Page 1

Instructions for Sharpening No. 904725

Heavy-Duty Carbide Tipped Tool Bit

Read these instructions over carefully, and look at the Tool Bit

before it is used to become familiar with its shape.

1. Use a green Silicone Carbide Grinding Wheel about 54 Grit, H

Grade.

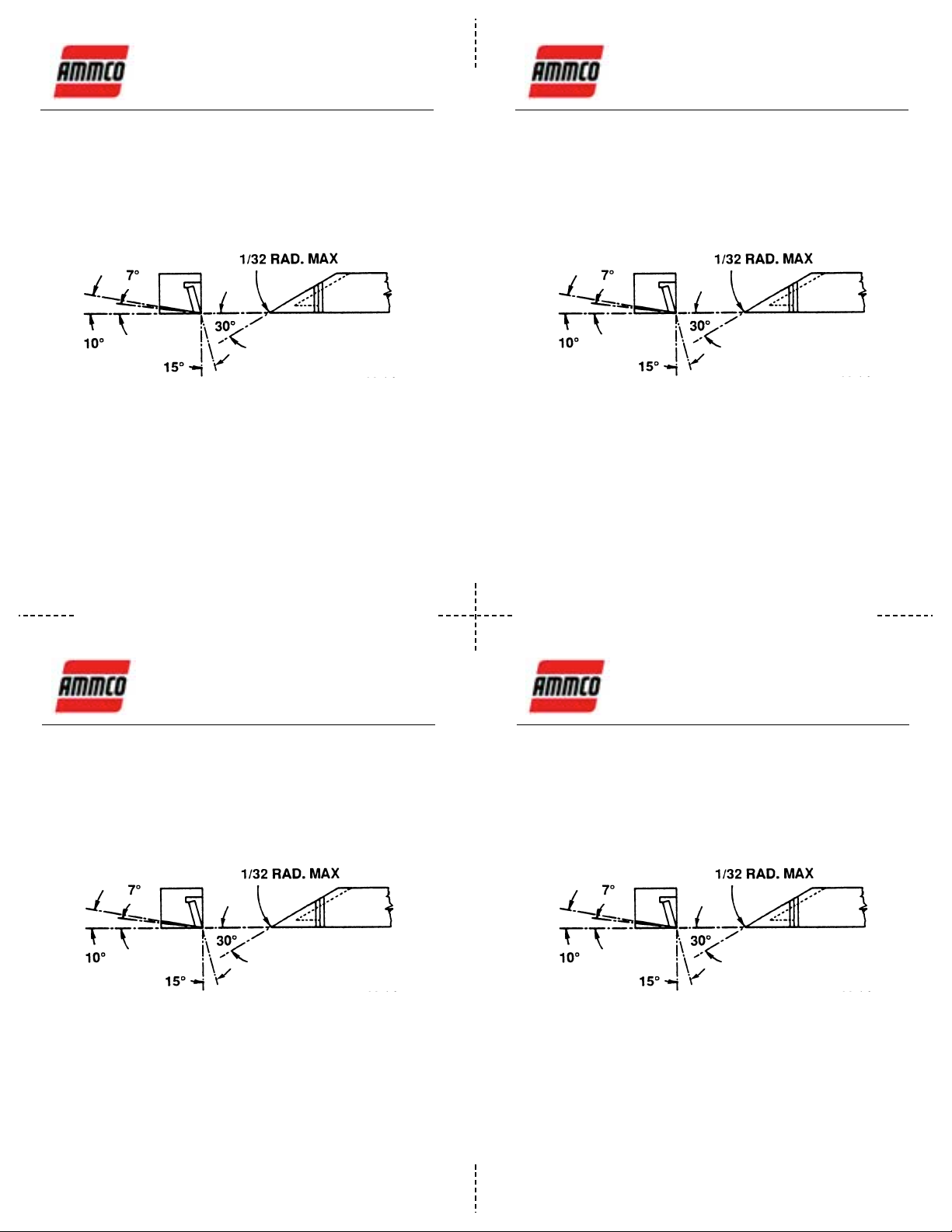

2. The angle of the Carbide (7°) and the Holder Body (10°) and the

Rake (15°) are indicated in the illustration. These angles must be

maintained when grinding.

3. The Radius at the tip of the Carbide is important. Hold it as close as

possible to 1/32 of an inch.

4. Grind the Shank first. Dress the Grinding Wheel to clean all metal

out of it, then grind the Carbide.

5. Remove stock a little at a time. Do not allow the Tool Bit to heat up.

6. Dress the Radius on the Carbide Tip with an AMMCO No. 905764

Carbide Tool Bit Sharpening Stone. Be careful to blend the Radius

into the angle of the Carbide.

7. Air cool the Tool Bit. Never cool the Carbide in a liquid.

928808 01 05/03

Instructions for Sharpening No. 904725

Heavy-Duty Carbide Tipped Tool Bit

Read these instructions over carefully, and look at the Tool Bit

before it is used to become familiar with its shape.

1. Use a green Silicone Carbide Grinding Wheel about 54 Grit, H

Grade.

2. The angle of the Carbide (7°) and the Holder Body (10°) and the

Rake (15°) are indicated in the illustration. These angles must be

maintained when grinding.

3. The Radius at the tip of the Carbide is important. Hold it as close as

possible to 1/32 of an inch.

4. Grind the Shank first. Dress the Grinding Wheel to clean all metal

out of it, then grind the Carbide.

5. Remove stock a little at a time. Do not allow the Tool Bit to heat up.

6. Dress the Radius on the Carbide Tip with an AMMCO No. 905764

Carbide Tool Bit Sharpening Stone. Be careful to blend the Radius

into the angle of the Carbide.

7. Air cool the Tool Bit. Never cool the Carbide in a liquid.

928808 01 05/03

Instructions for Sharpening No. 904725

Heavy-Duty Carbide Tipped Tool Bit

Read these instructions over carefully, and look at the Tool Bit

before it is used to become familiar with its shape.

1. Use a green Silicone Carbide Grinding Wheel about 54 Grit, H

Grade.

2. The angle of the Carbide (7°) and the Holder Body (10°) and the

Rake (15°) are indicated in the illustration. These angles must be

maintained when grinding.

3. The Radius at the tip of the Carbide is important. Hold it as close as

possible to 1/32 of an inch.

4. Grind the Shank first. Dress the Grinding Wheel to clean all metal

out of it, then grind the Carbide.

5. Remove stock a little at a time. Do not allow the Tool Bit to heat up.

6. Dress the Radius on the Carbide Tip with an AMMCO No. 905764

Carbide Tool Bit Sharpening Stone. Be careful to blend the Radius

into the angle of the Carbide.

7. Air cool the Tool Bit. Never cool the Carbide in a liquid.

928808 01 05/03

Instructions for Sharpening No. 904725

Heavy-Duty Carbide Tipped Tool Bit

Read these instructions over carefully, and look at the Tool Bit

before it is used to become familiar with its shape.

1. Use a green Silicone Carbide Grinding Wheel about 54 Grit, H

Grade.

2. The angle of the Carbide (7°) and the Holder Body (10°) and the

Rake (15°) are indicated in the illustration. These angles must be

maintained when grinding.

3. The Radius at the tip of the Carbide is important. Hold it as close as

possible to 1/32 of an inch.

4. Grind the Shank first. Dress the Grinding Wheel to clean all metal

out of it, then grind the Carbide.

5. Remove stock a little at a time. Do not allow the Tool Bit to heat up.

6. Dress the Radius on the Carbide Tip with an AMMCO No. 905764

Carbide Tool Bit Sharpening Stone. Be careful to blend the Radius

into the angle of the Carbide.

7. Air cool the Tool Bit. Never cool the Carbide in a liquid.

928808 01 05/03

Loading...

Loading...