AMF Z Dough Pump IV User Manual

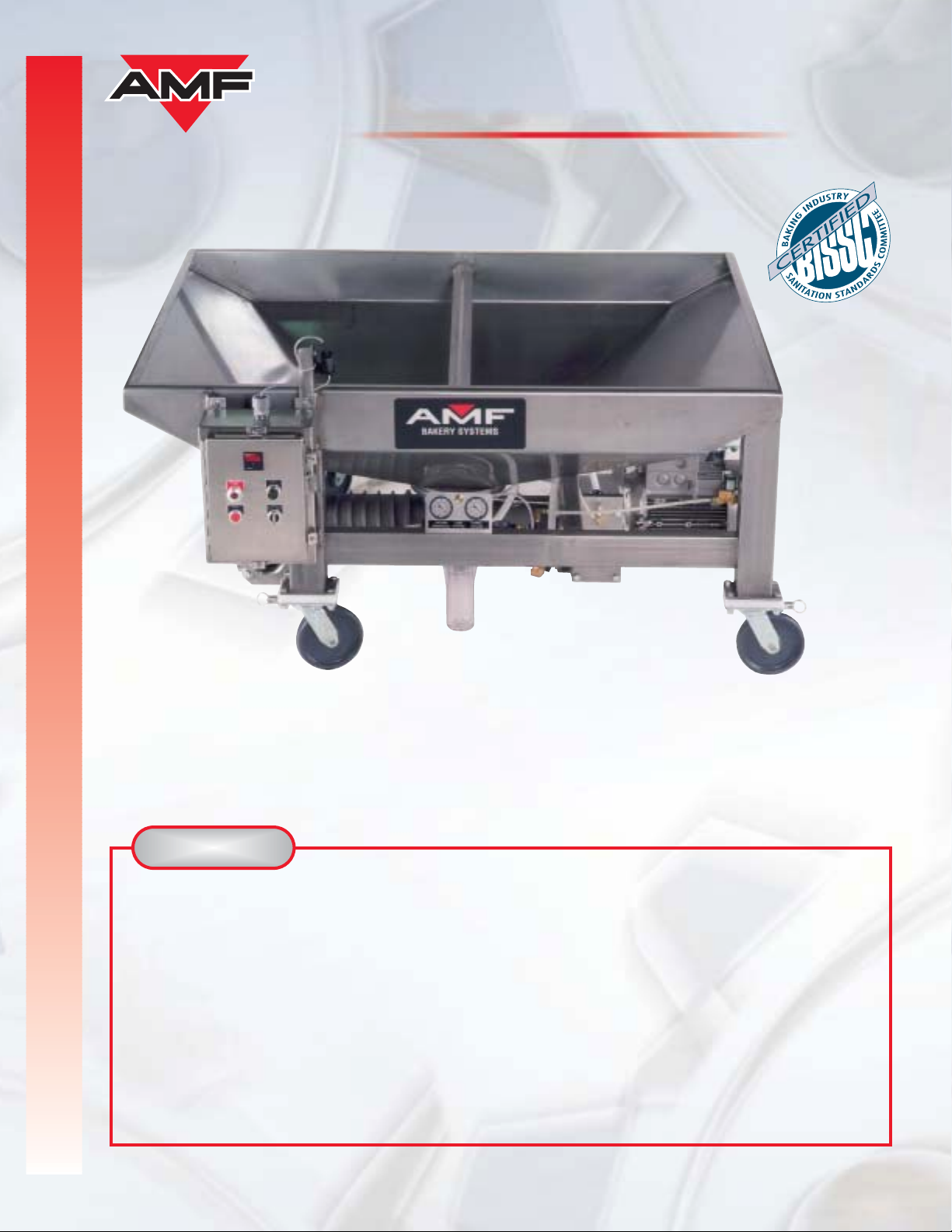

SERIES IV “Z”

DOUGH PUMP

Productivity, Speed, and Safety

• Offers better machinability and increased productivity

• Key refinements lead to greater safety and reduced

labor

Unparallelled Reliability

• The screw on the Series IV “Z” Dough Pump is

designed for easy removal and installation, and to

prevent foreign object damage

• Downtime due to parts replacement is greatly

reduced, helping the Series IV to provide a significant

return on investment within two years

• Simple, Efficient Pumping System for All Types of Dough

• Available for All Sizes and Types of Horizontal Mixers

Improved Scaling and Make-up

• Consistent degassing and throughput is achieved by

applying vacuum at the rear of the pump inlet

• Gentle, single-screw action provides greater scaling

accuracy and improves machinability for all yeastraised products

• Economical 4-inch diameter pumps are available for

smaller tortilla and bread/roll lines

Sanitary Design

• The BISSC-compliant guardless safety / minimal

framework design of the Series IV “Z”Dough Pump

speeds clean-up and reduces labor

Features &

Benefits

*Shown with optional temperature probe

Dough Mixers

Dough Developers

Vertical and Horizontal Conveyors

Metal Detector

SERIES IV “Z” DOUGH PUMP

• Designed and manufactured in accordance with BISSC standards

• Large diameter casters

• Exhaust air from the Venturi vacuum generator vents through a heat exchanger to

maintain low drive temperatures

• Stainless steel pipe manifold

• Revised vacuum system with larger drain bowl for longer service intervals

• Hopper reinforcement brace on large capacity units

• Stainless steel frame and hopper

• Allen Bradley Micrologix PLC control

Peripheral

Equipment

Mechanical

Features

Loading...

Loading...