AMF Switches and Diverters User Manual

SWITCHES AND DIVERTERS

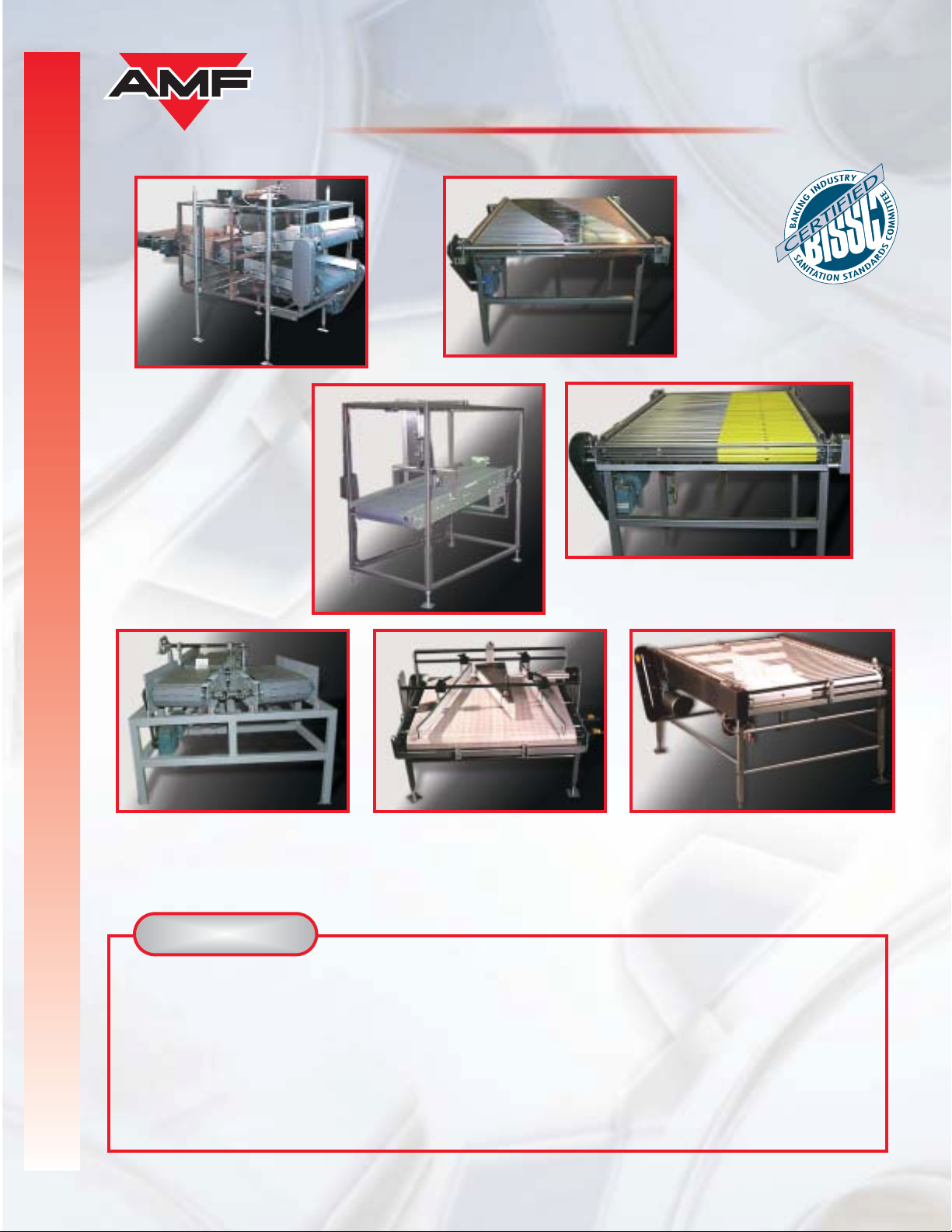

SWITCHES

AND DIVERTERS

• High Speed Vertical Switch

• Vertical Selector Switch

• Pivoting Conveyor Horizontal Diverter

• Swing Arm Type Horizontal Diverter

• Heavy-Duty Select-O-Flow Horizontal Diverter

• Medium-Duty Select-O-Flow Horizontal Diverter

• Light-Duty Select-O-Flow Horizontal Diverter

• AMF offers a variety of switches and diverters for products, pans, lids,

trays and baskets to meet any production requirements.

VERTICAL DIVERTER

Vertical Selector Switch

Our Vertical Selector Switch is used to switch Pans, Lids, Trays,

Baskets or Products from one Conveyor Line into two or three

superposed (same vertical plane) receiving lines. This type of

switch is generally used when the selection of the receiving

conveyor lines is made prior to the start-up of the production,

generally the switching is not possible while running.

The switch consist of one (1) Switching Frame into which is

mounted a conveyor with an extended tail shaft, acting as the pivot.

The switching is done by a pneumatic cylinder mounted under or

over the conveyor. The conveyor is not included and should be

selected for the specific application.

Configuration according to your layout (Elevation In & Out)

High Speed Vertical Switch

Our High Speed Vertical Switch is used to switch pans, lids, trays or baskets from one conveyor line into two or three

superposed (same vertical plane) receiving lines. This type of switch is used in pans, lids or basket return

conveyor lines, for high speed line selection (Up to 35 actions/min).

The switch consist of : one (1) Infeed Switching Conveyor and two (2) or three (3) Fixed Receiving Conveyors

mounted inside a steel frame. The Infeed Conveyor pivots around its infeed shaft axis and its discharge goes up

and/or down accordingly in order to discharge onto the receiving conveyors that are fixed mounted. The switching is

done by a pneumatic cylinder mounted under or over the Infeed Conveyor.

• Standard length 76”, 1 in – 2 out and 1 in – 3 out configurations according to your layout (Elevations In & Out)

• Stand-alone or system integrated unit.

• Intralox, Series 1100, Friction Top Belting. (No more tracking problems)

• Anodized aluminum conveyor side frames, steel-it painted frame and

conveyor cross members.

• Black oxided steel shafts and zinc plated steel hardware.

• Switch is equipped with air tank, 3/8” FRL and high Cv pneumatic valves for dependable

high speed switching and shut-off valve for safety.

• Lexan® panels and doors equipped with safety switches.

• Two drives : one (1) for infeed conveyor, and one (1) for Outfeed Conveyors.

• Optional : Magnets, additional drives (for different Outfeed Conveyor speeds).

Loading...

Loading...