AMF SW-75 User Manual

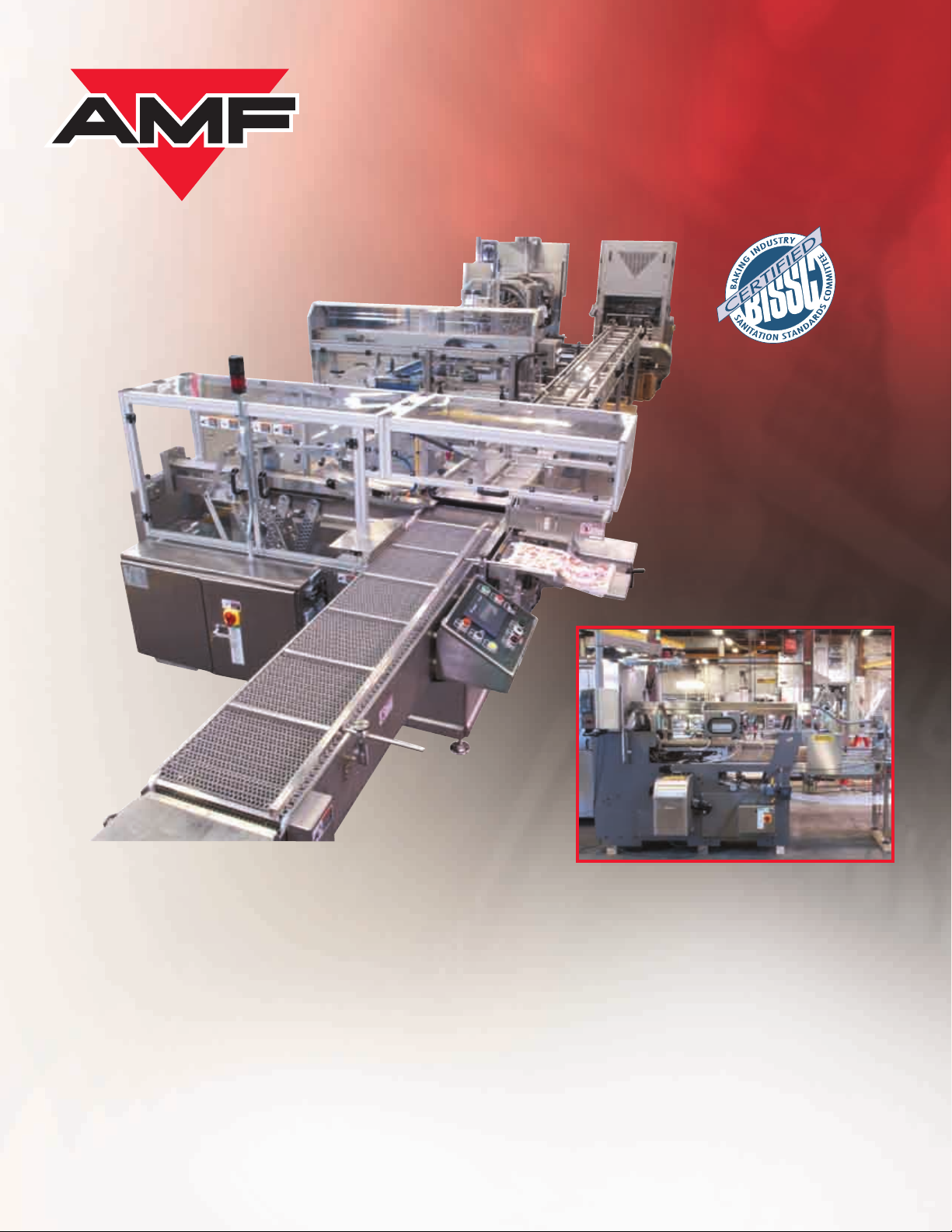

COMPLETE WRAPPING SYSTEM

COMPLETE WRAPPING SYSTEM

WITH BY-PASS OPTION AND

WITH BY-PASS OPTION AND

LOAF SPLITTER-TURNER

LOAF SPLITTER-TURNER

• The SW-75 is designed for today’s bread wrapping needs

• The SW-75 is designed to work in conjunction with the AMF Saber 75 Slicer and Mark 75

Bread Bagger to provide an efficient and comprehensive bread packaging system

• The SW-75 features a durable design focused on long term machine life including the only

solid frame design available

• The SW-75 incorporates the latest automated electronics including servo drives, AC drives,

electronic solenoids, PLC, and operator interface controls with recipe management and

diagnostic capabilities

Solid Frame

A solid frame was chosen over a stainless steel tubular

weldment for long term durability. We back this with

a 25-year warranty.

Simplicity

Only 4 of the original 9 cams

remain. Most of the

linkages and adjustment points related to these cams

have been

removed as well, resulting in greatly

improved access for maintenance or changeovers. The

Bottom Bed is now very similar to our Side Sealer

System, as there are no driven parts

Automatic Set-up and Monitoring

Servos, AC drives, Electric Solenoids and Pneumatics now

control most machine functions through a PLC.

These features dramatically simplify set-up and greatly

reduce operator input and adjustment. Critical set-up

systems are automatically measured and will not allow

the machine to run if they are out of specification.

Machine set-up can be accomplished 2 ways; by selection

of a product on the standard touch screen, or by

selection of a “Size to Pusher” option (Patent Pending).

Either way automatically measures the pusher plate, top

end and cross-feed and sets the correct positions.

Remote Access

The control system is Ethernet / Modem

ready for

remote troubleshooting and monitoring. Most machine

functions can be diagnosed remotely without the time

delay of dispatching a technician. Costs associated

with equipment service, and more

importantly down

time, can be greatly reduced with this feature.

Load Sharing and POD

Packaging on Demand (POD) is a feature to save machine

wear. If

product is not present, it will sequentially shut

down or idle subsystems of the machine and “wake up”

when product is again present. In multiple unit

installations, product load to each machine can be

sensed. If

one machine is idled, the remaining units can

increase speed to help absorb the load.

Film Feed

The standard paper feed system requires only the

operator to load the film

and set the width. The rest of

the system is automatic and

requires no operator

adjustments.

The film spool sits on a pair of rollers that

are driven with an AC drive and controlled by a dancer

sensor. This is less complicated

and less expensive than a

servo controlled unit that pulls the film through a series

of rollers.

An automatic film splicer is available as an option.

Production is never interrupted or slowed down during

film changes and the splice is hardly noticeable.

Sealing

The patented Side Sealer System is undisputedly

recognized as the best in the industry. So much so, that

our customers have installed them on competitive

machines. With no driven parts, flexibility of

arrangement

and very accurate temperature control, it

continues to lead the industry

.

FEATURES & BENEFITS

PRODUCT SPECIFICATIONS

• Rated for 60 PPM continuous operation (65 in temporary situation)

• Loaf lengths: 5.75” to 14” standard (smaller and larger loaf set-up are available as an option)

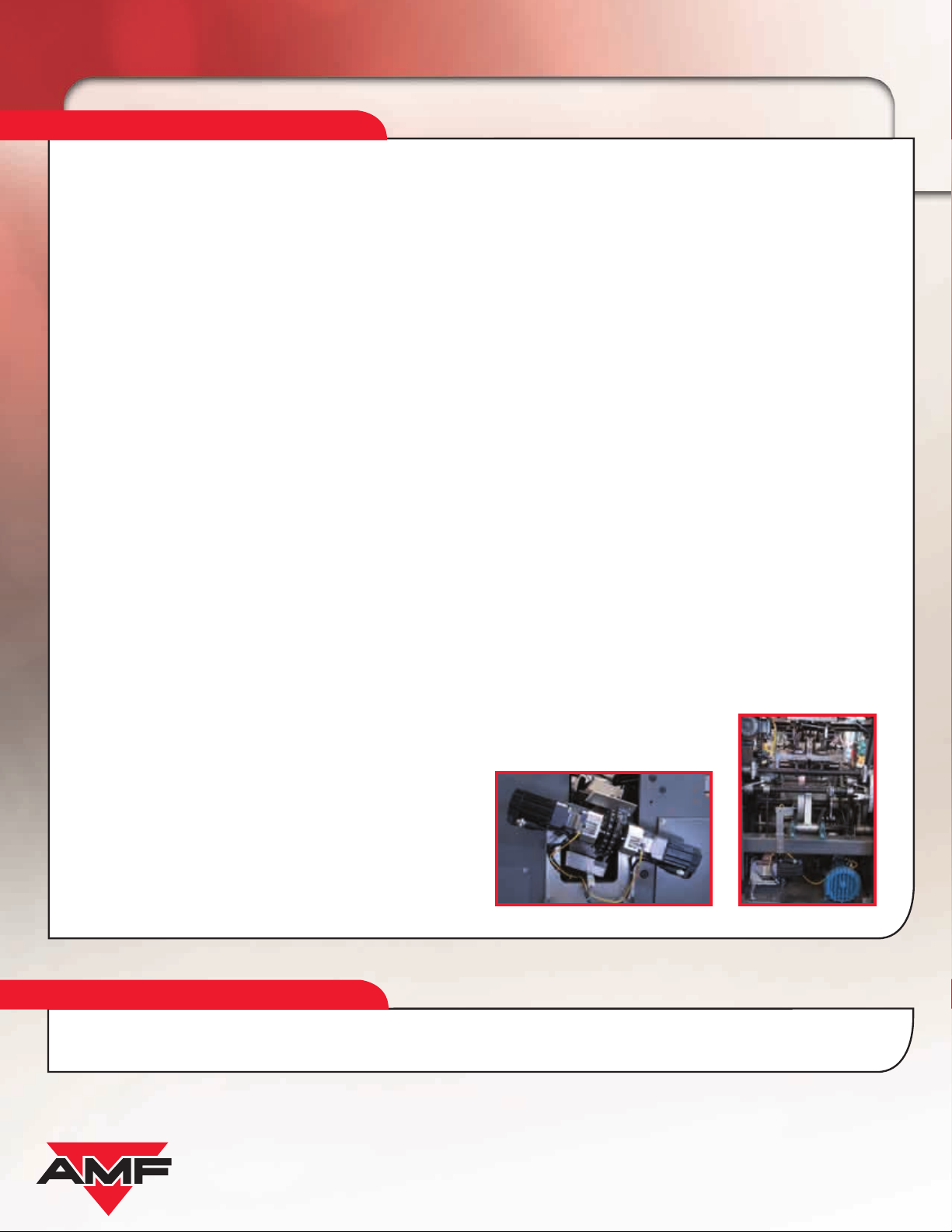

Servo Motor Drive Cam Drive

Loading...

Loading...