. Bei einer offenen oder rückwärts betriebenen Diode wird o angezeigt.

Messen von NCV (Non-Contact

Voltage/Kontaktlose Spannung) Siehe Abbildung -8-

1. Der Bereichschalter kann auf OFF oder beliebige andere Funktionen/Bereiche

geschaltet werden.

2. Für den NCV-Test werden die Messleitungen nicht benötigt.

3. Die Taste NCV drücken. Die Anzeige wird gelöscht, ein Ton wird abgegeben und

die rote LED neben der Taste NCV auf dem vorderen Bedienfeld leuchtet auf,

um anzuzeigen, dass das Instrument funktionsfähig. Die Taste gedrückt halten

und die obere Mitte des Messgeräts (Lage des Sensors) nahe an den zu

messenden Leiter/Schaltkreis halten.

4. Wenn eine Spannung zwischen 70 und 600 V vorliegt, wird ein Signalton

abgegeben und die rote LED neben der Taste NCV auf dem vorderen Bedienfeld

leuchtet auf.

Prüfen von Batteriespannung

(1.5 und 9 Volt) Siehe Abbildung -9-

1. Den Bereichschalter auf die betreffende BATT-Einstellung – 1.5 V oder 9 Vschalten.

2. Die Messleitungen anschließen. Rot an BATT 1.5 V oder BATT 9 V, Schwarz

an COM.

3. Die Testsonden über der Batterie anlegen. Das Messgerät legt eine

entsprechende Last an die Batterie an.

4. Die Anzeige ablesen. Eine gute 1.5 Volt-Batterie muss >1.2 V anzeigen, eine

gute 9 Volt Batterie muss >7.2 V anzeigen.

Zusätzliche Eigenschaften

Eingangsleiter-Warnung

Der 30XR-A gibt einen Dauerton ab, um anzuzeigen, dass der Benutzer eine

möglicherweise gefährliche Konfiguration auf dem Gerät eingestellt hat. Dies gilt

insbesondere, wenn ein Messleiter an einem Stromanschluss angeschlossen ist und

der Bereichschalter ist für das Messen einer anderen Funktion eingestellt. Wenn das

DMM in dieser Konfiguration an eine Spannungsquelle angeschlossen ist, können sehr

hohe und möglicherweise gefährliche Stromstärken auftreten. Das Messgerät enthält

flinke Sicherungen zum zusätzlichen Schutz für alle Strombereiche.

MIN-MAX-Messungen

XW ACHTUNG

Um fehlerhafte Messergebnisse zu vermeiden, die Stellung des

Funktion/Bereichschalters nicht verändern, während die

Funktionen MIN MAX oder HOLD aktiviert sind.

Die MIN MAX-Funktion funktioniert innerhalb des aktiven Messmodus, um den

Niedrigst- bzw. Höchstwert der betreffenden Messfunktion zu erfassen. Die

Funktion wird aktiviert durch Drücken der Taste MIN MAX weniger als 1 Sekunde

lang. Anschließend wird MIN oder MAX neben dem jeweiligen Minimal- oder

Maximalwert auf der Anzeige eingeblendet. Durch jedes weitere Drücken der Taste

wird zwischen den beiden Modi umgeschaltet. Um die Funktion zu beenden, die

Taste MIN MAX länger als 1 Sekunde drücken.

HOLD-Messungen

XW ACHTUNG

Um fehlerhafte Messergebnisse zu vermeiden, die Stellung des

Funktion/Bereichschalters nicht verändern, während die

Funktionen MIN MAX oder HOLD aktiviert sind.

Page 33

5

Mit der Funktion HOLD kann ein Messwert erfasst und festgehalten werden, auch

wenn die Messleitungen vom geprüften Schaltkreis entfernt werden. Wird die Taste

HOLD während einer Messung gedrückt, hält das Messgerät den Messwert fest.

Wenn die Taste HOLD erneut gedrückt wird, wird die Anzeige für weitere

Messungen freigegeben.

Produktwartung

Reinigung

Das Messgerät mit einem weichen, mit Wasser angefeuchteten Lappen reinigen.

Durch die Verwendung von Benzin, Alkohol, Azeton, Äther, Farb- oder

Lackverdünner, Keton oder anderer Lösungsmittel können das Messgerät und die

Anzeige verformt oder verfärbt werden.

Fehlerbehandlung

Wenn das Messgerät nicht ordnungsgemäß zu funktionieren scheint, zuerst die

folgenden Punkte prüfen.

1. Die Bedienungsanleitung prüfen, um sicherzustellen, dass das Messgerät

ordnungsgemäß verwendet wird.

2. Die Kontinuität der Messleitungen untersuchen und prüfen.

3. Sicherstellen, dass die Batterie in einwandfreiem Zustand ist. Das Batterieladesymbol B

wird eingeblendet, wenn die Spannung der Batterie unter den Wert abfällt, der die

Messgenauigkeit gewährleistet. Eine schwache Batterie unverzüglich ersetzen.

4. Den Zustand der Sicherungen prüfen, wenn der Strombereich nicht einwandfrei

funktionieren.

XWACHTUNG

Zur Vermeidung von Stromschlag vor dem Ersetzen der Batterie

oder von Sicherungen die Messleitungen vom Messgerät und

vom zu prüfenden Schaltkreis entfernen.

Ersetzen der Batterie und Sicherung Siehe Abbildung -10-

Um auf diese Teile zugreifen zu können, muss zuerst die Abdeckung vom Batteriefach

entfernt werden. Die Abdeckung der Batterie befindet sich auf der Rückseite des

Messgeräts und wird von zwei Schrauben gehalten. Nachdem diese Schrauben entfernt

wurden, kann die Batterie einfach entfernt und ausgewechselt werden. Um die mASicherung zu entfernen, diese mit einem kleinen Schraubendreher aus den Halteklammern

herausdrücken. Zwischen der Batterie und der mA-Sicherung befindet sich eine

Ersatzsicherung.

Batterie: 9 V NEDA mA Sicherung: Flinke Sicherung 250 mA/600 V (Amprobe

FP375)

Um die 10 A Sicherung zu ersetzen, die Batterie herausnehmen, die vier Schrauben an der

Rückseite des Gehäuses entfernen, das Gehäuse abnehmen, die Abdeckung der 10 A

Sicherung abnehmen, und die 10 A Sicherung herausnehmen und ersetzen. Die Abdeckung

der Sicherung wieder anbringen.

10 A Sicherung: Flinke Sicherung 10 A/600 V, Unterbrechernennleistung min. 30 kA (10 x

38 mm) (Amprobe

FP160) oder gleichwertige Sicherung.

Reparatur

Zu allen Geräten, die zur Reparatur oder Kalibrierung im Rahmen der Garantie oder

außerhalb der Garantie eingesendet werden, muss folgendes beigelegt werden: Name des

Kunden, Firmenname, Adresse, Telefonnummer und Kaufbeleg. Zusätzlich bitte eine kurze

Beschreibung des Problems oder der gewünschten Wartung sowie die Messleitungen dem

Messgerät beilegen. Die Gebühren für Reparaturen außerhalb der Garantie oder für den

Ersatz von Instrumenten müssen als Scheck, Geldanweisung, Kreditkarte

(Kreditkartennummer mit Ablaufdatum) beglichen werden oder es muss ein Auftrag an

Amprobe

Test Tools formuliert werden.

Page 34

6

Garantiereparaturen oder -austausch - alle Länder

Bitte die Garantieerklärung lesen und die Batterie prüfen, bevor Reparaturen

angefordert werden. Während der Garantieperiode können alle defekten Geräte zum

Umtausch gegen dasselbe oder ein ähnliches Produkt an den Amprobe Test

Tools-Distributor gesendet werden. Ein Verzeichnis der zuständigen Distributoren

ist im Abschnitt „Where to Buy“ (Verkaufsstellen) auf der Website

www.amprobe.com zu finden. Darüber hinaus können in den USA und in Kanada

Geräte an ein Amprobe Test Tools Service-Center (Adresse siehe weiter unten) zur

Reparatur oder zum Umtausch eingesendet werden.

Reparaturen und Austausch außerhalb der Garantie - USA und

Kanada

Für Reparaturen außerhalb der Garantie in den Vereinigten Staaten und in Kanada

werden die Geräte an ein Amprobe Test Tools Service-Center gesendet. Auskunft

über die derzeit geltenden Reparatur- und Austauschgebühren erhalten Sie von

Amprobe Test Tools oder der Verkaufsstelle.

In den USA: In Kanada:

Amprobe Test Tools Amprobe Test Tools

Everett, WA 98203 Mississauga, ON L4Z 1X9

Tel.: 888-993-5853 Tel.: 905-890-7600

Fax: 425-446-6390 Fax: 905-890-6866

Reparaturen und Austausch außerhalb der Garantie - Europa

Geräte außerhalb der Garantie können durch den zuständigen Amprobe Test

Tools-Distributor gegen eine Gebühr ersetzt werden. Ein Verzeichnis der

zuständigen Distributoren ist im Abschnitt „Where to Buy“ (Verkaufsstellen) auf der

Website www.amprobe.com zu finden.

Korrespondenzanschrift für Europa*

Amprobe Test Tools Europe

P. O. Box 1186

5602 BD Eindhoven

Niederlande

*(Nur Korrespondenz – keine Reparaturen, kein Umtausch unter dieser Anschrift.

Kunden in Europa wenden sich an den zuständigen Distributor.)

GARANTIE

Es wird gewährleistet, dass das 30XR-A Digital Multimeter innerhalb eines

Zeitraums von einem (1) Jahr ab dem Datum des Kaufes des Multimeters durch

den Erstkäufer oder Erstnutzer frei von Material- oder Fertigungsfehlern ist.

Multimeter, die während der Garantieperiode als defekt angegeben werden, müssen

mit dem Kaufbeleg an ein autorisiertes Amprobe Test Tools Service-Center oder

den örtlichen Amprobe Test Tools-Händler/-Distributor (bei dem das Gerät

gekauft wurde) gesendet werden. Nähere Einzelheiten siehe Abschnitt "Wartung".

Alle aus dem Kauf eines Amprobe Test Tools-Multimeters abgeleiteten Garantien,

einschließlich, aber nicht beschränkt auf die abgeleiteten Garantien der

Marktfähigkeit oder Eignung für einen bestimmten Zweck, sind auf die Dauer des

oben angegebenen Zeitraums von einem (1) Jahr beschränkt. Amprobe

Test

Tools haftet nicht für Nutzungsausfall des Multimeters oder andere Begleit- oder

Folgeschäden, Ausgaben oder wirtschaftliche Verluste oder für jegliche Ansprüche

bezüglich solcher Schäden, Ausgaben oder wirtschaftlicher Verluste. In einigen

Ländern ist die zeitliche Begrenzung der abgeleiteten Gewährleistung sowie der

Ausschluss oder die Begrenzung von Begleit- oder Folgeschäden nicht zulässig, so

dass die oben genannten Einschränkungen und Ausschlüsse nicht für jeden Käufer

gelten. Diese Gewährleistung gibt dem Eigentümer bestimmte Rechte, sowie

möglicherweise andere Rechte, die von Land zu Land verschieben sind.

Page 35

7

Technische Daten

Allgemeine technische

Daten

Anzeige: Flüssigkristallanzeige (LCD)

mit 3½ Stellen, mit Maximalanzeige

1999.

Polarität: Automatisch, positiv =

Standard, negativ = Anzeiger.

Überlast: (OL) oder (-OL) wird

angezeigt.

Null: Automatisch.

Batterieladeanzeige: B wird

eingeblendet, wenn die

Batteriespannung unter den

Betriebswert abfällt.

Messintervall: 2.5 mal pro Sekunde,

Nennwert.

Betriebsbereich: 0 °C bis 50 °C bei

< 70 % relativer Luftfeuchtigkeit.

Lagertemperatur: -20 °C bis 60 °C,

0 bis 80 % relative Luftfeuchtigkeit,

Batterie aus dem Gerät entfernt.

Temperaturkoeffizient: 0.1 X

(spezifizierte Genauigkeit) / °C. (0 °C bis

18 °C, 28 °C bis 50 °C).

Umgebung: Innenverwendung, bis

2000 m Höhenlage.

Speisung: Eine Standard-9-V-Batterie,

NEDA 1604, JIS 006P, IEC 6F22.

Batterielebensdauer: 200 Stunden,

typisch; mit Zink-Kohle.

Abmessungen: 196 x 92 x 60 mm

( 7.7” x 3.5” x 2.4”).

Gewicht: Ungefähr 426 g ( 0.94 lb.)

ohne Halterung mit Batterie.

Zubehör: Ein Paar Messleitungen

(TL36), 9-V-Batterie (eingebaut), Magna

Grip Halterung und Bedienungsanleitung.

Garantie: (1) Ein Jahr

Zertifikate:

>

LISTED

950Z

P

Sicherheit: Stimmt überein mit EN61010- 1:

Cat II – 600 V / Cat III – 300 V; Class 2,

Pollution degree II; UL1244.

Anwendung ist empfohlen für lokal e

Stromverteilung, Haushaltsgeräte, tragbare

Geräte usw., bei denen nur kleinere

Spannungsspitzen auftreten können;

Anwendung für primäre Stromverteilung,

Hochspannungsleitungen und Kabelsysteme

wird nicht empfohlen.

EMC (elektromagnetische Verträglichkeit):

Stimmt überein mit EN61326-1.

Dieses Produkt erfüllt die Anforderungen

der folgenden EU-Richtlinien: 89/ 336/ EEC

(Elektromagnetische Verträglichkeit) und

73/ 23/ EEC (Niederspannung) mit dem

Zusatz 93/ 68/ EEC (CE-Kennzeichnung).

Doch elektrisches Rauschen oder intensive

elektro-magnetische Felder in der Nähe des

Gerätes können den Messschaltkreis

stören. Messinstrumente reagieren auch

auf unerwünschte Impulse/Signale, die

unter Umständen im Messschaltkreis

vorkommen. Die Benutzer müssen die

nötige Sorgfalt walten lassen und geeignete

Vorkehrungen treffen, um irreführende

Ergebnisse bei Messungen bei