Page 1

GGrriinnddiinngg WWhheeeell DDrreesssseerr

OOppeerraattiinngg IInnssttrruuccttiioonnss

NNoo.. 990066006611

FFoorr UUssee WWiitthh MMooddeellss 990066885500 AAnndd 990044885500

BBrraakkee DDrruumm GGrriinnddeerrss,, AAnndd MMooddeell 990066225500

CCuupp WWhheeeell GGrriinnddeerr

The No. 906061 Grinding Wheel Dresser is used

to true the face of a Grinding Wheel so that its surface is parallel to the surface to be ground. The

diamond nib of the Dresser cleans and shapes the

Grinding Wheel to assure proper grinding action.

Safety Notes:

Be sure that the Lathe Motor will

not be turned on during the dressing operation.

The Grinding Wheel spins at a high speed. DO

NOT use a damaged Wheel. ALWAYS use a Wheel

Guard with the Grinder. WEAR SAFETY GOGGLES

AT ALL TIMES.

Dressing The 906850 and 904850 Brake

Drum Grinders

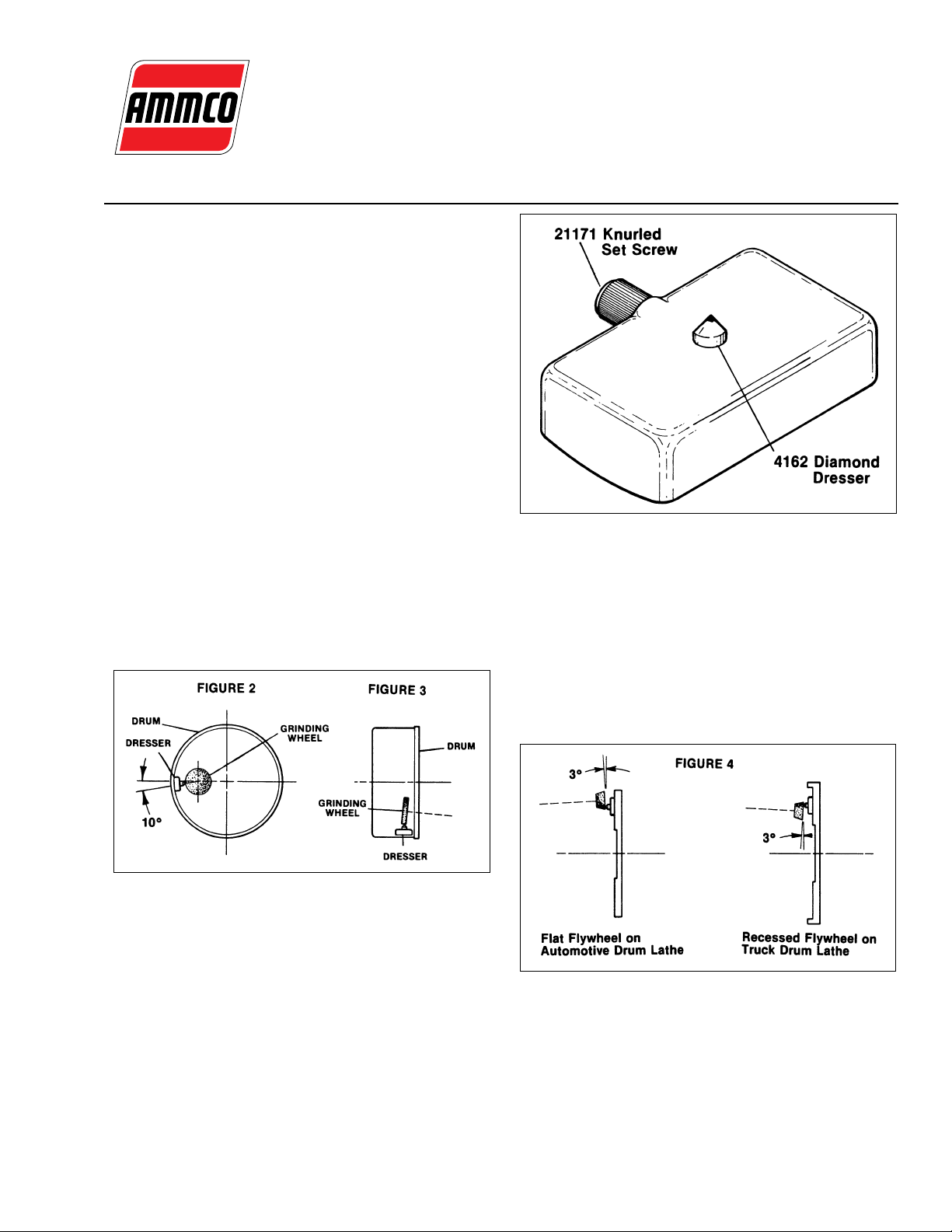

The Dresser is magnetically held inside the drum on the

same surface that will be ground. Visually align the diamond tip 10-degrees below the center of the Grinding

Wheel, as shown in Figure 2. This is particularly important when dressing the Grinding Wheel at an angle,

Figure 3.

The Drum Grinder should be securely mounted in the

Boring Bar Clamp of the Lathe. Turn the Grinder on and

manually move it across the stationary diamond nib by

operating the Parallel Slide Feed Handwheel. Only the tip

of the diamond should make light contact with the

Grinding Wheel. The depth of cut is controlled by the

Cross Slide Hand Wheel — the maximum cut recommended is 0.005-inches. Dress the wheel until its full

face is parallel to the drum wall. DO NOT waste the

wheel by overdressing. Feed the wheel across the diamond nib slowly for the best possible finish.

After dressing a wheel, do not change position of the

Boring Bar Clamp in which the Grinder is mounted.

Remove the Dresser from the drum wall and, after loos-

ening the knurled set screw, rotate the diamond nib

slightly. This will help keep the nib pointed and prolong

its life — as well as set it up for the next dressing job.

The Grinding Wheel should be dressed before finishing

each drum.

Dressing The 906250 Cup Wheel Grinder

Place the Grinder in the right angle Boring Bar Holder

which is mounted in the outer Clamp of the Twin Cutter.

Position the Grinder so the grinding surface of the Cup

Wheel inclines toward the direction of feed and is angled

approximately 3-degrees to the flywheel, Figure 4.

Place a magnetic Silencer on the back side of the flywheel. On the front side, mount the 6061 Dresser so the

diamond is on a horizontal center line with the Cup

Wheel. Adjust the Crossfeed so the leading edge of the

Cup Wheel is in front of the Dresser. Turn on the Grinder

but DO NOT start the Lathe. Back the parallel feed by

hand until the Cup Wheel just touches the diamond nib.

Set the depth of cut no more than 0.005-inches. Slowly

hand feed the Cup Wheel across the diamond until the

full face is parallel to the flywheel.

921109 04 02/06 © COPYRIGHT 1979 HENNESSY INDUSTRIES AND AMMCO ALL RIGHTS RESERVED PRINTED IN U.S.A.

AMMCO, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Loading...

Loading...