Page 1

CATRAC

®

&

SnapTrac®Cable & Hose Carrier Products

Ordering Guide & Technical Information

CATRAC Cable & Hose Carrier Products

Ordering Guide & Technical Information

Page 2

CATRAC® is used on various types of machinery as

a means of safely and effi ciently conveying power,

electrical, air, or fl uid (or a combination of these) to

equipment in motion. CATRAC is designed to be

maintenance free and to protect cables and hoses from

abrasion, wear and twisting. A wide variety of options are

available.

split aluminum bar carriers, rod carriers, removable pipe,

spring loaded rods, vertical pins, double deck, custom

radius “M” dimension (including double radius), custom

and special widths, including single widths, double

widths, triple widths, etc.. We offer various support

systems from a single stationary roller support to a

complete CATRAC carriage support system.

The center pivot design allows for smoother cycling and

minimal hose movement. The CATRAC design offers

“No Pinch Points” to insure operator safety. Standard

side links are high tensile steel for maximum strength.

Steel CATRACs are zinc plated with a yellow dichromate

dip for superior corrosion resistance. Optional materials,

such as aluminum and stainless steel are available.

We also offer a line of Mill Duty CATRACs that are used

in rugged applications and environments such as steel

mills. These CATRACs offer a box beam type carrier

for maximum strength and stability. Spring loaded rods

offer the customer easy access to cables and hoses.

They also eliminate the concern of fi tting sizes that must

pass through the (fi xed) compartment opening on a box

beam style carrier. Hardened shoulder bolts and locknuts

(referred to as bolted construction) are recommended

for use in rugged environments. The CATRAC is

manufactured so that pieces or sections can be removed

or replaced in the fi eld.

Our CATRAC product offers: a variety of sizes from 2.00”

to 14.00” high links, carrier options from welded carriers,

We can provide you with the optimum system to suit

your needs either with our standard carriers and options

or by means of a custom designed system to meet

your specifi c requirements. In addition to our standard

systems used in a standard linear motion, we can also

provide you with double radius side mounted systems.

Contact our applications engineers for additional

information or to discuss your needs in detail.

Get on the right track with CATRAC cable & hose

carriers.

Mounting Variations

Horizontal

Double Wide

Side Mounted

2

Vertical

Triple Wide

Double Radius

Side Mounted

CATRAC® Features

Horizontal/Vertical

Combo

• No pinch points

• Center pivot design for minimal cable and

hose wear

• Wide variety of standard carrier designs

• Available in any radius or width

Dual CATRAC

(Opposed)

• Custom designs available to optimize your

system

• Superior fi nish and corrosion resistance

• JIT programs

• Short lead times

• Designed and manufactured in the USA

Vertical Hanging

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 3

CATRAC

®

Selection Guide

CATRAC

Selection Guide

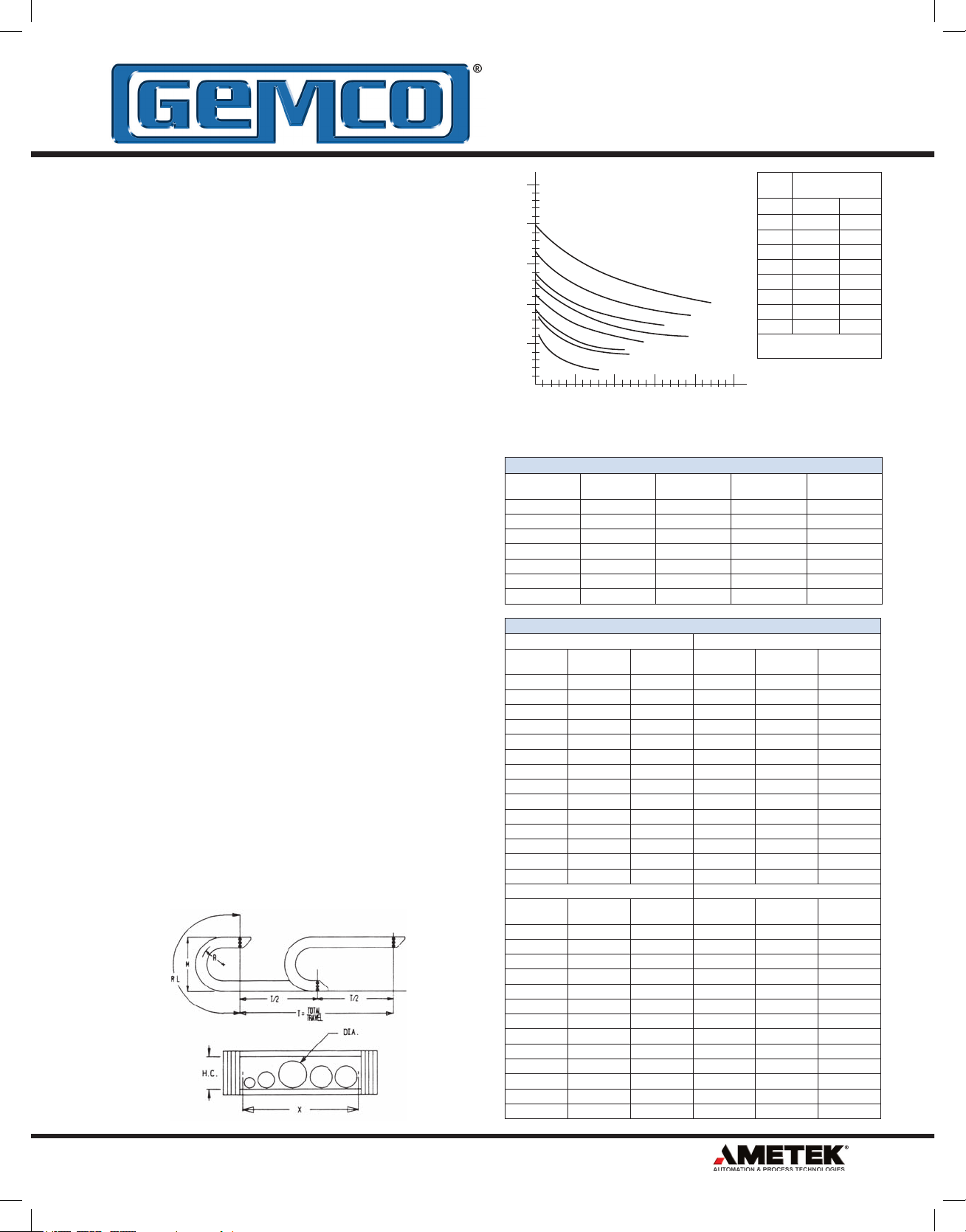

Which CATRAC is right?

1. Determine the outside diameter of the largest cable or

hose to be carried.

2. Determine total machine travel. Unsupported length

of CATRAC® on horizontal applications is total travel

÷ 2 when no supports are used and the stationary

mounting foot is placed at the center line of travel.

3. Determine total weight to be carried per foot.

4. Use the charts to select the proper CATRAC style for

your application. Please note that hose area varies

with type of carriers used.

5. Determine the rolling radius of the CATRAC by:

A) Minimum bend radius of cable or hose

recommended by the manufacturer. If this is not

available, we recommend a minimum of 6 times the

O.D. of the largest cable or hose.

B) Space limitations. The “M” dimension of the

CATRAC must be less than the available space where

track will be installed. The rolling radii shown in the

dimension pages are standard. Special radii and “M”

dimensions are available to suit your application at no

additional cost.

6. Determine CATRAC “X” or inside width. Add the O.D.

of all cables and hoses. Allow a minimum of 0.12”

between each hose or cable and on both sides of the

CATRAC. If vertical separators or hose straps are

used, additional clearance is required.

7. Determine the length of the CATRAC. If the mounting

foot is placed on the center line of travel as shown on

the dimension pages, CATRAC Length = “RL” (radial

length) + 1/2 of total travel (T/2). If the mounting foot is

placed on either side of center line, the distance from

the center line to the mounting foot (Y) must be added.

8. Determine mounting feet requirements and positioning

on the CATRAC assembly.

If you need assistance or have any questions on

special applications, feel free to contact our application

engineers.

50

40

30

20

456

Max. Unsupported Length in Feet

10

0

Lbs/Ft Weight of Cable and/or Hose/Ft Including Liquid in Hoses

The charts below give conservative estimates of cable and hose O.D. and weight

and should be used for quick reference only. Diameters and weights will vary and

should be verifi ed with manufacturer.

Hose Size

I.D x O.D.

1/4 x 18/32 2 300 .18 .03

3/8 x 22/32 2 250 .23 .05

1/2 x 22/32 2 250 .29 .09

3/4 x 1 7/32 2 225 .46 .16

1 x 1 1/2 2 225 .64 .34

1 1/4 x 1 25/32 2 225 .70 .53

1 1/2 x 2 1/32 2 225 .80 .77

No. Cond. Dia. in in/mm Weight lb/ft

2 0.41/10.4 .091/0.14 2 0.53/13.5 .151/0.22

3 0.43/10.9 .112/0.17 3 0.56/14.2 .186/0.26

4 0.49/12.5 .150/0.22 4 0.61/15.5 .221/0.33

5 0.53/13.5 .168/0.25 5 0.62/15.8 .288/0.43

6 0.57/14.5 .195/0.29 6 0.74/18.8 .332/0.49

7 0.61/15.5 .222/0.33 7 0.80/20.3 .362/0.54

8 0.65/16.5 .243/0.36 8 0.85/21.6 .407/0.61

10 0.72/18.3 .306/0.46 10 0.90/22.9 .477/0.71

12 0.74/18.8 .343/0.50 12 0.93/33.6 .529/0.79

16 0.83/21.1 .425/0.63 16 1.08/27.4 .723/1.08

20 0.90/22.9 .512/0.76 20 1.18/30.0 .865/1.29

24 1.02/25.9 .630/0.94 24 1.29/32.8 1.01/1.50

30 1.07/27.2 .745/1.11 30 1.40/35.6 1.25/1.86

36 1.16/29.5 .888/1.32 36 1.51/38.4 1.47/2.19

No. Cond. Dia. in in/mm Weight lb/ft

2 0.61/16.5 .207/0.31 2 0.65/16.5 .243/0.36

3 0.64/16.3 .253/0.38 3 0.70/17.8 .311/0.46

4 0.67/17.0 .297/0.44 4 0.75/19.1 .385/0.57

5 0.73/18.5 .351/0.52 5 0.82/20.8 .461/0.69

6 0.80/20.3 .409/0.61 6 0.88/22.4 .532/0.79

7 0.86/21.8 .472/0.70 7 0.98/24.9 .649/0.97

8 0.92/23.4 .519/0.77 8 1.05/26.7 .717/1.07

10 1.02/25.9 .635/0.95 10 1.13/28.7 .838/1.25

12 1.05/26.7 .706/1.05 12 1.16/29.5 .938/1.40

16 1.16/29.5 .921/1.37 16 1.29/32.8 1.23/1.83

20 1.29/32.8 1.10/1.64 20 1.46/37.1 1.55/2.31

24 1.45/36.8 1.35/2.01 24 1.60/40.6 1.81/2.69

30 1.53/38.9 1.60/2.38

2CP

10 20 30 40 50

16 AWG 14 AWG

12 AWG 10 AWG

304

203

3CP

General Purpose Hose

Braid Max. PSI Hose Weight

Small Cable

kg/m

kg/m

808

606

375

No. Cond. Dia. in in/mm Weight lb/ft

No. Cond. Dia. in in/mm Weight lb/ft

Max. Hose or

Cable Clearance

Style RP/RC, SL WC, AB

203 1.10 1.25

304 1.93 2.00

375 2.67 2.75

456 3.14 3.50

606 4.37 4.50

808 6.00 6.50

2CP 1.18, 1.20 1.25

3CP 1.90 2.00

Consult manufacturer for special

carrier designs.

Lbs/Ft

Liquid Weight

Lbs/Ft

kg/m

kg/m

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

3

Page 4

CATRAC

CATRAC

®

Carrier Designs

Carrier Designs

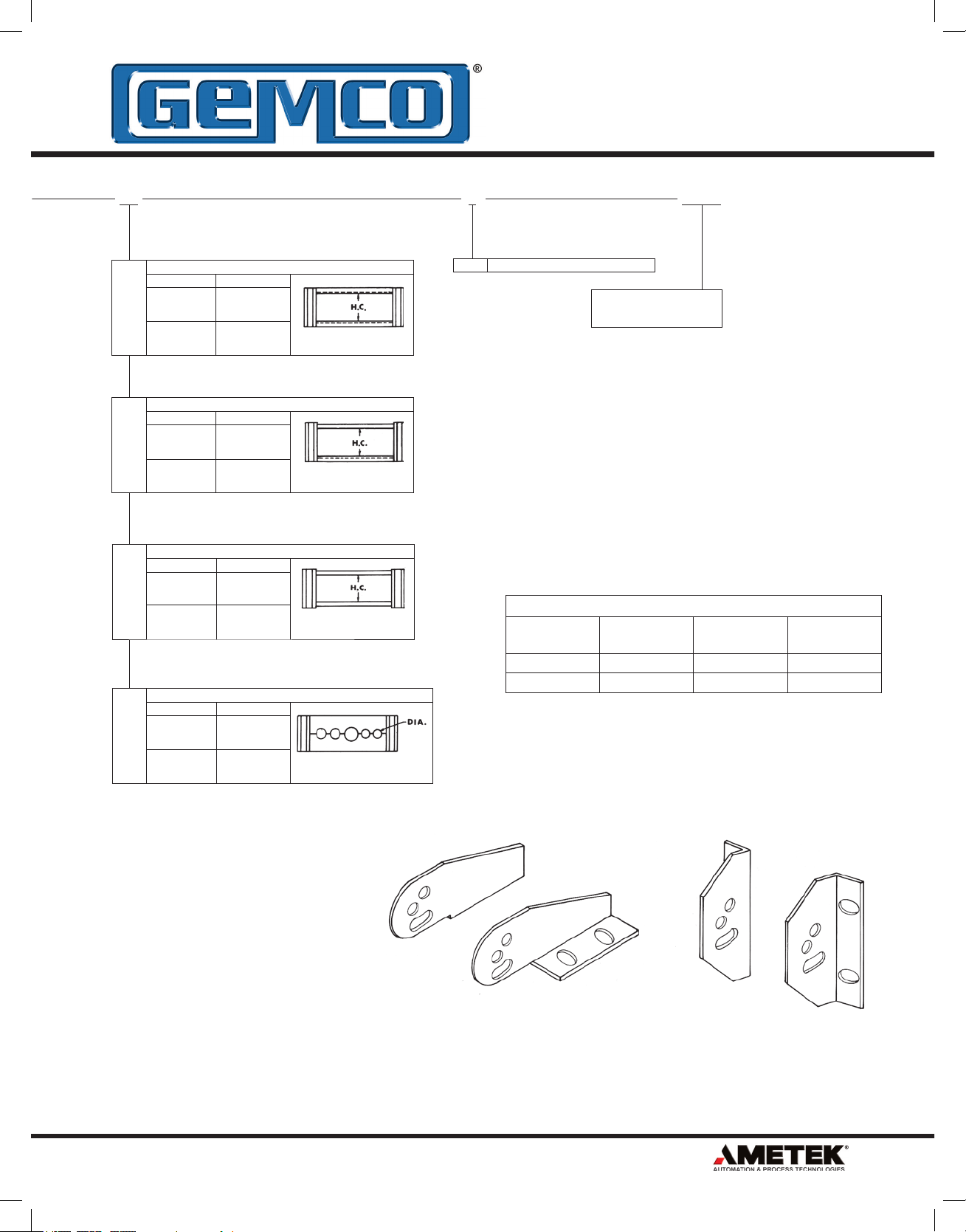

RC Rod Carriers

Available on 2CP, 3CP, 203, 375, 304 style tracks, this

tubing is used to hold the entire CATRAC® together. They

are fastened to links with a self tapping screw that can be

removed from top or bottom rod to make installation of

hose or cable easier.

WC Welded Carriers

The carrier is widely used in very rugged applications. It

can withstand severe hydraulic shock and has no loose

parts which can be lost during installation of the hose

cable. The welded carrier bars alternate position top to

bottom on styles 203, 375 and 304. Styles 456, 606 and

808 use a box beam construction with top and bottom

beams across from each other for added strength.

RP Removable Pipe (Standard)

This assembly provides easy installation of cable and

hose. The pipe can be removed by knocking out a roll pin

and pulling it out the side of the CATRAC.

SL Spring Loaded Removable Pipe

This design provides the quickest way to install or

change cable and hose in the fi eld. Simply compress the

plunger and pull the pipe out. No screws or pins need

to be removed and no side space limitations need to be

considered.

4

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 5

CATRAC

CATRAC

®

Carrier Designs

Carrier Designs

AB Split Bar Carriers

1/2” wide aluminum or 3/4” wide wood split bar carriers

can be provided. This carrier is custom machined to your

specifi cations. Note: Holes must be at least 1/8” larger

than cable hose diameter.

VP Vertical Pins

Vertical pins, also referred to as separators or dividers,

can be welded into RP, SL and WC style carriers to

separate cables or hoses to prevent twisting or overlap.

Extra Heavy Duty (Mill-Duty) Construction

For steel mills and other heavy duty service, the double

welded carrier (MD option) is used as well as bolted

construction (BC option). This structure has the ultimate

strength for a carrier. Box beam construction is standard

in the 456, 606, and 808 styles and can withstand severe

hydraulic shock loads.

Optional & Special Carrier Designs

Special perforated carriers can be supplied which provide

openings for hose straps. The hose straps, if used,

should be very loose and used as a hose and cable

separator rather than a tie down.

Many carriers and stiffeners are designed in cooperation

with our customers. We welcome ideas to fi t your specifi c

application needs.

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

5

Page 6

2CP and 3CP CATRAC

®

Part Number System

2CP and 3CP CATRAC

Part Number System

®

8060 2CP 2.75 04

CATRAC

CATRAC Side Link

2CP

Ass’y Weight/Ft. 3#

3CP

Ass’y Weight/Ft. 5#

Weight based on 8” carrier.

Radius

“R”*

2CP

3CP

NOTE: Mounting feet must be ordered separately

by the pair. All dimensions are in inches.

2.75 7.50

4.75 11.50

5.63 13.25

*Consult factory for

special radius.

5.13 13.25

6.63 16.25

8.19 19.38

10.90 24.80

15.13 33.25

Overall

Height “M”

Carrier Width*

2CP

3CP

02

04

06

08

*Consult factory for

special widths.

04

06

08

10

12

6

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 7

2CP and 3CP CATRAC

2CP and 3CP CATRAC

®

Part Number System

Part Number System

®

WC P Length

P

Pin & Retaining Ring Construction

NOTE: CATRAC Length must

be divisible by pin centers for

that style.

Standard Mounting Feet

CATRAC

Style

2CP PC-0126000-B PC-0127900-B 2 Pair

3CP PC-0128000-B PC-0128100-B 2 Pair

Horiz. Mount

Feet P/N

Normally one (1) pair of mounting feet are used at each end of the

CATRAC. Unless speci ed, anges are mounted inward on standard

CATRAC.

WC

SL

RC

AB

Style HC

Welded Carrier

2CP 1.25

3CP 2.00

Spring Loaded Removable Pipe

Style HC

2CP 1.20

3CP 1.90

Rod Carrier

Style HC

2CP 1.18

3CP 1.90

Split Aluminum Bar Carrier

Style Max. DIA.

2CP 1.25

3CP 2.00

Vert. Mount

Feet P/N

Req’d per

CATRAC

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Vertical Mounting FeetHorizontal Mounting Feet

7

Page 8

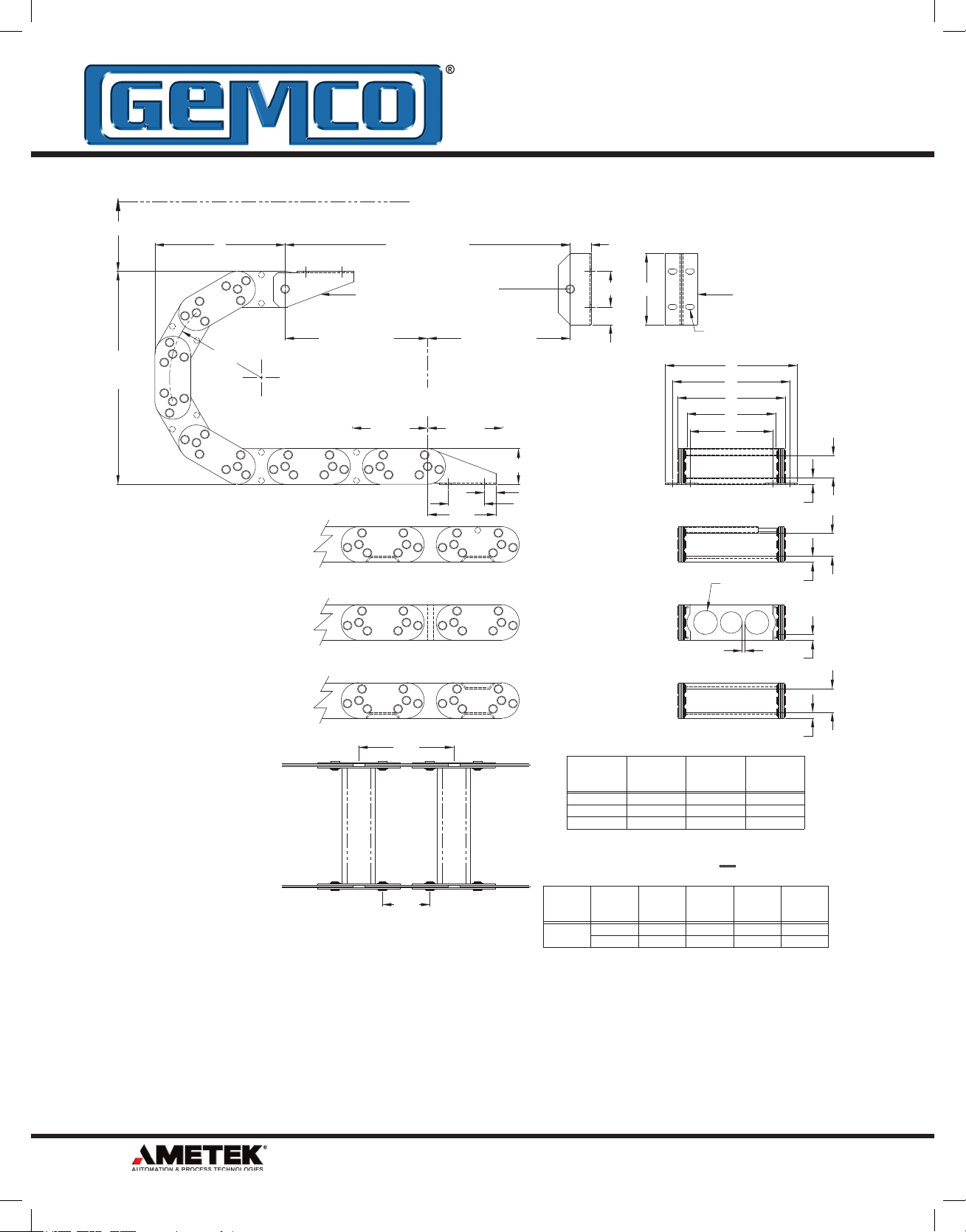

®

CATRAC

®

2CP Dimensions

CATRAC

2CP Dimensions

2.00 CLEARANCE REQUIRED ABOVE LINKS

M

OVERALL

HEIGHT

R

Z

ADIUS

HALF TRAVEL

TOTAL TRAVEL

HORIZONTAL

MTG. FEET

T/2

CENTER LINE

OF TRAVEL

Y** Y**

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 2" THRU 8".

3) FOR SPECIAL WIDTHS, CONSULT

FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

5) MOUNTING SLOTS ARE DESIGNED TO

ALLOW "2CP" REPLACEMENT OF

EXISTING "1A", "2A", & "203" STYLE

CATRAC', STANDARD MTG. FEET.

6.00

3.00

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

T

T/2

HALF TRAVEL

3.00

(SEE BELOW)

2.00

.50

1.50

CATRAC LENGTH = + RL + Y**

STYLE

2CP

REMOVABLE PIPE

* CONSULT FACTORY FOR SPECIAL RADIUS

1.50

3.00

1.50

.75

(RC)

ROD

CARRIER

(SL)

SPRING LOADED

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

RADIUS *

2.75

4.75

5.63

CARRIER

X

WIDTH

4.00

X

10.00

X + 3.32

Z M

7.00

9.00

C

7.32

VERTICAL

MTG. FEET

.41 X .75 MOUNTING

SLOTS TYPICAL

C

A

B

X

E

dia.

1.25

MAXIMUM

.25

RADIAL

7.50

11.50

13.25

LENGTH

15.00

21.00

24.00

T

2

A

OUTSIDE

MTG.

6.07

X + 2.07

B

OVERALLEINSIDE

5.50

X + 1.50

1.18

.41

1.20

.38

.38

1.25

.38

RL

MTG.

3.54

X - .48

8

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 9

®

CATRAC

®

3CP Dimensions

CATRAC

3CP Dimensions

3.00 CLEARANCE REQUIRED ABOVE LINKS

Z

ADIUS

M

OVERALL

HEIGHT

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 12".

3) FOR SPECIAL WIDTHS, CONSULT

FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

5) MOUNTING SLOTS ARE DESIGNED TO

ALLOW "3CP" REPLACEMENT OF

EXISTING "BB", "CC", & "304" STYLE

CATRAC'S, STANDARD MTG. FEET.

R

HORIZONTAL

MTG. FEET

T/2

HALF TRAVEL

Y** Y**

T

TOTAL TRAVEL

CENTER LINE

OF TRAVEL

5.75

8.00

T/2

HALF TRAVEL

(SEE BELOW)

3.00

1.00

3.00

1.75

6.00

3.00

1.50

(RC)

ROD

CARRIER

(SL)

SPRING LOADED

REMOVABLE PIPE

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

RADIUS *

5.13

6.63

8.19

10.90 17.28 24.80 44.00

15.13 20.87 33.25 56.00

Z M

10.57

13.72

14.83

VERTICAL

MTG. FEET

.41 X .75 MOUNTING

SLOTS TYPICAL

C

A

B

X

E

2.00 dia.

MAXIMUM

13.25

16.25

19.38

.25

RL

RADIAL

LENGTH

24.00

32.00

36.00

1.90

.55

1.90

.50

.38

2.00

.50

* CONSULT FACTORY FOR SPECIAL RADIUS

4.00

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

CATRAC LENGTH = + RL + Y**

STYLE

CARRIER

3CP

X

WIDTH

4.00

X

C

7.32

X + 3.32

A

OUTSIDE

MTG.

6.21

X + 2.21

T

2

B

OVERALLEINSIDE

5.50

X + 1.50

MTG.

3.38

X - .62

9

Page 10

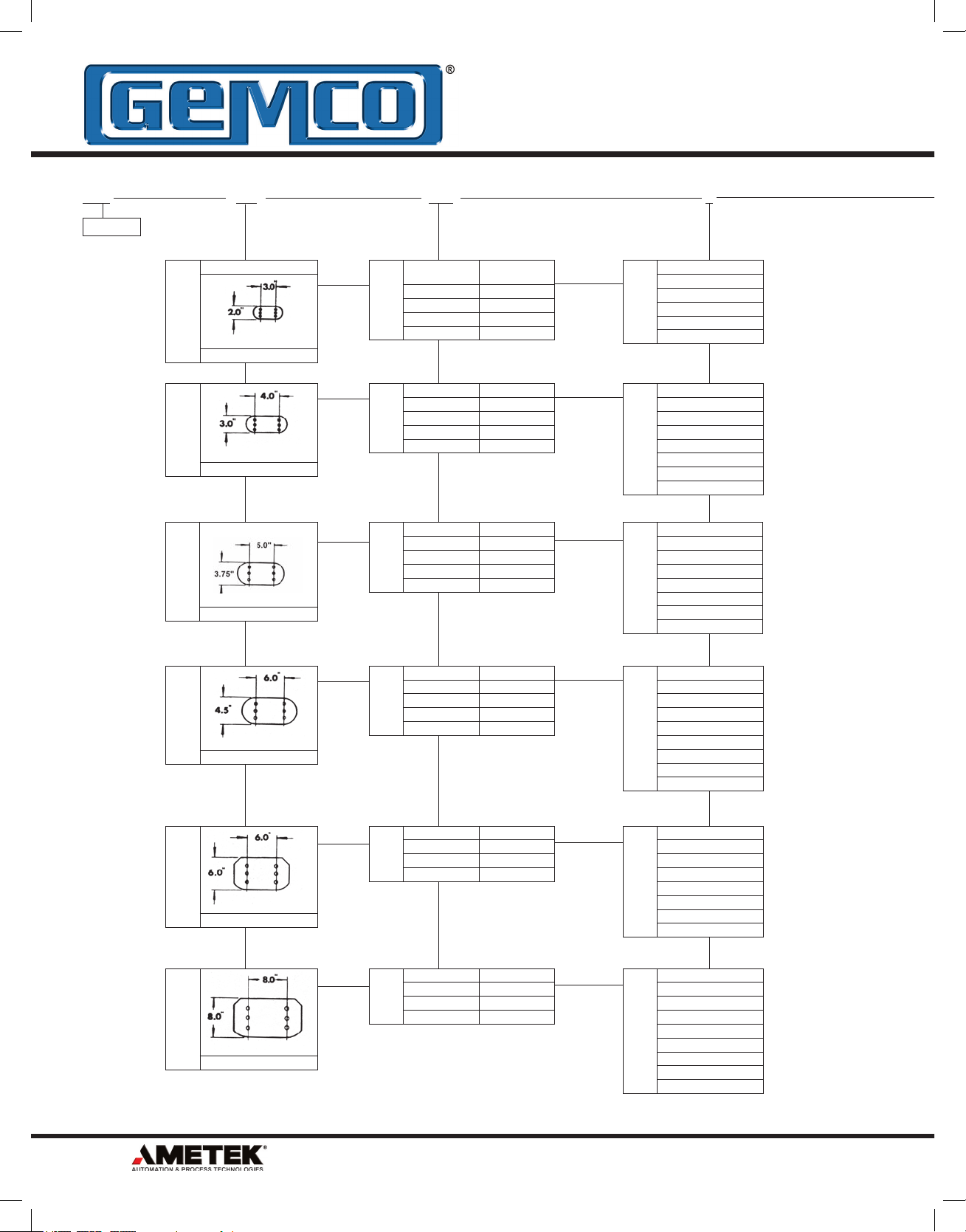

®

Mill-Duty CATRAC

®

Part Number System

Mill-Duty CATRAC

Part Number System

8060 203 2.75 4

CATRAC

CATRAC Side Link

203

Ass’y Weight/Ft. 5#

304

Ass’y Weight/Ft. 11#

375

Ass’y Weight/Ft. 13#

203

304

375

Radius “R”

2.75 7.50

4.75 11.50

5.63 13.25

8.69 19.38

5.13 13.25

6.63 16.25

8.19 19.38

10.90 24.80

15.13 33.25

5.62 15.00

7.37 18.50

11.12 26.00

14.87 33.50

24.12 52.00

Overall

Height “M”

375

Carrier Width

203

304

4

6

8

10

12

4

6

8

10

12

14

16

18

4

6

8

10

12

14

16

18

456

Ass’y Weight/Ft. 15#

606

Ass’y Weight/Ft. 21#

808

Ass’y Weight/Ft. 30#

Weight based on 8” carrier.

456

606

808

5.88 16.25

7.44 19.38

10.15 24.80

14.38 33.25

21.25 47.00

11.00 28.00

14.81 35.62

20.50 47.00

24.12 54.25

10.50 29.00

12.50 33.00

19.50 47.00

23.12 54.25

456

606

808

4

6

8

10

12

14

16

18

20

6

8

10

12

14

16

18

20

8

10

12

14

16

18

20

22

24

10

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 11

®

Mill-Duty CATRAC

®

Part Number System

Mill-Duty CATRAC

Part Number System

WC VP BC Length

Welded Vertical Pins On

Carrier Types RP, SL & WC

VP

X

No Charge

Quantity & Location Per Customer

No Vertical Pins

CATRAC

Style

203 PC-0089000-B PC-0089200-B 2 Pair

304 PC-0091000-B PC-0091200-B 2 Pair

375 PC-0191900-B PC-0192000-B 2 Pair

456 PC-0093000-B PC-0093200-B 2 Pair

606 PC-0095000-B PC-0095200-B 4 Pair

808 PC-0097000-B PC-0097200-B 4 Pair

X

Snap Ring Const.

BC

Bolted Const.

Note: CATRAC Length must

be divisible by pin centers for

that style.

Standard Mounting Feet

Horiz. Mount

Feet P/N

Vert. Mount

Feet P/N

Vertical Mounting Feet

Req’d per

CATRAC

WC

SL

RP

AB

Style HC

Welded Carrier

203 1.25

304 2.00

375 2.75

456 3.50

606 4.50

808 6.50

Spring Loaded Removable Pipe

Style HC

203 1.10

304 1.93

375 2.67

456 3.14

606 4.37

808 6.00

Removable Pipe

Style HC

203 1.10

304 1.93

375 2.67

456 3.14

606 4.37

808 6.00

Split Aluminum Bar Carrier

Style Max. Hole

203 1.25

304 2.00

375 2.75

456 3.50

606 4.50

808 6.50

Normally one (1) pair of mounting

feet are used at each end of the

CATRAC. Unless specified flanges

are mounted inward on standard

CATRAC.

Horizontal Mounting Feet

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

11

Page 12

®

CATRAC

®

203 Dimensions

CATRAC

203 Dimensions

2.00 CLEARANCE REQUIRED ABOVE LINKS

M

OVERALL

HEIGHT

R

Z

ADIUS

HALF TRAVEL

TOTAL TRAVEL

HORIZONTAL

MTG. FEET

T/2

CENTER LINE

OF TRAVEL

Y** Y**

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 12".

3) FOR MULTIPLE OR SPECIAL WIDTHS,

CONSULT FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

6.00

3.00

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

T

T/2

HALF TRAVEL

(SEE BELOW)

2.00

.50

3.50

1.50

REMOVABLE PIPE

* CONSULT FACTORY FOR SPECIAL RADIUS

CATRAC LENGTH = + RL + Y**

STYLE

203

PIN

203

BOLTED

1.50

3.00

1.50

.75

(RP)

REMOVABLE

PIPE

(SL)

SPRING LOADED

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

*

RADIUS

2.75

4.75

5.63

8.69

CARRIER

10.00

14.00

X

WIDTH

4.00

X

X + 3.39

4.00 7.39

X

X + 3.39

7.00

9.00

.38 X .56 MOUNTING

SLOTS TYPICAL

Z M

7.50

11.50

13.25

19.38

C

7.39

A

OUTSIDE

MTG.

6.28

X + 2.28

6.28

X + 2.28

VERTICAL

MTG. FEET

C

A

B

X

E

1.25 dia.

MAXIMUM

.25.38

RL

RADIAL

LENGTH

15.00

21.00

24.00

36.00

T

2

B

OVERALLEINSIDE

5.79

X + 1.79

6.29

X + 2.29

1.10

.38

1.10

.38

.38

1.25

.38

MTG.

3.65

X - .35

3.65

X - .35

12

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 13

®

CATRAC

304 Dimensions

3.00 CLEARANCE REQUIRED ABOVE LINKS

M

OVERALL

HEIGHT

R

Z

ADIUS

HALF TRAVEL

TOTAL TRAVEL

HORIZONTAL

MTG. FEET

T/2

CENTER LINE

OF TRAVEL

Y** Y**

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 18".

3) FOR MULTIPLE OR SPECIAL WIDTHS

CONSULT FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

8.00

4.00

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

T

T/2

HALF TRAVEL

5.75

(SEE BELOW)

3.00

1.00

3.00

CATRAC LENGTH = + RL + Y**

STYLE

304

PIN

304

BOLTED

1.75

1.00

1.00

6.00

1.00

1.50

(RP)

REMOVABLE

PIPE

(SL)

SPRING LOADED

REMOVABLE PIPE

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

RADIUS *

5.13

6.63

8.19

10.90

15.13

*

CONSULT FACTORY FOR SPECIAL RADIUS

Z

10.57 13.25

13.72

14.83

17.28

20.87 33.25 56.00

VERTICAL

MTG. FEET

.41 X .75 MOUNTING

SLOTS TYPICAL

C

A

B

X

E

Ø2.00

MAXIMUM

.25.38

RL

M

16.25

19.38

24.80

RADIAL

LENGTH

24.00

32.00

36.00

44.00

T

2

X

CARRIER

WIDTH

4.00

X

4.00

X

7.88C6.55

X + 3.88

7.88

X + 3.88

A

OUTSIDE

MTG.

X + 2.55

6.55

X + 2.55

B

OVERALL

5.79

X + 1.79

6.29

X + 2.29

.50

.50

.50

.50

E

INSIDE

MTG.

3.38

X - .62

3.38

X - .62

1.93

1.93

2.00

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

13

Page 14

CATRAC

®

375 Dimensions

3.75 CLEARANCE REQUIRED ABOVE LINKS

CATRAC

®

456 Dimensions

A

B

C

X

E

4.50

3.00

.75

6.00

M

OVERALL

HEIGHT

R

ADIUS

T/2

HALF TRAVEL

T/2

HALF TRAVEL

T

TOTAL TRAVEL

CENTER LINE

OF TRAVEL

Z

HORIZONTAL

MTG. FEET

VERTICAL

MTG. FEET

1.00

1.50

1.00

1.00

6.00

.41 X .75 MOUNTING

SLOTS TYPICAL

4.50 CLEARANCE REQUIRED ABOVE LINKS

3.50

.50

.50

(WC)

WELDED

CARRIER

(RP)

REMOVABLE

PIPE

3.14

(SL)

SPRING LOADED

REMOVABLE PIPE

3.14

.50

(AB)

SPLIT ALUMINUM

BAR CARRIER

.50

3.50 dia.

MAXIMUM

.25.50

Y** Y**

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

**

CATRAC LENGTH = + RL + Y**

*

CONSULT FACTORY FOR SPECIAL RADIUS

X + 4.13

X + 4.13

24.00

20.50

Z

6.00

X

CARRIER

WIDTH

STYLE

PIN

456

BOLTED

456

X

4.00

X

4.00

7.44

5.88

12.00

RADIUS *

R

RADIAL

LENGTH

3.42

X - .58

E

INSIDE

MTG.

X - .58

3.42

B

OVERALL

A

OUTSIDE

MTG.

X + 2.75

8.13

X + 2.75

6.75

8.13C6.75

X + 2.03

X + 2.53

6.53

6.03

T

2

19.38

33.25

24.80

60.00

48.00

36.00

30.00

M

RL

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 20".

3) FOR MULTIPLE OR SPECIAL WIDTHS,

CONSULT FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

32.00 47.00 84.00

14.38

21.25

16.00

14.00 16.25

(SEE BELOW)

3.50

10.15

Z

ADIUS

M

OVERALL

HEIGHT

R

HALF TRAVEL

TOTAL TRAVEL

.41 X 1.27 MOUNTING SLOTS

HORIZONTAL

MTG. FEET

T/2

CENTER LINE

Y** Y**

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 20".

3) FOR MULTIPLE OR SPECIAL WIDTHS,

CONSULT FACTORY.

4) STANDARD CONSTRUCTION IS WITH

SNAP RINGS OUTSIDE.

5) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

10.00

5.00

T

OF TRAVEL

®

CATRAC

375 Dimensions

T/2

HALF TRAVEL

(SEE BELOW)

3.75

.75

6.13

3.00

REMOVABLE PIPE

*

CATRAC LENGTH = + RL + Y**

STYLE

375

PIN

375

BOLTED

2.13

6.00

3.00

1.50

(RC)

ROD

CARRIER

(SL)

SPRING LOADED

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

RADIUS *

5.62

7.37

11.12

14.87

24.12

CONSULT FACTORY FOR SPECIAL RADIUS

X

CARRIER

WIDTH

4.00

X

4.00

X

Z

13.67 15.00

15.18

18.04

23.39

33.11 52.00 90.00

8.11C6.31

X + 4.11

8.11

18.50

26.00

33.50

A

OUTSIDE

MTG.

X + 2.31

6.31

X + 2.31X + 4.11

VERTICAL

MTG. FEET

.41 X .75 MOUNTING

SLOTS

C

A

B

X

E

2.75 dia.

MAXIMUM

M

.25.50

RL

RADIAL

LENGTH

30.00

35.00

45.00

60.00

.54

.50

.50

.50

T

2

B

OVERALL

5.22

X + 1.22

5.88

X + 1.88

E

INSIDE

MTG.

2.32

X - 1.68

2.32

X - 1.68

USABLE

INSIDE

WIDTH

3.78

X - .22

3.78

X - .22

2.67

2.67

2.75

14

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 15

®

CATRAC

®

456 Dimensions

CATRAC

456 Dimensions

4.50 CLEARANCE REQUIRED ABOVE LINKS

M

OVERALL

HEIGHT

R

Z

ADIUS

HALF TRAVEL

TOTAL TRAVEL

HORIZONTAL

MTG. FEET

T/2

CENTER LINE

OF TRAVEL

Y** Y**

NOTE:

1) CATRAC LENGTH MUST BE DIVISIBLE

BY PIN CENTERS.

2) ALL STANDARD CARRIER WIDTHS IN 2"

INCREMENTS 4" THRU 20".

3) FOR MULTIPLE OR SPECIAL WIDTHS,

CONSULT FACTORY.

4) ALL PARTS ZINC PLATED UNLESS

OTHERWISE SPECIFIED.

12.00

6.00

IF THE STATIONARY FOOT IS MOUNTED ON EITHER SIDE OF THE

CENTER LINE OF TRAVEL, THE DISTANCE (Y) BETWEEN CENTER LINE

**

AND STATIONARY FOOT MUST BE ADDED TO CATRAC LENGTH.

T

T/2

HALF TRAVEL

(SEE BELOW)

4.50

.75

6.00

3.00

3.50

1.00

1.00

1.00

1.50

(RP)

REMOVABLE

PIPE

(SL)

SPRING LOADED

REMOVABLE PIPE

(AB)

SPLIT ALUMINUM

BAR CARRIER

(WC)

WELDED

CARRIER

R

RADIUS *

5.88

7.44

10.15

14.38

21.25

*

CONSULT FACTORY FOR SPECIAL RADIUS

14.00 16.25

16.00

20.50

24.00

32.00 47.00 84.00

CATRAC LENGTH = + RL + Y**

STYLE

456

PIN

456

BOLTED

X

CARRIER

WIDTH

4.00

X

4.00

X

X + 4.13

X + 4.13

6.00

Z

19.38

24.80

33.25

OUTSIDE

8.13C6.75

8.13

MTG.

X + 2.75

6.75

X + 2.75

VERTICAL

MTG. FEET

.41 X .75 MOUNTING

SLOTS TYPICAL

C

A

B

X

E

3.50 dia.

MAXIMUM

.25.50

RL

M

RADIAL

LENGTH

30.00

36.00

48.00

60.00

T

2

A

B

OVERALL

6.03

X + 2.03

6.53

X + 2.53

.50

.50

.50

.50

E

INSIDE

MTG.

3.42

X - .58

3.42

X - .58

3.14

3.14

3.50

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

15

Page 16

®

CATRAC

606 Dimensions

16

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 17

®

CATRAC

808 Dimensions

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

17

Page 18

Stationary Roller

Part Number System

PD-486 203 5.63 4

Stationary Roller

Part Number System

Stationary

Roller

Support

CATRAC

Style

203

304

375

456

606

808

Radius B Dim.

5.63 11.25

8.69 17.38

5.13 10.25

6.63 13.25

8.19 16.38

10.90 21.80

15.13 30.25

5.62 11.25

7.37 14.75

11.12 22.25

14.87 29.75

24.12 48.25

5.88 11.75

7.44 14.88

10.15 20.30

14.38 28.75

21.25 42.50

11.00 22.00

14.81 29.62

20.50 41.00

24.12 48.25

10.50 21.00

12.50 25.00

19.50 39.00

23.12 46.25

Carrier Width

4

6

8

10

12

14

16

18

20

22

24

Consult factory for

carrier widths and

radii not shown.

PILLOW BLOCK BEARINGS FOR EASY REPAIR

NOTE:

HEAVY DUTY MTG. FEET

USED WHEN B-DIMENSION

IS 23.50 OR OVER

CATRAC® with roller support systems

The roller supports provide a means of

maintaining the maximum unsupported length

while increasing the total travel. There are four

methods of extending the total travel:

1. Utilize a CATRAC with a high side link which

provides a greater unsupported length.

2. Utilize stationary roller supports.

3. Utilize a combination of stationary and

retractable roller supports.

4. Utilize a carriage support system.

OR REPLACEMENT IN FIELD IF DAMAGED

11.00 dia.

3.00

X

203, 304, 456, 606, 808 Styles of CATRAC*

Carrier Width A Dim. C Dim.

4.00 13.52 11.52

x x + 9.52 x + 7.52

Nuts Out x + 10.02 x + 8.02

Note: Approximate dimensions, not for construction unless certified.

All dimensions in inches unless otherwise specified.

*375 Style Consult Factory.

NO ROLLER SUPPORT UL =

T

2

T

T

2

CLEARANCE FOR

.5

6.00

8.00

18.00

20.00

T = TOTAL TRAVEL

UL= MAXIMUM UNSUPPORTED LENGTH

ONE STATIONARY ROLLER SUPPORT UL =

B

0 dia. BOLTS

C

A

T

3

T

T

3

18

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 19

Retractable Roller

50

M

OVERALL

CATRAC

HEIGHT

*

A

C

X

B

G

F

E

D

NOTE:

FOR CATRAC SYSTEMS WITH RETRACTABLE ROLLER SUPPORTS,

OVERALL HEIGHT OF SYSTEM WILL BE INCREASED BY 1.38"

UNLESS RETRACTABLE ROLLER SUPPORT BASE IS RECESSED.

*

1.38

1.38

27.75

21.75

5.14

ADJUSTABLE HEIGHT

Retractable Roller

Part Number System

Part Number System

PD-1218 304 5.13 8

Retractable

Roller

Support

CATRAC

Style

304

375

456

606

808

Radius B Dim.

5.13 11.13

6.63 14.13

8.19 17.26

10.90 22.68

15.13 31.13

5.62 12.13

7.37 15.63

11.12 23.13

14.87 30.63

24.12 49.13

5.88 12.63

7.44 15.76

10.15 21.18

14.38 29.63

21.25 43.38

11.00 22.88

14.81 30.50

20.50 41.88

24.12 49.13

10.50 21.88

12.50 25.88

19.50 39.88

23.12 47.13

Carrier Width

8

10

12

14

16

18

20

For radii not shown and

for multiple carrier widths,

consult factory.

Carrier

Width

8.00 34.50 12.50 10.75 20.00 32.00 36.50

x x + 26.50 x + 4.50 x + 2.75 x + 12.00 x + 24.00 x + 28.50

Nuts Out Consult Factory

304, 456, 606, 808 Styles of CATRAC*

A Dim. C Dim. D Dim. E Dim. F Dim. G Dim.

Note: Approximate dimensions, not for construction unless certified.

All dimensions in inches unless otherwise specified.

*375 Style Consult Factory.

T = TOTAL TRAVEL UL = MAXIMUM UNSUPPORTED LENGTH

TWO STATIONARY ROLLER SUPPORT UL =

T

TWO STATIONARY ROLLER SUPPORT UL =

T

T

4

T

4

T

6

T

4

T

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

6

T

6

T

6

T

6

19

Page 20

Carriage Support Systems

CATRAC® Carriage

Support System

Carriage support systems are used when cable/hose

loads and travel exceed the limits available with fi xed

roller supports and designed for applications requiring

long travels, high speeds, quick accelerations and

constant cycling. These systems are normally used in

®

CATRAC

Carriage

Support System

conjunction with 304 and 456 CATRAC styles. Special

Mill-Duty carriage support systems are available for

extreme environments. Some of the varieties available

are shown on this page. Call our application engineers

for more information at 800.325.8074.

20

Section AA Section DDSection BB Section CC

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 21

CATRAC® Applications

CATRAC® Applications

CATRAC

®

Applications

Primary Metals

Tundish Cars

Ladle Cars

Torch Cut Off Machines

Slab Markers

Mud Gun

Ladle Lance

Pickling Line

Strip Mills

Furnaces

“Dummy” Bar

Continuous Annealing Lines

Construction Machinery

Manlifts

Aerial Lifts

Utility Trucks

Underground Boring

Milling/Drilling Machinery

Drilling Machines

Offshore Drilling Platforms

Rolling Mill Machinery

Coil Processing Equipment

Slitting Line

Roll Grinders

Walking Beam

Machine Tool & Specialty

Equipment

Lathes

Milling Machines

Routers

Shearing

Stamping

Loaders/Extractors

Flame Cutters

Automatic Vehicle Wash

Gantry Crane

Part Shuttles

Press Feeders

High-Pressure Water Washdown

Equipment

Stackers/Reclaimers

X-Ray Gauges

Packaging/Material Handling

Palletizers

Wrappers

Shuttles

Rubber Tired Vehicles

Factory Automation

Automation Storage & Retrieval

System

Other

Pulp/Paper Industry

Lumber Industry

CATRAC Automotive

Applications

Stamping Related

Coil Handling Equipment

Die Transfer Carts

Shuttles

In Die Transfer Equipment

Stacker & Destacker Equipment

Stamping Press Heads

Assembly Plants

Radiator Fluid Filling Lines

Brake Fluid Filling Lines

Body Transfer Lines

Welding Lines

Chassis Assembly Lines

Raw Material

Loading/Unloading Cranes

Stacker/Reclaimer Cranes

Steel Making

Ladle Lance

Ladle Transfer Cars

Tundish Cars

Starter Bar

Torch Cut-Off Machine

Run Out Table

Soaking Pit Transfer Car

Scarfi ng Machine

Hot/Cold Strip Mills

Walking Beam

Reheat Surface

Coil Buggies

X-Ray Machines

Slitter Machines

Back Up Roll Sleds

Pay Off Reel

Coil Upender

Entry/Exit Cars

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

21

Page 22

Steel Mill Applications

Steel Mill Applications

Mining - Iron Ore - Coal Limestone

Ore Beneficiation

Preparation

Cleaning

Belt Trippers

Stackers

Reclaimers

Bedding Machines

Trenchers

Shipping - Rail - Water - Raw

Material Storage

Stackers

Reclaimers

Belt Trippers

Car Dumpers

Integrated Steel Making

Plants

Raw Material - Storage &

Preparation

Stackers

Reclaimers

Belt Trippers

Car Dumpers

Trenchers

Sinter Plants

Belt Trippers

Bedding Machine

Trenching Machine

Reclaimer

Coke Oven Batteries

Coke Battery Ovens - Coke

Side

Door Machine

Smoke Suppressor

Quench Cars

Wharf Plows

Blast Furnaces

Taphole Drills

Mud Guns

Burden Distributor Car

Sensing Lances

Steel Making Open Hearth

Charging Machine

Ladle Transfer Cars

Hot Metal (Molten Iron)

Teeming Aisle (Molten Steel)

Slag Pot

Mold Preparation Vacuum & Dust

Machine

Basic Oxygen Furnace (BOF)

Scrap Prep. Cutting Gantry

Water Cooled Doors

Removable Hood Section

Belt Tripper - Flux Handling

Refractory Gunning Machines

Lance Carriage

Horizontal

Preheat

Temperature Data

Ladle Transfer Cars

Hot Metal (Molten Iron)

Teeming Aisle (Molten Steel)

Slag Pot

Argon Lance

Continuous Casting - Slab,

Boom, Billet

Ladle Transfer Car

Tundish

Transfer Car

Heat Shield Car

Pouring Station

Shroud Positioner

Starting Bar

Transfer Car

Heat Shield Car

Pouring Station

Shroud Positioner

Starter Bar

Storage Rack

Cut Off Machine

Torch Machine

Cutoff Torch Traverse

Torch Edge Cutting Machine

Upcut Shear

Slab Sizing Mill - Roll Sleds

Stamping Marking Machine

Disappearing Stop

Piler - Pusher

Slab, Blooming, Billet Mills

- Shapers

Soaking Pit Transfer Cars

Double Manipulator - Rolling Edge

Guides

Roll Sleds

Scarfi ng Machine

Supply

Adjustable Heads

Crop Shear

Marking - Stamping Machine

Coal Preparation - Coke

Storage

Stackers

Reclaimers

Belt Trippers

Trenchers

Coke Battery Ovens - Coal

Side

Lary Charge Cars

Smoke Blow Pipe Cleaners

Charge & Cover Machine

Pushing Machine - Levelers

22

Electric Furnace

Ladle Transfer Cars

Furnace Tilt

Teeming Aisle (Molten Steel)

Cover Turn

Charge Machines

Argon Lance

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 23

Steel Mill Applications

Steel Mill Applications

Hot Strip Mills

Primary Rolling

Roll Sleds, Backup and Work Roll

Vertical Scale Breaker

Horizontal Scale Breaker

Roughing Mills

Finishing Mills

Descale Systems

Morgoil Lubrications

Coilers

Mandrel Carriage

Stripper Cars

X-Ray Machines

Finishing - Processing

Transfer Cars

Oil Buggies

Combo Line

Skin Pass Line

Slitters & Shears

Coil Carrier Hook

Walking Beam Coil Transfer

Auxiliaries

Transfer Cars

Work Rolls

Backup Rolls

Bearing Extractor Car

Sheet Mills - Cold Rolling

Continuous Pickling Line

Entry Coil Cars - Buggies

Welders

Tension Wheels - Exit Coil Cars

Mandrel Carriages - Coilers

Belt Wrappers

Oilers

Pay Off Reels

Upender/Downender

Tandem Cold Rolling Mills

Coil Transfer Cars

Entry Horn Car

Quick Work Roll Change Car

Backup Roll Sled

Work Roll Turntable Sled

Belt Wrapper Transfer

Lift & Turn Coil Transfer

Temper Mill - Single Stand - Duo Mill

Coil Prep & Transfer

Entry Coil Car

Quick Work Roll Change Car

Exit Transfer Car

Back Uproll Sleds

Auxiliary Cold Mill Equipment

Dechocking Car - Roll Shop

Lathes & Grinders - Roll Shop

Slitter & Shear Process Lines

Entry & Exit Coil Cars

Recoil Mandrel Carriage

Payoff Reels

Belt Wrapper Transfer

Coil Band & Strapping

Upender/Downender

Continuous Anneal Lines

Exit & Entry Coil Cars

X-Ray Machines

Tension Reel Mandrel Carriages

Coating & Plating

Lines - Tin - Al - Chrome - Zinc

Galvanize

Vertical Spangle Unit

Horizontal Steam Supply

Zinc Hot Metal Pot

Welding Machine

Corrugating Lines

Upender/Downender

Plate Mills

Roll Change Sleds

Morgoil & Lube Systems

X-Ray Gauge

Descale Piping

Side Shear & Edge Gauge

End Gauge

Leveler

Structural Mills - Rail Mills

Rolling Mill Sleds

End Shear

Straightener

Bar and Rod Mills

Roll Sleds

End Shears

Straightener

Coiler Mandrel Carriage

Seamless and Butt Weld Pipe

Mills

End Piercing Machine

Billet Charging Machine

Roll Shops

Grinders

Lathes

Chock Extractors

Roll Transfer Cars

Auxiliary Process Lines

Tension Leveling

Degreasing

Paint Coating

Shear

Shot Blast

Cut to Length

Slitting Line

Continuous Paint Line

Galvanize Line

Edge Trim Line

Grind & Polish

Anneal

Embossing

Side Trim

Chrome - TFS

Tin Line

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

23

Page 24

Mill-Duty CATRAC

Mill-Duty CATRAC

®

®

CATRAC® MD for the Primary Metals Industry

This industry readily accepts only those products that

are made exceptionally strong to the point of being

“overbuilt”. If the product doesn’t look like it belongs in

that environment, it doesn’t.

Reliability is the Foremost Requirement

This industry knows no product that they can’t destroy

regularly, our mill-duty CATRACs are designed to be the

most rugged assemblies available.

CATRAC is Stronger

All steel construction fabricated from 80,000 lb. tensile

steel links, assembled with 9/16, 3/4 or 1” hardened

shoulder bolts and locknuts, welded box beam carriers

absorb side thrust loads, can be made to travel and span

the longest distances in the industry.

Cable & Hose Replacement is Easy

The box beam carrier has free space that allows the bad

cable or hose to be easily snaked out. The carrier bars

can have spring loaded retaining rods, allowing the whole

bundle of hoses to be removed and replaced at once.

Available in Any and ALL Sizes

Made to any width or radius with more hose and cable

carrying capacity in a box beam carrier, it can handle 8”

I.D. hose or 12” O.D. cable. We also offer multiple widths

and double deck carrier assemblies.

Retrofit into Present Track Systems

CATRAC is the only known track that can be easily

and regularly made to retrofi t into competitors original

applications. We need only four dimensions to build

CATRAC:

Track Height - “M”

Track Height - “B”

Track Height - “TL”

Hose & Cable Clearance - “HC”

We’ll deliver a stronger system quicker, and at a minimum

cost.

CATRAC is Field Repairable

Because the CATRAC is all steel, it can be straightened

or welded in position. It can be easily unbolted to replace

carriers and links.

CATRAC Value

The competitively priced CATRAC offers more options

for your dollar. Since 1967, CATRAC brand carriers

have been solving customer problems. These years

of experience have supplied us with an opportunity to

provide solutions for numerous applications. This data

allows us to incorporate new and better features into all

CATRAC styles.

24

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 25

Chip Covers

CATRAC® Options

Stainless steel chip covers protect hoses against damage

from hot metal chips. The chip covers fi t over the full

length of the CATRAC® assembly, on either the top or

bottom or both sides for maximum protection. The ends

of the chip covers extend six inches beyond the ends

of the CATRAC assembly for attachment. Chip covers

should be fastened on either end to allow them to roll

with the CATRAC. When ordering, specify either outside

or inside covers or both.

Heavy Duty Mounting Feet

Heavy Duty horizontal and vertical mounting feet are

made from 3/16” or 1/4” plate steel and provide the

ultimate in strength at the mounting point. Typical

applications include mill duty equipment and high speed

applications. Custom designs are also available upon

request.

CATRAC

®

Options

Glide Bars and Transfer Bar for Side Mounted

Applications

We offer a wide range of options for side mounted

applications including Nylatron glide bars, round pads

and steel or stainless steel ball casters. We can side

mount virtually any style of CATRAC. Dual radius

CATRACS are also available for rotary applications.

Multiple Carrier Widths

All styles of 3 Pin Center Pivot CATRAC are available

in multiple widths. This type of construction provides

additional strength in wide systems. When width is

a problem double decking of compartments is also

available.

Transfer Balls

Alternated for

Stability

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

25

Page 26

®

SnapTrac

®

Nylon Carriers

SnapTrac

Nylon Carriers

Available in a Variety of Sizes

SnapTrac® was developed to offer a light weight, low cost

carrier for protected and controlled movement of cables

and hoses. This corrosion resistant, nonconductive carrier

is made of a longwearing nylon composition. SnapTrac

can be used with electric, air, gas or hydraulic hoses.

A variety of carriers are available offering solutions for

every type of travel. Typical applications for this carrier

include robotics, machine tools, and all types of industrial

equipment. Our application engineers are at your

disposal to study and solve problems related to complex

applications.

Technical Characteristics

Light and secure even at high speeds, SnapTrac

carriers will provide protection for the components

inside the carrier. The carrier is durable against harsh

corrosive environments as found in refi neries and

marine application, chemical fumes, refrigeration fl uids,

lubricating oils and solvent present in a temperature

range from -13°F to 257°F.

Choosing a Carrier

The designer must consider the travel length of the carrier

and the minimum bending radii of the hoses to be carried.

The additional load per foot must also be considered.

Layout of Cable in Carrier

Observe the allowable minimum bending radii of the

cables and hoses to be carried; it is advisable to add an

additional 10%. Cables of small diameter may be grouped

together and tied.

Options

• Enclosed Designs

• Vertical Separator

• Horizontal Separator

• Vertical/Horizontal Separators

• Drilled Frames

26

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 27

®

SnapTrac

®

Nylon Carriers

SnapTrac

Nylon Carriers

Light SnapTrac

Light series SnapTrac with small to medium sections for

applications where high fi lling weight is not required.

Light SnapTrac

Series

8061SR200

8061SR250

8061

SR30090

8061SR325A

8061SR325

8061SR200 8061SR325A8061SR300908061SR250 8061SR325

A

External

Width mm

18-41 15 12-35 12 18-40

23 22 15 18 40

29-49 23.5 18-38 18.5 33-100

57-120 37 40-103 25.5 50-150

55-118 37 40-103 25.5 50-150

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

27

Page 28

SnapTrac

®

Nylon Carriers

Medium SnapTrac

Small to medium size SnapTrac with yellow connecting pivot

pins offer high capacity in high performace applications.

Available with snap open cover or closed styles.

Medium SnapTrac

Series

8061SR300A

8061SR300

8061SR305A

8061SR305

8061SR355A

8061SR355

8061SR400

8061SR435MI/ME

8061SR445MI/ME

8061SR660A

8061SR770A

8061SR475MI/ME

A

External

Width mm

27-87 23 15-75 18 40-120

30-52 23 14-36 18 40-120

54-74 30 30-50 24 50-150

52-72 30 30-50 20 50-150

74-124 43 45-95 31 75-200

74-124 45 45-95 30 75-200

62-82 35 40-60 25 50-150

60-170 49 40-150 35 60-170

72-384 64 50-362 45 75-300

75-387 55 50-362 37 100-250

80-392 78 45-357 60 150-300

112-412 100.5 74-374 75.5 150-400

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

®

SnapTrac

Nylon Carriers

8061SR300A 8061SR3058061SR305A8061SR300

8061SR355A 8061SR435MI/ME8061SR4008061SR355

8061SR445MI/ME 8061SR475MI/ME8061SR770A8061SR660A

28

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 29

®

SnapTrac

®

Nylon Carriers

SnapTrac

Nylon Carriers

Heavy SnapTrac

A strong design with triple connecting pivot pins. This design

allows unsupported length up to 6.5 m and extends the

service life of the SnapTrac and cables.

Heavy SnapTrac

Series

8061SR308SI/SE

8061SR309SI/SE

8061SR310T

A

External

Width mm

82-394 75 38-350 57 150-400

120-420 100 64-364 75.5 200-500

260-660 150 200-600 112 200-750

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

Protection SnapTrac

A completely enclosed design prevents contact between

cables, chips or dust. Each link has a quickly removable

cover for easy installation of the cables and hoses.

8061SR310T8061SR309SI/SE8061SR308SI/SE

Protection SnapTrac

Series

8061SR435PI/PE

8061SR660

8061SR445PI/PE

8061SR770

8061SR309C

8061SR475PI/PE

8061SR435PI/PE 8061SR445PI/PE8061SR660

A

External

Width mm

60-170 49 40-150 35 75-200

79-179 55 50-150 36 100-250

72-384 64 50-362 45 100-300

120-285 78 85-250 51 150-300

256-456 100 200-400 72 200-500

112-412 100.5 74-374 75.5 180-400

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

8061SR660

8061SR770 8061SR475PI/PE8061SR309C

8061SR770

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

29

Page 30

®

SnapTrac

®

Nylon Carriers

SnapTrac

Nylon Carriers

Sliding SnapTrac

Sliding SnapTrac is made to be used where travel distance

is long. The links are equipped with skids, allowing the trac

to slide on itself. It is made of special polymers to reduce

friction and wear.

Sliding SnapTrac

Series

8061SR326SI/SE 106-418 59 61-373 37 107-300

8061SR328SI/SE 119-431 79 61-373 57 150-400

8061SR319B 164-464 107 100-400 70 200-500

8061SR200 8061SR300908061SR250

A

External

Width mm

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

Robot SnapTrac

SnapTrac offers an innovative solution for circular

applications like welding and painting robots by allowing

rotation of over 360°. Available in 9 different models, each

link has an opening cross piece to allow easy installation of

cables and hoses.

Robot SnapTrac

Series

8061SR495 69 45 45 35 100

8061SR500 93 43 65 30 100-150

8061SR510TN 132 55 88 46 125

8061SR515TN 132 55 88 46 175

8061SR545 123 62 100 46 100

8061SR599 272 85 210 59 220

8061SR250

A

External

Width mm

B

External

Height mm

C

Inner

Width mm

D

Inner

Height mm

R

Bending

Radius mm

8061SR325A8061SR30090

8061SR200

8061SR200

30

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

Page 31

®

CATRAC

®

Development Sheet

CATRAC

Development Sheet

Please fi ll in completely and accurately and fax to the CATRAC Sales Department @ (810) 378-5516.

Customer Information

Contact Name Fax

Company Email

Phone Date

Machine / Environment Specifications

Machine Type or Name

Machine Total Travel Distance

Direction / Orientation of Travel

Fixed End Mounting Location

Mounting Bracket Position

Operating Speed (ft/sec)

Acceleration (ft/sec)

Environmental Data

Operating Temperature

Dimensional Limitations OAW = ___________ OAL = ___________ OAH = ___________ (Allow an additional 2 in. for operating clearance in OAH)

❑ Horizontal ❑ Vertical ❑ Side Running ❑ Other If other, please provide sketch.

❑ Center (Of total machine travel) ❑ Off Center (Distance from center_________________)

❑ Inward ❑ Outward ❑ Both ❑ Other

❑ ≤ 5 ft/sec ❑ ≤ 10 ft/sec ❑ ≤ 15 ft/sec ❑ ≥ 15 ft/sec

❑ ≤ 5 ft/sec² ❑ ≤ 10 ft/sec² ❑ ≤ 15 ft/sec² ❑ ≥ 15 ft/sec²

❑ Indoor ❑ Outdoor ❑ Wet* ❑ Dry ❑ Corrosive ❑ Abrasive ❑ Humidity* ❑ Chemical* ❑ Chips* ❑ Hot Metal ❑ Fluid Exposure*

*Please explain type or level________________________________________________________________________________

❑ ≤ 40F (5C) ❑ ≤ 150F (66C) ❑ ≤ 250F (121C)

Carrier Contents

Critical information. Please include MFG cut sheets when possible.

Note: If a bend radius is not provided, the customer agrees to using 8 to 10 times the cable or hose diameter as a factor.

Cable / Hose

Quantity

Outside

Diameter

Weight Per Foot

(Fluid fi lled on hoses)

Min. Bend Radius

(MFG Specifi cations)

6380 Brockway Road • Peck, MI 48017 • 800.325.8074 • 810.378.5511 • Fax 810.378.5516 • www.AMETEKAPT.com

31

Page 32

Other Products

Copyright 2010 by AMETEK AUTOMATION & PROCESS TECHNOLOGIES. All Rights Reserved. Made in the USA.

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248.435.0700 Toll Free: 800.635.0289

Fax: 248.435.8120 www.ametekapt.com

8060.C5R

3/10.Z88

1M

Loading...

Loading...