Page 1

Half Rack

Full Rack

PROGRAMMABLE POWER

XG Family Programmable DC

Power Supply

Operating Manual

(firmware v 2.0 and higher)

670 Watts – 1700 Watts

6 V to 600 V Models:

6-110 6-220 6-220

8-100 8-187.5 8-200

12-70 12.5-120 12-140

20-42 20-76 20-84

33-25 30-50 33-50

40-21 40-38 40-42

60-14 60-25 60-28

80-10.5 80-19 80-21

100-8.5 100-15 100-17

150-5.6 150-10 150-11.2

300-2.8 300-5 300-5.6

600-1.4 600-2.6 600-2.8

M370430-01 Rev E www.programmablepower.com

Page 2

Page 3

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the

design and manufacture of precision, programmable power supplies for R&D, test and

measurement, process control, power bus simulation and power conditioning applications

across diverse industrial segments. From bench top supplies to rack-mounted industrial power

subsystems, AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen,

California Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and

electromechanical devices with annualized sales of $2.5 billion. The Company has over 11,000

colleagues working at more than 80 manufacturing facilities and more than 80 sales and

service centers in the United States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. Sorensen is a trademark owned by

AMETEK, Inc. Other trademarks, registered trademarks, and product names are the property

of their respective owners and are used herein for identification purposes only.

Notice of Copyright

XG Family Programmable DC Power Supply Operating Manual (firmware v 2.0 and higher) ©

2008-2014 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER,

INC. (“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR

OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS

OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.

THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER'S RISK,

AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN

ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY

OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED

AMETEK CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION,

WHICH IS POSTED AT WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

June 2014 Revision E

Part Number

M370430-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

M370430-01 Rev E i

Page 4

Product Family: XG Family Programmable DC Power Supply

Warranty Period: Five Years

WARRANTY

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect

in material or workmanship within the applicable warranty period stated above, then AMETEK

may, at its option: repair or replace the Product; or issue a credit note for the defective Product;

or provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if

the Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

•

is damaged by misuse, accident, negligence or failure to maintain the same as

•

•

•

•

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order

Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

•

•

2. When requesting an RMA, have the following information ready:

•

•

•

TERMS

specified or required by AMETEK;

is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

is installed or operated contrary to the instructions of AMETEK;

is opened, modified or disassembled in any way without AMETEK's consent; or

is used in combination with items, articles or materials not authorized by AMETEK.

In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

Outside the United States, contact the nearest Authorized Service Center (ASC). A

full listing can be found either through your local distributor or our website,

www.programmablepower.com, by clicking Support and going to the Service Centers

tab.

Model number.

Serial number

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper's

expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject

to an evaluation fee and applicable freight charges.

ii M370430-01 Rev E

Page 5

Purpose

The Operating Manual provides inst

allation and operating information

Scope

The Manual provides safety information, features and specifications,

The Manual also provides information on the GPIB interface option and

Audience

The Manual is intended for the user who is familiar wi

th electronic

The following conventions are used in this guide.

Important:

Important notes provide information that is important for you

About This Manual

for the XG Family Programmable DC Power Supply.

installation procedures, functional test procedures, and operating

procedures for both local (front panel) operation and remote operation.

LXI compliant Ethernet (ENET) interface for models with the MEB

options.

power supplies, Constant Voltage, Constant Current, and/or Constant

Power operating modes, and the control of output power. The user

should be familiar with practicing safe techniques while making

supply or pin connections.

(firmware v2.0 and higher)

Conventions Used

WARNING

Warnings identify conditions or practices that could result in personal

injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the

unit or other equipment.

to know. They are not as serious as Warnings or Cautions.

M370430-01 Rev E iii

Page 6

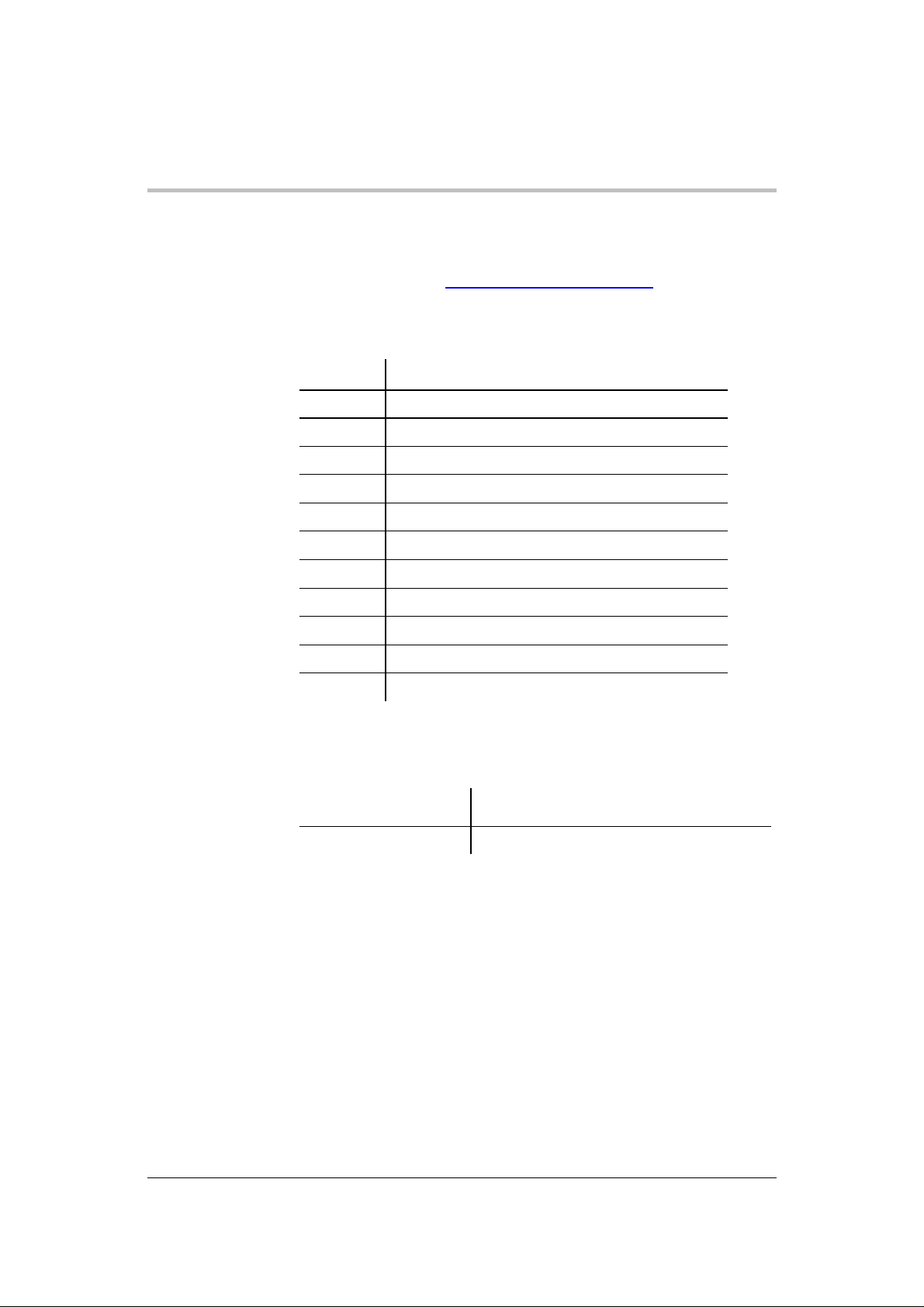

Acronym

Definition

About This Manual

Related Information

More information about AMETEK Programmable as well as its products and

services, is available at www.programmablepower.com.

Acronyms

APG

AUX

ENET

FGA

ISOL

OCP Over Current Protection

OTP

OVP Over Voltage Protection

PSU

TVS

UVP

Font Conventions

This Manual uses the following typographical conventions:

Command body text

Analog Programming

Auxiliary

Ethernet

Finished Goods Assembly

Isolated Analog Programming

Over Temperature Protection

Power Supply Unit

Transient Voltage Suppressor

Under Voltage Protection

7 Segment

For display and readback information on the

output voltage and current displays.

Represents SCPI commands.

iv M370430-01 Rev E

Page 7

Filter capacitors store potentially dangerous energy for some time after power is

Operate the power supply in an environment free of flammable gases or fumes.

power supply as specified in this Manual and do not substitute parts or make any

interrupt the DC voltage of the battery, will provide adequate current protection.

Where several power supplies are in parallel, it is best to fuse each power supply

Important Safety Instructions

WARNING: High energy and high voltage

Exercise caution when using a power supply. High energy levels can be stored

at the output voltage terminals on a power supply in normal operation. In

addition, potentially lethal voltages exist in the power circuit and on the output

and sense connectors of a power supply with a rated output greater than 40 V.

removed.

WARNING: Fire hazard

To ensure that the power supply's safety features are not compromised, use the

unauthorized modifications. If service is necessary, please return the power

supply to the Authorized Service Center. See the Warranty on page ii.

WARNING: Limitations on use

The XG Family Programmable DC Power Supply is not intended for use in

connection with life support systems or other medical equipment or devices.

CAUTION: For use as a battery charger

When you are using a power supply for battery charging applications, it is

essential to provide an appropriately sized fuse or circuit breaker in series

between the power supply output and the battery.

Installation of a protector (fuse or DC circuit breaker), rated for about 115% of

the maximum current rating of the power supply and designed specifically to

rather than use one fuse at the battery.

Power Supply Safety Markings

Earth (Ground) Terminal Off (Supply)

Protective Conductor Terminal

Alternating Current

M370430-01 Rev E v

On (Supply)

Caution (Check the Manualfor

additional information.)

Page 8

1. Before installing and using the XG Family Programmable DC

cautionary markings on the

This instrument is for indoor use only. Do not expose the instrument

To avoid a risk of fire and electric shock, make sure that the existing

instrument yourself may result in

a risk of electrical shock or fire. Internal capacitors remain charged

Safety

Standard Warnings

WARNING: Keep these instructions

This chapter contains important safety and operating instructions. Read and

keep this Operating Manual for future reference.

Power Supply, read all instructions and

instrument and all appropriate sections of this Manual.

2.

to moisture. To reduce risk of fire hazard, do not cover or obstruct

the ventilation openings. Be sure to install the instrument in a

compartment which allows air to reach the ventilation inlets on the

front and rear of the unit to prevent overheating. For more

information, see “

3.

wiring is in good condition and the wire is not undersized. Do not

operate the instrument with damaged or substandard wiring.

Ventilation

” on page 2-4.

4. Do not operate the instrument if it has received a sharp blow, been

dropped, or otherwise damaged in any way. If the instrument is

damaged, see the Warranty on page ii.

5. Do not disassemble the instrument. It contains no user-serviceable

parts. See the Warranty on page ii for instructions on obtaining

service. Attempting to service the

after all power is disconnected.

6. To reduce the risk of electrical shock, disconnect AC power from

the instrument before attempting any maintenance or cleaning or

working on any circuits connected to the instrument. Turning off

controls will not reduce this risk.

vi M370430-01 Rev E

Page 9

Contents

1 INTRODUCTION ............................................................................................. 1-1

F

EATURES AND OPTIONS

XG M

ODELS (FIRMWARE VERSION

F

RONT PANEL

Front Panel Display and Controls ....................................................................... 1-6

R

EAR PANEL CONNECTORS ON

R

EAR PANEL CONNECTORS ON

................................................................................................... 1-5

................................................................................... 1-2

2.0

850 W

1500

AND HIGHER

ATT MODELS

AND

1700 W

) ............................................ 1-3

............................................ 1-7

ATT MODELS

............................ 1-9

2 INSTALLATION .............................................................................................. 2-1

B

ASIC SETUP PROCEDURE

S

TEP 1: INSPECTING AND CLEANING

Initial Inspection ................................................................................................. 2-3

Periodic Cleaning ............................................................................................... 2-3

S

TEP 2: LOCATION AND MOUNTING

Rack Mounting ................................................................................................... 2-4

Purchasing Rack Mount Kits ............................................................................... 2-4

Ventilation .......................................................................................................... 2-4

S

TEP 3: CONNECTING AC INPUT POWER

XG 850 Watt AC Input Connector ....................................................................... 2-5

XG 1500 and 1700 Watt AC Input Connector ...................................................... 2-6

XG 1500 and 1700 Watt AC Input Wire .............................................................. 2-6

XG 1500 and 1700 Watt AC Input Wire Connection ............................................ 2-7

S

TEP 4: SELECTING LOAD WIRES

Load Wiring ........................................................................................................ 2-8

Insulation Rating ................................................................................................ 2-8

Current Carrying Capacity .................................................................................. 2-8

Maximum Load Wiring Length For Operation With Sense Lines .......................... 2-9

Noise and Impedance Effects ............................................................................. 2-9

S

TEP 5: PERFORMING FUNCTIONAL TESTS

Powering the Power Supply On/Off .................................................................. 2-10

Voltage and Current Mode Operation Checks ................................................... 2-11

S

TEP 6: CONNECTING LOADS

DC Output Connectors ..................................................................................... 2-12

Inductive Loads and Batteries........................................................................... 2-13

Connecting Single Loads .................................................................................. 2-14

Connecting Multiple Loads ............................................................................... 2-14

S

TEP 7: CONNECTING REMOTE SENSING

................................................................................ 2-2

................................................................... 2-3

.................................................................... 2-4

............................................................ 2-5

....................................................................... 2-8

....................................................... 2-10

.......................................................................... 2-12

.......................................................... 2-15

M370430-01 Rev E vii

Page 10

Contents

3 LOCAL OPERATION ...................................................................................... 3-1

I

NTRODUCTION

C

ONFIGURING SETTINGS FROM THE FRONT PANEL

Using the 9-Position Mode Control ..................................................................... 3-2

Using the Rotary Adjust/Enter Control ................................................................ 3-2

Coarse and Fine Adjustment Modes ................................................................... 3-3

N

AVIGATING THE MENU SYSTEM

Setting VOLTS and AMPS Modes ...................................................................... 3-4

Normal Display Mode and Inactivity Timeout ...................................................... 3-6

D

ISPLAY MESSAGES ON THE FRONT PANEL

S

TANDARD (LOCAL) OPERATION

Operating Modes .............................................................................................. 3-10

Shipped Configuration (Local Operation) .......................................................... 3-16

E

NABLING THE OUTPUT

E

NABLING THE AUXILIARY OUTPUT

O

UTPUT AUTO START MODE (AUTO RESTART

A

UXILIARY AUTO START MODE

C

ONSTANT POWER MODE (VERSION

A

LARMS AND ERRORS

Clearing Alarms ................................................................................................ 3-21

Front Panel ALARM LED .................................................................................. 3-22

Alarm Masking ................................................................................................. 3-23

Alarm Output Latching ...................................................................................... 3-24

S

ETTING FOLDBACK MODE

Resetting Activated Foldback Protection ........................................................... 3-26

U

SING OVER VOLTAGE PROTECTION

Defining the OVP Set Point .............................................................................. 3-28

U

SING UNDER VOLTAGE PROTECTION

Defining the UVP Set Point ............................................................................... 3-29

O

VER CURRENT PROTECTION

U

SING OVER TEMPERATURE PROTECTION LOCK

Defining the OTP Mode .................................................................................... 3-31

Resetting in Latch Mode ................................................................................... 3-31

U

SING THE EXTERNAL SHUTDOWN FUNCTION

Activating the External Shutdown Function ....................................................... 3-32

Controlling the External Shutdown Function ..................................................... 3-32

Defining the Polarity of the External Shutdown Signal ....................................... 3-33

L

OOP PROTECTION (VERSION

Setting up Loop Protection ............................................................................... 3-34

I

NTERLOCK FUNCTION

................................................................................................. 3-2

............................................. 3-2

........................................................................ 3-4

........................................................ 3-8

...................................................................... 3-10

................................................................................... 3-16

................................................................... 3-17

) ................................................. 3-17

........................................................................ 3-18

2.21

AND HIGHER

) ..................................... 3-18

..................................................................................... 3-20

.............................................................................. 3-25

(OVP) ..................................................... 3-27

(UVP) ................................................... 3-29

(OCP) ............................................................... 3-30

(OTP) .................................... 3-31

................................................... 3-32

2.21

AND HIGHER

) ............................................... 3-33

..................................................................................... 3-35

viii M370430-01 Rev E

Page 11

Defining the Interlock Mode .............................................................................. 3-35

O

UTPUT PROTECTION

Programming Voltage Output Preset ................................................................ 3-35

Programming Current Output Preset ................................................................ 3-36

Power On Status Signal ................................................................................... 3-37

H

ARDWARE MALFUNCTION ALARMS

C

URRENT CONFIGURATION MEMORY SETTINGS

U

SER SETTING MEMORY LOCATIONS

Saving User Setting Memory Locations ............................................................ 3-40

Recalling User Setting Memory Locations ......................................................... 3-40

L

OCAL LOCKOUT

Enabling Local Lockout .................................................................................... 3-41

Disabling Local Lockout .................................................................................... 3-41

R

ESETTING THE POWER SUPPLY

U

SING MULTIPLE POWER SUPPLIES

Configuring Multiple Supplies for Series Operation ........................................... 3-46

Configuring Multiple Supplies for Current Sharing Operation (APG Method) ..... 3-49

Connecting to the Load in Local Sensing Mode (Parallel Control Method) ......... 3-51

Connecting to the Load in Remote Sensing Mode (Parallel Control Method) ..... 3-52

..................................................................................... 3-35

............................................................................................. 3-41

...................................................................... 3-42

Contents

................................................................. 3-37

................................................ 3-38

............................................................... 3-39

................................................................. 3-44

4 ANALOG PROGRAMMING (APG) AND ISOLATED ANALOG

PROGRAMMING (ISOL) ................................................................................. 4-1

I

NTRODUCTION

Analog Programming (APG) of Output Voltage and Output Current .................... 4-2

Remote Programming Options ........................................................................... 4-3

Analog Programming (APG) Connector J1 ......................................................... 4-5

A

NALOG PROGRAMMING MODE

Analog Programming With External Voltage Source ........................................... 4-9

Voltage-Controlled Voltage APG Setup ............................................................ 4-10

Voltage-Controlled Current APG Setup ............................................................. 4-12

Resistive-Controlled Voltage APG Setup .......................................................... 4-15

Resistive-Controlled Current APG Setup .......................................................... 4-17

Voltage and Current Readback ......................................................................... 4-19

I

SOLATED ANALOG PROGRAMMING MODE

AUX Output and Isolated Analog Programming (ISOL) Connector .................... 4-20

Voltage-Controlled Voltage ISOL Setup ............................................................ 4-23

Voltage-Controlled Current ISOL Setup ............................................................ 4-25

Resistive-Controlled Voltage ISOL Setup .......................................................... 4-28

Resistive-Controlled Current ISOL Setup .......................................................... 4-30

V

OLTAGE AND CURRENT READBACK (ISOLATED

................................................................................................. 4-2

.......................................................................... 4-9

(ISOL) ............................................. 4-20

) ............................................... 4-32

M370430-01 Rev E ix

Page 12

Contents

5 REMOTE OPERATION ................................................................................... 5-1

I

NTRODUCTION

H

ARDWARE AND CONNECTION SETUP

Configuring Remote Control Using RS-232 ......................................................... 5-2

Configuring Remote Control Using RS-485 ......................................................... 5-7

Configuring Remote Control using the USB Connector ....................................... 5-9

Setting Up the PC to Use the USB Connection ................................................... 5-9

GPIB Connector (Optional) ............................................................................... 5-15

Ethernet/LAN (ENET) Connector (Optional) ...................................................... 5-19

Multiple Power Supply Connections to RS-485 Bus .......................................... 5-19

T

ERMINAL CONFIGURATION

Data Format ..................................................................................................... 5-21

End of Message ............................................................................................... 5-21

HyperTerminal.................................................................................................. 5-21

Selecting the Appropriate Communication Port ................................................. 5-24

Multichannel Address Setting ........................................................................... 5-25

Remote Interface Addressing ........................................................................... 5-26

Multichannel Commands Explained .................................................................. 5-27

Status Reporting in SCPI .................................................................................. 5-29

S

TATUS REGISTERS MODEL FROM

S

TATUS BYTE

Error/Event Queue (ERR) ................................................................................. 5-32

Questionable Status Register Summary (QSR) ................................................ 5-32

Message Available (MAV) ................................................................................ 5-33

Standard Event Status Summary (ESB) ........................................................... 5-33

Master Summary Status (MSS) ........................................................................ 5-33

Request Service (RQS) .................................................................................... 5-33

Operation Status Register Summary (OSR) ...................................................... 5-34

Standard Event Status Register (SESR) ........................................................... 5-35

S

TANDARD

OPER

C

QUES

ATION STATUS REGISTER

URRENT SHARE SUB-REGISTER

Operation Status Register Commands .............................................................. 5-43

Current Sharing Sub-Register Commands ........................................................ 5-44

Shutdown Sub-Register Commands ................................................................. 5-45

Protection Sub-Register Commands ................................................................. 5-46

TIONABLE STATUS REGISTER

VOLTage Sub-Register .................................................................................... 5-50

TEMPerature Sub-Register .............................................................................. 5-50

Questionable Status Register Commands ........................................................ 5-51

................................................................................................. 5-2

................................................................ 5-2

............................................................................. 5-21

IEEE 488.2 ................................................. 5-31

................................................................................................. 5-32

SCPI R

EGISTER STRUCTURE

......................................................... 5-38

...................................................................... 5-39

.................................................................... 5-42

................................................................. 5-47

x M370430-01 Rev E

Page 13

Voltage Status Register Commands ................................................................. 5-52

Temperature Status Register Commands ......................................................... 5-53

SCPI E

L

C

RROR/EVENT QUEUE

Reset Command .............................................................................................. 5-56

Clear All Status Registers ................................................................................. 5-57

SCPI Preset Status .......................................................................................... 5-58

Command Line Help System ............................................................................ 5-59

OCKING AND UNLOCKING THE FRONT PANEL

Auto Sequence Programming ........................................................................... 5-62

ONFIGURE OTHER PROTECTION MECHANISMS

Foldback Protection .......................................................................................... 5-68

Over Temperature Protection ........................................................................... 5-69

Loop Protection Enable/Disable ........................................................................ 5-69

Interlock Enable/Disable ................................................................................... 5-70

Save and Recall ............................................................................................... 5-71

Set Analog Programming Level ........................................................................ 5-71

Set Remote Programming Interface .................................................................. 5-72

Protection Mask (Enable Alarms)...................................................................... 5-73

Power Saving Control (Sleep Mode, XG 1700 W Only) ..................................... 5-74

........................................................................... 5-54

Contents

................................................... 5-62

................................................ 5-68

6 COMMUNICATIONS OPTIONS ...................................................................... 6-1

INTRODUCTION ............................................................................................. 6-2

SETTING UP LAN/ETHERNET ....................................................................... 6-3

Basics ................................................................................................................ 6-3

LOCAL AREA NETWORK (LAN) OPTION ....................................................... 6-5

Media Access Control (MAC) Address ................................................................ 6-5

Communication Configuration............................................................................. 6-6

LAN Connection ................................................................................................. 6-6

Direct-to-PC Connection ..................................................................................... 6-6

Private Network Connection ............................................................................... 6-7

CONNECTING TO A NETWORK .................................................................... 6-8

Connecting with PC on Same Side of Router as Power Supply ........................... 6-8

Connecting with Power Supply Hidden Behind a Router ................................... 6-10

Socket Port Number ......................................................................................... 6-12

Instrument Drivers and Application Software ..................................................... 6-13

AMETEK LXI DISCOVERY BROWSER ......................................................... 6-13

Installing the AMETEK LXI Discovery Browser ................................................. 6-13

Using the AMETEK LXI Discovery Browser ...................................................... 6-21

AMETEK E

Installing the AMETEK EnetTest Utility ............................................................. 6-22

Using the AMETEK Ethernet Test Utility ........................................................... 6-28

NETTEST

UTILITY ......................................................................... 6-22

M370430-01 Rev E xi

Page 14

Contents

SETTING LAN PARAMETERS ...................................................................... 6-29

Setting LAN Parameters via Ethernet ............................................................... 6-29

Setting LAN Parameters via Serial or USB Port ................................................ 6-29

Setting LAN Parameters via Web Interface ....................................................... 6-30

S

ETTING A STATIC IP ADDRESS THROUGH ETHERNET,

USB, S

ERIAL INTERFACES

...................................................................................................................... 6-35

Ethernet ........................................................................................................... 6-35

USB ................................................................................................................. 6-36

RS232 (SERIAL) .............................................................................................. 6-44

SYSTEM COMMANDS.................................................................................. 6-53

Subsystem Syntax............................................................................................ 6-53

LXI COMPLIANCE ........................................................................................ 6-56

Introduction to the LXI Standard ....................................................................... 6-57

VXI Discovery .................................................................................................. 6-57

LAN Requirements ........................................................................................... 6-57

Web Page ........................................................................................................ 6-57

Remote Procedure Calls (RPC) ........................................................................ 6-58

Drivers ............................................................................................................. 6-58

7 CALIBRATION AND TROUBLESHOOTING .................................................. 7-1

I

NTRODUCTION

M

AIN VOLTAGE AND CURRENT CALIBRATION PRINCIPLE

Understanding the Problem ................................................................................ 7-3

Step 1: Gain Calibration ..................................................................................... 7-4

Step 2: Offset Calibration ................................................................................... 7-4

Step 3: Recalibrate Gain .................................................................................... 7-5

S

TORING CALIBRATION DATA

C

ALIBRATING THE OUTPUT VOLTAGE

Gain Calibration ................................................................................................. 7-6

Offset Calibration ............................................................................................... 7-6

C

ALIBRATING THE OUTPUT CURRENT

Gain Calibration ................................................................................................. 7-7

Offset Calibration ............................................................................................... 7-8

O

VER VOLTAGE PROTECTION CALIBRATION

NON-

ISOLATED ANALOG PROGRAMMING CALIBRATION

Non-isolated Voltage Monitoring Calibration ..................................................... 7-10

Non-isolated Current Monitoring Calibration ..................................................... 7-11

Non-isolated Voltage Programming of Voltage Calibration ................................ 7-12

Non-isolated Resistive Programming of Voltage Calibration .............................. 7-13

Non-isolated Voltage Programming of Current Calibration ................................ 7-14

Non-isolated Resistive Programming of Current Calibration .............................. 7-15

................................................................................................. 7-2

...................................... 7-3

............................................................................. 7-5

.................................................................. 7-6

................................................................. 7-7

........................................................ 7-9

...................................... 7-10

xii M370430-01 Rev E

Page 15

C

ALIBRATION PROCEDURE FOR ISOLATED MODES

Isolated Voltage Monitoring Calibration ............................................................. 7-16

Isolated Current Monitoring Calibration ............................................................. 7-17

Isolated Voltage Programming of Voltage Calibration ....................................... 7-18

Isolated Resistive Programming of Voltage Calibration ..................................... 7-19

Isolated Voltage Programming of Current Calibration ........................................ 7-20

Isolated Resistive Programming of Current Calibration ..................................... 7-21

Calibrating the Input Voltage APG Signal .......................................................... 7-22

Calibrating the Input Current APG Signal .......................................................... 7-23

R

ESTORE FACTORY CALIBRATION

R

ESTORE DEFAULT CALIBRATION

U

SER DIAGNOSTICS

Emergency Shutdown ...................................................................................... 7-26

Unusual or Erratic Operation ............................................................................ 7-26

Troubleshooting for Operators .......................................................................... 7-27

APPENDIX A

SCPI C

SCPI C

ONFORMANCE INFORMATION

Codes and Standards ......................................................................................... A-2

IEEE 488.2/SCPI Syntax and Style ..................................................................... A-2

SCPI Command Hierarchy ................................................................................. A-3

Using SCPI Commands ...................................................................................... A-4

Parameter Types ................................................................................................ A-7

OMMAND TREE

SCPI Command Summary ............................................................................... A-14

APPENDIX B

E

RROR MESSAGES

Command Error List ........................................................................................... B-3

Execution Error List ............................................................................................ B-4

Device-Specific Error List ................................................................................... B-5

Query Error List .................................................................................................. B-6

APPENDIX C

E

LECTRICAL SPECIFICATIONS FOR XG FAMILY,

AC Line Input Specifications for XG 850 Watt ..................................................... C-3

E

LECTRICAL SPECIFICATIONS FOR XG FAMILY,

AC Line Input Specifications for XG 1500 Watt ................................................... C-5

E

LECTRICAL SPECIFICATIONS FOR XG FAMILY,

AC Line Input Specifications for XG 1700 Watt ................................................... C-7

R

EMOTE OPERATION PROGRAMMING

C

OMMON SPECIFICATIONS FOR ALL MODELS

APPENDIX D

........................................................................................ 7-25

SCPI C

OMMAND REFERENCE

..................................................................................... A-8

ERROR MESSAGES

.......................................................................................... B-2

SPECIFICATIONS

RACK MOUNT OPTIONS AND INSTALLATION INSTRUCTIONS

.................................................................... 7-25

.................................................................... 7-25

................................................................... B-1

....................................................................... C-1

Contents

............................................ 7-16

.................................................... A-1

................................................................. A-2

850 W ....................................... C-2

1500 W ..................................... C-4

1700 W ..................................... C-6

................................................................ C-8

..................................................... C-9

.......... D-1

M370430-01 Rev E xiii

Page 16

Contents

R

ACK MOUNT KIT OPTIONS

XG Single (Half Rack) and Dual (Full Rack) ........................................................ D-2

Location Requirements ....................................................................................... D-3

M

OUNTING OPTION A: 1U RAILS

Tools and Materials Required ............................................................................. D-4

Installation Procedures ....................................................................................... D-4

M

OUNTING OPTION B: MANUFACTURED SLIDES FROM JONATHAN® ENGINEERED

S

OLUTIONS

APPENDIX E

I

NTRODUCTION

Setting Up the Computer .................................................................................... E-2

Software Installations ......................................................................................... E-4

Configuring the Device Using DeviceInstaller ...................................................... E-6

Terminal Configuration ..................................................................................... E-12

Advanced Section ............................................................................................ E-17

Network Topology 1: Simple LAN ..................................................................... E-17

Network Topology 2: ENET and RS-485 Bus .................................................... E-20

Troubleshooting for XG 850W Model with ENET and/or RS-485 Communication

........................................................................................................................ E-23

I

NDEX

...................................................................................................... D-6

LANTRONIX PROCEDURES FOR

................................................................................................ E-2

.................................................................................................................. 1

.............................................................................. D-2

....................................................................... D-4

MEA O

PTION

............................. E-1

Figures

Figure 1-1 XG Front Panels (Half Rack, above; Full Rack, below; not to-scale) ............ 1-5

Figure 1-2 Front Panel Display and Controls ................................................................ 1-6

Figure 1-3 XG 850 Watt Units: 6 V to 40 V Models ....................................................... 1-7

Figure 1-4 XG 850 Watt Units: 60 V to 150 V Models .................................................. 1-7

Figure 1-5 XG 850 Watt Units: 300 V to 600 V Models ................................................. 1-7

Figure 1-6 XG 1500 and 1700 Watt Units: 6 V to 40 V Models ..................................... 1-9

Figure 1-7 XG 1500 and 1700 Watt Units: 60 V to 600 V Models ................................ 1-10

Figure 2-1 1500 and 1700 Watt AC Input Cover and Strain Relief ................................ 2-6

Figure 2-2 Maximum Load Wire Length for 1 V Line Drop ............................................ 2-9

Figure 2-3 Diode Placement ...................................................................................... 2-13

Figure 2-4 Connecting Single Loads .......................................................................... 2-14

Figure 2-5 Remote Sense Connection ....................................................................... 2-15

Figure 3-1 9-Position Mode Control .............................................................................. 3-2

Figure 3-2 Front Panel Menu System ........................................................................... 3-7

Figure 3-3 Operating Modes ...................................................................................... 3-13

Figure 3-4 Split Supply Operation .............................................................................. 3-45

Figure 3-5 Series Operation ....................................................................................... 3-47

Figure 3-6 Load Connections in Remote Sensing Mode ............................................. 3-48

Figure 3-7 Load Connections in Local Sensing Mode ................................................. 3-51

Figure 3-8 Load Connections in Remote Sensing Mode (Parallel Control Method) ..... 3-52

Figure 4-1 APG Connector Terminals .......................................................................... 4-5

Figure 4-2 Inserting Screwdriver into Spring Terminal Block ......................................... 4-7

Figure 4-3 APG and DC Output Connector .................................................................. 4-7

xiv M370430-01 Rev E

Page 17

Contents

Figure 4-4 Programming Output Voltage using an External Voltage Source ................. 4-9

Figure 4-5 Programming Output Current using an External Voltage Source .................. 4-9

Figure 4-6 Programming Output Voltage using an External Resistor .......................... 4-14

Figure 4-7 Programming Output Current using an External Resistor ........................... 4-14

Figure 4-8 Voltage Readback Using APG Connector J1 ............................................. 4-19

Figure 4-9 Current Readback Using APG Connector J1 ............................................. 4-19

Figure 4-10 AUX Output and ISOL Connector Pinout ................................................... 4-20

Figure 4-11 Programming Output Voltage using an Isolated External Voltage Source .. 4-22

Figure 4-12 Programming Output Current using an Isolated External Voltage Source .. 4-22

Figure 4-13 Programming Output Voltage using an Isolated External Resistor ............. 4-27

Figure 4-14 Programming Output Current using an Isolated External Resistor ............. 4-27

Figure 4-15 Isolated Voltage Monitoring ....................................................................... 4-32

Figure 4-16 Isolated Current Monitoring ....................................................................... 4-32

Figure 5-1 Remote Control Connectors ........................................................................ 5-3

Figure 5-2 RS-232 Communication Cable with DB-9 Pinout ......................................... 5-5

Figure 5-3 DB-25 Pinout .............................................................................................. 5-5

Figure 5-4 RS-232 Communication Cable with DB-25 Pinout ....................................... 5-6

Figure 5-5 RS-485 Communication Cable with DB-9 .................................................... 5-7

Figure 5-6 RS-485 Communication Cable from Master to Slave Unit ............................ 5-8

Figure 5-7 Found New Hardware Wizard ................................................................... 5-10

Figure 5-8 Install Hardware Device Drivers ................................................................ 5-10

Figure 5-9 Completing the New Hardware Wizard ...................................................... 5-11

Figure 5-10 Device Manager ........................................................................................ 5-12

Figure 5-11 Communications Port (COM1) Properties .................................................. 5-13

Figure 5-12 Completing the new hardware wizard ........................................................ 5-13

Figure 5-13 Scanning for Instruments .......................................................................... 5-17

Figure 5-14 Instrument Properties ............................................................................... 5-18

Figure 5-15 Multi Power Supply Connection to RS-485 Bus ......................................... 5-19

Figure 5-16 USB Settings ............................................................................................ 5-22

Figure 5-17 ASCII Setup .............................................................................................. 5-23

Figure 5-18 SCPI Status Reporting Model .................................................................... 5-30

Figure 5-19 IEEE 488.2 Register Model ....................................................................... 5-31

Figure 5-20 Summary of Standard Event Status Register ............................................. 5-36

Figure 5-21 SCPI Register Model ................................................................................ 5-38

Figure 5-22 Operation Status Register Fanout ............................................................. 5-39

Figure 5-23 SCPI QUEStionable Registers Fanout ...................................................... 5-48

Figure 6-1 Computer or HUB Plug ............................................................................... 6-3

Figure 6-2 Power Supply Plug ...................................................................................... 6-3

Figure 6-3 RJ-45 Plug .................................................................................................. 6-3

Figure 6-4 Scheme of ENET Cross-Cable .................................................................... 6-4

Figure 6-5 XPort® ENET Connector and LEDs ............................................................ 6-4

Figure 6-6 Single Computer, Single Power Supply ....................................................... 6-6

Figure 6-7 PC on Same Side of Router as Power Supply ............................................. 6-8

Figure 6-8 Home Page ................................................................................................. 6-9

Figure 6-9 AMETEK LXI Discovery Browser ................................................................. 6-9

Figure 6-10 Power Supply Hidden Behind a Router ..................................................... 6-10

Figure 6-11 Router Home Page ................................................................................... 6-11

Figure 6-12 Port Forwarding ........................................................................................ 6-12

Figure 7-1 Offset (Intercept) Error and Gain (Slope) Error ............................................ 7-3

Figure 7-2 Calibration: Step 1 Gain Calibration ............................................................ 7-4

Figure 7-3 Calibration: Step 2 Offset Calibration ........................................................... 7-4

Figure 7-4 Calibration: Step 3 Recalibrate Gain............................................................ 7-5

M370430-01 Rev E xv

Page 18

Contents

Figure C-1 XG 850 Watt Mechanical Dimensions: 6 to 40 V Models ........................... C-11

Figure C-2 XG 850 Watt Mechanical Dimensions: 60 V to 600 V Models .................... C-12

Figure C-3 XG in Full Rack Mechanical Dimensions: 6 V to 40 V Models .................... C-13

Figure C-4 XG in Full Rack Mechanical Dimensions: 6 V to 40 V Models DC Output Cover

Figure C-5 XG in Full Rack Mechanical Dimensions: 60 V to 600 V Models ................ C-15

Figure C-6 XG in Full Rack Mechanical Dimensions: 60 V to 600 V Models w/DC Output

Figure C-7 XG850 with Full Rack and Foot Options, Front, Side, and Rear Views ....... C-17

Figure C-8 XG850 Standard in Full Rack Option ......................................................... C-17

Figure C-9 XG850 Low Voltage Model Dimensions, Top, Side, and Rear ................... C-18

Figure C-10 XG850 Medium and High Voltage Models Dimensions, Top and Rear ....... C-19

Figure C-11 XG850 with Front Panel Output Voltage Option*, Top, Side, and Rear ....... C-20

Figure D-1 Single (left,) and Dual (right) Half Rack Mount Kit Options ........................... D-2

Figure D-2 Full Rack Mount Kit Option .......................................................................... D-3

Figure D-3 RM-XG1 Rack Rails .................................................................................... D-5

Figure D-4 Finding Rack Depth ..................................................................................... D-6

Figure D-5 Selecting a Rail Type .................................................................................. D-7

Figure D-6 Modifying Rear Bracket ............................................................................... D-8

Figure D-7 Removing Chassis Member From Slides ..................................................... D-8

Figure D-8 Attaching Front and Rear Bracket To Cabinet Section ................................. D-9

Figure D-9 Mounting Cabinet Section Into Rack .......................................................... D-10

Figure D-10 Installing Chassis ...................................................................................... D-11

Figure E-1 Configuring the Network Connection of the Computer .................................. E-2

Figure E-2 LAN Properties Dialog Box .......................................................................... E-3

Figure E-3 Internet Protocol (TCP/IP) Properties Dialog Box ......................................... E-4

Figure E-4 DeviceInstaller Setup Wizard ....................................................................... E-5

Figure E-5 Select Installation Folder Window ................................................................ E-6

Figure E-6 Multiple Network Adapters ........................................................................... E-7

Figure E-7 Selecting Network Adapter .......................................................................... E-7

Figure E-8 Auto-IP Address Message ........................................................................... E-8

Figure E-9 Searching for Power Supply IP Address ...................................................... E-8

Figure E-10 IP Address Details Window ......................................................................... E-9

Figure E-11 Entering the Lantronix Interface ................................................................. E-10

Figure E-12 Lantronix XPort® Interface ........................................................................ E-10

Figure E-13 Assigning IP Settings ................................................................................ E-11

Figure E-14 HyperTerminal Connection ........................................................................ E-13

Figure E-15 Connection Description Window ................................................................ E-13

Figure E-16 New Connection Dialog Box ...................................................................... E-14

Figure E-17 Main Terminal Window .............................................................................. E-15

Figure E-18 ENET Properties Window .......................................................................... E-15

Figure E-19 ENET Properties Dialog Box ..................................................................... E-16

Figure E-20 ASCII Setup Dialog Box ............................................................................ E-17

Figure E-21 Multiple Power Supplies and Two Computers ............................................ E-18

Figure E-22 HyperTerminal Session ............................................................................. E-19

Figure E-23 System with Two Connected Devices ........................................................ E-20

Figure E-24 ENET and RS-485 Bus ............................................................................. E-21

Figure E-25 HyperTerminal Window ............................................................................. E-21

C-14

Cover ........................................................................................................ C-16

xvi M370430-01 Rev E

Page 19

Contents

Tables

Table 1-1

Table 1-2

Table 1-3

Table 2-1

Table 2-2

Table 2-3

Table 3-1

Table 3-2

Table 3-3

Table 3-4

Table 3-5

Table 3-6

Table 3-7

Table 3-8

Table 3-9

Table 4-1

Table 4-2

Table 4-3

Table 4-4

Table 5-1

Table 5-2

Table 5-3

Table 5-4

Table 5-5

Table 5-6

Table 5-7

Table 5-8

Table 5-9

Table 5-10 Status Byte Summary Register ................................................................. 5-32

Table 5-11 Standard Event Status Register ................................................................ 5-36

Table 5-12 OPERation Status Register ....................................................................... 5-40

Table 5-13 OPERation SHUTdown Status Register .................................................... 5-41

Table 5-14 OPERation SHUTdown PROTection Status Register ................................ 5-41

Table 5-15 OPERation CSHare Status Register.......................................................... 5-42

Table 5-16 QUEStionable Status Register .................................................................. 5-49

Table 5-17 QUEStionable VOLTage Status Register .................................................. 5-50

Table 5-18 QUEStionable TEMPerature Status Register ............................................. 5-50

Table 5-19 Preset Values of User Configurable Registers ........................................... 5-58

Table 5-20 Alarms Bit Mask ........................................................................................ 5-73

Table 6-1

Table 6-2

Table 6-3

Table 6-4

Table 7-1

Table A-1 IEEE 488.2 Commands ............................................................................. A-14

Table A-2 Readback Commands............................................................................... A-16

Table A-3 SCPI Commands for Output Control.......................................................... A-17

Table A-4 SCPI Commands for Calibration ............................................................... A-18

Table A-5 SCPI Commands to Clear All Protection Mechanisms ............................... A-21

XG 850 Watt Series Voltage and Current Ranges ....................................... 1-3

XG 1500 Watt Series Voltage and Current Ranges ..................................... 1-4

XG 1700 Watt Series Voltage and Current Ranges ..................................... 1-4

Basic Setup Procedure ............................................................................... 2-2

XG 1500 and 1700 Watt: Recommended AC Input Wire (higher power) ...... 2-6

Current Carrying Capacity for Load Wiring .................................................. 2-8

Select and Set from the Front Panel ............................................................ 3-3

Front Panel Display Text ............................................................................. 3-8

Shipped Configuration............................................................................... 3-16

Alarm Order of Precedence ....................................................................... 3-20

Alarm Mask Bit Positions .......................................................................... 3-23

Alarm Latch Bit Positions .......................................................................... 3-24

Power Cycle Saved/Recalled Settings ....................................................... 3-38

User Accessible Saved/Recalled Settings Voltage Setpoint ....................... 3-39

Power Supply Default Settings .................................................................. 3-42

Monitor Lines .............................................................................................. 4-3

Remote Programming Options .................................................................... 4-4

APG Pins and Functions J1 ........................................................................ 4-5

AUX Output and ISOL Connector Pins and Functions J3 ........................... 4-21

Remote Control Connector Pins and Functions J4 and J61 .......................... 5-3

DB-9 Pinouts .............................................................................................. 5-4

RJ-45 Pinouts ............................................................................................. 5-4

DB-25 Pinouts............................................................................................. 5-5

DB-9 Pinouts .............................................................................................. 5-7

RJ-45 Plug Pinouts ..................................................................................... 5-7

RJ-45 Plug on Slave Unit ............................................................................ 5-8

GPIB Pin Description (J2) ......................................................................... 5-15

Rules for Multichannel Responses ............................................................ 5-27

Description of Pins on RJ-45 Plug ............................................................... 6-4

Description of LEDs .................................................................................... 6-5

LAN Setting Screens ................................................................................. 6-32

Factory Default LAN Settings .................................................................... 6-57

Troubleshooting ........................................................................................ 7-27

M370430-01 Rev E xvii

Page 20

Contents

Table A-6 SCPI Commands for Foldback Protection ................................................. A-22

Table A-7 SCPI Commands for Power ...................................................................... A-23

Table A-8 SCPI Commands for Triggering ................................................................ A-23

Table A-9 System Commands ................................................................................... A-24

Table A-10 Status Commands .................................................................................... A-27

Table A-11 Protection Commands ............................................................................... A-35

Table A-12 Auto Sequence Commands ...................................................................... A-35

Table B-1 Command Error List .................................................................................... B-3

Table B-2 Execution Error List ..................................................................................... B-4

Table B-3 Device-Specific Error List ............................................................................ B-5

Table B-4 Query Error List .......................................................................................... B-6

Table C-1 XG 850 Watt Electrical Specifications for 6 V to 600 V Models .................... C-2

Table C-2 XG 1500 Watt Electrical Specifications for 6 V to 600 V Models .................. C-4

Table C-3 XG 1700 Watt Electrical Specifications for 6 V to 600 V Models .................. C-6

Table C-4 Remote Operation Programming ................................................................. C-8

Table C-5 Output Performance Specifications ............................................................. C-9

Table D-1 Table Rack Mount Options .......................................................................... D-2

Table D-2 Part Numbers for Jonathan Manufactured Slides ......................................... D-7

Table E-1 Troubleshooting for the Combined ENET – RS-485 Communication ......... E-23

Table E-2 Troubleshooting for ENET Communication ................................................ E-24

xviii M370430-01 Rev E

Page 21

Chapter 1, Introduction, describes the features of the XG Family

Introduction

1

Programmable DC Power Supply.

Page 22

The XG Family Programmable DC Power Su

pply provides stable,

variable output voltage and current for a broad range of development and

system requirements. The power supplies have a high power density and

circuit protection of DC outputs provideing greater operating

M10 Option preprograms the voltage to reset to zero upon power on

Introduction

Features and Options

numerous industry standard interfaces:

•

RS-232, RS-485, analog programming (APG), and USB built-in

ports.

•

Optional GPIB or Ethernet (ENET), isolated analog programming

(ISOL), control for remote operation and readback.

•

Seamless switching between front panel and any digital interface

(RS-232, RS-485, USB, GPIB or ENET).

•

Simultaneous digital displays for both voltage and current.

•

Front panel control by rotary Adjust/Enter knob, permitting high

resolution output setting.

•

Active Power Factor Correction (PFC) reduces input current and

input current harmonics.

•

Automatic crossover system allowing the power supply to switch

between Constant Current, Constant Voltage and Constant Power

(available in version 2.21 and higher) operating modes.

•

Parallel or series connection among multiple units to produce

greater diversity or to use in higher power applications.

•

Shortsafety.

•

Built-in APG and ISOL (optional) interface to provide a

galvanically isolated analog voltage control of the output,

master/slave output tracking, and remote Enable/disable for safety

and precision.

•

Remote output voltage sensing to automatically compensate for

cable losses.

•

Software calibrated.

•

Three user setting memory locations.

•

and upon output enable.

1-2 M370430-01 Rev E

Page 23

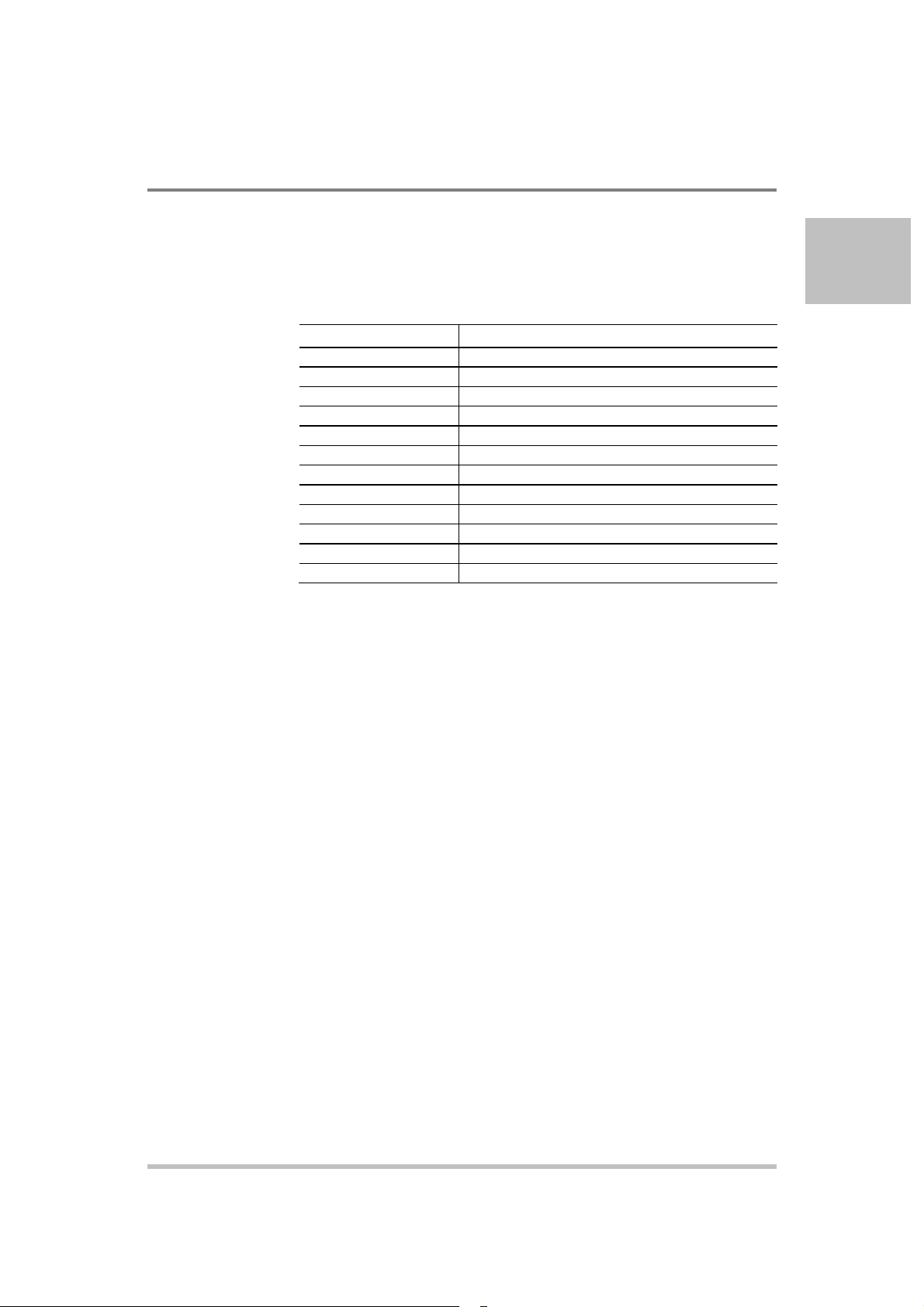

Model

Output V

oltage

Output Current

Introduction

XG Models

(firmware version 2.0 and higher)

Table 1-1 lists the models in the XG 850 Watt series covered by this

Manual.

Table 1-1 XG 850 Watt Series Voltage and Current Ranges

6-110

8-100

12-70

20-42

33-25

40-21

60-14

80-10.5

100-8.5

150-5.6

300-2.8

600-1.4

0-6 V

0-8 V

0-12 V

0-20 V

0-33 V

0-40 V

0-60 V

0-80 V

0-100 V

0-150 V

0-300 V

0-600 V

1

0-110 A

0-100 A

0-70 A

0-2 A

0-25 A

0-21 A

0-14 A

0-10.5 A

0-8.5 A

0-5.6 A

0-2.8 A

0-1.4 A

M370430-01 Rev E 1-3

Page 24

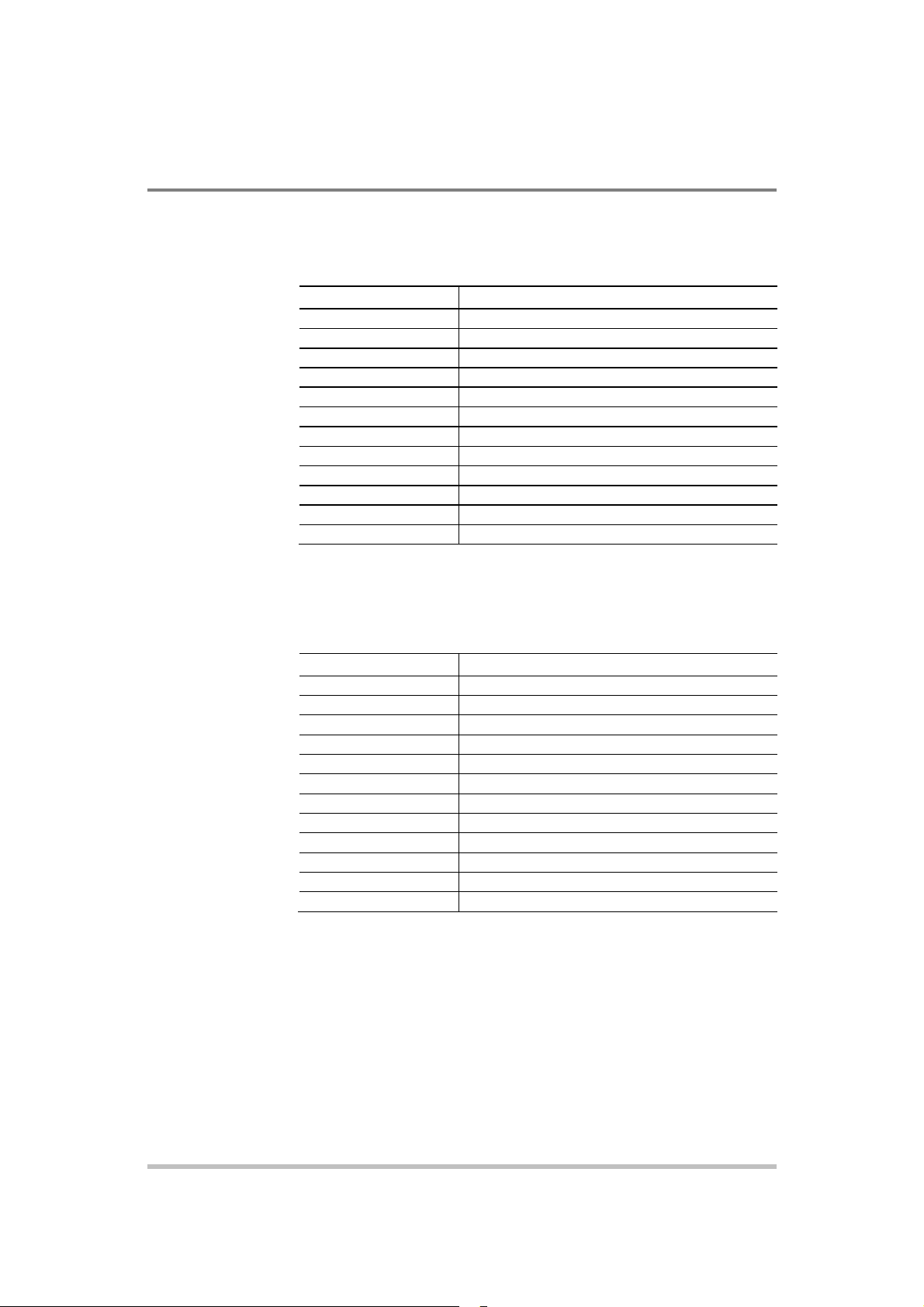

Model

Out

put Voltage

Output Current

Model

Output Voltage

Output Current

Introduction

Table 1-2 lists the models in the XG 1500 Watt series covered by this

Manual.

Table 1-2 XG 1500 Watt Series Voltage and Current Ranges

6-220

8-187.5

12.5-120

20-76

30-50

40-38

60-25

80-19

100-15

150-10

300-5

600-2.6

0-6 V

0-8 V

0-12.5 V

0-20 V

0-30 V

0-40 V

0-60 V

0-80 V

0-100 V

0-150 V

0-300 V

0-600 V

Table 1-3 lists the models in the XG 1700 Watt series covered by this

Manual.

Table 1-3 XG 1700 Watt Series Voltage and Current Ranges

6-220

8-200

12-140

20-84

33-50

40-42

60-28

80-21

100-17

150-11.2

300-5.6

600-2.8

0-6 V

0-8 V

0-12 V

0-20 V

0-33 V

0-40 V

0-60 V

0-80 V

0-100 V

0-150 V

0-300 V

0-600 V

0-220 A

0-187.5 A

0-120 A

0-76 A

0-50 A

0-38 A

0-25 A

0-19A

0-15 A

0-10 A

0-5 A

0-2.6 A

0-220 A

0-200 A

0-140 A

0-84 A

0-50 A

0-42 A

0-28 A

0-21 A

0-17 A

0-11.2 A

0-5.6 A

0-2.8 A

1-4 M370430-01 Rev E

Page 25

Item

Description

Front Panel

Introduction

1

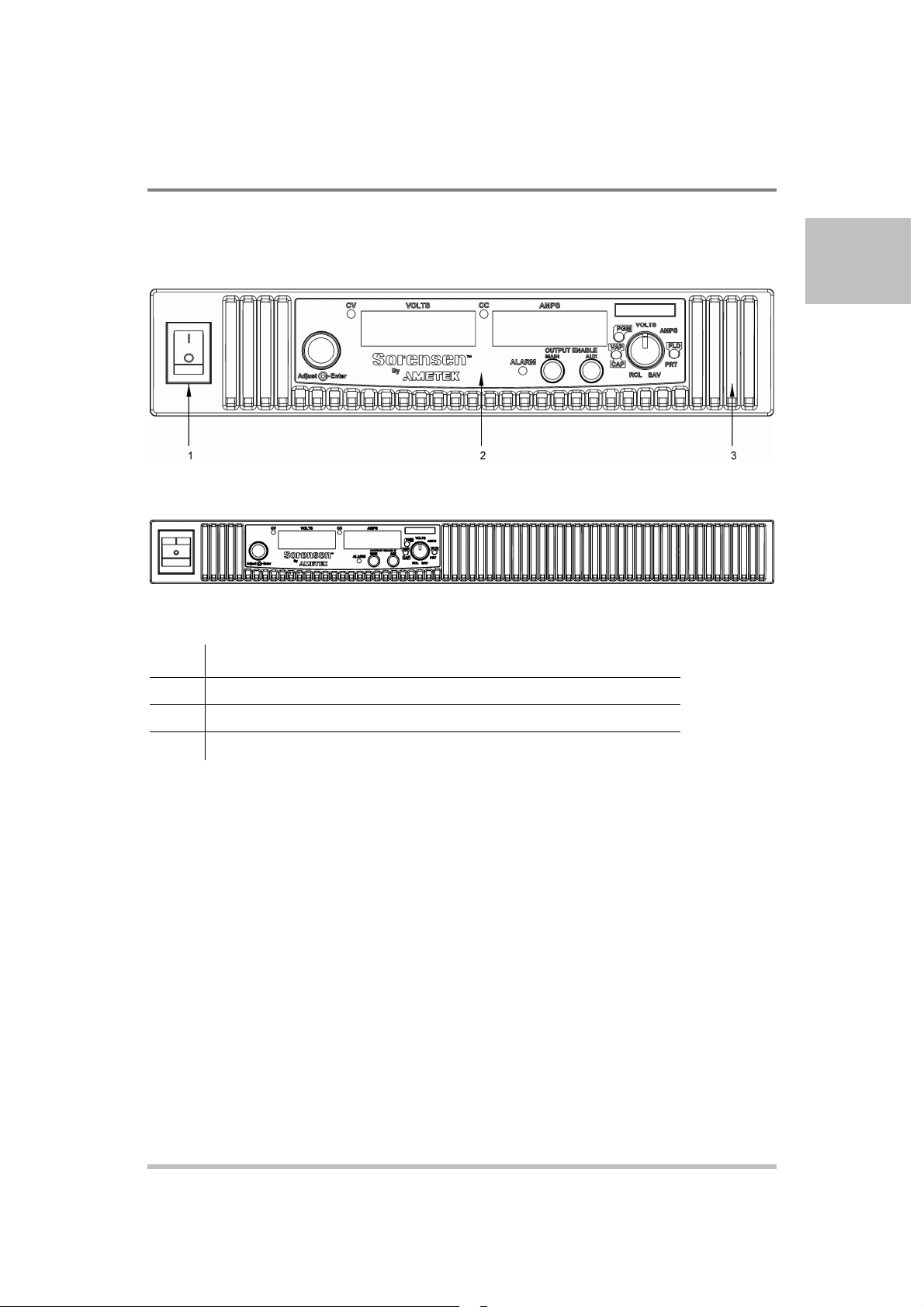

Figure 1-1 XG Front Panels (Half Rack, above; Full Rack, below; not to-scale)

1 Front panel power switch

2

3 Air Intake Vents

Front panel display see Figure 1-2

M370430-01 Rev E 1-5

Page 26

Item

Description

Configuring Settings from the Front

Introduction

Front Panel Display and Controls

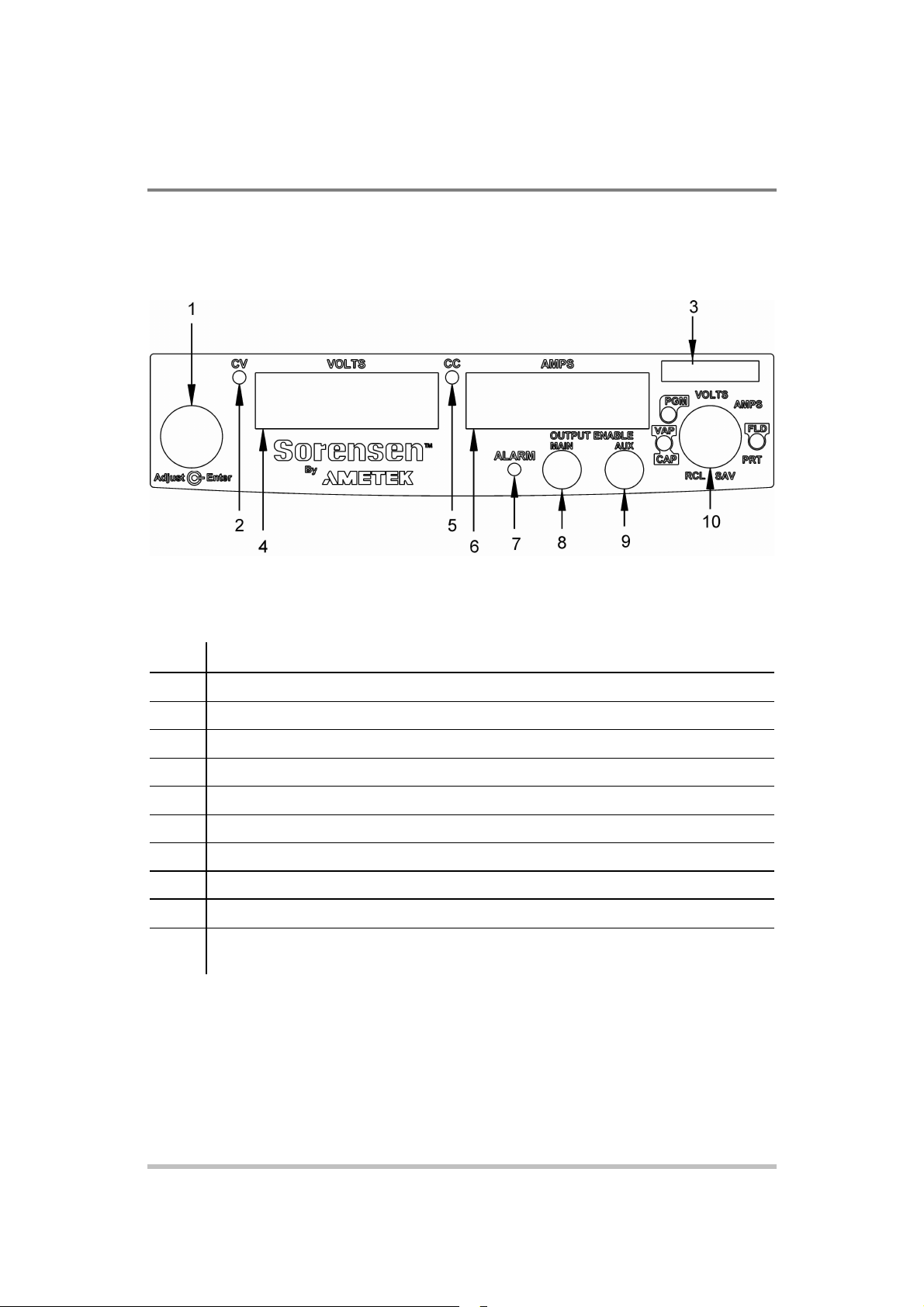

Figure 1-2 Front Panel Display and Controls

1

2

3

4

5

6

7

8

9

10

Rotary Adjust/Enter control

Constant Voltage (CV) Mode LED (green)

Model Identification Label

Output Voltage Display

Constant Current (CC) Mode LED (green)

Output Current Display

Alarm Indicator LED (red)

OUTPUT ENABLE Main button

OUTPUT ENABLE Aux button

9-Position Mode Control (For detailed information, see “

Panel” on page 3-2).

1-6 M370430-01 Rev E

Page 27

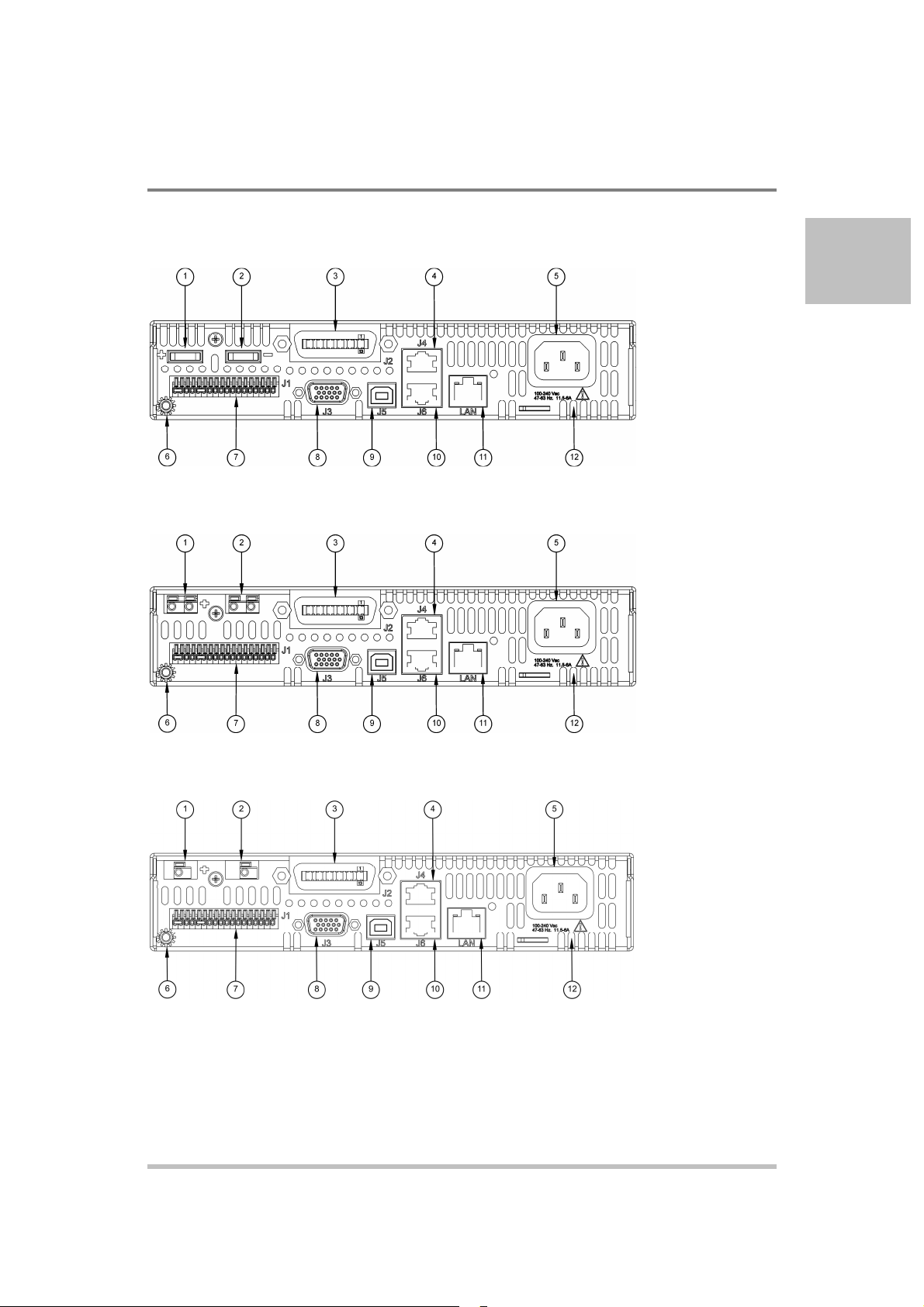

Rear Panel Connectors on 850 Watt Models

Figure 1-3 XG 850 Watt Units: 6 V to 40 V Models

Introduction

1

Figure 1-4 XG 850 Watt Units: 60 V to 150 V Models

Figure 1-5 XG 850 Watt Units: 300 V to 600 V Models

M370430-01 Rev E 1-7

Page 28

Item

Description

Introduction

1 6 V– 40 V Models: DC Output Terminal Positive

60 V–150 V Models: DC Output Connectors Positive (6.5 mm hole diameter)

300 V–600 V Models: DC Output Connectors Positive (6.5 mm hole diameter)

2 6 V– 40 V Models: DC Output Terminal Negative

60 V–150 V Models: DC Output Connectors Negative (6.5 mm hole diameter)

300 V–600 V Models: DC Output Connectors Negative (6.5 mm hole diameter)

3 (J2) Ethernet (ENET) or GPIB Connector (optional)

4 (J4) RS-232/RS-485 Connector In Port

5 AC Input Connector (IEC Type)

6 Chassis Ground Stud

7 (J1) Analog Programming (APG) Connector. For pin information, see page 4-5.

8 (J3) AUX Output and Isolated Analog Programming (ISOL) Connector. For pin information, see

page 4-20.

9 (J5) USB Connector

10 (J6) RS-485 Connector Multichannel Port

11 Ethernet/LAN (option) Connector

12 Fan Exhaust Vents

1-8 M370430-01 Rev E

Page 29

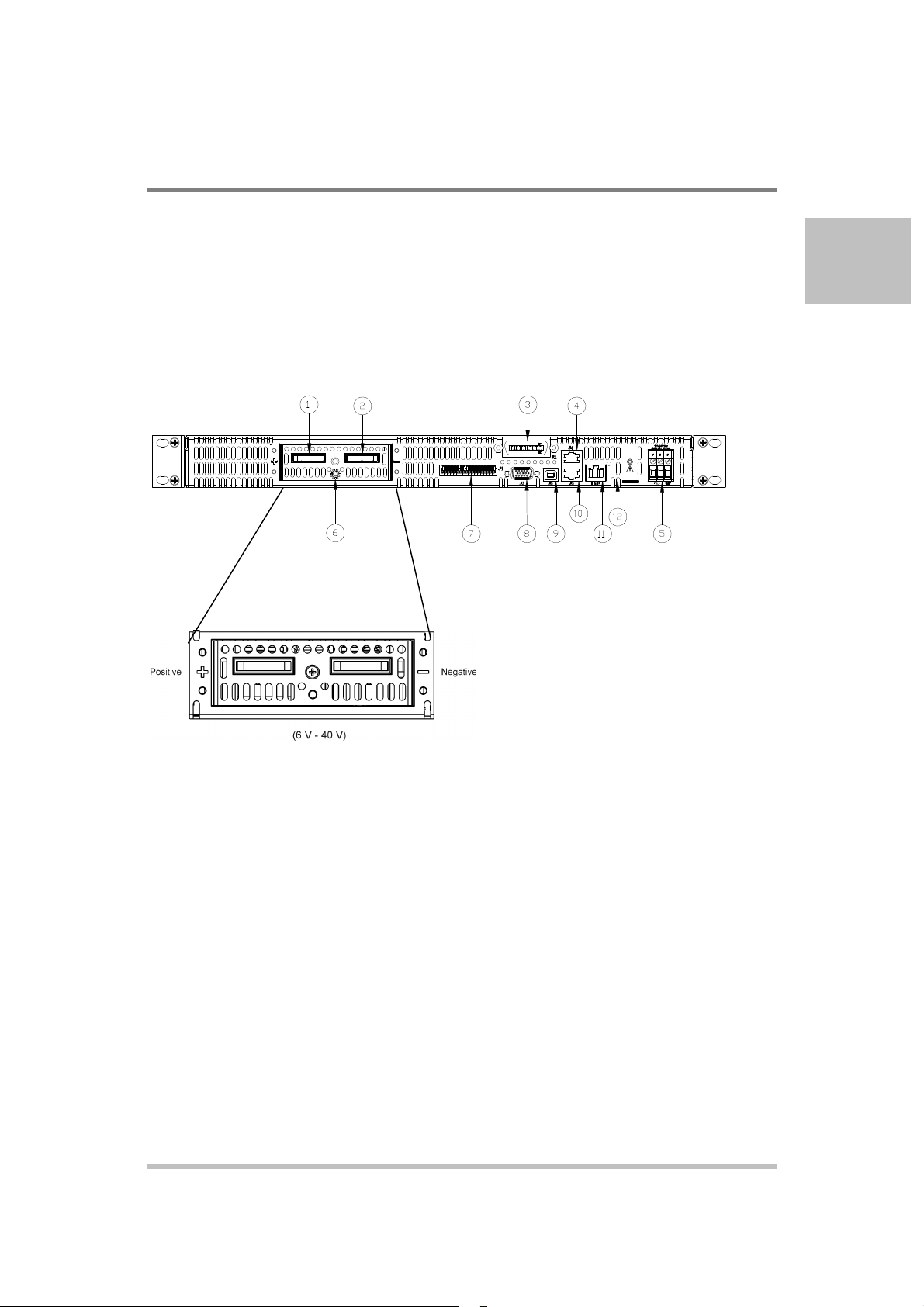

Introduction

Rear Panel Connectors on 1500 and 1700 Watt

Models

1

Figure 1-6 XG 1500 and 1700 Watt Units: 6 V to 40 V Models

M370430-01 Rev E 1-9

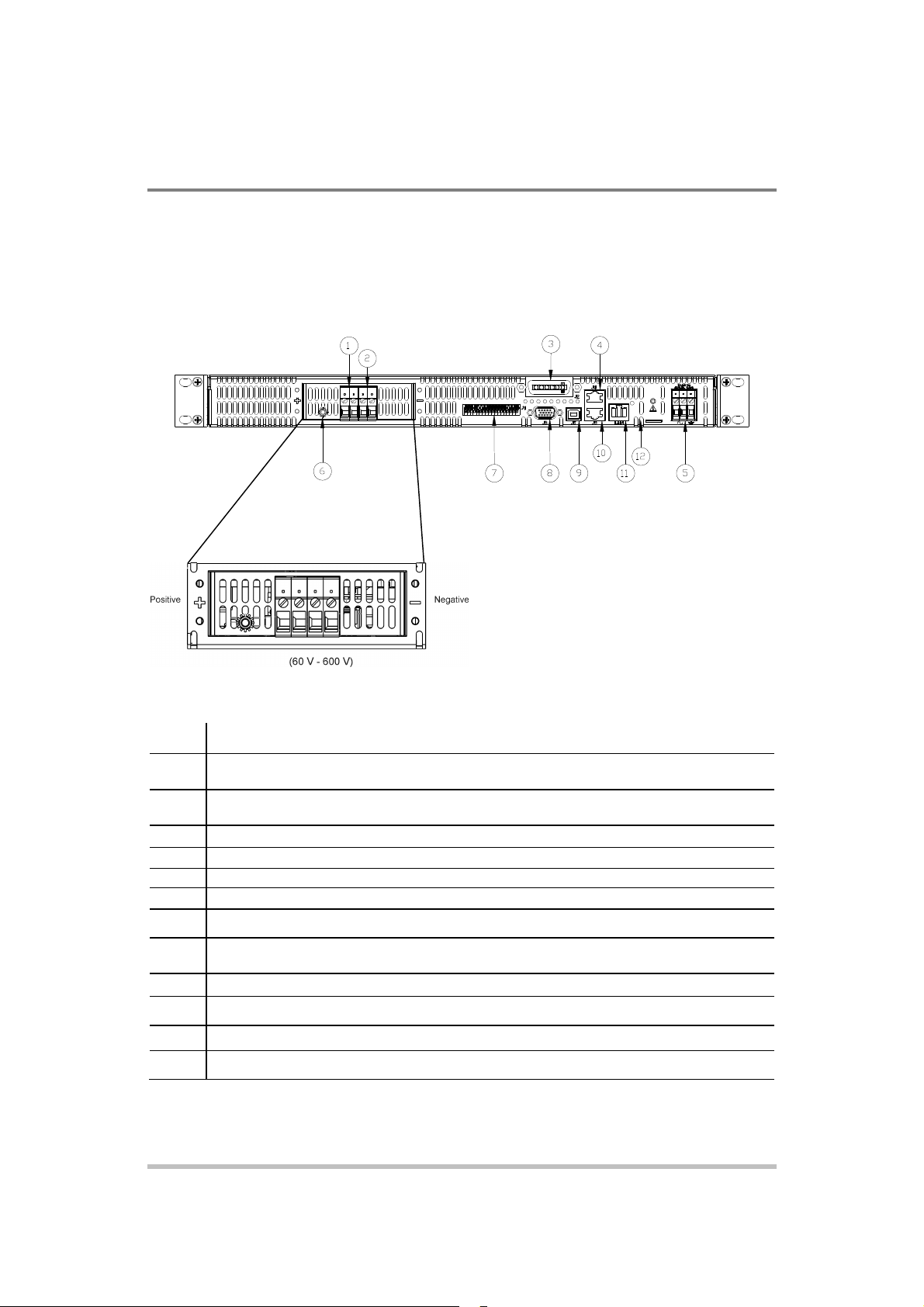

Page 30

Item

Description

Introduction

Figure 1-7 XG 1500 and 1700 Watt Units: 60 V to 600 V Models

1 6 V– 40 V Models: DC Output Terminal Positive (8.5 mm hole diameter)

60 V–600 V Models: DC Output Connectors Positive

2 6 V– 40 V Models: DC Output Terminal Negative (8.5 mm hole diameter)

60 V–600 V Models: DC Output Connectors Negative

3 (J2) Ethernet (ENET) or GPIB Connector (optional)

4 (J4) RS-232/RS-485 Connector In Port

5 AC Input Terminal

6 Chassis Ground Stud

7 (J1) Analog Programming (APG) Connector. For pin information, see page 4–5.

8 (J3) AUX Output and Isolated Analog Programming (ISOL) Connector. For pin information, see

page 4–20.

9 (J5) USB Connector

10 (J6) RS-485 Connector Multichannel Port

11 Ethernet Connector

12 Fan Exhaust Vents

1-10 M370430-01 Rev E

Page 31

procedures for inspecting, installing, and testing the power

Installation

2

Chapter 2, Installation, provides information and

supply.

Page 32

Installation

Basic Setup Procedure

Table 2-1 provides a summary of the basic setup procedure with references to the relevant

sections in this chapter. Refer to this table if you are unfamiliar with the installation

requirements for the power supply. Complete each step in the sequence given.

Table 2-1 Basic Setup Procedure

Step Description

1

2

3

4

5

6

7

Inspect

Install

Connect Input

Power

Select Wires

Te s t

Connect Loads

Connect Remote

Sensing (if

required)

Action

Reference

Inspect the power supply. “Step 1: Inspecting and Cleaning”

on page 2-3.

Install the power supply

(benchtop or rack mount).

“Step 2: Location and Mounting” on

page 2-4.

Ensure adequate ventilation.

Connect AC input power. “Step 3: Connecting AC Input

Power” on page 2-5.

Select wires that are correctly

rated for the maximum DC

“Step 4: Selecting Load Wires” on

page 2-8.

output current.

Perform functional tests for

voltage mode operation, current

“Step 5: Performing Functional

Tests” on page 2-10.

mode operation, and front panel

controls.

Connect the load wires to the

DC output.

Connect remote sensing

connectors on power supply to

“Step 6: Connecting Loads” on

page 2-12.

“Step 7: Connecting Remote

Sensing” on page 2-15.

load.

2-2 M370430-01 Rev E

Page 33

Step 1: Inspecting and Cleaning

Initial Inspection

When you first receive your unit, perform a physical check:

1. Inspect the unit for any scratches and cracks, broken switches,

connectors or displays.

2. Ensure that the packing box contains the 7.5 foot (2.5 m)

power cord (supplied with the XG 850 W model only).

3. If you see external damage or suspect internal damage,

contact the carrier immediately.

Periodic Cleaning

The power supply only requires periodic cleaning, not routine servicing.

Whenever a unit is removed from operation, clean the metal surfaces

with naptha or an equivalent solvent, and clean the front panel with a

weak solution of soap and water. Use low-pressure compressed air to