Page 1

Model 1475

Mobile Washer

Safety Instructions

Setup Instructions

Operating Instructions

Maintenance Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 95000178 00a

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®. and BADA® Automotive Service Equipment and Tools. Revision: 05/12

Page 2

Table of Contents

Safety Instructions

Safety Instructions ...................................2

Owner’s Responsibility ..........................................2

Safety Notices and Decals ....................................2

O.S.H.A. 29 CFR 1910, et al., Compliance .............3

IMPORTANT INFORMATION

READ BEFORE OPERATING .................................3

Setup Instructions ....................................4

Receiving ...............................................................4

Specifications ........................................................4

Assembly ...............................................................4

Operating Instructions ....................... 4 - 5

Disk Brakes ...........................................................4

Drum Brakes ....................................................4 - 5

Maintenance Instructions ........................5

Disposal Of Filters And Cleaning Solution .............5

Filter Sock ..............................................................5

Solution Cartridge Filter .........................................5

Cleaning Solution...................................................5

Cleaning Brush ......................................................5

Parts Identification ............................. 6 - 7

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

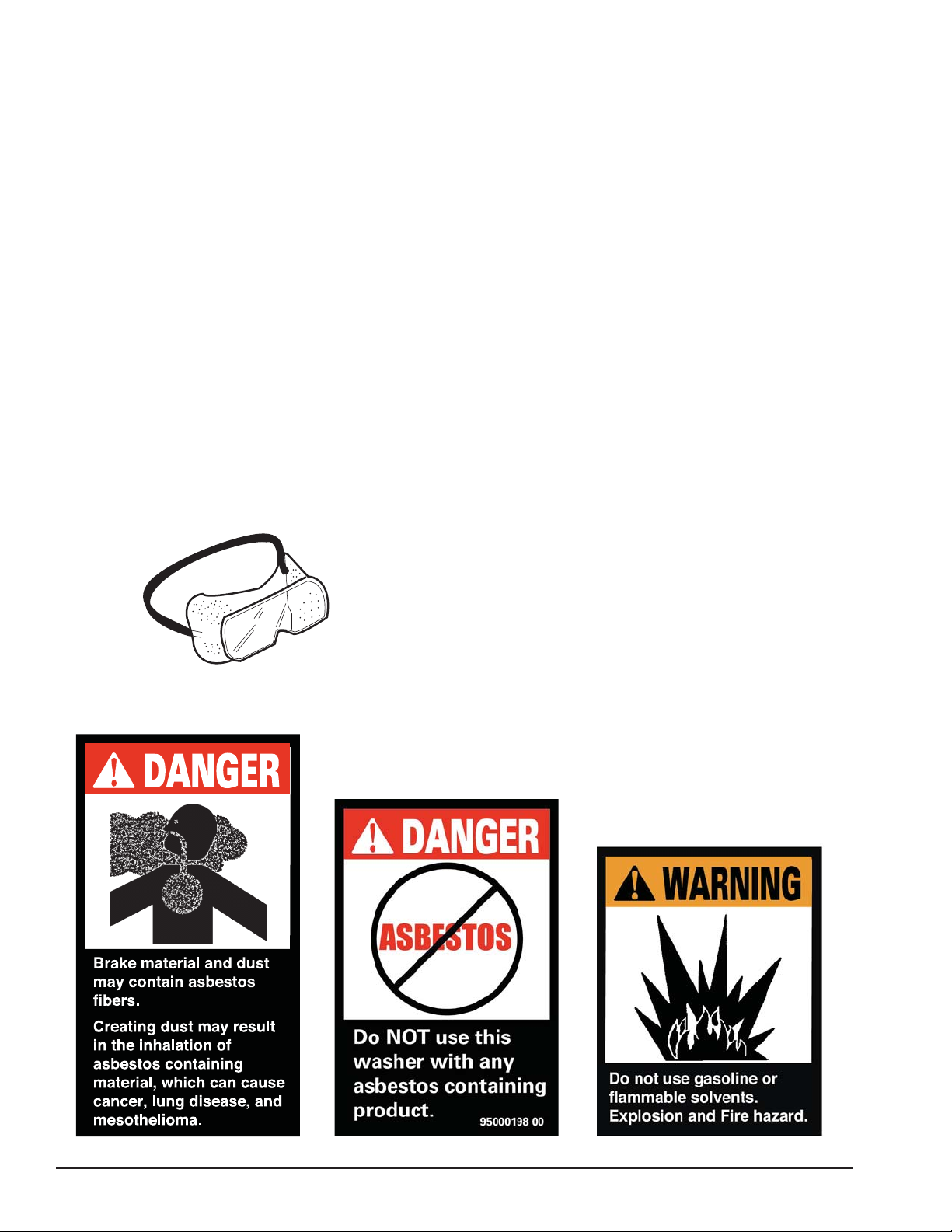

• This machine is not to be used with asbestos

containing products. Asbestos containing products can cause cancer, lung disease, and other

serious illnesses, including mesothelioma.

• Follow all installation instructions and make sure

installation conforms to all applicable Local, State,

and Federal OSHA Regulations and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep them

readily available for machine operators.

• Make certain all operators are properly trained, know

how to safely and correctly operate the unit, and are

properly supervised.

• Allow unit operation only with all parts in place and

operating safely.

• Carefully inspect the unit on a regular basis and perform all maintenance as required.

• Service and maintain the unit only with authorized or

approved replacement parts.

ALWAYS WEAR SAFETY

GOGGLES

ALWAYS

WEAR

SAFETY

• Keep all instructions permanently with the unit and

all decals/labels/notices on unit clean and visible.

• If ownership of the unit is transferred, provide

new owner all information, manuals, and provide

AMMCO new ownership information.

Safety Notices

For your safety, and the safety of others, read and

understand all of the safety notices included here and

on the unit.

2 • Mobile Washer

Page 3

O.S.H.A. 29 CFR 1910, et al., Compliance

To the extent an individual erroneously utilizes this

machine with an asbestos containing product, strict

compliance with the Occupational Safety & Health

(“OSHA”) Standard Regulation 29 CFR 1910, et al., is

mandatory.

Protective Clothing. For any individual that is exposed

to airborne concentrations of asbestos that exceed the

Occupational Safety & Health Administration (“OSHA”)

permissible exposure level, the individual must use

protective clothing such as coveralls or similar fullbody clothing, head coverings, gloves, respirators, and

foot covering. Wherever the possibility of eye irritation

exists, face shields, vented goggles, or other appropriate protective equipment must be provided and worn.

Always use the brake washer in compliance with

O.S.H.A. 29 CFR 1910, et al., regulations:

1. Place the catch basin or catch tray under the brake

assembly, positioned to avoid splashes and spills.

2. Use our Aqueous degreaser to wet or flood the

brake assembly gently, to prevent the asbestos

containing brake dust from becoming airborne.

3. Allow the Aqueous degreaser to flow between the

brake drum and brake support before the drum is

removed.

4. After removing the brake drum, thoroughly wet the

wheel hub and back of the brake assembly to suppress the dust.

IMPORTANT INFORMATION

READ BEFORE OPERATING

1. Do not modify this machine. This parts cleaner is

intended for use with approved cleaning solvents.

2. Do not add other chemicals such as kerosene, fuel

oil or gasoline.

3. Do not leave solvent-soaked rags in parts cleaner.

4. Always wet the shoes and inside the drum thoroughly before removing, if cleaning brakes.

5. Always maintain the proper solution level above the

bottom band on the drum.

6. Use the full flow nozzle to soak down brake drums

before removal.

7. The air pressure has been preset on your air operated parts cleaner. Never exceed 20 pounds of pressure.

8. Replace filters as needed.

9. To change fluid, pump fluid into separate container

using full flow nozzle. Remove snap ring and lower

onto drum. Remove filters and set aside or dispose

of in the proper manner. Remove cleaning basin

from drum. Clean drum and refill with new fluid.

Replace basin and filters. Replace snap ring and

fasten basin to drum.

5. Thoroughly wash the brake support plate, brake

shoes and brake components used to attach the

brake shoes before removing the old shoes.

6. Be sure to clean up your spills of Aqueous degreaser

immediately and dispose of according to all Local,

State, and Federal regulations.

7. Never dry brush. Always make sure that you wet

the brake assembly before any work begins.

Mobile Washer • 3

Page 4

Setup Instructions

Operating Instructions

Receiving

The shipment should be thoroughly inspected as

soon as it is received. The signed bill of lading is

acknowledgement, by the carrier, of receipt in good

condition of the shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the carrier

makes a notation of the shorted or damaged goods on

the freight bill. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request him to

make an inspection. If the carrier will not do so, prepare

an affidavit to the effect that you have so notified the

carrier (on a certain date) and that he failed to comply

with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER YOU HAVE GIVEN THE CARRIER A CLEAR

RECEIPT.

File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if possible.

Although AMMCO’s responsibility ceases upon

delivery of shipment to the carrier, we will gladly assist

in tracing lost shipments. Our willingness to assist

in every possible manner does not make AMMCO

responsible for collection of claims or replacement of

lost or damaged materials.

Specifications

Basin Dimensions .........................20" W x 24" L x 7" D

Overall Dimensions .................... 28" W x 28" L x 41" H

Shipping Dimensions ......... 30" W x 26A" L x 34.25" H

Shipping Weight ................................................ 72 lbs.

Operating Liquid Capacity .................... 8 to 12 Gallons

Assembly

1. Remove machine from shipping carton and inspect

for any damage. Report any damage to the delivering

carrier.

2. Install the four casters and hold-down brackets to

the base using the hardware supplied. Place the locking

casters directly across from each other. Do not tighten

fasteners yet.

Note: Do not add air tool oil or other oils to air inlet of

washer. Oils could damage the air pump and will void

the warranty.

1. Connect shop air to washer. The air regulator on

the washer is pre-set and cannot be adjusted. The maximum air pressure that can be supplied to the washer is

200 psi.

2. The pump will automatically function when the

valve lever is depressed on either the brush or the flex

spout.

Note: It will take a few seconds to prime the fluid

system the first time it is used. After the initial priming,

do not let the pump run dry. Damage to the pump could

occur which will void the warranty.

3. Store cover on basin when the washer is not in use

to help prevent evaporation of cleaning solution. This

also prevents any asbestos in the dried solutions from

becoming air-born.

4. The cover can be used as a catch basin when doing

brake work on the floor or on a service/alignment rack.

Thoroughly rinse cover into basin after using.

Disc Brakes

1. Simply saturate the entire brake assembly using

the flex spout prior to working on brakes.

Note: Never use the brush to clean brake friction

material that will not be replaced nor drums or rotors

that won’t be turned. Any oil or grease that might be

on the brush could be transferred to these brake components.

Drum Brakes

1. Before loosening or removing drum, use the flex

spout to wet the outside and inside of the drum and

brake assembly; first, between the drum and backing

plate. Then, if the vehicle had adjustment slots; remove

the plug and insert the flex spout to wet the inside.

2. If you are doing an inspection, wet the inside of

the drum everywhere except the area between the 10

o’clock and the 2 o’clock to make it easier to determine

if the wheel cylinder is leaking..

3. Place the drum into the base making sure it fits

completely to the bottom. Now tighten caster and

bracket fasteners.

4. Fill unit with the proper amount of water (1/2 full).

Pour one quart of AMMCO cleaner into the barrel.

5. Make sure the basin is locked to the drum using

the snap ring.

6. Connect the unit to your air supply.

7. Make sure brush and spigot assemblies remain

inside of basin whenever pump is on.

4 • Mobile Washer

Page 5

3. Pull the drum off approximately one-inch and wet

the brake assembly again.

4. Remove drum and rinse in basin of washer.

5. Check for wheel cylinder leakage and finish wash-

ing the assembly.

6. If after inspection the brakes do not need servicing,

allow them to air dry before reinstalling the drum.

Note: Never use the brush to clean brake friction

material that will not be replaced nor drums or rotors

that won’t be turned. Any oil or grease that might be

on the brush could be transferred to these brake components.

7. When doing a complete brake job, thoroughly clean

off shoes, drums, and backing plate.

Cleaning Solution

Every two months, or more often as required, the

cleaning solution should be replaced to allow the washer

to continue its cleaning efficiency. Tape or clamp valve

levers open so the cleaning solution can be pumped

down a sanitary sewer in accordance with your local

waste disposal regulations.

Note: Never dispose of cleaning solution into a storm

sewer.

When most of the solution has been pumped out and

the fluid is not a solid stream, add one or two gallons

of water to the washer pan. Disconnect air supply to

the washer when the clean rinse water is almost gone.

Note: Do not let pump run dry. Damage to pump will

occur that will void warranty.

Maintenance

Instructions

Note: Use only original AMMCO® products for your

safety and to ensure compliance to O.S.H.A regulations.

Disposal Of Filters And Cleaning Solution

The AMMCO 1475 Brake Washer is designed to comply with federal, state, and local regulations concerning

the disposal of liquid and solid wastes. However, these

regulations do vary from place-to-place and it is the

shop owner/manager’s responsibility to comply with all

applicable Local, State and Federal regulations.

Filter Sock

If the filter sock becomes full, there will be standing

water in the basin. Remove drain grate and strainer, pull

up on filter sock, and discard sock in accordance with

your local waste disposal regulations. Replace with new

sock.

Solution Cartridge Filter

When solution does not flow in a continuous stream,

replace the cartridge filter on the side of the barrel.

Unscrew filter canister, remove and discard dirty cartridge filter in accordance with your local waste disposal

regulations. Replace with a new cartridge and handtighten canister.

Un-tape valve levers, fill barrel half full with water, and

add one quart of AMMCO cleaner.

Note: Wear eye protection and rubber gloves when

handling the concentrated cleaner.

When replacing the cleaning solution, it is a good prac-

tice to replace all filters at the same time.

It is a good practice to establish a regular routine for

replacing all filters and cleaning solution, such as every

month or two months. The interval for your unit will

depend on local conditions, types of vehicles serviced,

and your volume of brake work. Also, the interval for

changing the solution may be different than that for the

filters.

Cleaning Brush

When brush gets dirty from brake fluid, axle grease,

etc.; clean brush with a degreaser or solvent. Clean

brush in solvent tank, NOT in brake washer. To prolong

brush life and to decrease maintenance, use a shop rag

for removal of heavy grease deposits.

Mobile Washer • 5

Page 6

Parts Identifi cation

ITEM PART NO. DESCRIPTION

1 95000173 Washer Sink

2 95000165 Washer Cover

3 95000168 Mount BW Flange

4 95000180 Brake Washer Base

5 95000172 16 Gal. Red Drum

6 95000181 Drain Plate

7 95000184 Hold Down Bracket

9 95000164 Flo-thru Brush

10 95000185 Nozzle Valve

11 95000186 Valve Fitting

12 95000167 1/4 Loc Line Nozzle

14 NA Brush & Spigot Bracket

15 NA Reg. Mount Bracket

16 NA Lid Bracket

17 95000179 4" Swivel Caster w/Brake

18 95000166 4" Swivel Caster

19 629696 Jet Air Flo Pump

20 95000169 1/4 PTF Mini 5-100 PSI Regulator

21 NA Metal Panel Nut

22 629700 Sock Filter

23 95000183 Sink Strainer

24 95000182 Suction Strainer

25 95000138 Filter Housing

26 629706 50 mic Filter

27 NA Filter Bracket

28 95000188 1/4 Hose x 1/4 MPT Filling EL

29 95000189 5/16 x 3/8 MP, Fitting EL

30 95000191 Fluid Suction Hose

31 95000192 Filter Out Hose

32 95000193 Pump In Air Hose

33 95000190 Air Inlet Hose

34 NS 1/4" Flat Washer

35 NS 1/4-20 Keps Nut

36 NS 1/4-20 x 1.75 HHC Screw

37 NS #10 x 1 Fender Washer

38 NS #10-24 x 1/2 PPHM Screw

39 NS #10-24 Nyloc Nut

* 629702 Oil Absorbent Boom

* 629710 Cleaning Solution, 1 Qt.

* Not Shown

NA = Not Available

NS = Non-stocking

6 • Mobile Washer

Page 7

Mobile Washer • 7

Page 8

95000178 00a 05/12 © Copyright 2012 Hennessy Industries and COATS All Rights Reserved

Loading...

Loading...