AMMCO 2800, 2801 User Manual

2800/2801/2802

Environmental Lathe-Enclosure™

Safety Instructions

Setup Instructions

Operating Instructions

Maintenance Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 940086 07

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 09/12

Table of Contents

Important Safety instructions ................................. 1

Safety Instructions ................................................... 2

Owner’s Responsibility ............................................ 2

Operator Protective Equipment ............................... 2

Definitions of Hazard Levels .................................... 2

Safety Notices and Decals ...................................... 3

Warning ................................................................... 3

Before You Begin ....................................................... 4

Receiving ................................................................. 4

Set-up .................................................................... 4 -8

Unpacking the Enclosure ......................................... 4

Preparing the Bench for Installation ........................ 4

Assembling and Installing the Enclosure............ 5 - 6

Assembling Shield — 2801 and 2802 ...................... 7

Electrical Wiring — 2801 Only ................................. 7

Additional Installation — 2802 Only ........................ 8

Operation .................................................................. 9

Operation — 2800 Only .......................................... 9

Operation — 2801 Only ........................................... 9

Operation — 2802 Only........................................... 9

Maintenance ............................................................10

Electrical Source .....................................................10

Parts Identification .......................................... 11 - 13

2800, 2801 and 2802 ..............................................11

Shield Assembly — 2801 and 2802 ....................... 12

Wiring View — 2801 Only...................................... 12

Foot Switch Assembly — 2801 and 2802 .............. 13

Magnet Mounting — 2801 Only ............................ 13

Hood Switch Mounting — 2801 Only .................... 14

Hood Switch Mounting — 2802 Only .................... 14

Stop Switch Mounting — 2801 and 2802 .............. 15

Wiring Schematic ............................................ 16 - 17

Wiring Schematic — 2801 ..................................... 16

Wiring Schematic — 2802 ......................................17

ii • Important: Always read and follow operating instructions.

IMPORTANT SAFETY INSTRUCTIONS

Before operating the lathe, review the warning information on the lathe and the cautions, warnings and dangers in

this manual. Also review the following general safety instructions. Failure to follow safety instructions could result

in personal injury to operator or bystanders and damage to the lathe or personal property.

READ ALL INSTRUCTIONS

When using your garage equipment, basic safety

precautions should always be followed, including the

following:

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches from the

tool before turning it on. Make this a habit.

3. Keep work area clean. Cluttered areas and benches

invite accidents.

4. Avoid dangerous operating environments. Do not

use power tools in areas where explosive vapors are

present or in damp of wet locations. Do not expose

them to rain. Keep the work area clean and well lighted.

5. Keep children away. All bystanders should be kept

completely away from the work area.

6. Make the workshop kid-proof. Use padlocks and

master switches, and remove starter keys.

7. Don’t force a tool. It will do the job better and safer

at the rate for which it was designed.

8. Use the right tool. Don’t force a tool or an attachment to do a job for which it was not designed.

9. Dress properly. Keep loose clothing, gloves, neckties, shop rags or jewelry may get caught in moving

parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

10. Wear eye protection. Safety glasses, goggles,

or a face shield will help protect the operator from

injury. Use a face shield and dust mask during dusty

operations.

11. Secure the work properly to the unit for setup

and tool bit positioning. Do not attempt to hold a drum

or rotor steady on the arbor with your hands. Both

hands must be free to operate unit.

12. Don’t overreach. Keep proper footing and balance

at all times when lathe is in operation or when working

around the unit.

13. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow instructions for lubricating and changing accessories.

14. Remove power from the unit and disconnect

tools before servicing and when changing accessories

such as blades, bits, cutters, etc. Follow lock-out and

tag-out procedures as required.

15. Avoid unintentional starting. Make sure the

switch is in the OFF (O) position before plugging the

machine in or performing any maintenance or service

work.

16. Use recommended accessories. Consult the

manufacturer’s catalogs for recommended accessories.

Use of improper accessories may cause risk of injury to

operator or bystanders.

17. Never stand or lean on a lathe. Serious injury

could occur if the lathe is tipped or if the cutting tool is

unintentionally contacted.

18. Check damaged parts carefully. Before further

use of the lathe, a guard or other part that is damaged

should be carefully checked. Immediately replace all

damaged, missing, or non-functional parts. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect operation. Guards and other parts that

are damaged should be properly repaired or replaced

before lathe is used again.

19. Always feed the work into a blade or cutter and

against the direction of rotation. Cutters and tool bits

are designed to cut from the inside of a drum or rotor to

the outer edge. Do not attempt to cut from the outside

edge in to the center.

20. Never leave tools running unattended. Turn the

power off. Don’t leave the tool until it comes to a complete stop.

21. Never use compressed air to blow the tool clean.

Chips and dust may be driven between machined parts

and into bearings, causing undue wear. They may also

contact persons in the area causing personal injury.

22. Operate the lathe in the proper environment.

The lathe incorporates parts such as snap switches

and power receptacles which tend to produce arcs or

sparks. Therefore, when located in a garage,the unit

should be in a room or enclosure provided for the purpose, or should be at least 18” or more above the floor

to minimize the risk of igniting fuel vapors.

SAVE THESE INSTRUCTIONS

Important: Always read and follow operating instructions. • 1

Safety Instructions

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and Regulations; such as State, Federal OSHA Regulations

and Electrical Codes.

• Make certain guards and safety devices comply

with the requirements of applicable regulatory

authorities. Where specific applications require

guards or safety devices not provided by the manufacturer, make sure the appropriate safeguarding is

installed. Make sure written instruction is provided

for the inspection of these additional safeguards.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep them

readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the

following definitions and signal words:

DANGER

Watch for this symbol:

DANGER

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

WARNING

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

• Allow unit operation only with all parts in place and

operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override or bypass safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury

in typical shop activities. Eye protection is essential

during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are also

helpful in providing operator protection. Consideration

should also be given to the use of hearing protection if

tire service activity is performed in an enclosed area, or

if noise levels are high.

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

2 • Important: Always read and follow operating instructions.

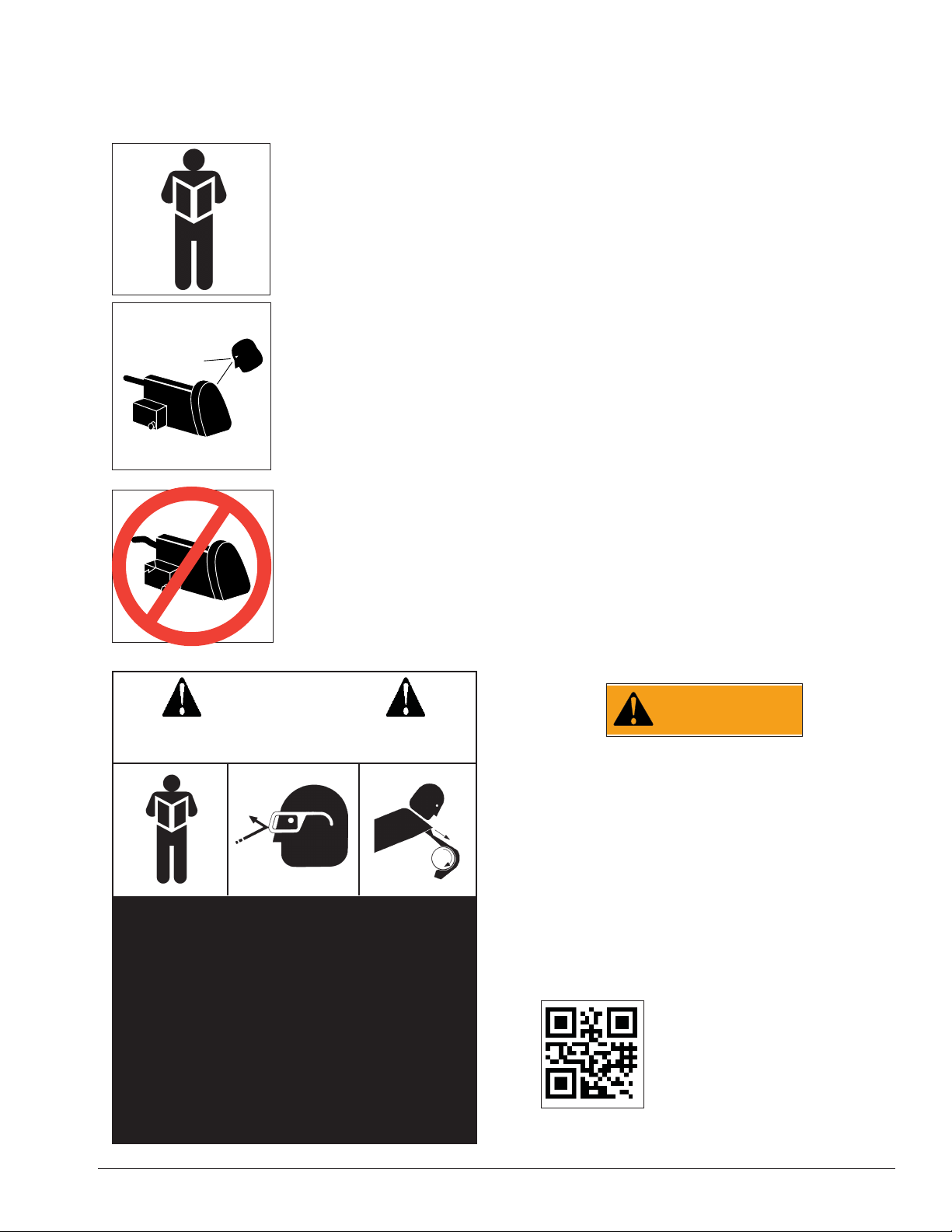

Safety Notices and Decals

For your safety, and the safety of others, read and

understand all of the safety notices and decals included

here and on the unit.

Read entire manual

before installing,

operating, or servicing

this equipment.

Warning

This equipment incorporates parts such as snap

switches and power receptacles which tend to produce

arcs or sparks. Therefore, when located in a service

facility, the unit should be in a room or enclosure provided for the purpose, or should be at least 18” or more

above floor to minimize the risk of igniting fuel vapors.

Cautions and Dangers

1. Eye and face protection requirements:

“Protective eye and face equipment is required to be

used where there is a reasonable probability of injury

that can be prevented by use of such equipment.”

OSHA 1910.133 (a).

Proper maintenance and

inspection is necessary

for safe operation.

Do not operate a

damaged lathe.

CAUTION

Prevent accidents and injury,read and

follow instructions.

Protective goggles, safety glasses, or a face shield

must be provided by the purchaser/user and worn by

the operator of the equipment. Make sure all eye and

face safety precautions are followed by the operator(s).

Keep bystanders out of the area.

2. Do not remove any safety equipment, belt guards,

or shortcut controls or operations.

3. Make sure drums and rotors are properly and

squarely mounted before starting lathe, and that all

parts are secure.

4. Do not wear loose clothing, jewelry, or gloves

when operating or working around a lathe.

5. Do not overload the lathe. Read and understand

the lathe specifications. Overloading is poor machine

tool practice, shortens the life of the lathe, and could

cause a failure resulting in personal injury.

WARNING

Failure to follow danger, warning, and caution

instructions may lead to serious personal

injury or death to operator or bystander or

damage to property. Do not operate this

machine until you read and understand all

the dangers, warnings and cautions in this

manual. For additional copies of either, or

further information, contact:

1. Read and follow instructions.

2. Always wear eye protection, avoid loose

clothing and jewelry.

3. Keep all guards, shields, and covers in place

and in working order.

4. Keep bystanders out of work area.

5. Unplug unit from power source before ser-

vicing or adjusting.

6. Maintain unit properly, keep work surfaces

and work area clean.

Hennessy Industries, Inc.

1601 JP Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

Important: Always read and follow operating instructions. • 3

Before You Begin

Receiving

The shipment should be thoroughly inspected as soon

as it is received. The signed bill of lading is acknowledgement by the carrier of receipt in good condition of

shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the carrier makes a notation on the freight bill of the shorted or

damaged goods. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss

or damage is discovered after receipt and request the

carrier to make an inspection. If the carrier will not do

so, prepare a signed statement to the effect that you

have notified the carrier (on a specific date) and that the

carrier has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER YOU HAVE GIVEN THE CARRIER A CLEAR

RECEIPT.

File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if available.

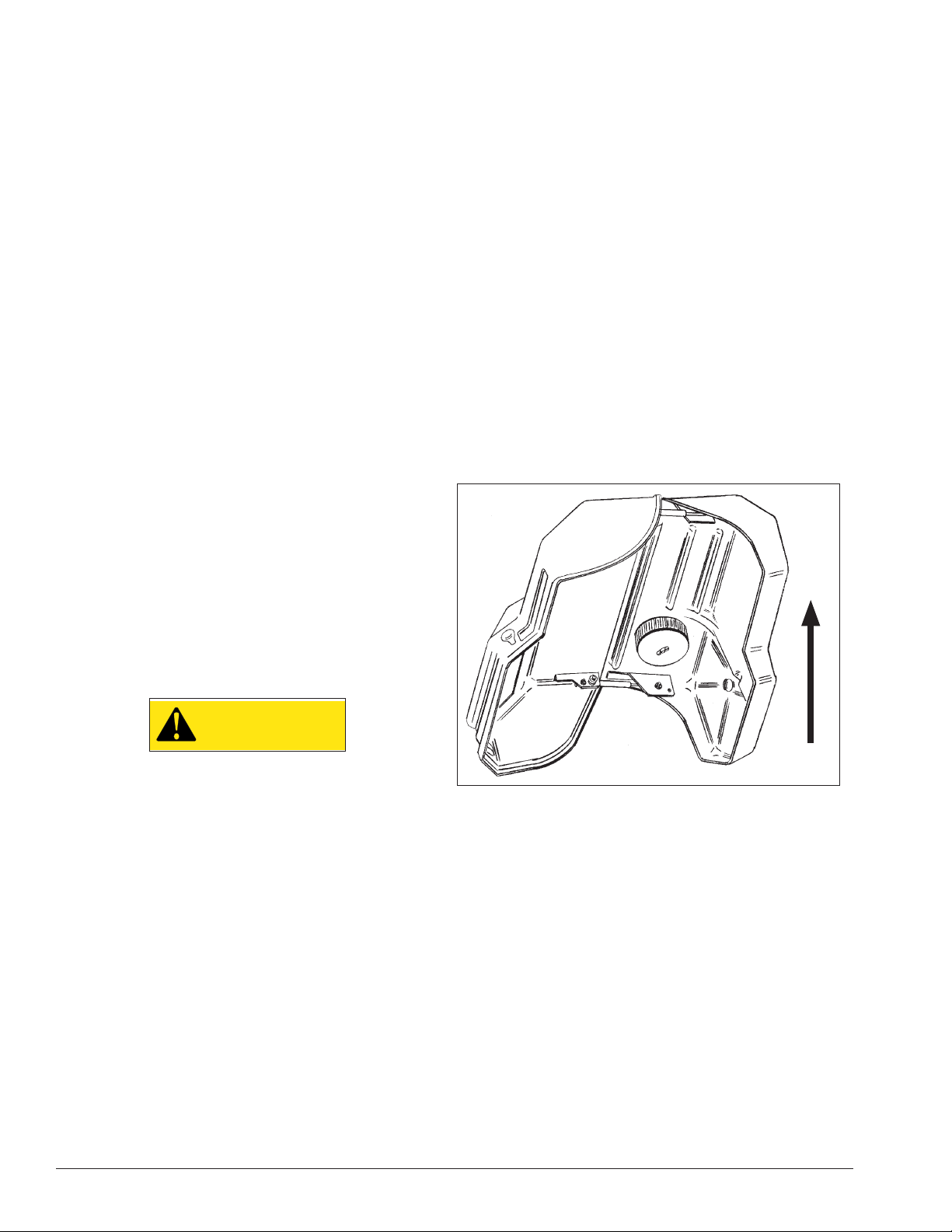

Unpacking the Enclosure

The collector is packed standing on end in the shipping carton. The required brackets and hardware are

included inside the carton. Unpack the unit in an area

large enough to allow the unit to be laid out, opened,

and spread out.

1. Remove the strapping from the shipping container

and remove the top cover.

2. Remove the TOOL BOARD and all other items

packed around the Enclosure. Be careful not to scratch

the viewing WINDOW.

Note: The CHIP BUCKET contains the CHIP TUBE, all

the necessary fasteners, and some of the bracketry.

3. Carefully lay the Enclosure on a pad on the floor.

4. Slide the lower carton off of the unit.

5. Stand the Enclosure on end in the middle of the

work area (fig. 1).

Note: Place a pad or blanket under the Enclosure to

avoid damaging the outside surfaces of the unit.

Although AMMCO’s responsibility ceases upon delivery of the shipment to the carrier, we will gladly assist

in tracing lost shipments. Our willingness to assist in

every possible manner does not make AMMCO responsible for collection of claims or replacement of lost or

damaged materials. Shipping damage claims will not be

handled under warranty.

Set-up

CAUTION

This installation procedure requires two

persons to complete. The Enclosure is large

and heavy and cannot be unpacked, moved,

or positioned safely by one person. The

removal and reinstallation of a lathe requires

two persons.

Use care to avoid dropping or damaging the Enclosure.

Have one person hold the collector while the other

removes packing materials or shipping cartons. During

installation, one person will need to hold the Enclosure

in place on the bench until it is securely fastened to the

bench.

UP

Figure 1 – Stand Unit On End And Open

6. Open the Enclosure and remove any parts or

materials packed inside.

Important: Use care not to scratch the WINDOW.

Preparing the Bench for Installation

7. If a lathe is attached to the bench, remove it now.

8. Move the bench to a position where all sides are

easily accessible, and there is sufficient room to install

the collector.

9. If the bench has a tool board or sign attached,

remove them now. Be sure to remove all mounting for

the board and/or sign as well.

10. Clear the bench of all tools and materials.

4 • Important: Always read and follow operating instructions.

Loading...

Loading...