Page 1

Type T Series Operation Manual

for T, T-1, T-1-CPF, T-2, T-3, and Systems F

Page 2

Contents

Overview ............................................................. 1

Introduction ............................................................1

Features and Parts Lists..................................................3

Safety Instructions ................................................ 6

Warnings, Cautions, and Notes...........................................6

Setup .................................................................. 7

Assembly ...............................................................7

Operation and Maintenance .................................... 9

Generating Pressure.....................................................9

Priming................................................................10

Connection Diagram ............................................. 13

Crystal Reference Indicators ............................................13

Specifications ...................................................... 14

Support .............................................................. 15

Troubleshooting .......................................................15

Fitting Kits and Spare Parts .............................................19

Appendix A: Assembly Drawings and Parts Lists..........................21

Contact Us.............................................................28

Returning product to AMETEK ..........................................28

Warranty ..............................................................28

Page 3

Overview

INTRODUCTION

The Type T Series hand pump, mounted on a drip pan with a manifold assembly, is capable of producing pressures up to 1000 bar/15 000 psi.

These units are self-contained pressure sources designed to test instruments. They may be used to calibrate pressure gauges or to set hydraulic relief valves

F

and pressure switches. These units produce pressure to test components or systems, and work independently of other pressure sources. CP

Crystal Pressure Fittings (CPF), which allow users to produce leak-free seals without tools or thread tape. CPF ttings also include a self-venting weep hole to

help assure a safe disconnection from a pressurized system.

U.S. Patent No. 8,794,677

T, T-1, and T-2 pumps1 may be ordered as part of a Pump System, complete with a JOFRA or Crystal Pressure Indicator. T-3 pumps ship as part of a complete

comparator testing kit, including four analog test gauges and necessary mounting tools and ttings, all housed in a rugged metal carrying case. For more

details on T-3 comparator testing kits, refer to T-3 Pumps for Hydraulic Comparator Kits on page 2.

All Type T Series Pump Systems include the most commonly used pressure ttings, seals, etc., all packaged in a carrying case with a custom insert.

1 T designates a pump only. T-1 designates a pump with a manifold and tools. T-2 designates a pump with manifold, tools, and a carrying case.

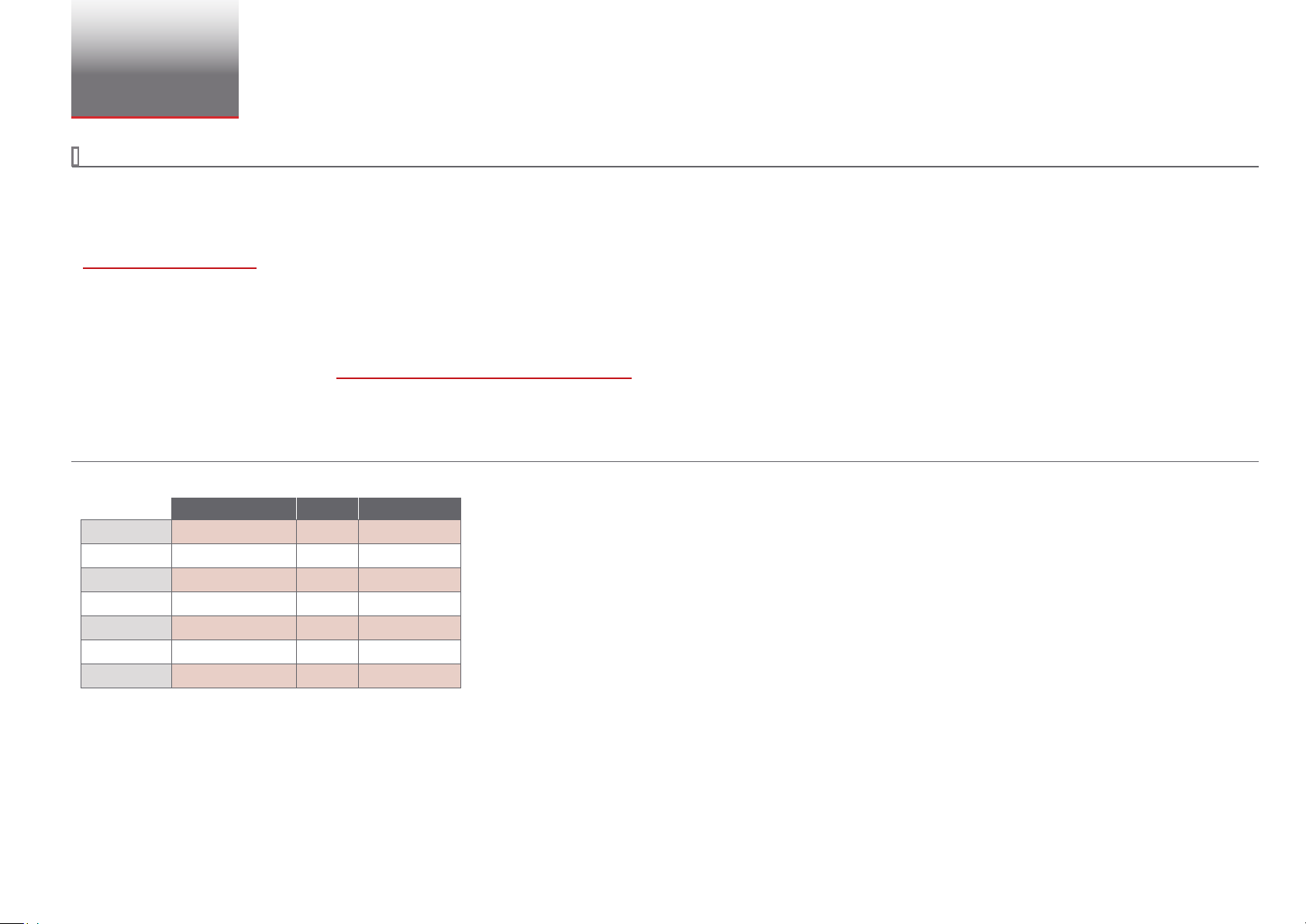

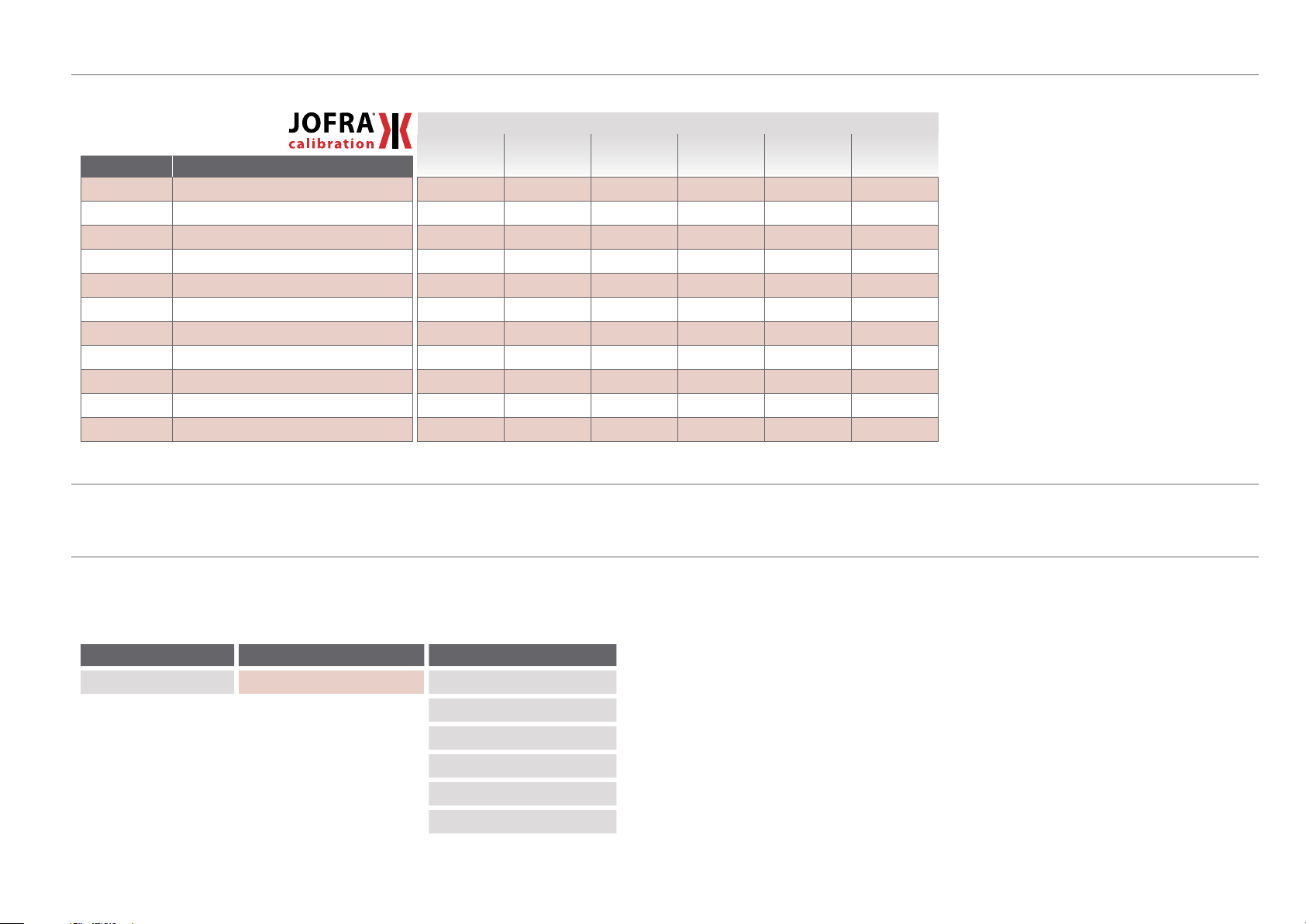

T, T-1, and T-2 Pumps

versions include

Overview 1

Pressure Medium O-rings

T-1 Water

T-1- CPF Oil or Water

T-1/VITON Water

T-1/EPT Water

T-1/OIL Oil Buna-N FOB

T-1/OIL/VITON Oil Viton® FOV

T-1/OIL/EPT Oil EPT

*

Water is a 50/50 mixture of water and Isopropyl Alcohol.

*

*

*

*

Buna-N

Viton® FOV or FWV

Viton® FWV

EPT FWE

Pump System

FWB

FOE

Type T Series Pump System

Type T Pump Operation Manual

Page 4

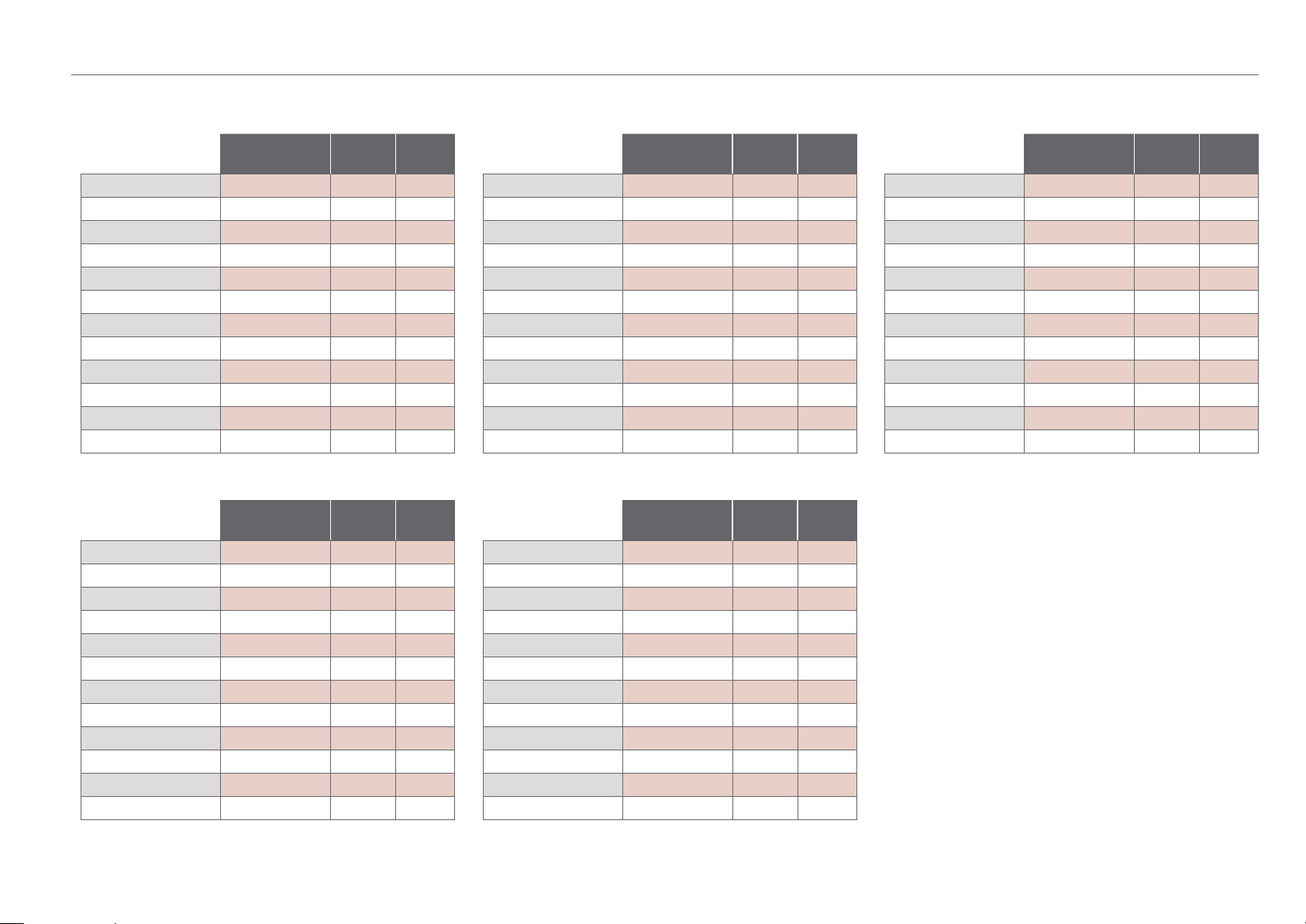

T-3 Pumps for Hydraulic Comparator Kits

Overview 2

X

With 160, 600, 5000, and 10 000 psi Gauges

Cal. Certication

with Data

T-3

T-3/EPT

T-3/VITON

T-3/OIL

T-3/OIL /EPT

T-3/OIL/VITON

T-3/C

T-3/C/EPT

T-3/C/VITON

T-3/C/OIL

T-3/C/OIL /EPT

T-3/C/OIL/VITON

X

With 30, 600, 3000, and 5000 psi Gauges

No Water

No Water

No Water

No Oil Buna-N

No Oil EPT

No Oil VITON

Yes Water

Yes Water

Yes Water

Yes Oil Buna-N

Yes Oil EPT

Yes Oil VITON

Cal. Certication

with Data

T-3A

T-3A/EPT

T-3A/VITON

T-3A/OIL

T-3A/OIL/EPT

T-3A/OIL/VITON

T-3A/C

T-3A/C/EPT

T-3A/C/VITON

T-3A/C/OIL

T-3A/C/OIL/EPT

T-3A/C/OIL/VITON

No Water

No Water

No Water

No Oil Buna-N

No Oil EPT

No Oil VITON

Yes Water

Yes Water

Yes Water

Yes Oil Buna-N

Yes Oil EPT

Yes Oil VITON

Pressure

Medium

Pressure

Medium

X

With 2, 42, 210, and 350 kg/cm² Gauges

O-rings

*

Buna-N

*

EPT

*

VITON

T-3AM

T-3AM/EPT

T-3AM/VITON

T-3AM/OIL

T-3AM/OIL/EPT

T-3AM/OIL/VITON

*

Buna-N

*

EPT

*

VITON

T-3AM/C

T-3AM/C /EPT

T-3AM/C/VITON

T-3AM/C /OIL

T-3AM/C /OIL/EPT

T-3AM/C/OIL/VITON

X

With 200, 4000, 21 000, and 35 000 kPa gauges

O-rings

*

Buna-N

*

EPT

*

VITON

T-3AN

T-3AN/EPT

T-3AN/VITON

T-3AN/OIL

T-3AN/OIL /EPT

T-3AN/OIL/VITON

*

Buna-N

*

EPT

*

VITON

T-3AN/C

T-3AN/C/EPT

T-3AN/C/VITON

T-3AN/C/OIL

T-3AN/C/OIL/EPT

T-3AN/C/OIL/VITON

Cal. Certication

with Data

No Water

No Water

No Water

No Oil Buna-N

No Oil EPT

No Oil VITON

Yes Water

Yes Water

Yes Water

Yes Oil Buna-N

Yes Oil EPT

Yes Oil VITON

Cal. Certication

with Data

No Water

No Water

No Water

No Oil Buna-N

No Oil EPT

No Oil VITON

Yes Water

Yes Water

Yes Water

Yes Oil Buna-N

Yes Oil EPT

Yes Oil VITON

Pressure

Medium

*

*

*

*

*

*

Pressure

Medium

*

*

*

*

*

*

O-rings

Buna-N

EPT

VITON

Buna-N

EPT

VITON

O-rings

Buna-N

EPT

VITON

Buna-N

EPT

VITON

X

With 11, 42, 350, and 700 bar gauges

Cal. Certication

with Data

T-3/BARS

T-3/BARS/EPT

T-3/BARS/VITON

T-3/BARS/OIL

T-3/BARS/OIL/EPT

T-3/BARS/OIL/VITON

T-3/BARS/C

T-3/BARS/C/EPT

T-3/BARS/C/VITON

T-3/BARS/C/OIL

T-3/BARS/C/OIL/EPT

T-3/BARS/C/OIL/VITON

*

Water is a 50/50 mixture of water and Isopropyl Alcohol.

No Water

No Water

No Water

No Oil Buna-N

No Oil EPT

No Oil VITON

Yes Water

Yes Water

Yes Water

Yes Oil Buna-N

Yes Oil EPT

Yes Oil VITON

T-3 Hydraulic

Comparator Testing Kit

Pressure

Medium

*

*

*

*

*

*

O-rings

Buna-N

EPT

VITON

Buna-N

EPT

VITON

Type T Pump Operation Manual

Page 5

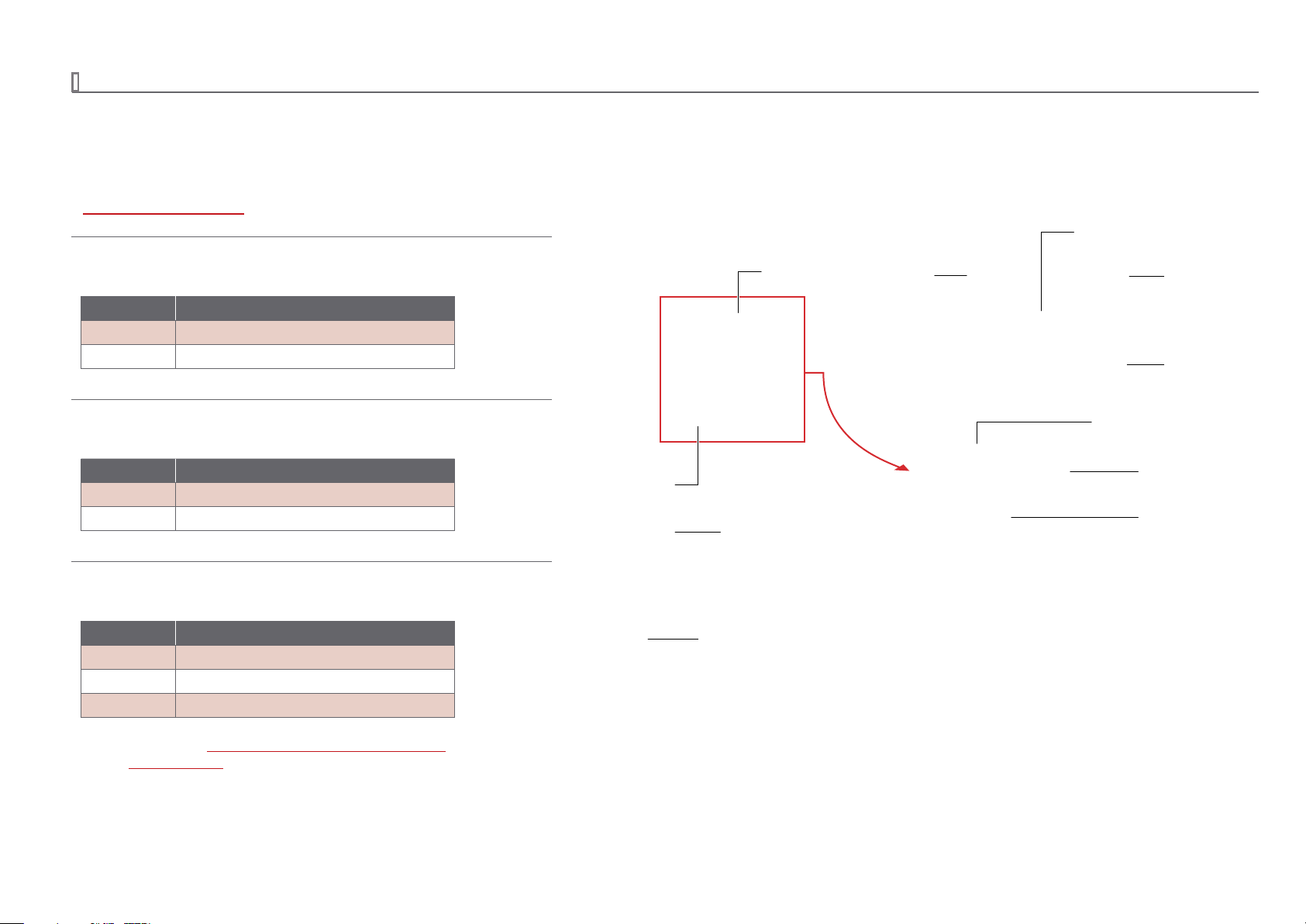

FEATURES AND PARTS LISTS

Type T Series hand pumps may be ordered with either oil or a water/alcohol mixture as the pressure medium. There are three available seal packages for the

system: Buna-N, Viton®, and EPT.

All Type T Series hand pumps feature a vent valve, and dual volume control for rapid pressure increase at lower pressures and easier pumping at higher

pressures. T-1,

T-2, and T-3 models include a dual pressure port manifold with ne adjust, plus replacement o-rings and a set of service tools.

Refer to Figure 3 on page 25 for more details on the included tools.

T-1 and T-2 – Included Parts

X

Reference and Device Under Test Pressure Ports

Part Number Description

T-134 15/16-20 Male to 1/4" NPT Female Adapter

T-135 15/16-20 Male to 1/2" NPT Female Adapter

Check Valve Plug

CPF Fitting

Overview 3

Fine Adjust

NPT Union Body

Manifold Assembly

T-1-CPF – Included Parts

X

Reference and Device Under Test Pressure Ports

Part Number Description

5255 CPF Male to 15/16-20 Male Adapter (2)

4715 MP Female to 1/4" Female NPT Fitting

T-3 – Included Parts

X

Reference and Device Under Test Pressure Ports

Part Number Description

T-134 15/16-20 Male to 1/4" NPT Female Adapter

T-135 15/16-20 Male to 1/2" NPT Female Adapter

– Set of 4 Test Gauges

*

For more details refer to T-3 Pumps for Hydraulic Comparator Kits on page 2

and to Figure 4 on page 26.

*

Fill and Vent Relief Plug

Vent Valve

Valve Rod Selector

Check Valve Plug

Pump Handle

Reservoir Tube

Type T Pump Operation Manual

Page 6

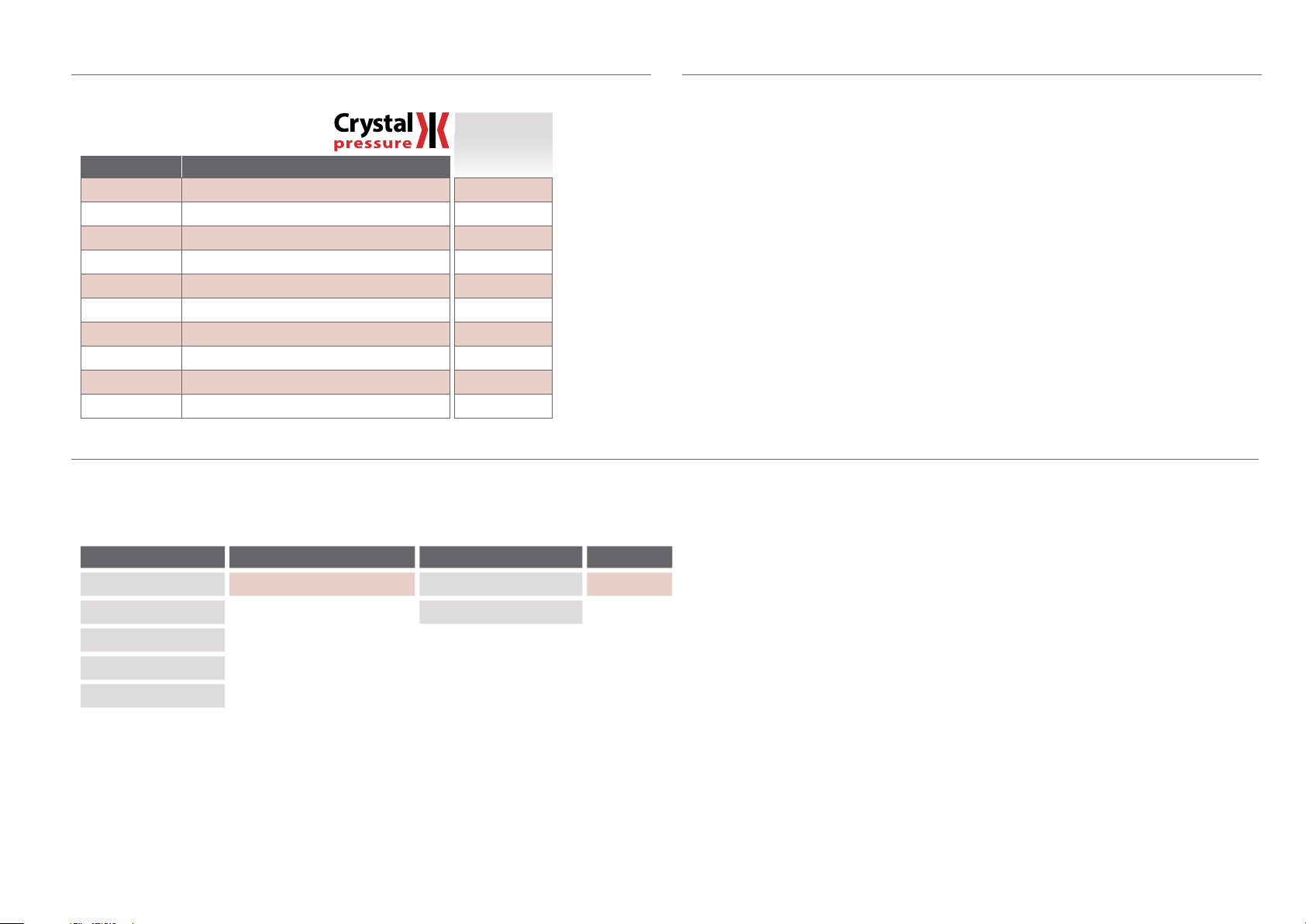

Parts Included with Pump Systems for JOFRA Reference Indicators

Part Number Description

T-134 15/16-20 Male to 1/4" NPT Female Adapter

T-135 15/16-20 Male to 1/2" NPT Female Adapter

T-786 1/4" NPT Male to 1/4" BSP Female Fitting

*

1274 00

*

1274 01

*

1274 02

60 R120 1/4" Bonded Seals

*

404203

60I104 Pack Tape (1 roll)

124004 Shoulder Strap

12430 4 Aluminum Carrying Case

*

Included with HPC.

1/4" NPT Male to 1/8" BSP Male Fitting

1/4" BSP Female to 1/8" BSP Male Fitting

1/8" Bonded Seals

Test Leads; Red & Black, including clips

FWB

(T-1)

FWV

(T-1/Viton)

FWE

(T-1/EP T)

System F

FOB

(T-1/Oil)

FOV

(T-1/O il/Viton)

Overview 4

FOE

(T-1/Oil/EPT)

Hydraulic Fluid

Type T Series Pump Systems are only available delivered empty. You will still need to specify what uid type you are going to use (for example; FOV for Oil or FWV for Water).

Ordering a Pump System

Any Type T Series Pump System may be ordered with or without a reference indicator. The table below provides an explanation of the Pump System ordering

scheme when ordering a system without an indicator. For details on ordering the Pump Systems with an indicator, see the indicator datasheet.

X

Reference Indicator Reference Indicator Included Pump System

HPC500 Series ...HPC500 No ...-NONE System F (T-1) .............-FWB

System F (T-1/Viton) .......-FWV

System F (T-1/EPT) ........-FWE

System F (T-1/Oil) .........-FOB

System F (T-1/Oil/Viton) ...-FOV

System F (T-1/Oil/EPT) .....-FOE

SAMPLE PART NUMBERS

HPC-NONE-FWB ..........System F pump system (for HPC500), for use with water.

HPC-NONE-FOE ...........System F pump system (for HPC500), for use with oil.

HPC500-700G-FOB ........System F pump system for use with oil with a 0.82 to 35 bar HPC500 included.

Type T Pump Operation Manual

Page 7

Overview 5

Parts Included with Pump Systems for Crystal Reference Indicators

System F

FOV and FWV

Part Number Description

5255 CPF Male to 15/16-20 Male Adapter

MPF15K-1/4F PT CPF Female to 1/4" NPT Female Fitting

MPF-1/4BSPF CPF to 1/4" BSP Female Fitting

MPF-1/8MPT

60 R120 1/4" Bonded Seals

1351

5249

60I104 Pack Tape (1 roll)

124004 Shoulder Strap

12430 4 Aluminum Carrying Case

*

The MPF-1/8MPT ttings and 1351 Test Leads are included only with Pump Systems for the 30 Series Calibrator.

*

1/8" MPT Fitting (for 30 Series Calibrator)

*

Test Leads; Red & Black, including clips

Protective Vinyl Cap

(T-1- CPF)

(2 )

(2 )

( 5 )

( 4 )

Hydraulic Fluid

Type T Series Pump Systems are only available delivered empty. You will still need to specify what uid

type you are going to use (for example; FOV for Oil or FWV for Water).

Ordering a Pump System

Any Type T Series Pump System may be ordered with or without a reference indicator. The table below provides an explanation of the Pump System ordering

scheme when ordering a system without an indicator. For details on ordering the Pump Systems with an indicator, see the indicator datasheet.

Reference Indicator Reference Indicator Included Pump System Liquid

nVision ......... NV No ...-NONE System F (T-1-CPF) ... -FOV Drained ...-E

30 Series ........IS30 System F (T-1-CPF) ... -FWV

XP2i ............XP2i

m1 .............. M1

HPC40 Series ...HPC40

X

SAMPLE PART NUMBERS

NV-NONE-FOV-E .......System F pump system (for nVision) drained of uid, for use with oil.

IS30-NONE-FWV-E ....System F pump system (for 30 Series) drained of uid, for use with water.

15KPSIXP2i-FWV-E ...System F pump system, drained, for use with water, with a 15 000 psi XP2i gauge included.

Type T Pump Operation Manual

Page 8

Safety Instructions

WARNINGS, CAUTIONS, AND NOTES

WARNINGS:

!

Do not connect any external pressure source to this instrument. This unit is designed to test pressure measuring devices connected to the manifold

•

only. Pressure from an external source can result in explosion of the liquid reservoir and possible bodily injury.

This pump produces pressure up to 15 000 psi. The pressure rating of tubing and ttings used to connect the pump to the test device should exceed

•

15 000 psi.

Do not operate above 15 000 psi/1000 bar.

•

CAUTIONS:

!

To prevent the reservoir from overowing upon venting, the volume of oil pumped should never exceed the reservoir volume.

•

Never operate the pump without uid in the reservoir. The piston and o-rings require lubrication.

•

Do not operate the ne adjust knob above 3500 psi.

•

The vent plug must be open to operate this instrument.

•

Notes: All wetted parts are stainless steel, Monel, or Buna-N. Optional o-ring materials are Viton and EPT .

Safety Instructions 6

Type T Pump Operation Manual

Page 9

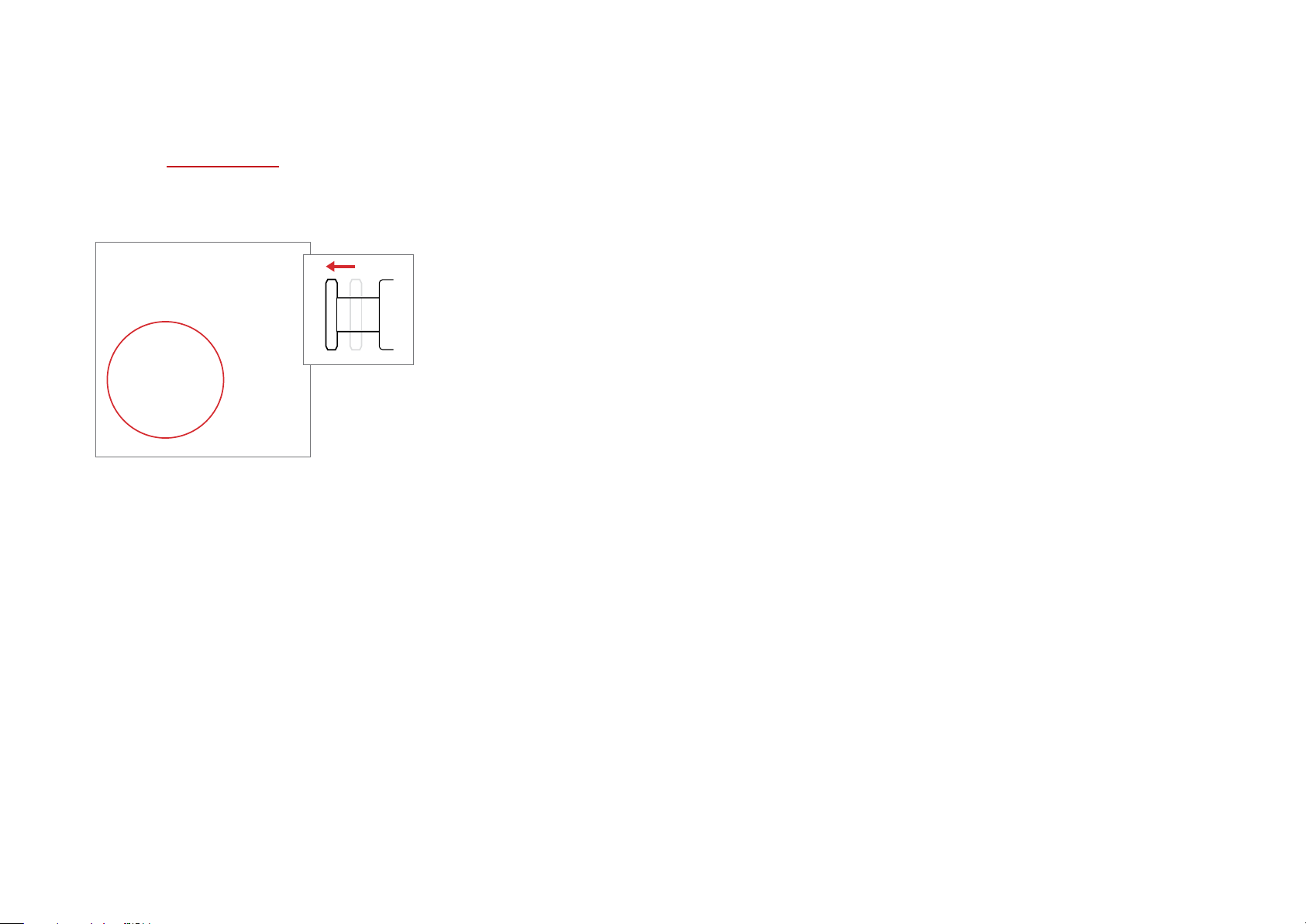

Setup

ASSEMBLY

1 Open the vent valve.

2 Attach the pressure manifold to the pump body.

Setup 7

Manifold Assembly

Type T Pump Operation Manual

Page 10

3 Close the vent valve.

Note: If using the T-1-CPF, ll with test uid through the gauge connections. This may take approximately 15 minutes.

Setup 8

Note: It may be necessary to prime the pump, particularly for rst time use, or if the pump has been inactive for an extended period of time.

Refer to Priming on page 10 for instructions on priming the pump.

Pull the pump handle to the top of its stroke.

4

5 Pull out the valve rod selector to select the low pressure/high volume setting.

6 Gently operate the pump handle until test uid lls the top of the pressure ports on the pressure manifold.

Note: Lightly tap the manifold to make sure that any air bubbles sticking to the walls or in low ow areas are released to oat to the surface.

7 Attach the reference instrument and the device under test to the manifold.

Note: If CPF Fittings are used in your pressure system, remaining air can be purged by applying 10 psi or less and loosening the CPF tting closest to the pres

sure device. When uid and air escape from the CPF weep hole, that portion of the system is purged. Repeat this process for each pressure device in the

essur

e system which is connected to a CPF tting.

pr

-

CAUTION: Always choose a reference instrument with a range equal to or greater than the range of the device under test.

!

8 Ensure all connections are tight and leak free.

Type T Pump Operation Manual

Page 11

Operation and Maintenance

GENERATING PRESSURE

Note: It may be necessary to prime the pump, particularly if the pump has been inactive for an extended period of time. Refer to Priming on page 10

for instructions on priming the pump.

Check that the vent ll plug is fully open by turning it counter-clockwise.

1

2 Open the vent valve.

Operation and Maintenance 9

Open the vent plug… then open the vent valve.

3 Set the valve rod selector to control your desired uid output volume.

Low Pressure/

High Volume

CAUTION: Only move the valve rod selector while the pump handle is stationary, in the up position.

!

Note: With the valve rod in the “out” position, uid ow will be at maximum and the maximum achievable pressure will be 1000 psi. To exceed 1000 psi,

push the valve rod in.

High Pressure/

Low Volume

Type T Pump Operation Manual

Page 12

4 Zero the reference indicator and the device under test.

5 Close the vent valve.

6 Operate the pump handle to achieve a system pressure close to, but less than, your desired target pressure.

7 Pull the pump handle to the top of its stroke.

8 Push in the valve rod selector to select the high pressure/low volume setting.

9 Wait for the pressure to stabilize.

10 Carefully push down the pump handle to achieve the target pressure.

Note: Below 3500 psi, you may also use the ne adjust knob for small pressure adjustments.

11 After obtaining your readings, open the vent valve to vent the system.

WARNING: The device under test and the reference indicator should only be removed when there is no pressure in the system.

!

PRIMING

All pumps are thoroughly tested at the factory before shipment. One of the most common diculties encountered is the loss of prime, which is evidenced by

an inability to build pressure. This is caused by entrapped air in the reservoir, which may collect in the high pressure/low volume check valve. When this occurs, the pump will not develop pressure with the valve rod selector positioned in, to the high pressure/low volume setting. The following priming procedure

or

rect the condition.

will c

Operation and Maintenance 10

Note: For priming purposes, pump vigorously with full strokes of the hand lever.

Note: Verify the pump reservoir has sucient uid.

X

To Prime the Pump

1 Connect a reference indicator with a pressure range of at least 5000 psi to the manifold.

CAUTION: Signicant pressure can develop during the priming process. Therefore, any device mounted to the manifold should have a range of at least

!

2 Plug the remaining port of the manifold.

300 bar / 5000 psi. Alternately, all devices may be removed, and the manifold plugged.

Manifold Plug

Type T Pump Operation Manual

Page 13

3 Pull the pump handle to the top of its stroke.

4 Open the vent valve.

5 Pull out the valve rod selector to select low pressure/high volume.

Open the vent valve… then select low pressure/high volume.

6 Pump ten full strokes.

7 Close the vent valve

Operation and Maintenance 11

8 Continue pumping to verify the low pressure/high volume setting operates properly and that the pump holds pressure.

9 Open the vent valve.

10 Pump ten more strokes.

11 Remove the high pressure/low volume check valve plug.

Type T Pump Operation Manual

Page 14

12 Slowly pump two and one-half strokes, positioning the pump lever at approximately 45 degrees, halfway through its stroke.

13 Allow system uid to ow out of the high pressure check valve, ushing entrapped air.

14 Examine the port for air bubbles which may adhere to the threads or parts.

Note: If air bubbles are present, repeat steps 12 through 14 until no more air bubbles appear.

15 Replace the high pressure/low volume check valve plug and tighten partially.

Operation and Maintenance 12

16 Use slight pressure on the hand lever to push system uid past the high pressure/low volume check valve plug to ensure complete purging of the

valve port.

Tighten the high pressure/low volume check valve plug.

17

18 Operate the pump handle until pumping becomes dicult.

19 Raise the pump handle.

20 Push in the valve rod selector to the high pressure/low volume position.

21 Resume pumping to verify the pump is operating properly.

Note: If the high pressure/low volume setting does not operate properly, there is more air trapped in the high pressure/low volume check valve. The priming

procedure must be repeated.

Type T Pump Operation Manual

Page 15

Connection Diagram

CRYSTAL REFERENCE INDICATORS

Thread tape

required.

MPF-1/8MPT

10

Connection Diagram 13

CPF Fittings Non-CPF MP Fittings

NPT MALE

NPT FEMALE

BSP

MPF-1/8QTM 1/8" Quick Test NPT Male

MPF-1/8MPT 1/8" NPT Male

MPF-1/4QTM 1/4" Quick Test NPT Male

MPF-1/4MPT

Additional N PT sizes available in non- CPF MP adapters

MPF-1/8QTF 1/8" Quick Test NPT Female

MPF-1/4QTF 1/4" Quick Test NPT Female

MPF-1/4FPT 1/4" NPT Female

MPF-1/2QTF 1/2" Quick Test NPT Female

Additional N PT sizes available in non- CPF MP adapters

MPF-1/8BSPF G 1/8" Female

MPF-1/4BSPF G 1/4" Female

MPF-3/8BSPF G 3/8" Female

MPF-1/2BSPF G 1/2" Female

1/4" NPT Male

Medium Pressure FEMALE to NPT FEMALE

10

10

10

10

4501 1/8 NPT

4715

*

4502 3/8 NPT

4503

Medium Pressure FEMALE to NPT MALE

10

10

10

5

4714 1/4 NPT

4494 3/8 NPT

4495 1/2 NPT

4496 3/4 NPT

Medium Pressure MALE to NPT FEMALE

10

10

10

10

4497 1/8 NPT

4498 1/4 NPT

4499 3/8 NPT

4500 1/2 NPT

1/4 NPT

1/2 NPT

15

15

15

15

15

15

15

10

15

15

15

15

15

5255 *

TRANSMITTER

MPF-5/16TRM

MPF-1/4TRM for Honey well

15

5255 *

TUBE

MPF-1/4TBM 1/4" Tube Male

MPF-3/8TBM 3/8" Tube Male

MPF-1/2TBM 1/2" Tube Male

CPF

MPF-MPF Female to Female

MPF-MPFT U T-Union (Female)

MPF-MPFBULK Bulkhead (Female to Female)

MPF-CAP Cap

ADDITIONAL

MPF-M20QTF M20 x 1.5 Quick Test Female

MPF-M20X1.5F M20 x 1.5 Female

MPF-QCN Quick-Connect Nut

MPF-AN4M AN4 Male

* These parts are included with the T-1-CPF pump.

Additional parts are supplied as part of a pump system, or may be ordered separately.

All BSP connections require bonded seals.

for Foxboro, Rosemount,

and Yokogawa

Medium Pressure MALE to NPT MALE

5

5

5

5

5

5

300 bar/5000 psi

10

700 bar/10 000 psi

10

15

10

10

10

5

10

5

5

1000 bar/15 000 psi

(Non-CPF MP adapters require wrench tightening.)

4698 1/4 NPT

4492 3/8 NPT

4493 1/2 NPT

Type T Pump Operation Manual

15

15

15

Page 16

Specifications

Pressure Ranges

T, T-1, T-1-CPF, T-2, and T-3 . . . . . . .0 to 1000 bar / 0 to 15 000 psi

Recommended Test Fluids

The following uids are recommended for use with this pump:

Standard .............................Distilled water or Isopropyl alcohol

Optional .............................. MGAAA oil

Other uids compatible with stainless steel, Monel, Buna N and Teon may be used. Optional Viton and EPT o-rings are available.

Volume ............................... 30 oz (887 mL)

Low Volume / High Pressure Setting ... 2.8 to 3.2 cc per stroke

High Volume / Low Pressure Setting ... 3.0 to 4.0 cc per stroke

Pressure Connections

Specications 14

X

Reference Port

T-1, T-2, and T-3 . . . . . . . . . . . . 1/4" FNPT or 1/2" FNPT

T-1-CPF . . . . . . . . . . . . . . . . . . . . CPF Male

X

Device Under Test Port

T-1, T-2, and T-3 . . . . . . . . . . . . 1/4" FNPT or 1/2" FNPT

T-1-CPF . . . . . . . . . . . . . . . . . . . . 1/4" Female NPT

Note: Additional sizes, including metric ttings, are available. Contact us, or see our CPF datasheet for details.

Dimensions

Pump . . . . . . . . . . . . . . . . . . . . . 224 (L) x 127 (W) x 217 (H)* mm.

Weight . . . . . . . . . . . . . . . . . . . . 18.6 lbs / 8.4 kg

*

Height includes manifold.

Type T Pump Operation Manual

Page 17

Support

TROUBLESHOOTING

Failure to Pump

X

Problem: The pump fails to develop pressure when the hand lever is operated.

X

Solution: Verify that the vent valve is closed and that there is sucient uid in the reservoir. If necessary, add uid through the ll plug and follow the Pump

Priming Procedure.

If the failure continues, one or both of the check valves may be leaking. Use the following procedure to replace both the high pressure and low pressure o-rings.

X

To Replace the Check Valve O-rings

1 Raise the pump handle to the top of its stroke.

2 Position the valve rod selector for the o-ring you wish to replace.

(a) Pull out the valve rod selector to select the low pressure/high volume setting.

(b) Push in the valve rod selector to select the high pressure/low volume setting.

3 Remove the plug and o-ring from the port for the check valve o-ring you wish to replace.

Support 15

Low pressure/high volume check valve plug and o-ring. High pressure/low volume check valve plug and o-ring.

Type T Pump Operation Manual

Page 18

4 Remove the check valve spacer, spring, valve poppet, and check valve o-ring.

Check Valve O-ring

Valve Poppet

Spring

Check Valve Spacer

5 Inspect the check valve o-ring, and replace it if necessary. Then re-install the o-ring, valve poppet, spring, and check valve spacer.

6 Slowly pump two and one-half strokes, positioning the pump lever at approximately 45 degrees, halfway through its stroke.

7 Allow system uid to ow out of the low pressure check valve, ushing entrapped air.

8 Examine the port for air bubbles which may adhere to the threads or parts.

Note: If air bubbles are present, repeat steps 2 through 5 until no more air bubbles appear.

Support 16

9 Install the check valve plug and o-ring and tighten partially.

10 If installing the low pressure/high volume check valve plug... Tighten the check valve plug.

The procedure for the low-pressure/high volume side is now complete.

11 If installing the high pressure/low volume check valve plug... Use slight pressure on the hand lever to push system uid past the high

pressure/low volume check valve plug to ensure complete purging of the valve port.

Tighten the high pressure/low volume check valve plug.

12

13 Operate the pump handle until pumping becomes dicult.

14 Raise the pump handle to the top of its stoke.

15 Push in the valve rod selector to the high pressure/low volume position.

16 Resume pumping to verify the pump is operating properly.

Type T Pump Operation Manual

Page 19

Pump Does Not Hold Pressure

Retaining Plug

X

Problem: The pump operates but the pressure declines beyond normal adiabatic eects.

X

Solution: One of two o-rings may be leaking. As the pressure drops, observe the hand lever. If the hand lever rises, the discharge check valve is leaking and

its o-ring should be replaced.

X

To Replace the Discharge Check Valve O-ring

1 Remove the plug and o-Ring from the front of the pump body.

Support 17

2 Use a screwdriver to loosen and remove the retaining plug. then remove the guide rod, spring, valve poppet and check valve o-ring.

Check Valve O-ring

Valve Poppet

Spring

Guide Rod

3 Inspect the check valve o-ring, and replace it if necessary. Then re-install the o-ring, valve poppet, spring, and guide rod.

4 Thread in the retaining plug until it is tightly seated. Then back o 3 ½ turns to provide sucient travel for the valve poppet.

5 Install the check valve plug and o-ring.

Type T Pump Operation Manual

Page 20

X

To Replace the Vent Valve O-ring

1 Apply a wrench to the nut at the base of the pressure relief valve.

2 Remove the vent valve and its o-ring.

3 Remove the relief valve seat and its o-ring.

Support 18

Relief Valve Seat O-ring

Relief Valve Seat

4 Inspect the relief valve seat o-ring, and replace it if necessary. Then re-install the o-ring, valve poppet, spring, and guide rod.

5 Install the vent valve and o-ring.

Type T Pump Operation Manual

Page 21

FITTING KITS AND SPARE PARTS

Service Kits

Support 19

X

T, T-1, T-2, and T-3

T-250 .............Buna N rebuild kit

T-559 .............Viton rebuild kit

T-326 .............EPT rebuild kit

Hoses

X

T-1

KH-18 .............Hose. 0.46 m 1/4" NPT male x 1/4" NPT male 700 bar / 10 000 psi.

Adapters

X

T-1, T-2, and T-3

T-134 ..............Union Body. 15/16-20 UNEF male x 1/4" NPT female.

T-135 ..............Union Body. 15/16-20 UNEF male x 1/2" NPT female.

T-186 ..............Union Body. 15/16-20 UNEF male x 7/16" NPT female.

T-331 ..............Union Body. 15/16-20 UNEF male x 3/8" NPT female.

T-863 ..............Union Body. 15/16-20 UNEF male x 1/8" NPT female.

T-786 ..............Adapter. 1/4" NPT male x 1/4" BSP female.

X

T-1-CPF

T-559 ..............Viton rebuild kit

X

T-1-CPF

MPH-1. . . . . . . . . . . . .1 meter CPF hose. 700 bar / 10 000 psi.

X

T-1-CPF

Refer to the Connection Diagram on page 13 for a complete list of adapters.

T-787 ..............Adapter. 1/4" NPT male x 1/2" BSP female.

T-915 ..............Quick Connector. 1/4" NPT male.

T-916 ..............Quick Connector Plug. 1/4" NPT male.

Type T Pump Operation Manual

Page 22

Frequency of Recertication

Four test gauges are included with each T-3 Comparator. Gauges rated up to 5000 psi / 350 bar / 21000 kPa / 210 kg/cm2 are 0.25% of full scale. Gauges rated

2

at 10 000 psi / 700 bar / 35000 kPa / 350 kg/cm

are 0.5% of full scale. All of the gauges can be ordered with or without calibration certicates. For detailed

information on the gauges refer to Figure 4 on page 27.

As a general rule, AMETEK, M&G test gauges should be tested and recertied every 12 months. Testers used frequently, or with dirty uids, should be tested

and certied at more frequent intervals. Master units, used infrequently with clean uid, may need to be tested and certied less frequently.

Note: It is not necessary to send in the pump if it is operating properly. Pumps may be refurbished at a nominal charge.

Note: In order to reduce process time and your overall cost, please do not send in any customized ttings, hoses, tools, or small miscellaneous parts.

Certication Options for New and Used Comparators

Before ordering a new T-3 comparator or sending an old comparator back to M&G, specify one of the following certication options and any

additional requirements on your purchase order. Contact your distributor if you need any assistance.

Option Description Details

A Standard certication of accuracy traceable to NIST standards. Item is repaired and calibrated. No data is provided.

Options with Additional Cost

B "With Data" — Option A Plus Data. Item is repaired and calibrated. Data is provided.

C "As Received/As Left" — Data plus Option A.

Item is cleaned and tested with no adjustments or repairs. Then the item is adjusted

or repaired and recalibrated if necessary.

Support 20

Type T Pump Operation Manual

Page 23

APPENDIX A: ASSEMBLY DRAWINGS AND PARTS LISTS

X

Figure 1.1 • Hydraulic Hand Pump Type T Assembly

Support 21

5 ( pg 25)

Detail A

Detail B ( pg 22)

Detail C

( pg 23)

6

7

8

Detail A

7

1

2

3

9

10

11

4

Type T Pump Operation Manual

Page 24

X

Figure 1.2 • Hydraulic Hand Pump Type T Assembly

12

Support 22

25

26

27

**

*

Detail B

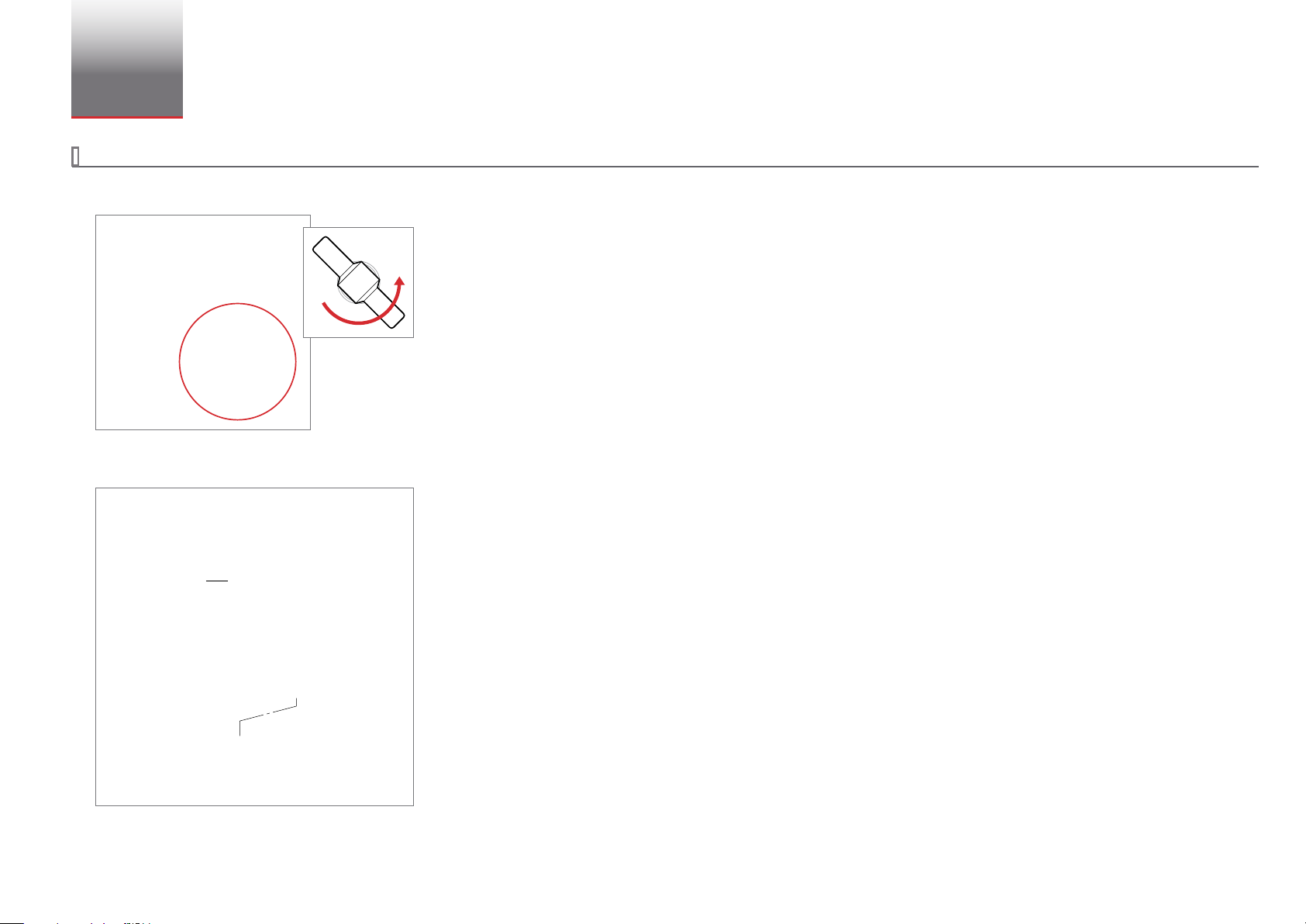

The pump handle and piston can be removed as an

*

assembly for inspection of the o-rings and backup rings.

Remove the upper clevis pin (15) and cotter hair pin (17).

Then unscrew the cylinder retaining plug (18) and pull

the assembly straight up.

At the bottom of the pressure stroke, the piston should

rest on the body plate liner (29) before the pump handle

hits the cylinder retaining plug. If it does not, loosen the

piston pin screw (14), insert a small rod in the hole

provided at the top of the piston, and rotate the piston

counterclock-wise to raise the pump handle. When the

pump handle is raised to the proper height, tighten the

piston pin screw.

The pump cylinder must be removed and reassembled

**

from the top. Otherwise, the o-rings may be cut by the

angular, intersecting hold in the lower portion of the

pump body casting bore. To remove the cylinder, rst

detach the body plate (30) and body plate liner (29), then

push the cylinder up and out from the bottom.

On reassembly, moisten the o-rings with system uid and

rotate the cylinder as you insert it, to avoid cutting or

pinching the o-rings. A tapered piece of wood may be

helpful to rotate the cylinder.

13

14

15

16

19

17

18

20

21

22

23

24

26

25

28

29

18

30

31

16

(17)

Type T Pump Operation Manual

Page 25

X

Figure 1.3 • Hydraulic Hand Pump Type T Assembly

Support 23

38

37

36

35

44

33

32

Detail D

51

Detail D

Detail C

54

33

34

35

36

37

38

26

14

23

42

41

39

40

33

44

35

45

46

*

47

48

52

53

49

50

**

43

14

Thread in the retaining plug until all parts are solid. Then back o about 3 1/2 turns to provide sucient travel for the poppet.

*

The valve rod is held in place with parts 49, 50, and 51. Access to these parts is gained by rst draining the uid, then removing the reservoir.

**

Type T Pump Operation Manual

Page 26

X

Figure 1.4 • Hydraulic Hand Pump Type T Assembly Parts List

Support 24

Item

Number

1 – Type T Pump Assy 1

2 01-90007 Screw, Drip Pan Attaching 4

3 T-167 Washer, Drip Pan Attaching 4

4 T-118 Drip Pan 1

5 T-149 Manifold Assembly (see page 32) 1

6 T-328 Cap, Reservoir 1

7 10-90010 O-ring, Reservoir Tube (T-156) 2

8 T-131 Tube, Reservoir 1

9 T-130 Stud, Reservoir 1

10 T-140 Tube, Inlet 1

11 12-90152 Fitting, Inlet Tube 1

12 T-165 Handle, Pump 1

13 T-145 Pin, Piston 1

14 T-161 Shoe, Piston Pin 1

15 T-16 0 Screw, Piston Pin 3

16 T-142 Pin, Clevis 2

17 T-143 Clevis 1

18 T-14 4 Hair Pin, Cotter 2

19 T-10 8 Plug, Cylinder Retaining 1

20 10 -90019 Back-up Ring, Piston (T-158) 1

21 10-90006 O-ring (T-154) 1

22 T-10 6 Piston 1

23 10-90005 O-ring (T-151) 2

24 10-90018 Back-up Ring, Piston (T-159) 1

25 10-90020 Back-up Ring, Cylinder (T-112) 2

26 10-90 013 O-ring (T-153) 3

27 T-236 Cylinder, Pump 1

28 10 -90012 O-ring, Cylinder (T-164) 1

29 T-595 Liner, Body Plate 1

30 T-408 Plate, Body 1

31 01-90004 Screw, Body Attaching 3

32 IGT-302 Plug and Spacer, Fill and Vent Relief Assy 1

Part

Number

Description

Units Per

Assembly

Item

Number

33 10-90001 O-ring (T-152) 3

34 T-194 Poppet, Valve 1

35 C V-1-5 Spring, Check Valve 3

36 T-127 Spacer, Check Valve 2

37 10-90027 O-ring (T-154) 2

38 T-117 Plug, Pump Body 2

39 10-90002 O-ring (T-175) 1

40 T-111 Seat, Relief Valve 1

41 T-10 9 Body, Relief Valve 1

42 10-110 Stem, Relief Valve 1

43 T-773 Handle, Relief Valve 1

44 T-147 Poppet, High Pressure Valve 2

45 T-107 Guide Rod 1

46 T-141 Plug, Retaining 1

47 10-90009 O-ring (T-136) 1

48 T-103 Plug 1

49 T-166 Screw 1

50 T-116 Spring, Valve Rod 1

51 T-133 Detent Pin, Valve Rod 1

52 10-90004 O-ring 1

53 T -115 Valve Rod 1

54 T-12 0 B ody, Pump 1

Part

Number

Description

Units Per

Assembly

Type T Pump Operation Manual

Page 27

X

Figure 2 • Manifold Assembly and Parts List

Support 25

7

Item

Number

8

9

10

18

— T-149 Type T Manifold Assembly —

1 — Thread Protector, ½ NPT 1

Part

Number

Description

Units Per

Assembly

2 T-135 Body, Uni on — ½ NPT 1

7

11

19

3 10-90027 O-ring (T-154) 3

4 T-126 Nipple, Union 3

12

13

1

2

14

15

16

20

19

21

5 10-90009 O-ring, Union Nipple (T-136) 3

6 T-146 Nut, Union 3

7 T-102 Knob, Handle 2

8 T-119 Handle, Fine Adjust 1

9 T-132 Handle Hub, Fine Adjust 1

10 T-174 Screw, Hub 1

11 T-113 Bushing, Fine Adjust Piston 1

12 10 -9 0011 O-ring, Fine Adjust (T-157) 1

13 T-19 0 Plug, Friction 1

14 10 -9 0017 Back-up Ring, Fine Adjust (T-179) 1

3

3

15 10-90001 O-ring, Fine Adjust (T-152) 1

16 T-114 Piston, Fine Adjust 1

17 T-125 Manifold, Oset Pipe 1

4

5

17

3

4

5

18 99-90001 Cap 1

19 10-90005 O-ring, Nipple (T-151) 2

20 T-185 Nipple,

7

/16 –20 UNF 1

21 T-186 Body, Uni on — 7/16 –20 UNF 1

22 T-162 Plug, Pipe 1

23 T-13 4 B ody, Unio n — ¼ NPT 1

4

6

6

22

5

23

6

Type T Pump Operation Manual

Page 28

X

Figure 3 • Service Tools and Parts List

Support 26

Item

Number

Part

Number

Description

Units Per

Assembly

1 1GT-99 Puller and Set Assembly, Gauge Pointer 1

2 T-180 Wrench,

5

/32" Hexagon Key, Short Series 1

3 T-204 Wrench, 3/16" Hexagon Key, Tee Handle 1

1

4 T-239 Wrench, 1/4" Hexagon Key, Tee Handle 1

5 1GT-200 Wrench, Open End, Thin 1" 1

6 T-184 Wrench, Open End, Thin 1 5/8" 1

7 T-182 Wrench, Open End, Thin

5

6

2

3

7

5

/8" x 3/4" 1

4

Type T Pump Operation Manual

Page 29

X

Figure 4 • Gauge and Fitting Assembly and Parts List

Support 27

Item

Number

1

200

150

100

50

0

250

300

PSI

1

2

3

2

4

**

3 T-173 Body, Union

4 10-90027 O-ring, Body Union

Gauges will be provided based on the Comparator Testing Kit selected.

*

One each per Gauge Assembly.

Part

Number

— Gauge and Fitting Assembly 4

T-274 Test Gauge, 4 ½", 0-30 psi

T-275 Test Gauge, 4 ½", 0-160 psi

T-276 Test Gauge, 4 ½", 0-600 psi

T-277 Test Gauge, 4 ½", 0-3000 psi

T-278 Test Gauge, 4 ½", 0-5000 psi

T-279 Test Gauge, 4 ½", 0-10 000 psi

T-590 Test Gauge, 4 ½", 0 - 2 kg/cm²

T-591 Test Gauge, 4 ½", 0 - 42 kg/cm²

T-592 Test Gauge, 4 ½", 0 - 210 kg/cm²

T-593 Test Gauge, 4 ½", 0 - 350 kg/cm²

T-596 Test Gauge, 4 ½", 0 - 200 kPa

T-597 Test Gauge, 4 ½", 0 - 4000 kPa

T-598 Test Gauge, 4 ½", 0 - 21 000 kPa

T-599 Test Gauge, 4 ½", 0 - 35 000 kPa

T-604 Test Gauge, 4 ½", 0 - 11 bar

T-605 Test Gauge, 4 ½", 0 - 42 bar

T-606 Test Gauge, 4 ½", 0 - 350 bar

T-607 Test Gauge, 4 ½", 0 - 700 bar

10-90009 O-ring, Body Union (T-136)

Description

Units Per

Assembly

**

**

**

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Type T Pump Operation Manual

Page 30

CONTACT US

Support 28

United Kingdom

Tel +44 (0)1243 833 302

jofra@ametek.co.uk

France

Tel +33 (0)1 30 68 89 40

general.lloyd-instruments@ametek.fr

RETURNING PRODUCT TO AMETEK

Please contact your sales representative to complete a Return Material Authorization (RMA) form and/or receive an RMA number.

Return/shipping instructions will be provided with the RMA number.

WARRANTY

This instrument is warranted against defects in workmanship, material and design for one (1) year from date of delivery to the extent that AMETEK will, at its sole

option, repair or replace the instrument or any part thereof which is defective, provided, however, that this warranty shall not apply to instruments subjected to

tampering or, abuse, or exposed to highly corrosive conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED AND AMETEK HEREBY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ANY WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. AMETEK SHALL NOT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, ANY ANTICIPATED OR LOST PROFITS.

Germany

Tel +49 (0)2159 9136 510

info.mct-de@ametek.de

Denmark

Tel +45 4816 8000

jofra@ametek.com

USA

Florida - Manseld & Green

Tel +1 (800) 527 9999

cal.info@ametek.com

California - Crystal Engineering

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

Singapore

Tel +65 6484 2388

jofra@ametek.com

China

Shanghai

Tel +86 21 5868 5111

Beijing

Tel +86 10 8526 2111

Guangzhou

Tel +86 20 8363 4768

jofra.sales@ametek.com.cn

This warranty is voidable if the purchaser fails to follow any and all instructions, warnings or cautions in the instrument’s Instruction Manual.

If a manufacturing defect is found, AMETEK will replace or repair the instrument or replace any defective part thereof without charge; however, AMETEK’s obliga

tion hereunder does not include the cost of transportation, which must be borne by the customer. AMETEK assumes no responsibility for damage in transit, and

any claims f

or such damage should be presented to the carrier by the purchaser.

-

Type T Pump Operation Manual

Page 31

5104.H

© 2018 AMETEK Incorporated

8600 Somerset Drive, Largo, Florida 33773

Loading...

Loading...