Page 1

XDL Series II

DC Power Supply

Digital Programmable DC P ow er Supply

Operation Manual

Models:

XDL 35-5

XDL 35-5P

XDL 35-5T

XDL 35-5TP

XDL 56-4

XDL 56-4P

XDL 56-4T

XDL 56-4TP

M370499-01 Rev A www.programmablepower.com

Page 2

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

XDL Series II DC Power Supply Operation Manual ©2012 AMETEK Programmable Power, Inc.

All rights reserved.

Exclusion for Docume nt at ion

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER,

INC. (“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATI ON PROVIDED IN ITS MANUALS OR

OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQ UENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) RE MINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN

ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF

THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED

AMETEK CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION,

WHICH IS POSTED AT WWW.PROGRAMMABLEPOWER.COM

Date and Revision

February 2012 Revision A

Part Number

M370499-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

1

Page 3

Table of Contents

Introduction 4

Specification 6

Safety 9

Installation 10

Connections 11

Initial Operation 13

Manual Operation 16

Remote Operation (P models only) 26

Remote Commands 35

Calibration 40

Maintenance 42

Instructions en Francais

Sécurité 43

Installation 44

Connexions 45

Utilisation initiale 47

Fonctionnement manuel 50

Fonctionnement à distance (modèles P uniquement) 62

Commandes à distance 72

Maintenance 77

Bedienungsanleitung auf Deutsch

Sicherheit 78

Installation 79

Anschlüsse 80

Erste Inbetriebnahme 82

Manueller Betrieb 85

Fernbedienung (nur P Modelle) 97

Fernsteuerbefehle 107

Wartung 112

2

Page 4

Istruzioni in It aliano

Sicurezza 113

Installazione 114

Collegamenti 115

Primo utilizzo 117

Funzionamento in manuale 120

Funzionamento remoto (solo modelli P) 132

Comandi remoti 142

Manutenzione 147

Instrucciones en Espanol

Seguridad 148

Instalación 149

Conexiones 150

Funcionamiento inicial 152

Funcionamiento manual 155

Funcionamiento remoto (sólo modelos P) 167

Mandos remotos 177

Mantenimiento 182

Warranty Information 183

3

Page 5

Unmatched Precision, Unrivalled Performance

The XDL series II provides the highest performance levels available in a laboratory power supply.

Voltage and current are controlled using 16 bit DACs enabling voltages to be set to 1mV resolution

even at full output. Indeed, the accuracy is sufficient for the PSU to be used as a calibration

source for some hand-held DMMs.

The XDL series II uses pure linear technology and offers unrivalled performance in terms of

regulation, output noise and dynamics. Line and load regulation are close to the limit of

measurement. Output noise is less than 350µV rms in CV mode and down to 20µA rms in CI

mode. Recovery time from transient current pulses is better than 50µs.

It provides full remote sense capability via dedicated sense terminals. Remote sense is essential

to maintain precise regulation at the load. When remote sense is not required, internal local

sensing can be selected at the touch of a button.

Multiple Ranges for Greater Flexibility

The XDL series II provides multiple ranges for increased current capability at lower voltages. The

main range offers 0 to 35 Volts at up to 3 Amps (XDL 35-5) or 0 to 56 Volts at up to 2 Amps (XDL

56-4). The higher current range provides up to 5 Amps for voltages up to 15V (XDL 35-5) or 4

Amps for voltages up to 25V (XDL 56-4). A further low current range provides enhanced current

setting and measurement resolution of 0·1mA.

The product of voltage and current can be displayed at any time by pressing the VxA button. The

power is displayed to a resolution of 0·01 Watts.

Introduction

Fast, Simple and Safe to use

The user interface of the XDL series II has been carefully designed to provide rapid control whilst

guarding against any possibility of error.

Voltage and current setting can be performed either by direct numeric entry or, for applications

where the voltage or current must be gradually changed, by using the quasi-analogue Jog control.

To enable the current limit to be set before connecting the load, the limit setting is displayed when

the output is off. Pressing the View Limits key at any time provides a temporary display of the limit

values allowing precise adjustment to also be made with the output on.

Setting Memories for Added Convenience

The XDL series II provides storage of up to 50 power supply sets-ups in non-volatile memory for

each main output, plus (T models only) a further 50 set-ups for linked mode operation, plus 10 setups for the auxiliary output. Upon mains switch-off, the set -up of the PSU is saved and is

automatically restored at switch-on.

OVP and OCP Trips with 'Alarm' Output

The XDL series II provides fully adjustable over-voltage and over-current trips which can be used

both as a fail-safe against accidental mis-setting and as a protection against inappropriate load

conditions. In addition to turning the output off, a trip condition switches the rear panel alarm signal

enabling other equipment to be controlled.

For complete protection of the power supply, the trip will also be operated by over-temperature or

excess voltage on the sense terminals.

Auxiliary Output with Fully Variable Voltage (T models)

The XDL series II triple output power supplies incorporate an auxiliary output which is fully

variable between 1 volt and 6 volts to a resolution of 0.01V, and has a current capability of 3

amps.

A front panel button enables to voltage and current for the auxiliary output to be viewed on the

Output 1 display whenever required.

4

Page 6

Fully Programmable via GPIB, RS 232, USB or LAN

The programmable ‘P’ models incorporate a full bus interface permitting remote control and

readback via either GPIB (IEEE-488), RS232, USB or LAN.

The GPIB interface conforms fully with IEEE-488.2 and IEEE-488.1.

The RS232 interface uses a standard 9-pin D-connector and has a Baud rate variable from 600 to

19200.

The USB interface is compatible with USB 2.0 and USB 1.x.

The LAN interface is LXI version 1.2, Class C, compliant.

The XDL series II uses simple and consistent command structures which make programming

particularly easy regardless of which interface is used.

An IVI driver for Windows is included. This provides support for common high-level applications

such as LabView*, LabWindows*, and HP/Agilent VEE*.

All power supply settings can be controlled via the bus. Voltage and curre nt can be set to a

resolution of 1mV or 0·1mA (main outputs). Actual voltage and current can be read back together

with the power supply status.

* LabView LabWindows is a trademark of National Instruments Corp. Agilent VEE is a trademark of Agilent Technologies inc.

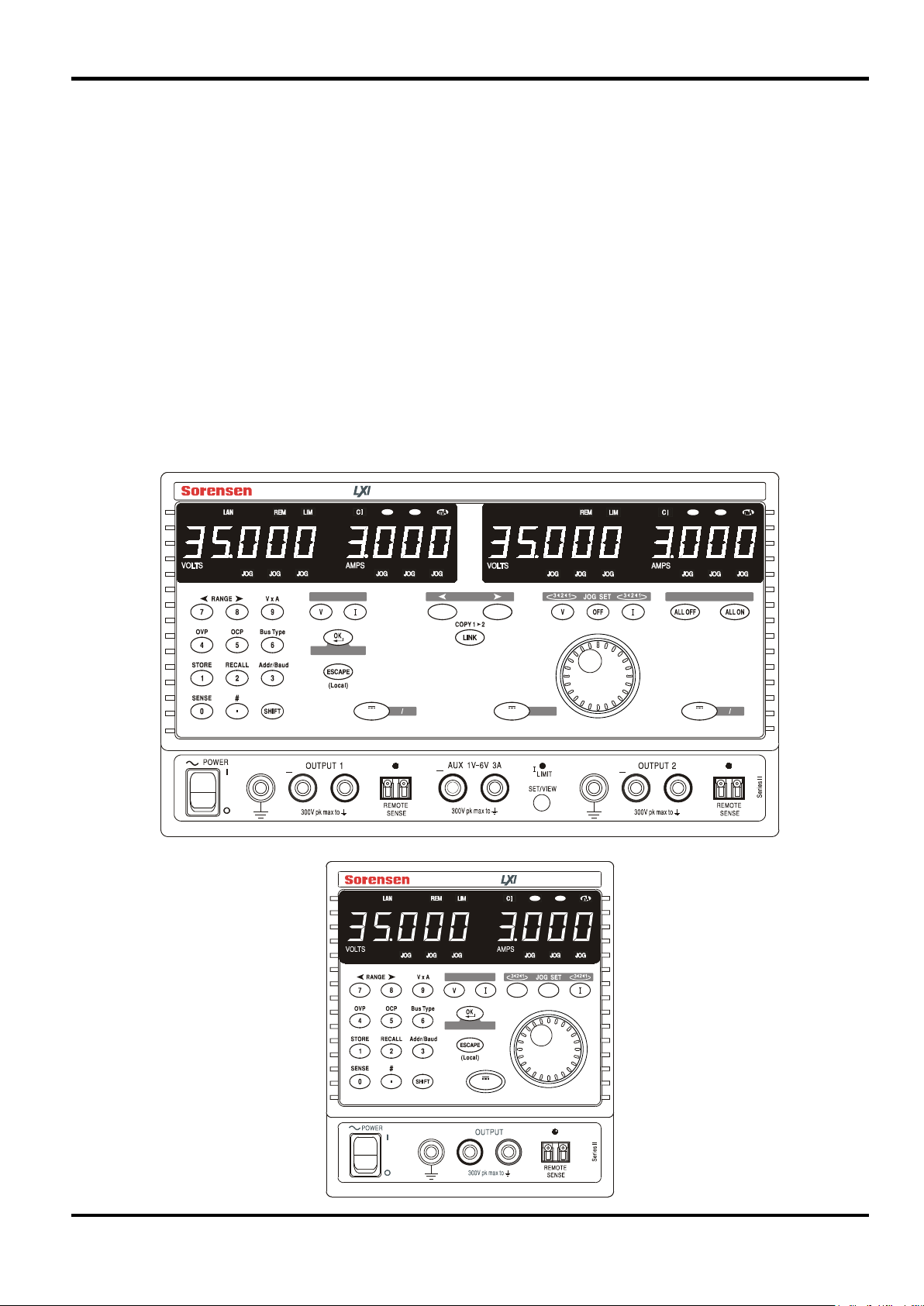

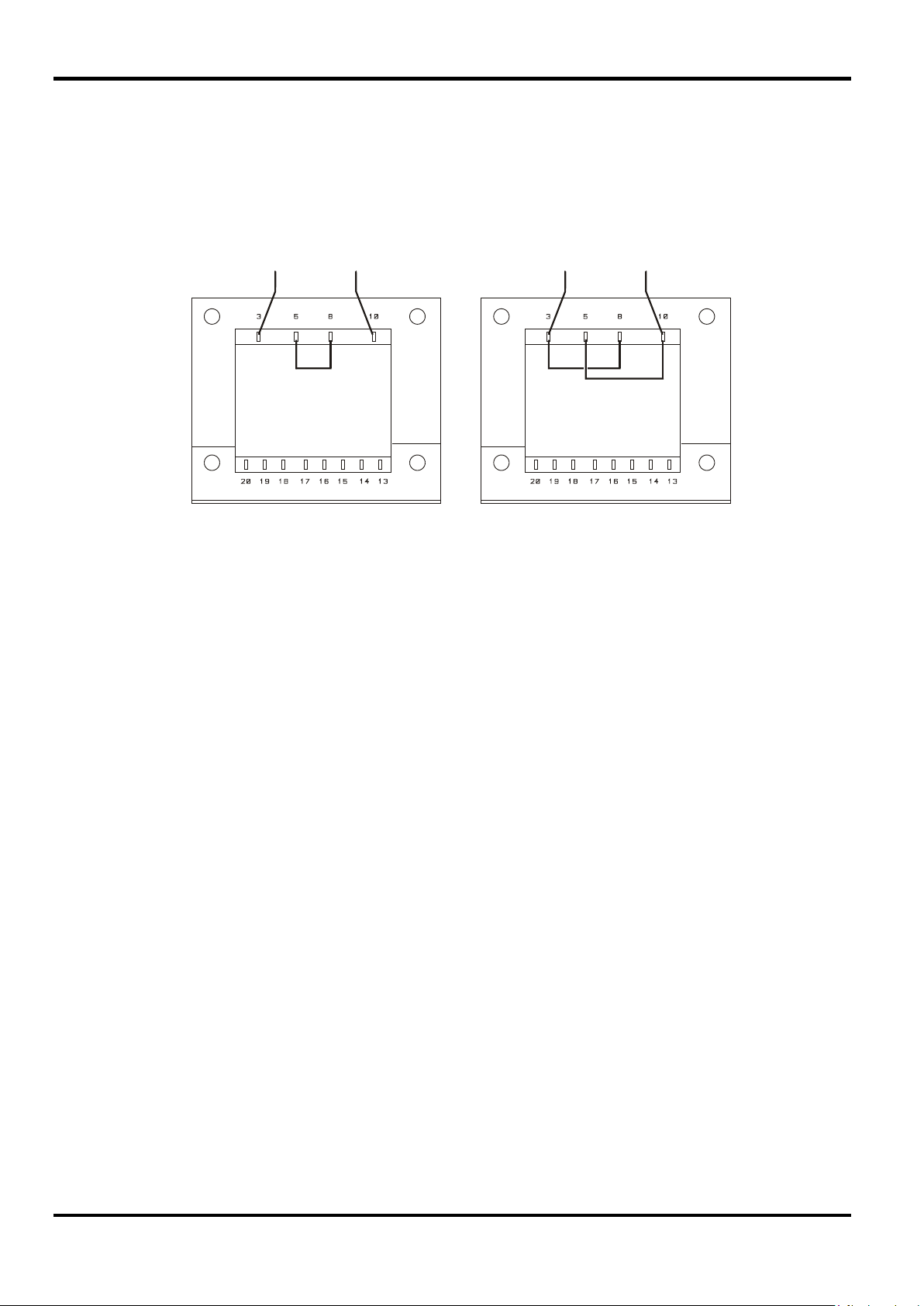

XDL 35-5TP DC Power Supply

15V5A35V3A35V

500mA

15V5A35V3A35V

500mA

NUMERIC SET

VIEW V/I LIMITS

O/P 1 AUX O/P 2

ON/OFF ON/OFF ON/OFF

_

+ +

+

1

CONTROL

2

+

XDL 35-5P DC Power Supply

NUMERIC SET

VIEW V/I L IM ITS

15V5A35V3A35V

OFF

V

500mA

MULTI-OUTPUT CONTROL

_

+

ON/OFF

_

+

_

+

5

Page 7

Voltage/Current Ranges:

XDL 3 5-5

XDL 5 6-4

0V to 15V/0·001A to 5A

0V to 25V/0·001A to 4A

Accuracy ± (0·03% + 5mV)

Accuracy ± (0·2% + 5mA); ± (0·2% + 0·5mA) on 500mA range.

CI indicator lit in constant current mode.

Preset voltage and current limit displayed when Output off.

Duplicate rear panel Output and Sense screw terminals on P models.

load to half load or vice versa.

Speed:

(for resistive load). Excludes command processing time.

XDL 3 5-5

XDL 5 6-4

Load

Load

Up

35V 500mA

200ms

40ms

56V/500mA

300ms

60ms

Down

35V 500mA

120ms

600ms

56V/500mA

200ms

800ms

(20MHz bandwidth):

Normal mode current: <0·2mArms; <20µArms on 500mA range.

Specification applies for sense lead resistance <0·5Ω.

Current <0·01% + 250µA; <0.01%+ 50µA on 500mA range.

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at

23°C. Typical specifications are determined by design and are not guaranteed.

MAIN OUTPUTS

Specification

0V to 35V/0·001A to 3A

0V to 35V/0·1mA to 500mA

Voltage Setting: Resolution 1mV

Current Setting: Resolution 1mA; 0·1mA on 500mA range

Output Mode: Constant voltage or constant current with automatic cross-over.

Output Switch: Electronic, non-isolating. Switch illuminated when Output on.

Output T e rminals: Universal 4mm safety binding posts on 19mm (0·75”) pitch for Output;

screwless terminals for Sense.

Transient Response:

Voltage Programming

<50µs to within 15mV of set level for a change in load current from full

Maximum time required for output to settle within 1% of its total excursion

Full Load

No

0V to 56V/0·001A to 2A

0V to 56V/0·1mA to 500mA

Full Load No

Up

Up

Down

Down

Ripple and Noise

Load Regulation: For any load change, measured at the output terminals, using

Line Regulation: Voltage <0·01% + 2mV for 10% line change.

Temperature Coefficient: Voltage: typically <(50ppm + 0·5mV)/°C

15V 5A

35V 3A

15V 5A

35V 3A

Normal mode voltage: <0·35mVrms and 2mVp-p

remote sense.

Voltage <0·01% + 2mV.

Current <0·01% + 250µA; <0.01% +50µA on 500mA range.

Add typically 2·5mV for a 0·5V drop in the positive output lead.

Current: typically <(100ppm + 1mA)/°C;

typically<(100ppm + 0·1mA)/°C on 500mA range.

6ms

20ms

6ms

25ms

6ms

7ms

250ms

600ms

25V/4A

56V/2A

25V/4A

56V/2A

10ms

40ms

10ms

50ms

6ms

15ms

400ms

800ms

6

Page 8

Response time typically 100µs

Response time typically 35ms

Protection Functions:

Output trips off for OVP, OCP, ove r -temperature and Sense miswiring

Display Type:

5-digit (Volts), 4-digit (Amps), 14mm (0·56") LED.

Accuracy ± (0·1% of reading + 10mV)

Accuracy ± (0·2% + 0·005A); ± (0·2% + 0·5mA) on 500mA range

Accuracy ± (0·3% + 0·05W); ± (0·3% + 0·005W) on 500mA range

Voltage Range:

1V to 6V

Accuracy: ± 0.5% ±10mV

Current Limit:

3A minimum

Output Switch:

Electronic, non-isolating. Switch illuminated when Output on.

screwless terminals on rear panel.

protection for currents up to 1A. Over-current trip.

(20MHz bandwidth)

Load & Line Regulation:

<1·0% for a 90% load change; 0·1% for a 10% line change.

Speed:

excursion (for resistive load). Excludes command processing time.

1V to 6V: 10ms, no load and full load

6V to 1V: 10ms, no load and full load

Output Protection: Output will withstand forward voltages of up to 20V above rated output

voltage. Reverse protection by diode clamp for currents up to 3A.

Over-voltage Protection:

(OVP)

Over-current Protection:

(OCP)

Range 1V to 40V (XDL 35-5), 1V to 60V (XDL 56-4)

Resolution 0·1V; accur acy ± (2% + 0·5V)

Range 0·01A to 5·5A (XDL 35-5), 0·01A to 4·4A (XDL 56-4)

Resolution 0·01A; accuracy ± (0·2% + 0·01A)

METER SPECIFICATIONS (Main Outputs)

Voltage (CI mode): Resolution 10mV

Current (CV mode): Resolution 0·001A; 0·1mA on 500mA range

V x A: Resolution 0·01W; 0·001W on 500mA range

AUXILIARY OUTPUT (T models only)

Voltage Setting: Resolution: 10mV

Output T e rminals: Universal 4mm safety binding posts on 19mm (0·75”) pitch. Duplicate

Output Protection: Output will withstand up to 16V forward voltage. Diode clamp reverse

Ripple & Noise:

Status Indication: Current limit lamp. Current overload trip indication.

Meter Specifications:

(use SET/VIEW button)

Voltage Programming

<2mV rms, 10mVp-p

Voltage Meter: Resolution 10mV, accuracy ± 0.5% ±10mV

Current Meter: Resolution 10mA, accuracy ± 0.5% ±10mA

Maximum time required for output to settle within 1% of its total

KEYBOARD & ROTARY CONTROL

All functions, including the selection and set-up of the remote control interfaces, can be set from

the keyboard. The rotary jog control can be used to adjust output voltage and current settings in

a quasi-analogue mode.

7

Page 9

General

RS232:

Standard 9-pin D-connector. Variable Baud rate (600 to 19200).

GPIB:

Conforming with IEEE488.1 and IEEE488.2

USB:

Standard USB 2.0 hardware connection. Operates as a virtual COM port.

MDIX. LXI V1.2, Class C compliant.

change.

Status Indication:

Remote mode and LAN status indicators

Main Outputs

Voltage Setting:

16-bit; Resolution 1mV, accuracy ± (0·03% +5mV)

Resolution 0.01mA, Accuracy ± (0·2% + 0·5mA) on 500mA r ange.

Readback V & I

See meter specifications.

Auxiliary Output (T models only)

Voltage Setting:

Resolution 10mV, accuracy ± 0.5% ±10mV

Current Setting:

Resolution 10mA, accuracy ± 0.5% ±10mA

Readback V & I

See meter specifications

Installation Category II

Power Consumption:

Single output: 250VA max; Triple output: 500VA max.

Operating Range:

+5ºC to +40ºC, 20% to 80% RH

Storage Range:

−40ºC to + 70ºC

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degree 2.

output if internal temperatures exceed predetermined thresholds.

interfaces.

Safety:

Complies with EN61010−1

EMC:

Complies with EN61326

Triple output: 280 x 160 x 290mm (WxHxD), excl. feet & terminals

ALARM OUTPUT

Isolated rear-panel open-collector output signal. User can select output to be activated for either

OVP, OCP, Overtemperature or Sense miswiring, or for any of those four faults.

DIGITAL INTERFACES (P models only)

Full digital remote control facilities are available through the RS232, USB, LAN and GPIB interfaces.

LAN: Ethernet 100/10base-T hardware connection. Auto speed detect, auto

Remote Command

Processing Time:

Current Setting: 16-bit; Resolution 0.1mA, accuracy ± (0·2% + 5mA)

GENERAL

AC Input: 230V AC or 115V AC ± 10%, 50/60Hz

Typically <25ms between receiving the command terminator for a step

voltage change at the instrument and the output voltage beginning to

Cooling: Intelligent variable-speed fan. Over-temperature trip shuts down

Store/Recall: Up to 50 set-ups each main output, 50 linked set-ups, and 10 auxiliary

output settings can be saved and recalled via the keyboard or remote

Size: Single output: 140 x 160 x 290mm (WxHxD), excl. feet & terminals.

Weight: Single: 5.5kg; Triple: 10·5kg

8

Page 10

l

mains supply ON.

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after

switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Earth (ground) terminal.

9

mains supply OFF.

alternating current (ac)

direct current (dc)

Page 11

for 230V operation:

1.6A (T) 250V HBC

for 115V operation:

3.15A (T) 250V HBC

for 230V operation:

4A (T) 250V HBC

for 115V operation:

8A (T) 250V HBC

for 230V operation:

1.6A (T) 250V HBC

for 115V operation:

3.15A (T) 250V HBC

BROWN BLUE

BROWN BLUEBROWN

115V230V

Installation

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Remove the screws which retain the top cover and lift off the cover.

3) Change the connections on both transformers following the appropriate diagram below:

4) Refit the cover and the secure with the same screws.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

6) Chang e all three fuses to ones of the correct rating, see below.

Fuse

The AC inlet fuse is located in the fuse drawer in the lower part of the IEC inlet connector. To

change the fuse remove the line cord and open the fuse drawer with a suitable tool.

XDL 35-5, XDL 35-5P, XDL 56-4 & XDL 56-4P

The correct mains fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

XDL 35-5T, XDL 35-5TP, XDL 56-4T & XDL 56-4TP

The correct mains fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

In addition, the two transformers are individually fused inside the power supply. To access these

fuses remove the cover as described above; both fuses are clipped to the small PCB which is

fitted directly onto the pins of the IEC inlet connector itself.

The correct fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

Make sure that only fuses with the required current rating and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuseholders are prohibited.

10

Page 12

Mains Lead

Connect the instrument to the AC su pply using the mains lead prov id ed. Should a mains plug be

required for a differ ent m ains outlet socket, a suitably rated and approved mai ns lea d s et should be

used which is fitted with the required wall plug and an IEC60320 C13 connector for the inst r ument

end. To determine the minimum current r at ing of the lead-set for the inten ded AC supply, refer to the

power rating information o n the equipment or in the Specification.

Any interruption of the ma i ns ear t h c onductor inside or outside t he instrument will make the instrument

dangerous. Intentional i nt er r upt io n is pr ohibited.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting XDL Series power supplies is available from the Manufacturers or their

overseas agents. The rack will accommodate 1, 2 or 3 single units or a triple and single unit; a

blanking piece is also available for unused positions in the rack.

Ventilation

The power supply is cooled by an intelligent multi-speed fan which vents at the rear. Take care

not to restrict the air inlets at the side panels or the exit at the rear. In rack-mounted situations

allow adequate space around the instrument and/or use a fan tray for forced cooling.

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Front Panel Connec tions

The loads should be connected to the positive (red) and negative (black) terminals marked

OUTPUT 1, OUTPUT 2, or AUX.

Remote sense connections to the loads on Outputs 1 or 2, if required, are made from the

corresponding positive (+) and negative (−) REMOTE SENSE terminals. Remote sense

operation is selected from the keyboard or via a remote control interface (P models only); the

REMOTE SENSE lamp is lit when remote sense is selected. Switching off remote sense returns

the instrument to local sensing at the output terminals.

The terminal marked

is connected to the chassis and safety earth ground.

Rear Panel Connections

Main Output Terminals (P models only)

The output and sense terminals are duplicated on the rear panel screw-terminal block marked

Output +, Output −, Sense + and Sense − ; these connections are paralleled with their front panel

equivalents.

Connections

Remote sense operation is selected from the keyboard or via a remote control interface. When

the rear panel terminals are used, remote sense should always be selected to ensure that output

regulation is maintained within specification.

Auxiliary Output Terminals (T models only)

The front panel AUX OUTPUT terminals are duplicated on the rear panel with screwless terminals

marked AUXILIARY OUTPUT.

11

Page 13

3

RXD

Received data to instrument

Alarm Outputs

Associated with each main output are recessed 2-pin connectors marked Alarm. These provide

access to an opto-isolated NPN switching transistor, the function of which can be set from the

keyboard, see the Alarm Output section of this manual.

The maximum operating voltage that can be applied across the terminals is 20VDC and the

maximum sink current for the switch 'closure' is 1mA.

Do not apply external voltages between the terminals exceeding 30VDC.

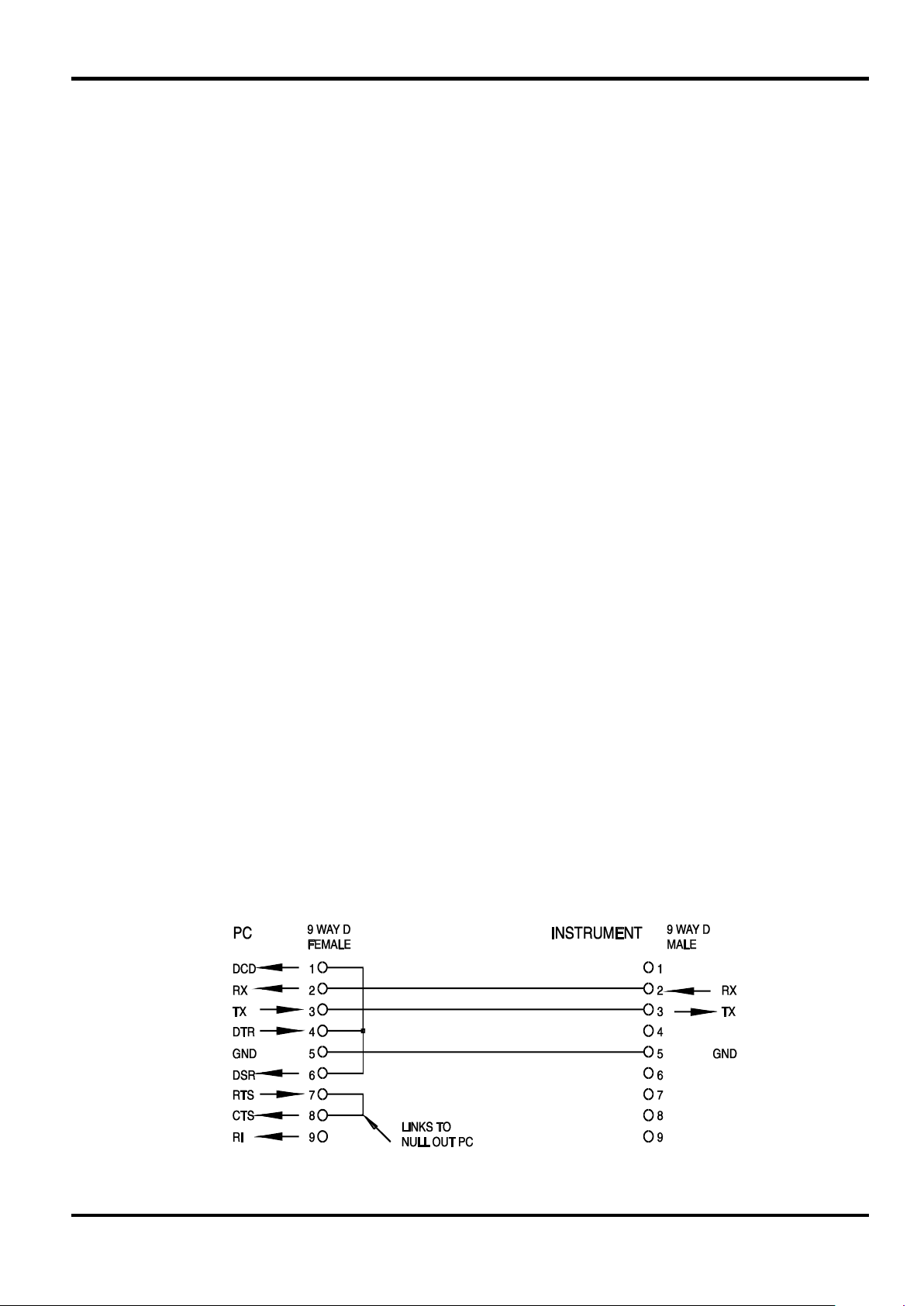

RS232 (P models only)

9−pin female D−connector with pin connections as shown below. Can be connected to a

standard PC port using a fully wired 1:1 male-female cable without any cross-over connections.

Pin Name Description

1 RI

2 TXD Transmitted data from inst rument

4 CTS

5 GND Signal ground

6 RTS

7 DSR No internal connection

8 DTR

9 CD No internal connection

Passively asserted (+V through 10kΩ)

Passively asserted (+V through 10kΩ)

Signal ground is connected to instrument ground.

USB (P models only)

The USB port is connected to instrument ground. It conforms with USB 2.0 (Full Speed) and

accepts a standard USB cable. The Windows plug-and-play functions should automatically

recognise that the instrument has been connected. If the correct driver is not found, follow the

Windows on-screen prompts and install the required files from the CD supplied.

LAN (P models only)

The LAN interface is designed to meet LXI ( Lan eXtensions for Instrumentation) version 1.2; the

instrument is Class C compliant. Remote control using the LAN interface is possible using a

TCP/IP Socket protocol. The instrument also contains a basic Web server which provides

information on the unit and allows it to be configured. Since it is possible to misconfigure the LAN

interface, making it impossible to communicate with the instrument over LAN, a LAN

Configuration Initialise (LCI) mechanism is provided via a recessed switch on the rear panel

(marked LAN RESET) to reset the unit to the factory default.

Further details are given in the Remote Operation chapter. For more information on LXI

standards refer to www.lxistandard.org/home

GPIB (P models only)

The GPIB signal grounds are connected to the instrument ground. The implemented subsets are:

SH1 AH1 T6 TE0 L4 LE0 SR1 RL2 PP1 DC1 DT0 C0 E2

The GPIB address is set from the front panel.

12

Page 14

This section of the manual is a general introduction to the controls and operation of the instrument

and is intended to be read before using the power supply for the first time.

In this manual front panel keys, connections and display indicators are shown in capitals,

e.g. STORE, ESCAPE, OUTPUT, JOG. Messages shown on the 7-segment display are printed

in a different type-font, e.g.

characters as they are shown on the 7-segment display.

StorE, GPIb, triP in upper or lower case to represent the

Switching On, Output On/Off

The power switch is located at the bottom left of the front panel.

At power-up the default behaviour is for the instrument's settings to be restored to those

automatically saved when it was switched off, but with all outputs always off. However, the user

can change the default setting such that selected outputs are restored at power-up to their status

at power-down, see the Extra Functions section.

The DC outputs are switched electronically with their respective ON/OFF keys; the key illuminates

when the output is on. In addition, all outputs can be switched on and off together using the ALL

ON and ALL OFF keys.

Synchronous Output On/Off Switching (T models only)

Pressing ALL OFF at any time will synchronously turn off any outputs that are on; under the same

load conditions outputs will typically turn off within 1ms of each other. With all outputs off the ALL

OFF key is illuminated green. Pressing the ALL ON key when all the outputs are off will turn all

the outputs on synchronously; outputs with identical settings and load conditions will typically turn

on within 1ms of each other. However, if one output is already on, pressing ALL ON will turn the

remaining outputs on but the turn-on delay between the outputs will be up to 80ms, even with the

same output setting and load conditions.

Initial Operation

Keypad

Only the principles of operation are outlined here; the setting of individual parameters is given in

detail in later sections.

The paramount consideration in designing the user interface has been to make changing settings

as 'safe' as possible (i.e. with minimal risk of accidentally applying excessive voltages to a target

system) whilst achieving ease of use. This has been achieved by requiring the user to confirm

(OK) new numeric settings, with the option to ESCAPE at any point or even to simply pause until

the operation times-out and the instrument returns to its original settings.

In addition a buzzer, illuminated keys, LED indicators and display messages prompt, guide or

warn the user such that entry or control errors are minimised. Where some of these features (e.g.

beeps or flashing indicators) are considered unnecessary by regular users, the option exists to

disable them, see the Extra Functions section.

On triple output (T) models the ability to change settings from the keypad or by using the Jog

controls is assigned to Output 1, Output 2 or both by using the 1, 2 or LINK CONTROL keys

respectively. The key (1 or 2) associated with the selected output illuminates to show which

output is under control. In LINK mode (both keys lit) both outputs are controlled at the same time,

including some of the shifted operations (RANGE, STORE, RECALL and V x A). The further

descriptions that follow apply to either or both main outputs as appropriate to the setting indicated

by the illumination of the CONTROL keys.

Under normal conditions the numeric keypad is disabled; pressing any key will cause the buzzer

to make a double beep, indicating an illegal operation. To set a voltage or current with the keypad

press the V or I NUMERIC SET key; the appropriate display shows 0·000V or 0·000A with the

digit to the left of the decimal point flashing. Digits are entered in response to the flashing prompt,

together with the decimal point at the appropriate time, and the entry is confirmed with the OK

key. If OK is not pressed within 10 seconds of the last numeric key the entry is cancelled and the

display returns to its original setting. If ESCAPE is pressed anywhere in the entry procedure,

entry is cancelled and the display returns to its original setting.

13

Page 15

The OK key is used to confirm most keypad entries. At all other times it becomes the VIEW V/I

LIMITS key and pressing it will cause the display to show preset output voltage and current limit

for 3 seconds; during this period the LIM indicator in the display flashes.

Pressing SHIFT illuminates the key and gives the numeric keys the functions marked above them

(e.g. STORE, RECALL, etc.). When a function is selected by pressing one of these keys SHIFT

is cancelled (the SHIFT key is no longer lit). The further key presses required to complete the

selected function are described in detail in the sections that follow; if no key is pressed within 10

seconds to complete the function, the function will terminate as if ESCAPE has been pressed.

SHIFT is a toggle key; pressing SHIFT again when it has been selected will cancel SHIFT. SHIFT

is also cancelled by ESCAPE, or by pressing SET V or SET I. Note that in LINK mode settings

accessed by STORE and RECALL are specific to the LINK mode and are in addition to settings

accessible when STORE and RECALL are used on individually selected outputs.

Jog Control

The rotary 'jog' control permits the output voltage or current limit to be incremented or

decremented in steps with a resolution set by the JOG SET keys; the output immediately follows

the setting, i.e. no OK is required.

At power-up jog is always off. To jog the voltage or current setting press the V or I JOG SET key;

the key will illuminate and the JOG indicator under the digit that was last jogged will flash. Whilst

the V or I JOG SET key is lit, each further press of the V or I key moves the JOG indicator one

digit to the left; the selection 'wraps-round' such that when the largest value of jog increment has

been reached the next press returns it to the lowest. The default position at power-up is under

the LSD, i.e. the lowest jog increment is selected.

Turning the rotary jog control clockwise/anti-clockwise increments/decrements the selected digit;

digits to the left of the one being jogged are automatically incremented/decremented when the

decade overflow/underflow point is reached. Digits to the right of the one being jogged remain

unchanged unless the jog step overflows/underflows the range maximum/minimum in which case

they are set to zero. On the XDL 35-5, for example, 33·65V goes to 34·65V goes to 35·00V for

the 35V range and a 1V jog increment; 0·160A goes to 0·060A goes to 0·001A for a 0·1A jog

decrement.

The jog steps that can be selected for the main range are 1mV, 10mV, 100mV and 1mA, 10mA,

100mA; if the 500mA range has been selected the current increment steps are 0·1mA, 1mA,

10mA.

To disable the jog rotary control press the JOG SET OFF key; reselecting JOG SET V or I will

enable jog on the last used digit position. Jog is not cancelled by using numeric entry or any of

the SHIFT functions but it is disabled whilst that function is enabled.

When in constant voltage mode, with the output on, the right-hand display will show actual current

rather than current limit. If JOG SET I is selected the JOG indicator under the selected digit will

flash at half-speed ('lazy' flash). To observe the effect of jogging the current limit it will be

necessary to either turn the output off (so that the display permanently shows the current limit) or

to press VIEW V/I LIMITS which causes the current limit to be displayed until 3 seconds after

movement of the jog control ceases. The 'lazy' flash is also used when JOG SET V has been

selected and actual voltage is being shown because the supply has gone into current limit.

The factory default is to flash the JOG indicator under the selected digit for the whole time that jog

is selected so that the user is constantly reminded which parameter can be incremented/

decremented. Where this degree of reminding is considered inadequate the user can select,

using the Extra Functions capability, t o flash the digit itself; conversely, where the flashing is

considered intrusive the user can select to not flash the JOG indicator (except when the 'lazy'

flash is shown).

14

Page 16

Display

The displays shows the voltage on the left (5 digits) and the current on the right (4 digits) for both

the main outputs. These 7-segment displays are also used to show prompts during some of the

function settings (e.g. memory store/recall or remote control address setting) using the limited

'character set' that can be achieved with a 7-segment display; these are necessarily a mixture of

upper and lower case letters.

Above and below the 7-segment display are several secret-until-lit annunciators.

To the right, above the current display, are the indicators which show the selected operating

range: 35V/3A, 15V/5A or 35V/500mA (XDL 35-5T & TP) or 56V/2A, 25V/5A or 56V/500mA (XDL

56-4T & TP); the indicators light beneath the range printed immediately above them and, in the

case of the 500mA range, the indicator is marked mA to emphasise that the current display is now

showing mA.

The other annunciators above the displays are:

CI, indicating that the instrument is in constant current mode;

LIM, which flashes when the VIEW V/I LIMITS key is pressed to show the set voltage/set current

limit in the display;

REM, which lights when the instrument is under control from a remote interface (P models only)

and LAN, which indicates the status of the LAN interface connection (P models only).

Below the three least significant digits of both the voltage and current displays are the JOG

indicators; the appropriate indicator flashes when the jog function is being used, see the Jog

Control section above.

The display of Output 1 can alternatively be used to show the voltage and current of the AUX

output (T models only). Full details are given in the Auxiliary Out put section.

15

Page 17

Main Outputs

New users should first read the Initial Operation chapter which describes the operating principles

of the keypad and rotary jog control. The following paragraphs describe the independent

operation of either Main Output. To select which output is to be controlled by the keypad/Jog

controls it is first necessary to select that output by pressing the appropriate CONTROL key

(1 or 2); the key lights to show that it is the selected output.

The additional features available on the triple output (T) models in LINK mode (both Main Outputs

selected) are described in the Main Outputs – Link Mode section later in this manual.

Set Voltage

The left-hand display shows the set voltage to a resolution of 1mV, except when the instrument is

in constant current (CI) mode. In CI mode the actual output voltage (which will be less than the

set voltage) is shown and the display resolution is 10mV; the least significant digit (1mV

resolution) is always displayed as a zero.

The voltage can be set directly from the numeric keypad: press the NUMERIC SET V key, enter

the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET V is pressed the display shows 0·000; a new voltage is then entered (e.g. 12·345V is

entered as 1, 2, ·, 3, 4, 5) and confirmed by OK. The position of the decimal point in the display is

fixed to reduce the risk of entering a wrong value. As a consequence, and to avoid the need to

enter leading zeroes (e.g. 2·345V is entered as 2, ·, 3, 4, 5, OK), numbers to the left of the

decimal point are shown slightly differently to the numbers to the right of the decimal point during

number entry; this is self-evident during number entry.

Manual Operation

The minimum voltage setting is 0·000V; the maximum setting for XDL 35-5 is 35·000V (15·000V

on the 15V/5A range) or 56.000V (25.000V on the 25V/4A range) for XDL 5 6-4.

Pressing OK at any point will set the voltage entered with any remaining digits set to zero,

e.g. 1, 2, ·, 3, OK will set 12·300V; 1, OK will set 1·000V; pressing OK immediately after SET V

(while the display shows 0·000V) will set 0·000V.

Pressing ESCAPE at any time during the sequence, or making no further key press within

10 seconds of the previous one will cause the display to return to its original reading before

SET V was pressed.

Entering a voltage outside the range maximum (including trying to enter 3 digits before the

decimal point) or trying to enter more than 5 digits will cause the buzzer to beep twice; the last

key entry will be ignored.

The voltage can also be set using the Jog control. Pressing JOG SET V will illuminate the V key

and the JOG indicator under the digit that was last jogged will flash. Whilst the V key is lit, each

further press will move the JOG indicator one digit to the left; the selection 'wraps round' such that

when the largest value of jog increment has been reached the next press returns it to the lowest.

The default position at power-up is under the LSD, i.e. the lowest jog increment is selected. The

jog steps that can be selected are 1mV, 10mV and 100mV.

With jog enabled the output voltage can be incremented or decremented with the rotary jog

control with a step resolution indicated by the position of the flashing JOG indicator. The output

immediately follows the setting, i.e. no OK is required. If the output goes into constant current

mode (indicated by the CI indicator flashing) the left-hand display shows actual voltage not set

voltage. If JOG SET V is selected the JOG indicator under the selected digit will flash at half

speed ('lazy' flash). To observe the effect of jogging the set voltage it will be necessary to either

turn the output off (so that the display permanently shows the set voltage) or to press

VIEW V/I LIMITS which causes the set voltage to be displayed until 3 seconds after movement of

the jog control ceases.

16

Page 18

Note that in constant current mode the actual voltage is measured and displayed to only 10mV

resolution; the 1mV digit permanently displays zero.

Further details on the jog control can be found in the Initial Operation chapter.

Set Current Limit

With the output off, the right-hand display shows the current limit to a resolution of 1mA (0·1mA on

the 500mA range).

The current limit can be set directly from the numeric keypad: press the NUMERIC SET I key,

enter the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET I is pressed the display shows 0·000; a new current is then entered (e.g. 1·234A is

entered as 1, · , 2, 3, 4,) and confirmed by OK. The position of the decimal point in the display is

fixed to reduce the risk of entering a wrong value. As a consequence, and to avoid the need to

enter or display leading zeroes (e.g. 0·234A is entered as ·, 2, 3, 4, OK), numbers to the left of

the decimal point are shown slightly differently to the numbers to the right of the decimal point

during number entry; this is self-evident during number entry.

The minimum current setting is 0·001A (0·1mA on the 500mA range); the maximum setting is

3·000A, 5·000A or 500·0mA (XDL 35-5) or 2·000A, 4·000A or 500·0mA (XDL 56-4), according to

range, i.e. there is no over-range capability.

Pressing OK at any point will set the current entered with any remaining digits set to zero,

e.g. 1, ·, 2, OK will set 1·200A; 1, OK will set 1·000A; pressing OK immediately after SET I (while

the display shows 0·000A) will set 0·00IA.

Pressing ESCAPE at any time during the sequence, or making no key press within 10 seconds of

the previous one will cause the display to return to its original reading before SET I was pressed.

Entering a value outside the range maximum (including trying to enter 2 digits before the decimal

point) or trying to enter more than 4 digits will cause the buzzer to beep twice; the last key entry

will be ignored.

The current limit can also be set using the rotary jog control. Pressing JOG SET I will illuminate

the key and the JOG indicator under the digit that was last jogged will flash. Whilst the I key is lit,

each further press will move the JOG indicator one digit to the left; the selection 'wraps round'

such that when the largest value of jog increment has been reached the next press returns it to

the lowest. The default position at power-up is under the LSD, i.e. the lowest jog increment is

selected. The jog steps that can be selected are 1mA, 10mA and 100mA (0·1mA, 1mA and 10mA

on the 500mA range).

With jog enabled the current limit can be incremented or decremented with the rotary jog control

with a step resolution indicated by the position of the flashing JOG indicator. The output

immediately follows the setting, i.e. no OK is required. With the output on, the right-hand display

shows actual current, not current limit (except in constant current mode). If JOG SET I is selected

the JOG indicator under the selected digit will flash at half speed ('lazy' flash). To observe the

effect of jogging the current limit it will be necessary to either turn the output off (so that the

display permanently shows the current limit) or to press VIEW V/I LIMITS which causes the

current limit to be displayed until 3 seconds after movement of the jog control ceases.

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 1mA

(0·1 mA on 500mA range). However, in common with all precision bench power supplies, a

capacitor is connected across the output to maintain stability and good transient response. This

capacitor charges to the output voltage and short-circuiting of the output will produce a current

pulse as the capacitor discharges which is independent of the current limit setting.

17

Page 19

Range Selection

The instrument has three ranges: 35V/3A, 15V/5A and 35V/500mA (XDL 35-5) or 56V/2A, 25V/4A

and 56V/500mA (XDL 56-4). The selected range is shown by an illuminated indicator below the

appropriate legend at the top right-hand side of the instrument; when the 500mA range is selected

the indicator legend is mA to emphasise that the current meter now shows milliamps not amps.

To change range press SHIFT followed by RANGE or RANGE; each press of RANGE

selects the next range to the left; each press of RANGE selects the next range to the right;

there is no 'wrap-round'. When the range is changed the indicator that represents the new range

and the OK key both flash; pressing OK sets the new range. To exit without changing range

press ESCAPE. Pressing any other key whilst in range change mode causes the warning buzzer

to beep twice; no other action is taken. If OK is not pressed within 10 seconds of the last range

change key press the range selection remains unchanged.

The range can only be changed when the output is off. Pressing the RANGE or RANGE

keys with the output on will cause the output ON/OFF key (as well as the OK key) to flash. The

output may be turned off with the ON/OFF key and the range then changed by pressing OK, or

OK may be pressed directly in which case the output is automatically turned off and the range

then changed.

If a range change causes a voltage or current limit setting to exceed the corresponding maximum

of the new range the range change is accepted but the setting is made equal to the maximum of

the new range.

Note that the OVP setting is not changed when the range is changed (e.g., for XDL 35-5, an OVP

setting of 38V remains valid on the 15V range); it is left to the user to independently change the

OVP setting if required.

Output Settings – Front Panel Lock

To avoid accidental changes to the output settings in a bench or rack set-up, front panel control of

Range, Voltage, Current Limit, OVP and OCP can be ‘locked’ and ‘unlocked’ with alternate uses

of the #33 function, see Extra Functions section. The output ON/OFF key remains unlocked, as

does selection of remote sense. Front panel lock still operates in remote control mode (P models

only) but is ignored by the remote commands.

On triple output models the AUX output voltage is also locked when Output 1 settings are locked

but, additionally, the CONTROL keys remain unlocked. All outputs are locked and unlocked

together if #33 is used in Link mode, see Auxiliary Output and Main Outputs-Link Mode sections.

Connection to the Load

The load should be connected to the positive (red) and negative (black) OUTPUT terminals. Both

are fully floating and either can be connected to ground.

Remote Sensing

The instrument has a very low output impedance, but this is inevitably increased by the resistance

of the connecting leads. At high currents this can result in significant differences between the

indicated source voltage and the actual load voltage (two 20mΩ connecting leads will drop 0·2V

at 5 Amps, for instance). This problem can be minimised by using short, thick, connecting leads,

but where necessary it can be completely overcome by using the remote sense capability. This

requires the sense terminals to be connected to the output at the load instead of at the source;

insert wires into the spring-loaded REMOTE SENSE terminals and connect directly to the load.

Select remote sense by pressing SHIFT, SENSE; the OK key flashes and the lamp above the

remote sense terminals lights to show that remote sense will be selected when OK is pressed.

Press OK to confirm; press ESCAPE to exit without changing state. Remote sense is turned off

by pressing SHIFT, SENSE again; the OK key flashes and the remote sense lamp goes off to

indicate that local sense will be restored when OK is pressed. Press OK to confirm; press

ESCAPE to exit without changing state.

18

Page 20

To avoid instability and transient response problems, care must be taken to ensure good coupling

between each output and sense lead. This can be done either by twisting the leads together or by

using coaxially screened cable (sense through the inner). An electrolytic capacitor directly across

the load connection point may also be beneficial.

The voltage drop in each output lead must not exceed 0·5 Volts.

The P models have rear panel output and sense terminals, appropriate for when the instrument is

used in a rack. The rear panel sense terminals should always be used with the rear panel output

connections.

Sense Miswiring Trip

The output will be tripped off if the voltage between an output terminal and its corresponding

sense terminal exceeds approximately 1V; this will happen if the sense wires are wired at the load

to the wrong output or if an attempt is made to draw power from the sense wires.

If the sense terminals are miswired in this way the display shows the message

and the output is turned off. Pressing ESCAPE at this point removes the message and the

display now shows the preset voltage and current limit. When the cause of the trip has been

corrected the output can be turned on again.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300V DC. It should be noted that the unit can

only source current and cannot sink it, thus units cannot be series connected in anti-phase.

SENSE triP

The maximum permissible voltage between any terminal and earth ground ( ) is 300VDC.

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for such use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be

connected in parallel to provide a current equal to the sum of the current limit settings.

Note that the output terminals are rated at 30A maximum; if several outputs are operated in

parallel to source higher currents than this the junction should be made at a separate point, not

one of the terminals.

Over-Voltage Protection

Over-Voltage Protection (OVP) can be set from 1·0V to 40V (XDL 35-5) or to 60V (XDL 56-4). If

the output voltage exceeds the set OVP the output is immediately shut down (typically within

100µs), thus avoiding damage to the circuit under test. The OVP circuit will protect against

accidental excessive voltage settings from the front panel or via the remote control interfaces,

external voltages impressed across the output terminals, or a failure in the control circuitry of the

instrument itself.

To set OVP press SHIFT, OVP; the 100mV step JOG indicator will start flashing and the jog rotary

control can be used to increment/decrement the OVP setting in 100mV steps. Press OK to

confirm the new setting; to exit without entering a new value press ESCAPE. The factory default

settings are 40·0V (XDL 35-5) and 60V (XDL 56-4).

If the OVP is tripped the display shows the message

Pressing ESCAPE at this point removes the message and the display now shows the preset

voltage and current limit. When the cause of the OVP has been removed (or the OVP limit

changed) the output can be turned on again.

Note that the OVP setting is not changed when the range is changed (e.g., for XDL 35-5, an OVP

setting of 38V remains valid on the 15V range); it is left to the user to independently change the

OVP setting if required. Note also that it is possible and valid to set OVP below the set voltage. If

the supply is in constant current mode the output voltage will be below the set voltage; OVP could

OUP triP and the output is turned off.

19

Page 21

be set such that is was above the actual output voltage but below the set voltage. This could be

sed to trip the output under a fault condition which caused the load impedance to increase and

the actual output voltage to therefore rise above the OVP point.

Over-Current Protection

Over-Current Protection (OCP) can be set from 0·01A to 5·5A (XDL 35-5) or to 4.4A (XD L 56-4).

If the output current exceeds the set OCP the output is shut down (typically within 35ms).

To set OCP press SHIFT, OCP; the 10mA step JOG indicator will start flashing and the jog rotary

control can be used to increment/decrement the OCP setting in 10mA steps. Press OK to confirm

the new setting; to exit without entering a new value press ESCAPE. The factory default setting

is 5·50A (XDL 35-5) or 4.4A (XDL 56-4).

If the OCP is tripped the display shows the message

Pressing ESCAPE at this point removes the message and the display now shows the preset

voltage and current limit. When the cause of the OCP has been removed (or the OCP limit

changed) the output can be turned on again.

Note that as with OVP, the OCP setting is not changed when the range is changed.

Note also that is possible and valid to set OCP below the set current limit. For example, the

power supply may be used to repetitively test a unit under test (UUT) which normally takes a peak

current of, say, 2 Amps. However, a f aulty UUT would take a current of more than 2 Amps and

would be damaged by being left in a 2 Amp current-limited state. In this case the current limit

could be set to 2·1A, say, and the OCP set to 2·0A to ensure that a faulty UUT will trip the supply

off.

OCP triP and the output is turned off.

Output Protection

In addition to OVP and OCP for forward over-voltage and over-current protection, the output is

protected from reverse voltages by a diode; the continuous reverse current must not exceed 3

Amps although transients can be much higher.

Output Power (V x A)

If SHIFT, V x A is pressed the voltage display shows the product of measured output voltage x

measured current and the current display shows

updated at the normal measurement rate. Output Power mode is cancelled by pressing either

ESCAPE or V x A again. Jog is temporarily disabled (and the JOG indicators are turned off)

during the V x A display.

Temperature Trip

If the safe internal temperature limit is exceeded because, for example, the fan vents have been

blocked, the output is turned off and the display will show

this point will do one of two things:

i. If the over-temperature condition has already cleared the message will be removed and the

display will show preset voltage and current limit. Assuming the cause of the over-temperature

has been rectified the output can be turned on again.

ii. If the instrument is still above the safe temperature limit the

slowly ('lazy' flash) until the instrument has cooled, at which point the display will show preset

voltage and current limit again. Assuming the cause of the over-temperature has been rectified

the output can be turned on again.

UA ; the output power reading is continuously

OtP triP. Pressing ESCAPE at

OtP triP message will flash

Alarm Output

The recessed 2-pin connector on the rear panel is directly connected to an opto-coupled NPN

switching transistor (pin 1 emitter, pin 2 collector) which is turned on (i.e. switch 'closure')

according to the conditions specified in the Extra Functions section, see later. The default

condition is switch closure for any trip condition (OVP, OCP, SENSE or OTP). The maximum

open-circuit voltage permitted across the switch is 30VDC and the nominal sink current for switch

closure is 1mA.

20

Page 22

•

Store Settings

The instrument can store 50 set-ups for each output in non-volatile memory; the parameters

stored are range, voltage, current limit, OVP and OCP. The output state and remote sense

setting are not stored. In addition, a further 50 Link Mode set-ups can be saved, see Main

Outputs – Link Mode section.

To store a set-up, first press SHIFT, STORE; the display shows

number (

right. The SHIFT function is cancelled (the light goes off) at this point. The store number (0 to

49) can be set directly from the keypad or by using the Jog control to increment/decrement the

displayed number; the JOG indicator beneath the store number flashes to indicate that the Jog

control is active. Set the required store number by either method and press OK to store the

settings and return the display to showing V & I. The store function can still be used when the

output settings have been ‘locked’ using the #33 function. A full store can be overwritten with new

settings. At any time before the OK key is pressed the store function can be exited without saving

a set-up by pressing ESCAPE or by waiting 10 seconds from the last key entry.

0 to 49) and store status (either E for store Empty or F for store Full) on the

Deleting Stored Settings

Any store can be returned to 'empty' as follows: press SHIFT, STORE, and set the required store

number via keypad or Jog control as described above; at that point press

shows

store. All of the output’s stored set-ups can also be deleted simultaneously by using the #98

function, see Extra Functions section.

dEL in place of Sto , e.g. dEL 29 F ; pressing OK deletes the content of the

Recall Settings

To recall a set-up, first press SHIFT, RECALL; the display now shows rEC. on the left with the

store number (

the right as each store is either selected in turn using the Jog control, or is set from the keypad

(as for storing set-ups, see above). The SHIFT function is cancelled (the light goes off) at this

point. If the store selected is full (

of that store; press OK to recall the settings of the store and return the display to showing V & I. If

the store selected is empty (

possible to recall an ‘empty’ store (pressing OK gives a warning beep); either select a full store or

press ESCAPE to exit Recall. Recall cannot be used if the output has been ‘locked’.

At any time before the OK key is pressed the Recall function can be exited without recalling a setup by pressing ESCAPE or by waiting 10 seconds from the last key entry.

Settings may be recalled with the output on or off. However, if the recalled setting involves a

range change the output is turned off to avoid any 'glitches'. After pressing SHIFT, RECALL, and

setting the store number, the ON/OFF key will flash (as well as the OK key) if completing the

recall involves a range change. The output may be turned off with the ON/OFF key and the recall

then completed by pressing OK, or OK may be pressed directly in which case the output is

automatically turned off and the recall completed.

0 to 49) and store status (either E for store Empty or F for store Full) on

Sto. on the left with the store

. The display now

F), the display changes to a flashing preview of the V & I values

E), the display flashes ----- ---- to indicate this. It is not

Extra Functions

Variations on some of the factory default functions can be set by the user by using the # extra

functions facility. Each function change, detailed in the list below is accessed by pressing SHIFT,

#, nn, when nn is the 2-digit num ber in the list below; the display changes to

SHIFT, # and the buzzer gives a confirmation beep when the 2-digit number entry is complete. As

indicated in the opening paragraph of this section, the # functions can be set independently (i.e.

differently) for each main output; note, however, that the #02, #03 and #21 functions which apply

to the Auxiliary Output can only be set when CONTROLis assigned to Output 1.

The settings of each Main Output can be ‘locked’/’unlocked’ individually by using #33 with the

CONTROL assigned to the respective output; on T models the AUX settings are also

locked/unlocked when Output 1 is locked/unlocked. The settings of all outputs are

locked/unlocked together if #33 is used with CONTROLset to LINK mode.

21

HASH No._ after

Page 23

# Code

Function

00

Main Output always off at power-up (factory default)

01

Main Output status at power-up the same as at last power-down

Set with control assigned to Output 1.

Set with control assigned to Output 1.

20

Alarm output 'open' for main Output off, 'closed' for main Output on

Set with control assigned to Output 1; applies to Output 1 alarm only.

22

Alarm output 'closed' when over-temperature trip occurs

23

Alarm output 'closed' when sense trip occurs

24

Alarm output 'closed' when over-current trip occurs

25

Alarm output 'closed' when over-voltage trip occurs

26

Alarm output 'closed' when any trip occurs (factory default)

30

Buzzer off

indicates a wrong entry.

33

Lock/Unlock settings. Note that the AUX output settings are locked with Output1.

40

Jog digit flashes, JOG indicator only flashes when jog is 'hidden'

41

JOG indicator always flashes, except when 'hidden' (factory default)

42

JOG indicator doesn't flash, except when 'hidden' (lazy flash)

91

Loads default calibration parameters. Refer to Service Guide

92

Shows firmware version number in the display

93

Sets these # settings to their factory default

94

Loads Factory Default settings (see below)

In LINK mode, clears all memories in all modes (O/P1, O/P2, AUX & LINK).

99

Enter calibration mode. Refer to Service Guide.

Range:

XDL 35-5: 35V/3A

XDL 56-4: 56V/2A

Voltage:

XDL 35-5: 1.000V

XDL 56-4: 1.000V

Current Limit:

XDL 35-5: 1.000A

XDL 56-4: 1.000A

OVP:

XDL 35-5: 40V

XDL 56-4: 60V

OCP:

XDL 35-5: 5.5A

XDL 56-4: 4.4A

Output:

Output off; local Sense

# Settings:

00 Main Output always off at power-up

02 Aux Output always off at power up (an Output 1 # function only).

26 Alarm output 'closed' when any trip condition occurs

31 Buzzer on

41 JOG indicator always flashes; 'lazy' flash when hidden

02 Aux Output (T models only) always off at power up (factory default).

03 Aux Output (T models only) status at power up the same as at last power down.

21 Alarm output 'closed' when Aux Output is in Current Limit.

31 Buzzer on (factory default). A single beep indicates confirmation, a double beep

98 Clears all the output’s set-up memories. AUX output always cleared with O/P1.

Factory Default Settings

The ex-factory default settings (which will apply at first power-up) are as follows:

22

Page 24

RS232:

9,600 Baud (P versions only)

Address:

11 (P versions only)

Error No.

Error Description

Action on pressing OK

1

Calibration constants corrupted at power-up

Loads default calibration parameters

2

# functions corrupted at power-up

Loads default # settings

power up

settings

Error Messages

The following hardware errors are indicated by showing the appropriate error number in the display.

The OK key will flash and if pressed the error will be ignored and operation will continue as described.

3 Power-do wn settings not correctly loaded at

Switching the instrument off with the error message showing will leave all settings unchanged.

Loads factory default power-up

Main Outputs – Link M ode (T models onl y)

In Link mode, selected by pressing the LINK key, the key parameters of the two Main Outputs are

adjusted together; when Link mode has been selected both CONTROLkeys (1 and 2) are lit

to show that both outputs are selected.

The following paragraphs only describe the differences between independent and linked

operation; they should be read in conjunction with the corresponding paragraphs in the Main

Outputs section.

Link Mode Operation − Overview

Control of the two main outputs can be "linked" so that changes are applied to both outputs

simultaneously. There can be several reasons for wanting to do this:

1. Series or Parallel Wiring

The user may wish to create an output with either twice the voltage or twice the current

capability, see the Series or Parallel Connection with Other Outputs section on page 19.

Link mode provides a convenient means for controlling the two outputs when they are series

or parallel connected.

2. Tracki ng Voltages (or Currents)

When in Link mode, using Numeric Set will set equal voltages and/or currents on the two

outputs. Control of the outputs can also be linked with different voltages and/or currents set

on the outputs. Use of the Jog control will then make equal changes to the two outputs.

3. Simultaneous Recall of Stored Settings

Each output has its own set of 50 memories. However, when in Link mode, a further set of

50 memories is available which can store settings for both outputs. Voltages and currents

can be set individually for each output and the control put into Link mode before storing. The

stored settings can then be recalled to both outputs simultaneously. Using #98 in Link

mode will clear all the memories of all 3 outputs in all modes, see Extra Functions section.

Notes: The existing settings for Output 1 can be duplicated on Output 2 using the Copy function

before or after linking.

When in Link mode the control functions are limited to Set Range, Set Volts and Set Current

(Numeric Set and Jog set), plus Store and Recall. OVP, OCP and Sense cannot be

changed while in linked mode.

Control of on/off for each output remains separate when in Link mode. To switch the

outputs on or off together the ALL ON/ALL OFF buttons must be used which are

independent of Link mode.

Using #33 in Link mode will lock/unlock front panel control of all 3 outputs simultaneously.

Selecting Link Mode

The only constraint on selecting Link mode is that both Main Outputs must already be set to the

same Range; in particular, the outputs may be linked even if their output voltage and current limit

23

Page 25

settings are different. Pressing LINK when different ranges are set will cause the buzzers to

sound twice and the Range indicator of the previously unselected output to flash for 2 seconds.

Selecting Link mode will cancel any Jog selection set on either Main Output.

Set Voltage and Set Current Limit

Setting the output voltage and current limit by numeric entry or Jog control is essentially the same

as for the outputs in independent mode. Using numeric entry the two outputs will be set to

exactly the same new voltage and current limit, irrespective of the settings at the time the outputs

were linked. Note that there can be a finite time difference between the changes on the two

outputs, even if they are changing from the same initial setting; typically this time difference

should be no more than 40ms (80ms max). However, if the settings were different at the time the

outputs were linked, changing the voltage or current limit using the Jog control will maintain the

difference between the two outputs by incrementing/decrementing each output by the same step,

i.e. the outputs will 'track' each other. Tracking will be maintained until one of the outputs reaches

the range limit, at which time each further Jog step will cause the buzzer to sound for that output

(but with the output remaining at the range limit) whilst the in-range output continues to change,

i.e. 'tracking' ceases and the outputs converge with each further step. If the increment/decrement

is reversed the new (smaller) difference between the outputs is maintained until one output

reaches the range limit in the other direction.

If Link mode is exited whilst Jog is selected, Jog continues to be active on the selected output.

Store and Recall

In Link mode a further 50 non-volatile memories are available which are quite separate from the

50 memories for each output in independent mode. The parameters stored are Range, Voltage,

Current Limit, OVP and OCP. Operation in Link mode is exactly as described in the Store, Recall

and Delete paragraphs of the Main Outputs section; the display messages described in these

sections appear in both displays when Link mode is selected.

OVP, OCP and Sense

OVP, OCP and Sense can only be set when either channel is independently selected. The

settings are maintained when Link mode is selected; OVP and OCP can be saved as part of a

Link mode set-up but the Sense setting cannot. If an attempt is made to change OVP, OC P or

Sense whilst in Link mode the display of Output 1 will flash SELCt 1or2 to remind the user

that these parameters must be set independently for each channel. Press ESCAPE to cancel the

flashing display, assign control to the appropriate channel using the CONTROL 1 or 2 keys

and set OVP, OCP, or Sense as described for the individual outputs.

Output Power

Pressing SHIFT, V x A causes the output power of both outputs to be displayed simultaneously in

their respective displays (V x A in the voltage display,

described for independent operation.

Extra Functions

The # functions described in the Extra Functions paragraph of the Main Outputs section can also

be set when the instrument is in Link mode; both displays will show

SHIFT, #. Any # function set in this way will of course be the same for both outputs. However,

the # functions can be different for each output if they are separately set whilst in independent

mode and the function selection will be maintained for each output even when the outputs are in

Link mode.

Bus Type and Address/Baud Rate

The Bus Type, Address and Baud Rate can only be selected when control is assigned to Output

2. The Output 2 display is used to show the parameters being set, exactly as described for

independent operation. If an attempt is made to set these parameters in LINK mode, or with

Output 1 selected, the display of Output 1 flashes

Output 2. Press Escape to clear the display prompt (or wait for it to time out), then select

Output 2.

UA in the current display) exactly as

HASH No._ after pressing

SELCt P.U._2 as a prompt to sel ect

24

Page 26

Main Outputs – Copy Function (T models only)

The principle settings of Output 1 can be copied to Output 2 using the Copy function, irrespective

of the CONTROL mode (1, 2 or LINK) currently selected. The parameters copied are Range,

Voltage, Current Limit, OVP and OCP; the status of Sense, ON/OFF, Jog and the Store contents

are not copied.

Pressing SHIFT, COPY 1>2 causes the Voltage, Current and Range settings of Output 1 to

appear on the displays of Output 2 in flashing mode; the OK key also flashes. Pressing OK

confirms and implements the Copy operation; pressing ESCAPE at that point abandons the

operation.

If the Copy operation will cause a range change to Output 2, and if Output 2 is ON, the Output 2

ON/OFF key also flashes and the output is turned OFF when OK is pressed; the output can also

be turned off directly with its ON/OFF key before OK is pressed.

Auxiliary Output (T models only)

The AUX output can provide up to 3 Am p at an output voltage of 1.00V to 6.00V. The output

voltage is set by the Jog control (only) with a fixed stepping resolution of 10mV; the current limit is

fixed at ≥3A.

The AUX output voltage can be set, and the voltage and current monitored, on the Main Output 1

display with alternate presses of the SET/VIEW button beside the AUX terminals. Press once to

show the AUX V & I (

& I of Output 1.

A shows in front of the V setting to indicate this), press again to show the V

The AUX output is switched on and off with the AUX ON/OFF key; the key is lit when AUX is on.

With the AUX output off, and the AUX V & I shown on the display of Output 1, the AUX output

voltage can be previewed and set using the Jog control; the current limit is fixed and the preview

shows 3.00A. With the AUX output turned on, the Output 1 display shows actual AUX output

voltage and current.

The AUX output is protected against current overload and momentary short-circuit as follows.

When the load current exceeds ~3.00A the I

lamp lights to show that regulation is no longer

LIMIT

maintained. If this overload condition persists for more than approximately 5s the output will trip

off; the AUX ON/OFF key is no longer lit, the I

(if set to show AUX V & I) shows the message

Pressing the AUX ON/OFF key then resets both the I

lamp now flashes, and the display of Output 1

LIMIT

triP in place of the current measurement.

lamp and the Output 1 display to show

LIMIT

preset AUX voltage and current limit. Once the overload condition has been removed the AUX

output can be switched on again.

A further 10 non-volatile memories, separate from the 50 memories for each Main output and Link

mode operation, are available to store AUX output voltage set-ups. Press the SET/VIEW key to

show AUX V & I in the display of Output 1; operation is then exactly as described in the Store,

Recall and Delete paragraphs of the Main Outputs section.

The output terminals are duplicated on the rear panel (screwless terminals) for rack use; there is

no remote sense capability.

The following features of the AUX output can be set/monitored via the remote interfaces:

Set output voltage; readback set output voltage.

Readback actual output voltage and current.

Set a deltaV increment; readback the set increment.

Increment/decrement the output voltage by deltaV.

Switch AUX output on and off.

Readback output on/off status.