Page 1

No. 908500

90850050

Brake Drum Micrometer

Operating Instructions and

Parts Identification

AMMCO Tools, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX

8500 8500-50

Unit of Measure Inch Metric

Drum Diameter 6" to 16.125" 15 cm to 41 cm

Scale Graduations .001" .1 mm

(Increments)

Graduated Shaft 1" and .125" 1 cm and 2 mm

Optional Shaft 16" – 26" 39 cm – 66 cm

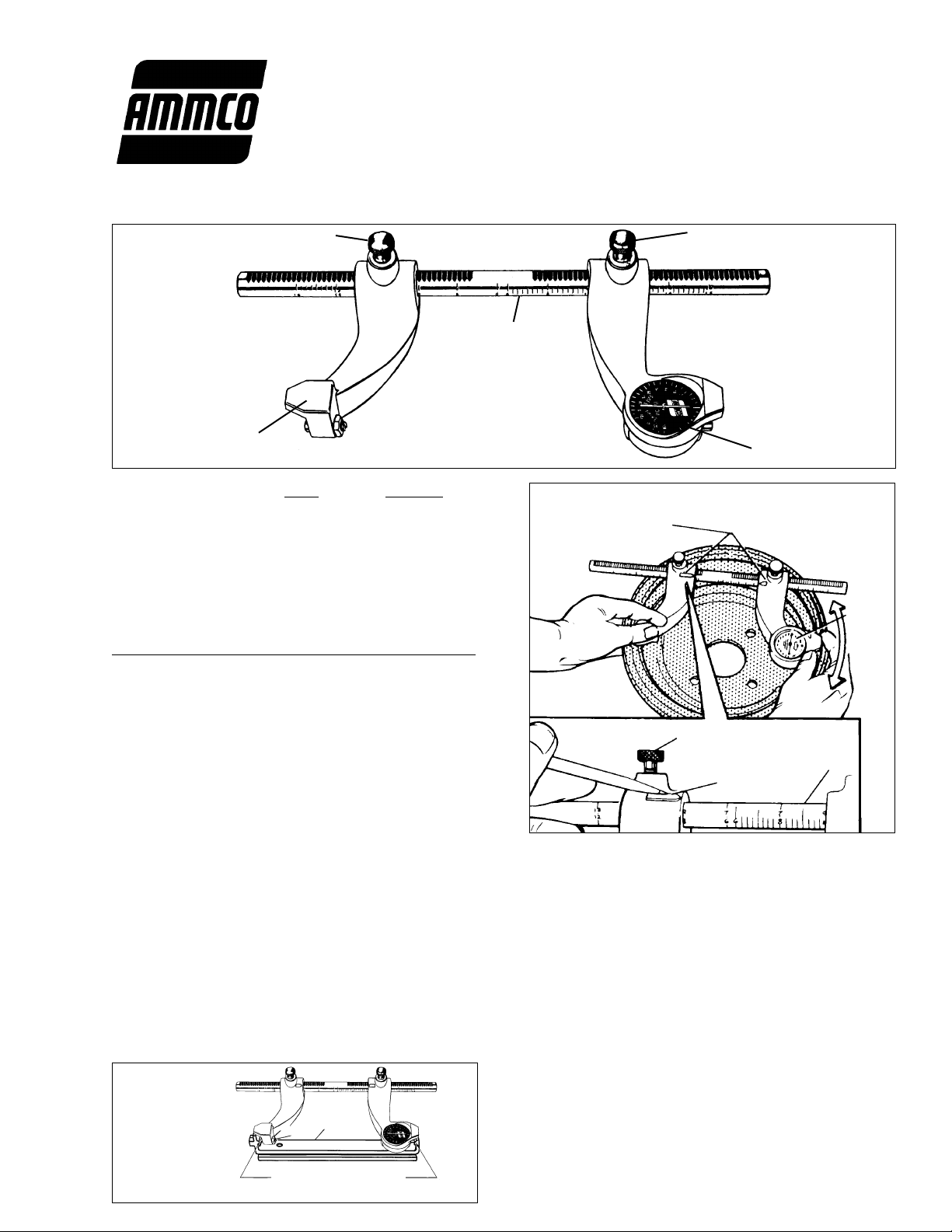

Measuring the Drum (Figure 2)

1. Loosen 2 lock screws and move both dial and

anvil along the shaft until the “whole” number of

the drum diameter is visible at each arrow.

NOTE: Metric shafts have even numbers on one

side, odd on the other. Inch shafts have identical

scales.

2. Place micrometer inside the drum across the

greatest diameter to be measured. Hold anvil

steady and move dial back and forth against the

braking surface to obtain the highest reading.

Calibration (Figure 3)

The micrometer is calibrated at the factory. Check

the calibration using a No. 909582 Checking Gauge

or a standard outside micrometer. To recalibrate,

loosen the jam nut (#22) and adjust set screw (#21)

until the correct reading is obtained. Tighten jam nut

while holding set screw stationary.

Drum Condition

Drums should always be carefully inspected for

cracks, worn or loose bearing races, scoring, heat

checks taper, bell-mouth, and out-of-roundness.

Drum out-of-round conditions are checked by taking

micrometer readings at 2 or more positions around

the drum. Scoring, out-of-roundness, bell-mouth,

and taper should be corrected by machining.

Correcting most of the above conditions will require

cutting material from the drum wall. If the drum

diameter after machining is larger than the

manufacturer’s specified rebore limit it must be

replaced.

Drums that are too thin are apt to be weak and

springy, and will not dissipate heat well, resulting in

a loss of braking power. Defective drums should be

scrapped.

Graduated Shaft

Lock Screw

Dial

Anvil

Lock Screw

Arrows for

Reading Scale

Dial

Lock Screw

Arrow

Scale

Figure 1 - Basic Parts Identification

11.000" Standard

27.94 cm Metric Equiv.

No. 909582

Gauge

28

29

Figure 3 Calibration

Figure 2 - Measuring the Drum

Page 2

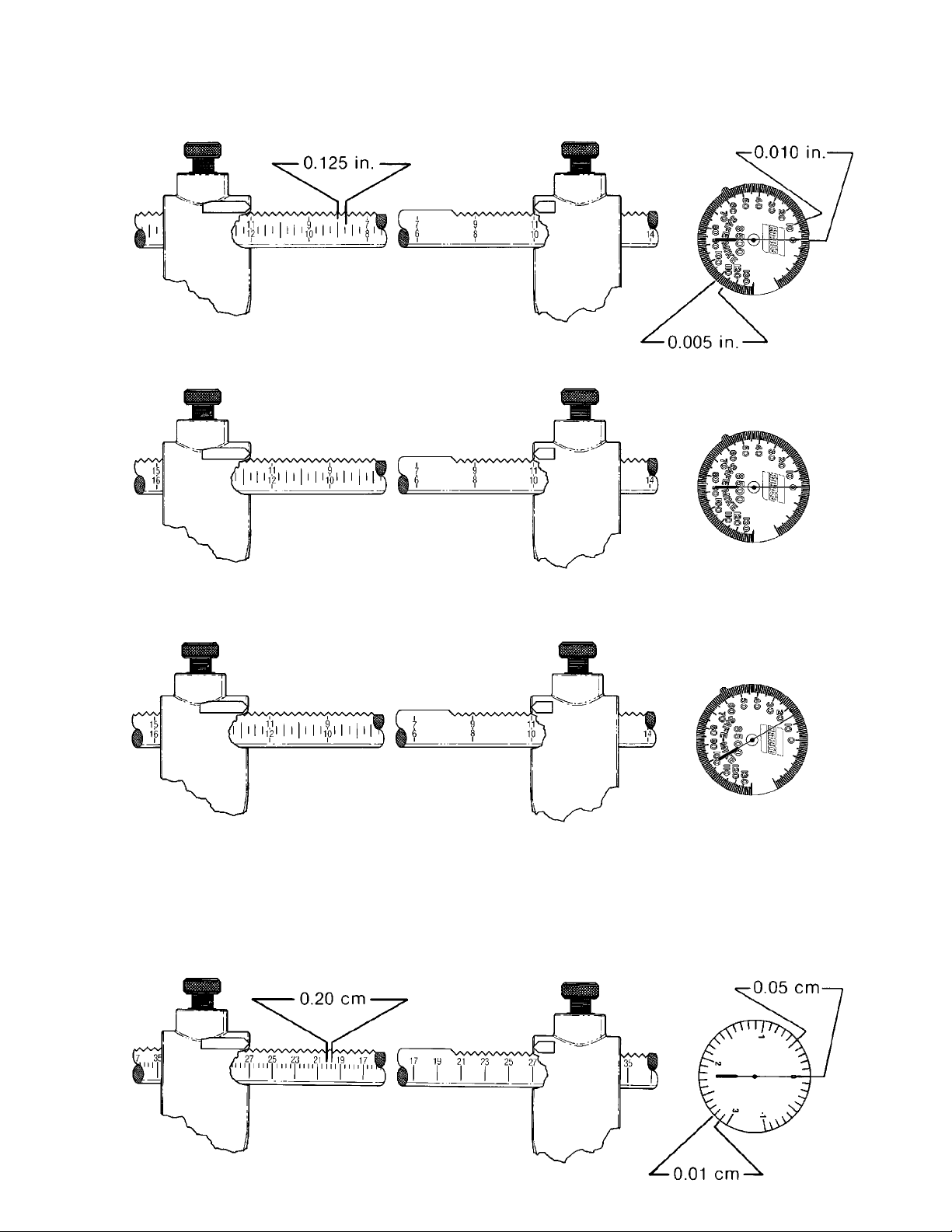

11.000 in.

Diameter

11.375 in.

Diameter

METRIC

INCH

(Examples For Reading The Inch Micrometer)

11.390 in.

Diameter

27.00 cm

Diameter

11.000 in. + 0.375 in. + 0.015 in. = 11.390 in.

11.000 in. + 0.375 in. = 11.375 in.

11.000 in.

27.00 cm

Page 3

METRIC (Examples For Reading The Metric Micrometer)

27.23 cm

Diameter

27.72 cm

Diameter

27.12 cm

Diameter

27.60 cm

Diameter

27.00 cm + 0.60 cm = 27.60 cm

27.00 cm + 0.12 cm = 27.12 cm

27.00 cm + 0.60 cm + 0.12 cm = 27.72 cm

27.00 cm + 0.20 cm + 0.03 cm = 27.23 cm

27.00 cm + 0.23 cm = 27.23 cm

Page 4

908532 10 08/02 © COPYRIGHT 1994 HENNESSY INDUSTRIES AND AMMCO TOOLS ALL RIGHTS RESERVED PRINTED IN U.S.A.

PART

ITEM NO. QTY DESCRIPTION

1 908515 1 Indicator Body

2 * 1 Driving Gear Segment

3 * 1 Shoulder Stud

4 * 1 Dowel Pin

5 909968 * 1 Intermediate Pinion & Gear

6 * 1 Retaining Ring

7 * 1 Groove Pin

8 * 1 Backlash Spring

9 908507 1 Inch Dial Assembly (0.005)

908507C 1 Inch Dial Assembly (0.001)

908508 1 Metric Dial Assembly

10 908528 * 1 Crystal

11 * 1 Retaining Ring

12 * 1 Plunger

13 * 1 Retaining Ring

14 * 1 Plunger Spring

15 * 1 Plug

16 * 1 Retaining Ring

17 909994 2 Plunger Screw Assembly

18 909879 2 Locating Screw

19 903528 2 Jam Nut, 1/4-20 Hex

20 908530 1 Anvil Arm

21 906844 1 Screw, 3/8-24x1 Hex Skt. Hd.

22 906509 1 Jam Nut, 3/8-24 Hex

23 908531

1

1 Shaft, Inch Grad., 6"-16-1/8"

908539

1

Opt. Shaft, Inch Grad., 16"-26"

908541

2

1 Shaft, Metric Grad., 15cm-41cm

90853950

2

Opt. Shaft, Metric Grad., 39cm-66cm

24 908502 1 Body Assembly, Inch (0.005)

908502C 1 Body Assembly, Inch (0.001)

90850250 1 Body Assembly, Metric

NOTES:

* Denotes part included in repair kit (part no. 929935).

1

Shaft for 908500 inch graduated micrometer

2

Shaft for 90850050 metric graduated micrometer

10

11

14

13

12

15

16

17

17

9

18

19

20

21

22

18

19

23

24

3

1

2

4

5

7

8

6

Loading...

Loading...