Page 1

P-Series Screw Pump Operation Manual

for P016, P017, and P-018-CPF, and Systems D

Page 2

Contents

Overview ............................................................. 1

Introduction .......................................................... 1

Features and Parts Lists ................................................ 2

Safety Instructions ................................................ 4

General Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended test uids ............................................. 4

Recommended Mounting ............................................. 4

Operating Instructions ........................................... 5

Generating Pressure ................................................... 5

Connecting the Auxiliary Reservoir ..................................... 6

Connection Diagram .............................................. 7

Crystal Reference Indicators ............................................ 7

Specifications ....................................................... 8

Support ............................................................... 9

Troubleshooting ....................................................... 9

Maintenance .......................................................... 9

Fitting Kits and Spare Parts ............................................ 10

Contact Us ........................................................... 11

Returning product to AMETEK ......................................... 11

Warranty ............................................................. 11

Page 3

Overview

INTRODUCTION

The P-Series hydraulic screw pump you have chosen, is an extremely eective pressure pump, and we are condent that it will live up to your expectations.

Over the course of many years, we have acquired extensive knowledge of industrial precision pressure calibration. This expertise is reected in our products,

all of which are designed for daily use in an industrial environment. If you have any ideas or suggestions for ways we might improve our products, we would

be very interested in hearing from you.

The P016, P017, and P-018-CPF hydraulic screw pumps are designed for easy, controlled, high pressure generation.

The screw pumps have a 4-connection manifold that can be used for the reference indicator, the device under test, a ne adjust, an isolation valve, or a uid

F

reservoir. The reference indicator mounted on the pump can easily be adjusted for the best viewing angle by using the banjo connector set. The CP

includes Crystal Pressure Fittings (CPF), which allow users to produce leak-free seals without tools or thread tape. CPF ttings also include a self-venting

weep hole to help assure a safe disconnection from a pressurized system.

U.S. Patent No. 8,794,677

The P-Series hydraulic screw pump may be ordered as part of a Pump System, complete with a JOFRA or Crystal Pressure Indicator. P-Series Pump Systems

include the most commonly used pressure ttings, seals, etc. All packaged in a carrying case with custom insert.

X

P-Series Pumps

version

Overview 1

Pressure Range Tes t Me dia Media Specics Pump System

P016 350 bar / 500 0 psi Hydraulic Oil Rando HDZ32

P017 350 bar / 50 00 psi Water Distilled Water DWX

P- 018 - CP F 350 bar / 500 0 psi

Hydraulic Oil

or

Water

Rando HDZ32

or

Distilled Water

DOX

DOX

or

DWX

P-Series Screw Pump Operation Manual

Page 4

FEATURES AND PARTS LISTS

Fine Adjust Knob

Handle with spindle

Banjo Connector Set

MPM-1/4BSPM

Isolation Valve

MPF-1/4FPT

129341

1/4" BSP Male Removable Plug

O-ring

Auxiliary Fluid Reservoir

Vent Valve Lid

Reference Indicator Port

Adjustment Screw

Overview 2

Parts List for all pumps

Part Number Description P016

60R955 1/4" BSP Male Removable Plugs

60 R120 1/4" BSP Bonded Seals N/A N /A

MPF-1/4FPT CPF Female to 1/4” NPT Female Adapter Fitting N/A N /A

MPM-1/4BSPM CPF Male to 1/4" BSP Male Adapter Fittings N/A N /A

5254 1/4" BSP Female to 1/4" BSP Female Adapter Fittings N/A N /A

129341 1/4" BSPP Male to 1/4" BSPT Female N/A N /A

SPK-HP C-00 4 1/4" BSP Male to 1/4" BSP Male Banjo Connector optional optional

60 P013 1/4" BSP Male Fine Adjust optional optional

60 R135 Isolation Valve optional optional

65-R975 Auxiliary Fluid Reservoir (with Vent Valve Lid) optional optional optional

*

Pump is delivered full of test uid; water or oil.

**

Pump is delivered empty of test uid; user must ll with water or oil.

*

Screw Pump

*

P017

P-018-CPF

**

( 4 )

( 4 )

( 2 )

Optional components shown

P-Series Screw Pump Operation Manual

Page 5

Overview 3

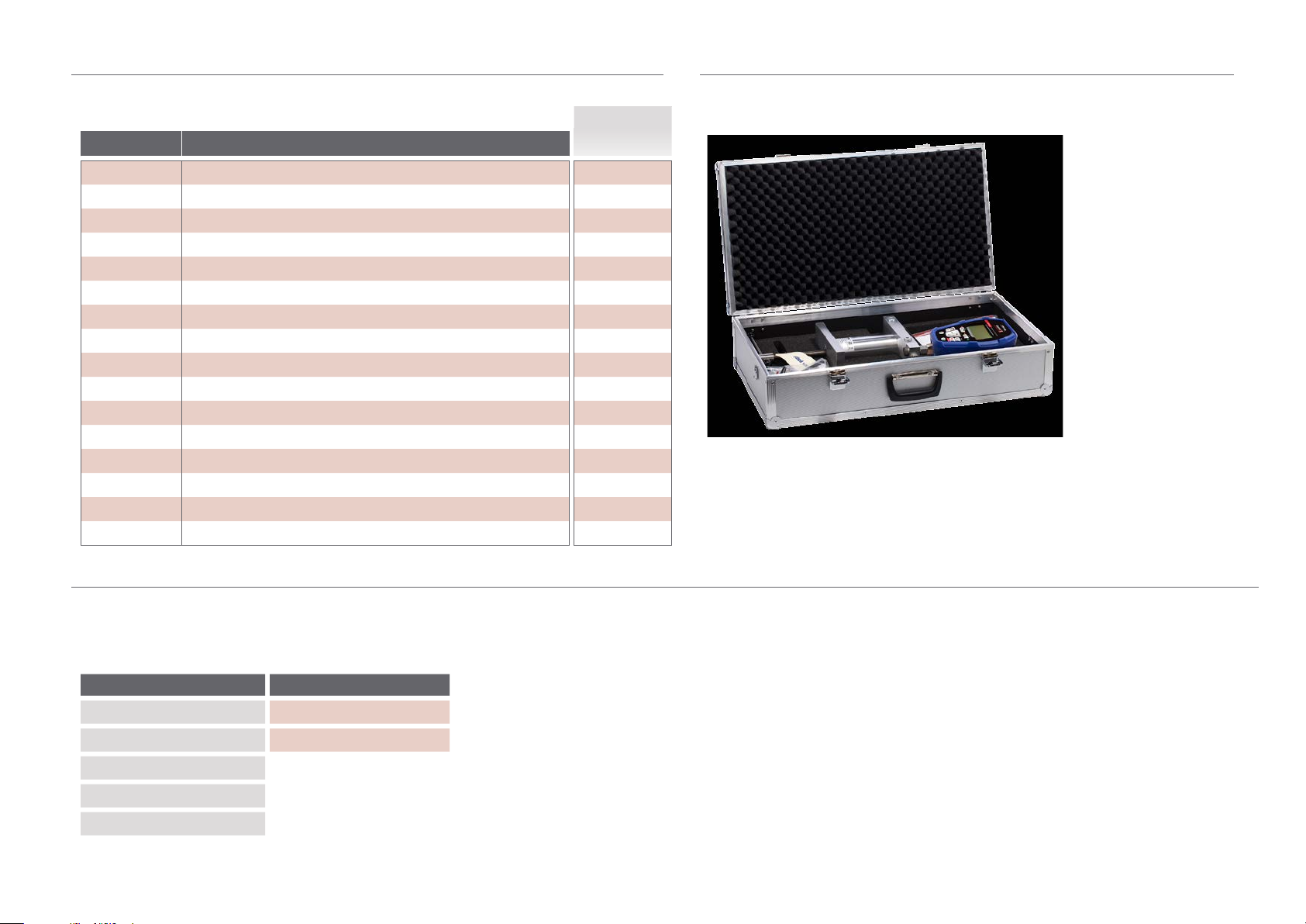

Parts Included with Pump Systems for Crystal Reference Indicators

System D

Part Number Description DOX and DWX

MPM-1/4BSPM CPF Male to Screw Pump Adapter

5254 1/4" BSP Female to 1/4" BSP Female Fitting

MPF-1/4FPT CPF Female to 1/4" NPT Female Fitting

MPF-1/4BSPF CPF Female to 1/4" BSP Female Fitting

MPF-1/8MPT

MPF-CAP CPF Female Cap Fitting

SPK-HP C-00 4 1/4" BSP Male to 1/4" BSP Male Banjo Connector

60R955 1/4" Male BSP Plugs

60 R120 1/4" Bonded Seals

60 P013 1/4" BSP Male Fine Adjust

1351

5249 Protective Vinyl Cap

60I104 Pack Tape (1 roll)

60 R159 Allen Key

124 0 0 4 Shoulder Strap

124301 Aluminum Carrying Case

Note: The P016 and P017 do not include the isolation valve.

1/8" MPT Fitting (for 30 Series Calibrator)

Test Leads; Red & Black, including clips

( 2 )

( 2 )

( 4 )

( 5 )

( 4 )

Carrying Case

Pump System D is delivered with an Aluminum Carrying Case.

Ordering a Pump System

Any P-Series Pump System may be ordered with or without a reference indicator. The table below provides an explanation of the Pump System ordering

scheme when ordering a system without an indicator. For details on ordering the Pump Systems with an indicator, see the indicator datasheet.

X

Reference Indicator Pump System

nVision ......... NV-NONE System D (P-018-CPF) ...-DOX

30 Series ........IS30 -NONE System D (P-018-CPF) ...-DWX

HPC40 Series ...HPC40-NONE

XP2i ............XP2i-NONE

m1 .............. M1- NONE

SAMPLE PART NUMBERS

NV-NONE-DOX ......System D pump system (for nVision) for use with oil.

IS30-NONE-DWX ... System D pump system (for 30 Series) for use with water.

5KPSIXP2i-DWX ...System D pump system for use with water, with an XP2i gauge (5000 psi).

P-Series Screw Pump Operation Manual

Page 6

Safety Instructions

Please follow the instructions and procedures described in this manual. They are designed so that you get the most out of your pressure system and avoid any

personal injuries and/or damage to the system.

GENERAL CAUTIONS

Avoid knocking, bumping or dropping the pressure system. This can cause permanent damage to the system and loss of accuracy.

•

The pressure system must not be used for any purposes other than those described in this manual and for any application other than precision pressure

•

calibration jobs.

The pressure system should only be used by TRAINED PERSONNEL.

•

None of our calibration systems are cleaned or prepared for OXYGEN MEDIUMS. DO NOT USE our systems for this purpose.

•

Do not disconnect any parts from the system when pressurized.

•

Do not connect any external pressure source to this system. This system is designed to test pressure measuring devices connected to the manifold only.

•

Pressure from an external source can result in explosion of the uid reservoir and possible personal injuries.

The pressure inside the pump can be extremely high. Ensure that all pressure connections have been established correctly.

•

For permanent installation, we recommend bolting/xing the pump to a table or other xed installation.

•

Safety Instructions 4

RECOMMENDED TEST FLUIDS

P016 pumps must use hydraulic oil (Rando HDZ32 or similar).

•

P017 pumps must use distilled water.

•

P-018-CPF pumps may use either hydraulic oil or distilled water.

•

The uid used must be compatible with the aluminum, brass, stainless steel, and Buna N wetted parts.

Note: The pump itself has a uid volume of approximately 24 ml. The volume of the auxillary uid reservoir is 300 ml.

RECOMMENDED MOUNTING

Fixed installation is recommended for regular, repetitive calibration and test routines. The P-Series pump can be permanently installed using the four m6

•

mounting holes in the pump’s base. (Remove the four rubber feet to access the mounting holes.)

Note: If a xed installation is not desired, the pump can be held in place by hand.

P-Series Screw Pump Operation Manual

Page 7

Operating Instructions

GENERATING PRESSURE

Follow these steps to use the pump.

1 Turn the spindle counterclockwise to the stop.

2 Loosen the adjustment screw and turn the banjo set to the desired position. Firmly tighten the screw.

Operating Instructions 5

3 Remove plugs using a 6mm Allen key, and ll with test uid

4 Connect the optional pressure hose and other connection ttings, as needed.

CAUTION: USE BONDED SEALS only, for attachment of any part or object directly to the manifold. Tighten all connections rmly.

!

5 Turn the spindle until test uid is evident at the top of the connection ttings.

6 Connect the reference indicator and the device under test. Tighten the threads rmly.

Note: If CPF ttings are used in your pressure system, remaining air can be purged through the weep hole, by applying 10 psi or less and loosening the CPF

tting closest to the pressure device about two and a half turns. Repeat this process for each pressure device in the pressure system which is connected

to a CPF tting.

7 Power on the reference indicator and the device under test.

8 Conrm there is no pressure in the system by removing the plug or by opening the isolation valve (if installed).

9 Zero the reference indicator and the device under test.

10 If the isolation valve is not installed, replace and tighten the removable plug. If the valve is installed, close it tightly.

11 Verify the system connections are tightened rmly and pressurize the system by turning the spindle clockwise until the approximate pressure is obtained.

12 Allow time for the adiabatic eect to stabilize.

13 Use the ne adjust knob, if installed, to obtain the exact calibration pressure.

14 After obtaining your readings, release pressure by turning the pump spindle counterclockwise until it stops.

(

if necessary).

15 Open the isolation valve, or remove the plug, to vent the system.

WARNING: The device under test and the reference instrument should only be removed when there is no pressure in the system.

!

Note: AMETEK Denmark’s liability ceases if: Parts are replaced/repaired using spare parts which are not identical to those recommended by the

manufacturer or non-original parts are used in any way when operating the system. AMETEK Denmark’s liability is restricted to errors, which

originated from the factory.

P-Series Screw Pump Operation Manual

Page 8

CONNECTING THE AUXILIARY RESERVOIR

1/4" Quick Test NPT Female

Thread tape required

Use the optional auxiliary reservoir if additional test uid is required to ll the pressure system.

Note: Use bonded seals.

1 Mount the isolation valve, auxiliary reservoir, and device under test per the example to the right.

2 Open the isolation valve.

3 Remove the lid of the reservoir by unscrewing the vent valve.

4 Fill the reservoir with desired media (hydraulic oil or distilled water).

5 Mount the reservoir lid and close the vent valve.

6 Turn the spindle clockwise to pressurize the system.

Note: If additional uid is needed, use a second isolation valve under the device under test.

7 If installed, close the isolation valve under the device under test.

Device Under Test

2000

1500 3000

500 4000

0 5000

PSI

Operating Instructions 6

Vent Valve

Auxiliary Reservoir

O-ring

8 Remove the lid of the reservoir by unscrewing the vent valve.

9 Turn the spindle clockwise until it stops.

10 Turn the spindle counterclockwise until it stops to pull the uid from the reservoir.

Note: Be ready to add uid to the reservoir if necessary.

11 Mount the reservoir lid and close the vent valve.

12 Open the isolation valve under the device under test.

13 Turn the spindle clockwise to pressurize the system.

14 If you require additional test uid, repeat steps 7-13.

15 When you are ready to vent the system, unscrew the vent valve. Any excess uid will go back

into the reservoir.

Isolation Valve

5254

1/4" Male BSP CPF Adapter

MPM-1/4BSPM

Bonded Seal

129341

Bonded Seal

P-Series Screw Pump Operation Manual

Page 9

Connection Diagram

Additional par ts are supplied as par t of a pump system, or may be ordered separately.

Thread tape

required

MPF-1/8MPT

MPM-1/4BSPM *

1/4" MBSP CPF Adapter

*

5254 *

60 R120 *

Bonded Seal

*

SPK -HPC- 004

1/4" MBSP/1/4" MBSP

Banjo Connector

*

* These parts are included with the P-018-CPF pump.

Connection Diagram 7

NPT MALE

MPF-1/8QTM 1/8" Quick Test NPT Male

MPF-1/8MPT 1/8" NPT Male

MPF-1/4QTM 1/4" Quick Test NPT Male

MPF-1/4MPT

Additional N PT sizes available in non- CPF MP adapters

1/4" NPT Male

NPT FEMALE

MPF-1/8QTF 1/8" Quick Test NPT Female

MPF-1/4QTF 1/4" Quick Test NPT Female

MPF-1/4FPT

MPF-1/2QTF 1/2" Quick Test NPT Female

Additional N PT sizes available in non- CPF MP adapters

*

1/4" NPT Female

BSP

MPF-1/8BSPF G 1/8" Female

MPF-1/4BSPF G 1/4" Female

MPF-3/8BSPF G 3/8" Female

MPF-1/2BSPF G 1/2" Female

MPF-1/8QTFB 1/8" Quick Test Female

MPF-1/4QTFB 1/4" Quick Test Female

MPF-3/8QTFB 3/8" Quick Test Female

MPF-1/2QTFB 1/2" Quick Test Female

MPF-5/16TRM for Foxbo ro, Rosemount, & Yokogawa

MPF-1/4TRM for Honeywell

*60 R135

1/4" MBSPT

Isolation Valve

Thread tape required

129341

1/4" BSPP Male to 1/4" BSPT Female

*

TRANSMITTER

*

TUBE

*MPM-1/4BSPM

1/4" MBSP CPF Adapter

MPF-1/4TBM 1/4" Tube Male

MPF-3/8TBM 3/8" Tube Male

MPF-1/2TBM 1/2" Tube Male

CPF

*

60 P013 *

1/4" MBSP Fine Adjust

ADDITIONAL

MPF-MPF Female to Female

MPF-MPFT U T-Union (Female)

MPF-MPFBULK Bulkhead (Female to Female)

MPF-CAP Cap

MPF-M20QTF M20 x 1.5 Quick Test Female

MPF-M20X1.5F M20 x 1.5 Female

MPF-QCN Quick-Connect Nut

MPF-AN4M AN4 Male

P-Series Screw Pump Operation Manual

Page 10

Specifications

Specications 8

Pressure Ranges

P016, P017, and P-018-CPF . . . . . . .0 to 350 bar / 0 to 5000 psi

O-Ring Material

P016, P017, and P-018-CPF . . . . . . .Buna N

Pressure Connections

X

Reference Port

P016, P017 . . . . . . . . . . . . . . . . . . . . . .1/4" BSP Female

P-018-CPF . . . . . . . . . . . . . . . . . . . . . . . Crystal CPF Male (1/4" BSP Female to CPF Male adapter)

X

Adapter/Accessory Ports

P016, P017 . . . . . . . . . . . . . . . . . . . . . .3 x 1/4" BSP Female

P-018-CPF . . . . . . . . . . . . . . . . . . . . . . . 2 x 1/4" BSP Female. Includes one MPM-1/4BSPM and one MPF-

1/4FPT (1/4" Female NPT)

Dimensions

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . .366 x 195 x 105 mm / 14.4 x 7.7 x 4.1 inch

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7 kg

Mounting Holes . . . . . . . . . . . . . . . . . M6 x 4 places

129

mm

175

mm

/ 8.2 lbs

P-Series Screw Pump Operation Manual

Page 11

Support

TROUBLESHOOTING

Unstable Pressure

X

Problem: Pressure cannot be generated correctly, or set pressure does not remain stable.

X

Solutions:

• Check that all adapters and pressure ttings have been tightened suciently to eliminate leaks.

• Conrm test uid does not contain air (air in the uid can increase adiabatic eects). You may have to adjust the pressure a few times before the

pressure is stable enough for calibration.

• Adiabatic and thermodynamic eects may be aecting the pressure reading. High pressure hydraulic systems are sensitive to temperature and move-

This eect will disappear after a period of time.

ments.

If the pressure is still not stabilizing, the system may be in need of service. Please contact your local distributor for advice.

Note: Always readjust the pressure after 5 to 10 minutes to allow time for settling of above eects.

Replace test uid if necessary.

Support 9

MAINTENANCE

Users should/must carry out the following cleaning procedures when required:

Standard exterior cleaning . . . . . . .Clean using a soft, damp cloth.

Heavily soiled cleaning . . . . . . . . . . . The instrument may also be cleaned using isopropyl alcohol when heavily soiled.

P-Series Screw Pump Operation Manual

Page 12

FITTING KITS AND SPARE PARTS

Service Kits

Support 10

X

P016 / P017

P/N: 60P016 .........For P016 pump.

P/N: 60P017 .........For P017 pump.

Hoses

X

P016 / P017

P/N: 65P175 .........Hose. 1.0 m, 1/4” BSP Female to 1/4” BSP Male connection.

P/N: 65P180 .........Hose. 2.0 m, 1/4” BSP Female to 1/4” BSP Male connection.

P/N: 60I156 ..........Hose. 1.5 m, 1/4” BSP Female to 1/4” BSP Male connection.

P/N: 60I157 ..........Hose. 5.0 m, 1/4” BSP Female to 1/4” BSP Male connection.

Adapters, Fittings and Plugs

X

P016 / P017

P/N: 65N000 .........Adapter. Extension tube, 120mm (Max. 350 bar / 5000 psi)

1/4" BSP Female to 1/4" BSP Male

P/N: 50-REP 615 .....Adapter. Quick connector set, Female 1/4" BSP to 1/4" BSP

P/N: SPK-HPC-004 ...Adapter. Banjo connector set for pump

P/N: 11-90109 .......Fitting. 1/4” BSP Male to 1/4” NPT Female

P/N: 60R955 .........Plug. 1/4” BSP Male

X

P-018-CPF

P/N: 60P016 .........For P-018-CPF pump.

X

P-018-CPF (Requires MPF-MPF adapter tting to connect)

P/N: MPH-1 ..........Hose. 1.0 m, CPF MP Male connection.

P/N: MPH-1.5 ........Hose. 1.5 m, CPF MP Male connection.

P/N: MPH-3 ..........Hose. 3.0 m, CPF MP Male connection.

P/N: MPH-5 ..........Hose. 5.0 m, CPF MP Male connection.

X

P-018-CPF

P/N: MPF-CAP .......Cap. CPF Female.

P/N: 4013. . . . . . . . . . . .Quick Test CPF Kit. (MPF-1/8QTF, MPF-1/4QTF, and MPF-1/2QTF)

P/N: 4015. . . . . . . . . . . .BSP Test Kit. (MPF-1/8QTFB, MPF-1/4QTFB, MPF-3/8QTFB, MPF-1/2QTFB)

Seals

X

P016, P017, and P-018-CPF

P/N: 101549 .........Bonded seal. For 1/2" BSP adapter.

P/N: 60R120 .........Bonded seal. For 1/4” BSP adapter.

P/N: 60R122 .........Bonded seal. For 1/8” BSP adapter.

Accessories

X

P016, P017, and P-018-CPF

P/N: 65-R975 ........Auxiliary uid reservoir. Includes vent valve lid.

P/N: 60R135 .........Isolation valve.

P/N: 60P013 .........Fine adjust knob

P/N: 60I104 ..........Teon tape. 1 roll.

P/N: 60R159 .........Allen Key. 6 mm.

P-Series Screw Pump Operation Manual

Page 13

CONTACT US

Support 11

United Kingdom

Tel +44 (0)1243 833 302

jofra@ametek.co.uk

France

Tel +33 (0)1 30 68 89 40

general.lloyd-instruments@ametek.fr

RETURNING PRODUCT TO AMETEK

Please contact your sales representative to complete a Return Material Authorization (RMA) form and/or receive an RMA number.

Return/shipping instructions will be provided with the RMA number.

WARRANTY

This instrument is warranted against defects in workmanship, material and design for one (1) year from date of delivery to the extent that AMETEK will, at its sole

option, repair or replace the instrument or any part thereof which is defective, provided, however, that this warranty shall not apply to instru¬ments subjected

to tampering or, abuse, or exposed to highly corrosive conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED AND AMETEK HEREBY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITA¬TION, ANY WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. AMETEK SHALL NOT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, ANY ANTICIPATED OR LOST PROFITS.

Germany

Tel +49 (0)2159 9136 510

info.mct-de@ametek.de

Denmark

Tel +45 4816 8000

jofra@ametek.com

USA

Florida - Manseld & Green

Tel +1 (800) 527 9999

cal.info@ametek.com

California - Crystal Engineering

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

Singapore

Tel +65 6484 2388

jofra@ametek.com

China

Shanghai

Tel +86 21 5868 5111

Beijing

Tel +86 10 8526 2111

Guangzhou

Tel +86 20 8363 4768

jofra.sales@ametek.com.cn

This warranty is voidable if the purchaser fails to follow any and all instructions, warnings or cautions in the instrument’s Instruction Manual.

If a manufacturing defect is found, AMETEK will replace or repair the instrument or replace any defec¬tive part thereof without charge; however, AMETEK’s obli

gation hereunder does not include the cost of transportation, which must be borne by the customer. AMETEK assumes no responsibility for dam¬age in transit,

and an

y claims for such damage should be presented to the carrier by the purchaser.

-

P-Series Screw Pump Operation Manual

Page 14

128685.H

© 2017 AMETEK Incorporated

Gydevang 32, 3450 Allerød, Denmark 4816 8000

Loading...

Loading...