AMF Bread And Bun Products Orientor Loader User Manual

PRODUCT

ORIENTOR LOADER

Features &

Benefits

Ergonomic, User-Friendly Design

• Low profile with emphasis on operator convenience

• Operator control panel can be reached from either

side of the infeed conveyor

• Menu-driven touch screen controls for ease of use

• Product order code or Graphic representations can be

used to specify patterns

Versatility and Accuracy

• Orientor Loader can serve both bread and bun lines

• Low back pressure infeed allows accurate product

positioning in all areas for consistent quality during

handling

Quiet, Easy Operation

• Fewer moving parts for quieter operation, with no

hydraulics or vacuum required

• Any number of patterns available for operator

selection

• Up to 8 Patterns per minute

• Smooth, Quiet Servo Drives

• The Next Generation of Orientor Loader Handles Higher

Rates of Product Quietly and Gently

• Discharge slide

• Discharge conveyor for tiered conveyor throughput

• Reload mechanism for double layering of

bun products

• Multiple basket size handling capability

• Air-operated rear product gate for manual loading

• Additional machine manuals

• S.A.E. Tool kit

• Food-grade contact surfaces option available for

unbagged product

• Variety of operator interface terminals and PLCs

available

• Stainless steel construction of frame and conveyor

available

PRODUCT ORIENTOR LOADER

Specifications

Options

Electrical requirements:

208/230/460 volts, 3 phase, 60 Hz

380/415, 3 phase, 50/60 Hz (International)

Total Connected Load : 8 KVA

Air Requirements: Clean dry air at 80 PSI (5.6 kg/cm

2

)

2 SCFM (944 cm

3

/sec)

Approximate dimensions:

154’’ X 76’’ X 58’’ (3910 mm X 1930 mm X 1470 mm)

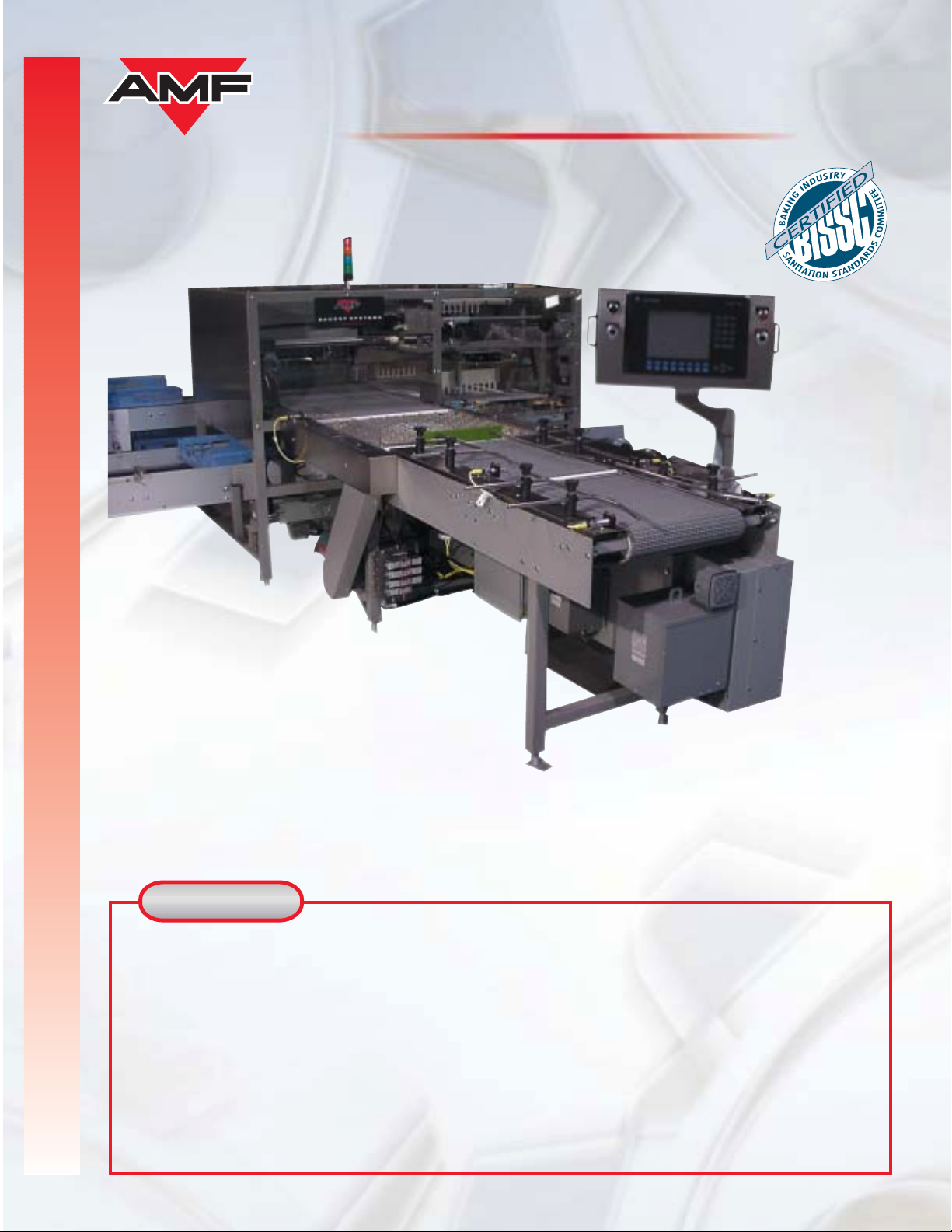

Discharge Conveyor with Kicker Conveyor

Contact your AMF representative for more informtion about our complete line of:

• Stackers Un-Stackers

• Pre-Stackers Separators

• Cross Nested Un-stackers Orientors and Turners

• Basket Conveyors Pan Conveyors

• Slicers Baggers

• Trash Dumps Washers

Smooth Servo Drives for Turntable, Product Pusher, and Loader

Belt enchance Operation and extra Life of Components

Loading...

Loading...