Page 1

FORM 85-02

June 1999

Revision 6

AMETEK

®

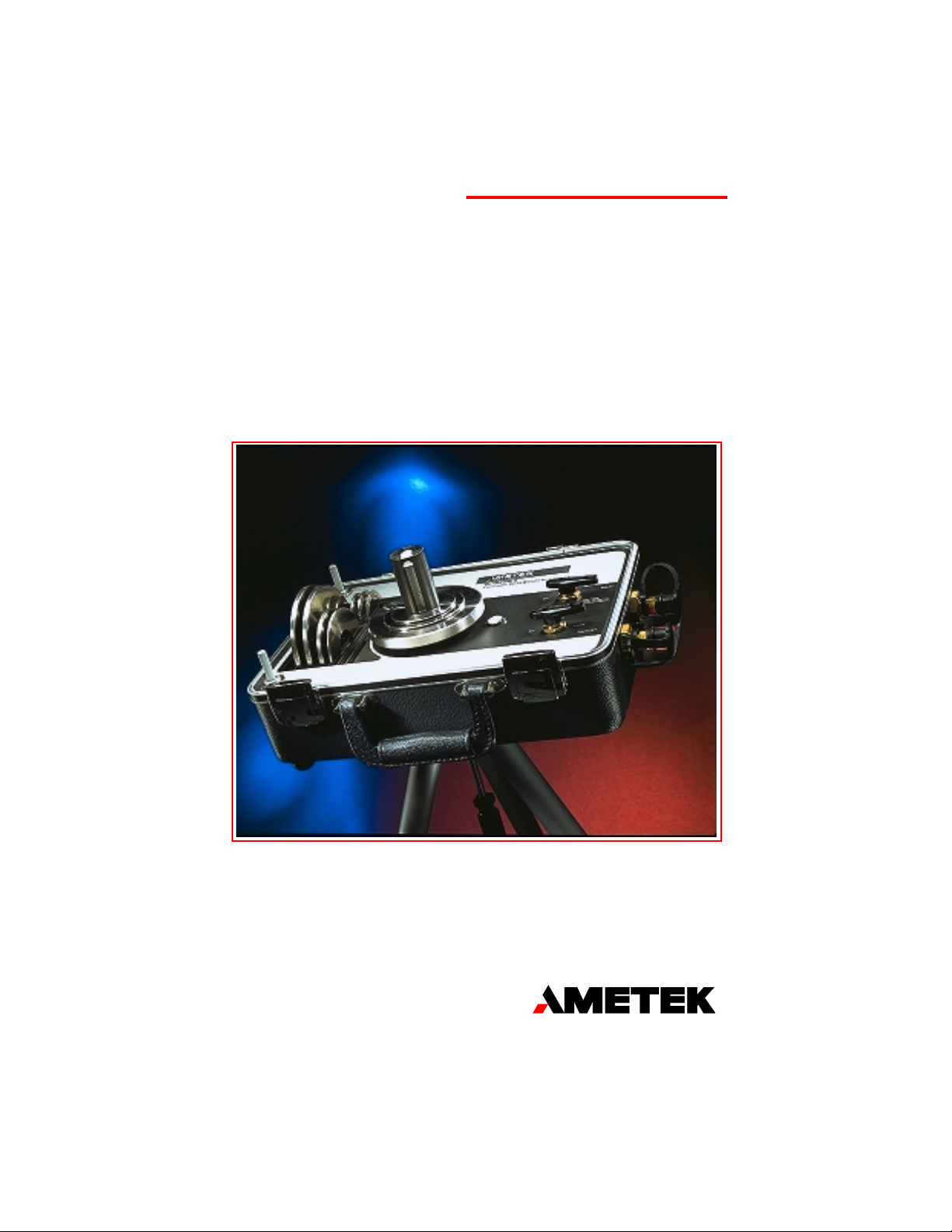

PK II Pneumatic

Deadweight Tester

Operating Instructions

- 1 -

®

CALIBRATION INSTRUMENTS

Page 2

T ABLE OF CONTENTS

Page

1.0 INTRODUCTION AND PRODUCT OVERVIEW ..................................................... 4

1.1 PRODUCT FEATURES ........................................................................................... 4

1.2 PK II PHYSICAL DIMENSIONS ............................................................................. 5

2.0 CORRECTION FACTORS....................................................................................... 6

2.1 Corrections for Gravity ........................................................................................... 6

2.2 Corrections for Temperature ................................................................................... 7

2.3 Corrections for Air Head ......................................................................................... 8

3.0 RECOMMENDED RECERTIFICATION PROCEDURE........................................... 8

3.1 Frequency of Certification ...................................................................................... 8

3.2 Materials Necessary for Recertification ................................................................. 8

4.0 SPECIFICATIONS ................................................................................................... 9

5.0 ASSEMBLY AND SETUP ......................................................................................... 13

5.1 Ball and Nozzle ........................................................................................................ 13

5.1.1Removing the Nozzle .............................................................................................. 13

5.1.2Removing the Ball ................................................................................................... 13

5.1.3Cleaning the Ball and Nozzle ................................................................................... 13

5.1.4Cleanliness Check .................................................................................................. 13

5.2 Leveling the Tester .................................................................................................. 13

5.2.1 Fast Leveling ........................................................................................................... 13

5.2.2Fine Leveling ........................................................................................................... 13

5.3 Connection .............................................................................................................. 14

6.0 OPERATING INSTRUCTIONS ................................................................................ 15

7.0 MAINTENANCE ....................................................................................................... 16

7.1 Output System ........................................................................................................ 16

7.2 Input System ........................................................................................................... 17

- 2 -

Page 3

T ABLE OF CONTENTS

Page

8.0 TROUBLESHOOTING ............................................................................................ 18

8.1 Correcting For Poor Weight Rotation ...................................................................... 18

8.2 Output and Internal Leakage ................................................................................... 18

8.2.1 Output Connection Leakage............................................................................. 18

8.2.2 Internal Leakage Within the Tester................................................................... 18

8.3 Replacing the Nozzle and O-Ring ............................................................................ 18

9.0 PARTS LIST ............................................................................................................. 19

TABLES

Page

2a Pressure in PSIG ..................................................................................................... 9

2b Pressure in Inches of Water @ 20°C ..................................................................... 10

2c Pressue in Grams per Square Centimeter .............................................................. 10

2d Pressure in Kilopascals ........................................................................................... 11

2e Pressure in Centimeters of Water @ 20°C ............................................................ 11

2f Pressure in Bar ........................................................................................................ 12

2g Pressure in Millimeters of Mercury ......................................................................... 12

PRODUCT WARRANTY

This instrument is warranted against defects in workmanship, material and design for one (1) year from

date of delivery to the extent that AMETEK will, at its sole option, repair or replace the instrument or any

part thereof which is defective, provided, however, that this warranty shall not apply to instruments

subjected to tampering or abuse, or exposed to highly corrosive conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED AND

AMETEK HEREBY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING, WITHOUT LIMIT ATION, ANY

WARRANTY OF FITNESS FOR A P ARTICULAR PURPOSE OR MERCHANTABILITY. AMETEK SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITED TO, ANY ANTICIPATED OR LOST PROFITS.

This warranty is voidable if the purchaser fails to follow any and all instructions, warnings, and cautions

in the instrument’s Instruction Manual.

If a manufacturing defect is found, AMETEK will replace or repair the instrument or replace any defective

part thereof without charge; however, AMETEK’s obligation hereunder does not include the cost of

transportation which must be borne by the customer. AMETEK assumes no responsibility for damage in

transit, and any claims for such damage should be presented to the carrier by the purchaser.

- 3 -

Page 4

1.0 INTRODUCTION AND PRODUCT OVERVIEW

The AMETEK® PK II Pneumatic Deadweight Tester is a primary standard that produces a

pressure by applying force (weight set) over area (the ceramic ball and nozzle). The PK II

tester is NIST traceable and accurate to +0.015% of indicated reading using stainless steel

weights calibrated to international standard gravity at 980.665cm/sec2. The unit is intended

for low pressure applications up to 30 PSIG (2 bar). The PK II tester may also be calibrated

to the user’s local gravity or to inches or centimeters of H2O at 20°C per ISA recommended

practices, or to reference water columns at 60°F per AGA standard practices.

The PK II tester is self-regulating with accuracy independent of the operator. The tester

utilizes a frictionless ceramic ball which floats on a layer of air within a stainless steel

cylinder.

The PK II tester features a sturdy cast-metal base with integral quick-leveling system for

field or laboratory use. The case also contains a tripod fixture allowing the unit to be tripod

mounted in the field.

1.1 PRODUCT FEA TURES

The key features of the

PK II Pneumatic Deadweight Tester

are:

G Accuracy up to +0.015% of indicated reading

G Floating ball operation eliminates need to rotate weights during testing

G Self regulating input air flow maintains ball and weights in a float position and compen-

sates for variations in air supply pressure

G Rugged ceramic measuring ball withstands harsh environments and field use

G Monocontaminating fluid eliminates the need to clean instruments after calibration or

before use

G Close cover operation eliminates wind effects in field calibrations

G Multi-position ball valves for both the inlet and outlet connections ensures trouble-free

operation

G Certificate of Accuracy and Traceability available with area, mass and intrinsic correc-

tion factors

G Rugged aluminum housing offers long life. Top (Front) housing is reversible.

- 4 -

Page 5

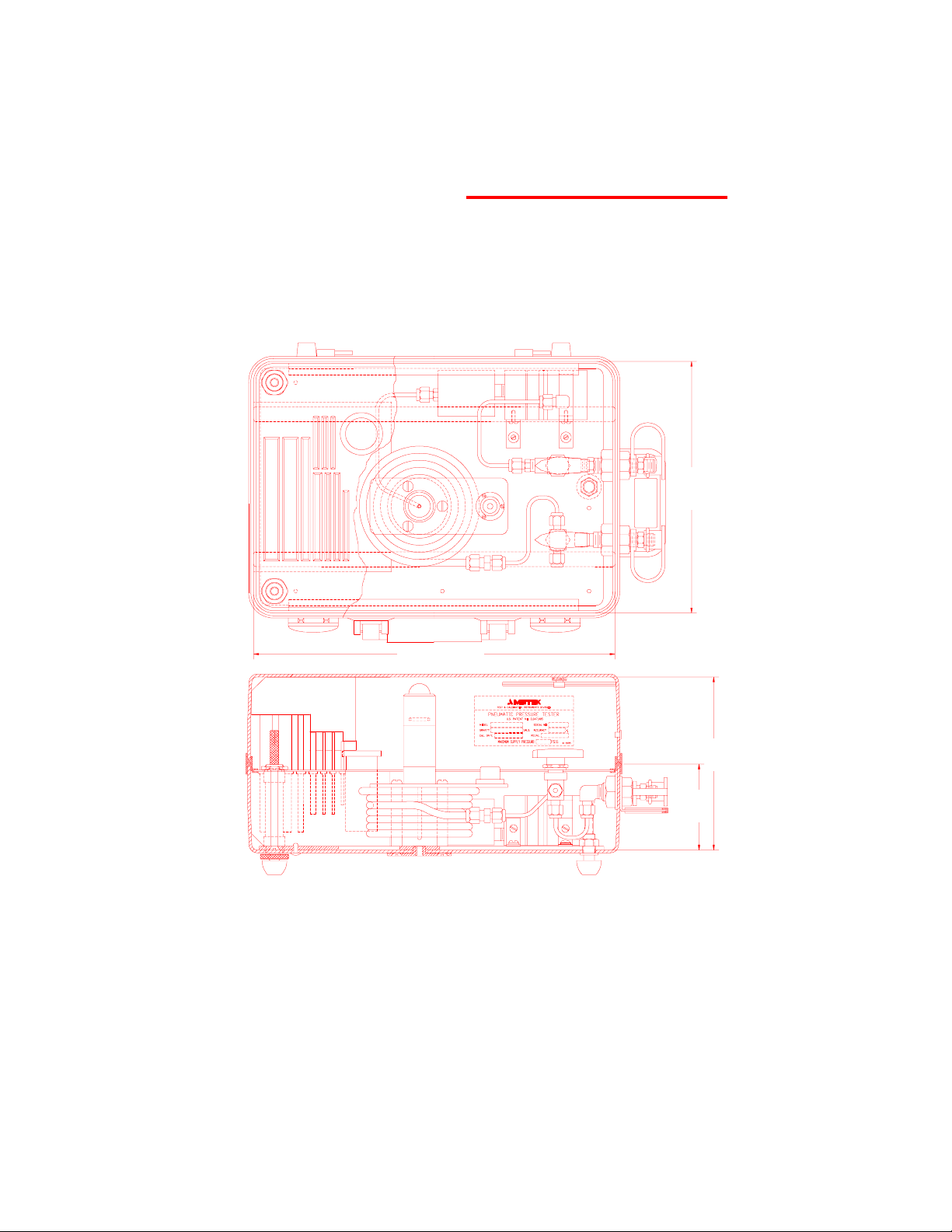

1.2 PK II PHYSICAL DIMENSIONS

12.75 in

323.85 mm

8.875 in

225.4 mm

Figure 1.1

PK II Dimensions

(Models 104, 254, 304 and Medical)

- 5 -

6.125 in

155.56 mm

3.0 in

76.2 mm

Page 6

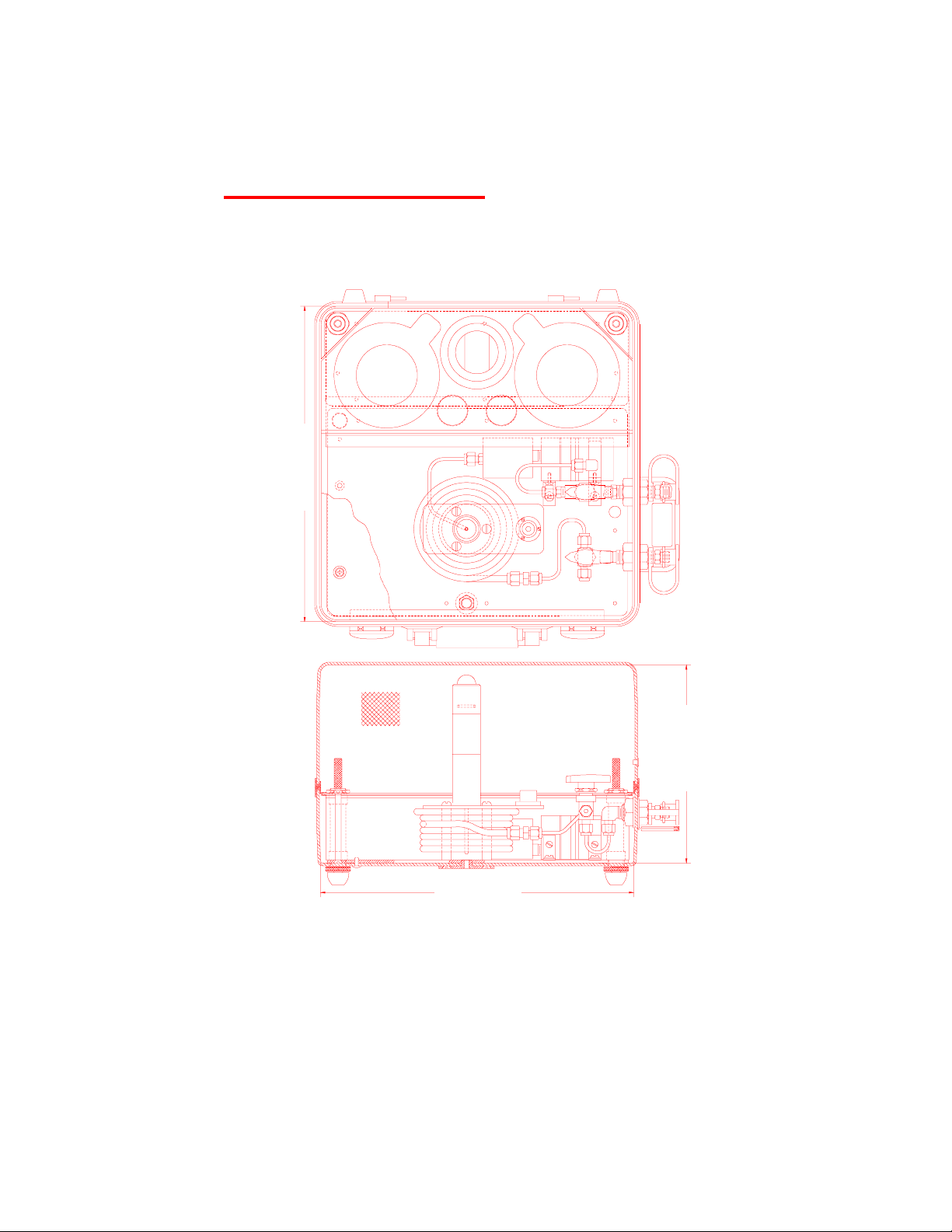

1.2 PK II PHYSICAL DIMENSIONS

12.75 in

323.85 mm

12.875 in

327.03 mm

Figure 1.2

PK II Dimensions

(Models 20SS, 30SS, 654, 854, 2000GM, 2010GM

200N, 201N, 500CM, 1000CM, 1500CM, 2000CM, 2B, 2B01)

- 6 -

8.0 in

203.2 mm

Page 7

2.0 CORRECTION F ACTORS

An error in pressure determinations may result from any uncertainty of the mass of the

loading weights and from the measurement of the effective area of the ball and nozzle.

Other sources of error, however, may not be easily recognized. Other sources of error

include the air buoyancy of the weights, gravity, thermal expansion and elastic deformation

of the ball and nozzle, and the air heads involved. All of these corrections, with the

exception of local gravity (except when specified), thermal expansion, and air heads have

been corrected for by AMETEK prior to the tester being shipped.

The following technique is suggested to compute the corrected tester output pressure

readings:

Gravity

Local gravity values differ depending upon geographic locations. Pressure is defined as

“force per unit area”, so that mass values must be converted to force values. To accomplish

this, the acceleration of gravity must be used. The acceleration of local gravity may be

determined by having a gravitational survey made of the local area with a gravimeter or by

contacting various governing bodies such as the National Oceanic and Atmospheric Administration, U.S. Department of Commerce. Once the local value of gravity is known, the

pressure may be corrected using the following formula:

G

P

G

=

G

x P

W

N

Where:

P

G

G = local gravity

G

W

P

N

= tester output pressure corrected only for gravity

= gravity value for which the tester is calibrated

= pressure value of weights applied

- 7 -

Page 8

Temperature

If the coefficient of expansion of the ball and nozzle is positive, the effective area will

increase with increasing temperature resulting in a corresponding decrease in pressure.

Corrections can be made using the following formula:

P

P

=

T

Where:

P

G

P

T

T = ambient temperature (°C)

Air Head

When pressurized, a correction is required only when the gauge height or reference plane

of the unit being calibrated is either higher or lower than that of the pneumatic tester. The

reference plane of the tester is at the top of the nozzle. Heights above the reference plane

are negative, while heights below the reference plane are positive. Corrections can be

made using the following formula:

= tester output pressure corrected only for gravity

= tester output pressure corrected for gravity and temperature

1 + 1.67 x 10-5 (T - 23°C)

G

P

=

A

Where:

H = air head (Inches)

P

T

P

A

= tester output pressure corrected for gravity and temperature

= tester output pressure corrected for gravity, temperature and air head

PT (1 + H x 2.84 x 10-6)

- 8 -

Page 9

3.0 CALIBRA TION AND RECERTIFICA TION

The accuracy of measurements can only be ensured through calibration against reference

standards of a known and well characterized measurement uncertainty; reference standards that are ultimately traceable through a national standards laboratory to the International Bureau of Weights and Measures (BIPM), to a natural physical constant, or to consensus standards.

All AMETEK pressure calibrations are traceable in the United States of America to reference

masters calibrated by the National Institute of Standards and Technology (NIST).

Measurement performance is affected by the frequency and severity of use, the environment, test conditions, and by other factors. AMETEK recommends calibration on a prescribed interval/frequency in order to ensure optimal measurement performance and reliability.

Two types of calibration services are offered:

G Calibration with a Certificate of Conformance/Certificate of Compliance

A statement of conformity which documents that the listed device(s) conforms to published specifications, or the terms of the order/contract. It can provide, in addition, a

statement of traceability to NIST.

G Calibration with a Calibration Report/Certificate

A report that outlines detailed information about the calibration process. This includes

actual calibration data, traceability information, test conditions, and other factors as may

be applicable to the type of device being calibrated.

3.1 RECOMMENDED CALIBRA TION FREQUENCY

As a general rule, AMETEK

months.

Testers used on a more frequent basis should be tested more frequently.

pneumatic testers should be tested and recertified every 12

3.2 MA TERIALS NECESSAR Y FOR RECERTIFICA TION

Both the tester assembly and weight set should be returned to AMETEK in order to allow for

calibration of the tester as a “system”. Pressure is a derived parameter requiring determinations of both effective area and force (weight-mass). Instruments not sent to AMETEK as

a “system” can only be provided with certifications on the parameter calibrated, e.g. effective area or mass.

All materials should be securely packaged to prevent damage during transportation and

handling. Testers should be returned in their case. The ball/nozzle assembly should be

wrapped with adequate padding material and well secured to avoid shifting, movement and

to protect them from shock during transportation.

- 9 -

Page 10

4.0 SPECIFICATIONS

The PK II Pneumatic Deadweight Testers are self-regulating, primary standards with a

pressure capacity of 104- 254-, 304- and 854-inches H

the deadweight principle using only fundamental units of force and area. Pressure equals

the weight force divided by the effective area of the ball.

All PK II Testers are shipped with tester and weight contained within a carrying case. The

instrument is available with accuracies of

+0.015%, +0.025% or +0.05% of indicated read-

ing with stainless steel weights.

O. These instruments operate on

2

MODEL RANGE INCREMENT SE T

MINIMUM WEIGHT

PK2-20SS 1-20 PSIG 1 PSI G T able 2a

PK2-30SS 1-30 PSIG 1 PSI G T able 2a

PK2-104WC-SS 4-100” H

O1” H2O Table 2b

2

PK2-254WC-SS 4-254” H2O1” H2O Table 2b

PK2-304WC-SS 4-304” H2O1” H2O Table 2b

PK2-654WC-SS 4-654” H2O1” H2O Table 2b

PK2-854WC-SS 4-854” H2O1” H2O Table 2b

PK2-2000GM-SS 25 - 2000 gm/cm

PK2-2010GM-SS 10 - 2000 gm/cm

2

2

25 gm/cm

5 gm/cm

2

Table 2c

2

Table 2c

PK2-200N-SS 2-200 KPa 2 KPa Table 2d

PK2-201N-SS 1 - 200 KPa 0.5 KPa T able 2d

PK2-500CM-SS 10 - 500 cm H2O 10cm H2O T able 2e

PK2-100CM-SS 10 - 1000 cm H2O 10 cm H2O Table 2e

PK2-1500CM-SS 10-1500 cm H2O 10 cm H2O Table 2e

PK2-2000CM-SS 10 - 2000 cm H2O 10 cm H2O Table 2e

PK2-2B-SS 0.02 - 2 bar 0.02 bar Table 2f

PK2-SB .01-SS 0.01 - 2 bar 0.005 bar Table 2f

PK2-MEDICAL 10 - 325 mm Hg 5 mm H g T able 2g

Table 2a

Pressure in PSIG

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (PSIG) 1 PSI 2 PSI 3 PSI 5 PSI

PK2-20SS 1213

PK2-30SS 1215

Part Number K-2000 (PK2-20, PK2-30) K-2011 K-2012 K-2013 K-2013-5

- 10 -

Page 11

Pressure in Inches of Water @ 20°C

Table 2b

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (in H2O) 1” H2O2” H2O5” H2O10” H2O20” H2O50” H2O 100” H2O

- 11 -

PK2-104WC-SS 4” H

O14 9 1

2

1

PK2-254WC-SS 4” H2O 1212121

PK2-304WC-SS 4” H

PK2-654WC-SS 4” and 10” H

PK2-854WC-SS 4” and 10” H

Part Number K-1279 (4” H

K-1265-1 (10” H

NOTE:

1

Weight insert accepts optional 100” H2O weight.

O 1212112

2

O 1212125

2

O 1212127

2

O)

2

O) K-1277 K-1278 K-2047-1 K-1294 K-2046-16 K-2030 K-2031

2

Pressure in Grams per Square Centimeter (g/cm

Table 2c

2

)

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (g/cm2) 5g/cm210g/cm225g/cm250g/cm2100g/cm2200g/cm2500g/cm

PK2-2000GM-SS 25g/cm

PK2-2010GM-SS 25 and 10g/cm

Part Number K-1279-4 (10g/cm

K-1265-13 (25g/cm

2

2

2

)

2

) K-2047-33 K-2047-32 K-2046-30 K-2046-19 K-2030-5 K-2039-14 K-2039-11

1211213

11213

2

Page 12

- 12 -

Pressure in Kilopascals (KPa)

Table 2d

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (KPa) 0.5 KPa 1 KPa 2 KPa 4 KPa 10 KPa 20 KPa 50 KPa

PK2-200N-SS 2 KPa 2 1 2 1 3

PK2-201N-SS 2 KPa & 1 KPa 1121213

Part Number K-1279-2 (1KPa)

K-1265-12 (2 KPa) K-2047-17 K-2047-18 K-1294-2 K-2046-29 K-2030-1 K-2031-3 K-2039-12

Pressure in Centimeters of Water @ 20°C

Table 2e

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (cm H2O) 10cm H2O 20cm H2O 50cm H2O 100cm H2O 200cm H2O 500cm H2O

PK2-500CM-SS 10 cm H

PK2-1000CM-SS 10 cm H

PK2-1500CM-SS 10 and 25 cm H

PK2-2000CM-SS 10 and 25 cm H

O 12 121

2

O 12 1211

2

O12 1212

2

O12 1213

2

Part Number K-2047-24 K-2045-10 K-2046-24 K-2031-18 K-2031-19 K-2031-20

Page 13

- 13 -

Table 2f

Pressure in Bar

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (Bar) 0.005 bar 0.01 Bar 0.02 Bar 0.04 Bar 0.1 Bar 0.2 Bar 0.5 Bar

PK2-2B-SS 0.02 Bar 2 1 2 1 3

PK2-.01-SS 0.01 and 0.02 Bar 1 1 2 1 2 1 3

Part Number K-2047-17 K-2047-18 K-1294-2 K-2046-29 K-2030-1 K-2031-3 K-2039-12

Pressure in Millimeters of Mercury (Hg)

WEIGHT CARRIER Weights Furnished per Pressure Increment

MODEL AND BALL (mm Hg) 5 mm Hg 10 mm Hg 20 mm Hg 50 mm Hg 100 mm Hg

PK2-MED 10 mm Hg 1 2 2 1 2

Part Number K-2047-23 K-2047-22 K-2046-25 K-2046-21 K-2012-1

Table 2g

Page 14

5.0 ASSEMBL Y AND SETUP

5.1 BALL AND NOZZLE

You should routinely check the ceramic ball and the nozzle for cleanliness. Never scrape

the nozzle or its associated parts with a hard object or anything that is abrasive or that may

remove material from the parts. AMETEK recommends that the ceramic ball and nozzle be

kept in place at all times, except when cleaning is required. This will prevent dirt from

entering the ball and nozzle assembly.

5.1.1 Removing Ceramic Ball

Cup one hand over the top (beveled end) of

the nozzle and push from the bottom of the

nozzle to remove the ball. If the ball tends to

stick when being removed, DO NOT FORCE

IT. Forcing the ball may cause serious damage to the nozzle.

Carefully, lift the ceramic ball from the nozzle assembly and

store in a secure location.

5.1.2 Removing the Nozzle

Carefully remove the nozzle by pulling the

nozzle upward while twisting to overcome

the friction of the O-ring seal.

Grasp the nozzle firmly and pull upward with a slight twisting

motion.

- 14 -

Page 15

5.1.3 Cleaning Ball and Nozzle

AMETEK recommends cleaning the ceramic ball and nozzle with a residue-free solvent.

Using a cottom swab or soft cloth with a solvent such as alcohol,

wipe the inside of the nozzle.

Dampen a clean cloth with alcohol or other residue-resistant

solvent, and clean the ceramic ball by rotating it within the cloth.

5.1.4 Ball & Nozzle Cleanliness Check

The ball should pass smoothly through the nozzle bore without any restriction or friction. If

resistance is felt, reclean the ceramic ball and nozzle and repeat cleanliness check.

After the ball and nozzle have been cleaned, slide the ball through

the nozzle. The ball should pass through the nozzle with no

resistance.

- 15 -

Page 16

5.1.4 Ball & Nozzle Reassembly

After ensuring that both the ceramic ball and nozzle are clean, reassembly by first placing

the nozzle back into proper position and alignment. Always make sure that the serial number

on the nozzle is directly above the serial number of the nozzle body.

CORRECT ALIGNMENT- The serial number for the nozzle

(top) aligns with the serial number of the nozzle body (bottom).

INCORRECT ALIGNMENT- The serial numbers DO NOT align

and may lead to inaccurate readings.

- 16 -

Page 17

5.2 LEVELING THE TESTER

For proper operation, the PK II tester should be placed on a support that is solid and free from

vibration.

5.2.1 Coarse Leveling

Both coarse and fine leveling are supported

by the PK II tester. Coarse leveling to raise

the tester is achieved by pushing the knurled

rod (located inside the case on either side of

the weight insert) and rotating the knurled

nut until it contacts the bottom of the case.

For coarse adjustment, use the knurled rod located on the top.

5.2.2 Fine Leveling

Fine leveling is obtained by rotating the

knurled rod clockwise to raise and counterclockwise to lower the tester.

A third adjustable foot is located under the

PK II case between the inlet and outlet valves.

A bull’s-eye level is located on the cover

plate for sighting level accuracy.

For fine adjustment, hold the bottom foot and rotate the knurled

knob at the top.

- 17 -

Page 18

5.3 CONNECTION

Connect a supply of clean, dry and oil-free air or nitrogen to the connection below the valve

marked “INLET”.

The use of other gases will result in an incorrect reading.

Always use clean, dry and oil-free air or nitrogen.

When using the tester thru full range, regulate the supply pressure at 30 PSIG minimum,

however take care NOT TO REGULA TE THE SUPPLY PRESSURE OVER 100 PSIG.

CAUTION

Do not regulate the supply pressure over 100 PSIG.

Connect clean, dry and oil-free air or nitrogen to the INLET valve. Connect instrument to be tested to the OUTLET valve.

Connect the instrument to be tested to the valve marked “OUTLET”. The tester’s input and

output connections are 1/4-inch male tube fittings.

The accuracy of the tester is seriously undermined by leaks in the output connections

and/or the instrument being calibrated. To check for leaks, load the tester so as to apply

a pressure indicating instrument and then turn off the tester output valve. If the pressure

indicated by the instrument being calibrated holds, it is safe to assume their are no leaks.

If, however, the pressure decreases, there is likely a leak in the calibration system. You

must locate and fix the leak before calibration can take place.

WARNING

Under no circumstances should mercury or corrosive fluids be permitted into the tester.

When the tester is used in connection with an instrument or pressure system that

contains a liquid, a suitable safeguard such as a trap or float-type manometer check

valve should be installed in the tester output line to prevent fouling of tester components.

- 18 -

Page 19

6.0 OPERA TING INSTRUCTIONS

The following steps are provided to guide the user through a typical calibration using the PK

II tester.

Step 1

Slip the weight carrier over the ceramic ball.

Slide the weight carrier over the ball and nozzle assembly.

Step 2

Admit the supply pressure to the tester by

turning on the valve marked “INLET”.

Open the INLET valve and supply pressure to the tester.

NEVER connect the PK II tester to a

WARNING

high pressure source.

Applying high pressure may result in

personal injury and

damage to the tester.

NEVER apply a pressure greater than

100 PSIG.

Step 3

Add weights as required. Exercise

caution when handling the weights.

Handle only one weight at a time to avoid

damaging the weights.

Add the required weights by sliding the weights over the carrier.

Apply the heavier weights first. Always store the weights in the

compartment provided in the PK II tester case.

- 19 -

Page 20

6.0 OPERA TING INSTRUCTIONS (Cont’d.)

Step 4

Weights may be given a slow rotary motion

to ensure that the weights rotate freely

without abrupt stopping.

to correct for poor weight rotation).

Note: It is not necessary to excessively

spin the weights of the pneumatic

deadweight tester to overcome friction.

Excessive rotation may affect accuracy.

(See Section 6.1

Slowly rotate the weights to ensure that there are no restrictions

and that the weights float freely.

Open the OUTLET valve to calibrate the instrument. Once the

calibration is completed, you may vent the pressure by rotating

the OUTLET knob to the VENT position.

Do NOT spin the weights unless the

WARNING

ceramic ball is floating.

Step 5

Open the tester “OUTLET” valve and

calibrate the instrument. Once calibration

is complete, the downstream pressure

may be vented by turning the outlet valve

to the “VENT” position.

CAUTION

The ceramic ball, weight carrier and

weights comprise a “system” for

your PK II calibrator and should be

used together to ensure a correct

calibration. Accuracy will be affected

if the ceramic ball, weight carrier and

weights are interchanged.

- 20 -

Page 21

7.0 MAINTENANCE

7.1 OUTPUT SYSTEM

The PK II tester features an output tank that may be cleaned. If any contamination is evident

in the output system, it may be easily removed using the following procedure:

Step 1

Remove the weights and weight carrier from

the tester leaving the ceramic ball in place.

Step 2

Connect an air supply to the tester.

Step 3

Disconnect the output line.

- 21 -

Page 22

Step 4

Fully open both the INLET and OUTLET

valves.

Step 5

While holding the ceramic ball (to ensure that

the ball does not fall out), tilt the tester so

that the output connection is pointing downward.

Step 6

Pressure the ball into its socket to provide an

output pressure sufficient to purge the system.

Step 7

After completing Steps 1 - 6, disconnect the

air supply from the INLET and connect the air

supply to the OUTLET . DO NOT APPLY PRESSURE AT THIS TIME.

Step 8

Using a screw driver, remove the ceramic

ball and restriction tube. The restriction tube

is located under the ceramic ball.

- 22 -

Page 23

Step 9

Remove the nozzle.

Step 10

Place a cloth or absorbent material over the

nozzle body.

Step 11

Apply 15 to 30 PSI to the OUTLET for a few

seconds or until the material on the nozzle

body is clean and dry when removed. Mild

solvents may be applied to the outlet fitting

and flushed out when applying pressure. If

a solvent is used, it should not leave any film

or residue once dried.

Step 12

Clean the output restriction using a 1/32” drill

or piece of 22 gauge wire to clean out any

obstructions.

Step 13

Clean the ceramic ball, nozzle and body thoroughly.

- 23 -

Page 24

7.2 INPUT SYSTEM

The PK II tester features an input filter located within the 1/4” male tube fitting on the outside

of the PK II tester case. As this filter becomes dirty, the tester may react by not supporting

the weights. To correct, remove the filter and examine the NPT opening for any contamination.

CLEANING THE INPUT FIL TER

Remove the input filter fitting and clean it by

backflushing from the downstream end with

clean compressed air. If an ultrasonic

cleaner is available, AMETEK recommends

that the filter fitting be cleaned using the ultrasonic cleaner for 10 to 15 minutes in a

residue-free solvent.

Do NOT attempt to remove the filter

element from the fitting.

Filters should be replaced periodically.

CAUTION

- 24 -

Page 25

8.0 TROUBLESHOOTING

The following represent common troubleshooting tips for the PK II tester.

8.1 CORRECTING FOR POOR WEIGHT ROTA TION

If weights do not rotate freely as described in Section 6.0, Step 4, perform the following:

Step 1

Check the cleanliness of the ceramic ball and nozzle.

Step 2

Make sure the tester is level by checking the bull’s eye.

Step 3

Isolate tester from environmental vibrations or relocate tester.

Step 4

Check for adequate air supply.

8.2 OUTPUT AND INTERNAL LEAKAGE

The accuracy of the tester is seriously undermined by leaks in the output connections and/

or instrument being calibrated. The following procedures are recommended to isolate and

correct for leakage.

8.2.1 Output Connection Leaks

Load the tester so as to apply a pressure to

the instrument being calibrated. Close (turn

OFF) the OUTLET valve. If the pressure indicated by the instrument being calibrated remains constant (holds at the indicated pressure), it is safe to assume there are no leaks

in the output system (between the tester and

the instrument).

- 25 -

Page 26

8.2.2 Internal Leaks

You can perform a check for internal leaks with the input pressure applied and with the

cover plate off.

Step 1

Place full range of weights onto tester.

Step 2

Turn OFF (Close) the OUTPUT valve.

Step 3

Apply liquid leak detector to all internal fittings from the input connection to the output

valve.

Step 4

Check for leaks by the presence of bubbles

on joints.

Step 5

If a leak is found, the PK II Tester must be

returned to AMETEK for repair.

WARNING

Leak checks should be done in the

otherwise the source of the leak may

order described above,

not be accurately identified.

CAUTION

DO NOT ATTEMPT T O REP AIR

Return the PK II tester to AMETEK for

Failure to do so may void product

INTERNAL LEAKS.

internal leak repairs.

warranty.

8.3 REPLACING THE NOZZLE AND O-RING

Remove the ball and nozzle and the nozzle O-ring (10-90013). The replacement O-ring

should be wiped clean with a lint-free cloth and placed within the groove in the nozzle

body. DO NOT LUBRICA TE THE O-RING WITH ANY FORM OF OIL OR GREASE.

Clean the ball and nozzle as described in Section 5.1.3.- Cleaning the Ball and Nozzle,

and reassemble.

- 26 -

Page 27

9.0 P ARTS LIST

P ART

NUMBER DESCRIPTION

K-1035 Nameplate

K-1048 Nozzle Body Restriction Screw

K-1050/ETCH Nozzle

10-90013 Nozzle O-Ring

K-1051 Ceramic Ball

K-1182 Spring

K-1193 Retainer

K-1209 Regulator Nozzle Block

K-1212 Disc, Clip and Diaphragm Assembly

K-1216 Regulator Ratio Disc Diaphragm (Stem Side)

K-1217 Regulator Ratio Disc Diaphragm (Flat)

K-1223 Gasket

K-1224 Regulator Assembly Screw

K-1246 Bulls-Eye Level

K-1273 Label (Inlet, Outlet, Caution)

K-1297 Capacity Tank Assembly

K-1303 Nozzle Body Restriction Assembly

K-1831 Tripod Mounting Plate

K-1832 Level Adjust Stud

K-1833 Level Retainer Stud

K-1834 Leveling Foot

K-1835 Leveling Foot Assembly

K-1836 Aluminum Adjusting Nut (3/8”-24)

K-1839 Nut (5/8-18 x 1/8”)

K-1840 Regulator Assembly

K-1850 Filter Assembly

K-1868/ASSY Internal Cover Assembly (Small Case)

K-1896/ASSY Internal Cover Assembly (Large Case)

K-1880 Regulator Bracket

K-1882 Weight Retainer Block

03-90020 Screw (2-56 x 5/16)

04-90047 Nut (7/16-20)

06-90040 Brass Washer (0.74” OD)

12-90040 1/8” NPT x 1/8” Tube Straight Connector

11-90062 Bulkhead Fitting

13-90003 Outlet Valve

13-90022 Inlet Valve

- 27 -

Page 28

CALIBRA TION INSTRUMENTS

®

AMETEK Test and Calibration

Instruments

8600 Somerset Drive

Largo, Florida 33773

Tel +1 (727) 536-7831

Tel +1 (800) 527-9999

Fax +1 (727) 539-6882

Internet Addresses:

www.ametek.com

Information within this document is subject to change

without notice.

AMETEK is a registered trademark of AMETEK, Inc.

Pub No. FORM 85-02 (Rev 6)

Issued 06/99 Printed in U.S.A.

AMETEK Precision

Instruments Europe GmbH

Rudolf-Diesel-Strasse 16

D-40670, Meerbusch

Germany

Tel +49 2159 9136 0

Fax +49 2159 9136 39

Copyright 1999, by AMETEK, Inc.

AMETEK Singapore Pvt. Ltd.

10 Ang Mo Kio Street 65

#05-12 TECHPOINT

Singapore

569059

Tel +65 484 2388

Fax +65 481 6588

AMETEK Denmark A/S

Gydevang 32-34

DK-3450 Allerod

Denmark

Tel +45 4816 8000

Fax +45 4816 8080

ISO 9001

Manufacturer

- 28 -

Loading...

Loading...