AMF HS 40 User Manual

HS 40 BULK

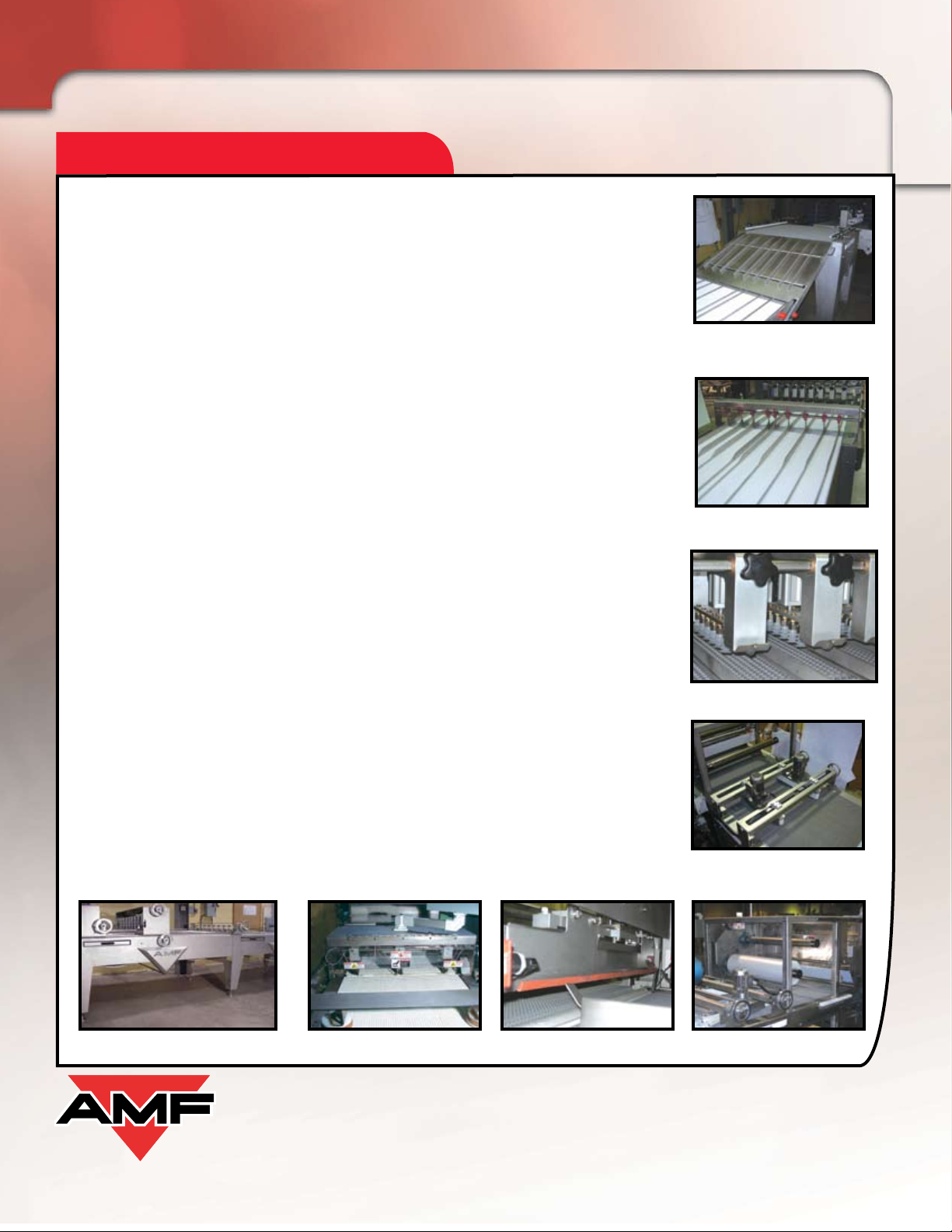

BUN PACKER

FEATURES & BENEFITS

• The HS 40 has been designed for efficient, high speed bulk bun

packaging of up to 40 packages per minute.

• The HS 40 incorporates many new design features that improve

package tightness and seal integrity that result in unmatched product

freshness and extended shelf life.

HS 40 BULK BUN PACKER

MECHANICAL FEATURES

Freshness Evacuation and Tight Package

• Aligner side wheel system assures a tightly configured package

• The HS 40 incorporates a new vacuum evacuation system and above belt seal system that

combine for the tightest, air tight package with the strongest seal integrity

• High speed “On the Fly” regrouping section provides a perfectly regrouped package

configuration on the fly prior to film feed. This assists in providing a tight package.

High Speed Design

• Variable speed infeed spread and accumulation conveyors for even product distribution and

lane filling

• Gentle collapsing cup grouping gate provides damage free hold-down. Individual control of

each lane reduces pressure and indexing errors.

• Efficient belt drive side guides provide “on-the-fly” regrouping

• Smooth product transfer points for high speed product control

• Precise temperature control system on the side seals and cross seal

• Above belt side sealing system allows for higher speeds through the sealing section

New Improved Seal Technology

• New above the belt side seal technology allows for significantly increased package size

flexibility

• New dual seal side seal insures outstanding seal quality

• New Bead Weld Cross Seal and Cut System provides the strongest seal available while

eliminating high maintenance seal bars. The cutting system requires no knife.

Accumulation Conveyor

and Slide

Adjustable Lane Guide System

Low Maintenance, Sanitary Design

• The HS 40 has an angular, laser cut steel-it-steel frame. The angular design prevents

sanitation issues caused by contaminant frame shelving. The laser cut steel frame is durable,

low maintenance, and is provided with a smooth, easy to clean surface.

• Close-coupled, independent VFD drives eliminate high maintenance chain and sprocket

sequence drives that traditionally run the length of the machine. The underside of the HS 40

is totally open with simplifies sanitation and maintenance.

Product Flexibility

• The HS 40 is designed for easy product changeover including “quick change” lane

adjustment.

• Easily adjustable multi-way conveyor lane guides in the grouper/indexing area for reduced

changeover time.

• Low film alarm and change-out indicator. Tool-less film change with expanding film core

clamps.

• A variety of slicing options including single and dual through slice, hinge/web slice, and top

slice. Each slicer is designed for easy changeover.

• A variety of package configurations are available including single center seal and dual center.

Clear Under Frame Design

Above Belt Side Seal

and Center Seal

One Piece Knife and Seal System

Collapsing Cup Grouping Gate

Driven Side Belt Regrouper

Pneumatic Film Roll Arms

Loading...

Loading...