Page 1

Revision J

May 2007

Copyright ♥ 1997-2014

By California

Instruments. All

rights reserved.

P/N 7003-973

CTSL

Compliance Test System

User Manual

TEL: +1 (858) 450-0085

FAX: +1 (858) 458-0267

Email:

sales.ppd@ametek.com

Web Site:

http://www.programablepower.com

Page 2

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

SAFETY SUMMARY

These power system components contain high voltage and current circuits that are potentially lethal. The

following safety guidelines must be followed when operating or servicing this equipment. These

guidelines are not a substitute for vigilance and common sense. California Instruments assumes no

liability for the customer's failure to comply with these requirements.

APPLYING POWER AND GROUNDING

Verify the correct voltage is applied to the equipment.

Verify that the input power cord to the PACS-X unit is plugged into a properly grounded utility outlet.

Verify that the input power line to the AC power source used is connected to a properly grounded utility

outlet.

FUSES

Use only fuses of the specified current, voltage, and protection speed.

Do not short out the fuse holder or use a repaired fuse.

The PACS-3-75 unit uses a North-American ferrule type input fuse rated at 0.5A and 250Volts. (Fast Acting)

DO NOT OPERATE IN A VOLATILE ATMOSPHERE

Do not operate the system in the presence of flammable gases or fumes.

DO NOT TOUCH ENERGIZED CIRCUITS

Disconnect power cables before servicing this equipment. Even with the power cable disconnected, high voltage

can still exist on some circuits. Discharge these voltages before servicing. Only qualified service personnel may

remove covers, replace components or make adjustments.

DO NOT SERVICE ALONE

Do not remove covers, replace components, or make adjustments unless another person, who can administer first

aid, is present.

DO NOT EXCEED INPUT RATINGS

Do not exceed the rated input voltage or frequency. Additional hazards may be introduced because of component

failure or improper operation.

DO NOT MODIFY INSTRUMENT OR SUBSTITUTE PARTS

Do not modify these instruments or substitute parts. Additional hazards may be introduced because of component

failure or improper operation.

MOVING THE POWER SOURCE

When moving the power source, observe the following:

1. Remove all AC power to system components.

2. Use two people to prevent injury.

Revision J

2

Page 3

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

CTSMXL Software License

Your MX Series CTSL Test System was shipped with one copy of the CTSMXL Software. This software model number CIC 652 - is owned by California Instruments and is protected by United States copyright

laws and international treaty provisions. Therefore, you must treat the software like any other copyrighted

material.

Software Revisions

Revision codes in the Help About screen of the CTSMXL Software indicate the current revision. Minor

changes to the software such as bug fixes usually do not require a change to the manual. Therefore, the

revision number of the software you received with the CTS system may be higher than the software

revision number shown below. In this case, the information in the manual still applies.

Software changes that require a manual change will be accompanied either by a new edition of the manual

or an errata sheet documenting the changes.

This manual applies to software revision 1.3.0.0 (revision 1.3.0.0 includes the higher speed A/D card from

Exacq Technologies). If you are using a software revision less than 1.3.0.0, contact ci.ppd@ametek.com

for upgrade information. The CTS software revisions can be shown by selecting the Help, About screen.

CTSMXL software revision 1.4.0.2 higher supports the new National Instruments M Series cards (PCI6220, PCI-6250).

Printing History

The manual printing date indicates the current edition. The printing date changes with each new edition or

update. Update packets or change sheets may be issued between editions to correct or add information.

Minor corrections incorporated at reprint do not cause a new edition.

December 2014 Revision I

Trademarks

Windows 7™, Windows Vista™, Windows 2000™, Windows XP™ and MS Excel™ are registered

trademarks of Microsoft Corporation.

Contacting California Instruments

To contact California Instruments, use any of the communication channels listed here:

Mail:

Ametek PPD 9250

Brown Deer Road

San Diego, CA 92121

USA

Phone: 858 450 0085 7:00 AM - 4:00 PM Pacific Standard Time

Voice Mail 24 hours

Fax: 858 458-0267

Email:

Web site: www.calinst.com

ci.ppd@ametek.com

Revision J

3

Page 4

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

WARRANTY INFORMATION

CALIFORNIA INSTRUMENTS CORPORATION warrants each instrument manufactured by them to be free

from defects in material and workmanship for a period of one year from the date of shipment to the original

purchaser. Excepted from this warranty are fuses and batteries that carry the warranty of their original

manufacturer where applicable. CALIFORNIA INSTRUMENTS will service, replace, or adjust any defective

part or parts, free of charge, when the instrument is returned freight prepaid, and when examination reveals

that the fault has not occurred because of misuse, abnormal conditions of operation, user modification, or

attempted user repair. Equipment repaired beyond the effective date of warranty or when abnormal usage

has occurred will be charged at applicable rates. CALIFORNIA INSTRUMENTS will submit an estimate for

such charges before commencing repair, if so requested.

SERVICE PROCEDURE

If a fault develops, notify CALIFORNIA INSTRUMENTS at repair.ppd@ametek.com or its local

representative, giving full details of the difficulty, including the model number and serial number. On receipt

of this information, service information or a Return Material Authorization (RMA) number will be given. Add

the RMA number furnished to the shipping label. Pack the instrument carefully to prevent transportation

damage, affix label to shipping container, and ship freight prepaid to the factory. CALIFORNIA

INSTRUMENTS shall not be responsible for repair of damage due to improper handling or packing.

Instruments returned without RMA No. or freight collect may be refused at California Instruments discretion.

Instruments repaired under Warranty will be returned either via prepaid surface freight or low cost airfreight

at California Instruments discretion. Instruments repaired outside the Warranty period will be returned

freight collect,

Ex Works CALIFORNIA INSTRUMENTS

San Diego, CA 92121

repairs not covered by the Warranty.

. If requested, an estimate of repair charges will be made before work begins on

9250 Brown Deer Road

DAMAGE IN TRANSIT

The instrument should be tested when it is received. If it fails to operate properly, or is damaged in any

way, a claim should be filed immediately with the carrier. The claim agent should obtain a full report of the

damage, and a copy of this report should be forwarded to us by fax or email (Fax: 858 677 0940, Email:

repair.ppd@ametek.com). CALIFORNIA INSTRUMENTS will prepare an estimate of repair cost and repair

the instrument when authorized by the claim agent. Please include model number and serial number when

referring to the instrument.

SPARE PARTS

To order spare parts, user manuals, or determine the correct replacement part for your California

Instruments products, please contact the Customer Service department by phone at + 1 858 450 0085,

press 2 or by email repair.ppd@ametek.com.

Revision J

4

Page 5

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

LIMITATION OF WARRANTY

California Instruments believes the information contained in this manual is accurate. This document has been

carefully reviewed for technical accuracy. In the event that technical or typographical errors exist, California

Instruments reserves the right to make changes to subsequent editions of this document without prior notice to

holders of this edition. The reader should consult California Instruments if errors are suspected. In no event shall

California Instruments be liable for any damages arising out of or related to this document or the information

contained in it.

CALIFORNIA INSTRUMENTS PROVIDES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THIS

SOFTWARE AND DOCUMENTATION. CALIFORNIA INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES

RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL

DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF.

This limitation of liability of California Instruments will apply regardless of the form of action, whether in contract or

tort, including negligence. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow California Instruments’ installation, operation, or maintenance

instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failures,

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF AN IMPLIED WARRANTY OR THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

If any part of this Agreement shall be determined by a court to be invalid, illegal or unenforceable, the remaining

provisions shall in no way be affected or impaired thereby.

GOVERNING LAW. This Agreement and Limited Warranty are governed by the laws of the state of California

without regard to conflict of law provisions.

INSTALLATION AND / OR USE OF THIS PROGRAM CONSTITUTES ACCEPTANCE OF THESE TERMS AND

RESTRICTIONS BY THE USER.

© 1997 - 2014 COPYRIGHT

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole or

in part, without the prior written consent of California Instruments Corporation.

California Instruments Corporation, © 1997 - 2014

Warning regarding Medical and Clinical use of California

Instruments products.

California Instruments products are not designed with components and testing intended to ensure a level of

reliability suitable for use in the treatment and diagnosis of human beings. California Instruments products are NOT

intended to be used to monitor or safeguard human health and safety in medical or clinical treatment and California

Instruments assumes no responsibility for this type of use of its products or software.

Revision J

5

Page 6

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

Table of Contents

1. Introduction .................................................................................................................................. 11

1.1 Manual Organization ................................................................................................................................ 11

1.2 Compliance Test System Description ....................................................................................................... 12

2. IEC Testing .................................................................................................................................. 15

2.1 About This Chapter .................................................................................................................................. 15

2.2 The EMC Directive ................................................................................................................................... 15

2.3 The EN 61000-3-2:2000 Standard ........................................................................................................... 16

2.4 The EN 61000-3-2:1998 Standard ........................................................................................................... 19

2.5 EN 61000-3-3 Flicker ............................................................................................................................... 21

2.6 EN 61000-4-11p Voltage Dips and Variations .......................................................................................... 22

2.7 EN 61000-4-13 Interharmonics and Harmonics Immunity Test ................................................................ 23

2.8 EN 61000-4-14 Voltage Fluctuations ........................................................................................................ 24

2.9 EN 61000-4-17 DC Ripple ........................................................................................................................ 24

2.10 EN 61000-4-27p Three Phase Voltage Unbalance ................................................................................... 25

2.11 EN 61000-4-28 Voltage Frequency Variations ......................................................................................... 25

2.12 EN 61000-4-29p DC Voltage Dips, Interruptions and Variations............................................................... 25

2.13 References ............................................................................................................................................... 26

3. System Installation ....................................................................................................................... 27

3.1 About This Chapter .................................................................................................................................. 27

3.2 Hardware Installation ................................................................................................................................ 27

3.3 PC Requirements ..................................................................................................................................... 28

3.4 OMNI-3-37MX Unit ................................................................................................................................... 29

3.5 OMNI-3-37MX Unit ................................................................................................................................... 32

3.6 PACS-3-75 Unit ........................................................................................................................................ 41

3.7 Functional Test ........................................................................................................................................ 46

3.8 Data Acquisition Card Installation - PCI Card Version .............................................................................. 47

3.9 CTSMXL Software Installation .................................................................................................................. 56

3.10 AC Source Control Software Installation ................................................................................................... 58

4. Program Menus ........................................................................................................................... 59

4.1 About this Chapter ................................................................................................................................... 59

4.2 Main Menus ............................................................................................................................................. 59

4.3 File Menu ................................................................................................................................................. 59

4.4 Edit Menu ................................................................................................................................................. 60

4.5 View Menu ............................................................................................................................................... 61

4.6 Options Menu ........................................................................................................................................... 61

4.7 Test Menu ................................................................................................................................................ 62

5. Harmonics Testing ....................................................................................................................... 63

5.1 About This Chapter .................................................................................................................................. 63

5.2 Test Standard Selection ........................................................................................................................... 63

5.3 Device Classes ........................................................................................................................................ 63

5.4 Stationary or Transitory Harmonics Test .................................................................................................. 66

5.5 Running a Harmonics Test ....................................................................................................................... 67

5.6 Additional Setup Parameters for Harmonics ............................................................................................. 69

5.7 Main Harmonics Test Window Operation ................................................................................................. 71

5.8 Running the Harmonics Test .................................................................................................................... 74

5.9 Printing Results ........................................................................................................................................ 76

5.10 Harmonics Test Data Files ....................................................................................................................... 77

5.11 Three Phase Testing. ............................................................................................................................... 77

5.12 Replay Mode ............................................................................................................................................ 77

6. Flicker Testing ............................................................................................................................. 80

6.1 About This Chapter .................................................................................................................................. 80

6.2 Principle of Operation ............................................................................................................................... 80

6.3 Running a Flicker Test ............................................................................................................................. 80

6.4 Printing Test Reports................................................................................................................................ 84

6.5 Flicker Replay Mode................................................................................................................................. 85

Revision J

6

Page 7

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

7. EN 61000-4-11p Voltage Dips and Variations (Pre-compliance) ................................................... 88

7.1 About This Chapter ................................................................................................................................... 88

7.2 Standard Revisions and EUT Classes ...................................................................................................... 88

7.3 Compliance Statement ............................................................................................................................. 89

7.4 Specifying test sequences for Dips and Variations .................................................................................... 90

7.5 Test Setup ................................................................................................................................................ 91

7.6 Test Options ............................................................................................................................................. 92

7.7 Test Results ............................................................................................................................................. 92

7.8 Report Format- 411 Test Files .................................................................................................................. 92

8. EN 61000-4-13 Harmonics and Inter harmonics Immunity Test .................................................... 93

8.1 About this Chapter. ................................................................................................................................... 93

8.2 Tab Controls ............................................................................................................................................. 94

8.3 Test Setup ................................................................................................................................................ 95

8.4 Test Sequence ......................................................................................................................................... 95

8.5 Test Results ............................................................................................................................................. 99

8.6 Measurements ........................................................................................................................................ 100

8.7 EN 61000-4-13 Test Reports .................................................................................................................. 100

9. EN 61000-4-14 Voltage Fluctuations Immunity Testing .............................................................. 101

9.1 About This Chapter ................................................................................................................................. 101

9.2 Test Setup .............................................................................................................................................. 102

9.3 Test Sequence ....................................................................................................................................... 103

9.4 Test Levels ............................................................................................................................................. 104

9.5 Voltage Fluctuation. ................................................................................................................................ 105

9.6 Test Execution ........................................................................................................................................ 106

9.7 Test Parameter File Creation and Limits ................................................................................................. 106

9.8 Test Results ........................................................................................................................................... 106

9.9 Report Format- 414 Test Files ................................................................................................................ 106

10. EN 61000-4-17 DC Ripple Immunity Testing .............................................................................. 108

10.1 About This Chapter ................................................................................................................................. 108

10.2 Test Setup .............................................................................................................................................. 109

10.3 Test Sequence ....................................................................................................................................... 109

10.4 Waveform Display .................................................................................................................................. 110

10.5 Test Results ........................................................................................................................................... 110

10.6 User Observations. ................................................................................................................................. 111

10.7 Report Format- 417 Test Files ................................................................................................................ 111

10.8 Saving and Loading Test Setups. ........................................................................................................... 111

11. EN 61000-4-27p Voltage Unbalance Immunity Testing .............................................................. 112

11.1 About This Chapter ................................................................................................................................. 112

11.2 Test Setup .............................................................................................................................................. 113

11.3 Equipment Classifications ....................................................................................................................... 114

11.4 Test Levels ............................................................................................................................................. 114

11.5 Waveform Display Tab ........................................................................................................................... 115

11.6 Operator Observations Tab .................................................................................................................... 115

11.7 Source Regulation .................................................................................................................................. 115

11.8 Test execution ........................................................................................................................................ 115

11.9 Test Implementation and Test Sequence ............................................................................................... 116

11.10 Test Reports ........................................................................................................................................... 116

12. EN 61000-4-28 Frequency Variations Immunity Testing............................................................. 117

12.1 About This Chapter ................................................................................................................................. 117

12.2 Test Setup .............................................................................................................................................. 118

12.3 Test Sequence ....................................................................................................................................... 119

12.4 Test Levels ............................................................................................................................................. 120

12.5 Test Options ........................................................................................................................................... 120

12.6 Test Results ........................................................................................................................................... 121

12.7 Test Reports ........................................................................................................................................... 121

Revision J

7

Page 8

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

13. EN 61000-4-29p DC Dips and Interruptions Immunity Test (Pre-compliance) .............................. 122

13.1 Test Setup ............................................................................................................................................. 123

13.2 Setting nominal values ........................................................................................................................... 124

13.3 Test sequence ....................................................................................................................................... 124

13.4 Test Options ........................................................................................................................................... 125

13.5 Test Execution ....................................................................................................................................... 125

13.6 Test Results ........................................................................................................................................... 125

13.7 EN 61000-4-29 Test Reports ................................................................................................................. 126

13.8 Source Requirements............................................................................................................................. 127

14. Customizing EN 61000-4-13 Test Parameters ........................................................................... 128

14.1 About This Chapter ................................................................................................................................ 128

14.2 Sample File IEC413.413 ........................................................................................................................ 129

15. Specifications ............................................................................................................................ 131

15.1 About This Chapter ................................................................................................................................ 131

15.2 PACS-3-75 Measurement Specifications ............................................................................................... 131

15.3 PACS-3-75 General Specifications......................................................................................................... 133

15.4 PACS-3-75 Environmental ..................................................................................................................... 134

15.5 PACS-3-75 Regulatory ........................................................................................................................... 134

15.6 Flicker Reference Impedances ............................................................................................................... 135

15.7 OMNI-3-37MX Specifications ................................................................................................................. 135

15.8 OMNI-3-37MX Environmental ................................................................................................................ 136

15.9 OMNI-3-37MX Regulatory ...................................................................................................................... 136

16. Configuration Options ................................................................................................................ 137

16.1 About this Chapter ................................................................................................................................. 137

16.2 Accessing the Calibration and Configuration Database .......................................................................... 137

17. Calibration ................................................................................................................................. 140

17.1 About This Chapter ................................................................................................................................ 140

17.2 Calibration .............................................................................................................................................. 140

17.3 Install A/D Card in PC ............................................................................................................................ 141

17.4 PACS-3-75 Calibration Setup ................................................................................................................. 141

17.5 Configuration Procedure ........................................................................................................................ 141

17.6 Installing New CTSMXL Calibration Data ............................................................................................... 144

18. Principle Of Operation ................................................................................................................ 145

18.1 General .................................................................................................................................................. 145

18.2 AC Power ............................................................................................................................................... 145

18.3 PACS-3-75 Measurement Unit ............................................................................................................... 145

18.4 OMNI-3-37MX Impedance ..................................................................................................................... 145

18.5 CTSMXL Software ................................................................................................................................. 145

19. Service ...................................................................................................................................... 147

19.1 Cleaning ................................................................................................................................................. 147

19.2 General .................................................................................................................................................. 147

19.3 Basic Operation ...................................................................................................................................... 147

19.4 Advanced Troubleshooting ..................................................................................................................... 150

Index .................................................................................................................................................... 152

Revision J

8

Page 9

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

List of Figures

Figure 3-1: MX30-3Pi-CTSH and MX45-3Pi-CTSH with OMNI-3-75 Wiring Diagram – Version 2 ................... 33

Figure 3-2: MX60-3Pi-CTSH and MX90-3Pi-CTSH with OMNI-3-75 Wiring Diagram – Version 2 ................... 34

Figure 3-3: MX30-3Pi-CTSL and MX45-3Pi-CTSL with OMNI-3-37MX Wiring Diagram. ................................. 35

Figure 3-4: MX60-3Pi-CTSL and MX90-3Pi-CTSL with OMNI-3-37MX Wiring Diagram. ................................. 36

Figure 3-5: MX30-3Pi-CTSHL and MX45-3Pi-CTSHL with dual OMNI's Wiring Diagram – Version 2. ............ 37

Figure 3-6: MX60-3Pi-CTSHL and MX90-3Pi-CTSHL with dual OMNI's Wiring Diagram. ............................... 38

Figure 3-7: MX30-3Pi-CTSH and MX45-3Pi-CTSH with OMNI-3-75 Wiring Diagram - version 1 .................... 39

Figure 3-8: MX30-3Pi-CTSHL and MX45-3Pi-CTSHL with dual OMNI's Wiring diagram – version 1 .............. 40

Figure 3-9: EUT Connection distance and wire gauge .................................................................................... 42

Figure 3-10: Power Connections for PACS-3-75 ............................................................................................. 44

Figure 3-11: Front and Rear Panel Views of the PACS-3-75 Module. ............................................................. 45

Figure 3-12: Exacq Control Center Screen. .................................................................................................... 51

Figure 3-13: Exacq Card Device Number ........................................................................................................ 52

Figure 3-14: Exacq Test Panel ........................................................................................................................ 53

Figure 3-15: Exacq DMM Screen. ................................................................................................................... 54

Figure 3-16: Exacq Scope Test Panel ............................................................................................................. 55

Figure 5-1: Class D Current Wave Shape Template ....................................................................................... 64

Figure 5-2: EUT Class Determination Flowchart .................................................................................................. 65

Figure 5-3: Typical Class A test setup ............................................................................................................. 67

Figure 5-4: Additonal Settings for Harmonics Test .......................................................................................... 69

Figure 5-5: Harmonics Test Window. .............................................................................................................. 71

Figure 6-1: Flicker Test Window ..................................................................................................................... 81

Figure 7-1: EN 61000-4-11 Test Window ........................................................................................................ 88

Figure 7-2: EN 61000-4-11 Voltage Variation specification ............................................................................. 90

Figure 7-3: EN 61000-4-11 Voltage Variation specification – Edition 2.0. ....................................................... 90

Figure 8-1: EN 61000-4-13 Test Window ........................................................................................................ 93

Figure 8-2: EN 61000-4-13 Flow Chart, Class 1 and 2 EUT’s. ........................................................................ 96

Figure 8-3: EN 61000-4-13 Flow Chart, Class 3 EUT ...................................................................................... 97

Figure 9-1: EN 61000-4-14 Test Window ...................................................................................................... 101

Figure 9-2: EN 61000-4-14 Test Sequence ................................................................................................... 103

Figure 10-1: EN 61000-4-17 Test Window .................................................................................................... 108

Figure 10-2: EN 61000-4-17 Waveform Acquisition Window ......................................................................... 110

Figure 10-3: EN 61000-4-17 User Observation Data Entry Window .............................................................. 111

Figure 11-1: EN 61000-4-27 Test Window .................................................................................................... 112

Figure 12-1: EN 61000-4-28 Test Window .................................................................................................... 117

Figure 12-2: EN 61000-4-28 Test Sequence ................................................................................................. 119

Figure 13-1: EN 61000-4-29 Test Window .................................................................................................... 122

Figure 17-1 : CTSMXL Calibration Program Main Screen ............................................................................. 141

Figure 17-2: Three Phase Calibration Setup ................................................................................................. 143

Figure 19-1: Location of AC Sensor Assy. 5004-700 in PACS-3-75 .............................................................. 149

Revision J

9

Page 10

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

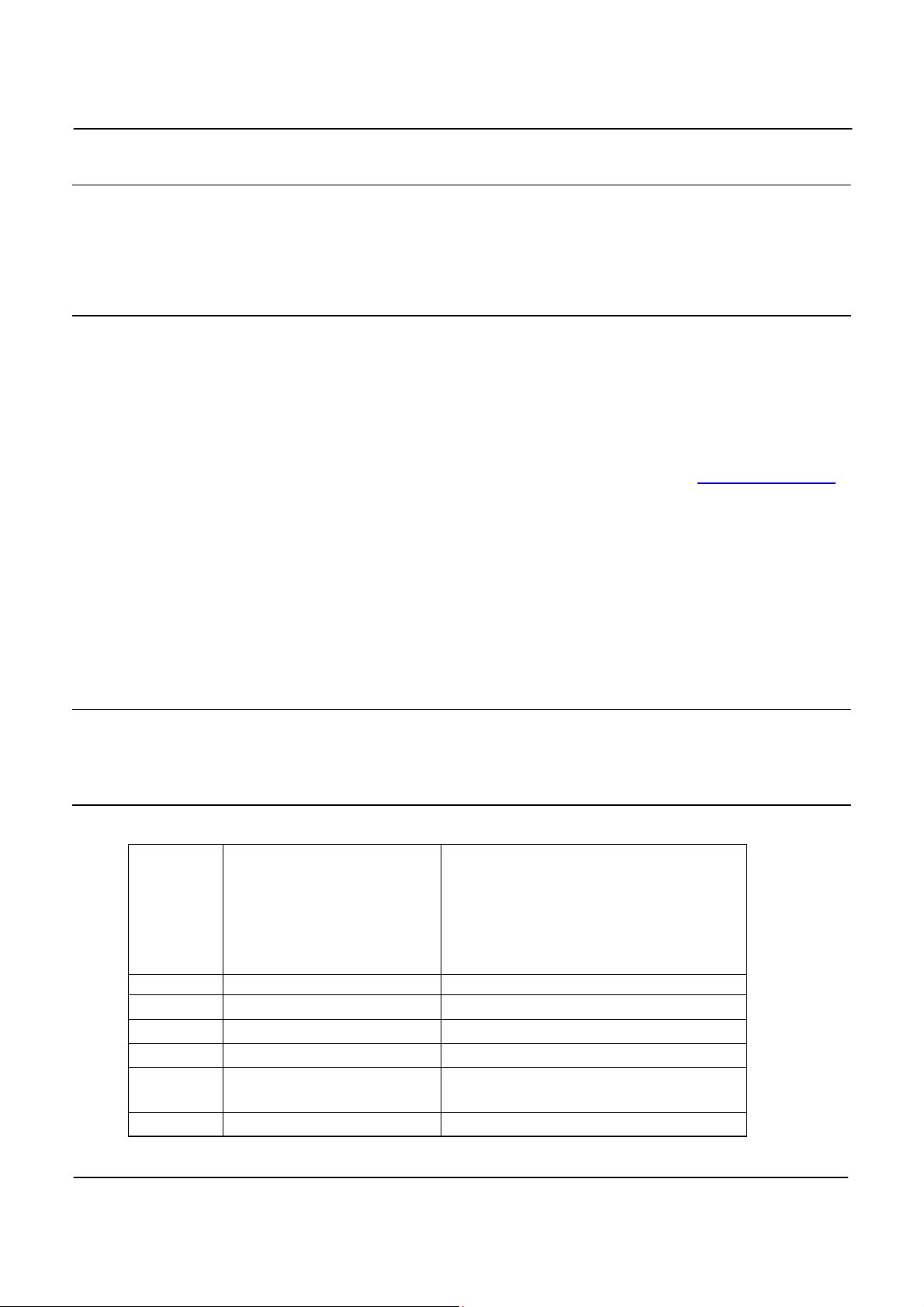

List of Tables

Table 2-1: EN 61000-3-2 Class Limits ............................................................................................................ 17

Table 2-2: Harmonics Amendment 14 Test Times .......................................................................................... 18

Table 2-3: EN 61000-3-2 Class Descriptions .................................................................................................. 20

Table 2-4: Average public utility disturbances per annum in Europe ............................................................... 23

Table 3-1: PC Pentium/Athlon Processor Clock Speed Requirement ............................................................. 28

Table 5-1: IEC Harmonics Setup Parameters ................................................................................................. 68

Table 5-2: IEC Harmonics Advanced Setup Parameters ................................................................................ 70

Table 5-3: IEC Harmonics Replay Settings ..................................................................................................... 79

Table 6-1: IEC Flicker Replay Settings ........................................................................................................... 87

Table 17-1: Required Calibration Equipment ................................................................................................ 140

Revision J

10

Page 11

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

1. Introduction

1.1

Manual Organization

This manual describes the operation of the California Instruments Compliance Test System Software when

used in conjunction with the CTS hardware. Its primary function is as a reference manual. If you have a

question about a specific screen or how to perform a certain task, turn to the appropriate section of the

manual. The manual is organized in accordance with the normal test procedure you would follow when

testing for IEC compliance.

Some assumptions were made when producing this documentation. Specifically, it is assumed that you are

familiar with the EN 61000-3-2 and EN 61000-3-3 standards and their requirements. Some background

information on the IEC standards covered by the CTS system is included in chapter 2. This information is

subject to change however as standards do change. We recommend you stay current with evolving test

standards and regulations. Furthermore, it is also assumed that you are familiar with operating a personal

computer under the Microsoft Windows™ environment.

The manual is organized as follows:

Chapter 1 describes the organization of the user manual and provides a brief overview of the

Chapter 2 provides an overview of the relevant IEC regulations and how compliance testing to

Chapter 3 covers installation of the hardware and software components required to operate the

Chapter 4 Overview of the program's menu structure

CTS system components.

these regulations is implemented in the CTSMXL Software.

CTS system. Proper installation of both hardware and software is essential. This

chapter walks the user through the hardware setup and the software installation,

process one step at a time.

Chapter 5 covers EN 61000-3-2 harmonics testing. This chapter provides step by step

instructions on how to set up the correct test mode and perform the necessary steps

to perform a quasi-stationary or transitory Harmonics test on the EUT.

Chapter 6 covers EN 61000-3-3 Voltage fluctuations testing. This chapter provides step by step

instructions on running a voltage fluctuation or flicker test.

Chapter 7 covers EN 61000-4-11p Voltage Dips and Variations immunity testing.

Chapter 8 covers EN 61000-4-13 standard Voltage Fluctuations immunity testing. [Draft version]

Chapter 9 covers EN 61000-4-14 standard Voltage Fluctuations immunity testing.

Chapter 10 covers EN 61000-4-17 standard DC Ripple immunity testing.

Chapter 11 covers EN 61000-4-27p standard Voltage Unbalance immunity testing.

Chapter 12 covers EN 61000-4-28 standard Frequency Variations immunity testing.

Chapter 13 covers EN 61000-4-29p DC Voltage dips and Variations immunity testing.

Chapter 14 covers EN 61000-4 customization to allow for future revisions of these standards and

to accommodate different product categories.

Revision J

11

Page 12

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

1.2

Chapter 15 provides the technical specifications for the Power Analysis and Conditioning System

(PACS) unit, which is a key component of the CTS system. For technical

specifications on the AC source supplied with the CTS system, refer to the AC source

manual provided.

Chapter 16 overview of available configuration options.

Chapter 17 overview of calibration procedures

Chapter 18 provides theory of operation information.

Chapter 19 provides service and troubleshooting procedures.

Compliance Test System Description

The California Instruments Compliance Test System is a complete IEC AC power test system that covers

many of the IEC regulatory test standards involving AC and/or DC powered equipment.

To ensure maximum flexibility of both the hardware and the software required to create a turn-key system,

the CTS system uses a modular structure consisting of the following components:

• Programmable MX Series AC power source. The AC source provides AC power at the user specified

frequency and voltage. The MX Series AC source also offers over current protection to avoid damaging

a load that exhibits a failure. The MX power source is a three-phase unit.

The following power source configurations are currently supported on MX-CTSH systems:

• MX30-3Pi-CTSL

• MX45-3Pi-CTSL

• MX60-3Pi/2-CTSL Two cabinet MX master/auxiliary power source.

• MX90-3Pi/2-CTSL Two cabinet MX master/auxiliary power source.

• RS90-3Pi-CTSL

This user manual generally refers to the power source as a MX45-3Pi model as it is most common.

Where relevant, the other power source system configurations will be covered specifically. In general,

operation of the MXCTSL system is the same for any of these four configurations.

• Power Analysis and Conditioning System unit. The PACS-3-75 unit creates the electrical and

mechanical interface between the AC source, the Equipment Under Test (EUT) and the PC based data

acquisition system. It provides the necessary signal conditioning and isolation for the acquisition

system.

• PC Based data acquisition system. The data acquisition system uses a fast Analog to Digital

conversion card that plugs into an available card slot in the user’s PC. The CTSMXL Software controls

all aspects of the A/D card and processes the data for IEC test purposes.

• CTSMXL Software. The CTSMXL Software implements the harmonics and flicker IEC tests. In addition

to the CTSMXL Software, the California Instruments MXGUI program is used to control the AC and DC

source used and to implement those IEC tests that run on the AC source, specifically the EN 61000-4

immunity tests.

The AC source output is connected to AC input terminal at the rear of the PACS-3-75 unit. The PACS-3-75

AC output rear terminals are used to connect the EUT. All user interactions with the CTS system are

accomplished through the CTSMXL and MXGUI software. There are virtually no front panel controls

required to operate the CTS system.

Revision J

12

Page 13

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

1.2.1 AC Source Models

The MXCTS system is supplied with one the following MX Series programmable AC power sources:

• MX30-3Pi-CTSL

• MX45-3Pi-CTSL

• MX60-3Pi/2-CTSL Two cabinet MX master/auxiliary power source.

• MX90-3Pi/2-CTSL Two cabinet MX master/auxiliary power source.

• RS90-3Pi- CTSL

No other MX Series power source models are supported by the CTSMXL Software. This user manual

generally refers to the power source as a MX45-3Pi model as it is most common. Where relevant, the

other power source system configurations will be covered specifically. In general, operation of the

MXCTSH system is the same for any of these four configurations.

Note: The MXCTS systems are rated for a maximum current of 75 amps rms per phase. Damage to the

standard PACS-3-75 units can occur if higher currents are present. Care must be taken to not

exceed this rating when using the system directly with the utility line or with the higher power

sources.

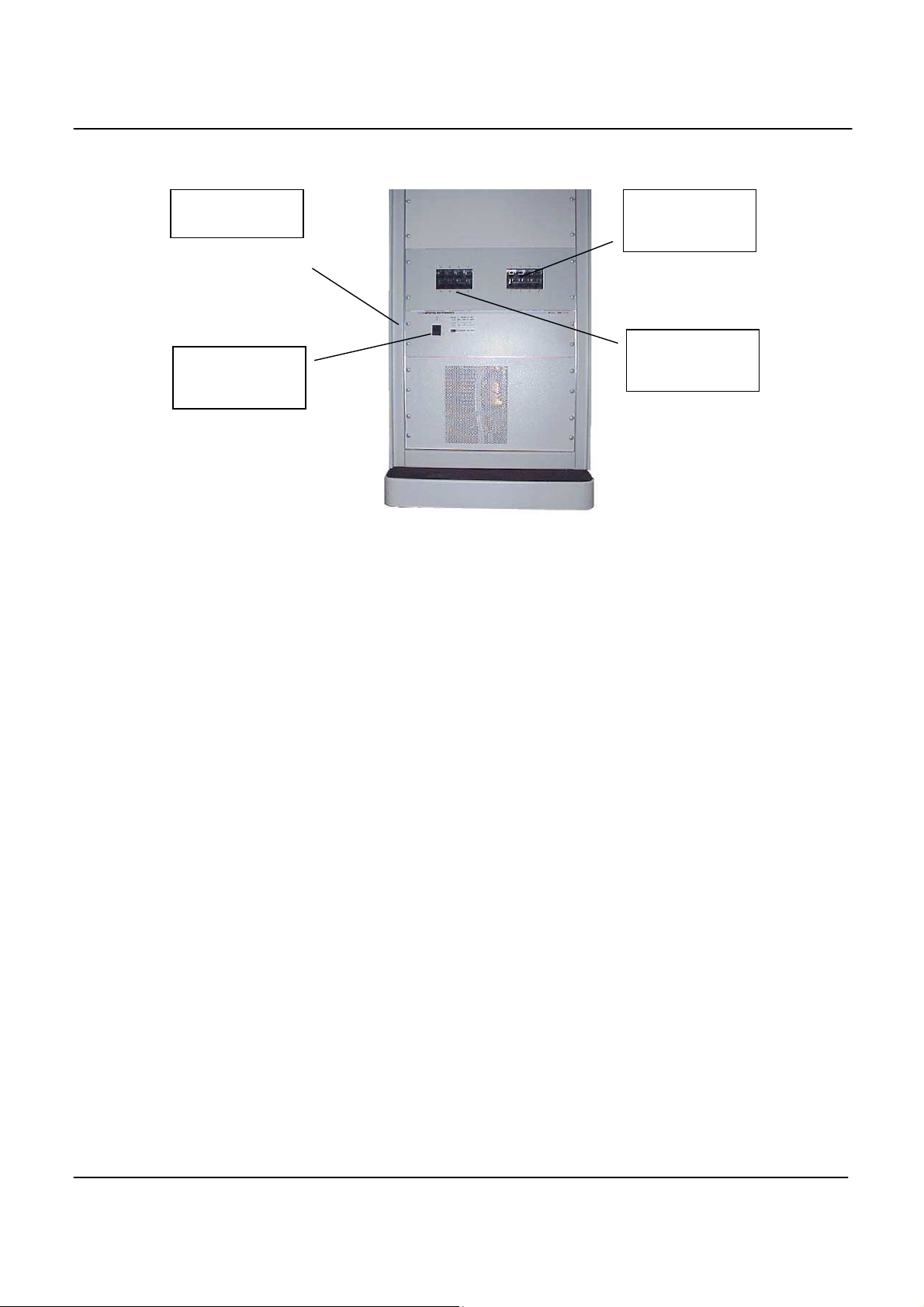

1.2.2 PACS-3-75 Unit

The Power Analysis and Conditioning System provides the required electrical and mechanical interface

between the AC source, the user’s equipment under test and the data acquisition PC system. This allows

all signal connections to be made easily and conveniently.

The PACS-3-75 unit has several AC power input and output connections as well as an interface connector

to the PC based data acquisition system.

1.2.3 PC Based Data Acquisition System (updated for new PCI data acquisition)

All measurements required for IEC testing are performed by the data acquisition system that resides on the

user’s PC. The measurement card needs to be installed in an available slot and the software needs to be

installed. All signal connections between the PC and the PACS-3-75 unit are made with a single 37 pin to

68 pin cable supplied with the system.

The following data acquisition cards are supported by the CTSMXL software:

CI400PCI PCI card NI 6032/4E. No longer provided on new system shipments but still

supported by CTS30 software revision 1.3.X

CI401PCI PCI card Exacq Technologies CM2110 PCI A/D card, 250 Ks/sec for single phase

systems (P/N 250803)

CI403PCI PCI card Exacq Technologies CM2210 PCI A/D card, 1 Ms/sec for three phase

systems (P/N 250797)

CI401PCI PCI card National Instruments M Series PCI-6220 A/D card, 250 Ks/sec for single

phase systems (P/N 250821) for software version 2.0.x or later

CI403PCI PCI card National Instruments M Series PCI-6250 A/D card, 1 Ms/sec for three

phase systems (P/N 250822) for software version 2.0.x or later

The data acquisition system samples all voltage and current channels at a high sampling rate and provides

the data to the CTSMXL Software for further processing. The PACS-3-75 provides a single voltage input

channel and three current input channels for each phase, to the PC. This allows for current range changing

Revision J

13

Page 14

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

on the fly. There is no need for the user to select a current range as the software automatically uses the

most suitable range available for the current signal.

1.2.4 CTSMXL Software Functions

The CTSMXL software application supports EN 61000-3-2 and EN 61000-3-3 compliance testing

requirements using an intuitive graphical user-interface from which you can:

• Set up and run compliance-level tests. The setting up of many IEC details is facilitated through the use

of embedded standards expertise.

• Collect real-time test data from the MX-CTSL System.

• Display and monitor real-time test results.

• Save test results to disk for analysis using other programs.

• Replay previously recorded test data and single step through the data frame by frame.

• Print reports and graphs in MS Word™ formats.

1.2.5 MXGUI Source GUI Functions

The CTS system also includes an AC source control software package. This Graphical User Interface

program can be used to control the AC source from the same PC using either the RS232C or IEEE-488

interface. An IEEE-488 interface is not included with the CTS system. The PC must have an available

RS232C port to use the RS232C control interface to the source.

In the absence of a suitable interface, the user can operate the AC source from the front panel. This does

not affect the ability to run harmonics and flicker tests. It does however preclude the use of the EN 61000-4

immunity tests, which are only available through the MXGUI1 AC source control program.

Note on Interface conflicts:

If the MXGUI program is set up to use the same serial or IEEE-488 port (any address) to communicate with

the AC source as the CTSMXL Software, it is not possible to have both the CTSMXL Software and the

MXGUI software running at the same time. This is due to the fact that both programs would attempt to use

the same interface to control the AC source. If this is the case, close one program before opening the

other.

If IEEE-488 is used to control the AC source with the MXGUI and RS232C is selected on the MXCTSL or

vice versa, both programs can be open at the same time but care should be taken not to control the source

from both programs at the same time. This setup is not recommended however.

Use either program in turn depending on the task at hand (MXCTSL for EN 61000-3 and MXGUI for EN

61000-4)

1

Some EN 61000-4 tests are pre-compliance only

Revision J

14

Page 15

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

2. IEC Testing

2.1

About This Chapter

This chapter provides some background information on the various IEC test standards that apply to AC

powered products. It also reviews some of the test equipment requirements that are important when testing

for IEC compliance. Note that this information is subject to change as IEC standards change over time.

This overview is by no means comprehensive and is only provided for reference. If the reader is not familiar

with IEC test requirements for AC powered products, we strongly recommend consulting information on this

subject that is available through other sources. References are provided at the end of this chapter.

The standards covered in this chapter include those, which the CTS system is capable of testing,

specifically:

• EN 61000-3-2 Quasi Static and Transitory Harmonics

• EN 61000-3-3 Flicker

• EN 61000-4-11p Voltage Dips and Variations (pre-compliance, requires option -411 on MX)

• EN 61000-4-13 Interharmonics and Harmonics Immunity Test (requires option –413 on MX)

• EN 61000-4-14 Voltage Fluctuations

2.2

• EN 61000-4-17 DC Ripple

• EN 61000-4-27p AC Voltage Unbalance (pre-compliance)

• EN 61000-4-28 Frequency Variations

• EN 61000-4-29p DC Voltage Dips and Variations (pre-compliance)

The EMC Directive

As the world population grows and the overall energy consumption increases, industrialized nations have

become increasingly concerned with the future availability of energy. Reducing energy consumption by

using more energy efficient lighting and motor drive systems is one approach being taken by European, US

and Japanese governments. The need of more efficient electrical systems however typically requires the

use of sophisticated semi-conductor based electronic circuits that produce current harmonics. This in turn

effects power quality which is an increasing problem on public utility networks. As lighting systems with

electronic ballasts and equipment with switching power supplies such as computers, TV’s, fax machines

and printers proliferate, power quality deteriorates. The same is true for PWM controller motor drives. The

International Electrical Committee (IEC) has released standards dealing with the low frequency public

supply system. Initial standards were 555.2 (Harmonics) and 555.3 (Flicker) which have since been refined

and are now available as EN 61000-3-2 and EN 61000-3-3 respectively. Effective January 1, 1996, most

electrical devices sold within the member countries of the European Union (EU) must meet these standards

as governed by the EMC directive.

Revision J

15

Page 16

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

2.2.1

2.3

Why do you have to test?

In general, these IEC directives do not have the legal force of law. However, the European Union (EU) has

issued Euro Norms in the context of these IEC directives that are legally binding and are enforced by the

EMC Police. The relevant enforceable standards are EN61000-3-2 and EN61000-3-3, which supersede

EN60555.2 and EN60555.3 respectively. These standards are also known under the IEC designator EN

61000-3-2 and EN 61000-3-3. Recently, the universal EN 61000 convention has been adopted for all IEC

standards.

Individual member countries have issued identical national norms, either in their native language or in

English, which carry the same legal enforceability. Other countries such as Japan and the USA are in the

process of adopting similar standards. Penalties for violating these norms range from hefty fines to jail time.

In cases where the manufacturer is not located in the EU, his distributor or authorized agent will be held

liable. Local customs agencies can stop equipment that does not meet these IEC norms at the border.

Compliance testing of equipment is performed by accredited laboratories run by European government

agencies assigned with enforcing these norms. Also, competing vendors have been known to submit

failing test results on competitors' products to local governments to force prosecution and gain a

competitive advantage in the market place.

Conformance to the EMC low voltage directive is indicated by the CE mark. Note however, that the CE

mark includes more than just EN 61000-3-2 and EN 61000-3-3.

The EN 61000-3-2:2000 Standard

This standard is often referred to as Amendment 14. It is less stringent for class C and D products

compared to the 1998 standard. Effective January 2001, products may be evaluated against this standard.

2.3.1 Test Classes

CENELEC-A14 changes the definition of Class-D products. Per the amendment, only TV’s, PC’s and PC

monitors are to be tested per Class-D limits. This means that many products migrate to Class-A. Note that

there is no change in classification for Class-A, B, and C products, but the harmonic analysis method for

products with fluctuating power is affected by A-14 for these products as well.

The limits for Class-C & D are proportional. Whereas this doesn’t cause any difficulties for products with a

constant current/power level, the situation was less clear for products with fluctuating load levels. Most test

systems implemented so-called dynamic limits, with the limits constantly being adjusted per the measured

power (or the fundamental current for Class-C) while others used some average power level to set the

limits. The latter systems determine this average power/current using some arbitrary method, and pre-test

period. Thus different test systems implement different limits for the same (fluctuating power) products,

which can result in one system PASSING a product while the other REJECTS it.

A second issue for fluctuating loads is the way the existing standard (1998 edition) defines criteria for

passing and failing the harmonics test. The existing standard permits the unit under test to occasionally

exceed the 100 % limit, provided the harmonics never exceed 150 % of the limit. In fact, the unit under test

is allowed to exceed the 100 % level for 10 % of the test time. The test time for fluctuating loads is to be at

least 2.5 minutes, i.e. the harmonics can exceed the 100 % limit for 15 seconds in every 150-second (2.5

min) period. For longer test times, one can perform this test in 2.5 minutes “time blocks” but another

interpretation is to just take 10 % of the overall test time. Thus, the testing method for fluctuating loads was

somewhat subject to interpretation by the test equipment manufacturer.

Revision J

16

Page 17

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

Pass/Fail criteria under the new standard are as follows:

The average value for the individual harmonic currents, taken over the entire test observation period shall be

less than or equal to the applicable limits.

For each harmonic order, all 1,5 s smoothed r.m.s. harmonic current values shall be less than or equal to

150% of the applicable limits.

Harmonic currents less than 0,6% of the input current measured under the test conditions, or less than 5 mA,

whichever is greater, are disregarded.

For the 21st and higher odd order harmonics, the average values obtained for each individual odd harmonic

over the full observation period, calculated from the 1,5 s smoothed values may exceed the applicable limits by

50% provided that the following conditions are met:

• The measured partial odd harmonic current does not exceed the partial odd harmonic current, which

can be calculated from the applicable limits.

• All 1,5 s smoothed individual harmonic current values shall be less than or equal to 150% of the

applicable limits.

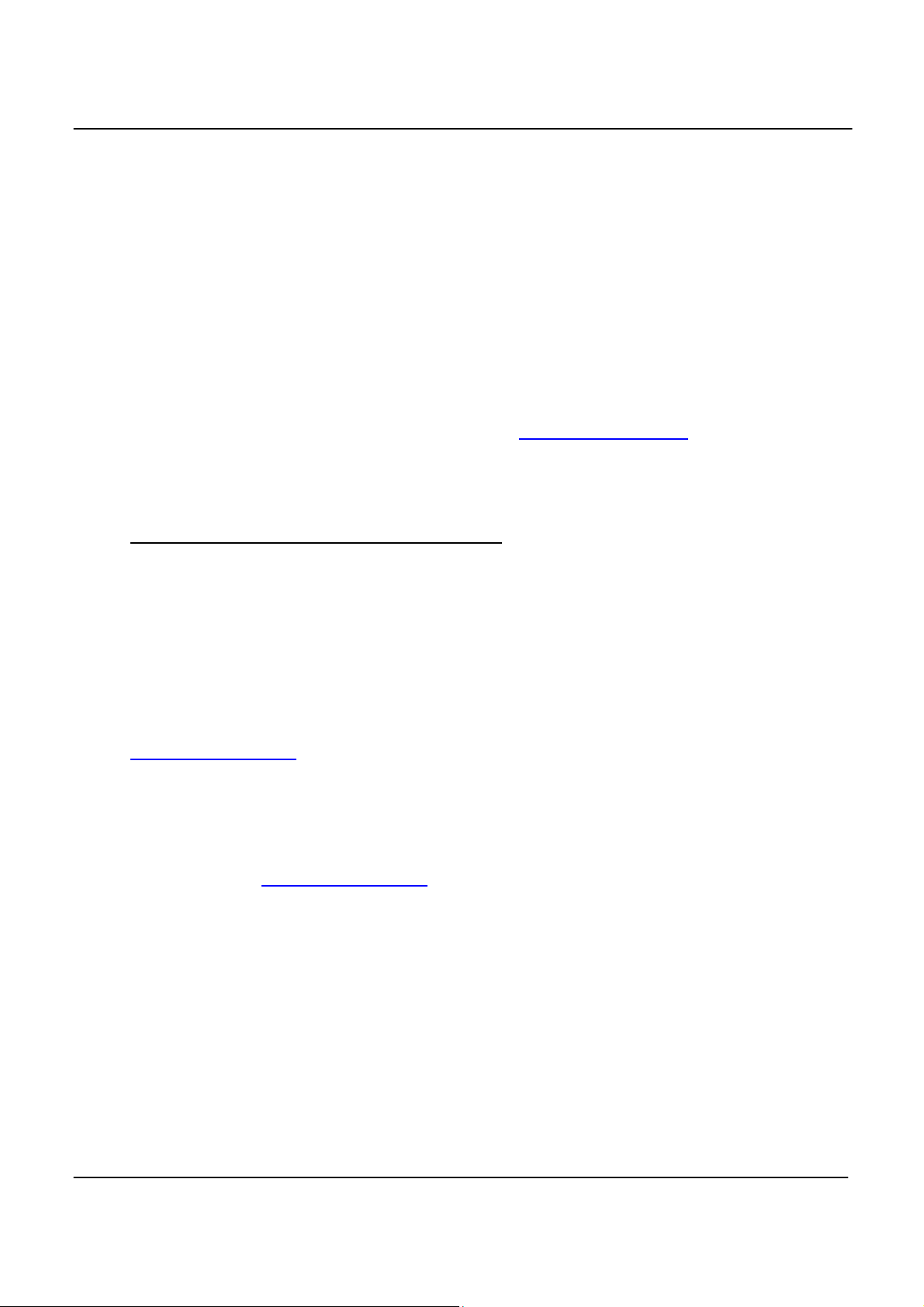

2.3.2 EN 61000-3-2 Test Limits

The following table summarizes the current harmonic limits for each device class that are presently in

effect. The limits are generally built into IEC test software programs such as California Instruments’

CTSMXL Test System software. If the power level of a class D device drops below 75 W (configurable see System Administrator Manual P/N 7003-794), no harmonic current limits are applied and the result will

always show a pass.

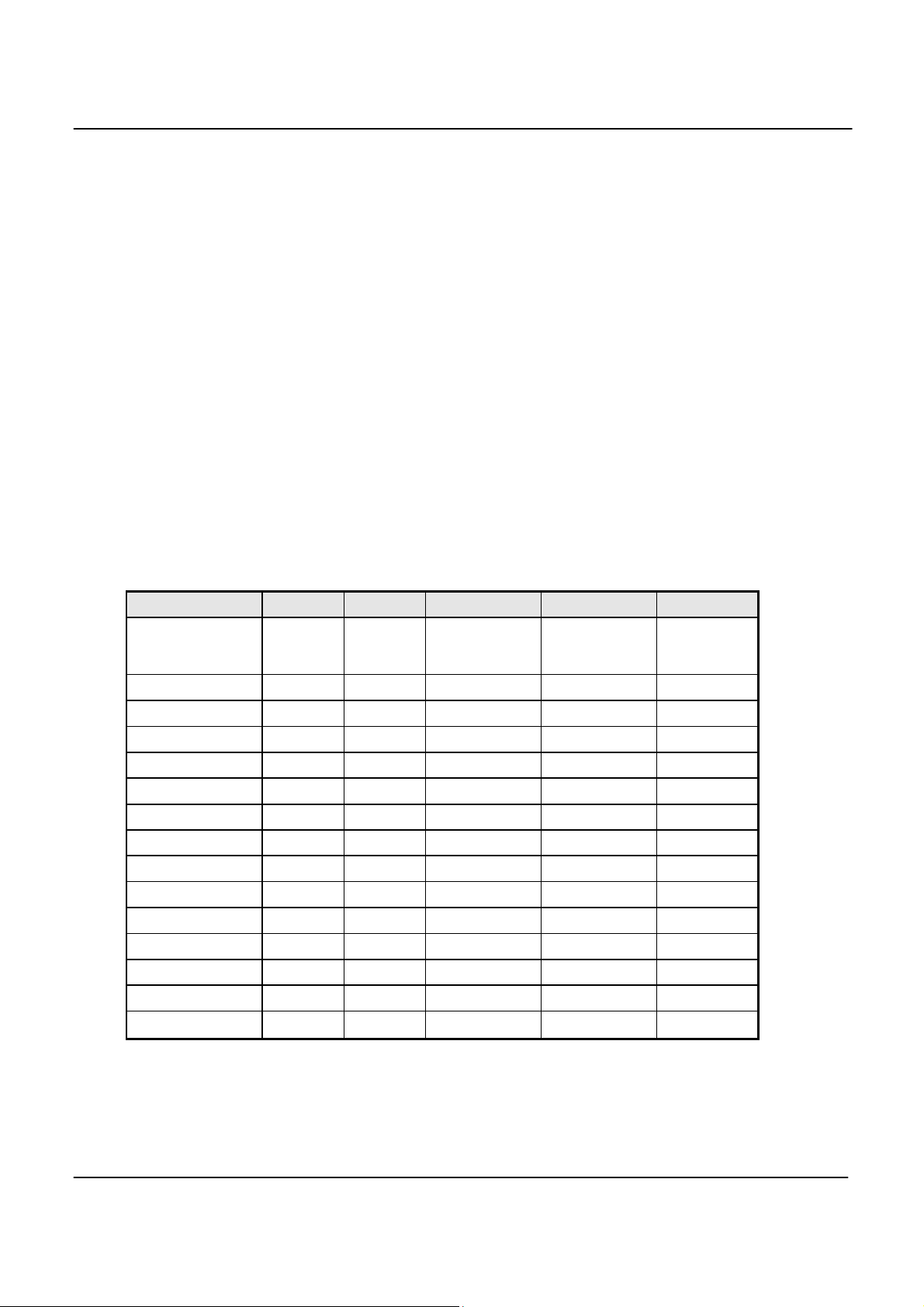

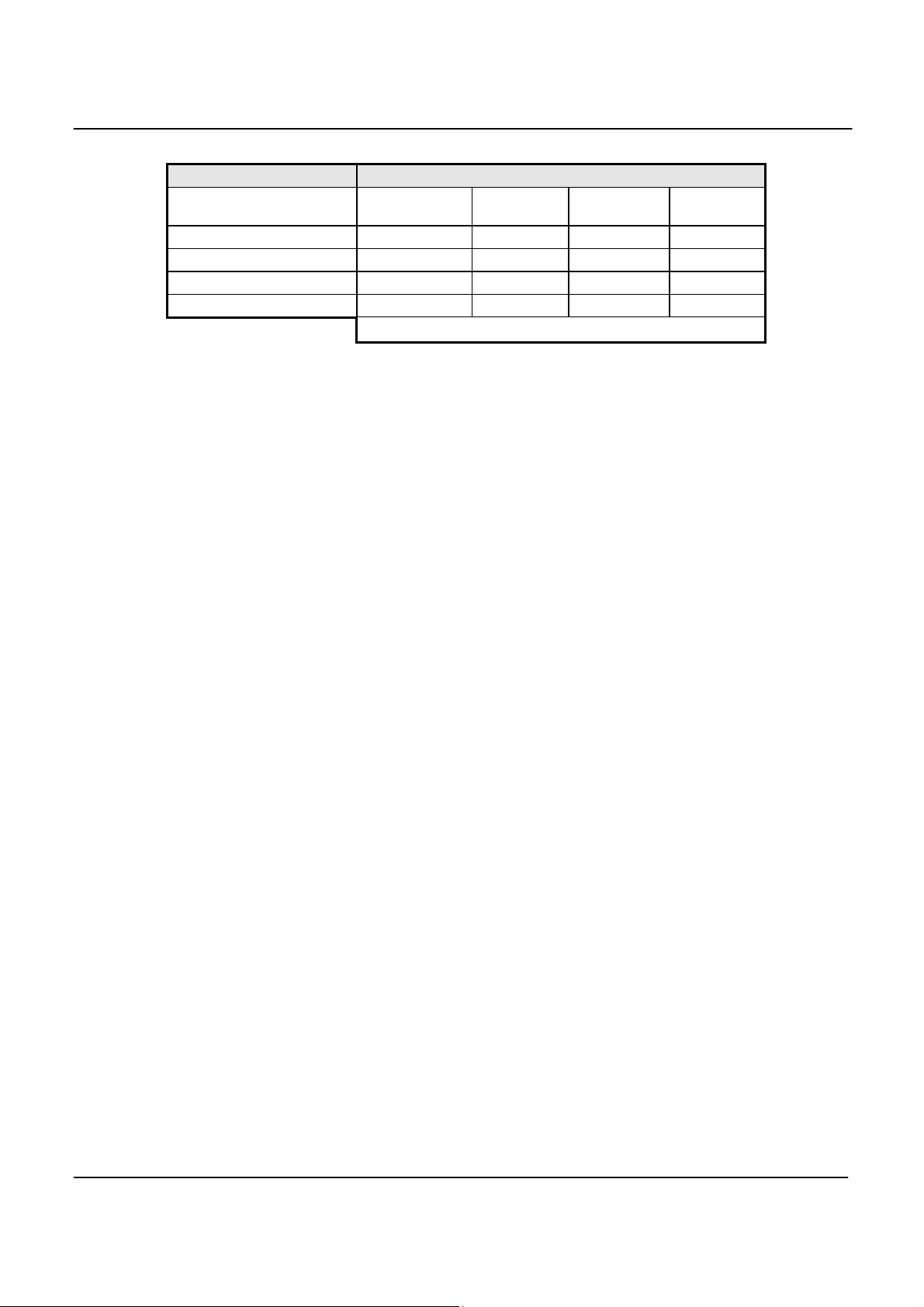

Harmonic no. (n) Class A Class B Class C Class D IEC 555-2

2 1.080 1.620 2 - 0.300

3 2.300 3.450 30 x PF 3.400 0.800

4 0.430 0.645 - - 0.150

5 1.140 1.710 10 1.900 0.600

6 0.300 0.450 - - 7 0.770 1.155 7 1.000 0.450

8 0.230 0.345 - - -

9 0.400 0.600 5 0.500 0.300

10 0.184 0.276 - - 11 0.330 0.495 3 0.350 0.170

12 0.153 0.230 - - 13 0.210 0.315 3 0.296 0.120

Even 14-40 1.84 / n 2.760 / n - -

Odd 15-39 2.25 / n 3.338 / n 3 3.850 / n

A RMS A RMS % of

fundamental

RMS current

Table 2-1: EN 61000-3-2 Class Limits

mA/Watt of

input power

(75 - 600 W)

A RMS

TV Receivers

> 165 W

-

1.500 / n

Revision J

17

Page 18

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

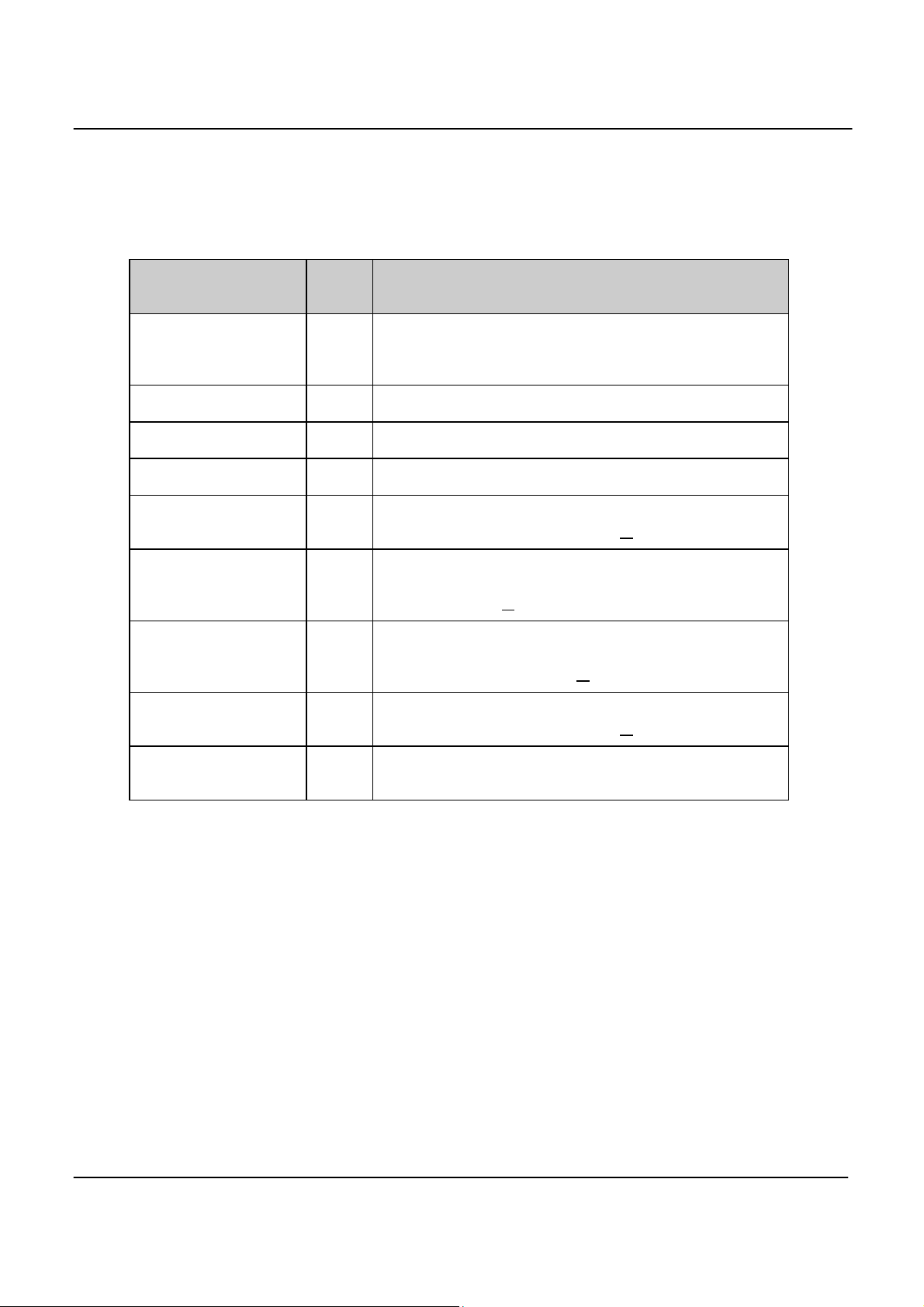

Type

of

equipment

Observation

period

The actual class limits for all classes have not changed with amendment 14. The power levels for Class D

on which these limits are calculated however and the fundament current and power factor for class C have

been changed however.

First of all, the manufacturer is required to declare the rated power (the fundamental current and Power

Factor for Class-C) for the product. This “rated power” (current & PF) will be used as the basis for the limit

calculation of Class-D (Class-C). Thus, a “rated power” of 150 Watt for example, will yield a third harmonic

limit of 150 x 3.4 = 510 mA. Similarly, a rated fundamental current of 0.4 Amp, and a rated PF of 0.98 for an

electronic ballast will result in a third harmonic limit of 0.4 x 0.3 x 0.98 = 117.6 mA. Thus, the amendment

requires that an automated compliance test system must allow the user to enter this rated power or rated

current. Also, the test system must verify the power (fundamental current and PF) because these “rated

vales” as declared by the manufacturer must be within +/- 10 % of the actual values. If not, the actually

measured values are to be used for the limit calculation. The method to measure these actual power,

fundamental current and PF differ from the “average method” used in existing test systems, and of course

differ also from the “dynamic limit method”.

The Pass/Fail criterion is given above. The “10 % of the time over 100 % of the limits” no longer exists. The

average harmonic level during the whole test must simply be below the limit, and individual values in each

acquisition window (after 1.5 sec filtering) must be below 150 % of the limit. There is also an extra

allowance for the higher harmonics from H

21

- H

39

.

The CTS fully supports and implements Amendment 14.

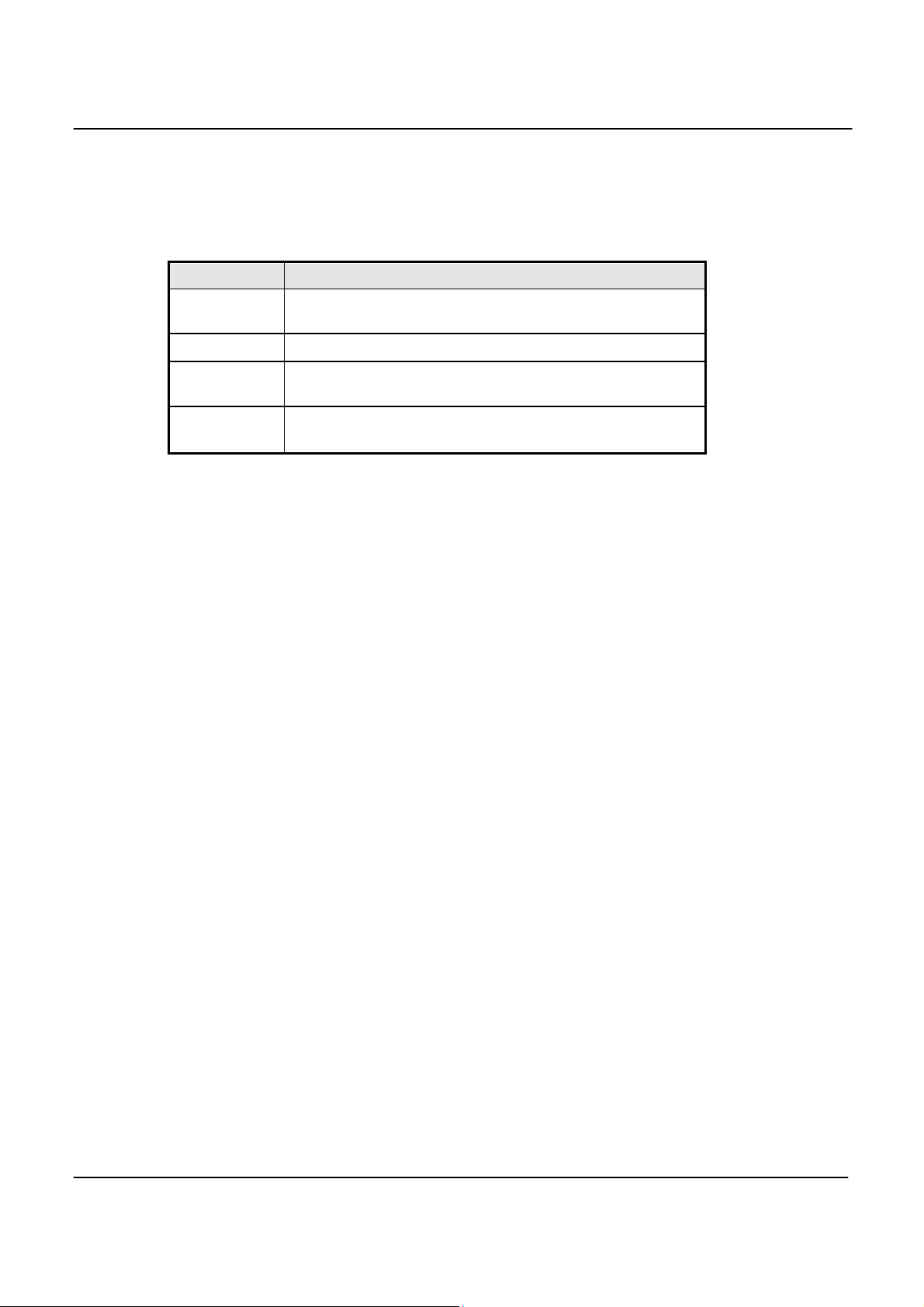

2.3.3

EN 61000-3-2:2000 Test Time

Under the new test standard, four test times (observation periods) are allowed depending on the nature of

the EUT. All are aimed at ensuring repeatability of test results when tests are performed under the same

conditions and on the same test system. Repeatability for this purpose is defined as results that are within

5 %. Available observation periods are shown in the table below.

behavior

Quasi-stationary

Short cycles (Tcycle < 2.5

min)

Random

Long cyclic (Tcycle > 2.5

min)

T

of sufficient duration to meet the requirements for repeatability.

obs

T

> 10 cycles (reference method) or Tobs of sufficient duration

obs

or synchronization to meet the requirements for repeatability.

'Synchronization' means that the total observation period is

sufficiently close to including an exact integral number of

equipment cycles such that the requirements for repeatability are

met.

T

of sufficient duration to meet the requirements for repeatability.

obs

Full equipment program cycle (reference method) or a

representative 2.5-min period considered by the manufacturer as

the operating period with the highest total harmonic content.

Table 2-2: Harmonics Amendment 14 Test Times

Revision J

18

Page 19

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

2.4

The EN 61000-3-2:1998 Standard

This section covers the 1998 standard including amendments 1 and 2. This standard may be used to test

products until January 2004. After this date, only the 2000 revision of the standard including Amendment

14 should be used.

The purpose of enforcing the EN 61000-3-2 standard is to limit the amount of current harmonics produced

by electronic loads. Since harmonic currents caused by a load in turn produce voltage harmonics across

the public utilities impedance, they affect other equipment connected to the same circuit. In fact, most

public utilities exhibit voltage distortion caused by non-linear loads. Because harmonics can have serious

effects on many electrical devices, efforts to set standards to limit their presence date back to the 1930’s.

This resulted in the IEC’s Technical Committee (TC) setting standards dealing with current harmonics as

far back as 1977. These standards became the basis for IEC standards 1000-3-2 and 1000-3-3 adopted in

1993. Because of their long history, many people still refer to these standards as 555.2 and 555.3 although

there are some differences between the older and newer versions and tests performed today should be

done according to the new standards, not the old ones.

Another confusing issue that is rooted in history is the nature of the products that fall under these IEC

norms. While the original 555 specifications focused primarily on consumer products and excluded many

professional and industrial products, the new IEC 1000-3 norms expanded coverage to include all electrical

products with a rated input current up to 16 A rms per phase. Presently, only products with a line input

voltage of 220 V and above are included. Japan and the US are working towards similar requirements that

would cover products that require 100 Volts and up. Due to the original scope of the IEC 555 norms, many

manufacturers are still under the impression that their products are exempt since they are not considered

consumer products. Especially manufacturers of switching power supplies - some of the worst “offenders”

when it comes to generating harmonics currents - have been caught off guard.

Revision J

19

Page 20

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

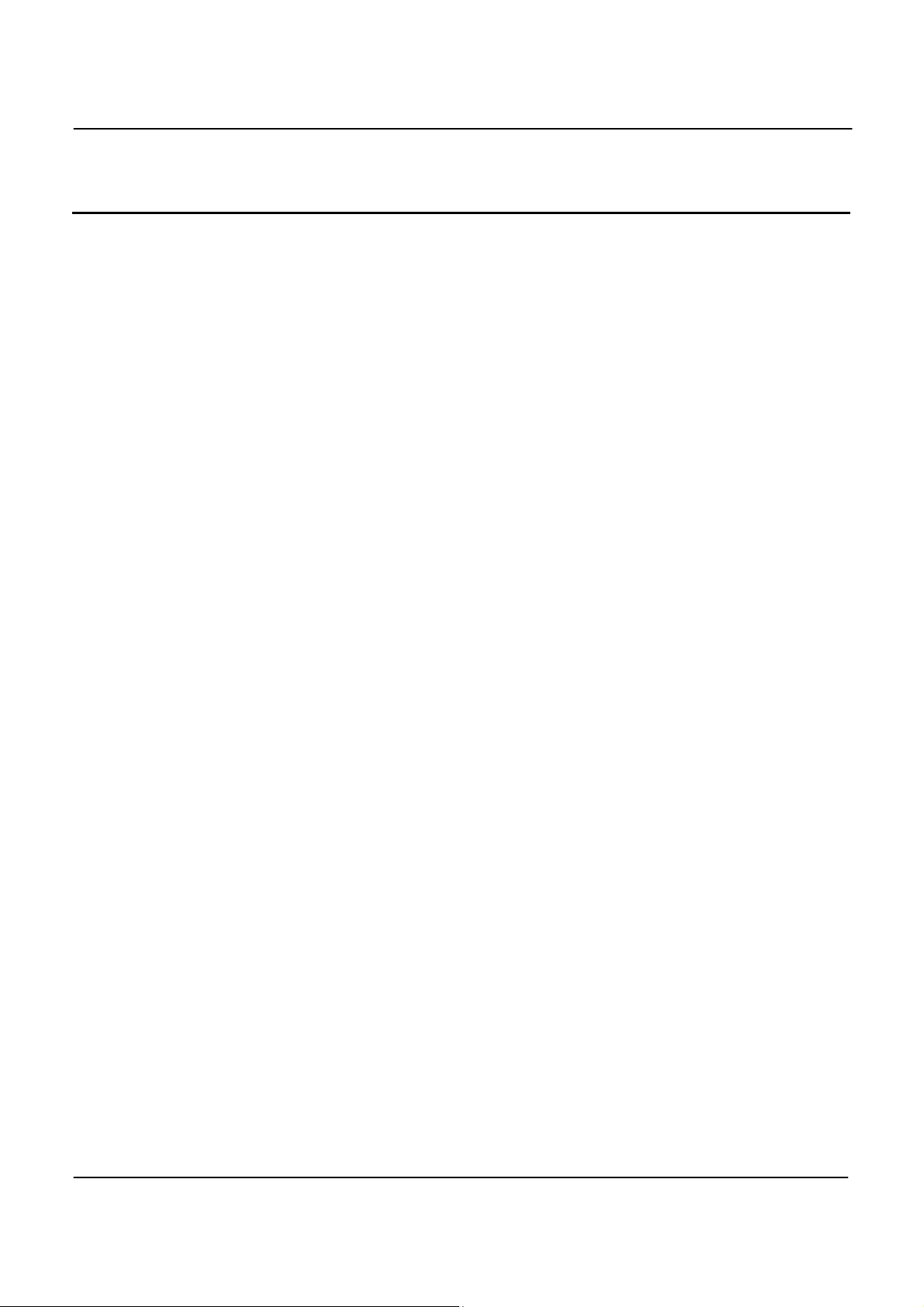

2.4.1 Test Classes

The standard divides products to be tested in to four classes, A, B, C and D. Each class has its own

harmonic current limits. Class A is the default class, meaning if a product does not fall into the categories

for class B, C or D, it is by default class A. The product classes are defined as follows:

Test limits are most stringent for Class-C and Class-D equipment. These classes were established to cover

Class Description

A All motor driven equipment, most “domestic” appliances and

virtually all 3 phase equipment (<16 A rms per phase)

B All portable electric tools

C All lighting products, including dimmers, with an active input

power above 25 Watts.

D Products having a power range from 75 to 600 Watts AND a

current waveform that has a special wave shape.

Table 2-3: EN 61000-3-2 Class Descriptions

the wide range of products that uses “cheap” switching power supplies with a rectifier capacitor input.

These units typically exhibit relatively high odd harmonics. Since this type of supply is so commonly used,

the effect of a large quantity of products like this can add up to significant problems. To limit this effect, the

current harmonic limits for class-D equipment are specified in mA/W instead of an absolute current value

as is done for class A and B. Many consumer and professional devices such as TV’s, VCR’s, stereos,

PC’s, fax machines, printers etc. may fall into the more stringent class D category.

Class-C limits are not specified in absolute values either but rather as a percentage of the fundamental

current. The third harmonic limit is also a function of the power factor so is harder to meet as the power

factor decreases. Neither class C nor D devices have to meet even current harmonics limits.

Since class C and D limits are load dependent, the power level and power factor have to be determined for

each test. In case of fluctuating power levels, it may be necessary to measure the power level during the

test and adjust the limits used to pass or fail the unit under test dynamically.

This dynamic nature of the class C and D limits has resulting in some confusion and a possible problem of

inconsistent test results when using IEC test systems for different vendors. The Standards body working

group for harmonics is in the process of clarifying some of the class and limit issues and these efforts are

likely to result in a revision of classes and limit calculations sometime in the year 2001. Until a new

standard is established, the CTSMXL software maintains a database of test limit values than can be

updated over time if needed without changing the core program.

CTSMXL software makes dynamic classification for Classes A and D. The classification follows the

following principle. If during either a Class A or D test the EUT becomes a Class A device, the EUT will be

considered a Class A device. If the EUT is a Class D device through out the test, then the device is a

Class D device. In other words, Class A is a latching classification. Please note that even though the

classification may change during a test, a Class A (or D) test will still be performed according to Class A (or

D) specification.

2.4.2 Steady State versus Transitory Harmonics

Two types of harmonics testing are called for in the EN 61000-3-2:1998 standard, a quasi steady state and

a transitory one. The transitory harmonics tests allow for equipment that has power demands that vary over

time to temporarily exceed the harmonic current limits by as much as 50 %, as long as such elevated levels

do not occur for more than 10 % of the test period. Since the minimum test time required is 2.5 minutes or

150 seconds, this means the current harmonics can be as high as 150% of the standard limits for no more

Revision J

20

Page 21

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

Revision

J

than 15 seconds in any 150 second period. This requirement imposes more demands on the power

analyzer being used than it does on the AC power source.

Steady state harmonics are those exhibited by equipment that has a constant current draw such as a

fluorescent lighting fixture. Many pieces of equipment, such as Laser printers that have a heating element

that kicks in any time a page is printed, have fluctuating power demands and may require transitory

harmonics testing.

Note that Amendment 14 does away with the distinction between stationary and transitory harmonics.

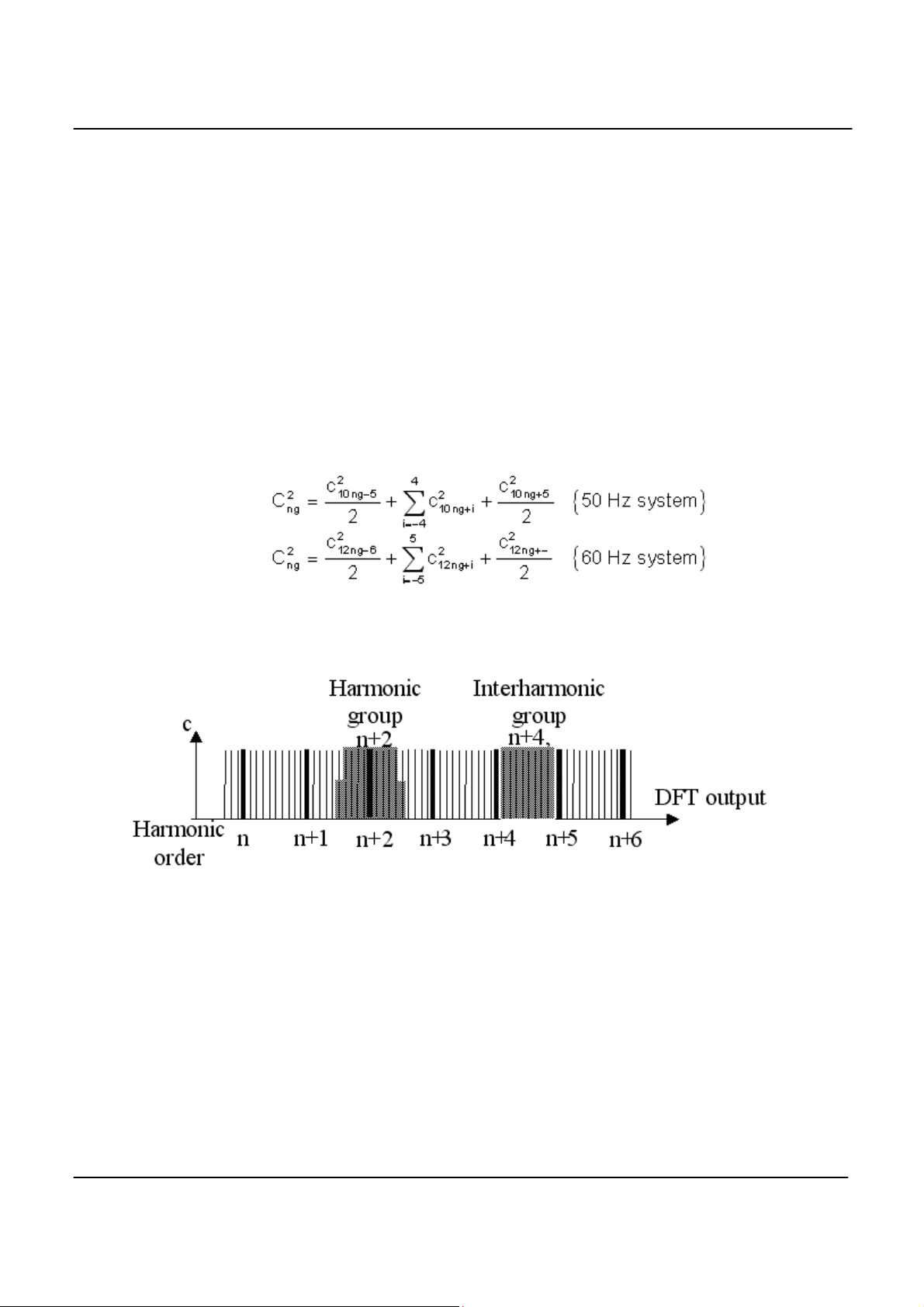

2.4.3 IEC 61000-4-7 Inter Harmonics Evaluation.

IEC61000-3-2 Edition 2.1 (2001-10) references measurement methods per IEC61000-4-7 and Edition 2.0

of this measurement standard specifies the inclusion of inter harmonics. For the assessment of harmonics,

the harmonic and inter-harmonic current levels are grouped to be the sum of squared intermediate lines

between two adjacent harmonics according to the equation below, as visualized also in the accompanying

figure. The resulting harmonic group component of order n (corresponding to the center line in the hatched

area) has the magnitude C (rms value).

2.5

In these equations, “c” is the modulus of the spectral component corresponding to an output bin of the

Fourier Transform of the data obtained from the 200 ms acquisition period , and “C” is the resulting

modulus of the harmonic which is to be compared against the limits in IEC61000-3-2 for the selected test

class.

This inter harmonics measurement is not mandatory as of this writing, as the use of equipment meeting the

previous version of IEC61000-4-7 (the older Edition 1) is permitted for a short period (until the existing

IEC61000-4-7 Edition 2 has gone through its maintenance cycle). Therefore the user has the option to

either disregard inter harmonics, or to group them into the assessment by selecting the appropriate field in

the “Test Category” settings.

It should be noted that selecting this “inter harmonics grouping” has little impact on the measurement

results for the vast majority of products. Only products with active power factor correction AND highly

fluctuating power consumption will produce inter harmonic levels that would add to the level of “C” as given

above. Most products do not produce inter harmonics, and therefore the measured harmonic currents will

be the same either way.

EN 61000-3-3 Flicker

Flicker standards are imposed to limit voltage variations caused by loads connected to the low voltage

supply network that would cause lights connected to the same circuit to flicker. A complex measurement

21

Page 22

User

Manual

MX-

CTSL

Compliance

Test System

California

Instruments

approach outlined in IEC 868, was devised to correlate voltage fluctuations to a human perceptibility factor

(P). The EN 61000-3-3 standard sets limits for voltage fluctuations caused by electrical apparatus with a