Page 1

Precision Linear DC Power Supplies

XEL Series

Operation Manual

Models:

XEL 15-5

XEL 15-5P(GP)

XEL 30-3

XEL 30-3P(GP)

XEL 60-1.5

XEL 60-1.5P(GP)

XEL 30-3D

XEL 30-3DP(GP)

M370093-01 Rev F www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

XEL & XEL-P Series Precision Linear DC Power Supplies Operation Manual © 2007-2009

AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK

CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS

POSTED AT: WWW.PROGRAMMABLEPOWER.COM

Date and Revision

May 2010 Revision F

Part Number

M370093-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

1

Page 6

Table of Contents

Introduction 4

Specification 5

Safety 8

Installation 9

Connections 10

Manual Operation 13

Remote Analog Control (Single programmable models only) 20

Remote Interface Operation 23

Remote Commands 34

Calibration 39

Maintenance 40

Instructions en Francais

Sécurité 41

Installation 42

Connexions 44

Fonctionnement manuel 48

Commande Analogique Distante (Modèles programmables simples uniquement) 56

Fonctionnement de l’Interface Distante 60

Commandes à distance 71

Entretien 77

Bedienungsanleitung auf Deutsch

Sicherheit 78

Installation 79

Anschlüsse 80

Manueller Betrieb 84

Analogfernsteuerung (nur programmierbare Einzelgeräte) 92

Bedienung der Fernschnittstelle 96

Fernbedienungsbefehle 107

Wartung 112

2

Page 7

Istruzioni in Italiano

Sicurezza 113

Installazione 114

Connessioni 115

Operatività manuale 119

Controllo analogico remoto (Solo modelli programmabili singoli) 126

Operatività con l’interfaccia remota 130

Comandi remoti 141

Manutenzione 146

Instrucciones en Espanol

Seguridad 147

Instalación 148

Conexiones 149

Funcionamiento manual 153

Control analógico remoto (modelos programables únicos solamente) 161

Funcionamiento remoto vía interfaz 165

Comandos Remotos 176

Mantenimiento 180

Warranty Information 181

3

Page 8

Introduction

The XEL Series has the following key features:

• Linear regulation for ultra-low output noise and fast transient recovery

• High accuracy four digit fixed-resolution meters

• True analog controls for quick and intuitive adjustment of voltage and current

• DC output switch to check settings before applying them

• Remote voltage sensing for exceptional load regulation

• Current meter averaging to reduce jitter with rapidly varying load currents

• High power density - up to 94 watts from an ultra-compact 3U ¼-rack case size

• Significantly higher energy efficiency than conventional linear regulated designs by using

an advanced phase-controlled pre-regulator

• Low current range giving ten times greater meter resolution and finer low current setting

• V-Span allows the user to redefine the end-stop values of the voltage control, giving high-

resolution analog control over the exact voltage range needed

• S-Lock digitally locks voltage and current settings at the touch of a button

• Setting limits can be viewed at any time

• Safety binding post terminals are touch-proof and uniquely accept fixed shroud 4mm

plugs as well as standard plugs, bare wires and fork connectors

The XEL-P Series is the programmable (remote control) version of the XEL Series and duplicates

all of its manual control features. RS-232, USB and LXI compliant LAN interfaces are fitted as

standard; GPIB is a factory option.

• Full bus interfacing permitting remote control and readback via either RS232, USB, LAN

(LXI) or GPIB (IEEE-488). GPIB is a factory fitted option.

• Simple command structures which make programming particularly easy regardless of

which interface is used. The commands are consistent with other power supply families

such as the XDL-P making inter-changeability straightforward.

• All power supply settings can be controlled via the bus. Voltage and current can be set to

a resolution of 1mV and 0.01mA (10mV on 120V and 250V models). Actual voltage and

current can be read back together with the power supply status.

• An IVI driver is supplied which provides support for common applications such as

LabView*, LabWindows*, and Agilent VEE**.

• Single XEL-P models additionally offer remote analog control of output voltage and current

which can be used independently or in parallel master-slave configurations. On 120V and

250V models the remote control inputs are galvanically isolated from the output.

* trademarks of National Instruments Corp. ** trademark of Agilent Technologies, inc.

4

Page 9

Specification

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at

23°C. Typical specifications are determined by design and are not guaranteed.

OUTPUTS

Voltage/Current Ranges:

XEL 15-5 0V to 15V/1mA to 5000mA; 0V to 15V/0.1mA to 500mA

XEL 30-3 0V to 30V/1mA to 3000mA; 0V to 30V/0.1mA to 500mA

XEL 60-1.5 0V to 60V/1mA to 1500mA; 0V to 60V/0.1mA to 500mA

XEL 30-3D 0V to 30V/1mA to 3000mA; 0V to 30V/0.1mA to 500mA (each output);

0V to 30V/2mA to 6000mA; 0V to 30V/0.2mA to 1000mA (parallel mode).

Note: In manual operation, actual maxima for voltage and current are typically 1% greater than the

figures given above.

Voltage Setting: By coarse and fine controls.

Current Setting: By single logarithmic control.

Configuration Selection:

(XEL 30-3D only)

Voltage Span Control

(V-Span)

Settings Lock

(S-Lock)

Output Mode: Constant voltage or constant current with automatic cross-over.

Output Switch: Electronic, non-isolating.

Output Terminals: Universal 4mm safety binding posts on 19mm (0·75”) spacing for Output;

Transient Response:

Voltage Programming

Speed (XEL-P models):

Independent, True parallel, Isolated Tracking & Isolated Ratio Tracking

modes via front panel rotary switch.

The voltage adjustment range can be controlled by digital setting of the

end-stop values of the coarse voltage control to any desired values.

The range for Vmax is 0.1V to 15V/30V/60V depending on model.

The range for Vmin is 0 to (Vmax – 0.1V).

Voltage and current settings can be locked by a single button press.

Lock accuracy is equal to meter accuracy (see Meter Specification)

CC indicator lit in constant current mode.

Preset voltage and current limit displayed when Output is off.

Output rise time with no load <15ms.

screwless terminals for Sense.

<50µs to within 50mV of setting for a 90% load change.

Maximum time required for output to settle within 1% of its total excursion

(for resistive load). Excludes command processing time.

Full Load No Load Full Load No Load

15V 5A

15V 500mA

30V 3A

30V 500mA

60V 1·5A

60V 500mA

Ripple and Noise

(20MHz bandwidth):

5

Up

Up

Up

Up

Up

Up

Normal mode voltage: <0·4mVrms and 2mVp-p

Normal mode current: <0·2mArms; <40µArms on 500mA range.

Common mode current: <5µArms

45ms

45ms

45ms

45ms

45ms

70ms

40ms

40ms

40ms

40ms

40ms

40ms

Down

Down

Down

Down

Down

Down

6ms

60ms

20ms

50ms

50ms

110ms

100ms

100ms

150ms

150ms

300ms

300ms

Page 10

Load Regulation: For any load change, measured at the output terminals, using

remote sense:

Voltage <(0·01% + 2mV).

Add typically 2·5mV for a 0·5V drop in the positive output lead.

Specification applies for sense lead resistance <0·5Ω.

Current typically <(0·01% + 500µA).

Line Regulation: Voltage <(0·01% + 2mV) for 10% line change.

Current <(0·01% + 250µA) for 10% line change.

Temperature Coefficient: Voltage: typically <(50ppm + 0·5mV)/°C

Current: typically <(100ppm + 1mA)/°C;

<(100ppm + 0·1mA)/°C on 500mA range.

Output Protection: Output will withstand forward voltages of up to 20V above rated output

voltage. Reverse protection by diode clamp for currents up to 3A.

OTP Protection: Output trips off for over-temperature.

OVP and OCP Protection:

(XEL-P models only)

Measure-and-compare over-voltage and over-current protection are

implemented in firmware and can be set via the remote interfaces only.

Output trips off for OVP and OCP. Setting resolution: 10mV and 1mA.

Response time: typically 500ms.

For manual operation (Local mode) OVP and OCP are fixed at 105% of

the instrument range maximum.

METER SPECIFICATIONS

Display Type: Dual 4-digit meters, 10mm (0·39") LED.

Voltage: Resolution 10mV

Accuracy ± (0·1% of reading + 10mV)

Current: Resolution 1mA; 0·1mA on 500mA range.

Accuracy ± (0·3% + 3mA) to 3A, ± (0·5% + 3mA) to 6A;

± (0·3% + 0·3mA) on 500mA range.

Current Meter Average: Selects a 2s time constant (normally 20ms) for averaging of rapidly

varying load currents.

ADDITIONAL SPECIFICATIONS – XEL 30-3D QUAD-MODE DUAL

Independent Mode: Each output is fully independent and isolated. Operation is equivalent to

two single power supplies.

Tracking Mode:

Tracking Accuracy:

Ratio (%) Tracking Mode:

Tracking Accuracy:

The two outputs remain isolated but the Slave voltage controls are

disabled and the Slave voltage is set equal to the Master voltage.

Slave voltage = Master voltage ±(0.1% of Master voltage ±10mV).

As tracking but the Slave voltage controls set an output voltage between

0% and 101% of the Master voltage. Once set, varying the Master voltage

will create the same percentage change in the Slave voltage setting.

% change in Slave voltage = % change of Master voltage ± 0.1% ±10mV.

Parallel Mode: The Master output operates as a single output power supply with twice

the current capability (0.2mA to 6A). The Slave is disabled (and its

displays are turned off).

Both On / Both Off: Each output has an independent DC On/Off control; these additional keys

can be used to turn both outputs on or off simultaneously. These keys

operate in all four modes.

6

Page 11

ANALOG REMOTE CONTROL (Single XEL-P models only)

Non-isolated inputs and outputs to set voltage and current limit

Control input and

output scaling:

Rear panel control inputs (CV and CC) permit external 0V to 5V or 0 to

10V signals to set 0 to 100% of rated output voltage and current.

Set values of 0 to 100% of rated output voltage and current generate

0 to 5V signals at the rear panel V

out

and I

outputs.

out

These signals are referenced to the positive output.

Control input

accuracy:

Control output

accuracy:

Voltage: 0.3% ±10mV. Input impedance 100kΩ; protected to 60V.

Current: 0.5% ±5mA. Input impedance 64kΩ; protected to 60V.

Voltage: 0.3% ±10mV

Current: 0.5% ±5mA.

Output impedance: 125Ω; output short-circuit protected.

Remote Off: Rear panel socket allows a switch closure or logic low to turn output off.

DIGITAL INTERFACES (XEL-P models only)

Full digital remote control facilities are available through the RS232,USB, LAN and GPIB interfaces

Voltage Setting: Resolution 1mV, Accuracy ± (0·05% + 5mV)

Voltage Readback: Resolution 1mV, Accuracy ± (0·1% + 5mV)

Current Setting and

Current Readback:

Resolution 0.1mA; 0.01mA on 500mA range.

Accuracy ± (0·3% + 3mA) to 3A, ± (0·5% + 3mA) to 6A;

± (0·3% + 0·3mA) on 500mA range.

RS232: Standard 9-pin D-connector. Baud rate 9600.

GPIB (optional): Conforming with IEEE488.1 and IEEE488.2

USB: Standard USB 2.0 hardware connection. Operates as a virtual COM port.

LAN: Ethernet 100/10base-T hardware connection. LXI V1.2, Class C

Remote Command

Processing Time:

GENERAL

AC Input: 230V AC or 115V AC ± 10%, 50/60Hz. Installation Category II

Power Consumption: Single: 280VA max. Dual: 560VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH

Storage Range:

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Cooling: Intelligent variable-speed low noise fan assists convection. Over-

Safety:

compliant.

Typically <25ms between receiving the command terminator for a step

voltage change at the instrument and the output voltage beginning to

change.

−40ºC to + 70ºC

temperature trip shuts down output if internal temperatures exceed

predetermined thresholds.

Complies with EN61010−1

EMC: Complies with EN61326

Size: Single: 107mm x 131mm (¼ rack 3U) x 288mm L (XEL-P: 343mm L),

excluding feet, knobs and terminals.

Dual: 214mm x 131mm (½ rack 3U) x 288mm L, excluding feet, knobs

and terminals.

Weight: Single: 4·5kg (XEL-P: 4.9kg). Dual: 8.5kg.

7

Page 12

Safety

This instrument is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after

switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

8

l

Caution - refer to the accompanying documentation, incorrect operation

may damage the instrument.

Earth (ground) terminal.

mains supply OFF.

mains supply ON.

alternating current (ac)

direct current (dc)

Page 13

Mains Operating Voltage

Check that the instrument operating voltage marked on the rear panel is suitable for the local supply.

Should it be necessary to change the operating voltage, proceed as follows:

1. Ensure that the instrument is disconnected from the AC supply.

2. Remove the plastic push-rivets at each side edge of the top cover. Use the blade of a small

screwdriver to first ease out the rivet head and then fully remove the rivet body. Remove the two

rear panel screws securing the top cover; slide the cover back and lift off.

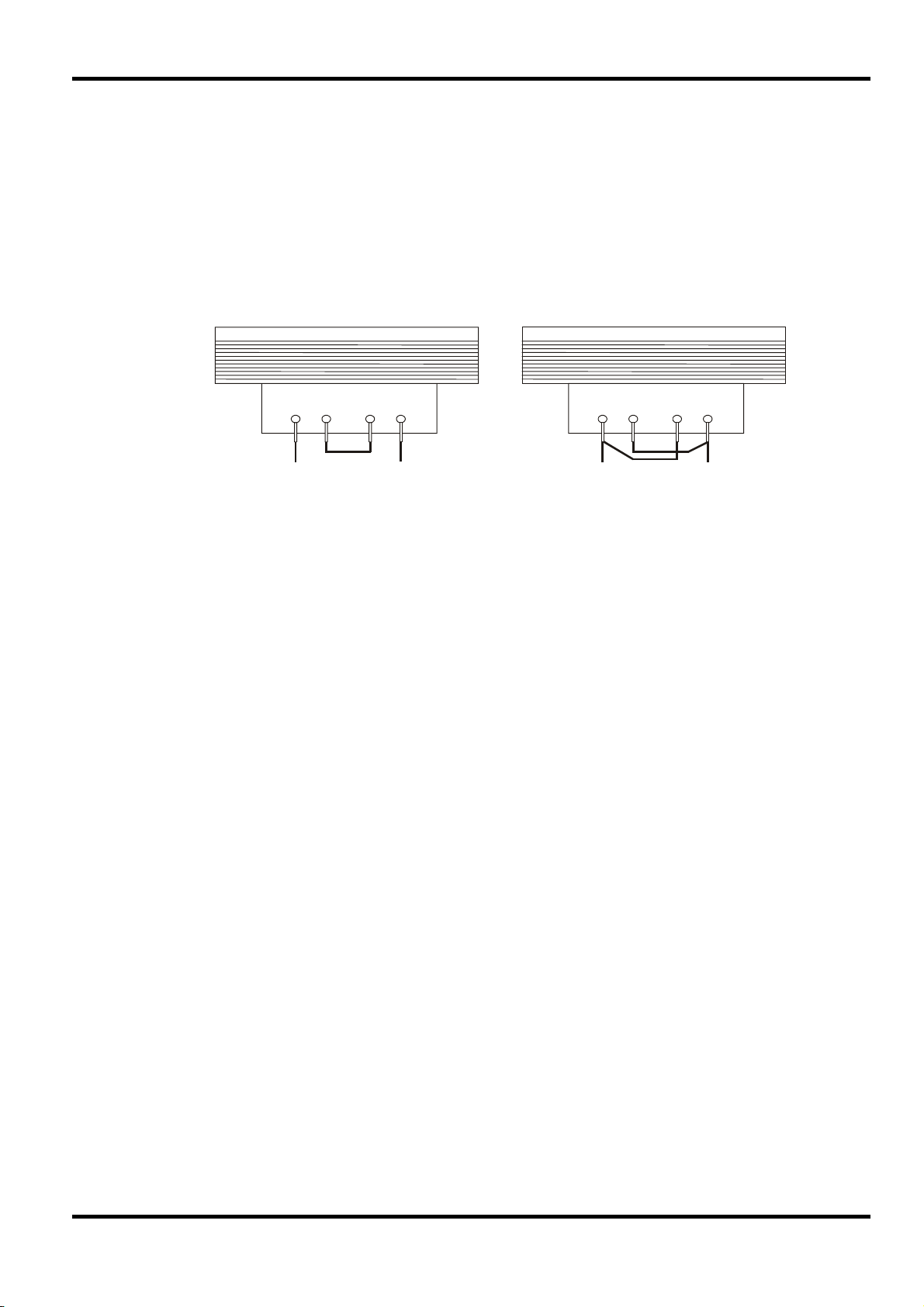

3. Change the transformer connections (two transformers on the dual) following the diagrams:

4. Re-assemble in the reverse order. To comply with safety standard requirements the operating

voltage marked on the rear panel must be changed to clearly show the new voltage setting.

Installation

230V Operation 115V Operation

BLUE BROWN BLUE BROWN

Fuse

The AC fuse is located in the fuse drawer in the lower part of the IEC inlet connector (single units) or

in separate fuseholders for each channel (dual units).

The correct fuse type in all cases is 20 x 5mm 250V HBC time-lag with the following rating:

Make sure that only fuses with the required current rating and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuseholders are prohibited.

Mains Lead

Connect the instrument to the AC supply using the mains lead provided. Should a mains plug be

required for a different mains outlet socket, a suitably rated and approved mains lead set should be

used which is fitted with the required wall plug and an IEC60320 C13 connector for the instrument

end. To determine the minimum current rating of the lead-set for the intended AC supply, refer to the

power rating information on the equipment or in the Specification.

Any interruption of the mains earth conductor inside or outside the instrument will make the instrument

dangerous. Intentional interruption is prohibited.

Mounting

This instrument is suitable both for bench use and rack mounting. A rack kit for mounting in a 19” rack

is available from the Manufacturers or their overseas agents.

230V operation : 1.6A (T)

115V operation : 3.15A (T)

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Ventilation

The power supply is cooled by an intelligent multi-speed fan which aids vertical convection. Take care

not to restrict the air inlets underneath or the vents on the top. When rack-mounted allow adequate

space above and below the instrument and/or use a fan tray for forced cooling.

9

Page 14

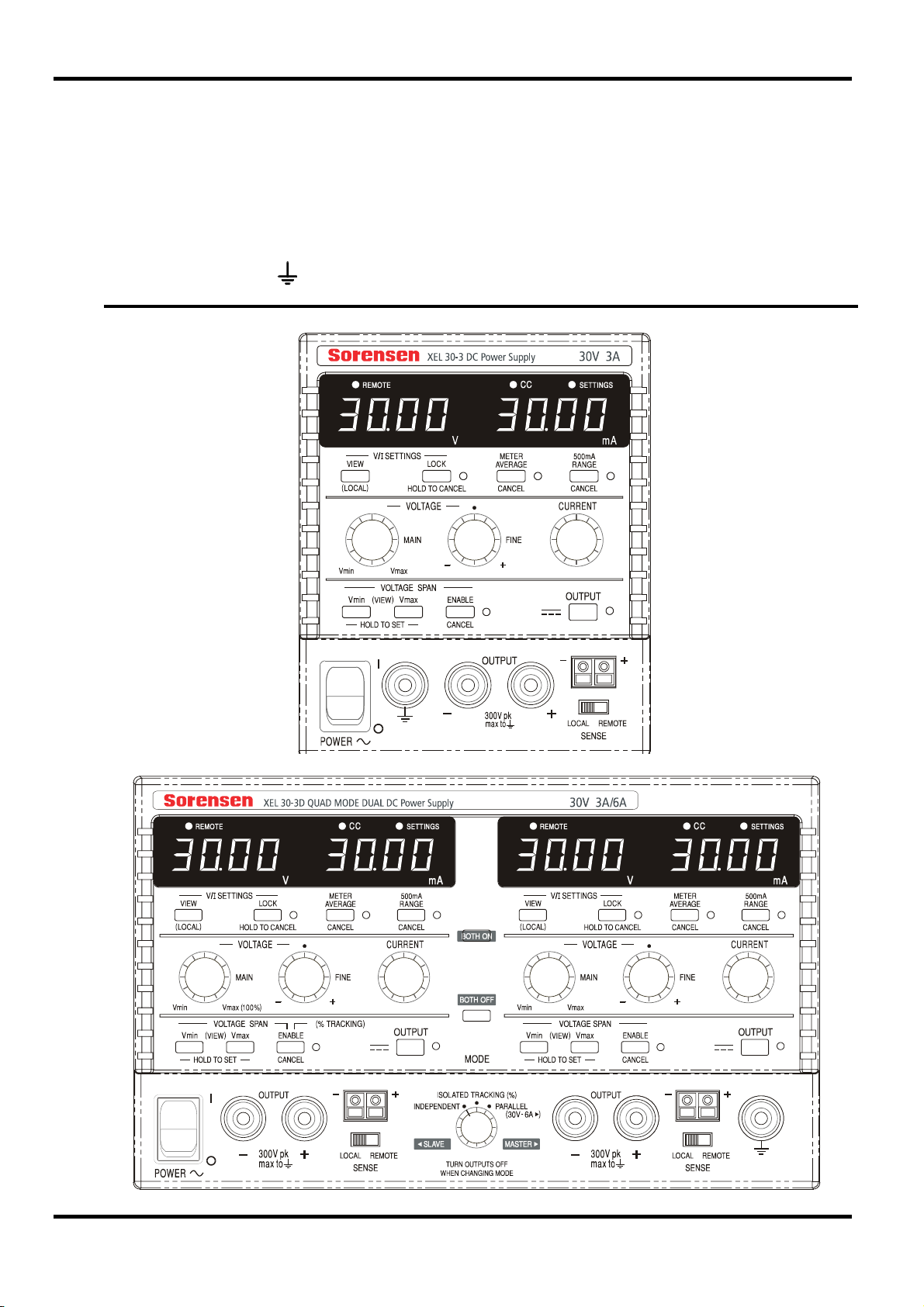

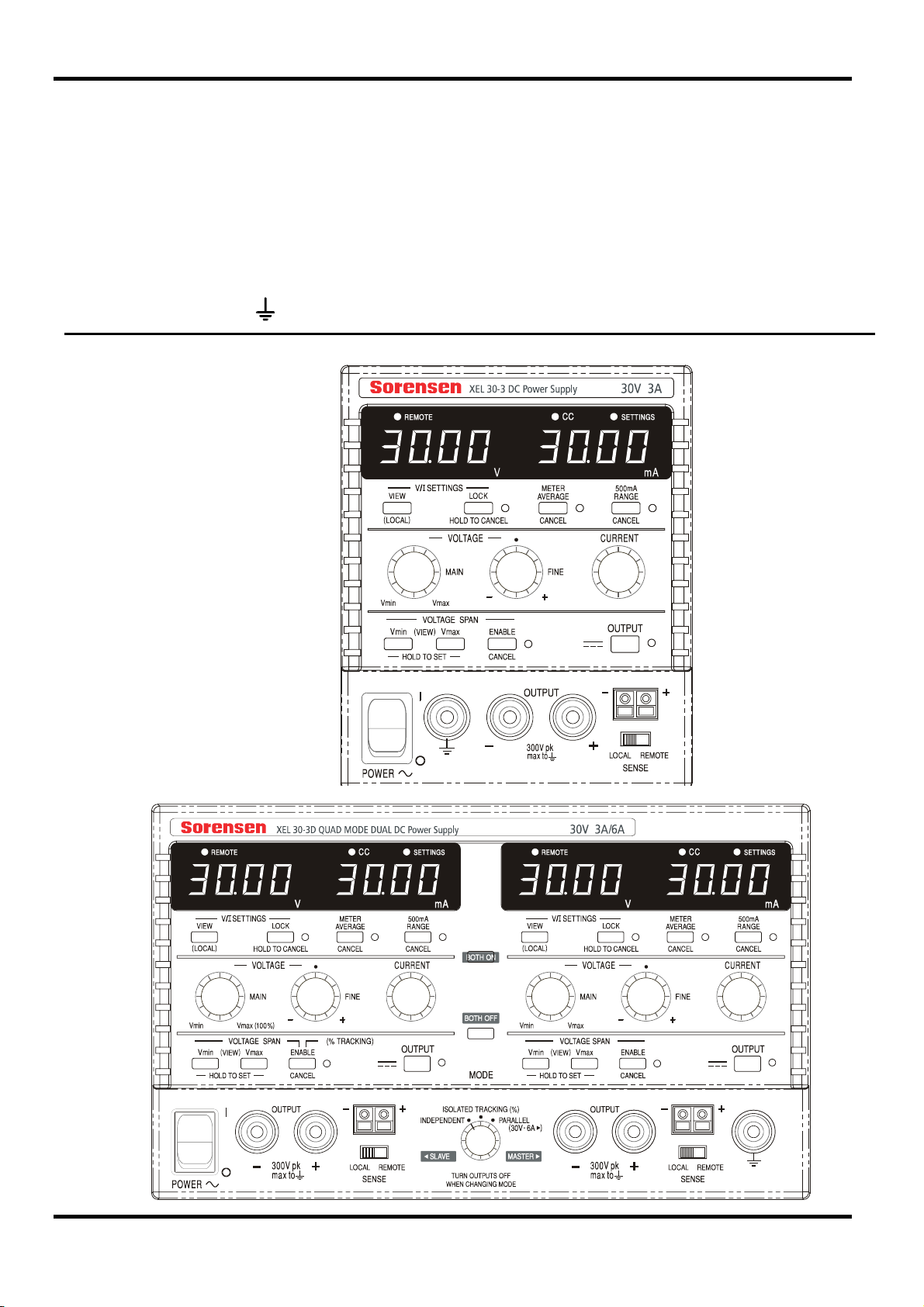

Front Panel Connections

The load should be connected to the positive (red) and negative (black) terminals marked

OUTPUT. Both are fully floating and either can be connected to ground.

Remote sense connections to the load, if required, are made from the positive (+) and

negative (−) SENSE terminals. Switch the LOCAL/REMOTE switch to REMOTE when remote

sensing is required. Switch back to LOCAL when remote sensing is not in use.

The terminal marked

FRONT PANEL VIEW

is connected to the chassis and safety earth ground.

Connections

10

Page 15

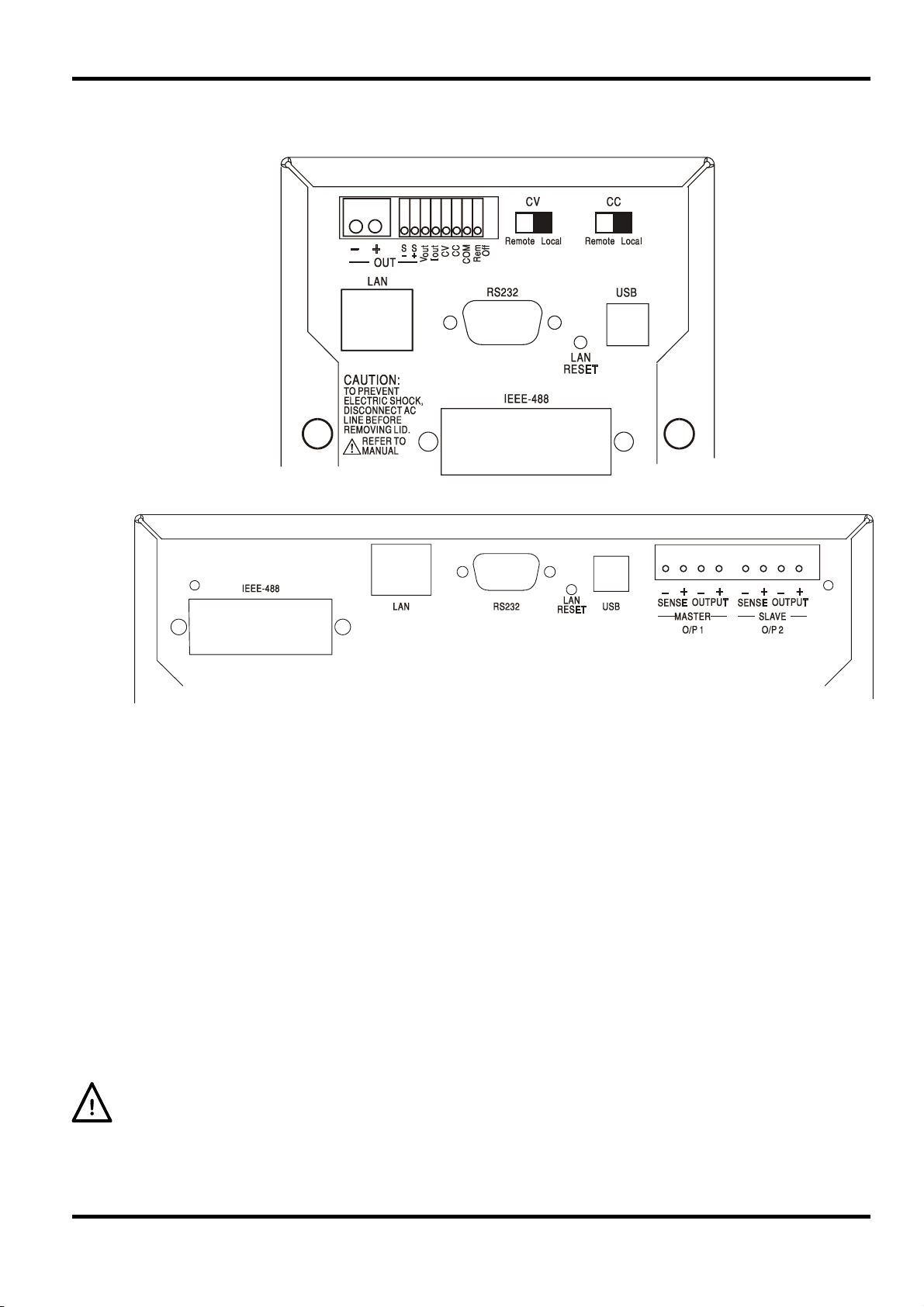

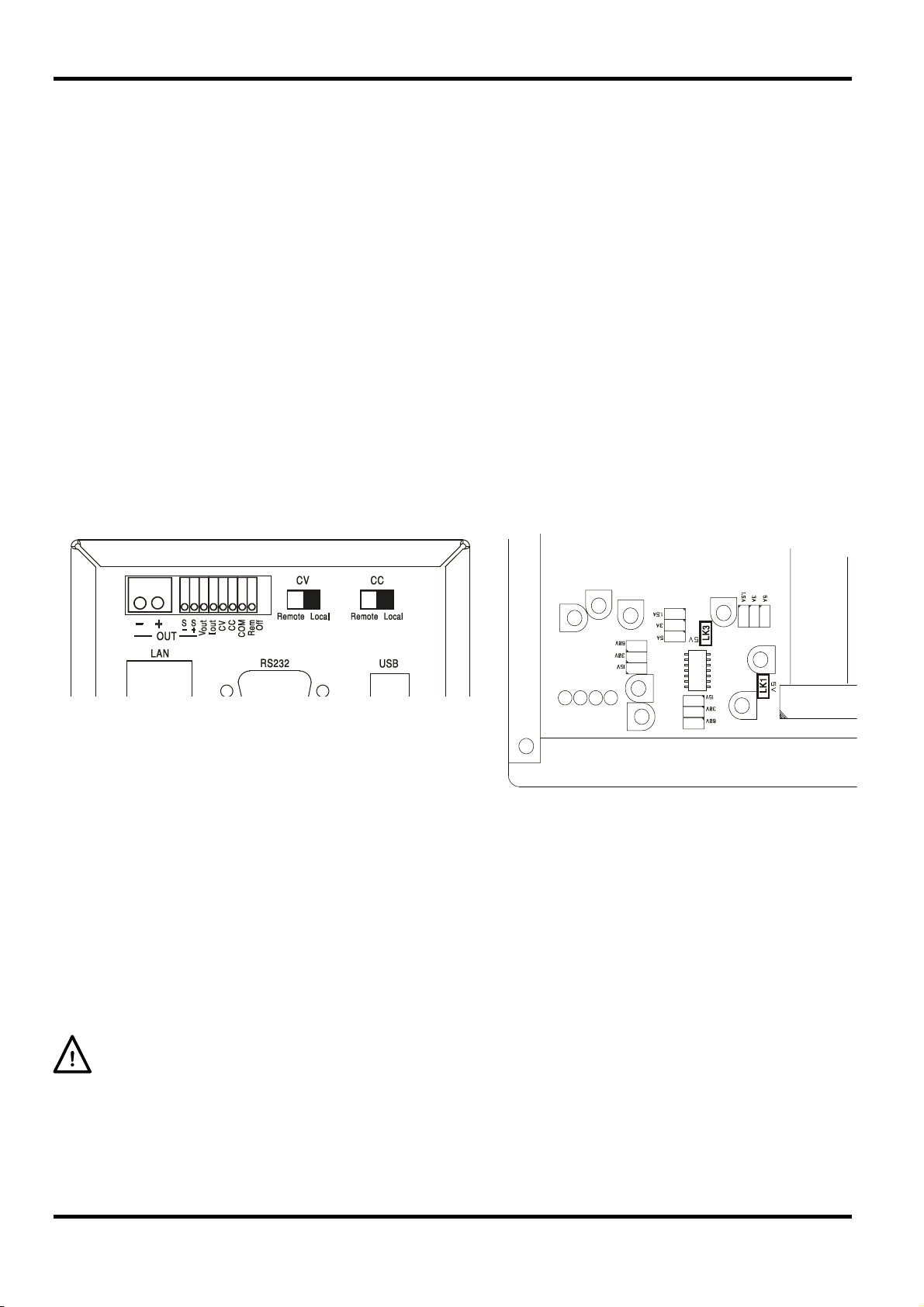

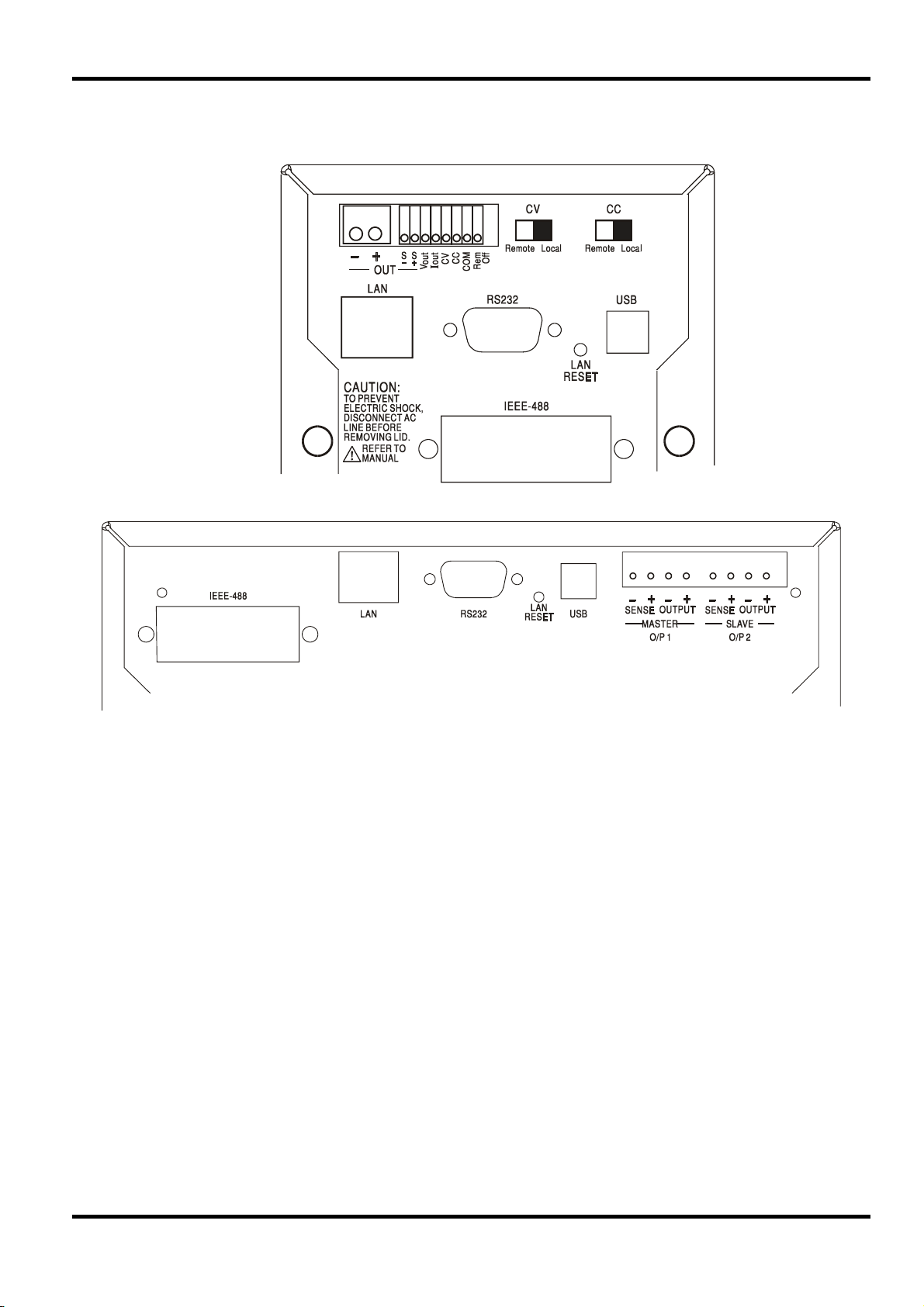

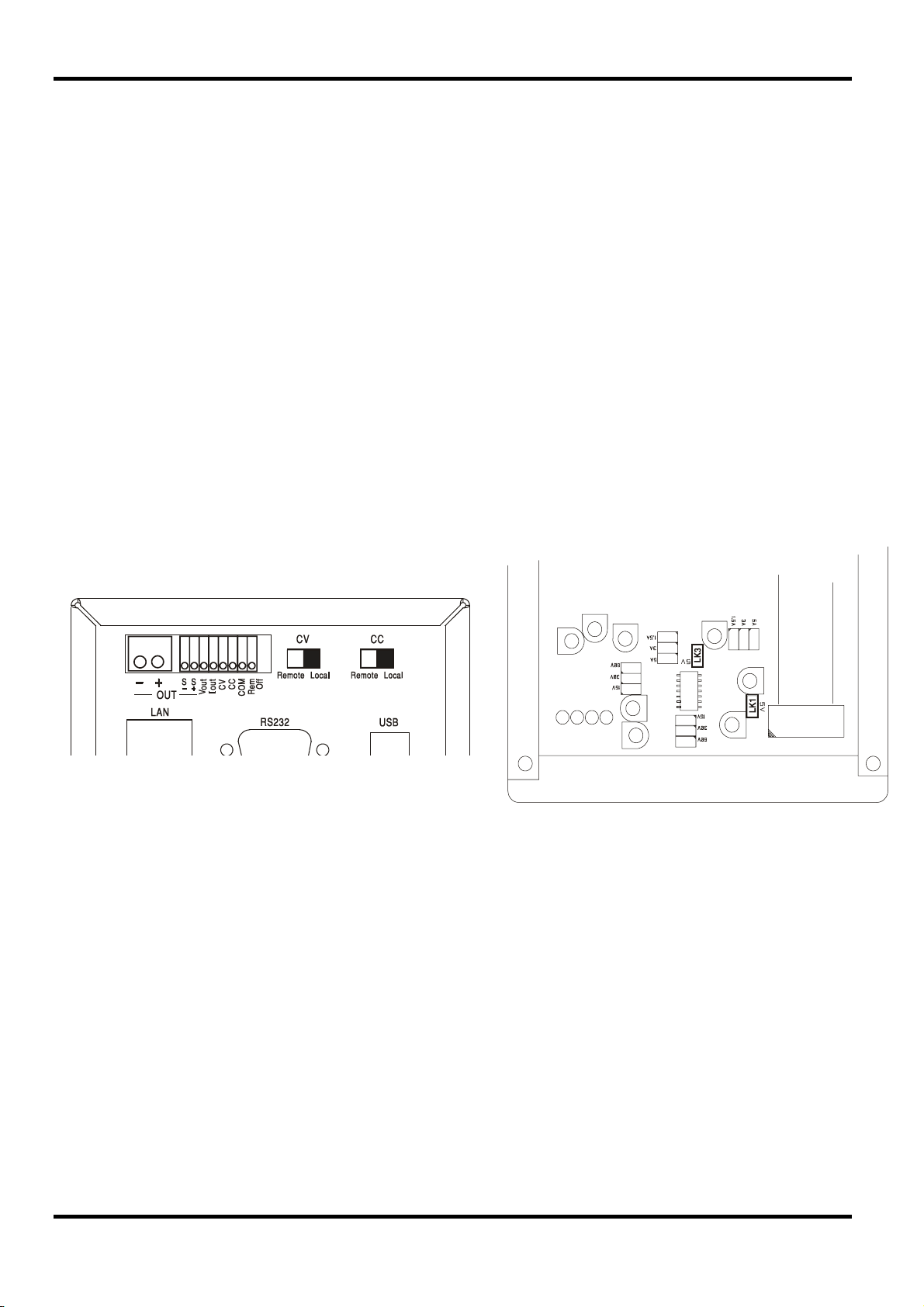

Rear Panel Connections

Non-programmable models have no rear panel connections. The rear panel connections of the

programmable units are shown below:

Main Output and Sense Terminals (all Programmable models)

The Output and Sense terminals are duplicated on the rear panel terminal block marked Output+,

Output −, Sense + and Sense − ; space restrictions on the single units limit the markings to +, −,

S+ and S− in the group marked OUT. These connections are paralleled with their front panel

equivalents.

Switch the LOCAL/REMOTE switch to REMOTE when remote sensing is required. When the

rear panel Output terminals are used, the use of remote sense is always recommended to ensure

that output regulation is maintained within specification; connections can be made to either the

front or the rear remote sense terminals but never to both pairs of terminals at the same time.

Switch back to LOCAL when remote sensing is not in use.

Analog Remote Control (Single Programmable models only)

Connections CV and CC provide analog control of the Output Voltage and Current Limit

respectively when slide switches CV and CC are set to Remote. The input scaling can be set

independently, by internal links, as 0 to 5 Volts (the factory default) or 0 to 10 Volts for 0 to 100%

of maximum output. The COMmon return signal is referenced to the positive output of the power

supply. CV and CC can be used independently or together.

Return slide switches CV and CC to Local when analog remote control is not in use.

Do not apply external voltages between the terminals exceeding the maximum for the selected

range (5V or 10V).

11

Page 16

Analog Out (Single Programmable models only)

Connections V

OUT

and I

provide analog outputs scaled to the set output voltage and set current

OUT

limit respectively. The scaling is fixed at 0 to 5 Volts for 0 to 100% of maximum output. V

I

are always present on the terminals, whether the instrument is under local or remote control.

OUT

The COMMON return signal is referenced to the positive output of the power supply.

Do not apply external voltages to these terminals.

Remote On/Off (Single Programmable models only)

A switch closure or logic low between connections Rem Off and COM will turn off the output. The

COM return signal is referenced to the positive output of the power supply.

Do not apply external voltages to these terminals.

RS232 (XEL-P models only)

9−pin female D−connector with pin connections as shown below. Can be connected to a

standard PC port using a fully wired 1:1 male-female cable without any cross-over connections.

Pin Name Description

1 RI

Passively asserted (+V through 10kΩ)

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 CTS

5 GND Signal ground

6 RTS

Passively asserted (+V through 10kΩ)

7 DSR No internal connection

8 DTR

9 CD No internal connection

Signal ground is connected to instrument ground.

OUT

and

USB (XEL-P models only)

The USB port is connected to instrument ground. It conforms with USB 2.0 (Full Speed) and

accepts a standard USB cable. The Windows plug-and-play functions should automatically

recognize that the instrument has been connected. If the correct driver is not found, follow the

Windows on-screen prompts and install the required files from the CD supplied.

LAN (XEL-P models only)

The LAN interface is designed to meet LXI ( Lan eXtensions for Instrumentation) version 1.2; the

instrument is Class C compliant. Remote control using the LAN interface is possible using a

TCP/IP Socket protocol. The instrument also contains a basic Web server which provides

information on the unit and allows it to be configured. Since it is possible to misconfigure the LAN

interface, making it impossible to communicate with the instrument over LAN, a LAN

Configuration Initialize (LCI) mechanism is provided via a recessed switch on the rear panel

(marked LAN RESET) to reset the unit to the factory default.

Further details are given in the Remote Operation chapter. For more information on LXI

standards refer to www.lxistandard.org/home

GPIB (factory option on XEL-P models only)

The GPIB signal grounds are connected to the instrument ground. The implemented subsets are:

SH1 AH1 T6 TE0 L4 LE0 SR1 RL2 PP1 DC1 DT0 C0 E2

The GPIB address is set from the front panel.

12

Page 17

In this operating manual, front panel keys, controls and sockets are shown in capitals, e.g.

CURRENT, OUTPUT, LOCK. Messages displayed on the 7-segment LEDs are shown in a

different type-font, e.g. turn oFF, OtP trip. The additional features of the Quad-mode Dual

instrument are described together at the end of this chapter.

Switching On and Power-On Conditions

The POWER switch is located at the bottom left of the front panel. When the POWER switch is

turned on (

shows Volts and Amps.

For programmable XEL-P models the default display sequence at power on is different: the right

hand meter briefly indicates the instrument firmware revision followed by the interface firmware

revision (

few seconds, no physical LAN connection is found, the instrument's display will flash alternately

between the normal voltage and current values and the message

seconds. Indication of no LAN connection at power on is an essential LXI compliance

requirement but can be disabled by the 'NOLANOK 1' command over any interface, see the LAN

Error paragraph in the Remote Interface Operation section for further details. This change of

power on setting is retained until reversed by a 'NOLANOK 0' command or by the use of the rear

panel LAN RESET switch to restore the factory default LAN setting, see the LAN paragraph in the

Remote Interface Operation section.

Note that the display messages do not affect the operation of the power supply itself.

At power on, the factory default setting is for the output to be off. The preset output volts and

current will be determined by the present control settings and shown in the display. All other

settings will be the same as they were at last power off.

l ) the right hand meter briefly indicates the firmware revision before the display

IF shows in the left hand meter) before the display shows Volts and Amps. If, after a

Manual Operation

LAn Err, for the next 10

Repeating the procedure will change the setting back to the previous state. Note that the poweron status of the two outputs of the dual supply need to be set individually.

Output Control

Setting Up the Output

With the POWER switch on and the

accurately preset using the VOLTAGE and CURRENT controls; the left-hand meter shows the set

voltage, the right-hand meter shows the set maximum current and the SETTINGS indicator is lit.

When the output switch is switched on, the OUTPUT indicator lights; the left-hand meter now

shows the actual voltage and the right-hand meter the actual load current.

The dc output state at power-on can be set to be ‘always off’ or ‘same as

at last power-off’. The setting can be changed as follows. With the VIEW

key held down, press and hold down the

will first show the present setting for 1 second (

default is still selected) before flashing the new setting for 2 seconds (

LASt Set in this instance). After 2 seconds the new setting is shown

continuously in the display and the change is implemented; release the

OUTPUT and VIEW keys.

OUTPUT off the output voltage and current limit can be

The upper limit of the CURRENT control can be switched

between the maximum for this model and 500mA with

alternate presses of the 500mA RANGE key to give finer

current limit setting and measurement resolution (0.1mA up to

500mA); the indicator beside the key is lit when the 500mA

range is selected.

OUTPUT key; the display

OP OFF if the factory

13

Page 18

To change the current limit range the output must be switched off; if the output is on the warning

message

range remains unchanged.

Constant Voltage

The output voltage is adjusted using the main and fine VOLTAGE controls; the CURRENT control

sets the maximum current that can be supplied.

Constant Current

If the load resistance is low enough such that, at the output voltage set, a current greater than the

current limit setting would flow, the power supply will automatically move into constant current

operation. The current output is adjusted by the CURRENT control and the VOLTAGE controls

set the maximum voltage that can be generated.

The CC indicator lights to show constant current mode.

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 1mA

(0.1mA on 500mA range). However, in common with all precision bench power supplies, a

capacitor is connected across the output to maintain stability and good transient response. This

capacitor charges to the output voltage and loading of the output will produce a current pulse as

the capacitor discharges which is independent of the current limit setting.

Current Meter Averaging

turn oFF is shown briefly in the display, the OUTPUT indicator flashes and the

To reduce the measurement jitter with rapidly varying load

currents a 2-second time constant can be selected by pressing the

METER AVERAGE key; the indicator beside the key lights when

meter averaging is selected. Press the key again to CANCEL

meter averaging and return to the standard 20ms time constant.

Efficiency

The power supply minimizes dissipation by using electronic line frequency pre-regulation to

maintain a low overhead voltage to the output regulators. In addition, to optimize operation at

extremes of line input voltage and DC output power, the transformer secondary is intelligently tapchanged by a relay. Hysteresis is used at the threshold point to prevent unnecessary switching

when the output is set at about that level. Apart from an audible ‘click’ the user will be unaware

that the relay has switched; there will be no disturbance on the output.

Programmable models use special transformers which do not require relay tap-changing.

Connection to the Load

The load should be connected to the positive (red) and negative (black) OUTPUT terminals. Both

are fully floating and either can be connected to ground.

Remote Sensing

The unit has a very low output impedance, but this is inevitably increased by the resistance of the

connecting leads. At higher currents this can result in significant differences between the

indicated source voltage and the actual load voltage (two 20mΩ connecting leads will drop 0.2V

at 5 Amps, for instance)

.

This problem can be minimised by using short, thick, connecting

leads, but where necessary it can be completely overcome by

using the remote sense facility.

This requires the sense terminals to be connected to the output

at the load instead of at the source; insert wires into the springloaded SENSE terminals and connect directly to the load. Switch

the LOCAL/REMOTE switch to REMOTE.

14

Page 19

To avoid instability and transient response problems, care must be taken to ensure good coupling

between each output and sense lead. This can be done either by twisting the leads together or by

using coaxially screened cables (sense through the inner). An electrolytic capacitor directly

across the load connection point may also be beneficial. The voltage drop in each output lead

must not exceed 0.5 Volts.

Switch the LOCAL/REMOTE switch back to LOCAL when remote sensing is not in use.

Output Connection and Remote Sensing on Programmable Models

All programmable models have duplicate rear panel Output and Sense terminals, appropriate for

when the instruments are used in a rack. When the rear panel Output terminals are used, the

use of remote sense is always recommended to ensure that output regulation is maintained within

specification; connections can be made to either the front or the rear remote sense terminals but

never to both pairs of terminals at the same time. Connect the Sense terminals to the load,

following the guidelines above, and set the LOCAL/REMOTE switch to REMOTE.

If the rear panel Output terminals are used without remote sense make sure that the front panel

switch is set to LOCAL. Regulation will be degraded a little when local sense is used because of

the additional small voltage drop in the wiring to the rear terminals.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300V DC.

The maximum permissible voltage between any terminal and earth ground (

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for such use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be

connected in parallel to provide a current equal to the sum of the current limit settings.

Protection

The output has intrinsic short-circuit protection and is protected from reverse voltages by a diode;

the continuous reverse current must not exceed 3 Amps, although transients can be much higher.

If the applied reverse voltage can source more current than the set current limit, and the output is

on, then the output will go into current limit (the CC indicator will flash) and its display will show

the reverse voltage across the protection diode; if the output is off, just the CC indicator will flash.

In common with all series regulated single-ended power supplies, the unit is not capable of

sinking current provided from an external source. If a voltage greater than the set output voltage

of the unit is applied from an external source, the internal regulator will turn off and no current will

flow; if the output is turned on the voltage meter will read the applied voltage. No damage will

result providing the applied voltage does not exceed the maximum output voltage of the power

supply by more than 20 Volts.

) is 300VDC

With the OUTPUT off the load is still connected to the power supply output stage; the output

voltage is simply set to zero. Do not apply external voltages to the power supply terminals in

excess of 20V above the rated output voltage, even with the output off, or damage may result.

15

Page 20

y

Over-temperature Protection

An internal sensor will detect over-temperature due to blocked airflow, fan failure or other circuit

fault. Over-temperature will turn the output off, the OUTPUT indicator will flash, and the display

will show the message

removed, and the instrument has cooled down, the output indicator will go off but the message

OtP triP continues to show. Pressing the OUTPUT key once will change the display to show

the preset voltage and current (the SETTINGS indicator will be lit) but the output will remain off;

pressing it a second time will turn the output on normally.

If the OUTPUT key is pressed while the instrument is still over-temperature (OUTPUT indicator is

flashing), the message

SETTINGS indicator will be lit) but the output will remain off; each subsequent press of the

OUTPUT key causes the

off until the over-temperature condition ends.

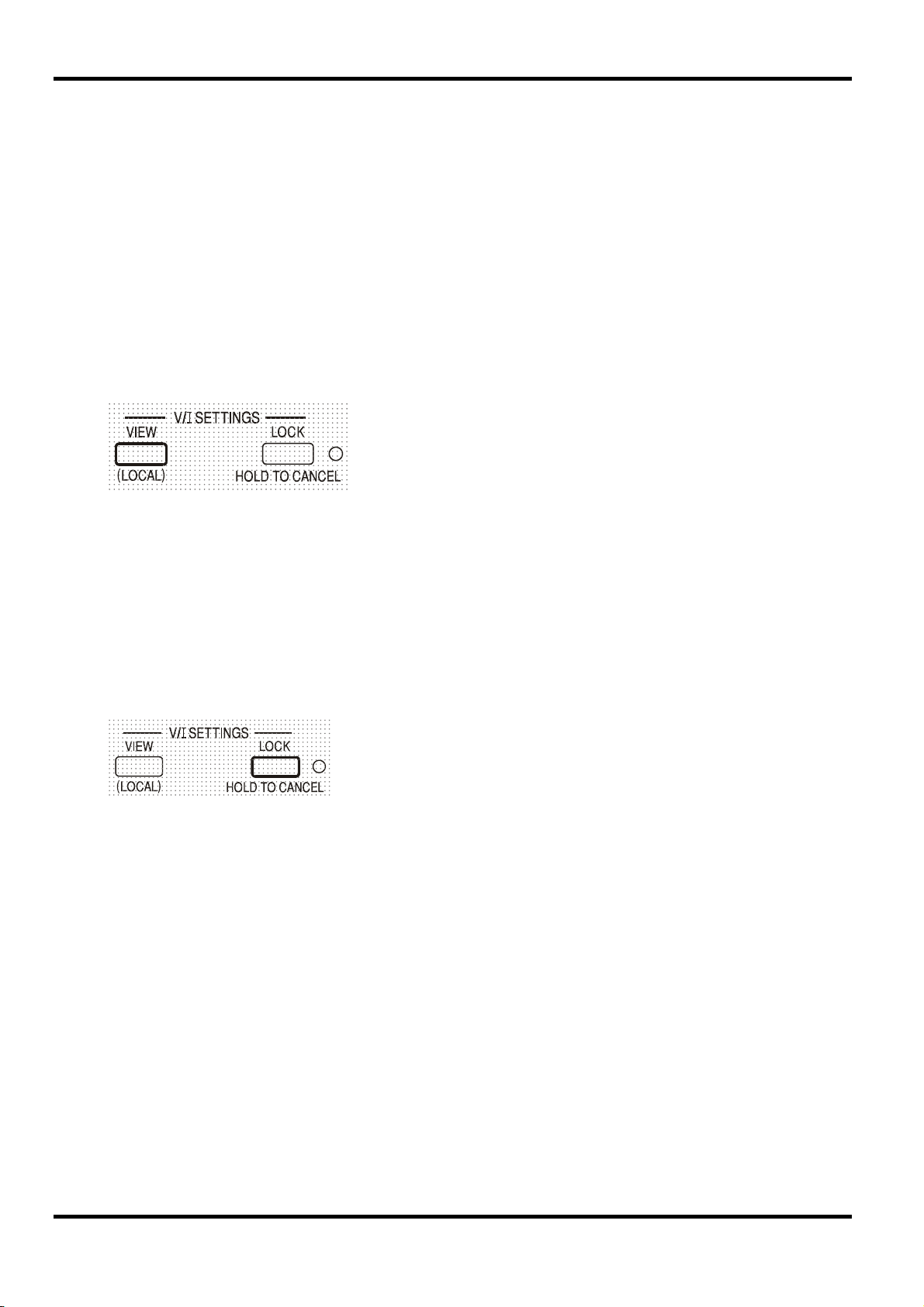

View Settings

Lock Settings

OtP triP . When the cause of the over-temperature has been

OtP triP is replaced by the preset voltage and current (the

OtP triP message to be displayed briefly but the output will remain

The set voltage and current limit are always shown when

the output is off but can also be viewed when the output is

on by pressing the VIEW key; the SETTINGS indicator is lit

whilst the VIEW ke

is pressed.

Pressing the LOCK key digitally locks the set voltage and current limit. The settings are stored

with a precision of better than 1 digit. Subsequent adjustments of the VOLTAGE and CURRENT

controls will have no effect.

Because canceling LOCK will cause the output settings to change if the VOLTAGE and

CURRENT control positions have been moved, warning reminders are given before LOCK is

cancelled. Press and hold the key to cancel LOCK.

If the OUTPUT is off (the safe condition) the display will flash the ‘unlocked’ settings twice before

the change is implemented; the LOCK lamp goes off.

Releasing the LOCK key at any time while the display is flashing will abort the LOCK cancellation.

Attempting to change the current limit range (see Setting up the Output section) or the voltage

span limits (see Voltage Span section) with LOCK enabled is not allowed; if attempted, the

message

output is also on when these actions are attempted the message

the display (accompanied by the output indicator flashing) followed by the message

(with the LOCK indicator flashing).

The LOCK status at power on is the same as at last power off.

Unloc is shown briefly in the display and the LOCK indicator is also flashed. If the

If the output is still on, OP on (output on) will flash twice in the

display, followed by flashing of the new ‘unlocked’ settings for 2-3

seconds (slowly at first, then faster) before the change is finally

implemented; the LOCK lamp goes off when the change is made.

turn oFF is first shown in

Unloc

Using Voltage Span

The VOLTAGE SPAN (V-Span) capability allows the end-stop values of the VOLTAGE controls to

be redefined by the user such that the controls operate within a specific, narrower, voltage range.

This not only has the advantage of protecting against the accidental application to the load of

voltages outside of the range, but also provides high-resolution analog control over the specified

voltage range using the full 300º rotation of the voltage controls.

16

Page 21

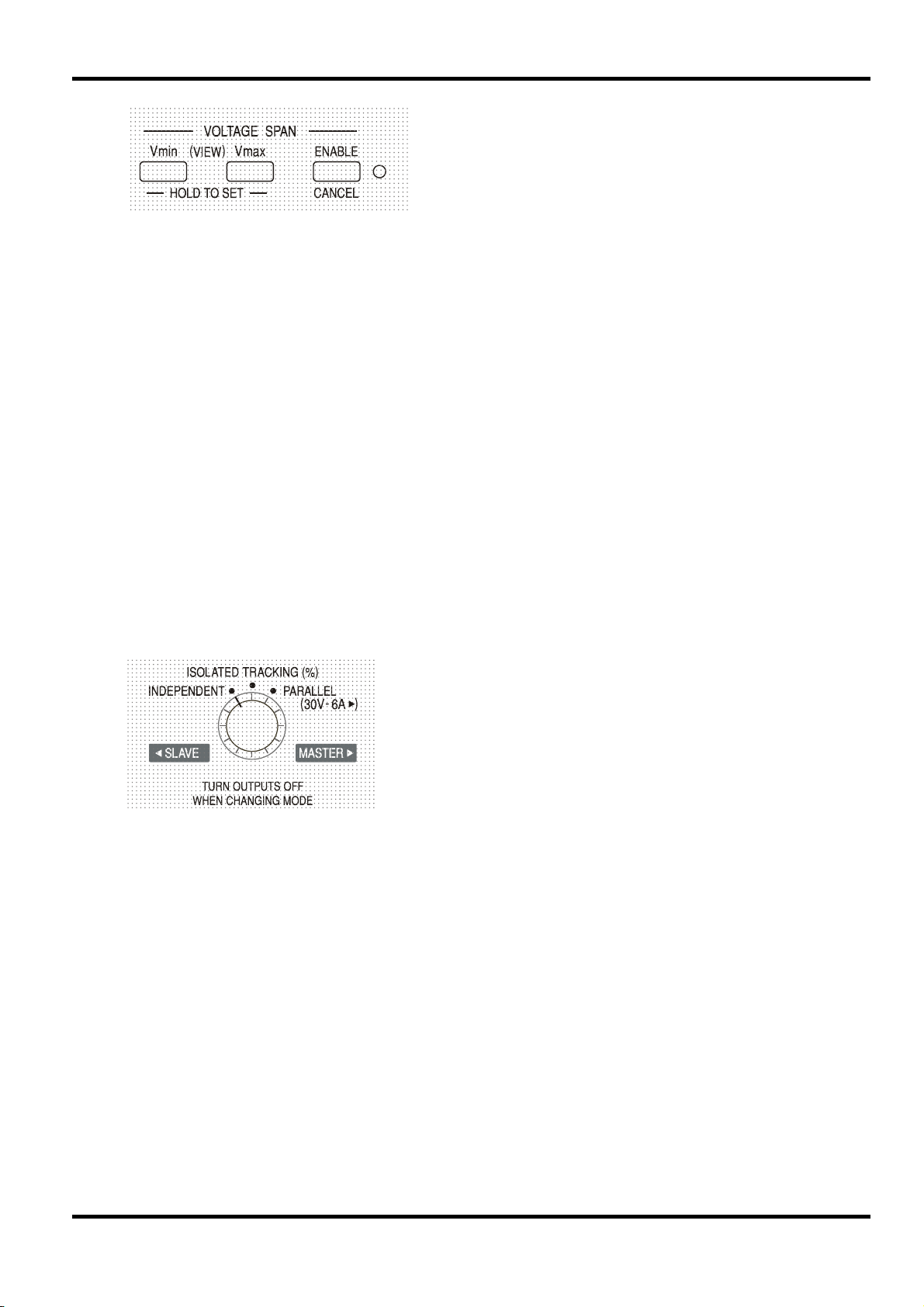

V-Span is turned on or off with the ENABLE key. The

ENABLE lamp is lit when V-Span is selected. The

factory default is V

= 3V, V

min

max

= 5V

Because turning V-Span on will always change the output voltage, it can only be enabled or

cancelled with the output off. If attempts are made to enable or cancel V-Span with the output on,

the display will briefly show the message

turn oFF to prompt the user to turn the output off.

To set new values for V

min

or V

the V-Span function must be off (cancelled).

max

The lower voltage limit is defined by using the MAIN and FINE VOLTAGE controls to set exactly

the required value; the V

key is then held pressed until the left-hand side (V) display stops

min

flashing and the right-hand side (mA) display shows

time by a short press (<1 second) of the V

key. The upper voltage limit is set and VIEWed in

min

exactly the same way using the VOLTAGE controls and the V

The limits can be set in any order and to any value within the output range of the instrument but

V-Span can only be turned on with the ENABLE key if V

met, the message Set Err is briefly displayed and the V-Span function is not implemented.

When V-Span is enabled, the range of the MAIN VOLTAGE control is exactly V

the FINE control is set at its mid-point, marked on the panel with a • . The FINE control itself

can be usefully used to give an additional fine adjustment of ±1% (of the voltage span).

The V-Span status at power on is the same as at last power off.

Mode Control of the Quad-Mode Dual

However, it is not possible to guarantee that there will never be any unwanted transients as the

mode is switched and the recommendation is therefore that both outputs should always be

switched off before any mode change.

The four operating modes of the Quad-Mode Dual are

described below; the mode is changed using the MODE

rotary switch. To prevent unintended voltages being

accidentally applied to the circuits connected to the outputs,

changing modes will always cause both outputs to be

switched off.

Set. The setting can be VIEWed at any

key.

max

max

≥ (V

+ 0.1V); if this condition is not

min

to V

min

max

when

Independent

Set the MODE switch to INDEPENDENT. The two outputs are completely independent and

electrically isolated; each can be set as described in the preceding Output Control section.

It is not possible to switch from Independent mode to Tracking with LOCK set on the Slave

output. The message

Un loc is shown in the Slave display and LOCK must first be switched

off (in Independent mode) before the Tracking modes can be used.

See also the Retained Slave Settings paragraph.

Isolated Tracking

Set the MODE switch to ISOLATED TRACKING. The two outputs remain electrically isolated but

the Voltage controls of the Master output set an identical voltage on the Slave output. The

Current controls of the Slave remain independent, including the 500mA Range and Meter

Average functions.

17

Page 22

The electrical isolation permits the two outputs to be connected to provide, for example, tracking

voltages of opposite polarity or identical voltages connected to different system references (e.g.

digital ground and analog ground).

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously

and, because the output voltage of the Slave tracks the Master, they control the Slave output

voltage as well. Note that only the output voltage of the Slave is ‘locked’ when the Master LOCK

is used; the current controls of the Slave, including the 500mA Range and Meter Average

functions, remain independent.

The LOCK key on the Slave output is ignored and pressing it causes the message

be shown momentarily in the Slave display as a reminder.

It is possible to switch from Tracking mode back to Independent mode with LOCK still set on the

Master. The ‘Master’ (right-hand output) settings stay ’locked’ but the settings of the left-hand

output, are not locked.

The Voltage Span keys of the Slave have a different function in Tracking mode, see next section.

Isolated Ratio (%) Tracking

Set the MODE switch to ISOLATED TRACKING.

The instrument operates as described above for Tracking mode but the Slave voltage can be set

to a percentage (0% to 101%) of the Master voltage using the Slave Voltage controls. The ratio is

then maintained as the Master voltage is varied.

Pressing ENABLE again returns the Slave to standard Tracking mode (ENABLE lamp off).

Ratio Tracking can only be enabled or disabled with the Slave output off. If the output is on the

display will briefly show the message

not be implemented.

Whenever Ratio Tracking mode is enabled the Slave display momentarily shows

before reverting to show the actual output voltage now set.

In trac to

Ratio Tracking is enabled by pressing the

ENABLE key in the Slave VOLTAGE SPAN

section (ENABLE lamp on)

turn oFF when ENABLE is pressed and the change will

Pcnt on

Parallel

18

The percentage value can be shown at any time by pressing either the V

Slave output. With either key held down the Slave display shows the percentage setting in the

form

90.0 Pcnt and the Slave Voltage controls can be used to set the ratio percentage

required. The ratio percentage can be set prior to Ratio Tracking being enabled (ENABLE lamp

off).

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously.

However, with Ratio Tracking enabled, the Slave Voltage controls can still be used to adjust the

ratio percentage of the Slave voltage even though the Master voltage is locked. The Ratio

Tracking mode status at power on is the same as at last power off. See also the Retained Slave

Settings paragraph.

The MODE switch is set to PARALLEL. The instrument operates in true parallel mode with all of

the power available from the Master output which can then supply up to 6 amps. The Slave

output is disabled and its displays are turned off.

In Parallel mode the value of the current limit is doubled for the same setting of the Current limit

control, including the 500mA range which becomes 1000mA max; as a warning, when Parallel

mode is first selected, the current display flashes twice before steadily displaying the new limit.

Similarly, the current display is flashed twice when the mode is changed from Parallel to Tracking,

as a warning that the Master output current limit has now halved.

min

or V

key of the

max

Page 23

The LOCK and VOLTAGE SPAN functions of the Master operate exactly as described previously.

It is possible to switch from Parallel mode back to Tracking mode (and vice-versa) with LOCK still

set on the Master; both the Voltage and Current controls of the Master stay in LOCK, as

described previously. However, the actual set current limit of the Master will still double (switching

from Tracking to Parallel) or halve (switching from Parallel to Tracking), even though LOCK is set,

but the current display flashes as a warning that this has happened.

Retained Slave Settings

If V-Span is enabled on the Slave output in INDEPENDENT mode, it is disabled when TRACKING

mode is selected but re-enabled when INDEPENDENT mode is re-selected.

If Ratio (%) Tracking is enabled on the Slave output in TRACKING mode, it is disabled when

INDEPENDENT or PARALLEL are selected but re-enabled when TRACKING mode is reselected.

Simultaneous Output On/Off Control

The Both On / Both Off keys are in addition to the individual OUTPUT switches

and permit both outputs to be turned on or off synchronously with a single key

press. The Both On / Both Off keys operate in all four configuration modes.

19

Page 24

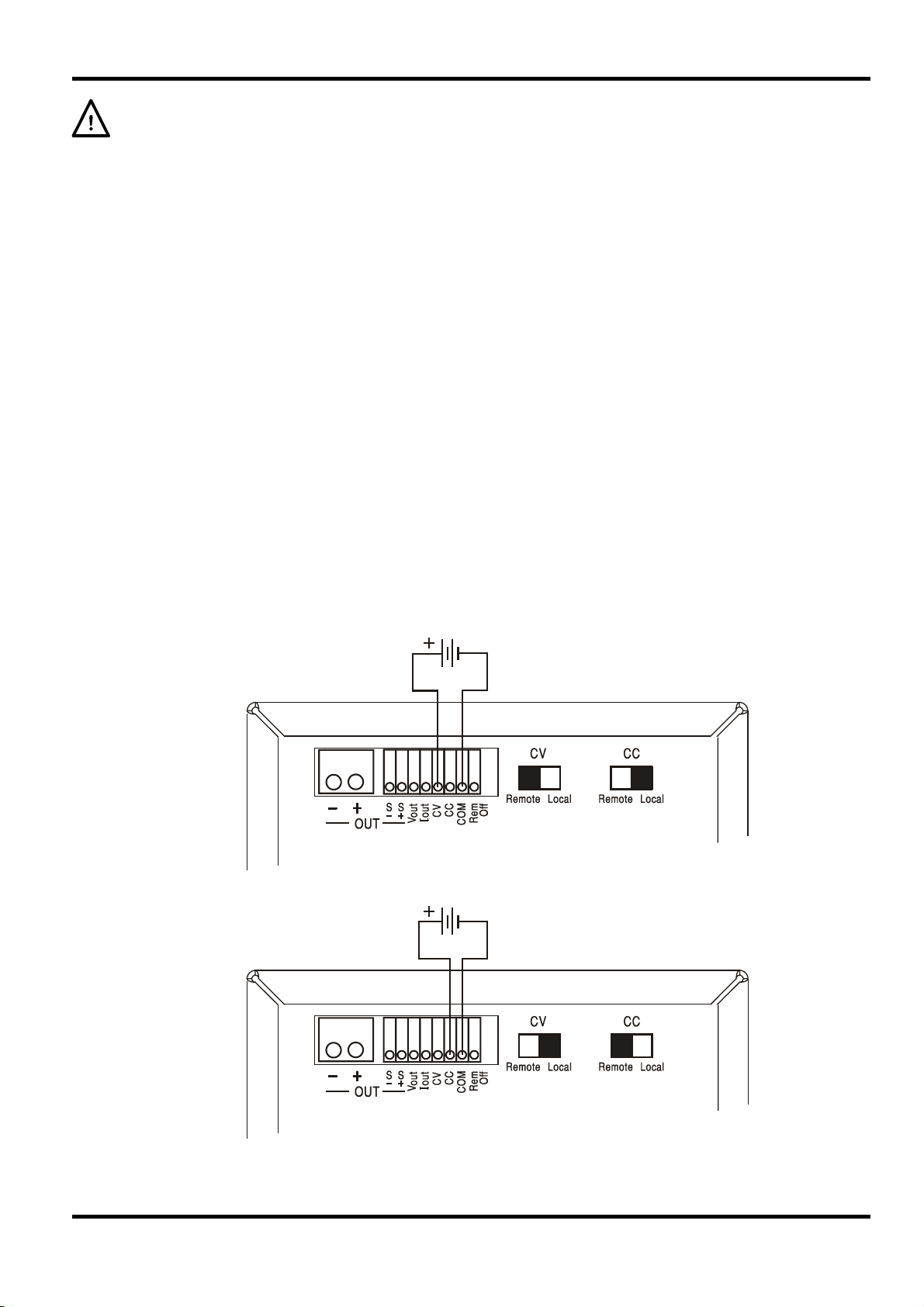

Remote analog control of output voltage and current is possible using variable external control

voltages applied between the rear panel CV and COM or CC and COM inputs respectively.

The Analog Out control voltages V

control a ‘slave’ unit via the slave’s CV and CC inputs respectively.

Analog Voltage Control

Remote analog voltage control is achieved by setting the rear panel CV switch to Remote and

applying a programming voltage between the inputs CV and COM.

The front panel VOLTAGE controls are disabled when Remote is set on the CV switch. Set the

switch to Local to return control to the front panel.

The default input voltage scaling is 0V to 5V for 0 to 100% of the rated output voltage. The input

voltage scaling can be changed to be 0V to 10V by removing an internal shorting link.

Disconnect the instrument from the AC source and remove the cover as described in the

Installation section. Referring to the top view of the instrument shown in the drawing, remove the

tall shorting link in position LK1.

Remote CV can be used with either Local or Remote CC.

Remote Analog Control

(Single programmable models only)

out

and I

of one unit acting as a ‘master’ can be used to

out

Analog Current Control

Remote analog constant current control is achieved by setting the rear panel CC switch to

Remote and applying a programming voltage between the inputs CC and COM. Remote analog

current control can only be used on the high current range, not the 500mA range.

The front panel CURRENT control is disabled when Remote is set on the CC switch. Set the

switch to Local to return control to the front panel.

The default input voltage scaling is 0V to 5V for 0 to 100% of the rated maximum current (high

range only). The input voltage scaling can be changed to be 0V to 10V by removing an internal

shorting link. Disconnect the instrument from the AC source and remove the cover as described

in the Installation section. Referring to the top view of the instrument shown in the drawing,

remove the tall shorting link in position LK3.

Remote CC can be used with either Local or Remote CV.

CAUTION. Do not apply external control voltages to either the CV or CC input that exceed the

maximum for the set input range (5V or 10V). The inputs are protected against excess voltages

but the instrument will attempt to supply an output voltage or current in excess of its maximum

rating if the control voltage exceeds its range limit, with possible consequential damage. If the

condition persists, OVP and/or OCP may trip the output off, see next section.

20

Page 25

OVP and OCP

OVP (over-voltage protection) and OCP (over-current protection) are implemented in firmware

and can only be set and used when under remote control via the RS232, USB, LAN (LXI) or GPIB

interfaces. Setting resolutions are 10mV and 1mA and typical response times are 500ms.

However, in local mode, OVP and OCP are still active but automatically default to 105% of the

instrument's range maximum. This usefully provides shut-down protection in the event of

prolonged application of a CV or CC control voltage which attempts to set the output beyond

105% of the range maximum.

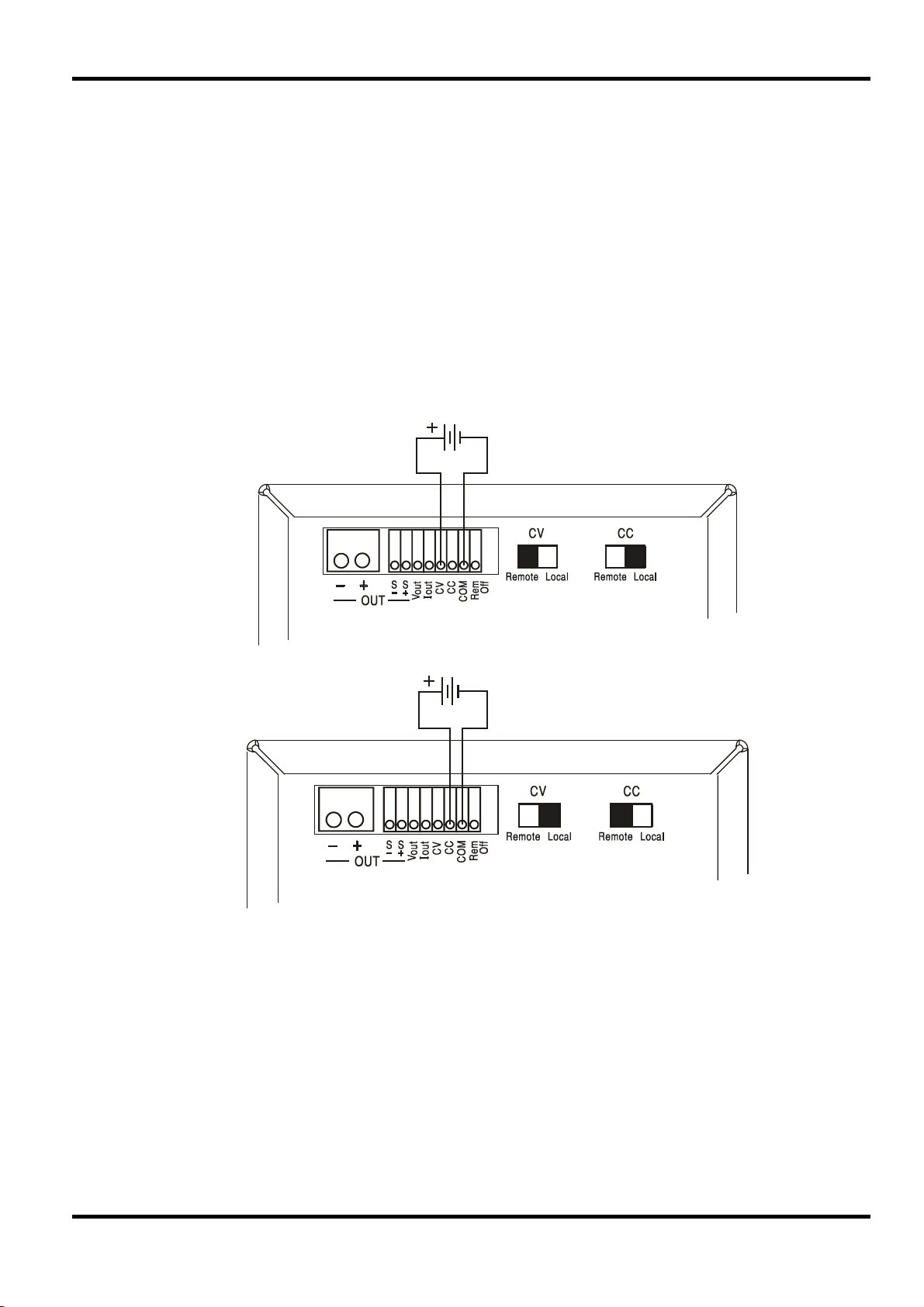

Practical Considerations when using CV and CC

The stability of the control voltages directly affects the stability of the output. Any noise on the

control signals will generate noise on the output. To minimize noise on the output connect the

control voltages to the CV, CC and COM inputs using twisted or screened pairs (screens

grounded at one end only) and keep the connections as short as possible. The diagrams below

show the connections for Constant Voltage (CV) and Constant Current (CC) control using an

external voltage.

Constant Voltage Control

Note that when the OUTPUT is on, the instrument’s display always shows the actual output

voltage and current, whichever control source is active. However, when the OUTPUT is off, the

display will show the preset voltage and current set by the front panel controls (or the digital

interface if active) and not the values determined by the CV and CC inputs even if they have been

made active (CV and CC set to Remote). To avoid confusion it is good practice to set the front

panel controls to minimum when remote CV and CC are used.

Analog Out Control Voltages

Analog Out control voltages V

for which the active source can be the front panel controls, the digital interface (RS232, USB,

LAN or GPIB) or the remote analog inputs CV and CC. V

100% of the rated output voltage and current (high range only) generate 0V to 5V at the rear

panel V

I

always corresponds to the set current, whether the output is on or off, but V

out

out

and I

terminals with respect to COM. COM is connected to the positive output.

out

the output is off.

Constant Current Control

and I

out

are generated from the actual internal control voltages,

out

out

and I

are scaled such that 0 to

out

goes to 0V when

out

21

Page 26

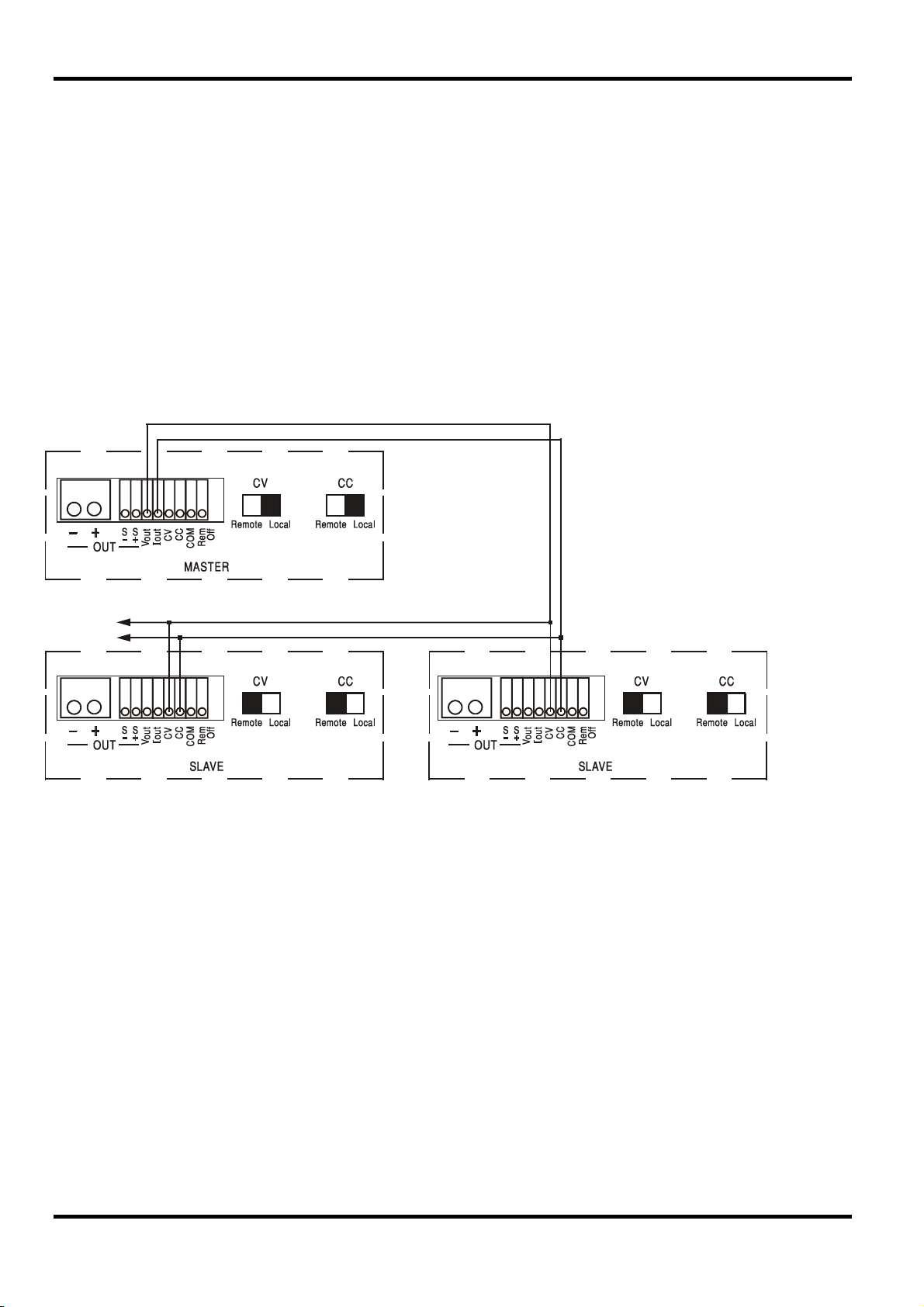

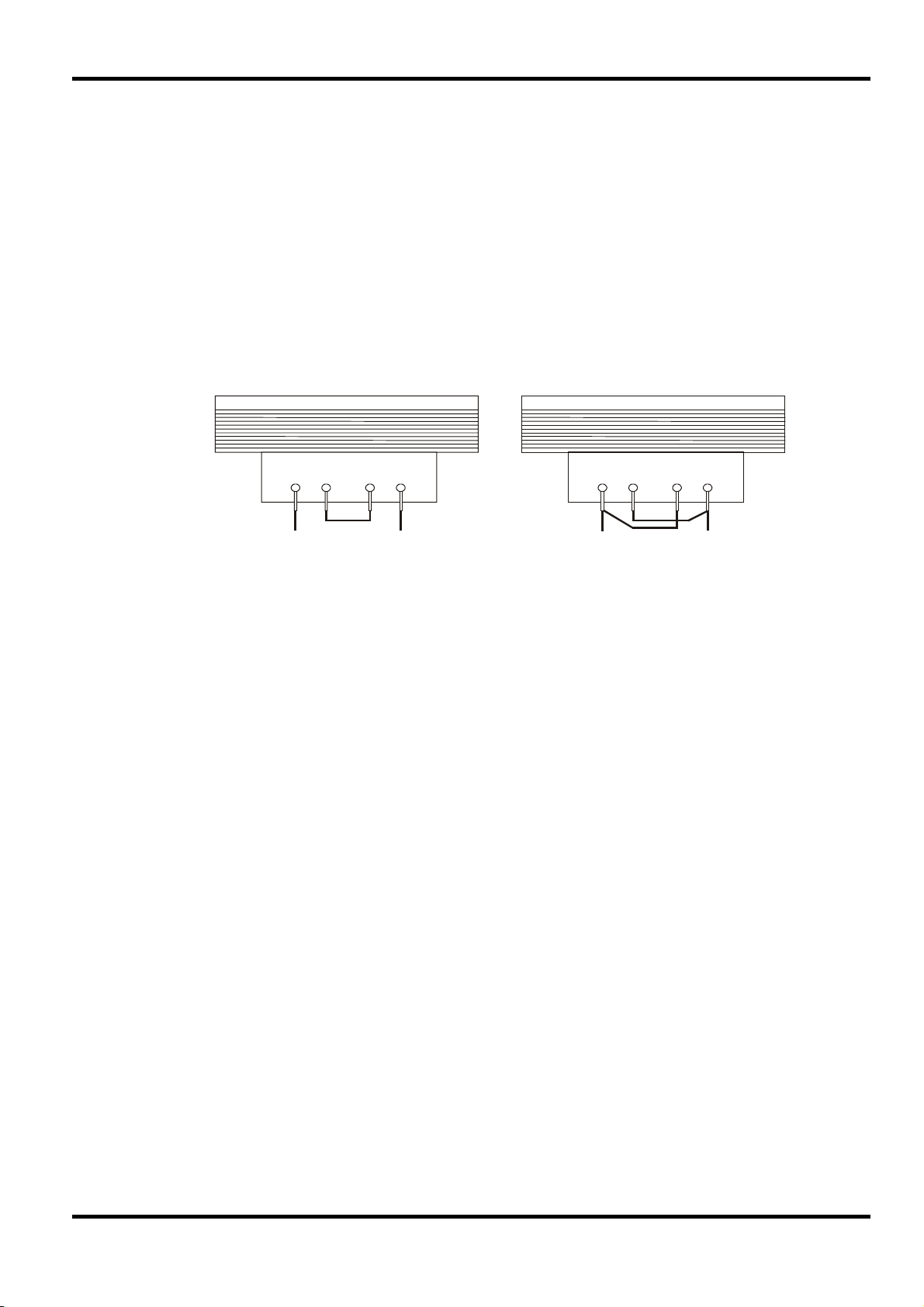

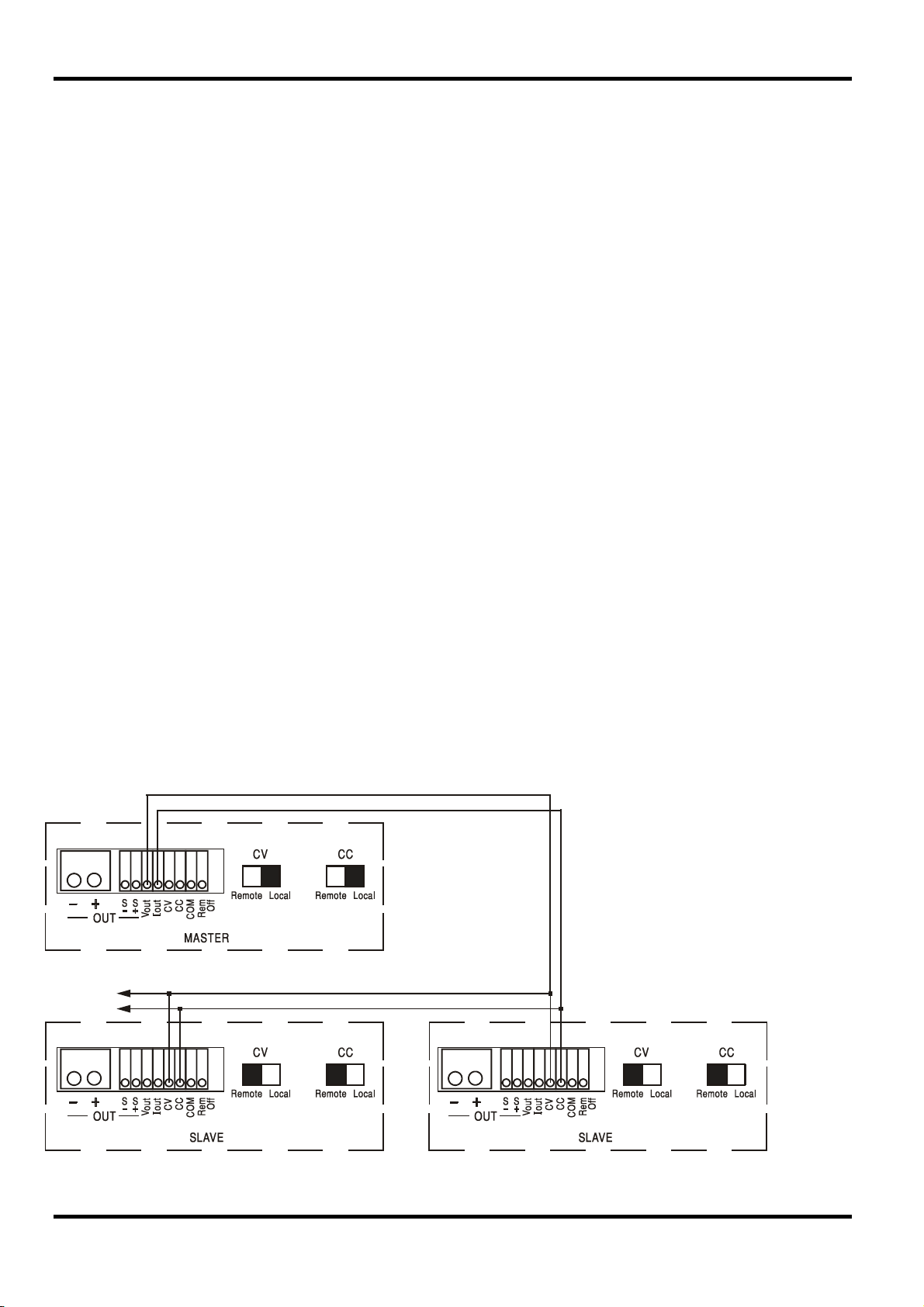

Parallel Operation in Master-Slave Configuration

Parallel operation in Master-Slave configuration permits higher output currents to be realized with

equal current sharing between units and control of both voltage and current from a single unit. All

units should be of the same type, i.e. same rated output voltage and current. The diagram shows

3 units connected in parallel. For equal current sharing each unit must be independently

connected to the load with pairs of wires of equal gauge and length to ensure equal voltage

drops. Connect the V

out

and I

of the master to the CV and CC inputs of the slaves (set CV and

out

CC switches to Remote) as shown.

Note: Do not make connections to the COM inputs of the slaves because these are already

linked to the master via the positive output connections.

The voltage and current of the master can be set by either the front panel controls via the digital

interface, or by an external voltage applied to its own CV and CC analog control inputs.

Parallel Operation in Master-Slave Configuration

Notes:

1. Units can be wired for CV (constant

voltage, CC (constant current) or both (both

shown). Set CV and/or CC switches of

slaves to Remote.

2. Connect outputs in parallel using equal

length wires to the load.

3. If remote sensing is required use only

remote sense from the master to the load.

4. For constant current operation set the

required voltage overhead on the master.

In constant voltage mode the voltage across the load is that set on the master unit by its front

panel controls, via the digital interface or by the analog CV remote control input. The current limit

for the system (i.e. the current in constant current mode) is the current limit set on the master x n,

where n is the total number of units connected in parallel.

Note: Because the analog remote control inputs are not isolated (COM is connected to the

positive output terminal) it is not possible to use analog remote control with instruments

connected in series.

Remote Off

A switch closure or logic low between the rear panel Rem Off and COM inputs will remotely turn

off the output if it was previously on; the front panel OUTPUT lamp will also go off. Opening the

switch between Rem Off and COM will turn the output on again.

22

Page 27

The instrument can be remotely controlled via its RS232, USB, LAN or GPIB (optional) interfaces.

Analog remote control is described in the previous section.

USB remote control operates in a similar way to RS232 but via the USB connector. Software

supplied with the instrument sets up the controlling computer to treat the USB connection as a

virtual COM port. Application software on the computer can then access the instrument via that

COM port.

The LAN interface is designed to meet LXI ( Lan eXtensions for Instrumentation) version 1.2; the

instrument is Class C compliant. Remote control using the LAN interface is possible using the

TCP/IP Sockets protocol. The instrument also contains a basic Web server which provides

information on the unit and allows it to be configured from a web browser. Simple command line

control from the browser is also possible.

The instrument is supplied with RS232, USB, and LAN as standard; GPIB is an option. All

interfaces are, by default, live at all times (a LXI requirement) but access to individual interfaces

may be restricted using the configuration options on the web pages.

Interface Locking

All interfaces are live at all times; this removes the need to select the active interface and is also

a LXI requirement. To reduce the risk of the instrument being inadvertently under the control of

two interfaces at once a simple lock and release mechanism is provided in the instruction set.

The lock is automatically released where it is possible to detect disconnection and when the local

button is pressed. Access to the interfaces may also be restricted using the web pages.

Remote Interface Operation

Any interface may request to have exclusive control of the instrument by sending an “IFLOCK”

command. The lock may only be released by sending an “IFUNLOCK” command from the

interface instance that currently has the lock and may be queried from any interface by sending

an “IFLOCK?” command. The reply to any of these commands will be “-1” if the lock is owned by

another interface instance, “0” if the interface is free and “1” if the lock is owned by the requesting

interface instance. Sending any command from an interface without control privileges that

attempts to change the instrument status will set bit 4 of the Standard Event Status Register and

put 200 into the Execution Error Register to indicate that there are not sufficient privileges for the

required action.

Note: it is also possible to configure the privileges for a particular interface to either ‘read only’ or

‘no access’ from the Web page interface.

Address Selection

The instrument address capability is strictly required only by the GPIB interface. However, use

can be made of the ADDRESS? command over any of the interfaces to easily identify which

instrument is being controlled by a particular COM port (for RS232 or USB) or TCP socket (for

LAN). Note that the LAN interface also has a separate ‘Identify’ function, accessible from the

instrument’s web pages, that flashes the instrument’s display until the function is cancelled.

The address is set from the instrument’s front panel as follows. Start with the instrument off and,

with the Lock, Meter Average and Current Range keys all held down (SLAVE output only on dual),

switch the instrument on. The display will show

display where

and incremented by the Meter Average and Current Range keys respectively in the range 1 to 31

inclusive (not 0), with 'wrap-round'. The address is confirmed and the process exited by holding

down the Lock key; the display will show

seconds, returning to the normal Volts and mA display when the new address has been accepted.

nn is the present setting (default Addr 11 ). The address can be decremented

Addr in the Volts display and nn in the mA

SEt and the new address for approximately 2

The address can also be set from the instrument’s web pages.

23

Page 28

Remote/Local Operation

At power-on the instrument will be in the local state with the REMOTE indicator off. In this state

all front panel operations are possible. When the instrument is addressed to listen and a

command is received the remote state will be entered and REMOTE will be turned on. In this

state the front panel is locked out and remote commands only will be processed. The V/I settings,

Meter Average setting, Current Range and output state(s) are unchanged but LOCK and V-Span

are cancelled if they were on. The Vmin and Vmax values are retained. The MODE (XDL-P

models only) and Sense settings remain as set by the front panel switches. The instrument may

be returned to the local state by pressing the LOCAL key; however, the effect of this action will

only remain until the instrument is addressed again or receives another character from the

interface, when the remote state will once again be entered. Returning to Local by this action, or

by the use of the LOCAL command, will keep the V/I settings at their last remotely set values,

with Lock Settings on, and will leave the output(s) in their present state.

RS232 Interface

RS232 Interface Connector

The 9-way D-type serial interface connector is located on the instrument rear panel. The pin

connections are as shown below:

Pin Name Description

1 RI Passively asserted (+V through 10kΩ)

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 CTS

5 GND Signal ground

6 RTS Passively asserted (+V through 10kΩ)

7 DSR No internal connection

8 DTR

9 CD No internal connection

RS232 Connections

The RS232 interface should be connected to a standard PC port using a fully wired 1:1 malefemale cable without any cross-over connections. Alternatively, only pins 2, 3 and 5 need be

connected to the PC, but with links made in the connector at the PC end between pins 1, 4 and 6

and between pins 7 and 8, see diagram.

24

Page 29

Baud Rate for this instrument is fixed at 9600; the other parameters are fixed as follows:

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

RS232 Character Set

Because of the need for XON/XOFF handshake it is possible to send ASCII coded data only;

binary blocks are not allowed. Bit 7 of ASCII codes is ignored, i.e. assumed to be low. No

distinction is made between upper and lower case characters in command mnemonics and they

may be freely mixed. The ASCII codes below 20H (space) are not used. In this manual 20H, etc.

means 20 in hexadecimal. The unit will send XOFF when there are 50 free bytes remaining and

XON when this increases to 100 bytes.

USB Interface

The USB interface is a virtual COM port which can be controlled by a PC as if it was a RS232

device. The instrument is supplied with a CD containing an .inf file for the standard Microsoft

drivers available in Windows 2000, XP, Vista and Windows 7; the installation wizard will install the

driver (32-bit or 64-bit) appropriate to the PC’s operating system. Any updates are available via

the AMETEK website, www.programmablepower.com .

Installation of the interface driver is achieved by connecting the instrument to a PC via a standard

USB cable. The Windows’ plug and play functions should automatically recognize the addition of

new hardware attached to the USB interface and, if this is the first time the connection has been

made, prompt for the location of a suitable driver. Provided that the standard Windows prompts

are followed correctly Windows will install the appropriate driver and establish a virtual COM port

within the PC. The number of the new COM port will depend upon the number of co-existing

COM ports within the PC. The virtual COM port can be driven by Windows applications in exactly

the same way as a standard COM port, except that the Baud rate setting of the virtual COM port

is ignored.

LAN

The driver will remain installed on the PC so that the establishment of a virtual COM port is done

automatically each time the instrument is connected to the PC via USB in the future.

Further virtual COM ports are created for each additional instrument connected to the PC via

USB. Each instrument is assigned a separate virtual COM port when it is first connected and the

same COM port will be assigned each time that instrument is subsequently connected; the PC

software makes use of the unique code embedded in each instrument to link it to the same virtual

COM port irrespective of which physical USB port it is connected to.

Use can also be made of the ADDRESS? command to easily identify which instrument is being

controlled by a particular COM port. Although the addressing capability is ignored in USB

operation the address can still be set and used as an identifier; set each USB-connected

instrument to a different address and send the ADDRESS? command from each virtual COM port

to confirm which instrument is connected to that port.

The LAN interface is designed to comply with the LXI standard version 1.2 and contains the

interfaces and protocols described below. Since it is possible to misconfigure the LAN interface,

making it impossible to communicate with the instrument over LAN, a LAN Configuration Initialize

(LCI) mechanism is provided via a recessed switch on the rear panel to reset the unit to the

factory default. The default setting is for the instrument to attempt to obtain settings via DHCP if

available or, if DHCP times out (30 seconds), via Auto-IP. In the very unlikely event that an AutoIP address cannot be found a static IP address of 192.168.0.100 is assigned. Resetting the LAN

removes any password protection.

For more information on LXI standards refer to www.lxistandard.org/home .

25

Page 30

LAN Connection

To use the LAN interface, the IP address of the unit must be known. There is a LXI Discovery

Tool on the supplied CD-ROM which can be used to display the IP addresses (and other

associated information) of all connected devices that comply with the VXI-11 discovery protocol.

This tool is a Windows PC application that should be installed and run on the controlling PC with

the unit either connected directly to the PC network connector or via a router. Connecting via a

router is recommended as this is significantly quicker to assign an IP address; connecting directly

to the PC will begin to assign an IP address only after a 30 second DHCP timeout. Double

clicking on any entry in the list of devices discovered will open the PC's web browser and display

the Home page of that device.

There are also tools for LAN discovery included as part of the National Instruments Measurement

and Automation Explorer package and the Agilent Vee application.

The unit will, when first powered up, attempt to obtain settings via DHCP if available or, if DHCP

times out (30 seconds), via Auto-IP. In the very unlikely event that an Auto-IP address cannot be

found a static IP address of 192.168.0.100 is assigned. If a connection is still not made the

instrument will flash LAn Err in the display, see LAN Error section for details.

Web Server; Configuration Password Protection

The unit contains a basic web server. This provides information on the instrument and allows it to

be configured. The Configure page can be password protected to deter unauthorized changes to

the remote operation configuration; the default configuration is ‘no password’.

The Configure page itself explains how to set the password. The password can be up to 15

characters long; note that the User Name should be left blank. The password will, however, be

reset to the default (no password) if the rear panel LAN RESET switch is used to reset all the LAN

parameters to their factory default.

The web pages also have an ‘Identify’ function which allows the user to send an identifying

command to the instrument which causes its display to flash until the command is cancelled.

ICMP Ping Server

The unit contains an ICMP server allowing the instrument to be ‘pinged’ via either its host name

or IP address.

VXI-11 Discovery Protocol

The instrument has very limited support of VXI-11 which is sufficient for the discovery protocol

and no more.

The instrument implements a Sun RPC Port-mapper on TCP port 111 and UDP port 111 as

defined in RPC1183. The calls supported are: NULL, GET PORT and DUMP.

On TCP port 1024 a very simple VXI-11 protocol is implemented sufficient only for instrument

discovery. This implements the following calls: CREATE LINK, DEVICE_WRITE, DEVICE_READ

and DESTROY_LINK.

Once a link has been created anything written to the device is ignored and any read from the

device returns the identification string as would be expected from a “*IDN?” of the form

26

‘Manufacturer,Model,Serial No.,X.xx – Y.yy’

for example

SORENSEN, XEL601P,279730,1.00 – 1.00

where ‘X.xx’ is the revision of the main firmware and ‘Y.yy’ is the revision of the interface

firmware. Interface firmware is user field updateable via the USB port.

Page 31

VISA Resource Name

Because of the limited support for VXI-11(Discovery Protocol only), the instrument must be

referred to by its raw socket information when used in software packages which communicate via

a VISA resource name. For example, an instrument at IP address 192.168.1.100 would normally

have a VISA resource name of "TCPIP0::192.168.1.100::inst0::INSTR" but for this instrument the

name must be modified to read "TCPIP0::192.168.1.100::9221::SOCKET" where 9221 is the TCP

port used by this instrument for control and monitoring, see below.

XML Identification Document URL

As required by the LXI standard, the instrument provides an XML identification document that can

be queried via a GET at “http://<hostname>:80/lxi/identification” that conforms to the LXI XSD

Schema (available at http://www.lxistandard.org/InstrumentIdentification/1.0) and the W3C XML

Schema Standards ( http://www.w3.org/XML/Schema ). This document describes the

instrument.

TCP Sockets

The instrument uses 2 sockets on TCP port 9221 for instrument control and monitoring. Text

commands are sent to this port as defined in ‘Remote Commands’ and any replies are returned

via the same port. Any string must be one or more complete commands. Commands may be

separated with either semicolons “;” or line feeds. No terminator is required since the TCP frame

contains complete commands though commands may be sent with a terminator if desired (it will

be ignored). Each command over TCP behaves as if it is terminated with a command terminator

(ASCII character 0AH, line feed).

LAN Error

If a LAN connection is made but an error is detected (e.g. the IP address is the same as another

device on the network) then the instrument’s display will flash alternately between the normal

voltage and current values and LAn Err, until the error is corrected. If a LAN error occurs;

check and correct the configuration of the instrument; a LAN Configuration Initialize (LCI)

mechanism is provided via a recessed switch on the rear panel ( marked LAN RESET) to reset

the unit to the factory default. The default setting is for the instrument to attempt to obtain

settings via DHCP if available or, if DHCP times out (30 seconds), via Auto-IP. In the very unlikely

event that an Auto-IP address cannot be found a static IP address of 192.168.0.100 is assigned.

The display will also flash alternately between the normal values and

LAN connection is found at power on, but will stop flashing after 10 seconds. To disable this

message at every power on send the command 'NOLANOK 1' over any interface. To re-enable

the message at power on send the command 'NOLANOK 0 ' or use the recessed rear panel LAN

RESET switch to reset all LAN parameters to their factory default settings, see the introduction to

the LAN section.

GPIB Interface

The GPIB interface 24-way connector is located on the instrument rear panel. The pin

connections are as specified in IEEE Std. 488.1-1987 and the instrument complies with IEEE Std.

488.1-1987 and IEEE Std. 488.2-1987.

GPIB Subsets

LAn Err if no physical

This instrument contains the following IEEE 488.1 subsets:

Source Handshake SH1

Acceptor Handshake AH1

Talker T6

Listener L4

Service Request SR1

27

Page 32

Remote Local RL2

Parallel Poll PP1

Device Clear DC1

Device Trigger DT0

Controller C0

Electrical Interface E2

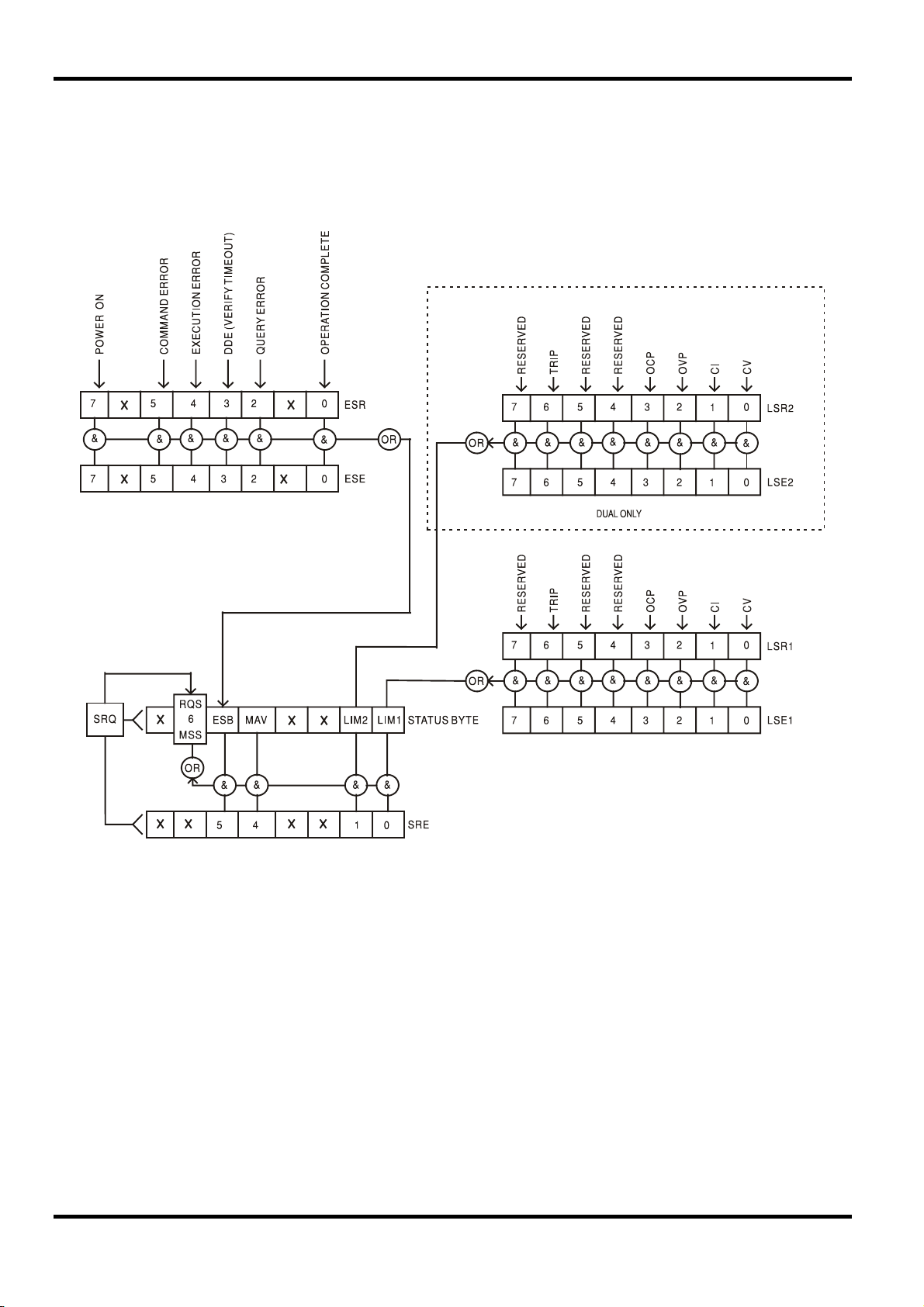

Query Error Register - GPIB IEEE Std. 488.2 Error Handling

The IEEE 488.2

If the instrument is addressed to talk and the response formatter is inactive and the input queue is

empty then the

the Standard Event Status Register, a value of 3 to be placed in the Query Error Register and the

parser to be reset. See the Status Reporting section for further information.

The IEEE 488.2

send a response message and a

or the input queue contains more than one END message then the instrument has been

INTERRUPTED and an error is generated. This will cause the Query Error bit to be set in the

Standard Event Status Register, a value of 1 to be placed in the Query Error Register and the

response formatter to be reset thus clearing the output queue. The parser will then start parsing

the next

<PROGRAM MESSAGE UNIT> from the input queue. See the Status Reporting section for

further information.

The IEEE 488.2

a response message and the input queue becomes full then the instrument enters the

state and an error is generated. This will cause the Query Error bit to be set in the Standard Event

Status Register, a value of 2 to be placed in the Query Error Register and the response formatter

to be reset thus clearing the output queue. The parser will then start parsing the next

MESSAGE UNIT> from the input queue. See the Status Reporting section for further information.

GPIB Parallel Poll

Complete parallel poll capabilities are offered on this instrument. The Parallel Poll Enable

Register is set to specify which bits in the Status Byte Register are to be used to form the

message The Parallel Poll Enable Register is set by the *PRE <nrf> command and read by the

*PRE? command. The value in the Parallel Poll Enable Register is ANDed with the Status Byte

Register; if the result is zero then the value of

UNTERMINATED error (addressed to talk with nothing to say) is handled as follows.

UNTERMINATED error is generated. This will cause the Query Error bit to be set in

INTERRUPTED error is handled as follows. If the response formatter is waiting to

<PROGRAM MESSAGE TERMINATOR> has been read by the parser

DEADLOCK error is handled as follows. If the response formatter is waiting to send

DEADLOCK

<PROGRAM

ist local

ist is 0 otherwise the value of ist is 1.

28

The instrument must also be configured so that the value of

ist can be returned to the controller

during a parallel poll operation. The instrument is configured by the controller sending a Parallel

Poll Configure command (PPC) followed by a Parallel Poll Enable command (PPE). The bits in

the PPE command are shown below:

bit 7 = X don't care

bit 6 = 1

bit 5 = 1 Parallel poll enable

bit 4 = 0

bit 3 = Sense sense of the response bit; 0 = low, 1 = high

bit 2 = ?

bit 1 = ? bit position of the response

bit 0 = ?

Page 33

Example. To return the RQS bit (bit 6 of the Status Byte Register) as a 1 when true and a 0 when

false in bit position 1 in response to a parallel poll operation send the following commands

*PRE 64

The parallel poll response from the instrument will then be 00H if RQS is 0 and 01H if RQS

is 1.

During parallel poll response the DIO interface lines are resistively terminated (passive