Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 925979 09

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 11/02

7900

Twin Cutter

Tool

®

Operating Instructions

with Parts Identification

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

2 • AMMCO 7900 Twin Cutter Tool

Twin Cutter Tool

Page 3

AMMCO 7900 Twin Cutter Tool • 3

The No. 907900 Twin Cutter mounts on the cross

feed tool post to resurface both rotor faces simultaneously. Each tool bar is individually adjustable (in

thousandths of an inch or millimeters) to permit precise depth-of-cut settings, Fig.1.

Installation

1. Remove the nut and self-aligning washers retaining the boring bar. (Older lathes have a tool post pivot

screw which must be loose before the lower clamp

can be removed.)

2. Place the tool bar support over the cross feed

tool post stud and replace self-aligning washers and

nut. (If the lathe has a recess in the top of the tool

post, the chip plate supplied with the twin cutter

should be placed on the tool post before installing the

twin cutter.)

3. Align the tool bar support parallel with the arbor

and wrench tighten the nut.

Reconditioning Disc Brake Rotors

Each brake rotor should be carefully inspected for

SCORING and RUST RIDGES (at the inner and outer

circumference of the rotor). Any excessive wear or

deformity should be noted and, if not within acceptable limits, the rotor should be replaced.

Use a micrometer to check the thickness of the rotor

at no less than three points around circumference

about 1" (2.54 cm) in from the outer diameter. If the

rotor thickness varies between readings, it should be

machined; however, if the thickness is less than the

minimum established by the car manufacturer (or if it

will be less after reconditioning), the rotor should be

replaced. Note: Most often the discard thickness

dimension is cast into the rotor, not the minimum

“machine to” thickness.

The tool bars mount on top of the tool bar support,

carbide bits up, and are used to recondition both brake

surfaces of a rotor at the same time.

Rotor Mounting

Use the cross feed handwheel to move the tool bar

support away from the arbor to permit mounting the

rotor. Mount the rotor on the arbor using the appropriate adapters. Hubbed rotors are mounted on

adapters that fit into the bearing races. Hubless rotors

use a spring loaded cone in the center hole and a hubless adapter on each side of the rotor. Spacers are

used to fill out the arbor shaft so that the arbor nut can

be tightened. The adapters, cones, and spacers supplied with your lathe will allow you to recondition the

majority of rotors on today's vehicles. Optional

adapters, cones, and spacers are available to meet

special needs.

Note: Adapters may also be used as spacers to fill

out the arbor if care is taken to prevent damage to

their machined surfaces.

The patented self-aligning spacer prevents diagonal

thrust on the adapters. The self-aligning spacer should

always be used adjacent to the arbor nut.

Set-Up and Machining

1. Install either a weighted silencer band (vented

rotors), Fig. 2, or a non-weighted silencer band (nonvented rotors), or an optional friction rotor silencer to

dampen vibrations during machining.

2. Use the cross feed handwheel to position the

tool bar support about 1/2" from the rotor or silencer

band. Loosen the tool post nut to center the tool bar

support to the rotor. Wrench tighten the nut. If the tool

bar support cannot be centered with the rotor by moving the tool bar support, it may be necessary to move

the tool bar support, it may be necessary to move the

rotor in or out by using the spindle feed handwheel

Twin Cutter Tool

Figure 2

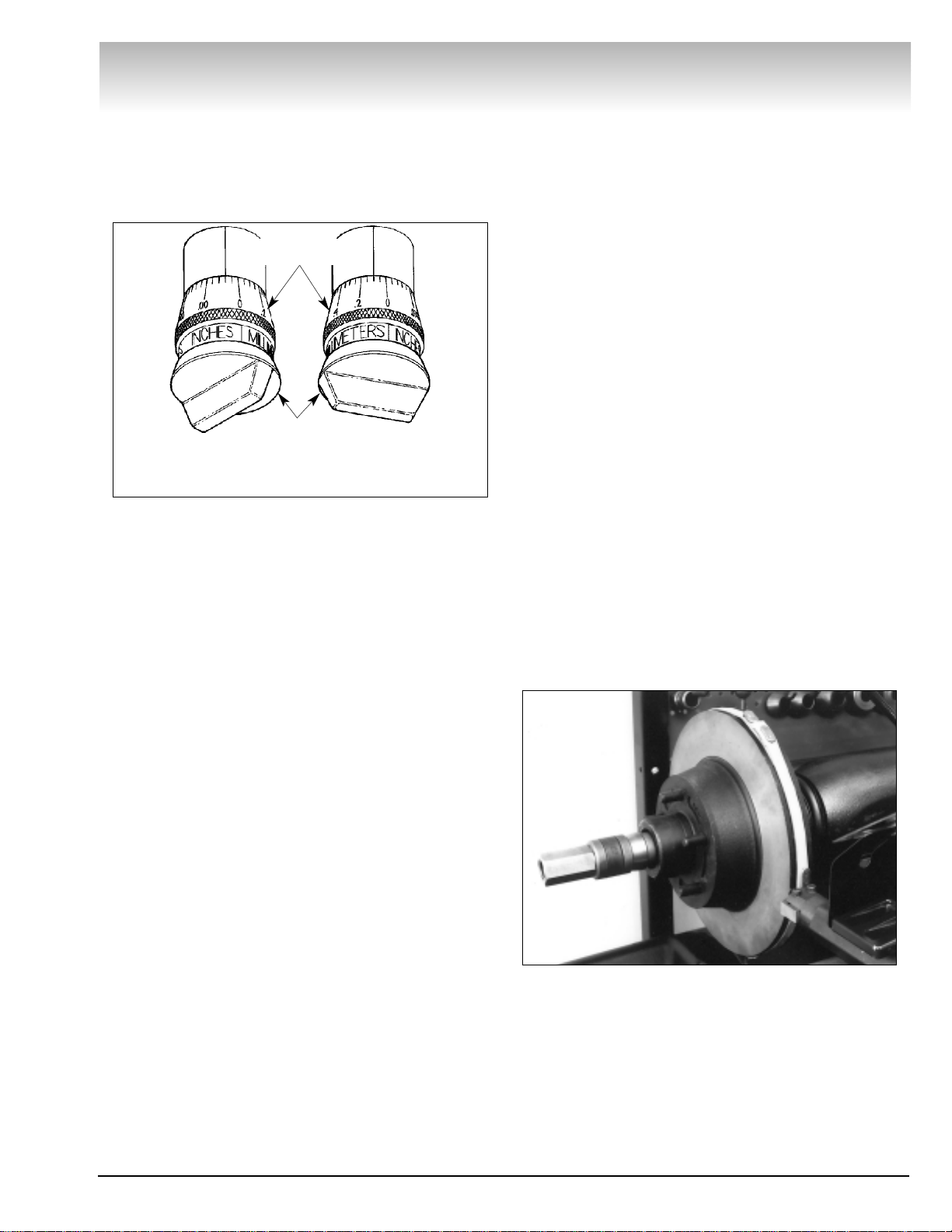

With the lathe on, turn the adjustment knob until the tool bit

lightly contacts the rotor face. Turn the micrometer dial to

zero. Turn the adjustment knob to set the desired depth-of-cut.

Dial Set To

.004 "

Inch/Millimeter

Micrometer Dials

Dial Set To

0.1 mm

Adjustment

Knob

Figure 1

Page 4

4 • AMMCO 7900 Twin Cutter Tool

Twin Cutter Tool

(except Model 7000 Disc Lathe) to make the adjustment.

3. Install the tool bar, carbide tool bit up, on the right

side of the rotor slide with the T-bolt and clamp. Slide

the tool bar into the clamp. Mount the other tool bar,

carbide tool bit up, on the left side of the rotor slide.

4. Turn the end knob of each tool bar micrometer

counterclockwise to fully withdraw the tool bit holders.

5. Position the left tool bar approximately parallel to

the outer brake surface so the tool bit is 1/8" away

from the brake surface and reaches to the groove at

the base of the brake surface. Tighten the T-bolt nut.

Position the right tool bar approximately parallel to the

inner brake surface so its tool bit is directly across

from the left tool bar tool bit and about 1/8" from the

inner brake surface, Fig. 3. Tighten the T-bolt nut.

6. Turn the cross feed handwheel counterclockwise

until the tool bits are about 1/2" in from the outer edge

of the brake surface.

7. Turn the end knob of the left boring bar micrometer clockwise to advance the tool bit until if lightly contacts the outer brake surface making a “scratch cut”

approximately .001" deep. Turn the lathe off.

8. If the tool bit did not scratch the brake surface all

the way around, there is runout in the rotor and/or

runout caused by improper rotor mounting.

9. Use the “scratch cut” method as outlined in

steps 9A, 9B, 9C, and 9D to determine if the runout is

caused by an improper mounting.

9A. Turn the end knob of the left tool bar micrometer

counterclockwise one (1) full turn to back the tool bit

away from the brake surface.

9B. Turn the rotor slide handwheel clockwise to

move the tool bit 1/4" toward the arbor.

9C. Loosen the arbor nut and rotate the rotor 180˚ on

the adapters (do not allow the adapters to turn on the

arbor). Retighten the arbor nut.

9D. Turn the lathe on, then turn the end knob of the

left tool bar micrometer clockwise until the tool bit

makes light contact with the brake surface. Turn the

end knob of the left tool bar micrometer counterclockwise to withdraw the tool bit from the brake surface.

10. Turn the lathe off. If the two scratch cuts are

side by side, Fig. 4, the runout is in the rotor and NOT

in the mounting, continue with step 11. If the two

scratch cuts are 180˚ apart, the runout is caused by an

improper mounting. In this case, inspect the mounting

for cleanliness and the adapters for burrs, nicks, and

scratches as well as the bearing races for looseness.

Remount the rotor and check for runout again. If the

runout has been corrected, proceed with step 11.

11. Turn the lathe on. Turn the end knob of the left

tool bar micrometer clockwise until the tool bit lightly

contacts the brake surface. Hold the end knob of the

micrometer still and rotate the depth-of-cut dial to

zero.

12. Turn the end knob of the right tool bar micrometer clockwise until it lightly contacts the brake surface. Hold the end knob of the micrometer still and

rotate the depth-of-cut collar to zero.

Note: Once you have zeroed a depth-of-cut collar,

use only the end knob to advance or withdraw the tool

bit. The collar will rotate with the knob to show the

depth-of-cut. Any other disturbance of the collar will

lose the zero position.

13. Turn the cross feed handwheel clockwise until

the outer toolbit reaches the groove at the rotor hub.

The right tool bit will automatically be positioned

beyond the inner brake surface.

Figure 3

Figure 4

Page 5

AMMCO 7900 Twin Cutter Tool • 5

14. Turn the end knob of each tool bar micrometer,

individually, to set each tool bit to the desired depthof-cut. Remove only enough material to clean up each

side.

15. Engage the automatic cross feed to begin the

cut.

16. When the tool bits have cleared the rotor, disengage the cross feed and turn the lathe off to inspect

both surfaces.

17. If part of the brake surface was not cut, leave

the tool bars locked in position. Turn the lathe on.

Slowly turn the cross feed handwheel clockwise until

the outer tool bit reaches the groove at the rotor hub.

Repeat steps 14, 15, 16, and 17.

Tool Bar Adjustment

1. Turn the micrometer dial couterclockwise to

unscrew the dial from the boring bar. Remove the

micrometer dial assembly.

2. Unscrew the two (2) allen head cap screws from

the tool holder against a solid stop, pull the screws

from the boring bar and carefully ease the bar away

from the stop.

3. Clean all metal chips and dirty grease from all the

working parts.

4. Slip the spring into the bore of the tool bar.

Grease the sleeve with white grease and slip it into

the bore of the tool bar.

5. Slip the tool holder between the ears of the boring bar, press the tool holder against a solid stop and

insert the allen head cap screws. Run the screws all

the way in.

6. Insert the micrometer dial assembly into the tool

bar and screw the micrometer all the way in.

7. Fully tighten one (1) of the allen head cap screws,

then back the micrometer dial out two (2) turns.

8. Slowly loosen the allen head cap screw until the

tool holder slips back.

9. Screw the micrometer all the way in and repeat

steps 7 and 8 for the other allen head cap screw.

Twin Cutter Tool

Page 6

6 • AMMCO 7900 Twin Cutter Tool

Twin Cutter Tool

Page 7

AMMCO 7900 Twin Cutter Tool • 7

Part

Item No. Qty. Description

1 925982 1 Support, Tool Bar

5 923556 1 Bolt, T

6 903214 1 Washer, Flat

7 925756 3 Spring, Compression

8 911227 1 Nut & Washer, Hex, Self-Aligning,

Assy.

9 926018 1 Clamp Assy.

10 925985 1 Clamp

11 904508 2 Screw, Pan HD, Machine

12 926015 1 Shield, Safety, Assy.

13 * 2 Screw

14 926014 1 Bracket

15 * 2 Nut

16 911154 1 Shield

17 941117 1 Decal

18 925980 1 Bar, Tool, RH, Assy.

19 906499 2 Screw, Oval HD, Machine

20 9069142 1 Bit, Carbide (Pkg./2)

21 925762 1 Holder

22 925754 2 Sleeve

23 924922 2 Washer, Flat

24 925757 4 Screw, Shoulder

25 925984 2 Bar, Boring

26 925759 2 Ring, Retaining, External

27 925758 2 Washer, Wave

28 925752 2 Dial, Micrometer

29 925983 2 Rod, Dial

30 903338 2 Screw, Set, Cup Point

31 925751 2 Dial, Depth

32 925981 1 Bar, Tool, LH, Assy.

33 925761 1 Holder

34 906930 1 Band, Silencer HD, Assy.

35 * 2 Washer

36 * 2 Spacer

* 927822 1 Shield Hardware Kit

Twin Cutter Tool

Page 8

925979 09 11/02 © Copyright 1992 Hennessy Industries All Rights Reserved Printed in USA

Loading...

Loading...