Page 1

904850

Brake Drum Grinder

Installation and

Operation Instructions

with Maintenance Instructions

and Parts Identification

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 921203 07

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 10/06

®

The No. 904850 Brake Drum Grinder

is a precision grinder used in brake

drum refinishing. The high-speed

grinding wheel produces a very even

finish on the drum braking surface by

grinding away any raised hard spots

that have not been removed in normal machining with the carbide cutting tool.

Page 2

2 •

AMMCO Brake Drum Grinder

GRINDER INSTALLATION

After the first brake drum has been turned, remove

the boring bar from the clamp and place the grinder in

position, Fig. 1. DO NOT overtighten the clamp on

the grinder spindle housing. For proper setup, be

sure to move the lathe spindle manually to its full back

position. DO NOT plug in the grinder power cord

until the grinder is completely setup.

Figure 1 - Grinder Installation

MOUNTING THE GRINDING WHEEL

To mount the grinding wheel, insert the Grinding

Wheel Removal Tool, (Item 28) on the parts drawing,

through the spindle housing to lock the spindle. Install

the new wheel, Fig. 2.

Figure 2 - Mounting The Grinding Wheel

Before proceeding further, the grinding wheel must

be dressed. Dressing cleans, shapes, and trues the

surface of the grinding wheel. Refer to the instruction

sheet for the No. 906061 Grinding Wheel Dresser

(PN/921109).

SAFETY PRECAUTIONS: When dressing a grinding wheel, extra care must be taken to protect the

operator. The lathe must not be turned on while

dressing the grinding wheel with a drum-mounted

dresser. Be sure the dresser is removed from the

drum before starting the lathe.

GRINDING WHEEL DRESSING

The No. 906061 Diamond Wheel Dresser is used to

true the surface of the grinding wheel to be parallel

with the surface of the machined drum. The diamond

nib cleans and shapes the wheel to assure full grinding wheel contact.

The grinding wheel is normally dressed one time to

finish grind one set of brake drums. However, if the

grinding wheel gets dull or “loaded”, redress it.

Dressing takes but a moment-don’t overlook it. Note

that the Grinding Wheel should be dressed before finishing each drum.

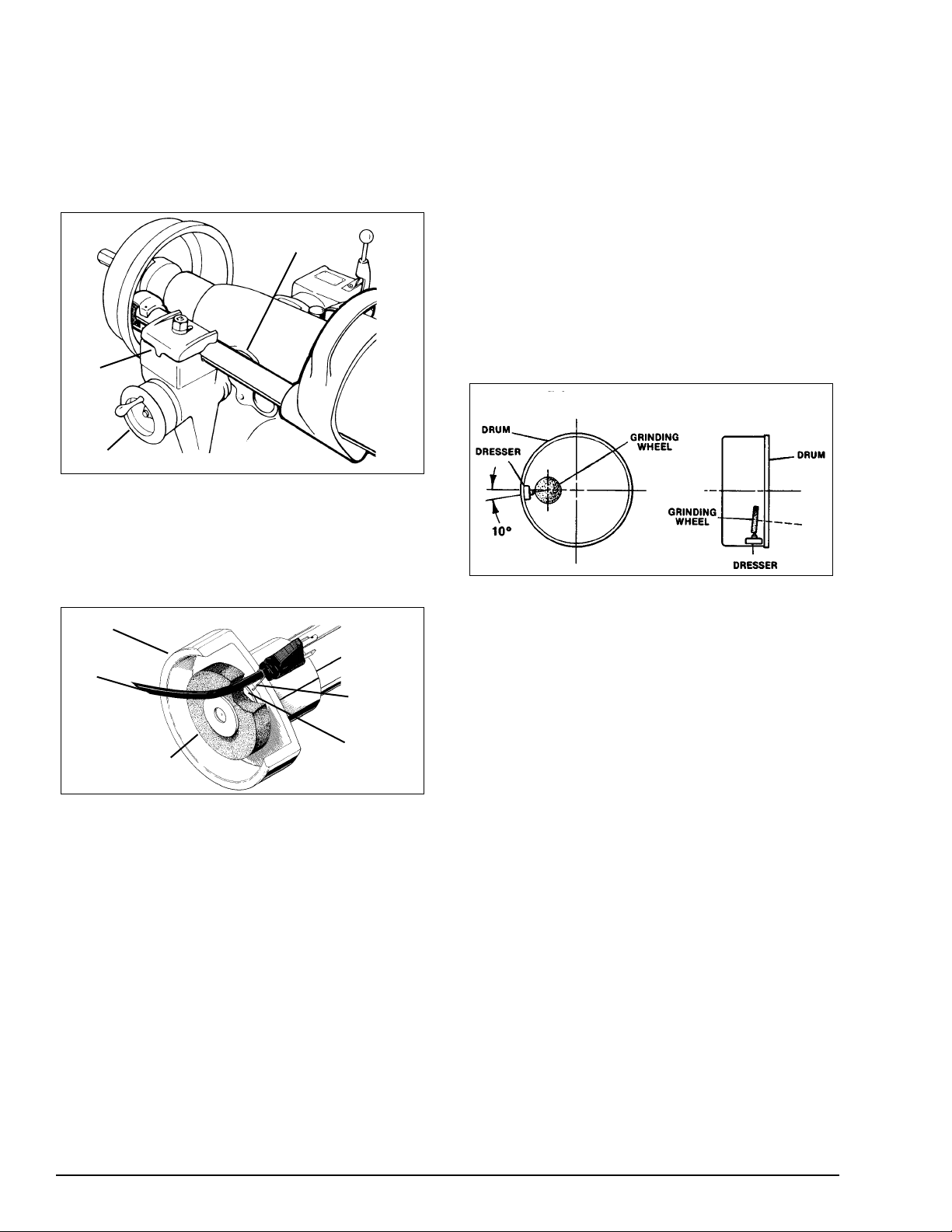

1. The dresser is magnetically held inside the drum

on the same surface that will be ground. Visually align

the diamond tip 10-degrees below the center of the

Grinding Wheel, as shown in Fig. 3. This is particularly

important when dressing the Grinding Wheel at an

angle, Figure 4.

The Drum Grinder should be securely mounted in the

Boring Bar Clamp of the Lathe.

It may be necessary to remove the silencer band

when mounting the dresser.

Figure 3 & 4 - Visually Align Diamond Tip

2. Make sure that the grinding wheel will clear the

brake drum after it passes the diamond nib. Manually

move the lathe spindle back and forth to check this.

Use the cross feed hand wheel to adjust clearances.

CAUTION: The grinding wheel spins at a high

speed. DO NOT use a damaged wheel. DO NOT

use the grinder with the wheel guard removed.

WEAR SAFETY GOGGLES AT ALL TIMES!

3. Plug in the grinder power cord and turn the switch ON.

Use the cross feed hand wheel to move the grinding

wheel until it just touches the diamond. Using the

spindle feed hand wheel, manually move the diamond

tip back and forth across the grinding wheel face. Set

the depth-of-cut at about .005" (.127 mm) per pass.

Dress the grinding wheel until its full face is parallel to the drum wall. DO NOT overdress or use

too fast a spindle feed. Moving the dresser across

the wheel too fast will leave too rough a surface on

the face of the wheel.

4. After dressing a wheel, do not change the position

of the Boring Bar Clamp in which the Grinder is

mounted. Remove the Dresser from the drum wall

and, after loosening the knurled set screw, rotate the

diamond nib slightly. This will help keep the nib

pointed and prolong its life — as well as set it up for

the next dressing job.

Spindle Housing

Boring

Bar

Clamp

Cross Feed Handwheel

Grinding Wheel Guard

Power Cord

Grinding Wheel

Removal

Tool

Hole

Figure 4

Figure 3

Page 3

AMMCO Brake Drum Grinder

• 3

GRINDING THE DRUM

Brake drums may be finished in either of two ways:

Two Step Process - Each brake drum is mounted on

the brake lathe arbor, rough turned and then finish

ground before moving on to the next drum. Only the

boring bar and the grinder are interchanged to maintain the absolute accuracy that is necessary for the

professional brake job. DO NOT turn all the drums

then remount and grind each one.

One Step Process - Brake drums with little wear or

those with no out-of-round distortions may simply be

finish ground without prior machining. DO NOT

exceed the recommended depth-of-grind .002" to

.005" (.051 to .127 mm) on any one pass.

The position of the clamp must not be changed

until the set of drums for which the grinding wheel

was dressed have been ground.

Remove the dresser from the drum wall. Check to be

sure that the lathe motor switch is OFF. Adjust the

lathe spindle manually to bring the drum back over the

grinding wheel as far as possible. It may be necessary

to turn the wheel guard on the grinder spindle to gain

clearance. Loosen the wheel guard cap screw to do

this, but DO NOT remove the wheel guard. Also it is

wise to turn the drum by hand for at least one revolution to make sure that everything is clear.

CAUTION: Always wear safety glasses while

operating grinder.

1. Set the lathe spindle speed to its slowest R.P.M.

2. Start the grinder and the lathe.

3. Use the cross feed handwheel to move the grind-

ing wheel into contact with the drum wall.

4. Set the depth-of-grind from .002" to .005" (.051 to

.0127 mm).

5. Set the infimatic spindle feed from .008" to .010"

(.203 to .254 mm). Engage the feed mechanism.

6. Set the feed stop so that the spindle will automatically stop feeding when the grinding wheel clears the

drum.

Turn, then grind each of the remaining drums of the

set in the same manner. Remember—it is not necessary to dress the grinding wheel for each drum—only

when the grinding angle is changed, when the wheel

becomes “loaded” or dull, or when a new wheel is

installed.

NOTE: Figure 5 illustrates the positioning of the

boring bar clamp for large and small drums. Once

setup for one or the other, the tool post pivot set

screw is locked.The boring bar clamp is not moved

when the boring bar is exchanged with the

grinder.

Figure 5

Hubless drum 10" (254 mm) and smaller may also be

turned and finish ground on AMMCO lathes. These

smaller drums must be mounted differently than full

size types. The larger diameter hubless adapter

(shown in Fig. 6a) on the inside of the drum is NOT

used. Instead, an appropriately sized centering cone

and a spacer are used on the inside with the hubless

adapter on the outside. This clears a working area for

both cutting and grinding, Fig. 6b.

Figure 6a - Mounting For Hubless Drums Over 10" (254mm)

Figure 6b - Mounting For Hubless Drums 10" (254mm) And

Under

Boring Bar Clamp

Swiveled For

Large Diameter

Brake Drums

Swiveled For

Small Diameter

Brake Drums

Centering

Cone

Arbor Nut

Spacer

Cross Section Of Hubless Brake Drum

Self-Aligning

Spacer

Hubless Adapter

Cones

Centering

Cone

Arbor Nut

Cross Section Of Hubless Brake Drum

Self-Aligning

Spacer

Hubless

Adapter

Cone

Page 4

PART

ITEM NO. QTY. DESCRIPTION

*1 910245 1 Grinding Wheel

2 910990 1 Grinding Wheel Guard

3 902308 3 Set Screw

4 921202 1 Seal Washer

5 904006 1 Roll Pin

6 921041 1 Retaining Ring

7 927103 1 Bearing

8 927104 1 Bearing Spacer

9 927562 3 Bearing

10 921045 3 Ring

11 921043 2 Retaining Ring

12 921188 1 Drive Tube Assembly

13 901963 1 Roll Pin

14 921187 1 Spindle Housing

15 903093 1 Retaining Ring

16 921018 1 Bearing Spacer

17 921028 1 Driven Pulley

18 900278 1 Washer

19 903184 1 Nut

PART

ITEM NO. QTY. DESCRIPTION

20 921046 4 Screw

21 921022 4 Shoe

22 900207 2 Screw

23 921031 1 Drive Case

24 920615 4 Screw

25 921029 1 Cover

26 921044 1 Belt

27 921027 1 Drive Pulley

MOTOR ASSEMBLY #921196:

28 921200 1 Motor, w/switch

29 920287 1 Wheel Removal Tool

30 910749 1 CordSet

31 921200-1 1 Switch

37 8150128 1 Connector

921203 07 10/06 ©Copyright 1998 Hennessy Industries and AMMCO Tools All Rights Reserved Printed in U.S.A.

* Replacement Wheel: #905393 (Pkg. of 3)

Loading...

Loading...