Page 1

STS Series

Superior Temperature

Reference Sensors

Page 2

Product Description

SUPERIOR TEMPERATURE REFERENCE SENSORS are a series of high quality sensors, ideal for

STS

important. STS sensors are based on more than 50 years of industrial temperature sensor manufacturing

experience.

industrial temperature calibration applications where accuracy and long-term stability are

Features

The main requirement of a reference sensor is stability: The less the sensor drifts, the lower the mea-

surement uncertainty. All JOFRA Superior Temperature Reference Sensors are economical and oer fast

—

response times, low immersion depths, compact physical sizes, and specied low drift rates

temperatures. These are all important considerations when selecting a reference sensor.

In addition to the standard straight sensors, we oer a special cable type reference sensor, permitting the

sensor to be positioned throughout the depth of the well in a dry block (for example) under a sanitary

ange. In addition, we have a specic series of intelligent sensors developed for use with the DTI050 refer-

ence indicator.

even at high

Key Features

Wide Temperature Range

-150 to 700° C (-238 to 1292° F). A single sensor may cover the complete

temperature range.

Fast Response Time

Ensures correct monitoring of temperature stability in liquid baths or dry-block

calibrators.

Specied Low Drift

Maintains a minimal uncertainty budget over the entire period between re-calibration

intervals. Allows for easier recalibration scheduling.

Calibration Certicate

Wide choice of accredited and traceable certicates.

Page 3

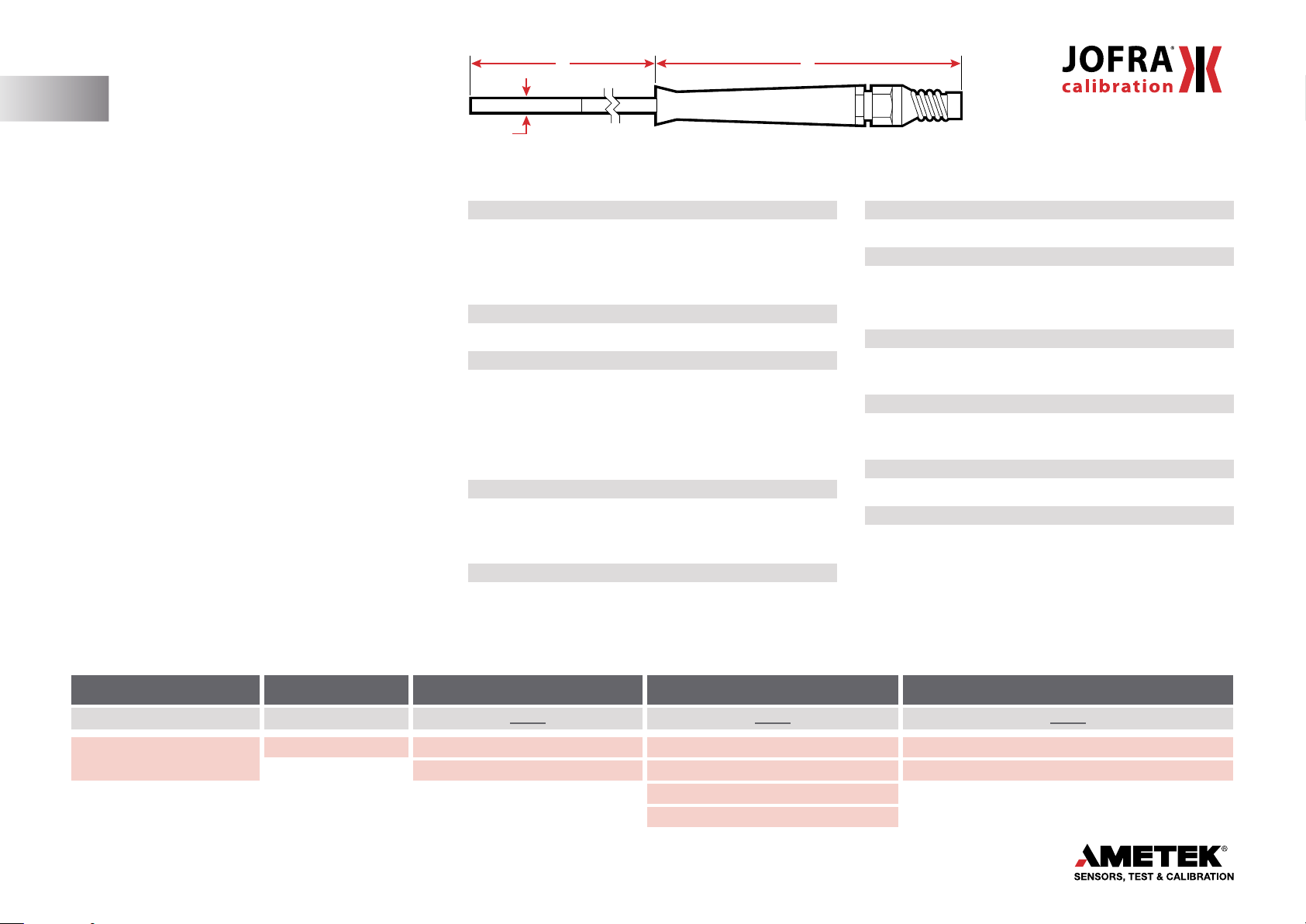

STS-050 A

CA

B

Measuring Temperature with

JOFRA Reference Sensors

The JOFRA STS-050 A probes are designed for fast and accurate,

traceable calibration of temperature. STS-050 can be used for

measuring and calibration with AMETEK DTI Series, PTC B & C

Series, RTC B & C Series, HPC Series, ATMi and ASC series.

Standard delivery includes International traceable calibration

certicate, and accredited (ISO/EN/IEC 17025) calibration cer-

ticate can be chosen by selecting calibration option H. Several

connection options can be selected, to adapt our wide range of

calibrators.

Standard Delivery

STS-050 A sensor with handle Sensors delivered in carton box

Traceable calibration certicate, 7 calibration points from -45 to

400° C

Cable – according to order number User manual.

Specications

Dimensions

Reference A ....................................250 mm (9.84 in)

350 mm (13.78 in)

Reference B ...................................... 4 mm (0.16 in)

Reference C ....................................140 mm (5.51 in)

Temperature Range

All Sensors ...........................-50 to 400° C (-58 to 752° F)

Accuracy

Hysteresis

Long Term Stability

Repeatability

(1) When used in the range -50 to 400° C (-58 to 752° F).

(2) When exposed to 400° C (752° F) for 100 hours. Stability will depend on

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

Temperature Coecient .....................

Minimum Immersion Depth

STS-050 A – 4 mm (0.16 in). . . . . . . . . . . . . . . . . . . . . .100 mm (3.94 in)

(1)

@ 0° C (32° F) .......................0.01° C (0.02° F)

(2)

@ 0° C (32° F) ..... typical 0.014 ° C (0.025° F)

(1)

@ 0° C (32° F) ...................0.005° C (0.009° F)

actual use of the sensor.

α

=0.00385 1/°C

100

Self-Heating Eect

0.06 °C /mW (0.11 °F/mW)

Response Time

STS-050 A – 4 mm (0.16 in): τ

–

STS-050 A

Liquid in motion v = 0.4 m/s.

Electrical Connections

Cable .................................................... 4-wire

Connection ..See "Cable Length and Termination" options below

Insulation Resistance

@ 23° C (73° F) .......................................100 Gohm

@ 400° C (752° F) ......................................70 Mohm

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 0 to 90% RH

Protection Class .................................DIN 40050 IP-50

4 mm (0.16 in): τ

(50%) ...................8 seconds

0.5

(90%) ................. 26 seconds

0.9

Ordering Information

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS050 A

Pt100 reference sensor, solid, with handle,

-50 to 400° C (-58 to 752° F)

Sample Order Number

STS050A250DF ...4 mm STS-050 reference sensor, straight 250 mm, cable length 1 m (3.3 ft)

with REDEL connector for DTI050, and NPL traceable calibration certicate.

Overall diameter 4 mm (0.16 in) Straight sensor, 250 mm (9.8 in) in carton ....250 1 m (3.3 ft) REDEL connector for RTC/PTC/DTI050. . . . . . D Traceable certicate to international standards. Standard -45 to 400° C ...F

Straight sensor, 350 mm (13.8 in) in carton ...350 1 m (3.3 ft) 4 banana plugs for ASC Series .............F Accredited certicate. ISO17025. Option -45 to 400° C ..................H

1 m (3.3 ft) 4 pin LEMO connector for DTI 1000/HPC ... G

1 m (3.3 ft) 6 pin LEMO connector for ATMi ...........H

Page 4

A

B

STS-100 A/B

Quality Dened

It is not easy to make a good quality reference sensor. The main requirement of a reference sensor

is stability. This means minimal drift as a function of operating time at the actual temperature. The

less the sensor drifts, the lower the measurement uncertainty.

Standard Diameter — Fast Response

The STS-100 A/B series has a relatively small diameter: STS-100 A is 4 mm / 0.16 in, and STS-100 B is

6.35 mm / 0.25 in. This leaves optimum space for sensors-under-test in the dry-block, and ensures

a fast response time. A fast reacting sensor will optimize the measurement information.

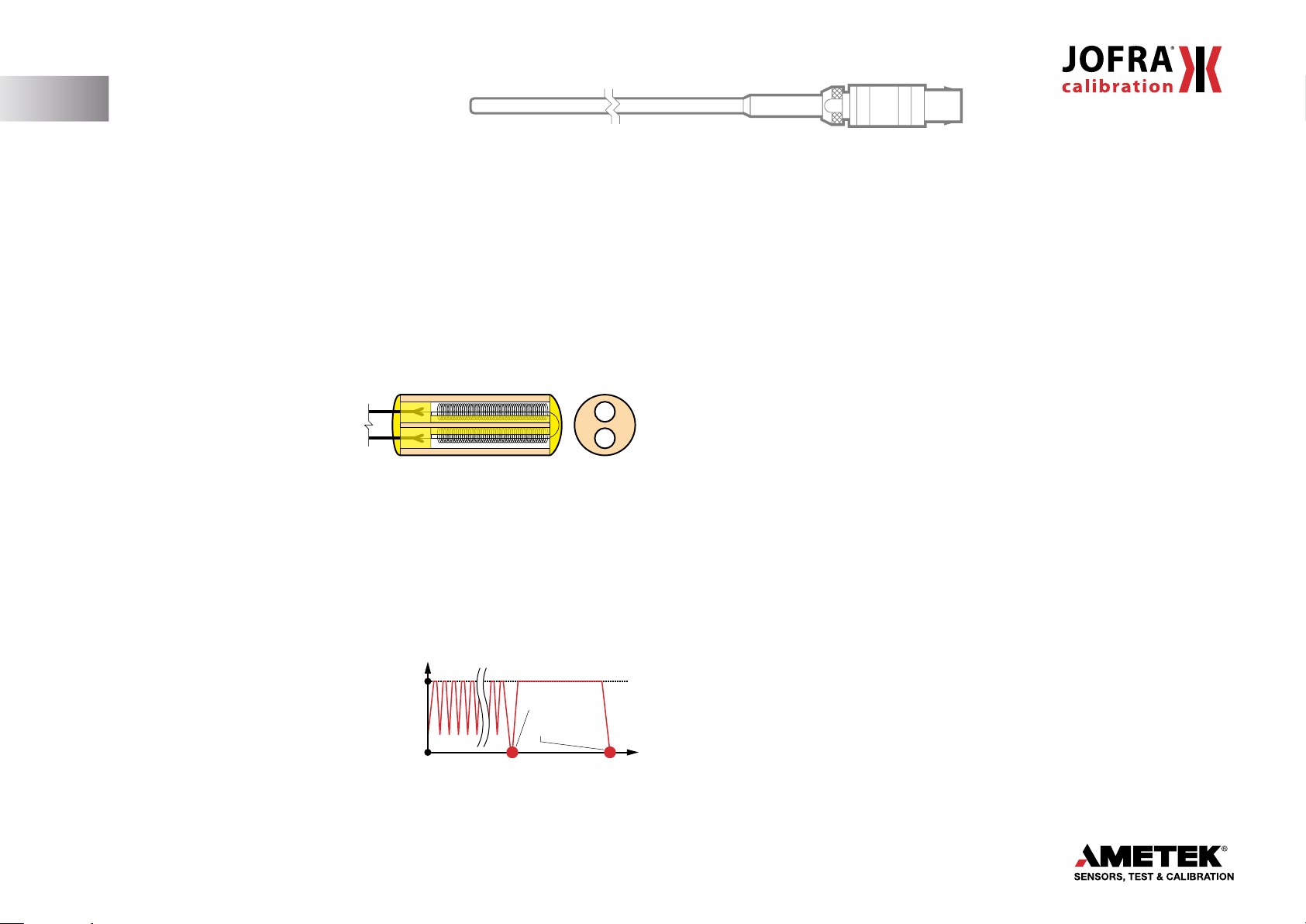

Reduced Hysteresis and Drift

The sensing element is comprised of a pure plat-

inum coil. This coil is suspended in a way that

minimizes stress and ensures a near zero hysteresis value.

The main reason for drift within a sensor assembly is impurities within the element, especially at

temperatures above 350° C (660° F). All internal parts must be cleaned thoroughly. AMETEK has

developed a unique cleaning method for the internal bore of the Inconel® sheath. The platinum

sensor is embedded within an ultra-clean, temperature resistant ceramic; and assembly of the

components is performed in a clean room. These precautions ensure minimum contamination of

the element during use, and provide the user with the best possible performance.

Aging /Annealing

Once the sensors are assembled, they are subjected

to a long approval process. This includes mechani-

cal stress reduction of the entire assembly as well

as aging the sensor element itself. The purpose of

aging the sensor is to remove the initial drift.

The procedure involves heating the sensor up to 650° C (1202° F) and holding it for 1 hour before

cooling down. This process is repeated over a period of several days. The resistance is then mea-

sured at 0° C (32° F) and recorded. The sensor is again heated up to 650° C (1202° F), and this time

the temperature is held constant for 100 hours.

(1202º F)

JOFRA STS-100 A Annealing the probes

650º C

0º C

(32º F)

First

measurement

Second

measurement

Time

Finally the output from the sensor is again measured at 0° C (32° F) and recorded. The dier-

ence between the rst and second measurement is recorded. The dierence between these two

measurements is our verication of the stability qualities of the sensor. To be accepted for nal

calibration and certication, the sensor must meet our minimum tolerance, which we document

in a quality certicate.

Reduced Isolation — Resistance-Error

Electrical isolation resistance (parasite-resistance-error) when measured at the highest operat-

ing temperature should be as high as possible. A low isolation resistance would cause the output

signal to be incorrect in relation to the temperature. JOFRA STS-100 A/B series sensors meet the

IEC-751 requirements of isolation resistance by several hundred percent.

The Final Quality-Certificate-Check

Upon completion of every certicate, after nal calibration of the sensor, examination and ap-

proval cycles are performed according to our established procedures. The critical verication is

to ensure that the dierence between the initial and the nal 0° C (32° F) measurement on the

certicate meets our minimum tolerance. These requirements are based on a vast amount of data,

which has been evaluated statistically. This value indicates if the sensor has a sucient long-term

stability. We also check that the linearization coecients have values that correlate to an accept-

able curve sequence in accordance with our requirements.

Certification

The nal documentation on sensors is the calibration certicate. JOFRA sensors have the follow-

ing calibration options.

Accredited Certificate (Standard) Traceable to the European Accreditation Organization.

Temperature range from -45 to 650° C (-49 to 1202° F).

The certicate contains a minimum of 6 temperature points starting and ending at 0° C (32° F).

The certicate also contains calculated linearization coecients.

Delivery Without Certificate — Annealed Only (Optional) In some cases, the customer

may prefer to calibrate the sensor themselves. It is possible to purchase the sensor without any

certication. We do not recommend this option because we are not able to complete the nal

“quality-certicate-check.”

Page 5

STS-100 A/B

Specications

A

B

Dimensions

Reference A ....................................250 mm (9.84 in)

350 mm (13.78 in)

500 mm (19.69 in)

Reference B ..................4 mm (0.16 in) or 6.35 mm (0.25 in)

Temperature Range

All Sensors .......................-150 to 650° C (-238 to 1202° F)

Accuracy

Hysteresis

Long Term Stability

Repeatability

(1) When used in the range -90 to 650° C (-130 to 1202° F).

(2) When exposed to 650° C (1202° F) for 100 hours. Stability will depend on

(1)

@ 0° C (32° F) .......................0.01° C (0.02° F)

(2)

@ 0° C (32° F) ......typical 0.014° C (0.025° F)

(1)

@ 0° C (32° F) ................. 0.002° C (0.0036° F)

actual use of the sensor.

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

α

Temperature Coecient .....................

=0.00385 1/°C

100

Ordering Information

Minimum Immersion Depth

STS-100 A – 4 mm (0.16 in). . . . . . . . . . . . . . . . . . . . . . . 100 mm (3.9 in)

–

STS-100 B

6.35 mm (0.25 in) ....................110 mm (4.3 in)

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

Response Time

STS-100 A – 4 mm (0.16 in): τ

–

STS-100 A

STS-100 B

STS-100 B

Liquid in motion v = 0.4 m/s.

4 mm (0.16 in): τ

–

6.35 mm (0.25 in): τ

–

6.35 mm (0.25 in): τ

(50%) ...................8 seconds

0.5

(90%) ................. 26 seconds

0.9

(50%) .............. 18 seconds

0.5

(90%) .............. 44 seconds

0.9

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...................................LEMO goldplated

Insulation Resistance

@ 23° C (73° F) .......................................100 Gohm

@ 650° C (1202° F) .....................................70 Mohm

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 0 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxW.H ....................... 750x150x140 mm (29.5x5.9x5.5 in)

Shipping Weight, including packing ................ 3.0 kg (6.6 lb)

Standard Delivery

STS-100 A/B sensor Sensors delivered in aluminum case

Accredited calibration certicate, 6 points from -45 to 650° C

Cable – according to order number

User manual.

Accessories

For a complete list of accessories, please see page 11.

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS100

Pt100 reference sensor, solid,

-150 to 650° C (-238 to 1207° F)

Sample Order Number

Overall diameter 4 mm (0.16 in) ......A Straight sensor, 250 mm (9.8 in) in aluminum case ....250 0.5 m (1.6 ft), with LEMO connector ........A Accredited certicate. ISO17025. Standard -45 to 650° C .... H

Overall diameter 6.35 mm (0.25 in) ...B Straight sensor, 350 mm (13.8 in) in aluminum case ...350 2 m (6.6 ft), with LEMO connector .........B Accredited certicate. ISO17025. Standard -90 to 125° C ...HL

Straight sensor, 500 mm (19.7 in) in aluminum case ...500 2 m (6.6 ft), with banana plug connector ...C No certicate (Annealed only) ............................I

Useless without calibration certicate / coecients.

STS100A350BH ...4 mm STS-100 reference sensor, straight 350 mm, cable length 2 m (6.6 ft)

with LEMO connector, and accredited calibration certicate.

Page 6

STS-102 A

Cable Type

The custom insert and STS-102 A refer-

ence sensor placed in a JOFRA RTC 156

dry-block calibrator. On the right, the

sanitary sensor has been tted into the

insert and is ready for calibration. Note

that the design makes room for the

reference sensor cable.

Specications

For sanitary sensor calibra-

tion, JOFRA has also designed

a special cable type reference

sensor, the STS-102 A. Due

to the small size and exible

connection, the design per-

mits positioning of the sensor

throughout the depth of the

well in a dry-block, eg. under

a sanitary ange.

The reference sensor must be

placed at the same level and in parallel with the sensor-under-test

as indicated in the illustration above. The illustration shows cali

bration of a sanitary sensor. The sensor is in contact with the insert.

Standard Delivery

STS-102 A sensor Sensors delivered in plastic case

Accredited calibration certicate, 6 points from -45 to 155° C

Cable – according to order number

Calibration Tube.

User manual

Temperature Range

All Sensors ...........................-50 to 155° C (-58 to 311° F)

Accuracy

Hysteresis @ 0° C (32° F) .........................0.01° C (0.018° F)

Long Term Stability

Repeatability @ 0° C (32° F) ....................0.002° C (0.0036° F)

(1) When exposed to 155° C (311° F) for 200 hours. Stability will depend on

actual use of the sensor.

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

Temperature Coecient .....................

Minimum Immersion Depth

30 mm (1.18 in)

-

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

Response Time

τ

(90%) ........................................... 16 seconds

0.9

Measured in water.

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...................................LEMO goldplated

(1)

@ 0° C (32° F) ......typical 0.025° C (0.045° F)

α

100

=0.00385 1/°C

Insulation Resistance

@ 23° C (73° F) ..........................................3 Gohm

Outer Tube

AISI 316TI

Operating Conditions

Sensor Connection ...........................Max. 70° C (158° F)

Sensor Cable ................................Max. 175° C (347° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 0 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxW.H ....................... 360x290x50 mm (14.2x11.4x1.9 in)

Shipping Weight, including packing ................ 1.0 kg (2.2 lb)

Accessories

Complete application kit for

calibration of sanitary sensors

including, STS102A030SH, Recalibration Tube, Manual, 5-pack

Undrilled Insertion Tubes with

Cable Grove, and Carrying Case.

Order No ................127279

Ordering Information

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS102 A 030

Pt100 reference sensor, cable, -50 to 155° C (-58 to 311° F) Overall diameter 4 mm (0.16 in) Short sensor, 30 mm (1.18 in) in plastic case 1 m (3.3 ft), integrated Teon cable, with LEMO connector ...S Accredited certicate. ISO17025. Standard -45 to 155° C ...H

1 m (3.3 ft), with REDEL connector for DTI050 ..............D No certicate (Annealed only) ...........................I

Sample Order Number

STS102A030DH ...4 mm STS-102, short 30 mm reference sensor, cable length 1 m (3.3 ft)

with REDEL connector for DTI050, and accredited calibration certicate.

1 m (3.3 ft), with LEMO/REDEL connector for RTC. . . . . . . . . . . .

Useless without calibration certicate / coecients.

E

Page 7

STS-103 B

A

B

ETC-400 R Calibrator Sensor

JOFRA has designed a special 3 mm STS reference sensor for

the ETC-400 R calibrator. The sensor can be used as a reference

sensor when a higher accuracy is required, or for recalibration

of the ETC-400 R. Due to the small immersion depth require-

ment of the sensor, it can be placed under the surface of the

target.

Standard Delivery

STS-103 B sensor Sensor delivered in aluminum case

Accredited calibration certicate, 6 points from -45 to 400° C

Cable – according to order number

User manual.

Accessories

For a complete list of accessories, please see page 11.

Specications

Dimensions

Reference A ....................................150 mm (5.91 in)

Reference B ...................................... 3 mm (0.12 in)

Temperature Range

All Sensors ...........................-50 to 400° C (-58 to 752° F)

Accuracy

Hysteresis

Long Term Stability

Repeatability

(1) When used in the range -45 to 400° C (-49 to 752° F).

(2) When exposed to 400° C (752° F) for 100 hours. Stability will depend on

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

Temperature Coecient .....................

Minimum Immersion Depth

40 mm (1.6 in)

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

(1)

@ 0° C (32° F) .......................0.01° C (0.02° F)

(2)

@ 0° C (32° F) ......typical 0.014° C (0.025° F)

(1)

@ 0° C (32° F) ...................0.005° C (0.009° F)

actual use of the sensor.

α

=0.00385 1/°C

100

Response Time

τ

(50%) .............................................5 seconds

0.5

τ

(90%) ........................................... 15 seconds

0.9

Liquid in motion v = 0.4 m/s.

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...................................LEMO goldplated

Insulation Resistance

@ 23° C (73° F) .......................................100 Gohm

@ 400° C (752° F) ......................................70 Mohm

Outer Tube

Incolel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 0 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxW.H ....................... 750x140x150 mm (29.5x5.5x5.9 in)

Shipping Weight, including packing ................ 3.0 kg (6.6 lb)

Ordering Information

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS103 B 150

Pt100 reference sensor, -50 to 400° C (-58 to 752° F) Overall diameter 3 mm (0.12 in) Straight sensor, 150 mm (5.9 in) 0.5 m (1.6 ft), with LEMO connector ........A Accredited certicate. ISO17025. Standard -45 to 400° C ...H

2 m (6.6 ft), with LEMO connector .........B No certicate (Annealed only) ...........................I

Useless without calibration certicate / coecients.

2 m (6.6 ft), with banana plug connector

Sample Order Number

STS103B150AH ...3 mm STS-103, straight 150 mm reference sensor, cable length 0.5 m (1.6 ft)

with LEMO termination, and accredited calibration certicate.

...

C

Page 8

C

B

915 and 935

C

STS-120 A

Specications

Dimensions

Reference A (915) ...........................................N/A

(935) ...........................................N/A

(966) ...............................117 mm (4.6 in)

Reference B ...................................... 4 mm (0.16 in)

Reference C (915) ..............................140 mm (5.51 in)

(935) ..............................135 mm (5.31 in)

(966) ..............................151 mm (5.94 in)

Temperature Range

STS-120 A -915 .......................-45 to 155° C (-49 to 311° F)

STS-120 A -935 .........................0 to 350° C (32 to 662° F)

STS-120 A -966 ........................0 to 660° C (32 to 1220° F)

Accuracy

Dead Band

Long Term Stability

Repeatability

(1) When used in the range shown above.

(2) When exposed to the maximum temperature shown above for 100 hours.

(1)

@ 0° C (32° F) ......................0.01° C (0.02° F)

(2)

@ 0° C (32° F) ......typical 0.014° C (0.025° F)

(1)

@ 0° C (32° F) ...................0.004° C (0.007° F)

Stability will depend on the actual use of the sensor.

B

A

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

α

Temperature Coecient .....................

=0.00385 1/°C

100

Minimum Immersion Depth

STS-120 A -915/935 ............................. 60 mm (2.36 in)

STS-120 A -966 .................................100 mm (3.93 in)

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

Response Time

STS-120 A -915/935: τ

STS-120 A -915/935:

STS-120 A -966:

STS-120 A -966:

τ

τ

(50%) .........................7 seconds

0.5

τ

(90%) ....................... 18 seconds

0.9

(50%) ..............................8 seconds

0.5

(90%) ............................ 26 seconds

0.9

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...............................................Redel

STS-120 A -915/935 ...... Cable with integrated Redel connector

and memory

STS-120 A -966 ..... LEMO plug with memory and separate cable

966

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 5 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxWxH ....................... 360x50x290 mm (13.1x1.9x11.4 in)

Shipping Weight, including packing ................ 1.0 kg (2.2 lb)

Standard Delivery

STS-120 A sensor Sensors delivered in plastic case Accredited

calibration certicate, 5 to 7 points

number

User manual.

Cable – according to order

Ordering Information

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS120 A E

Pt100 reference sensor, solid,

with intelligence

Sample Order Number

STS120A915EH ...4 mm STS-100 reference sensor, 90° angled, 140 mm, cable length 0.5 m (1.6 ft)

with LEMO/Redel connector, and accredited calibration certicate.

Overall diameter 4 mm (0.16 in) 90° angled sensor, 140 mm (5.5 in) in plastic case .....915 0.5 m (1.6 ft), with LEMO/Redel connector Accredited certicate. ISO17025. Standard -45 to 660° C ....H

90° angled sensor, 135 mm (5.3 in) in plastic case .....935 No certicate (Annealed only) ............................I

90° angled sensor, 151 mm (5.9 in) in plastic case .....

966

Useless without calibration certicate / coecients.

Page 9

C

B

912, 915, and 935

C

STS-150 A

Specications

Dimensions

Reference A (912) ...........................................N/A

(915) ...........................................N/A

(935) ...........................................N/A

(966) ..............................167 mm (6.57 in)

Reference B ...................................... 4 mm (0.16 in)

Reference C (912) ..............................210 mm (8.26 in)

(915) ..............................180 mm (7.08 in)

(935) ..............................165 mm (6,49 in)

(966) ..............................201 mm (7.91 in)

Temperature Range

STS-150 A -912 ..................... -90 to 155° C (-130 to 311° F)

STS-150 A -915 .......................-25 to 155° C (-13 to 311° F)

STS-150 A -935 .........................0 to 350° C (32 to 662° F)

STS-150 A -966

(1) For PTC-425 B or C.

Ordering Information

(1)

......................0 to 660° C (32 to 1220° F)

B

A

Accuracy

Hysteresis

Long Term Stability

Repeatability

(2) When used in the range shown above.

(3) When exposed to the maximum temperature shown above for 100 hours.

(2)

@ 0° C (32° F) .......................0.01° C (0.02° F)

(3)

@ 0° C (32° F) ......typical 0.016° C (0.029° F)

(2)

@ 0° C (32° F) ...................0.004° C (0.007° F)

Stability will depend on the actual use of the sensor.

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

α

Temperature Coecient .....................

=0.00385 1/°C

100

Minimum Immersion Depth

STS-150 A -912/915/935 ........................60 mm (2.36 in)

STS-150 A -966 .................................100 mm (3.93 in)

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

Response Time

STS-150 A -912/915/935: τ

STS-150 A -912/915/935:

τ

STS-150 A -966:

STS-150 A -966:

(50%) ..............................8 seconds

0.5

τ

(90%) ............................ 26 seconds

0.9

(50%) ....................7 seconds

0.5

τ

(90%) .................. 18 seconds

0.9

966

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...............................................Redel

STS-150 A -912/915/935 . Cable with integrated Redel connector

STS-150 A -966 ..... LEMO plug with memory and separate cable

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 5 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxWxH ....................... 360x50x290 mm (14.2x1.9x11.4 in)

Shipping Weight, including packing ................ 1.0 kg (2.2 lb)

Standard Delivery

STS-150 A sensor Sensors delivered in plastic case Accredited

calibration certicate, 5 to 7 points

number

User manual.

Cable – according to order

and memory

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS150 A E

Pt100 reference sensor, solid,

with intelligence

Sample Order Number

Overall diameter 4 mm (0.16 in) 90° angled sensor, 210 mm (8.2 in) in plastic case .....912 0.5 m (1.6 ft), with LEMO/Redel connector Accredited certicate. ISO17025. Standard -25 to 660° C ....H

90° angled sensor, 180 mm (7.0 in) in plastic case .....915 No certicate (Annealed only) ............................I

90° angled sensor, 165 mm (6.5 in) in plastic case .....

90° angled sensor, 201 mm (7.9 in) in plastic case .....966

935

Useless without calibration certicate / coecients.

STS150A935EH ...4 mm STS-100 reference sensor, 90° angled, 165 mm, cable length 0.5 m (1.6 ft)

with LEMO/Redel connector, and accredited calibration certicate.

Page 10

STS-200 A/B

A

B

Specications

Dimensions

Reference A (915) ...............................145 mm (5.7 in)

(916) ..............................167 mm (6.57 in)

(917) ..............................176 mm (6.92 in)

(918) ...............................145 mm (5.7 in)

(925) ..............................167 mm (6.57 in)

(970) ...............................211 mm (8.3 in)

Reference B ..................4 mm (0.16 in) or 6.35 mm (0.25 in)

Reference C (915) ..............................179 mm (7.05 in)

(916) ..............................201 mm (7.91 in)

(917) ..............................210 mm (8.27 in)

(918) ..............................179 mm (7.05 in)

(925) ..............................201 mm (7.91 in)

(970) ..............................245 mm (9.65 in)

Temperature Range

STS-200 A/B -915 .....................-65 to 160° C (-85 to 320° F)

STS-200 A/B -916 .....................-65 to 160° C (-85 to 320° F)

STS-200 A/B -917 ..................-100 to 155° C (-148 to 311° F)

STS-200 A/B -918 ......................-65 to 180°C (-85 to 356°F)

STS-200 A/B -925 .......................0 to 250° C (32 to 482° F)

STS-200 A/B -970 ......................0 to 700° C (32 to 1292° F)

C

Accuracy

Hysteresis

Long Term Stability

Repeatability

(1) When used in the range shown above.

(2) When exposed to the maximum temperature shown above for 100 hours.

(1)

@ 0° C (32° F) .......................0.01° C (0.02° F)

(2)

@ 0° C (32° F) ......typical 0.016° C (0.029° F)

(1)

@ 0° C (32° F) ..................0.002° C (0.0036° F)

Stability will depend on the actual use of the sensor..

Sensing Element

Type ......................................................Pt100

Nominal Resistance @ 0° C (32° F) ..........................100 Ω

α

Temperature Coecient .....................

=0.00385 1/°C

100

Minimum Immersion Depth

STS-200 A – 4 mm (0.16 in). . . . . . . . . . . . . . . . . . . . . . . 100 mm (3.9 in)

–

STS-200 B

6.35 mm (0.25 in) ....................110 mm (4.3 in)

Self-Heating Eect

0.06° C /mW (0.108° F/mW)

Response Time

STS-200 A – 4 mm (0.16 in): τ

–

STS-200 A

STS-200 B

STS-200 B

4 mm (0.16 in): τ

–

6.35 mm (0.25 in): τ

–

6.35 mm (0.25 in): τ

(50%) ...................8 seconds

0.5

(90%) ................. 26 seconds

0.9

(50%) .............. 18 seconds

0.5

(90%) .............. 44 seconds

0.9

Electrical Connections

Cable .........................................4-wire plus shield

Connection ...............................................Redel

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ................Max. 70° C (158° F)

Storage Temperature ...................-20 to 70° C (-4 to 158° F)

Humidity .......................................... 5 to 90% RH

Protection Class (connectors). . . . . . . . . . . . . . . . . . . . .DIN 40050 IP-50

Shipping Dimensions

LxWxH ....................... 360x50x290 mm (14.2x1.9x11.4 in)

Shipping Weight, including packing ................ 1.0 kg (2.2 lb)

Standard Delivery

STS-200 A/B sensor Sensors delivered in plastic case Accredited

calibration certicate, 6 to 7 points

number

User manual.

Cable – according to order

Accessories

For a complete list of accessories, please see page 11.

Ordering Information

Base Model Number Sensor Diameter Shape and Length Cable Length and Termination Calibration Certicate

STS200

Pt100 reference sensor, solid,

with intelligence

Sample Order Number

STS200B925DH ...6.35 mm STS-200 reference sensor,

90° angled, 182 mm, cable length 2 m (6.6 ft) with LEMO/

Redel connector, and accredited calibration certicate.

Overall diameter 4 mm (0.16 in) ......A 90° angled sensor, 179 mm (7.05 in) in plastic case. . . .915 0.5 m (1.6 ft), with LEMO/LEMO connector ... A Accredited certicate. ISO17025. Standard -25 to 660° C .... H

Overall diameter 6.35 mm (0.25 in) ...B 90° angled sensor, 201 mm (7.91 in) in plastic case. . . . 916 2 m (6.6 ft), with LEMO/LEMO connector .... B No certicate (Annealed only) ...........................I

90° angled sensor, 210 mm (8.27 in) in plastic case. . . .

90° angled sensor, 179 mm (7.05 in) in plastic case. . . .918 2 m (6.6 ft), with LEMO/Redel connector ....D

90° angled sensor, 201 mm (7.91 in) in plastic case. . . .925 0.5 m (1.6 ft), with LEMO/Redel connector ....E

90° angled sensor, 245 mm (9.65 in) in plastic case. . . .970

917 2 m (6.6 ft), with LEMO/Banana connector ... C

Useless without calibration certicate / coecients.

Page 11

2018-11-15-HQB

Temperature Calibrators and Reference Sensors

Cable Accessories for STS Reference Sensors

STS-100 & STS-103

122801 .......................Cable 0.5m (1.6ft) w/ LEMO to LEMO

125522 ........Cable 2m (6.6ft) w/ LEMO/Redel for DTI050/RTC/PTC

65-PT100-LL-CABLE .............Cable 2m (6.6ft) w/ LEMO to LEMO

65-PT100-LB-CABLE ...........Cable 2m (6.6ft) w/ LEMO to banana

STS-120, STS-150, & STS-200

127131 ................... Cable 0.5m (1.6ft) w/ 6-POL LEMO/Redel

127285 .....................Cable 2m (6.6ft) w/ 6-POL LEMO/Redel

127286 ...................Cable 2m (6.6ft) w/ 6-POL LEMO/Banana

127287 ............Cable 2m (6.6ft) w/ 6-POL LEMO to 4-POL LEMO

127288 .......... Cable 0.5m (1.6ft) w/ 6-POL LEMO to 4-POL LEMO

127787 ........................... Cable 2m (6.6ft) w/ Redel/Redel

Singapore

Tel +65 6484 2388

jofra@ametek.com

USA, Florida

Tel +1 (800) 527 9999

cal.info@ametek.com

China, Shanghai

Tel +86 21 5868 5111

jofra.sales@ametek.com.cn

France

Tel +33 (0) 30 68 89 40

general.lloyd-instruments@ametek.fr

Reference Sensor Diameter

Calibrator

RTC-156 B & 156 C

Catalogue No. Name Shape 4 mm 1/4"

STS102A030EH R1 30 mm

STS200A915EH R2 Angled

STS200B915EH R3 Angled

RTC-157 B & 157 C

STS102A030EH R1 30 mm

STS200A915EH R2 Angled

STS200B915EH R3 Angled

RTC-158 B & 158 C

STS102A030EH R1 30 mm

STS200A916EH R6 Angled

STS200B916EH R7 Angled

RTC-159 B & 159 C

STS200A917EH R14 Angled

STS200B917EH R15 Angled

RTC-187 B & 187 C

STS200A918EH R17 Angled

STS200B918EH R18 Angled

RTC-250 B & 250 C

STS200A925EH R8 Angled

STS200B925EH R9 Angled

RTC-700 B & 700 C

STS200A970EH R4 Angled

STS200B970EH R5 Angled

PTC-125 C STS150A912EH R16 Angled

PTC-155 C

STS102A030EH R1 30 mm

STS150A915EH R11 Angled

PTC-350 C STS150A935EH R12 Angled

PTC-425 C STS150A966EH R13 Angled

PTC-660 C STS150A966EH R13 Angled

CTC-155 C

STS102A030EH R1 30 mm

STS120A915EH R21 Angled

CTC-350 C STS120A935EH R22 Angled

CTC-660 C STS120A966EH R23 Angled

USA, California

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

*

China, Beijing

Tel +86 10 8526 2111

jofra.sales@ametek.com.cn

United Kingdom

Tel +44 (0) 1243 833 302

stc.uk@ametek.com

Germany

Tel +49 (0) 2159 9136 510

info.mct-de@ametek.de

*

Denmark

Tel +45 4816 8000

jofra@ametek.com

ISO 17025 accredited calibration lab.

*

ametekcalibration.com

No part of this document may be reproduced or

modied in any form or by any means, electronic

or mechanical, without express written permission

from Crystal Engineering Corporation.

©2018 AMETEK Incorporated

Loading...

Loading...