Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 921657 18

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 06/01

Installation Instructions

Operating Instructions

Safety Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

6000, 6002

Heavy Duty

Drum/Disc Lathe

®

Page 2

ii • AMMCO 6000, 6002 Brake Lathes

Brake Lathes

Page 3

AMMCO 6000, 6002 Brake Lathes • iii

Table of Contents

Safety Notices and Decals . . . . . . . . . . . . .iv

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Cautions and Dangers . . . . . . . . . . . . . . . . . . . .iv

Owner’s Responsibility . . . . . . . . . . . . . . . .v

Definitions of Hazard Levels . . . . . . . . . . . .v

Important Safety Instructions . . . . . . . . . .vi

Installation

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Preferred Lifting Method . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Electrical Wiring Requirements . . . . . . . . . . . . . .2

Electrical Hook-Up . . . . . . . . . . . . . . . . . . . . . . . .2

Terminal Block Diagram . . . . . . . . . . . . . . . . . . . .2

Work Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Lathe Operation

Operating Specifications . . . . . . . . . . . . . . . . . . .3

Work Space Requirements . . . . . . . . . . . . . . . . .3

Control Panel Functions . . . . . . . . . . . . . . . . . . . .4

Electrical Overload Safety Breaker . . . . . . . . . . . .4

Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . .4

Saddle and Cross Slide Locks . . . . . . . . . . . . . . .5

Feed Gearbox Engagement Levers . . . . . . . . . . .5

Handwheel Depth-Of-Cut Dials . . . . . . . . . . . . . .5

Gearbox Function & Handwheel Operation . . . . .6

Typical Drum Mounting . . . . . . . . . . . . . . . . . . . .7

Brake Drum Reconditioning . . . . . . . . . . . . .8 - 10

Typical Rotor Mounting . . . . . . . . . . . . . . . . . . .11

Brake Rotor Reconditioning . . . . . . . . . . . . .12 - 13

Maintenance and Service

Oiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Adjusting Gibs . . . . . . . . . . . . . . . . . . . . . . . . . .14

Care of Arbors and Adapters . . . . . . . . . . . . . . .15

Drive Belt Replacement . . . . . . . . . . . . . . . . . . .16

Main Power Switch Bulb Replacement . . . . . . .16

Drive Motor Brush Replacement . . . . . . . . . . . .16

Feed Motor Brush Replacement . . . . . . . . . . . .17

Electrical Cords . . . . . . . . . . . . . . . . . . . . . . . . .17

Overload Safety Fuse Replacement . . . . . . . . . .17

Contents

Page 4

iv • AMMCO 6000, 6002 Brake Lathes

Safety

Safety Notices and

Decals

For your safety, and the safety of others, read and

understand all of the safety notices and decals included here and on the unit.

Read entire manual

before installing,

operating, or servicing this equipment.

Proper maintenance

and inspection is

necessary for safe

operation.

Do not operate a

damaged lathe.

Warning

This equipment incorporates parts such as snap

switches and power receptacles which tend to produce arcs or sparks. Theref ore, when located in a service facility, the unit should be in a room or enclosure

provided for the purpose, or should be at least 18” or

more above floor to minimize the risk of igniting fuel

vapors.

Cautions and Dangers

1. Eye and face protection requirements:

“Protective eye and face equipment is required

to be used where there is a reasonable

probability of injury that can be prevented by use

of such equipment.” OSHA 1910.133 (a).

Protective goggles, safety glasses, or a face

shield must be provided by the purchaser/user

and worn by the operator of the equipment.

Make sure all eye and face safety precautions are

followed by the operator(s). Keep bystanders out

of the area.

2. Do not remove any safety equipment, belt

guards, or shortcut controls or operations.

3. Make sure drums and rotors are properly and

squarely mounted before starting lathe, and that

all parts are secure.

4. Do not wear loose clothing, jewelry, or gloves

when operating or working around a lathe.

5. Do not overload the lathe. Read and understand

the lathe specifications. Overloading is poor

machine tool practice, shortens the life of the

lathe, and could cause a failure resulting in

personal injury.

Failure to follow danger, warning, and caution

instructions may lead to serious personal injury or

death to operator or bystander or damage to property. Do not operate this machine until you read

and understand all the dangers, warnings and cautions in this manual. For additional copies of either ,

or further information, contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.Hennessy-Ind.com

WARNING

Page 5

AMMCO 6000, 6002 Brake Lathes • v

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and

Regulations; such as State and Federal OSHA

Regulations and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep

them readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the

unit, and are properly supervised.

• Allow unit operation only with all parts in place

and operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with

authorized or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

Definitions of Hazard

Levels

Identify the hazard levels used in this manual with

the following definitions and signal words:

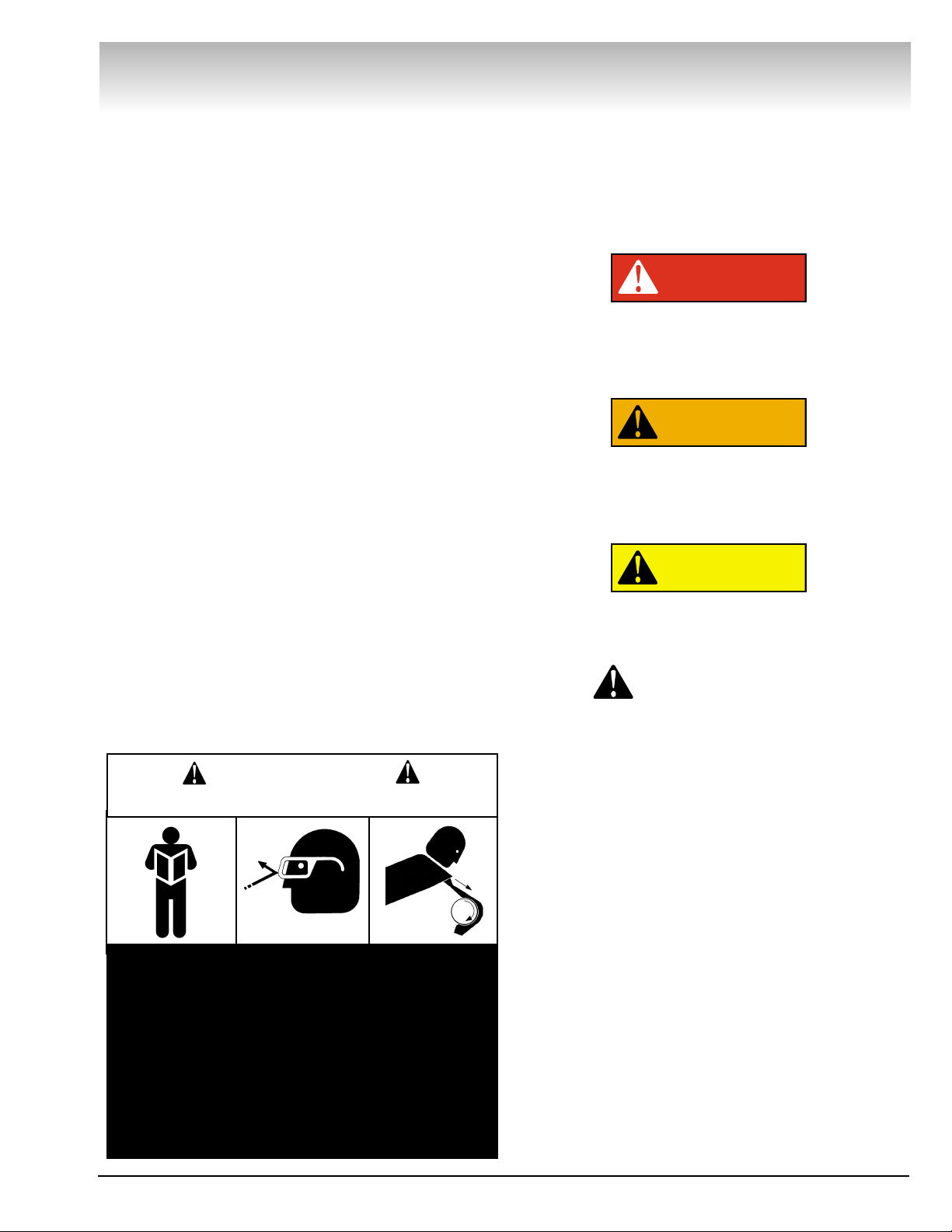

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Safety

1. Read and follow instructions.

2. Always wear eye protection, avoid loose

clothing and jewelry.

3. Keep all guards, shields, and covers in place and

in working order.

4. Keep bystanders out of work area.

5. Unplug unit from power source before servicing

or adjusting.

6. Maintain unit properly, keep work surfaces and

work area clean.

CAUTION

Prevent accidents and injury, read and follow instructions.

DANGER

WARNING

CAUTION

Page 6

vi • AMMCO 6000, 6002 Brake Lathes

READ ALL INSTRUCTIONS

When using your garage equipment, basic safety precautions should always be followed, including the following:

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches from the tool

before turning it on. Make this a habit.

3. Keep work area clean and well lighted. Cluttered

areas and benches invite accidents.

4.To reduce the risk of fire, do not operate equipment

in the vicinity of open containers of flammable liquids

(gasoline).

5. Adequate ventilation should be provided when working on operating internal combustion engines.

6. Care must be t aken as burns can occur from touching hot parts.

7. Do not operate equipment with a damaged cord or

if the equipment has been dropped or damaged—until it

has been examined by a qualified serviceman.

8. If an extension cord is necessar y, a cord with a current rating equal to or more than that of the equipment

should be used. Cords rated for less current than the

equipment may overheat. Care should be taken to

arrange the cord so that it will not be tripped over or

pulled.

9. To reduce the risk of electric shock, do not use on

wet surfaces or expose to rain.

10. Keep children away. All bystanders should be kept

completely away from the work area.

11. Make the workshop kid-proof. Use padlocks and

master switches, and remove starter keys.

12. Don’ t f orce a tool. It will do the job better and safer

at the rate for which it was designed.

13. Use the right tool. Don’t force a tool or an attachment to do a job for which it was not designed.

14. Dress properly. Keep hair, loose clothing, neckties,

shop rags, jewelry, fingers, and all parts of body away

from moving parts. Non-slip footwear is recommended.

15. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses, they are NOT

safety glasses. Safety glasses, goggles, or a face shield

will help protect the operator from injury. Use a face

shield and dust mask during dusty operations.

16. Secure the work properly to the unit for setup and

tool bit positioning. Do not attempt to hold a drum or

rotor steady on the arbor with your hands. Both hands

must be free to operate unit.

17. Don’t overreach. Keep proper footing and balance

at all times when lathe is in operation or when working

around the unit.

18. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow instructions for lubricating and changing accessories.

19. Remove power from the unit and disconnect tools

before servicing and when changing accessories such as

blades, bits, cutters, etc. Follow lock-out and tag-out procedures as required.

20. Avoid unintentional starting. Make sure the switch

is in the OFF (O) position before plugging the machine in

or performing any maintenance or service work.

21. Use of improper accessories may cause risk of

injury to operator or bystanders. Use only as described in

this manual. Use only manufacturer’s recommended

attachments.

22. Never stand or lean on a lathe. Serious injury could

occur if the lathe is tipped or if the cutting tool is unintentionally contacted.

23. Check damaged parts carefully. Before further use

of the lathe, a guard or other part that is damaged should

be carefully checked. Immediately replace all damaged,

missing, or non-functional parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect operation. Guards and other parts that are damaged should be

properly repaired or replaced before lathe is used again.

24. A lways feed the work into a blade or cutter and

against the direction of rotation. Cutters and tool bits are

designed to cut from the inside of a drum or rotor to the

outer edge. Do not attempt to cut from the outside edge

in to the center.

25. Never leave tools running unattended. Turn the

power off. Don’t leave the tool until it comes to a complete stop.

26. Never use compressed air to blow the tool clean.

Chips and dust may be driven between machined parts

and into bearings, causing undue wear. They may also

contact persons in the area causing personal injury.

Before operating the lathe, review the warning information on the lathe and the cautions, warnings and dangers in

this manual. Also review the following general safety instructions. Failure to follow safety instructions could result in

personal injury to operator or bystanders and damage to the lathe or personal property.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Page 7

Installation

Receiving

The shipment should be thoroughly inspected as soon as it is

received. The signed bill of lading is acknowledgement by the

carrier of receipt in good condition of shipment covered by our

invoice.

If any of the goods called for on this bill of lading are shorted or

damaged, do not accept them until the carrier makes a notation

on the freight bill of the shorted or damaged goods. Do this for

your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or damage

is discovered after receipt and request the carrier to make an

inspection. If the carrier will not do so, prepare a signed statement to the eff ect that y ou hav e notified the carrier (on a specific

date) and that the carrier has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER

YOU HAVE GIVEN THE CARRIER A CLEAR RECEIPT.

File your claim with the carrier promptly. Support your claim

with copies of the bill of lading, freight bill, invoice, and photographs, if available.

Although AMMCO’s responsibilit y ceases upon delivery of the

shipment to the carrier, we will gladly assist in tracing lost shipments. Our willingness to assist in every possible manner does

not make AMMCO responsible for collection of claims or

replacement of lost or damaged materials. Shipping damage

claims will not be handled under warranty.

Preferred Lifting Method

Lift the lathe by all four bed ways only. DO NOT lift

under the saddles, cross slides, boring bars, or spindle. Be sure the gearbox control wires and external

travel controls will not be damaged when lifting the

lathe.

Be sure the lifting slings are arranged so they will not crush or

exert pressure against any limit switch control parts, lock levers,

control wires, etc.

Both slings should be hung together in a hook or a loop of c hain

when lifting the lathe.

Installation

Bolt the lathe to the floor using the anchor bolts provided. Be

sure the lathe is resting solidly on its three feet. Shim with washers if necessary to eliminate rocking. After the lathe is bolted

down run the outer corner screws of the front support down

until they contact the floor and tighten the jam nuts. These

screws are not to be used for leveling. BEFORE RUNNING THE

LATHE, REFER TO THE OILING AND GREASING INSTRUCTIONS. Allow sufficient work space around the lathe as illustrated in the WORK SPACE REQUIREMENTS.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 1

CAUTION

Page 8

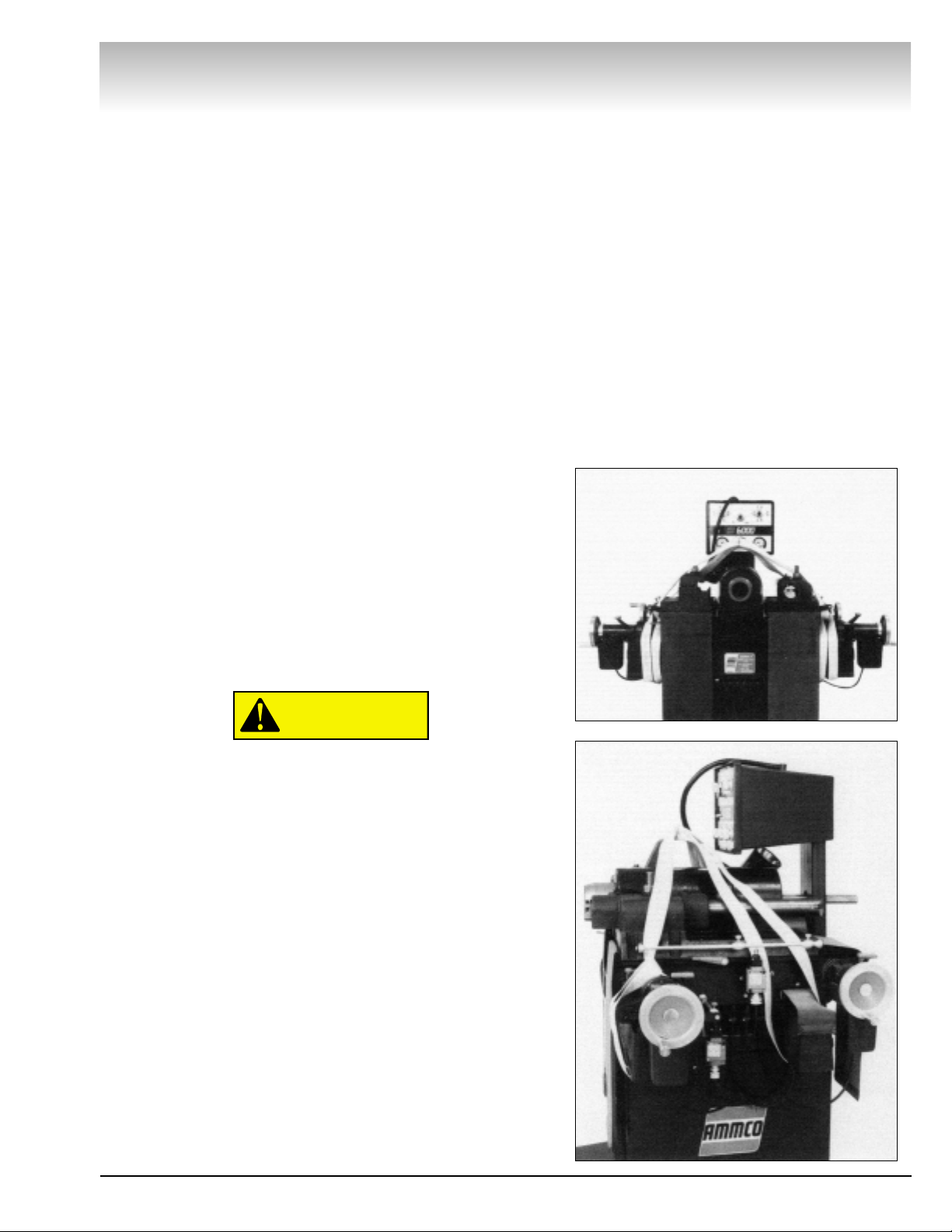

Electrical Wir ing Requirements

The lathe is factory wired to a disconnect box whic h should be

grounded to the power supply box in accordance with local code

requirements to protect the operator from shock.

The lathe is grounded to the disconnect box through the flexible conduit. The flexible conduit should not be removed or

eliminated.

This box is to be mounted to the wall behind the machine.

A qualified electrician should complete the hook-up to line

power of 220 VAC, 50~60 Hz, Single Phase, 20 amps.

Before operating the lathe be sure the drive motors are connected at the terminal plate as shown in Fig. 1.

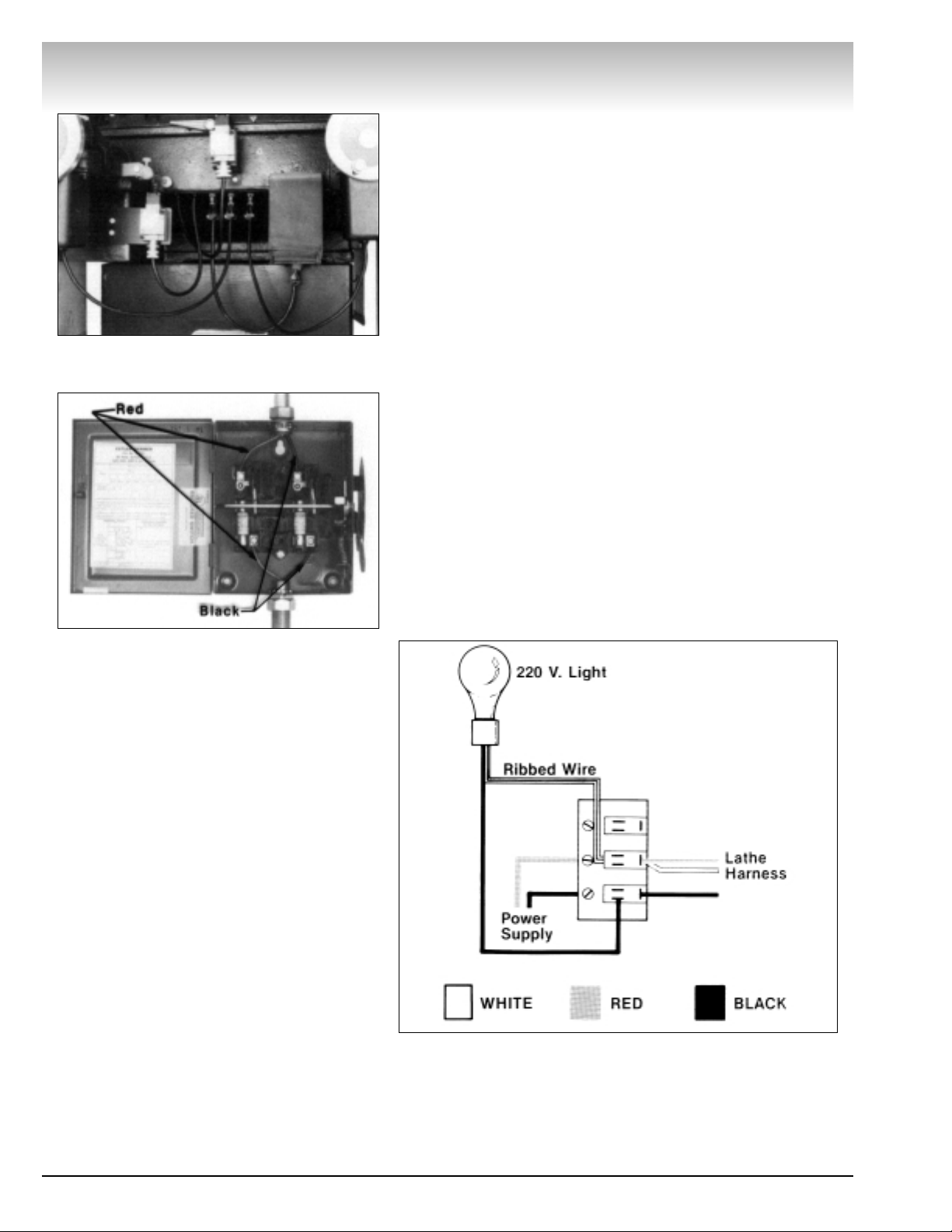

Electrical Hook-Up

Connect one incoming power line to the screw terminal at the

top of the fuse above the red lathe wire and the other power

line to the screw terminal at the top of the fuse above the black

lathe wire, Fig. 2. Check the voltage between the red and black

power lines with a voltmeter. The meter will show 220 volts

when properly wired.

Note:The incoming power lines must be supplied by the consumer and must be in accordance with local code requirements.

The incoming power lines may be colors other than red and

black.

Terminal Block Diagram

Work Lamp

The work lamp is designed for a maximum bulb wattage of 75

wat ts. Exceeding 75 w atts will damage the lamp shade. Be sure

to use 220 volt bulbs only.

Brake Lathes

2 • AMMCO 6000, 6002 Brake Lathes

Figure 1 - Drive Motor Electric Cables Connected To

Terminal Plate

Figure 2 - Disconnect Box Hook-up (Black To Black,

Red T o Red)

Page 9

Lathe Operation

Operating Specifications

Overall Lathe Height . . . . . . . . . . . . . . . . . . . . . . .57in. (1447.8 mm)

Spindle To Floor . . . . . . . . . . . . . . . . . . . . . . . . . .39 In. (990.6 mm)

Turning Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 In. (457.2 mm)

Facing Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 In. (177.8 mm)

Spindle Speed, Infinitely Variable . . . . . . . . . . . . . . . . .20—140 RPM

Feed Rates, Infinitely Variable . . . . . . ..0625 In./Min, To .750 In./Min.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .(1.6 mm/Min. To 19.1 mm/Min.)

Handwheel Graduations . . . . . . . . . . . . . . . . . . . ..001 In. (.020 mm)

Maximum Load, 2 1/2 In. Arbor . . . . . . . . . . . .1500 Lbs. (680.4 Kg)

Spindle Motor . . . . . . . . . . . . . . . . . . . . . . . . . .1 1/2 Hp—180 VDC

Electrical Requirements . . .220 VAC, 50/60 Hz, 1 Ph, Fused At 20 A

Lathe Weight . . . . . . . . . . . . . . . . . . . . . . . . . .1600 Lbs. (725.8 Kg)

Work Space Requirements

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 3

Page 10

Electrical Overload Safety Breaker

The control panel is equipped with an overload safety breaker

switch which will automatically turn the lathe off when the

motor is overloaded or when something is wrong in the lathe’s

electrical circuit.

To reset, wait approximately three minutes before moving the

switch to its RESET position. If the overload safety breaker continues to open, or if the line fuses are blown, have the circuit

checked by a qualified electrician.

If the feed motors do not function after resetting the safety

breaker, check the fuses on the back side of the control panel

assembly. Following the OVERLOAD SAFETY FUSE REPLACEMENT procedure.

Limit Switches

The lathe is equipped with external limit switches which can

be adjusted to stop the travel of either the saddles or cross

slides as a cut is completed. See how-to-use details under drum

reconditioning and rotor reconditioning in this section.

4 • AMMCO 6000, 6002 Brake Lathes

Brake Lathes

Control Panel Functions

Page 11

Saddle and Cross Slide Locks

The red handled saddle locks and cross slide locks tighten in a

clockwise direction. Use the locks to maintain a constant depthof-cut when machining drums (saddle locks) and turning rotors

(cross slide locks). Never engage a feed gearbox when its saddle or cross slide is locked, Fig. 1.

Feed Gearbox Engagement Levers

Each gearbox is labeled to indicate the ENGAGE and DISENGAGE positions. The gearboxes may be shifted in and out of

gear at any feed speed without danger to the gearboxes.

Hand Wheel Depth-Of-Cut Dials

The hand wheel dials are calibrated with both inch and metric

scales. The dials indicate the DEPTH-OF-CUT when setting the

cutting tool for turning a drum.

Inch Scale - A cut of .010" from a 16.000" diameter drum will

result in a refinished diameter of 16.020".

Metric Scale - A cut of .1 mm from a 418 mm diameter drum

will result in a refinished diameter of 418.2 mm.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 5

Figure 1 - Saddle & cross slide locks.

Figure 2 - Engagement Lever Operation

Page 12

6 • AMMCO 6000, 6002 Brake Lathes

Brake Lathes

Gearbox Function & Handwheel Operation

Page 13

AMMCO 6000, 6002 Brake Lathes • 7

Typical Drum Mounting

Large Truck Drum Mounted On 2 1/2" Arbor

A — Arbor

B — Arbor Nut

C — Arbor Washer

D — Spacers

E — Centering Cones Used As Spacers

F — Centering Cones

G — Lathe Spindle

H — Draw Bar

Floating Type Drum Mount ed On 1 7/8" Arbor

A — Arbor

B — Arbor Nut

C — Spacers

D — Clamping Cups

E — Centering Cone

F — Spring

G — Lathe Spindle

H — Draw Bar

Hub Type Drum Mounted On 1" Arbor

A — Arbor Nut

B — Arbor

C — Self-Aligning Spacer

D — Radii Adapters

E — Lathe Spindle

F — Draw Bar

Hub Type Drum Mounted On 11/16" Arbor

A — Arbor Nut

B — Self-Aligning Washers

C — Spacer

D — Centering Cone

E — Arbor

F — Lathe Spindle

G — Draw Bar

Brake Lathes

Page 14

Brake Drum Reconditioning

Although drum turning is usually done on the right side of the

lathe, the left side may also be used by turning the boring bar

upside down in the left hand boring bar clamp.

The following description assumes right hand operation:

1. Measure the diameter of the drum with a brake drum

micrometer. If the drum diameter will be larger than the manufacturer’s specified rebore limit after machining, it must be

replaced. Be sure the general condition of the drum is good.

2. Before mounting a hubbed brake drum, inspect the bearings and races for wear. Chec k a lubricant sample from the bearings for metal particles. An abundance of shiny metal chips

indicate a damaged bearing. Install a new bearing race before

machining the drum. Also, check the hub for a loose race. If the

bearing race can be turned by hand the race recess is worn.

Replace the hub or hub and drum. New bearing races are usually installed in the hub during manufacturing. Be sure the races

are fully seated in the hub. New bearings should be used with

new races.

3. Mount the drum on the arbor using appropriate adapters,

cones, and spacers. See TYPICAL DRUM MOUNTING illustrations.

4. Wrap a drum silencer band snugly around the drum and

secure it by sliding the buckle finger under the top layer of the

band.

5. Place the boring bar in the boring Bar clamp. Crank the

saddle to its innermost position, then back it out 2 turns.

Position the cross slide so it is close to the open side of the

drum; be sure the drum will not touch the cross slide when the

lathe is turned ON.

6. Position the boring bar and clamp so the inside corner of

the drum can be reached with the tool, and so the boring bar

and clamp will not run into the spindle housing as the cross slide

feeds out. Give the saddle hand wheel one full t urn clockwise to

move the tool away from the drum.

7. Set the cross slide limit switch by either estimating the

travel necessary to cut the full depth of the drum or, if cutting

several drums having the same depth, crank the cross slide

back so the tool bit is 1/4" to 1/2" outside the drum. be sure all

feed gearbox levers are in the DISENGAGE position. TURN THE

LATHE ON. Slide the left adjustable travel limit stop against the

microswitch plunger, Fig. 3. The feed motor will shut off as the

ramp of the adjustable stop depresses the microswitch plunger.

Tighten the lockscre w to hold the stop at this point. Set the right

hand feed direction knob to the DRUM TURN OUT position.

8. Crank the tool bit to the middle of the drum wall. Manually

advance the tool bit until it lightly contacts the drum wall making a “scratch” cut.

Brake Lathes

8 • AMMCO 6000, 6002 Brake Lathes

Figure 3 - Setting Limit Switch for Drum Turning

Page 15

Note: A “scratch” cut should be no more than .001" deep. If

the “scratch” cut is too deep it will show a continuous line on

the face of the drum and the runout will not be apparent. Back

the tool bit off, stop the lathe, and check the mounting as follows:

A. Loosen the arbor nut and rotate the drum one-half turn

(180º) on the adapters.

Note: The adapters must be held to keep them from turning.

Retighten the arbor nut, turn the lathe ON, and make a second

“scratch” cut. Turn the lathe OFF.

B. If the first and second “scratch” cuts are side-by-side,

the runout is in the drum — not in the mounting.

Note: A very small amount of runout is permissible. A large

amount of runout indicates either a bent drum or an incorrect

mounting.

If the “scratch” cuts are opposite each other (180° apart), the

drum is not properly mounted. Shut the lathe OFF. Inspect the

mounting for cleanliness and the adapters for burrs, nicks, or

scratches. Check the bearing races for looseness. Remount the

drum and check again for runout. Proceed to machine the drum,

if the runout has been corrected.

9. Turn the lathe ON. Carefully advance the tool bit by hand

until it just contacts the drum surface and makes a "scratch" cut.

Hold the saddle hand wheel in this position and rotate its dial to

the (0) position. This setting will be the reference used to help

determine the reconditioned diameter of the drum.

10. Align the tool bit with the deepest groove worn in the

drum. Start the lathe and manually advance the tool bit into the

bottom of the groo ve until it makes a continuous cut around the

drum. Do not cut any deeper than necessary to make the cut

continuous. The depth-of-cut dial will show the approximate

amount of material that must be removed to recondition the

drum. Double the depth-of-cut reading and add the result to the

brake drum micrometer reading to find the finished diameter of

the reconditioned drum. This calculated measurement must be

compared with:

a. The maximum rebore limit (available from the

manufacturer’s specifications).

b.The measured diameter of the drum before machining to

determine the amount of material to be removed in each

pass.

11. With the lathe still running, give the saddle hand wheel

one full turn clockwise to move the tool bit away from the drum

wall. Manually position the tool bit at the inside corner of the

drum and set the desired depth of cut. Engage the feed gearbo x

and set the feed speed.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 9

Figure 4 - Drum Mounting, First “Scratch” Cut

Figure 5 - Drum Mounting, Second “Scratch” Cut

Page 16

Note: FEED AND SPEED SETTINGS—The following spindle

speed and feed speed recommendations are intended to serve

as a starting point for a machine operator not familiar with the

lathe.

Drums Spindle Speed Feed Speed

Up To 12" Dia. Medium Fast Medium Slow

Over 12" Dia. Medium Medium Slow

Note: See CONTROL PANEL FUNCTIONS.

Although these settings are relatively slow, they should give

the manufacturer’s recommended finish and good tool life. The

settings may be increased considerably, however, tool life

decreases as spindle and feed speeds increase.

12. If a finish cut is to be made simultaneously with the

rough cut or a rough cut and grind are to be done at the same

time, repeat steps 5, 6, and 7 on the left side of the lathe.

Note: Both the lathe and the grinder must be running when

the grinder is moved into contact with the drum.

Start the second (finish) cut at least one inch behind the rough

cut. Find the zero setting for the left side by carefully advancing

the tool bit or grinder (both the lathe and the grinder must be

running) by hand until it makes light contact with the drum. Set

the micrometer dial to zero. Advance the tool bit to the desired

depth for the finish cut and tighten the saddle loc k lev er. Engage

the saddle feed gearbox and set the feed speed.

Disengage the feed gearbox and shut the lathe off when the

cut is completed.

Note: Determine the depth-of-cut by these general guidelines:

• Finishing cuts should not be shallower than .002 inches (.05

mm).

• Usually no more than two cuts are required to recondition a

drum.

Brake Lathes

10 • AMMCO 6000, 6002 Brake Lathes

Page 17

AMMCO 6000, 6002 Brake Lathes • 11

Brake Lathes

Typical Rotor Mounting

Large Truck Rotor Mounted On 2 1/2" Arbor

A — Arbor

B — Arbor Nut

C — Arbor Washer

D — Spacers

E — Centering Cones

Used As Spacers

F — Centering Cones

G — Lathe Spindle

H — Draw Bar

Hub Type Rotor Mounted On 1" Arbor

A — Arbor Nut

B — Arbor

C — Self-Aligning Spacer

D — Radii Adapters

E — Lathe Spindle

F — Draw Bar

Page 18

Brake Rotor Reconditioning

Each brake rotor should be carefully inspected for scoring,

hard spots, and rust ridges at the inner and outer circumferences of the rotor. Any excessive wear or deformity should be

noted and, the rotor should be replaced if not within acceptable

limits. The twin cutter is designed to be used on the left cross

slide in place of the boring bar clamp, to refinish both sides of a

rotor at the same time. The cross slide centers the twin cutter

to the rotor and the saddle feeds the twin cutter out when cutting.

1. Use a micrometer to check the thickness of the rotor at

three or more points around the circumference and about 1"

(2.54 cm) in from the outer diameter. If the thickness is less

than specified by the manufacturer at any point measured, or

will be less after machining, the rotor should be replaced.

2. Before mounting a hubbed rotor inspect the bearings and

races for wear. Check a sample of lubricant from the bearings

for metal particles. An abundance of shiny metal chips indicates

a damaged bearing. Install a new bearing race before machining

the rotor . Also, chec k the hub for a loose race. If the bearing race

can be turned by hand the race recess is worn. Replace the hub

or hub and rotor. New bearing races are usually installed in the

hub during manufacturing. Be sure the races are fully seated in

the hub. New bearings should be used with new races.

3. Mount the rotor on the arbor using the appropriate

adapters, cones and spacers. See the TYPICAL ROTOR

MOUNTING illustrations.

4. Install a silencer band by stretching it around the rotor and

hooking the wire loop over a lead weight.

5. Center the twin cutter to the rotor by manually moving the

cross slide forward or back so the rotor is evenly spaced

between the tool bits. Lock the cross slide in place.

6. Unlock the twin cutter tool slides and adjust them so they

are equally spaced from the center of the rotor.

7. Loosen the boring bar clamp nuts of the twin cutter and

position the boring bars so approximately one-half of their

length is forward of the clamp studs. Manually advance the saddle until the outer boring bar tool bit comes in contact with the

hub at the face of the rotor. Be sure the rotor has clearance with

the body of the twin cutter in this position. Wrench tighten the

outer clamp nut. Position the inner boring bar so its tool bit is

approximately 1/2" beyond the rotor face and wrench tighten its

clamp nut. Lock the tool slides in these positions. Be sure the

tool bits are not in contact with the rotor.

8. Set the saddle travel limit switch by either estimating the

travel necessary to cut the full width of the rotor faces or, if cutting several rotors having the same outside diameter, crank the

saddle out so the tool bits are 1/4" to 1/2" outside the rotor. Be

sure all feed gearbox levers are in the DISENGAGE position.

Slide the adjustable travel limit stop against the microswitch

plunger, Fig. 6. The feed motor will shut off as the ramp of the

Brake Lathes

12 • AMMCO 6000, 6002 Brake Lathes

Figure 6 - Setting Limit Switch For Face Cut

Clearance

Adjustable T ravel Limit Stop

Microswitch Plunger

Page 19

adjustable stop depresses the microswitch plunger. Tighten the

lock screw to hold the stop at this point.

9. Advance the tool bits to the approximate center of the rotor

faces. Turn the red and blue depth-of-cut knobs clockwise, one

at a time, until their respective tool bits make light contact with

the rotor face, making a “scratch” cut, Fig. 7.

Note: A “scratch” cut should be no more than .001" deep. If

the “scratch” cut is too deep it will show a continuous line on

the face of the rotor and the runout will not be apparent. Hold

the outer knobs still and turn the inner dials to zero (choose

either inches or millimeters). Back the tool bits away from the

rotor by turning the knobs counterclockwise. Turn the lathe OFF.

10.To check the rotor mounting:

A. Loosen the arbor nut and rotate the rotor one-half turn

(180°) on the adapters.

Note: The adapters must be held to keep them from turning.

Retighten the arbor nut. Back the saddle out one hand wheel

turn and start the lathe. Make a second “scratch” cut on the

outer surface of the rotor only. Turn the lathe OFF.

If the “scratch” cuts are side by side any runout or wobble is

caused by the rotor’s condition.

B. If the “scratch” cuts are opposite each other (180º

apart), the rotor is not properly mounted. Remove the rotor

from the arbor and examine each adapter and the arbor for

nicks, burrs, chips, dirt, and rust. Also inspect the rotor hub

for loose or damaged bearing cups. Clean, repair, remount,

or replace as necessary.

11. Check the settings of the depth-of-cut dials again. Move

the tool bits in until they lightly contact the rotor faces and reset

the dials to zero if necessary.

12. St art the lathe and manually advance the saddle to position the outer tool bit at the rotor hub. Set the dial knobs for the

desired depth of cut (inches or millimeters). Set the spindle

speed and set the left hand f eed direction knob to the FACE CUT

OUT position. Engage the saddle feed gearbox.

Note: The following spindle speed and feed speed recommendations are intended to serve as a starting point for a

machine operator not familiar with the lathe.

Rotors Spindle Speed Feed Speed

Up To 12" Dia. Fast Medium Slow

Over 12" Dia. Medium Medium Slow

Note: See CONTROL PANEL FUNCTIONS.

Although these settings are relatively slow they should give

the manufacturers recommended finish and good tool life. The

settings shown may be increased considerably; however, tool

life decreases as spindle speed and feed speed are increased.

When the cut is completed, disengage the feed gearbox and

shut the lathe OFF.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 13

Figure 7 - Rotor Mounting, First “Scratch” Cut

Figure 8 - Rotor Mounting, Second “Scratch” Cut

Page 20

Maintenance and Service

Oiling

The lathe is initially greased and the bare metal parts are

coated with an oil-soluble rust preventative at the factory. It is

not necessary to clean the rust preventative from these parts.

Before using the lathe, however, all bare metal parts (ways,

spindle, cross slides, etc.) should be wiped down with an oiled

rag. Use a light machine oil or way oil for the initial wipe down

and daily when oiling the bare metal parts. Keep the wipers

oiled by applying light machine oil to their top edges daily.

Greasing

Automotive chassis grease should be applied to the grease fittings called out in Figs. 1, 2 & 3 weekly using the hand grease

gun supplied with the lathe.

Sides (Right Side Illustrated), Fig. 1:

Align the red triangle index marks (1). Apply grease to the lead

screw nut fitting (2) located on top of the cross feed. Also,

grease the cross slide way fitting (3) and the rear saddle way fitting (4). Follow the same procedure when greasing the left side.

Rear (Right Rear Illustrated), Fig. 2:

With the lathe turned OFF, reach up under each saddle at the

back of the lathe and wipe grease onto the driving shaft gears

of the cross slide gear boxes.

Front (Front Right Illustrated), Fig. 3:

Fold the cross slide dove tail cover back. Align the red triangle

index marks (5). Apply grease to the saddle fitting (6) and the

lead screw nut fitting (7) located inside the hole in the front of

the saddle. Follow the same procedure when greasing the front

left side.

Motor Bearings: The motor bearings are sealed for life and

need no maintenance.

Cleaning

Keep the lathe as clean as possible for trouble free operation

as well as safety and longer lathe life. Use a brush to sweep

metal chips and dust of f the lathe. DO NOT USE COMPRESSED

AIR TO BLOW THE LATHE CLEAN as chips and dust may be

driven between machined parts and into bearings, and cause

undue wear.

Adjusting Gibs

The gibs, Figs. 1 & 3, should be adjusted periodically to minimize looseness in the slides and to obtain the best possible finish on the work. When adjusting the gibs, the cross slide and

the saddle must not overhang either end of their respective

dove tails. Tighten one gib adjusting screw then back it off until

the slide moves smoothly. Run the slide back and forth by hand

to check your adjustment. Repeat a second time if necessary.

Go through the same procedure for eac h individual gib adjusting

screw.

Brake Lathes

14 • AMMCO 6000, 6002 Brake Lathes

Figure 1 - Grease Fittings (Right Side Shown)

Figure 2 - Apply Grease To The Gear (Right Rear

Shown From Underneath)

Figure 3 - Grease Fittings (Right Front Shown)

Cross Slide Gib

Saddle Gib

1

2

3

4

5

6

7

Page 21

Care of Arbors and Adapters

Although the adapters, arbors, and the spindle are

made of top grade steel and are turned, hardened,

and precision ground to close tolerances, great care

should be taken in their use, handling, and storage.

Even the smallest nick, scratch, or loose chip can

cause incorrect rotor or drum alignment and the

result will be inaccurate machining.

Always inspect the faces and the seating tapers of each

adapter . Wipe each adapter clean before and after use. Carefully

correct any flaw with a fine stone. If the damage cannot be corrected, replace the part.

Handle and store arbors and adapters with great care. Keep

them clean and oiled with light machine oil. DO NOT dump

them together in a box to collect nic ks and dirt. DO NOT use the

adapters for any other purpose than they are intended.

Remove all adapters from the arbor after machining a drum or

rotor and wipe them clean - especially the inboard adapter.

When a finished drum or rotor is removed from the arbor, the

inboard adapter may move slightly away from the face of the

arbor and allow chips or dust to fall into the opening. If these

chips are not cleaned from between the arbor face and the

adapter, they may adversely affect the machining of the next

brake part.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 15

CAUTION

Page 22

Drive Belt Replacement

When replacing drive belts, the following procedure must be

followed:

1.Turn the wall switch OFF.

2. Remove the arbor and drawbar from the spindle.

3. Remove the upper and lower belt guards.

4. Remove the spindle pulley and the spindle belt.

5. Remove the counter shaft bushing and the counter shaft

belt.

6. Remove the access door, then the motor pulley and the

motor belt.

To remove the motor pulley:

a. Remove both set screws.

b. Insert a set screw into the threaded hole and tighten.

This will loosen the bushing, Fig. 4.

To install the motor pulley:

a. Clean the motor shaft, the bore, the outside of the

bushing, and the hub bore of all oil and dirt.

b. Insert the bushing in the hub and match the hole

pattern.

Note: Each hole will be threaded on one side only.

c. Oil the set screws and thread them into the holes

indicated in Fig. 4.

d. Alternately tighten the set screws. Torque to 175 in. lbs.

(1210 bushing - with 3/8 screws) or 55 in. lbs. (10 08

bushing - with 1/4 screws).

To install new timing belts, rev erse the procedure. Be sure the

motor pulley is correctly aligned.

Main Power Switch Bulb Replacement

1. Remove the red lens bezel by unscrewing it in a counter-

clockwise direction.

2. Pull gently on the black ring around the bulb to eject it.

3. Push the new bulb into the socket and replace the lens.

Drive Motor Brush Replacement

1.Turn the lathe OFF and turn the wall switch to its OFF posi-

tion.

2. Unscrew the brush retaining plugs from the motor and

remove the brushes, Fig. 5.

3. Install the new brushes and replace the retaining plugs.

Brake Lathes

16 • AMMCO 6000, 6002 Brake Lathes

Figure 5 - Drive Motor Brush Replacement

Figure 4 - Motor Pulley Removal & Installation

Page 23

Feed Motor Brush Replacement

1.Turn the wall switch OFF. Remove the motor cover and dis-

connect the electrical connector.

2. Unscrew the brush retaining plugs from the motor and

remove the brushes. Note how the brushes are positioned in

the motor, Fig. 6.

3. Inst all the new brushes so they contact the commutator

correctly.

4. Replace the retaining plugs, connect the electrical wires,

and replace the motor cover.

Electrical Cords

Replace or repair any damaged or worn cords immediately.

Overload Safety Fuse Replacement

1. Turn the wall mounted disconnect box off.

2. Remove the scre ws holding the control panel in the control

box and pull the control panel assembly out.

3. Disconnect the lathe harness connector from the panel.

4. Remove the four screws from the shield to gain access to

the fuses, Fig. 7.

Brake Lathes

AMMCO 6000, 6002 Brake Lathes • 17

Figure 6 - Feed Motor Brush Replacement

Figure 7 - Safety Fuse Replacement

Page 24

921657 18 06/01 © Copyright 1993 Hennessy Industries and AMMCO All Rights Reserved Printed in USA

Loading...

Loading...