Page 1

User Manual

Marine Temperature Calibrator

Jofra MTC-650 A MKII

Page 2

User Manual

Marine Temperature Calibrator

JOFRA MTC-650 A MKII

Copyright 2019 AMETEK Denmark A/S

Page 3

List of contents

1.0 Introduction ....................................................................................................................... 3

1.1 List of equipment received........................................................................................................ 3

2.0 Safety instructions ............................................................................................................ 4

3.0 Setting up the calibrator ................................................................................................... 7

3.1 Before use ................................................................................................................................ 7

3.2 Keypad - Functions ................................................................................................................ 10

3.3 Display ................................................................................................................................... 10

3.4 Connections ........................................................................................................................... 11

3.5 Stability of temperature values ............................................................................................... 11

4.0 Operating the calibrator .................................................................................................. 13

4.1 Operating principle ................................................................................................................. 13

4.2 System menu ......................................................................................................................... 13

4.3 Starting the calibrator ............................................................................................................. 15

4.4 Stability setting ....................................................................................................................... 15

4.5 Selecting the set-temperature ................................................................................................ 16

4.5.1 Editing the preset set-temperature .............................................................................. 17

4.6 Auto Step function .................................................................................................................. 17

4.6.1 Running an Auto Step test .......................................................................................... 17

4.6.2 The calibrator's Auto Step procedure .......................................................................... 18

4.7 Switch Test function ............................................................................................................... 19

4.7.1 Running a Switch Test ................................................................................................ 19

4.7.2 The calibrator's Switch Test procedure ....................................................................... 20

5.0 Setting the mains voltage and replacing the main fuses ............................................. 22

5.1 Replacing the main fuses ....................................................................................................... 22

6.0 After use ........................................................................................................................... 23

6.1 Storing and transporting the calibrator .................................................................................... 23

6.2 Switching off the calibrator ..................................................................................................... 24

130068 00 2019-03-26 2

Page 4

1.0 Introduction

The MTC-calibrator is a fast, timesaving, and reliable true industrial temperature calibrator

designed for on-site use calibrating temperature sensors and temperature switches.

Read this manual carefully before using the instrument and make sure that all safety

instructions and warnings are observed.

1.1 List of equipment received

When you receive the instrument, the following should be enclosed:

• 1 MTC Calibrator

• 1 USB memory stick containing electronic Reference manual and software package

JOFRACAL

• 1 mains cable

• 1 sets of test leads and test clips (black and red)

• Thermal protection shield

• 1 tool for insertion tube

• 1 USB cable

• 1 Calibration certificate (International traceable)

130068 00 2019-03-26 3

Page 5

instructions and warnings must be observed.

Disposal

These

disposed of properly (in accordance with the WEEE Directive 20

using compressed air!

2.0 Safety instructions

Read this manual carefully before using the instrument!

In order to avoid any personal injuries and/or damage to the instrument all safety

– WEEE Directive

calibrators contain Electrical and Electronic circuits and must be recycled or

Warning

About the use:

• The calibrator must not be used for any purposes other than those described in

this manual, as protection provided by the calibrator may be impaired and it might

cause a hazard.

• The calibrator has been designed for indoor use only and is not to be used in

wet locations.

• The calibrator is not to be used in hazardous areas, where vapour or gas

leaks, etc. may constitute a danger of explosion.

• The calibrator is not designed for operation in altitudes above 2000 meters.

•

The calibrator is a CLASS I product and must be connected to a mains outlet with

a protective earth connection. Ensure the ground connection of the calibrator is

properly connected to the protective earth before switching on the calibrator.

Always use a mains power cable with a mains plug that connects to the

protective earth.

12/19/EU).

• To ensure the connection to protective earth any extension cord used must also

have a protective earth conductor.

• Only use a mains power cord with a current rating as specified by the calibrator

and which is approved for the voltage and plug configuration in your area.

• Always make sure to position the power cord and other connected cables in a

secure way to prevent the risk of personnel falling.

• To prevent the calibrator from tipping over and causing damage to equipment or

systems, please avoid pulling the cables connected to the calibrator.

• Before switching on the calibrator make sure that it is set to the voltage of the

mains electricity supply.

• Always position the calibrator to enable easy and quick disconnection of the

power source (mains inlet socket).

• The calibrator must be kept clear within an area of 20 cm on all sides and 1

metre above the calibrator due to fire hazard.

• Never use heat transfer fluids such as silicone, oil, paste, etc. in the dry-block

calibrators. These fluids may penetrate the calibrator and cause electrical hazard,

damage or create poisonous fumes.

• The calibrator must be switched off before any attempt to service the instrument

is made. There are no user serviceable parts inside the calibrator.

• When cleaning the well or the insertion tube, REMEMBER to wear goggles when

130068 00 2019-03-26 4

Page 6

holders are prohibited and may cause a hazard.

•

•

•

•

•

• Remember to use appropriate protective equipment or get help when carrying the

calibrator (for a longer distance) in order to prevent injuries from dropping the

calibrator.

About the front panel:

• The connectors, on the front panel of the calibrator, must NEVER be connected

to a voltage source.

• Thermostats connected to the switch test input must not be connected to any

other voltage source during a test.

About the insertion tubes and insulation plug:

• Never leave hot insertion tubes which have been removed from the calibrator

unsupervised – they may constitute a fire hazard or personal injury.

If you intend to store the calibrator in the optional aluminium carrying case after

use, you must ensure that the instrument has cooled down to a temperature

below 50°C/122°F before placing it in the carrying case.

• Never place a hot insertion tube in the optional carrying case.

About the fuses:

• The fuse box must not be removed from the power control switch until the mains

cable has been disconnected.

• The two main fuses must have the specified current and voltage rating and be of

the specified type. The use of makeshift fuses and the short-circuiting of fuse

Caution – Hot surface

This symbol is visible on the grid plate.

Do not touch the grid plate, the well or the insertion tube as the calibrator is

heating up – they may be very hot and cause burns.

Do not touch the tip of the sensor when it is removed from the insertion

tube/well – it may be very hot and cause burns.

Do not touch the handle of the calibrator during use – it may be very hot and

cause burns.

Over 50°C/122°F

If the calibrator has been heated up to temperatures above 50°C/122°F, you must

wait until the instrument reaches a temperature below 50°C/122°F before you

switch it off.

Do not remove the insert from the calibrator before the insert has cooled down to

less than 50°C/122°F.

Caution…

130068 00 2019-03-26 5

About the use:

• Do not use the instrument if the fan is out of order.

• Before cleaning the calibrator, you must switch it off, allow it to cool down and

remove all cables.

Page 7

well to avoid damage to the instrument.

in this manual or uses unauthorised spare parts.

About the well, insertion tube and grid plate:

• The well and the insertion tube must be clean and dry before use.

• Do not pour any form of liquids into the well. It might damage the well or cause a

hazard.

• Scratches and other damage to the insertion tubes should be avoided by storing

the insertion tubes carefully when not in use.

• The insertion tube must never be forced into the well. The well could be damaged

as a result, and the insertion tube may get stuck.

• Before using new insertion tubes for the calibration, the insertion tubes must be

heated up to maximum temperature 650°C (1202°F) for a period of minimum 30

minutes.

• The insertion tube must always be removed from the calibrator after use.

The humidity in the air may cause corrosion oxidation on the insertion tube inside

the instrument. There is a risk that the insertion tube may get stuck if this is

allowed to happen.

• If the calibrator is to be transported, the insertion tube must be removed from the

Note…

The product liability only applies if the instrument is subject to a manufacturing

defect. This liability becomes void if the user fails to follow the instructions set out

130068 00 2019-03-26 6

Page 8

mains electricity supply.

3.0 Setting up the calibrator

ENVIRONMENTAL SPECIFICATIONS

Ambient operating temperature range: 0-50°C / 32-122°F

Storage temperature range: -20-50°C / -4-122°F

Humidity range: 5-90% RH, non-condensing

IP protection class: IP10

Altitude: 0-2000 m

Electromagnetic Compatibility:

POWER SUPPLY SPECIFICATIONS

Line voltage/frequency: 90-127VAC / 180-254VAC 47-63 Hz

IEC protection class: Class I

Power consumption:

Tested for use in domestic establishment and in

establishments directly connected to low voltage

power supply network which supplies buildings

used for domestic purposes as well as in an

industrial electromagnetic environment as

described in EN61326-1:2013.

1150 VA max.

3.1 Before use

Warning

• The calibrator has been designed for indoor use only and is not to be used in

wet locations.

• The calibrator is not to be used in hazardous areas, where vapour or gas

leaks, etc. may constitute a danger of explosion.

• The calibrator is not designed for operation in altitudes above 2000 meters.

• The calibrator is a CLASS I product and must be connected to a mains outlet

with a protective earth connection. Ensure the ground connection of the calibrator

is properly connected to the protective earth before switching on the calibrator.

Always use a mains power cable with a mains plug that connects to the

protective earth.

• To ensure the connection to protective earth any extension cord used must also

have a protective earth conductor.

• Only use a mains power cord with a current rating as specified by the calibrator

and which is approved for the voltage and plug configuration in your area.

• Always make sure to position the power cord and other connected cables in a

secure way to prevent the risk of personnel falling.

• To prevent the calibrator from tipping over and causing damage to equipment or

systems, please avoid pulling the cables connected to the calibrator.

• Before switching on the calibrator make sure that it is set to the voltage of the

130068 00 2019-03-26 7

Page 9

above the calibrator due to fire hazard.

cause burns

•

Always position the calibrator to enable easy and quick disconnection of the power

source (mains inlet socket).

•

The calibrator must be kept clear within an area of 20 cm on all sides and 1 metre

Caution – Hot surface

This symbol is visible on the grid plate.

• Do not touch the grid plate, the well or the insertion tube as the calibrator is

heating up – they may be very hot and cause burns.

•

Do not touch the handle of the calibrator during use – it may be very hot and

.

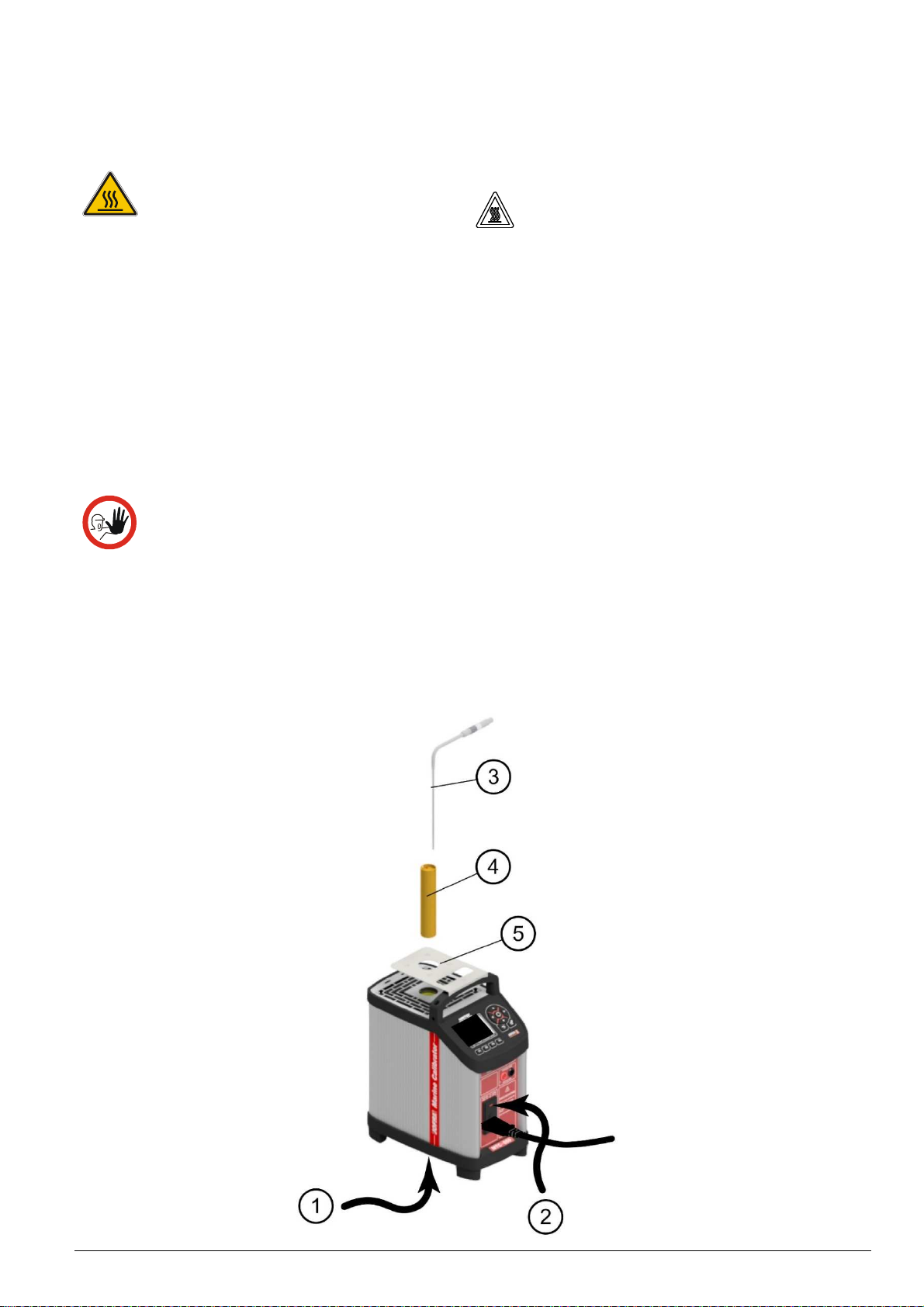

When setting up the calibrator, you must… (cf. the figure this page):

1. Place the calibrator on an even horizontal surface where you intend to use it and away

from all draughts. The calibrator must be kept clear within an area of 20 cm on all sides

and 1 metre above the calibrator due to fire hazard.

Caution…

Do not use the instrument if the internal fan is out of order

2. Ensure a free supply of air to the internal fan located at the bottom of the instrument (pos.

1). The area around the calibrator should be free of draught, dirt, flammable substances

etc.

3. Check that the fuse size corresponds to the applied voltage on (pos. 2). The fuse is

contained in the power control switch (on/off switch (230V/115V)).

.

130068 00 2019-03-26 8

Page 10

period of minimum 30 minutes.

Warning

The two main fuses must have the specified current and voltage rating and be of the

specified type. The use of makeshift fuses and the short-circuiting of fuse holders are

prohibited and may cause a hazard.

4. Check that the earth connection for the instrument is present and attach the cable.

5. Place the sensor (pos. 3) in the insertion tube (pos. 4) as shown in the figure.

Caution…

Before using new insertion tubes for the calibration in the MTC-650 instrument the

6. In order to protect the sensor and its connections use the thermal protection shield

insertion tubes must be heated up to maximum temperature 650°C (1202°F) for a

(129264 – pos. 5) at high temperatures.

130068 00 2019-03-26 9

Page 11

1

direction.

5

4

3

2

6

7

8

9

10

3.2 Keypad - Functions

Function keys - F1, F2, F3, F4

For operating the horizontal menu.

Arrow Keys

Navigation mode: Use the four keys to move the cursor in

the desired direction.

Edit mode: The Up and Down Arrow keys scroll through

the lists of options. If entering a number, the Left and Right

Arrow keys move the cursor one character in the desired

Action key / Enter key

Action function: Open and close edit fields or a menu

button. The action key also accepts the selected option or

entered value.

Enter function: Accept selected options or entered values.

When a value is entered with the Enter Key the cursor

selects the next configurable field in the list.

System menu key

Enter the System menu.

Back key

Cancel a selection or return to previous menu.

3.3 Display

1) Horizontal menu bar

Provides you with the relevant menu options that can be selected at the present point. Each option

can be selected and activated by pressing the function keys (F1, F2, F3 and F4).

2) Process Indicator

Indicates the status of the current process.

3) “Time to stable” Selection

Shows the selected specified stability criteria and states a time when the stable situation can be

achieved.

130068 00 2019-03-26 10

Page 12

4) Reference sensor info

Shows the reference sensor selected.

5) Memory reading

Shows the current memory selected from the System menu.

6) Warning/Error symbols.

If a warning or an error symbol occurs during operation, action needs to be taken.

7) Real Time Clock and date display.

8) True temperature reading

Shows the numeric value of the temperature being measured.

9) Units

Shows the unit of the current measurement.

10) Set temperature reading

Shows the numeric value of the current set temperature selected.

3.4 Connections

Device

USB 2.0 Device Port, 1 x USB.

Switch Test

Connection for thermostat switch test. Note that this connection

is for voltage free switches.

Power Control Switch

With a cable connection and On/Off switch. It also contains the

main fuse. See section 3.1 in the reference manual for

information on how to change the fuse. The text above the

Power Control Switch indicates the fuse value.

3.5 Stability of temperature values

The stability of the TRUE temperature is indicated by the following messages:

• "Not stable": Indicates that the measured temperature is not yet within the specified

stability criteria.

• Indicates "Time to stable": The temperature changes are within the specified stability

criteria and states a time (in minutes and seconds) when the stable situation can be

achieved.

130068 00 2019-03-26 11

Page 13

• Indicates that the “stable” situation is achieved and for how long the calibrator has been

stable. When the calibrator has been stable for more than 99 minutes, only the stable

sign is displayed (time is no longer displayed).

When the instrument is heating up and cooling down indication of this will be shown as following

symbols:

• The instrument is heating up.

• The instrument is cooling down.

Hot and cold symbols will be displayed in the upper black info bar when:

• the well temperature is below 5°C.

• the well temperature is above 45°C.

130068 00 2019-03-26 12

Page 14

4.0 Operating the calibrator

4.1 Operating principle

The calibrator is operated using the Functions keys, the Arrow keys and the

Action/Enter key.

1. Press the Functions keys to operate the horizontal menu bar.

2. Press any of the (Arrow) keys to enter Navigation Mode. Editable fields will be

highlighted in blue.

3. Use the Arrow) keys to move between the configurable fields within the display.

Selected fields will be highlighted in dark blue..

4. Press the (Enter) key to access the selected field for editing.

5. Use the (Up) and (Down) Arrow keys to select a new value.

6. Press the (Enter) key to accept the new value

7. To exit the Navigation Mode press the (Back) key. The (Back) key is also used

to cancel a selection or to return to a previous menu.

4.2 System menu

The System menu can be accessed at any stage of operation:

1. Press the (System) key to display the System menu.

2. Use the (Up) and (Down) Arrow keys to scroll in the list.

• System Settings menu

1. Use the (Enter) key and the (Up) and (Down) Arrow keys to access editable

fields, select new values and accept new values.

130068 00 2019-03-26 13

Page 15

upper part of the display.

editable in the System

Settings menu

.

Note…

• If the current set-temperature is higher than the new max-temperature, you will

need to adjust the set-temperature. The instrument will immediately begin to cool

(if required) as soon as the new max-temperature is accepted.

• The calibration interval can be set between 1 and 99 months. When the

calibration interval is exceeded, a yellow warning symbol will appear in the

• If Silent mode is selected, the cooling speed will be reduced.

• Presets menu

1. The preset temperatures can be changed manually using the (Arrows) keys.

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

• System Info menu

1. In the System Info menu important information such as serial numbers and

• Store menu (Save Settings)

calibration dates of the instrument are given.

It is not possible to edit any fields in this menu.

After you have configured the instrument, you can save the setup for future use using

the Store function.

130068 00 2019-03-26 14

Page 16

1. Use the (Up) and (Down) Arrow keys to select the Memory-setup you want to

modify, and press (Save). The new configuration is now saved.

F3

2. You can change the name of the highlighted saved setup by pressing (Enter), and

then using the (Up) and (Down) Arrow keys to change the characters.

The name is limited to seven (7) characters.

3. Press to save the new name.

F3

• Recall menu

To recall your memory setups select the Recall function.

1. Use the (Up) and (Down) Arrow keys to to scroll in the setup-list.

2. Select the requested setup, and press (Enter).

The name of the setup will appear in the upper-left corner of the display.

If selecting the Factory default function the active setup will be reset and change to

the initial setting.

4.3 Starting the calibrator

Switch on the calibrator using the power control switch.

A start up screen is displayed and then replaced with the main menu screen:

The functions in the horizontal menu bar are available using the Functions soft keys F1–

F4. For Operating principle – See section 4.1.

4.4 Stability setting

When internal reference is selected the calibrator uses a set of minimum internal

stability criteria that shall be met before stability is indicated.

The stability time can be adjusted from the minimum internal stability time (typical 5 min)

up to 99 min.

130068 00 2019-03-26 15

Page 17

4.5 Selecting the set-temperature

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu.

The set-temperature can be entered both manually and by selecting a preset

temperature.

1. For manually use press (Set)

F1

2. Use the (Arrow) keys to enter the temperature requested.

3. Press (Enter) to accept the entered temperature.

1. For selecting the preset temperature press (Preset).

F2

2. Select one of the 4 temperature options available from the menu bar by pressing the

correspondent Function key (F1 – F4).

3. The set-temperature is selected, once the Function key has been pressed.

The calibrator will now heat up / cool down.

The starting point is the last chosen set-temperature (even if the instrument has

been switched off).

The top display continuously shows the read-temperature and the lower display

shows the set-temperature.

In the top display the calibrator will indicate the estimated time in whole minutes

until the calibrator will be stable.

When the calibrator is stable the display will show a green checkmark

symbol and the instrument will emit an audible alarm. The instrument will indicate in

minutes and seconds for how long the instrument has been stable.

130068 00 2019-03-26 16

Page 18

4.5.1 Editing the preset set-temperature

It is possible to change the preset set temperature to whatever value desired.

1. Press (Preset).

F2

2. Press one of the (Arrow) keys and an editable field displaying the preset set

temperatures appears.

3. Navigate to the set temperature field using the arrows.

4. Press (Enter) to access the editable field and use the arrows (Up) and

(Down) to select a new set value.

5. Press (Enter) to accept the new set value.

6. Press (Back) to return to the previous menu.

4.6 Auto Step function

Auto Step is used to step automatically between a range of different calibration

temperatures. This is useful when calibrating sensors in places which are hard to reach,

and when calibrating sensors for which the output is displayed in a different location.

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu.

4.6.1 Running an Auto Step test

1. Press (Auto Step) to access the Auto Step setup. If you wish to return to the

F3

Main screen press (Main).

F1

2. Press one of the (Arrow) keys to access the editable fields for new values:

• No of steps: the number of temperature steps per direction (T1Tx) can be set

using integers from 2 to 12. You must select minimum 2

steps, maximum 12 steps.

• Hold time: defines the time (in minutes) the temperature is maintained

(after it is stable) for each step.

130068 00 2019-03-26 17

Page 19

•

Step values: must be set within the sensors permitted range.

3. Press (F4) to start the Auto Step test.

The Auto Step test is now in progress.

While the Auto Step test is in progress, 4 options are available:

• Stop : Press (F1) to stop the Auto Step test. The process will

end.

Pressing the (F4) key the process will start again running

step 1.

• Previous : Press (F2) to force the test to jump a step backwards to the

previous running step regardless of the step’s stability.

• Next : Press (F3) to force the test to jump a step forwards to the

next running step regardless of the step’s stability.

• Pause : Press (F4) to pause the test. Pressing start (F4)

again, the process will continue running from the current step.

4.6.2 The calibrator's Auto Step procedure

1) Once the Auto Step test is started, the calibrator starts working towards the given settemperature. An audible alarm will be emitted once the calibrator is stable.

2) The calibrator will wait the specified amount of hold time. The instrument indicates

this by counting down the amount of time remaining.

3) The calibrator will then go to the next step. The procedure is the same as for the first

step. This process will be repeated until the last step has been executed and the

function has been completed.

4) The measured TRUE temperatures for each step are displayed during operation.

130068 00 2019-03-26 18

Page 20

4.7 Switch Test function

Switch Test automatically locates the switch temperature of a thermostat.

Three parameters are required:

• Start temperature (T1)

• End temperature (T2)

• Rate of change in temperature pr. minute (Rate).

Dead band of a thermostat can also be determined here. Where the dead band

determines the tolerance between the upper switch temperature and the lower switch

temperature of the thermostat.

4.7.1 Running a Switch Test

Warning

Thermostats connected to the switch test input must not be connected to any other

source during test.

Note…

Before running the Switch Test, make sure that the switch is connected to the Switch

Test input.

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu.

1. Press (Switch) to access the Switch Test setup. If you wish to return to the

Main screen press (Main).

F4

F1

The small graph illustrates the current T1, T2 and dead band selections. Note that T1

can be greater than T2.

2. Press one of the (Arrow) keys to access the editable fields for new values:

• T

• T

130068 00 2019-03-26 19

First set temperature

1 :

2 :

Second set temperature

Page 21

....

....

....

• Dead band : To determine dead band, toggle between "Yes" (a two-way-

temperature measurement) and "No" (a one-way-temperature

measurement). A dead band result is only measured when

dead band is set to “Yes”.

• Rate : The permitted range is 0.01 - 10.0°C/min. / 0.02 - 18.0°F/min.

• Test runs: Can be set from 1 to 3 making it possible to run the test more

than once.

Note…

the Rate should be set so that the thermostat sensor can follow the

temperature in the calibrator's well.

3. Press (F4) to start the Switch Test.

The Switch test is now in progress.

While the Switch Test is in progress, 2 options are available:

• Stop : Press (F1) to stop the Switch Test. The process will end and

the results will be deleted from the results list.

Pressing the (F4) key the process will start from the

beginning heating towards T1.

• Results : Press (F3) to display the current Switch Test result. The

....

results change as the test progresses. The results list is also

accessible from the Switch Test menu screen.

4.7.2 The calibrator's Switch Test procedure

1) Once the Switch Test is started, the calibrator starts working towards T1 as quickly as

possible. The calibrator's temperature changes (heating or cooling) and switch status

are shown in the display.

2) When T1 is achieved and the temperature is stable, the text and the graphic in the

bottom of the screen will change accordingly.

3) The calibrator now starts working towards T2 at the specified Rate.

4) In a normal situation, the thermostat changes state before T2 is achieved. If T2 is

achieved and the temperature is stable, no results will be displayed.

130068 00 2019-03-26 20

Page 22

....

....

....

5) When dead band is not selected (single temperature change) (the graphic indicates

the choice), the finished switch test result is displayed.

When dead band is selected (two switch changes), the calibrator starts working

towards T1 at the specified Rate.

6) Normally, the thermostat changes state before T1 is achieved. If T1 is reached and

the temperature is stable, no results will be displayed.

7) The finished switch test results are displayed in the results list by pressing

....

(F3).

The results show the temperature when the thermostat has closed and the

temperature when it has opened – whichever comes first. The difference between

these 2 temperatures is calculated as the dead band.

130068 00 2019-03-26 21

Page 23

5.0 Setting the mains voltage and replacing the main fuses

5.1 Replacing the main fuses

Warning

• The calibrator must be switched off before any attempt to service the instrument is

made. There are no user serviceable parts inside the calibrator.

• The fuse box must not be removed from the power control switch until the mains

cable has been disconnected.

• The two main fuses must have the specified current and voltage rating and be of the

specified type. The use of makeshift fuses and the short-circuiting of fuse holders

are prohibited and may cause a hazard.

A. Locate the main fuses in the fuse box in the power control switch and check the

voltage of the power control switch (on/off switch (230V/115V)). If the voltage of the

power control switch differs from the line voltage, you must adjust the voltage of the

power control switch.

B. Open the lid of the fuse box using a screwdriver and remove the fuse box.

C. Replace the fuses. The fuses must be identical and should correspond to the line

voltage.

115V: 10AF/250V = 60B302

230V: 5AF/250V = 127573

If the fuses blow immediately after you have replaced them, the calibrator should be

returned to the manufacturer for service.

D. Slide the fuse box into place with the correct voltage turning upwards.

130068 00 2019-03-26 22

Page 24

6.0

working

order.

it off

.

After use

6.1 Storing and transporting the calibrator

Warning

Caution…

The following guidelines should always be observed when storing and transporting

the calibrator. This will ensure that the instrument and the sensor remain in good

• The calibrator must be switched off before any attempt to service the instrument is

made. There are no user serviceable parts inside the calibrator.

• Remember to use appropriate protective equipment or get help when carrying the

calibrator (for a longer distance) in order to prevent injuries from dropping the

calibrator.

The following routine must be observed before the insertion tube is removed and the

instrument switched off:

Over 50°C/122°F

If the calibrator has been heated up to temperatures above 50°C/122°F, you must

wait until the instrument reaches a temperature below 50°C/122°F before you switch

130068 00 2019-03-26 23

Page 25

removed from the well to avoid damage to the instrument.

6.2 Switching off the calibrator

1. Switch off the calibrator using the power control switch.

Note that the calibration procedure may be interrupted at any time using the power

control switch. Switching off the calibrator during the calibration process will not

damage either the instrument or the sensor.

2. Remove the insertion tube from the calibrator using the tool for insertion tube

supplied with the instrument as shown in the figure.

Caution – Hot surface

Do not remove the insert from the calibrator before the insert has cooled down to less

than 50°C/122°F

Caution…

• The insertion tube must always be removed from the calibrator after use.

The humidity in the air may cause corrosion oxidation on the insertion tube inside

the instrument. There is a risk that the insertion tube may get stuck if this is allowed

to happen.

•

If the calibrator is to be transported long distances, the insertion tube must be

130068 00 2019-03-26 24

Page 26

Warning

• Never leave hot insertion tubes which have been removed from the calibrator

unsupervised – they may constitute a fire hazard or personal injury.

If you intend to store the calibrator in the optional aluminium carrying case after

use, you must ensure that the instrument has cooled to a temperature below

50°C/122°F before placing it in the carrying case.

• Never place a hot insertion tube in the optional carrying case.

• Do not touch the well or insertion tube when these are deep frozen – they might

create frostbite.

130068 00 2019-03-26 25

Page 27

www.ametekcalibration.com

UK

Tel +44 (0)1243 833 302

stc.uk@ametek.com

France

Tel +33 (0)1 30 68 89 40

general.lloyd-instruments@ametek.fr

Germany

Tel +49 (0)2159 9136 510

info.mct-de@ametek.de

Information in this document is subject to change without notice. ©2019, by AMETEK, Inc., www.ametek.com. All rights reserved.

Denmark

Tel +45 4816 8000

jofra@ametek.com

USA - California

Tel +1 (800) 444 1850

crystal@ametek.com

USA - Florida

Tel +1 (800) 527 9999

cal.info@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

Singapore

Tel +65 6484 2388

jofra@ametek.com

China - Shanghai

Tel +86 21 5868 5111

stc.china@ametek.com

China - Beijing

Tel +86 10 8526 2111 ext. 19

stc.china@ametek.com

Loading...

Loading...