AMF High Speed Bun Divider User Manual

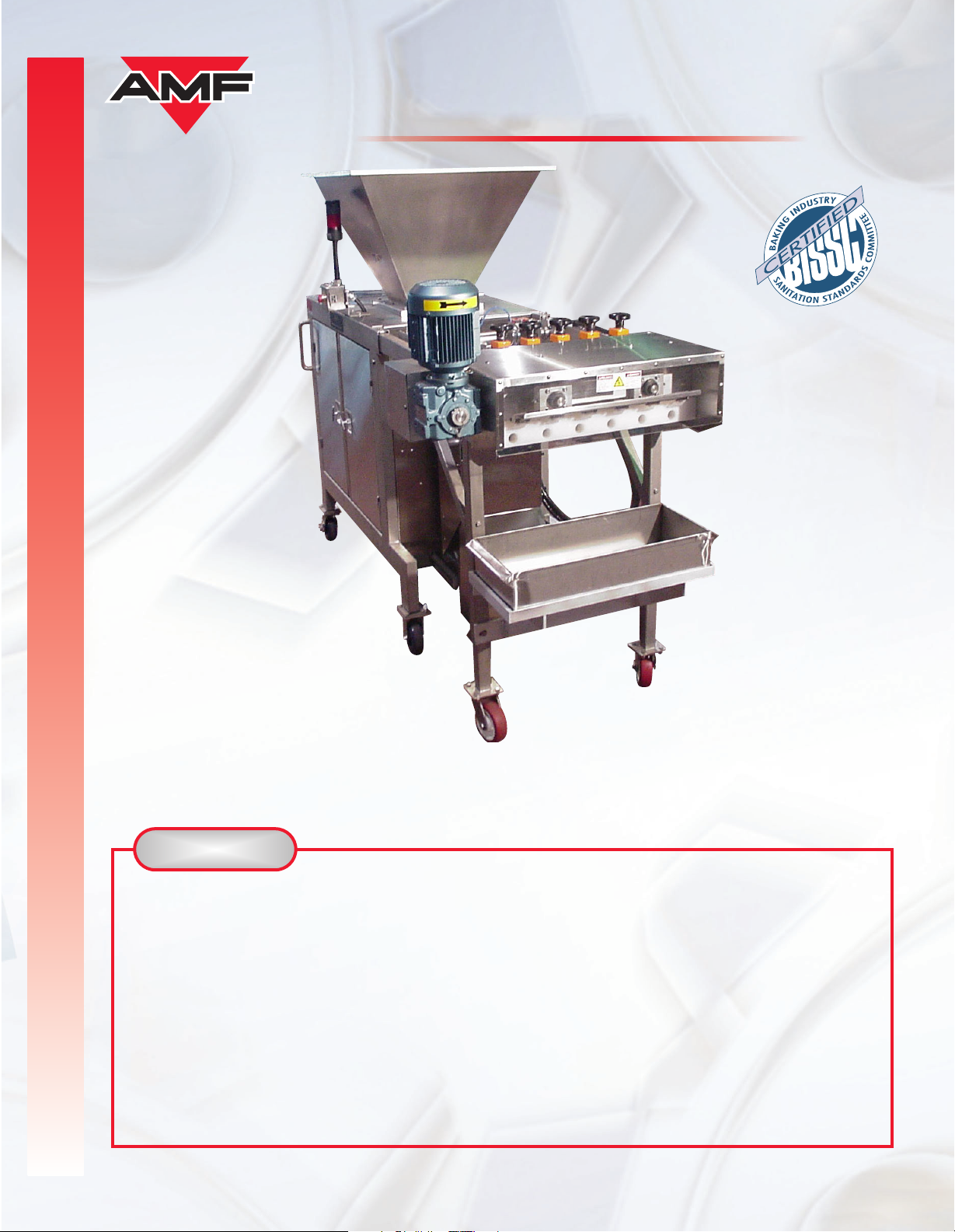

HIGH SPEED BUN

DIVIDER

Most Accurate Scaling available through advanced

extrusion technology

• Increased product yield

• Reduced waste

• Improved product uniformity

• Consistent scaling accuracy over the life of the

divider - 15 years or more*

Reduced Operating Cost

• No divider oil required with the HBD, which reduces

operating and sanitation cost

• Efficient design with few moving parts for reduced

maintenance cost

• Rotary drive design provides a service life 3-4 times

that of conventional dividers

•

Extrusion Divider Designed for High Speed Bun Production

•

Most Accurate Scaling Available

Increased Productivity and Flexibility

• Increased operating speeds up to 135 cuts per

minute can increase your hourly production yield

• Long, continuous runs for days at a time without

downtime for cleaning or maintenance adjustments

can increase profits per unit

Improved Automation

• Operator interface-based recipe management system

is provided for automated divider setup

• Electronic synchronization system is tied into the

Pan-O-Mat, allowing the HBD recipe management

system to automate the setup of the Pan-O-Mat as

well

Features &

Benefits

Mechanical

Features

HIGH SPEED BUN DIVIDER

• Designed and manufactured in accordance with

BISSC standards

• Heavy duty stainless steel frame for durability and

corrosion resistance

• Polished stainless steel guards and 500 lb. hopper for

easy sanitation

• Precision stainless steel tunnel housing for durability

and minimum dough flow resistance

• Dual auger design for gentle dough handling at high

throughputs

• All drives are Class F insulated Eurodrive Gearmotors

including augers, metering pump, cut-off knife and

proofer drive for dependability, long life, and 94%

mechanical efficiency

• 3” metering pump for precise flow control

• Patented UHMW free-flow manifold for even dough

distribution

• Patented diaphragm valves with position indicators

for minimum resistance and maximum flow control

• UHMW Rotary cut-off knife

Electrical

Features

• Easy access to all operational areas for easy

sanitation and maintenance

• Venturi-style vacuum system with vacuum transducer

• Freestanding with casters for easy mobility for

sanitation and maintenance

Operator panel is NEMA 4 rated and mounted

on a swivel arm for easy access

Operator Panel includes the following:

• Allen Bradley 600C keypad operator interface to con-

trol:

Auger speed

Metering pump speed

Vacuum Pressure

Alarm messages

Product codes

• Allen Bradley push-buttons for:

Two-button start

Stop / Emergency stop

Master relay control

• NEMA 4 stainless steel machine mounted electrical

enclosure including:

Main disconnect switch

Full voltage magnetic NEMA rated starters

Allen Bradley 5/03 PLC

Toshiba Inverters

Schmersal key safety switches

Closed loop pressure control system with

pressure transducer

PLC controlled cleaning cycle system for

reduced sanitation cost

Electronic proofer synchronization kit with

proofer drive

Loading...

Loading...