Page 1

No. 9310

No. 9311

No. 9312

No. 9313

ADAPTEK®Adapter Sets

for Hubless/Composite Rotors

and Odd Configured Rotors

AMMCO Tools, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX

These AMMCO brake lathe adapter sets are for use

with applications that include cast hubless rotors,

composite rotors, drums and flywheels. The flange

plates included in the sets simulate actual vehicle

mounting. These sets are for use on any brake lathe

with a 1 inch arbor.

Before You Begin

It is important in any machining operation that all

adapters and mounting hardware, as well as the

rotor, drum or flywheel to be machined, are clean

and free of nicks.

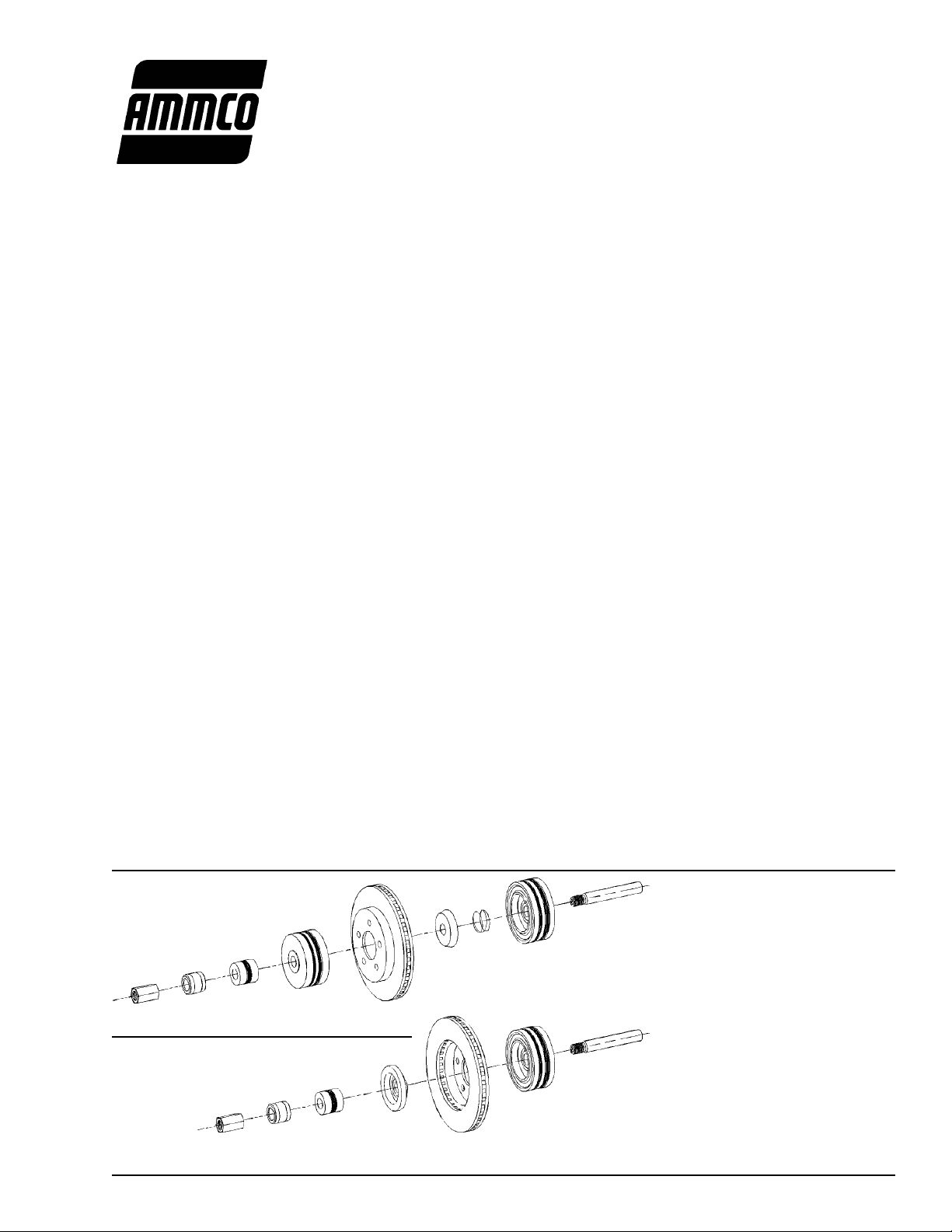

Typical Adapter Usage for Rotors

Figure 1 illustrates the typical adapter usage.

1. Determine which flange plate is most

appropriate for the current application and place

it on the arbor.

IMPORTANT: The flange plate must contact the

flat portion of the rotor hat, but must not contact

the rotor anywhere around the outside radius.

Always use the largest flange plate possible.

2. Place the spring onto the arbor and into the

flange plate. Twist it counterclockwise to hold it

in place.

3. Select the cone that best fits the rotor center

hole and slide it onto the arbor wide end first.

4. Slide the rotor onto the arbor, locating the center

hole over the cone. Push rotor and cone back

against spring and flange plate.

5. Slide the largest remaining flange plate (that fits

rotor as specified in step 1) onto the arbor.

6. Fill out the arbor with spacers as required to

secure entire rotor assembly to the arbor.

NOTE: On AMMCO lathes, the last item placed

on the arbor before the arbor nut must be the

self-aligning spacer.

7. Tighten the arbor nut by either rotating the rotor

while holding the arbor nut until they lock up, or

by using a wrench to turn the nut until the rotor

begins to turn and then continuing to advance

the wrench Z\zn of a turn. Do not overtighten.

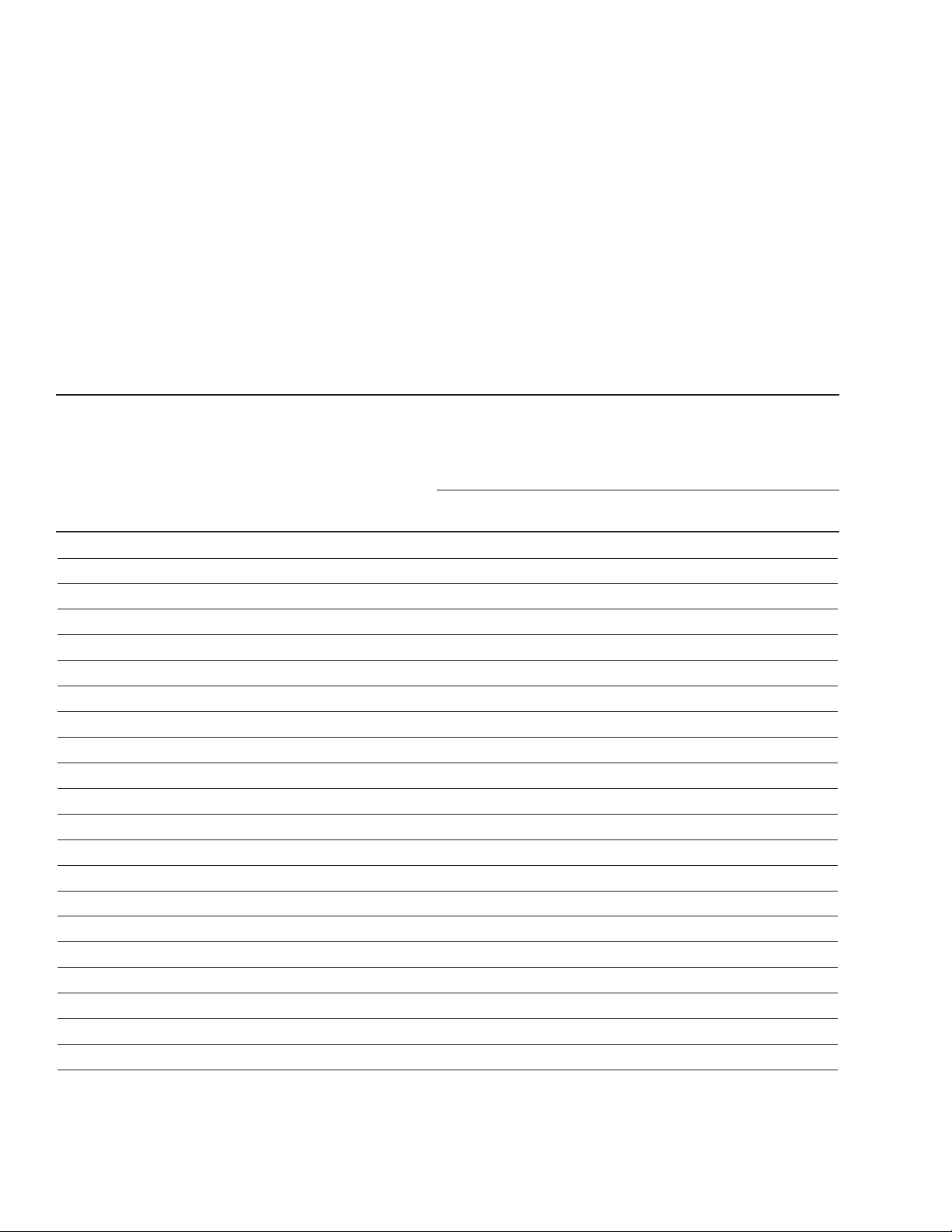

Odd Configured Cast Hubless Rotor Mounting

Figure 2 illustrates these mounting procedures.

1. Determine which flange plate is most

appropriate for the current application and place

it on the arbor.

IMPORTANT: The flange plate must contact the

flat portion of the rotor hat, but must not contact

the rotor anywhere around the outside radius.

Always use the largest flange plate possible.

2. Place rotor onto arbor. Note that some rotors

may need to be mounted backwards so that the

rotor’s machined surface contacts the first

flange plate.

3. Slide the 29573 reversible centering cone onto

arbor and into the rotor center hole with the

cone taper facing the rotor.

Figure 1 - Typical Adapter Usage

1 1” Arbor

2 Flange Plate

3 Spring

4 Centering Cone

5 Rotor, Drum or Flywheel

6 Flange Plate

7 Spacer(s)

8 Self-Aligning Spacer (AMMCO)

9 Arbor Nut

Figure 2 - Odd Configured Mounting

Page 2

4. Fill out the arbor with spacers as required to

secure entire rotor assembly to the arbor.

NOTE: On AMMCO lathes, the last item placed

on the arbor before the arbor nut must be the

self-aligning spacer.

5. Tighten the arbor nut by either rotating the rotor

while holding the arbor nut until they lock up, or

by using a wrench to turn the nut until the rotor

begins to turn and then continuing to advance

the wrench Z\zn of a turn. Do not overtighten.

Mounting Drums and Flywheels

For drums and flywheels, refer to Figure 1. Use the

same techniques as described in Typical Adapter

Usage for Rotors.

NOTE: When mounting drums, use the largest

flange plate possible inside the drum. The flange

plate must be as large as possible but still allow

clearance for the boring bar. On smaller drums, use

the 29573 Reversible Centering Cone as the inside

flange plate to allow for proper boring bar clearance.

Always refer to your lathe operating instructions for

additional information and procedures about

reconditioning rotors, drums and flywheels.

Parts List

Set No.

Part Auto & Truck Auto Lt. Truck Truck

No. For Description 9310 9311 9312 9313

29572 Auto Hubless Rotor Flange Plate 1 1

29573 Auto Reversible Centering Cone 1 1

29574 Auto/Trk Spacer 2 2

29575 Auto Composite Flange Plate 1 1

29576 Trk Large Lt. Truck Flange Plate 1

29577 Trk Large Lt. Truck Flange Plate 1

29578 Trk Composite Flange Plate 1 1

29579 Auto Centering Cone 1 1

29580 Auto Centering Cone 1 1

29581 Auto Centering Cone 1 1

29582 Auto Centering Cone 1 1

29583 Auto Centering Cone 1 1

29584 Trk Centering Cone 1 1

29585 Trk Centering Cone 1 1

29586 Trk Centering Cone 1

29587 Trk Centering Cone 1

29588 Trk Centering Cone 1

29589 Trk Centering Cone 1

29590 Trk Centering Cone 1

29591 Auto/Trk Spring 1 1 1

29727 Trk Centering Cone 1

929632 01 08/02 © COPYRIGHT 1994 HENNESSY INDUSTRIES AND AMMCO TOOLS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Loading...

Loading...