Page 1

909481 & 926015 Chip Shields

Operating & Assemby Instructions with Parts Identification

941121 02a 02/11 © COPYRIGHT 2002 ALL RIGHTS RESERVED PRINTED IN U.S.A.

• Deflects flying chips downward

• Allows a clear view of the work on the lathe

• Quickly retracts out of the way for work change

• Easy thumb screw mounting on the twin cutter

Threaded mounting hole provided.

Parts Identification

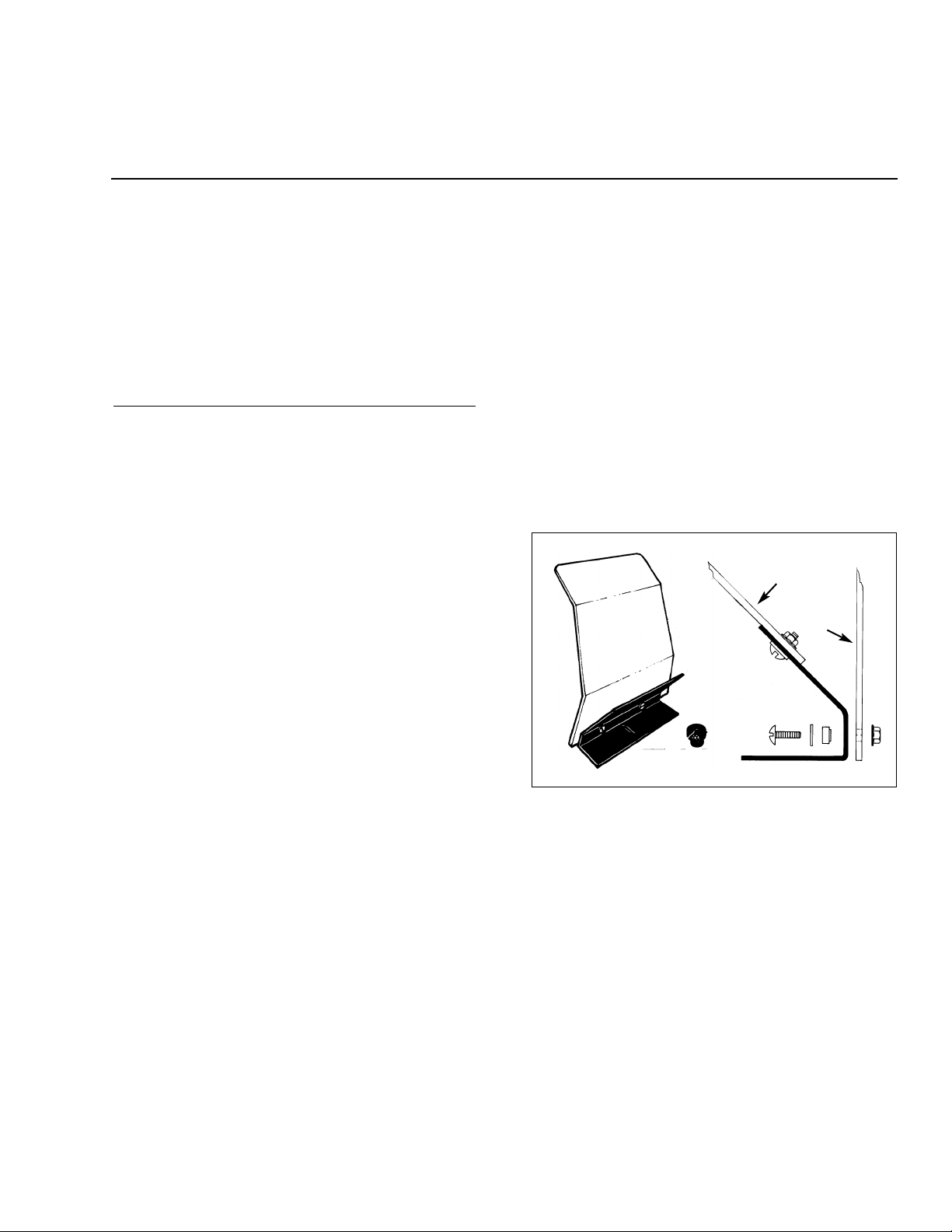

Refer to the assembly diagrams shown in Figure 1

for reference to the following numbered items.

PAR T

ITEM NUMBER QTY DESCRIPTION

1 941240 1 Shield

2 N/A 1 Bracket

3 911152 1 Thumb Screw

4 * 2 Screw

5 * 2 Washer

6 * 2 Spacer

7 * 2 Hex Nut

* 927822 1 Hardware Kit

Assembly

Check your safety shield against the diagrams in

Figure 1. The shield should slide up and down on

the bracket when a small amount of force is applied.

If the shield is too loose, it will not stay in the

retracted position (pulled up and towards the

operator). Tighten the shield to the bracket as

needed. Be careful not to overtighten and crack the

shield.

Installation and Use

1. Position the shield on top of the twin cutter,

aligning the threaded portion of the thumb screw

with the mounting hole on top of the cutter.

2. Turn the thumb screw to start the threads into

mounting hole. Hold the shield bracket in place

and tighten the thumb screw securely.

3. Gently push the shield down until it stops

against the bracket. This is the correct operating

postion.

4. To retract the shield for work changes on the

lathe, gently pull the shield up and towards you.

The shield and mounting hardware will slide up

to the top of the bracket and stop.

Operational Safety

Eye and Face Protection

Protective eye and face equipment is required to be

used where there is a reasonable probability of

injury that can be prevented by the use of such

equipment. – OSHA 1910.133 (a)

This shield shall be used by the operator when

turning or grinding disc brake rotors, flywheels, or

any other machining operation in which the cutting

or grinding is exposed and presents the hazard of

flying chips or particles.

In addition to this Chip Shield, protective goggles,

safety glasses, or a face shield must be provided by

the purchaser/user and worn by the operator of the

equipment. Care should be taken to see that all eye

safety precautions are observed by the operator.

1

2

3

4

5

6

7

Shield

Retracted

Operating

Position

Figure 1 - Assembled Safety Shield

Bracket shape may differ from illustration.

Loading...

Loading...